Application guide for ECL Comfort controllers

Get your job done swiftly

Easy selection of your

application is the key

The ECL Comfort series offers an optimum range of electronic controllers for

temperature control in heating and domestic hot water systems.

In this guide, you will find the full range of applications, intuitively described and

illustrated for you to plan and design systems with confidence.

125+

applications

covered by ECL

application keys.

www.ecl.danfoss.com

Electronic controllers from Danfoss:

Only a few products for an

endless number of applications

Based on the success and benets

of previous generations, the Danfoss

ECL Comfort 210, 296 and 310 controllers ensure comfort and convenience

for heating, cooling and domestic hot

water systems.

The components of ECL Comfort

The ECL Comfort range consists of ECL

Comfort 110, 210, 296 and 310 – each

in an elegant and timeless Scandinavian design.

ECL Comfort 110 is the choice for ba-

sic heating systems, for which the installer or user prefer a traditional operation.

ECL Comfort 210 appeals to users

who prefer an increased number of

options. The series oers many functional options and can be used for

commercial installations. Two control

circuits + thermostatic function, optimizer function, 3-point control of actuators, Modbus communication for

smaller SCADA systems etc.

ECL Comfort 296 covers the same as

ECL Comfort 210 and has in addition

M-bus and Ethernet connections. Furthermore, ECL 296 has the popular

size, 144 x 96 mm.

ECL Comfort 310 is the advanced con-

troller with a large number of functions, such as: Three control circuits

+ thermostatic function, optimizer

function, 3-point control of actuators,

Modbus/M-bus/Ethernet communication etc.

The intelligent key concept for ECL

Comfort 210 / 296 / 310 ensures optimum user-friendliness of these advanced controllers.

The ECL Comfort range also comprises

an elegantly designed remote control

in two versions, which can access all

parameters in the controller.

The future is in the keys

The ECL Comfort range and its advanced software key not only meet

your present demands but also the future requirements you might have for

heating control.

With ECL Comfort 210 / 296 / 310 new

demands are covered by new keys

with new settings. The few basic models and the large variety of ECL keys

give you a considerably better and

quicker overview of the unique application opportunities oered by the

ECL Comfort range. Menus are available in multiple languages.

By means of the chosen key, it is easy

to set the controller and change the

factory settings precisely to the relevant type of system and required settings.

The schedule in the ECL Comfort can

be programmed for each day in the

week. The building will be heated in

the comfort periods you request; also

holidays can be scheduled on beforehand. This is environmentally sound

and saves money.

Some features of ECL Comfort:

Optimizer and boost function

Return temperature limitation based

on outdoor temperature

Frost protection

Heating cut–out function

Year clock and automatic change over

between summer and winter time

Copy function to/from the intelligent

ECL key

Anti-bacteria function (DHW circuit)

2

2

Communication via the standardized

RS485/TCP/IP, M-bus and Modbus options

Motor protection

Automatic saving

Menus in multiple languages

Master/slave functions

Log and alarm

Holiday program

Analog input/output

Rell water function

Two pump control

Optimum control of heat

exchangers in cascade

Buer tank temperature control for

heating systems

0 - 10 Volt / PWM based speed control

of pumps

3

3

80

90

70

60

50

40

30

20

10

0

0 5

Flow rate (m

3

/h)

10 15

Time (min.)

20 25 30

Tap water temperature (°C)

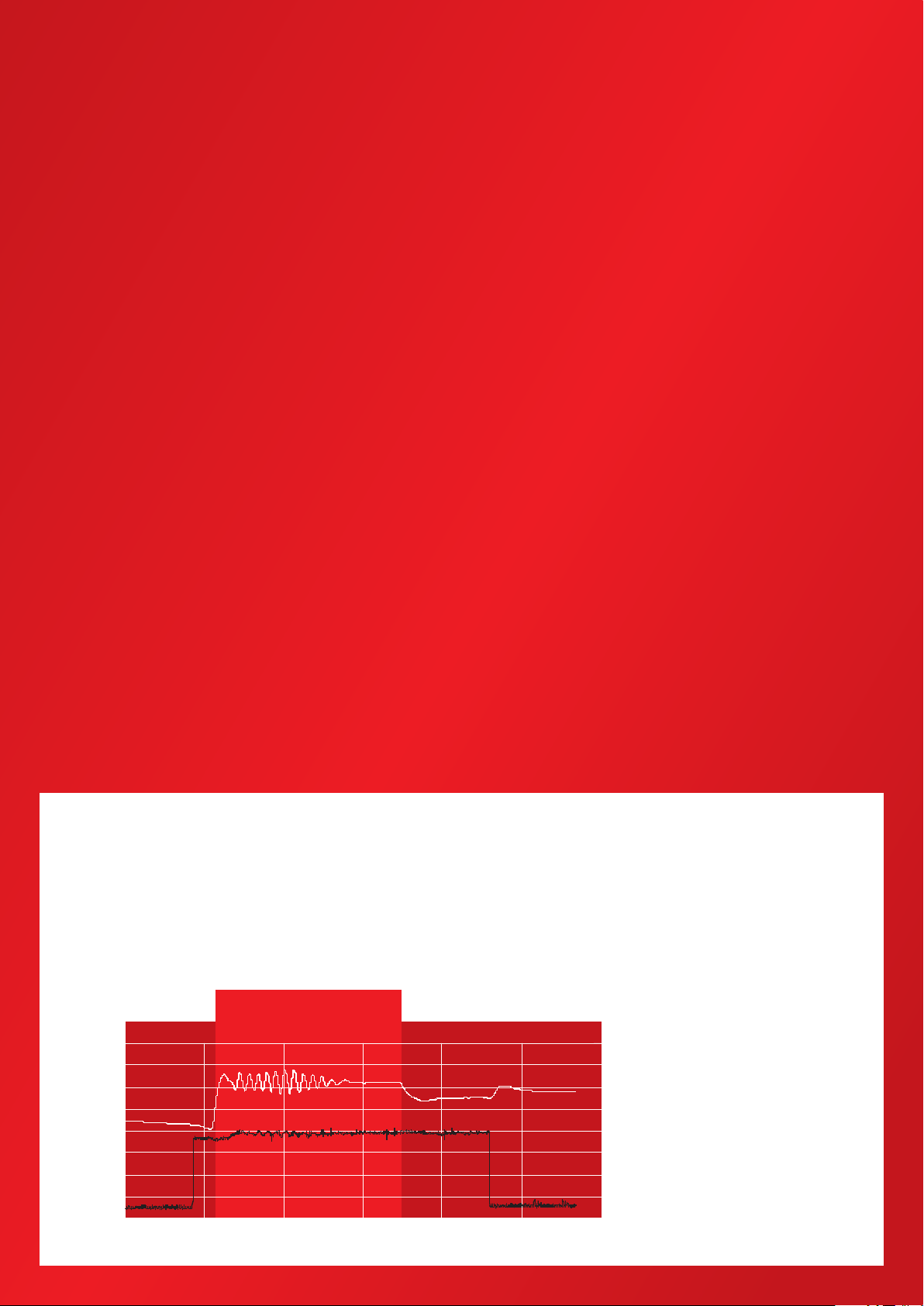

The result of Auto Tuning

Sec. ow (m

3

/h)

Tap water (°C)

Automatic setup of DHW parameters

A precondition for a well functioning heating system is that the correct settings

are made before it is put to use. Adjustments are necessary to preset the control

parameters.

Presetting gives the following benets:

A high degree of comfort

Improved protection against lime deposits in DHW heat exchangers

Energy saving

Long operating life

Minimum service

The introduction of automatic setting of control parameters on the controller

itself, i.e. auto tuning and motor protection, gives optimum control of the DHW

system. This ensures a high degree of comfort, stable control during idle operation and, subsequently, longer motor life.

The setting of control parameters can thus be reduced to one easy and reliable

procedure. Auto tuning is especially necessary in DHW systems.

4

How to do auto tuning with ECL Comfort?

Open for the tap water to get a constant tapping load

Activate auto tuning by pushing a button

Wait 7-25 minutes to complete the tuning

Intelligent communication solutions

Our solutions are wide-ranging – in

every respect. We cover almost every

area of application. From busy cities

and suburbs to idyllic villages – as well

as from public or commercial buildings to residential homes.

Intelligent solutions

– intelligent communication

Danfoss communication solutions provide the ultimate in control. We don’t

just supply controllers, but unique

software which facilitates remote

monitoring and control of district heating systems. Our oering ranges from

standard software fully integratable

with the existing plant and buildings,

to complete systems with full support.

There are many good reasons to

choose a solution which allows you to

monitor, control – and therefore service – your system remotely, regardless

of whether the system services buildings in urban areas or rural communities. Danfoss has – and will supply – an

advantageous solution for you.

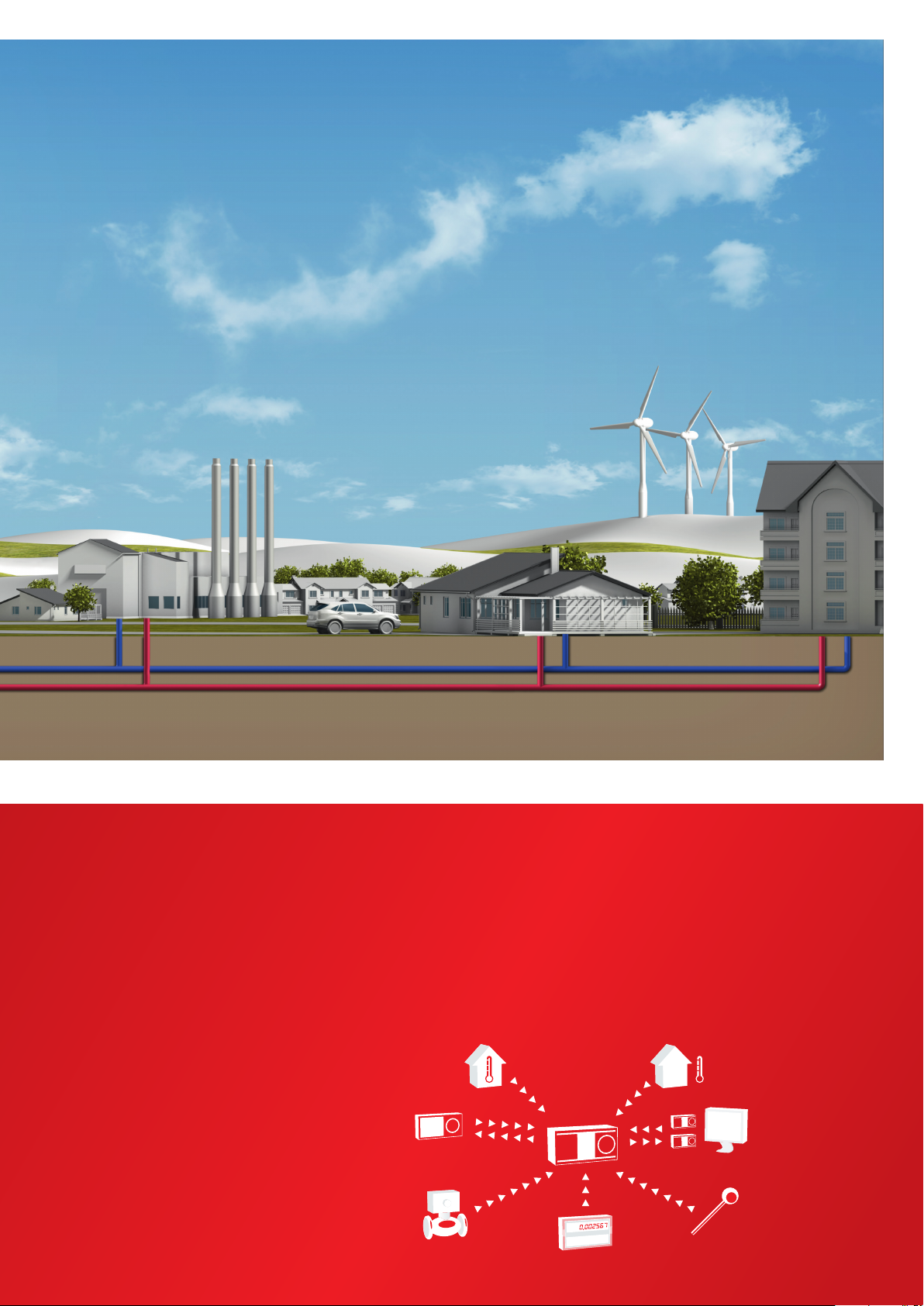

Your future communication platform

Remote monitoring and communication is the future as of today. Our solutions cover traditional forms of district

heating and alternatives, such as biomass plants. A Danfoss platform will

provide better, and simplied control

over a system, which not only optimizes the control processes, but also

yields savings and protects the environment. In some networks you have

large pumps and large controllers

leading to substantial energy usage.

Here it is important with an optimized

district heating network. An electronic

controller will not only simplify plant

management, it will also save energy.

Act proactive to service

Danfoss communication solutions enable you to act pro-actively to provide

better service. Thanks to ecient monitoring and alarm systems, they can

isolate and remedy problems – even

before the customer knows they exist.

For example; if the ow temperature is

incorrect, the system will automatically

activate an alarm, to warn about excessive energy consumption.

For optimum control in any system

Your requirements have been combined with our know-how to extend and

innovate our product range. Danfoss markets a comprehensive range of motorized control valves with features that give an optimum t with the ECL Comfort

controller. Our control valves are available in multiple sizes, dierent materials

and with a variety of connections. The range of motorized control valves meet

the requirements in any of these applications:

Terminal and zone

Heating and cooling

District heating

Steam

5

5

ENERGY SAVING AND

COMFORT IS A MATTER OF

OPTIMUM ENERGY CONTROL

When you look at urban and rural areas with varying housing densities,

the selection of heat sources for each

individual building will dier. Where

available, district heating will most often be a part of the solution. District

heating benets the individual homeowner or tenant as well as the society

at large. Where district heating is not

available, individual solutions will be

used – preferably in combination with

renewable energy sources.

One of the solutions for achieving energy savings in any building is the use

6

6

of electronic controllers for weather

compensation. By letting the ow in

the heating system of the house reect outdoor temperatures, optimum

operation and performance of the

heating installation is obtained.

In a recently published COWI report,

the advantages of weather compensation are sound and clear: In one

family houses, the expected energy

saving is on average 10% – and in

some cases up to 40%.

What role does the ECL Comfort play?

The ECL Comfort is an electronic controller for weather compensation. By

tting typical applications for district

heating, cooling and micro network

systems including communication,

it enables you easily to optimize system performance and operation. This

leads to energy savings and longer

system life.

A correctly installed and commissioned electronic controller is the

prerequisite for a stable and wellfunctioning heating system. Easy installation and an intuitive interface

makes sure that the ECL Comfort controller is always installed correctly for

the maximum benet.

The house owners/tenants favorite

For the end-user, ECL Comfort controllers are rst and foremost equal to energy savings. Lower energy consumption, registered by the Sonometer™

connected to the ECL Comfort, and a

Room

temperature

sensor

ECL Comfort

ECA Remote

Controller

Motorized

control valves

controller

Energy meter

smaller heat bill will always be popular. The comfort level is of course still

the same, and operation is made easy

with the single dial interface which

features a modern design.

Outdoor

temperature sensor

Network

Communication

facilities

System

temperature sensor

7

7

A few steps of commissioning that put you...

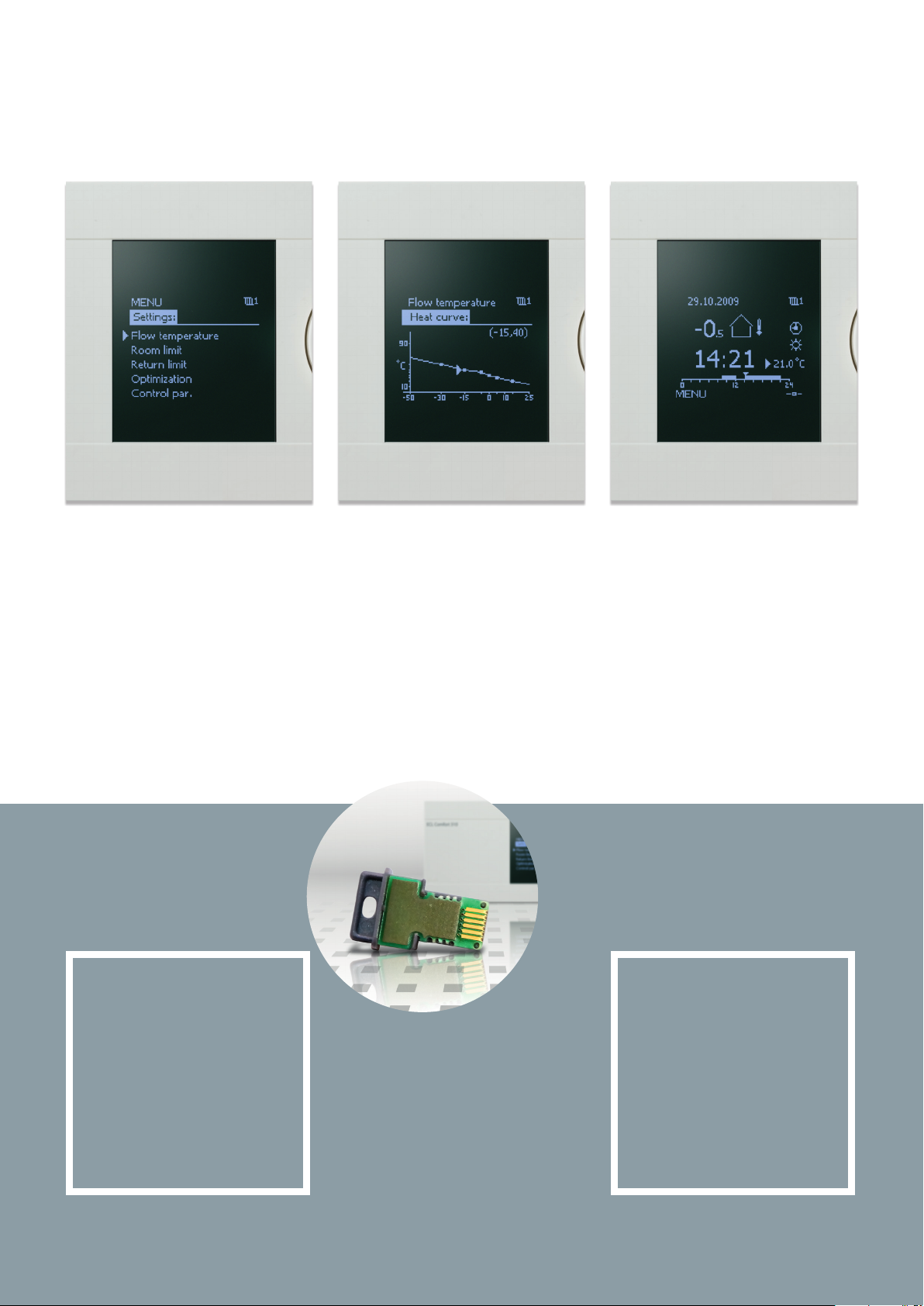

Countless advantages

For successful commissioning of

the Danfoss ECL Comfort controller

only a few steps are required. It is

very straightforward, and in fact you

don't need any special programming

knowledge.

Elegant no-fuss user interface

Intuitive software makes opera-

tion a breeze

Instant feedback displayed in your

own language

Access to user data, alarms, logs

and settings

User-friendly technical documen-

tation

Setup wizard

– Language selection

After wiring and connecting system

components, such as pumps, actuators and temperature sensors, you can

insert the ECL Application Key. Use the

turn/push dial to select your preferred

language and follow the setup progress on the display.

Setup wizard

– Application selection

Select your application from the system application range included on

the ECL Application Key.

You can choose from applicationspecic factory settings or user-specic settings if they have been stored

on the key.

The key to easy installation

The ECL Comfort controller is matched

with a full range of ECL Application

Keys. Each Application Key is programmed with specic parameters for

a particular district heating or cooling

application.

The ingenious ECL Application Key

makes it easier than ever to install

and set up your heating system appli-

8

8

cation in the ECL controller, all without any need for advanced programming. This makes it easy to manage

and adjust your application settings.

In the event of malfunction in the

heating system the application parameters won't be aected by e.g.

power failure since they are stored in

the controller. Besides the data log-

ging facility in the ECL controller facilitates troubleshooting and keeps

system maintenance at a minimum.

The Application Key also facilitates

copying of settings to other ECL controllers in the system. This makes it

easy to adjust settings and helps ensure smooth operation and energy

optimisation for years to come.

...one step ahead of schedule

Main controller settings

The main control parameters should

be congured for optimum commissioning. They are located in the “settings” menu. Room heating and DHW

ow temperatures are set in the user

menus.

Heating curve

With six congurable coordinates

for the exible heating curve, the

ECL Comfort 210 / 296 / 310 controller

meets all requirements for achieving an accurate comfort temperature

level in the system.

Favorite display

Select your favorite display from a set

of pre-dened displays in order to get

a quick system overview. Using your

favorite display, you can perform functions such as selecting the controller

mode (scheduled, comfort, saving or

frost protection mode) and desired

comfort temperature level (room and

DHW).

One key

100% application

expertise

The data programmed in every

ECL Application Key incorporates

dedicated and applied expertise

from worldwide experience with

district heating applications.

This is your best guarantee for

optimum system performance.

No

unplanned

service visits

With correct commissioning, the

lasting durability of ECL leads to

full customer satisfaction and no

unplanned service visits.

9

9

ECL COMFORT 210 ECL COMFORT 296 ECL COMFORT 310

Stand-alone controller

for multiple heating and

cooling applications with

up to 2 circuits

2 control circuits + thermostatic

function

Intelligent ECL Application Keys,

series A2xx

Turn/push dial navigation

Large graphical display with backlight

More room for cabling

Cable box and user interface can

be separated

Two 3-point control outputs

optimized for actuators

8 inputs: 6 Pt 1000, 2 congurable

4 relay outputs

Data logging readout on display or

via USB interface

USB port for service

Modbus RS485 for short cable distances

Master/slave option

Optimized for substations and

operation in a system using Danfoss

actuators, control valves, Pt 1000

sensors and pressure transmitters

Controller with

communication

interfaces for applications

with up to 2 circuits

In addition to the features of the

ECL Comfort 210, the ECL Comfort

296 gives you:

Integrated communication

interfaces:

Modbus RS485 for longer

distances

M-bus master dedicated for

heat meters

Modbus TCP

Connection to ECL Portal – easy

to install, access and adjust /

monitor

Smaller size, 144 x 96 mm

Controller with

communication

for applications

interfaces

with up

to 3 circuits

In addition to the features of the

ECL Comfort 210, the ECL Comfort

310 gives you:

3 control circuits + thermostatic

function

Integrated communication interfaces:

USB interface for service

Modbus RS485 for longer distances

M-bus master dedicated for heat

meters

Modbus TCP

10 input: 6 Pt 1000, 4 congurable

Three 3-point control output

optimized for actuators

6 relay outputs

Data logging readout on display or

via communication interface

Connection to ECL Portal – easy to

install, access and adjust / monitor

ECL 210 summary:

Basic requirements, high

performance in district heating

systems.

ECL 296 summary:

For basic requirements, with

communication and sized

144 x 96 mm.

ECA Remote controller

– Remote Control Unit (RCU):

In case of limited access to the basement or heating

system, the ECL Comfort controller can be supplemented with a remote control unit, ECA 30/31, which

can be placed at any desired location in the building.

This enables room temperature monitoring and control, easy interfacing, and remote access for overriding all the functions of the ECL Comfort controller.

10

10

ECL 310 summary:

For high requirements – with

communication and extension

options, without programming.

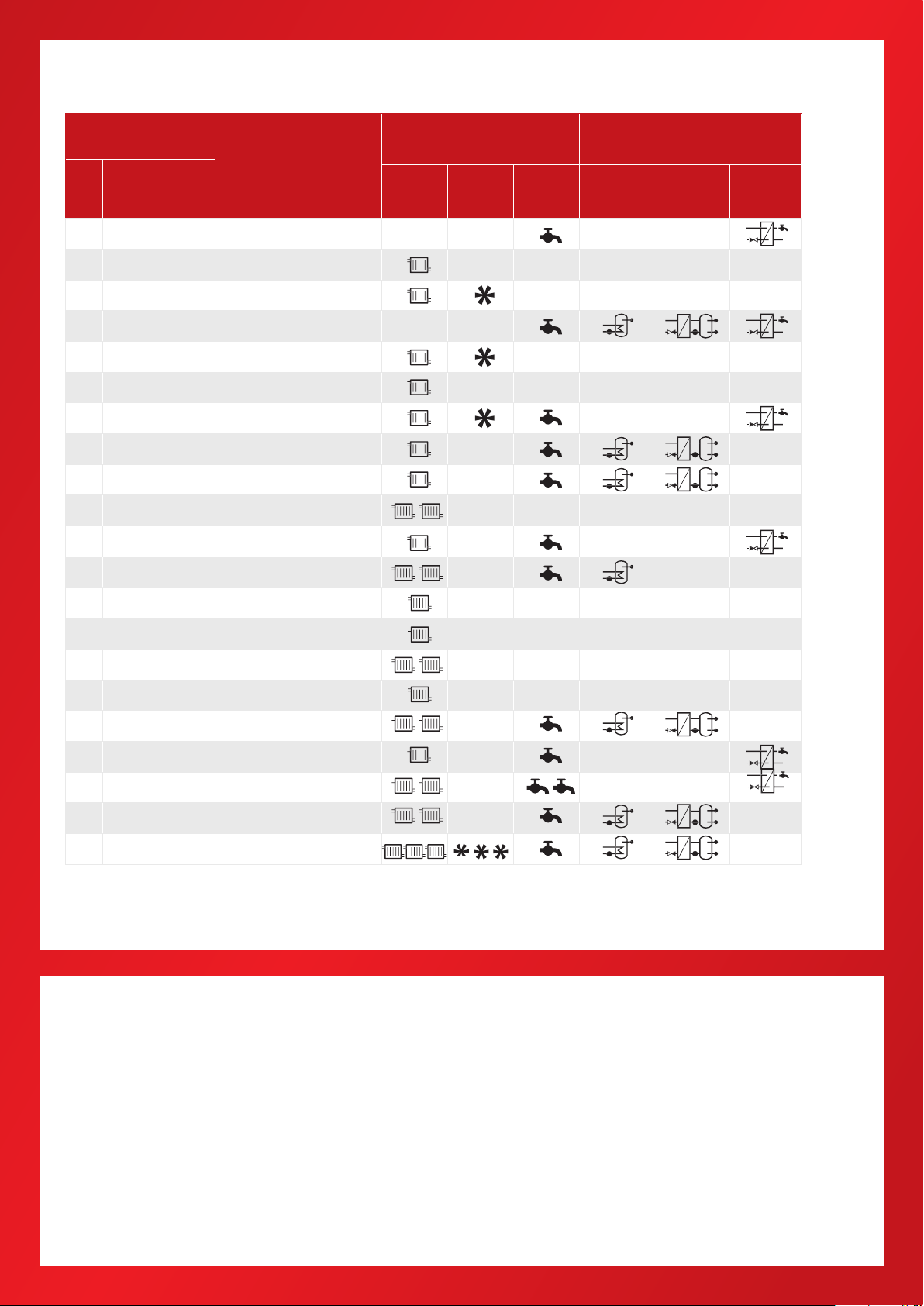

Select ECL Comfort for your application

ECL

COMFORT

ECL

ECL

110

210

ECL

296

ECL

310

ECL

Application

Key

Application

and system

type

Circuit types Domestic hot water (DHW)

designation

Heating Cooling DHW

116 DH

130 DH

A214 DH/DC ( Vent)

A217 DH

A230 DH/DC

1)

A231 DH

A232 DH/DC

A237 DH

A247 DH

A260 DH

A266 DH

A275 BOILER

1)

Storage with

internal heat

exchanger

Storage with

charging

DHW control

with HEX

Legend for ECL Application Key designation:

A = Application Key

2 = Suitable for ECL Comfort 210, 296 and 310

3 = Only suitable for ECL Comfort 310

xx = Specic application type

A319 DH

A333 DH

A361 DH

A362 DH

A367 DH

A368 DH

A376 DH

A377 DH

A390 DH

Abbreviations: DH (district heating); DC (district cooling)

Notes:

ECL Comfort 310 extension options

For applications with extended requirement the additional

internal I/O extension module ECA 32 and ECA 35 are

available.

For rell water and two pump function

For analog (0 - 10 V) control of motorized control valves,

dampers and rotating heat exchangers

Extra signal inputs

For analog (0 - 10 V) control of circulation pump speed

For PWM signal based control of circulation, charging

and control pump speed (ECA 35 only)

1)

1)

1)

= Either heating or cooling

ECL accessories and temperature sensors

Base part for mounting on wall or DIN rail

Temperature sensors (Pt 1000)

Outdoor and room

Pipe surface and immersion

11

11

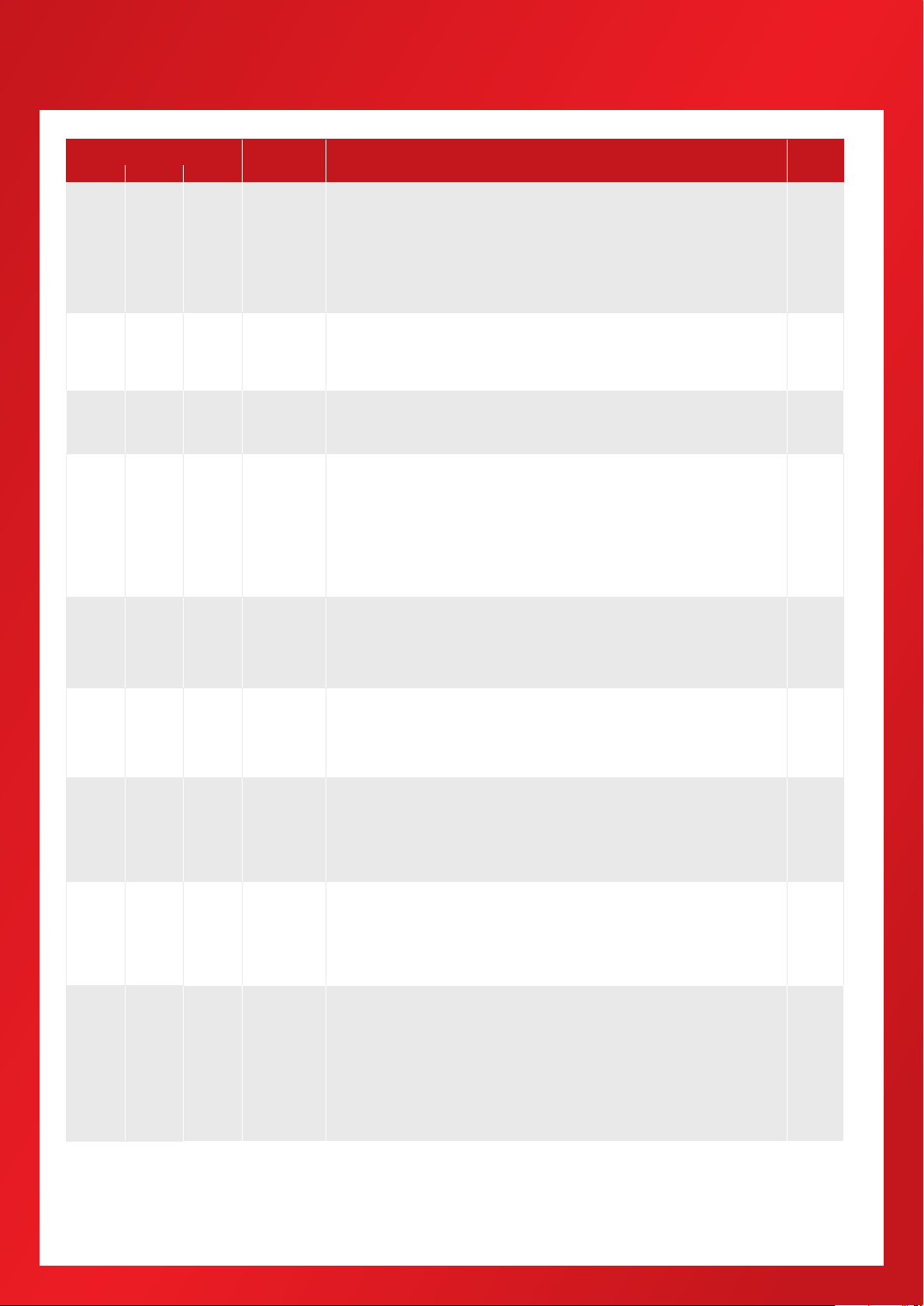

Index for applications keys

ECL Comfort 110

ECL Comfort

210 296 310

Application Description Page

116

130

Electronic temperature control of DHW circuits

Electronic temperature controller for weather compensated flow

temperature control of directly or indirectly connected heating systems

14

16

Application Description Page

A214

(A314)

A217

(A 317)

A2 30.1

Heating

A230.2

Cooling

A 230.4

Heating

A231

(A 331)

A232

(A332)

A237

(A337)

A247

(A347)

A260

A266

A275

(A375)

A214 also covering A314:

Multi purpose application. Temperature control of, for e xample, ventilation sys tems with heating or cooling or a combination of these. Weather based compensation, return temperature

limitation, frost and fire protection. Optional analog control of cross-flow or rotary heat exchanger. Alarm function related to duct / flow temperature, f ire and frost.

A217 also covering A317:

Advanced temperature control of DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Optional temperature control of DHW heating

temperature.

Alarm function related to flow temperature.

Weather compensated control of flow temperature in a heating circuit. Room temperature

and wind speed compensation. Sliding return temperature limitation. Alarm function

related to flow temperature.

Control of flow temperature in a cooling circuit. Room and weather compensation. Return

temperature limitation.

Weather compensated control of flow temperature in a heating circuit. Room temperature

compensation. Sliding return temperature and power / flow limitation. Alarm function

related to flow temperature. Monitoring of temperatures in self-acting controlled DHW

circuit.

A231 al so covering A331:

Weather compensated control of flow temperature in a heating circuit. Sliding return

temperature limitation. Control of one or two circulation pumps. Optional control of flow

temperature related to supply temperature. Refill water function.

Alarm function related to flow temperature, pressure and circulation pumps operation.

Additional function in A331: Control of one or two pumps for refill water function.

A232 also covering A332 :

Weather compensated flow temperature control of heating / cooling circuit(s). Automatic

change-over between heating and cooling. Circulation pump control. Dew point (cooling

mode only) and surface temperature compensation. Return temperature limitation.

A237 also coveri ng A337:

Weather compensated control of flow temperature in heating circuit. Room temperature

compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system.

Return temperature limitation. Possibility for DHW priority.

Alarm function related to flow temperatures.

A247 a lso covering A347:

Weather compensated control of flow temperature in heating circuit. Room temperature

compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system.

Return temperature limitation. Possibility for sliding DHW priority.

Alarm function related to flow temperatures.

Weather compensated control of flow temperature in two heating circuits. Room temperature compensation and sliding return temperature limitation. Circuits independent in

parallel or circuit 2 after circuit 1. Alarm function related to flow temperatures.

Weather compensated control of flow temperature in heating circuit. Room temperature

compensation and sliding return temperature limitation.

Flow temperature control in DHW circuit. Return temperature limitation. Sliding DHW

priority possibility. Optional DHW temperature control related to DHW flow detection.

Alarm function related to flow temperatures.

A275 also covering A375:

Weather compensated flow temperature control of 1-stage boiler based heating systems.

One direct heating circuit and one mixing circuit. Circulation pumps control, room temperature control and sliding return temperature limitation.

Temperature control of DHW storage tank with internal heat exchanger. Frost protection

and alarm function.

The A275 application key contains applications related to ECL Comfort 310 for increased

functionalities (multiple boiler stages).

17

31

35

40

42

47

49

55

57

59

12

12

ECL Comfort

210 296 310

116

Application Description Page

Weather compensated control of flow temperature in a heating circuit, based on an

advanced buffer temperature control. Charging pump is speed controlled, based on 0 - 10

Volt or PWM (Pulse Width Modulated) signal. Discharging of buffer is avoided according

A319

A333

A361

A362

A367

A368

A376

A377

A390

to built-in logic. Differential pressure can be maintained by means of speed controlled

circulation pump (0 - 10 Volt or PWM).

Optional sliding return temperature limitation.

Relay output present for buffer heating demand; override signal for remote setting of

desired flow temperature.

Alarm functions are related to flow and buffer temperatures.

Weather compensated control of flow temperature in heating circuit. Sliding return temperature limitation. Control of one or two circulation pumps. Refill water function for one

or two pumps and refill water storage control.

Pressure and temperature monitoring functions.

Alarm function related to flow temperature, pressure and circulation pumps operation.

Weather compensated control of flow temperature in two heating circuits. Sliding return

temperature limitation. Control of one or two circulation pumps in each heating circuit.

Optional control of flow temperature related to supply temperature. Refill water function.

Alarm function related to flow temperature, pressure and circulation pumps operation.

Weather compensated control of flow temperature in a heating circuit, based on advanced cascade control of 2 heat exchangers (HEX). Control valve characteristics are taken

into consideration and flow in unused HEX circuit can be stopped.

Optional sliding return temperature limitation. Scheduled shift for inversed cascade (HEX1 - HEX-2 and HEX-2 - HEX-1) can be set. Override inputs for start of HEX-1 and HEX-2 are

available. M-Bus based signal can be used for flow / energy limitation.

Up to 6 heat exchangers can be cascade controlled by 1, 2 or 3 ECL Comfort 310 controllers, each equipped with the application key A362; the ECL controllers are interconnected

by means of the ECL 485 Bus.

Alarm functions are related to flow and flow temperatures.

Weather compensated control of flow temperature in two heating circuits. Room temperature compensation and sliding return temperature limitation. Heating circuits work

independent in parallel or circuit 2 after circuit 1.

Temperature control in DHW circuit with storage tank, directly heated or charging system.

Return temperature limitation. DHW priority.

Alarm function related to flow temperatures.

Weather compensated control of flow temperature in heating circuit. Sliding return

temperature limitation. Control of one or two circulation pumps. Optional control of flow

temperature related to supply temperature. Refill water function for one or two pumps.

Flow temperature control in DHW circuit. Return temperature limitation. Sliding DHW

priority possibility. Control of one or two circulation pumps.

Alarm function related to flow temperature, pressure and circulation pumps operation.

Weather compensated control of flow temperature in two heating circuits. Room temperature compensation and sliding return temperature limitation. Heating circuits work

independent in parallel or circuit 2 after circuit 1.

Flow temperature control in DHW circuit. Return temperature limitation. Sliding DHW

priority possibility. Optional DHW temperature control related to DHW flow detection.

Alarm functions related to flow temperatures, pressures and extra alarm input.

Optional control of motorized control valves by means of analog signal (0 - 10 volt).

Weather compensated control of flow temperature in two heating circuits. Room temperature compensation and sliding return temperature limitation. Heating circuits work

independent in parallel or circuit 2 after circuit 1.

Temperature control in DHW circuit with storage tank, directly heated or charging system.

Return temperature limitation. DHW priority. Optional temperature control of DHW heating temperature.

Alarm function related to flow temperatures.

Weather compensated control of flow temperature in up to three heating circuits. Room

tem perature compensation and sliding return temperature limitation. Heating circuits

work independent in parallel or circuit 2 and 3 after circuit 1.

Control of flow temperature in up to three cooling circuits. Room tem perature compensation and return temperature limitation. Cooling circuits work independent in parallel or

circuit 2 and 3 after circuit 1.

Temperature control of DHW tank charging circuit. Control of DHW heating temperature.

Return temperature limitation. DHW priority possibility.

Alarm functions related to flow temperatures.

Optional control of motorized control valves by means of analog signal, 0 - 10 volt, (3 x

heating circuits only).

68

69

70

71

74

77

79

83

86

13

13

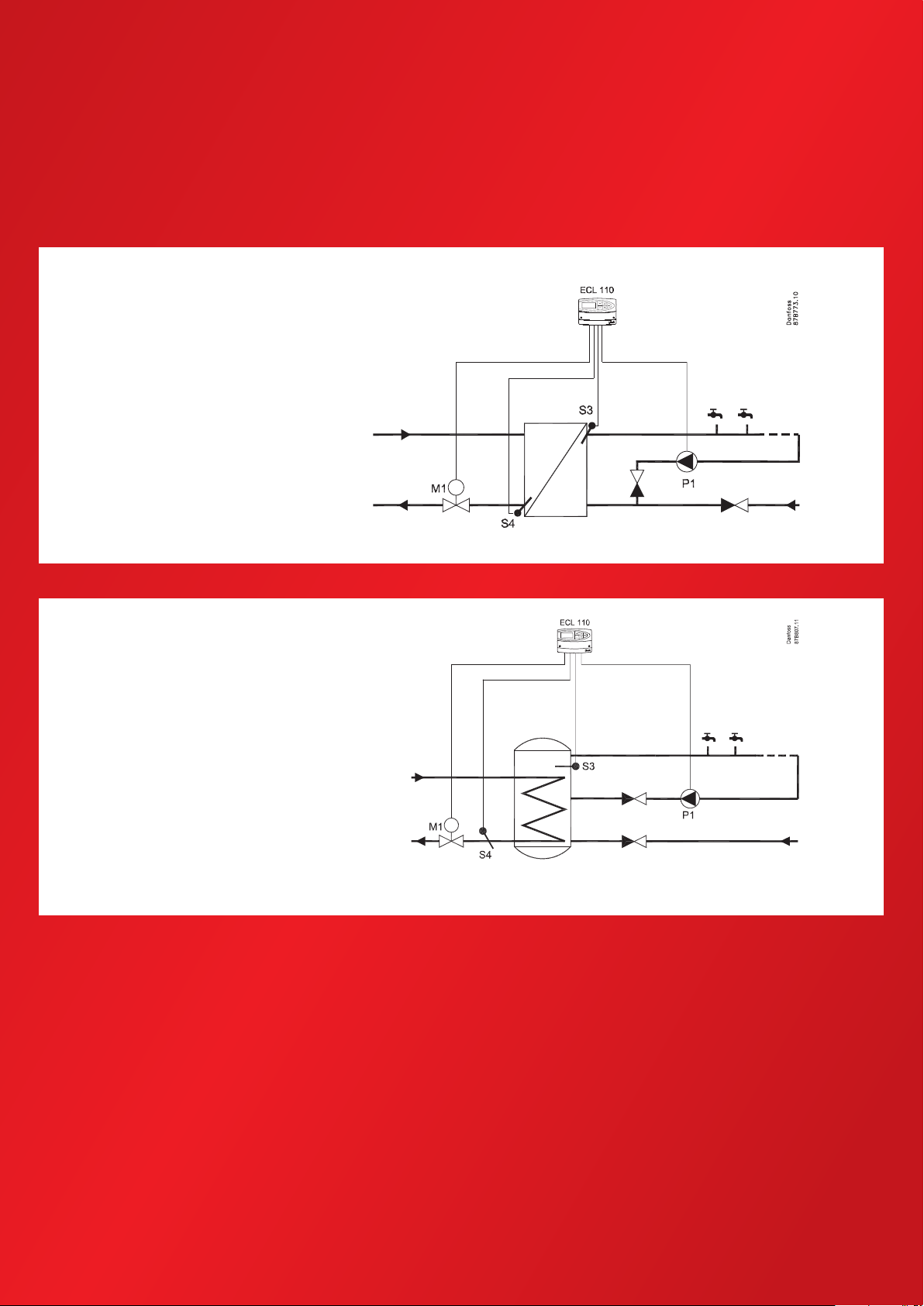

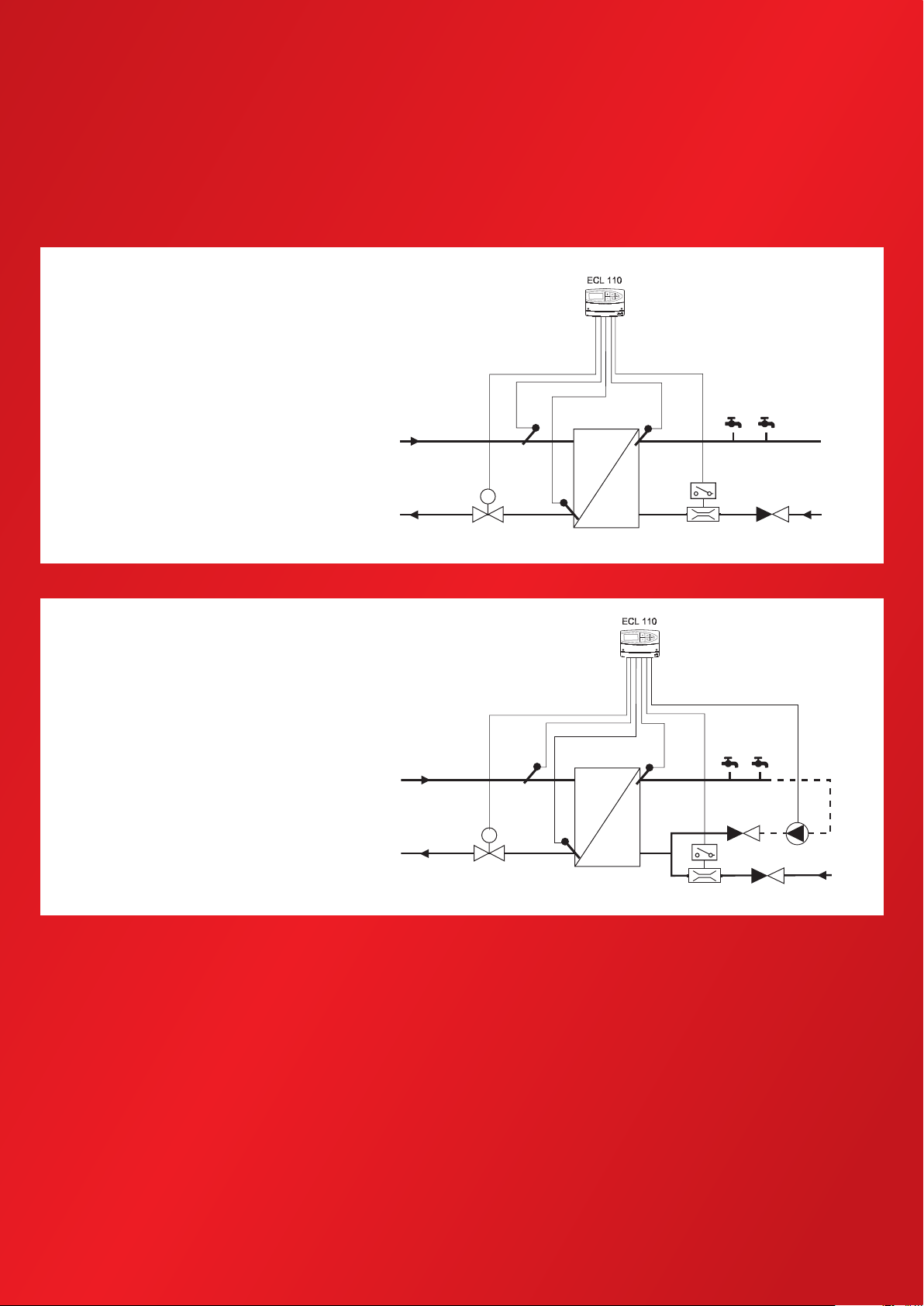

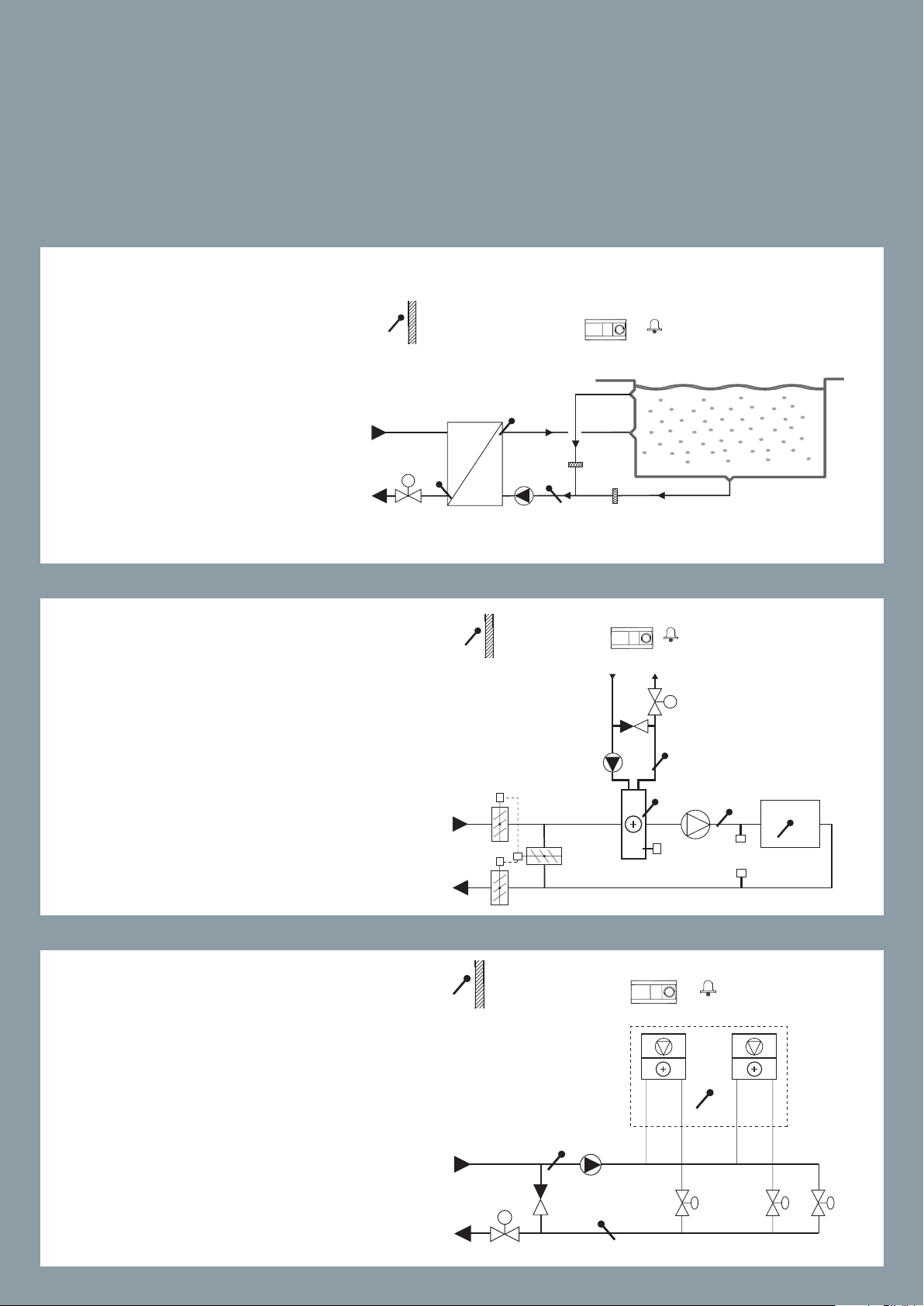

ECL Comfort 110 Application 116

Electronic temperature control of DHW circuits.

116

Example a

Constant DHW temperature control

with heat exchanger.

116

Example b

Constant temperature control of DHW

circuit with storage tank with built-in

heating coil.

14

14

116

116

Danfoss

87H2156.10

Example c

DHW temperature control at DHW

tapping (DHW draw-o) detected by

ow switch (FS).

116

116

Example d

DHW temperature control at DHW

tapping (DHW draw-o) detected by

ow switch (FS) (DHW circulation).

M1

M1

S2

S2

S4

S4

S3

S3

FS

FS

P1

Danfoss

87H2157.10

15

15

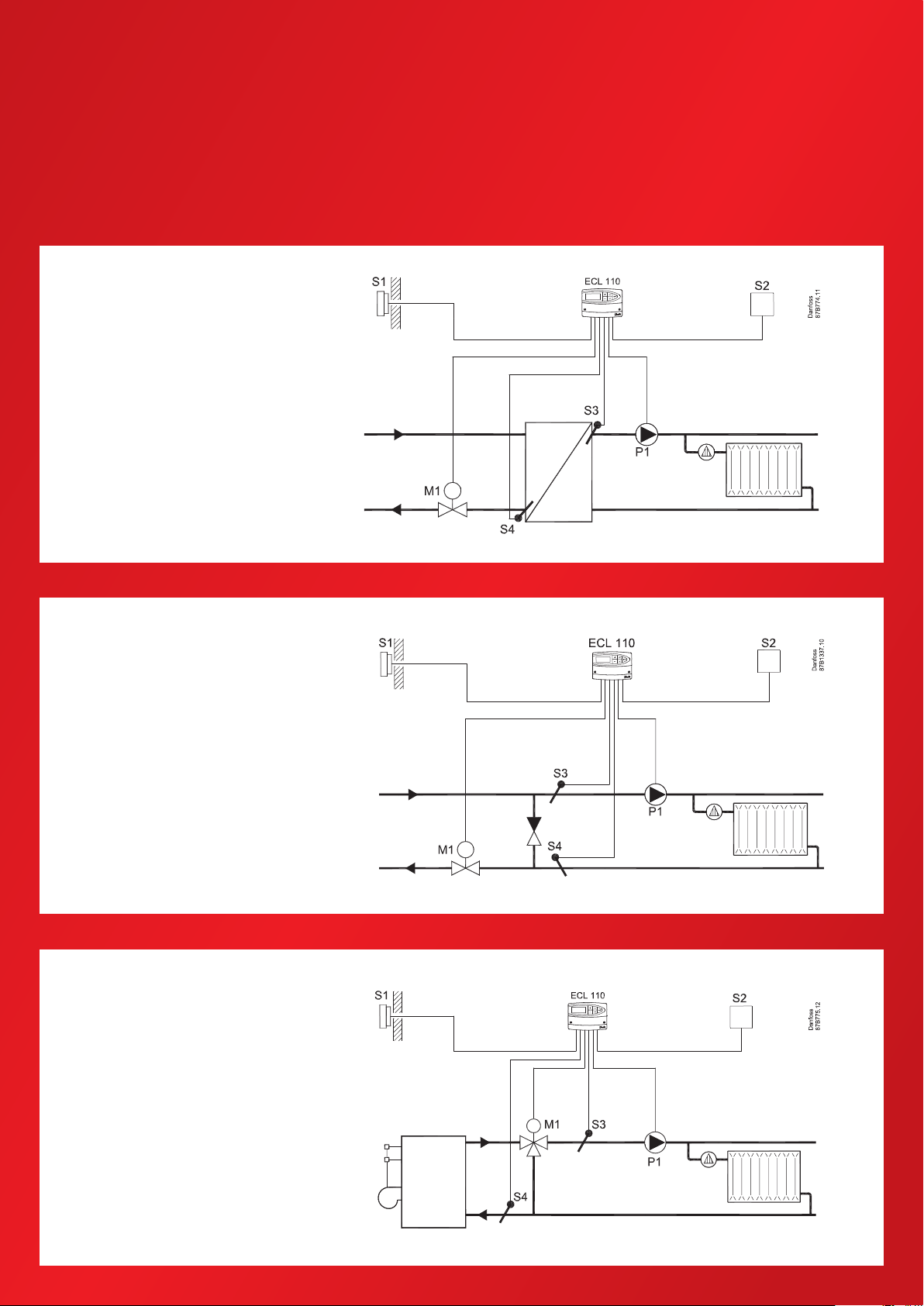

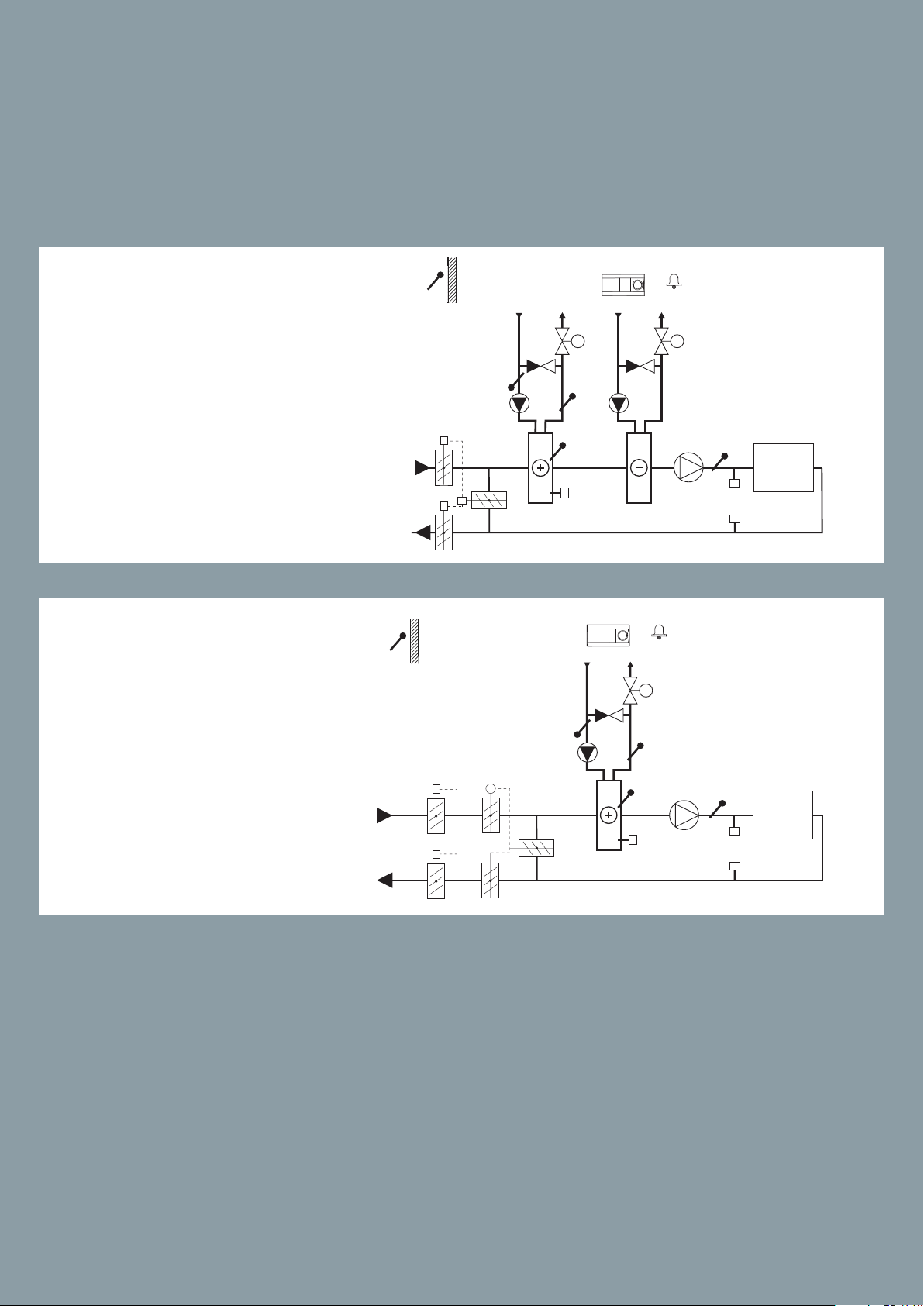

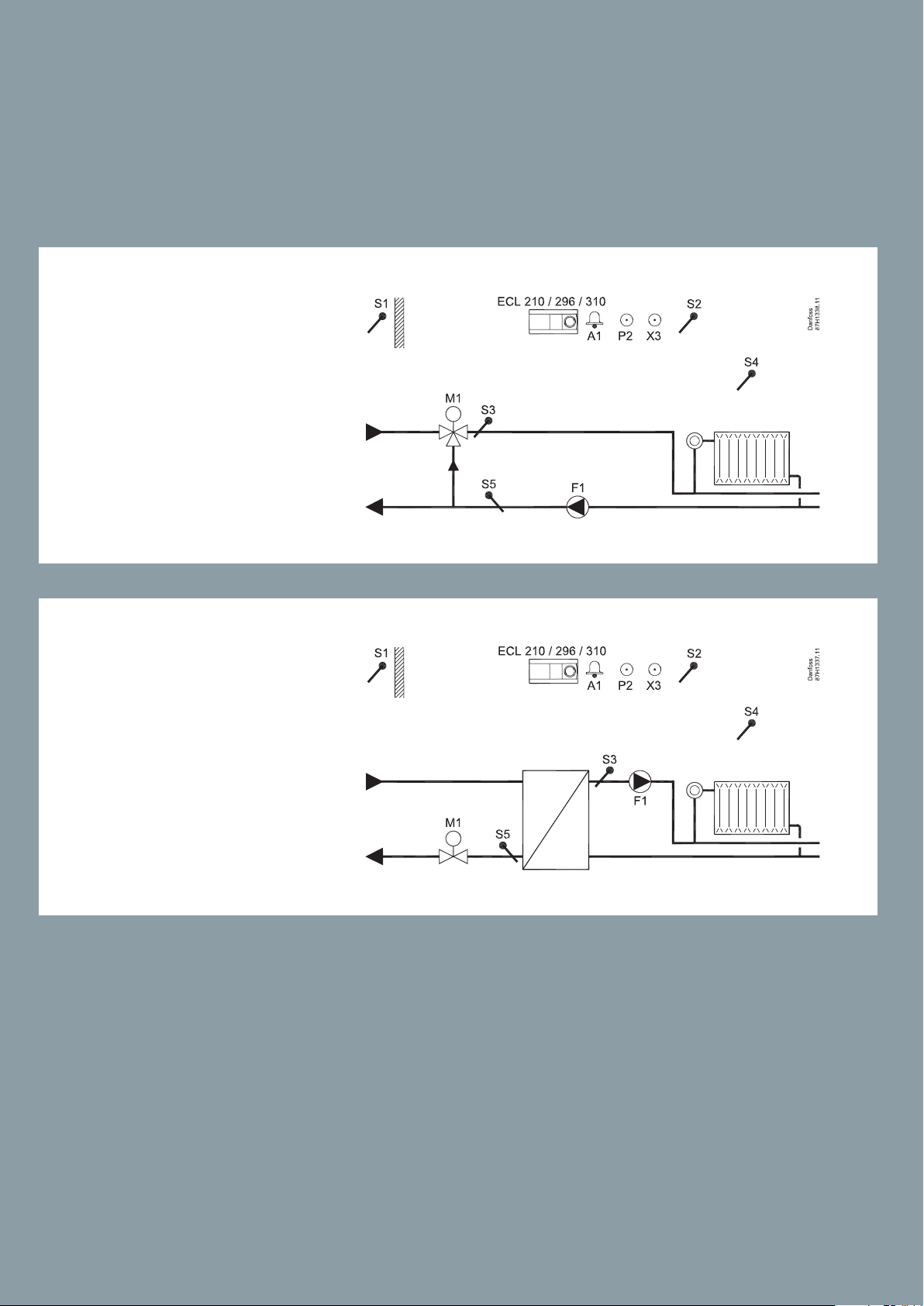

ECL Comfort 110 Application 130

Electronic temperature controller for weather compensated ow temperature.

130

Example a

District heating circuit with heat

exchanger (indirect connected

heating circuit).

130

Example b

Direct connected district heating

circuit

130

Example c

Boiler based heating circuit.

16

16

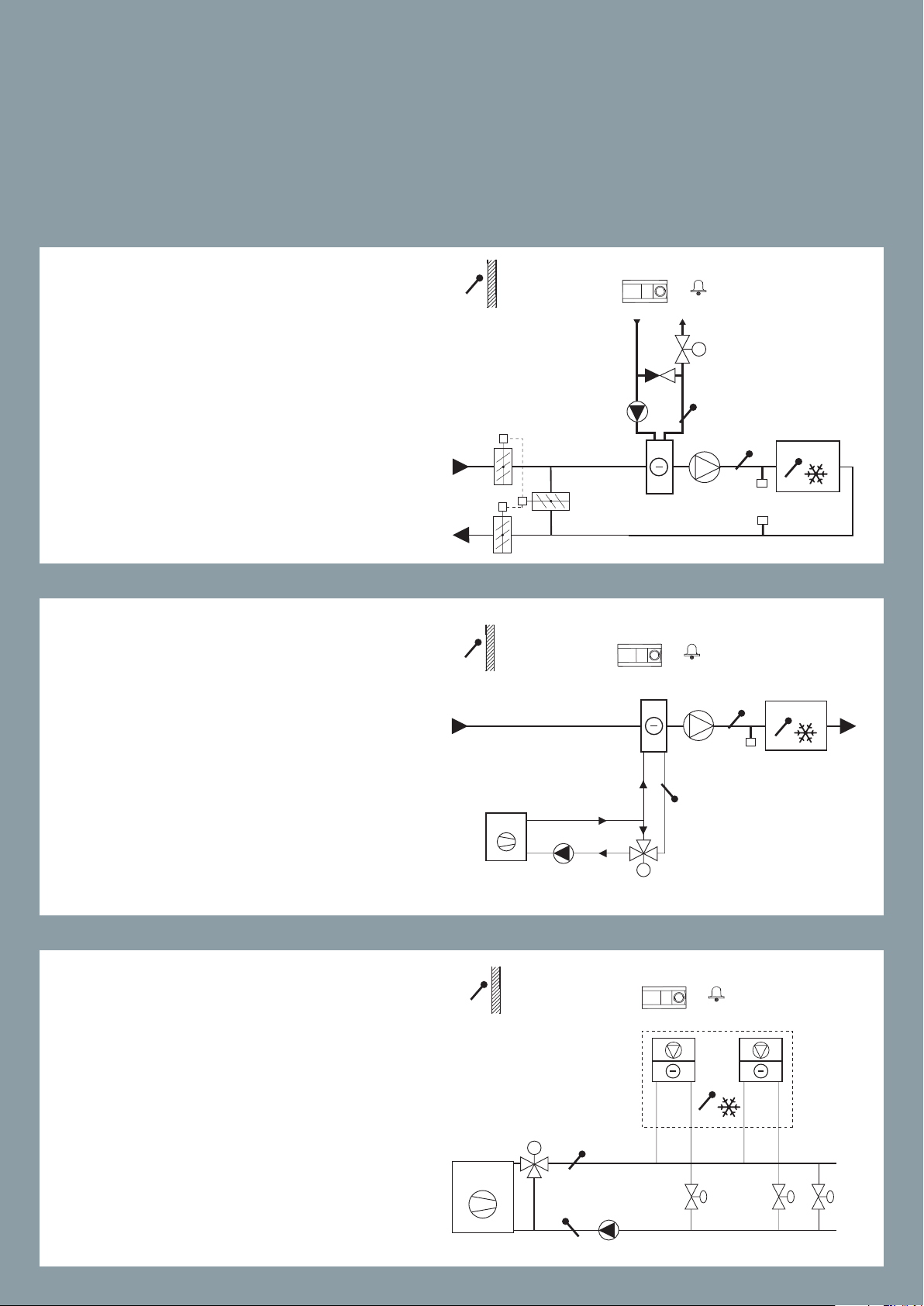

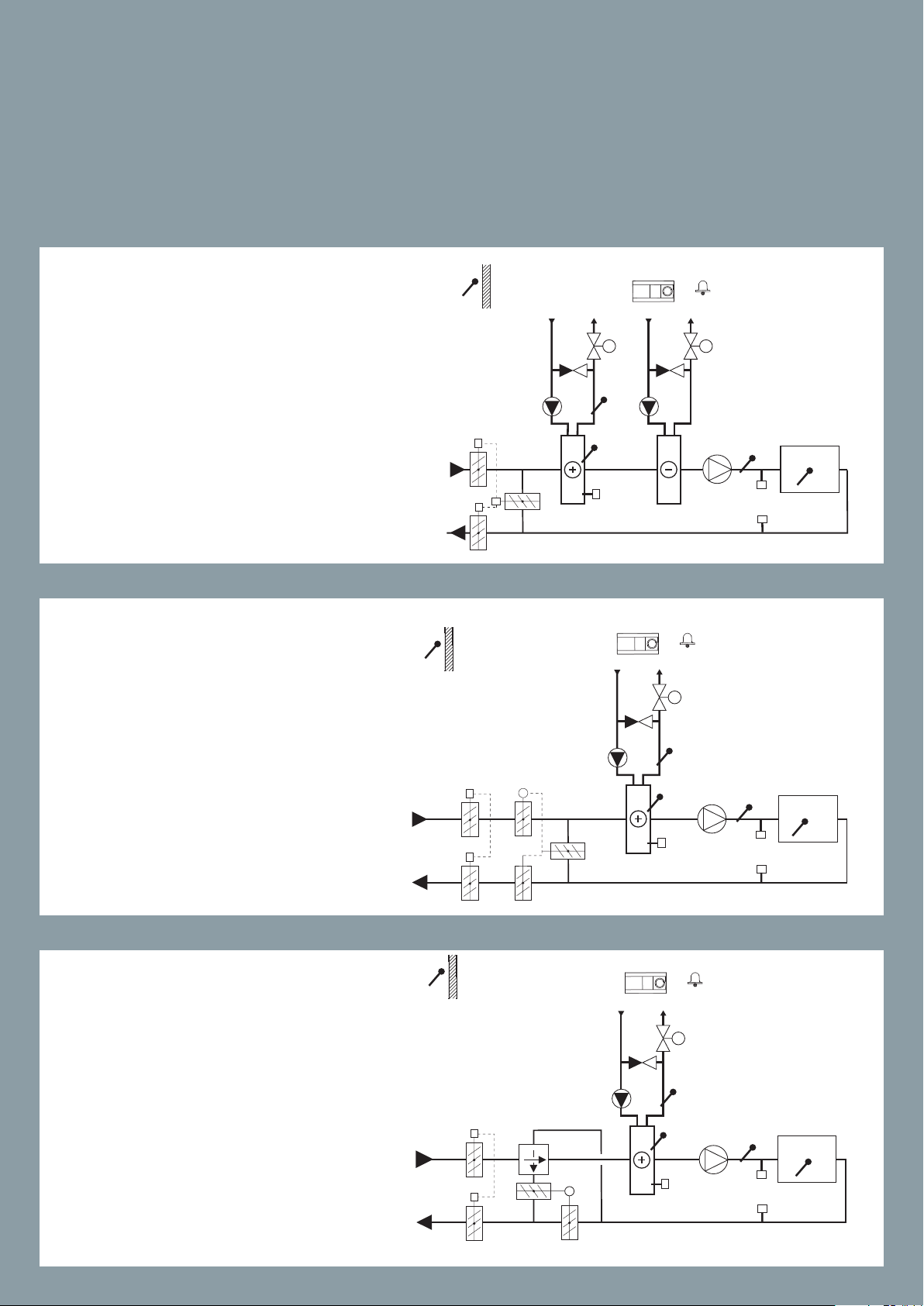

ECL Comfort 210/296/310 Application A214/A314

87H2113.13

M2

X3

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A214.1

Example a

Ventilation system with cooling and

constant room temperature control.

A214.1

S1

S1

P2

ECL 210 / 296 / 310

X3

ECL 210 / 296 / 310

S5

A1

A1

F1

F1

M2

S3

S3

S8S8S8

S4

S4

Danfoss

87H2114.13

Danfoss

Example b

Ventilation system with cooling and

constant room temperature control.

Chiller has constant ow.

A214.1

Example c

Ventilation system (fan coils) with

cooling and constant room temperature control.

S1

M2

X3

ECL 210 / 296 / 310

S3

S5

S5

A1

F1 F1

S4

S8

Danfoss

87H2115.13

17

17

F1

S1

87H2116.12

ECL 210 / 296 / 310

S1

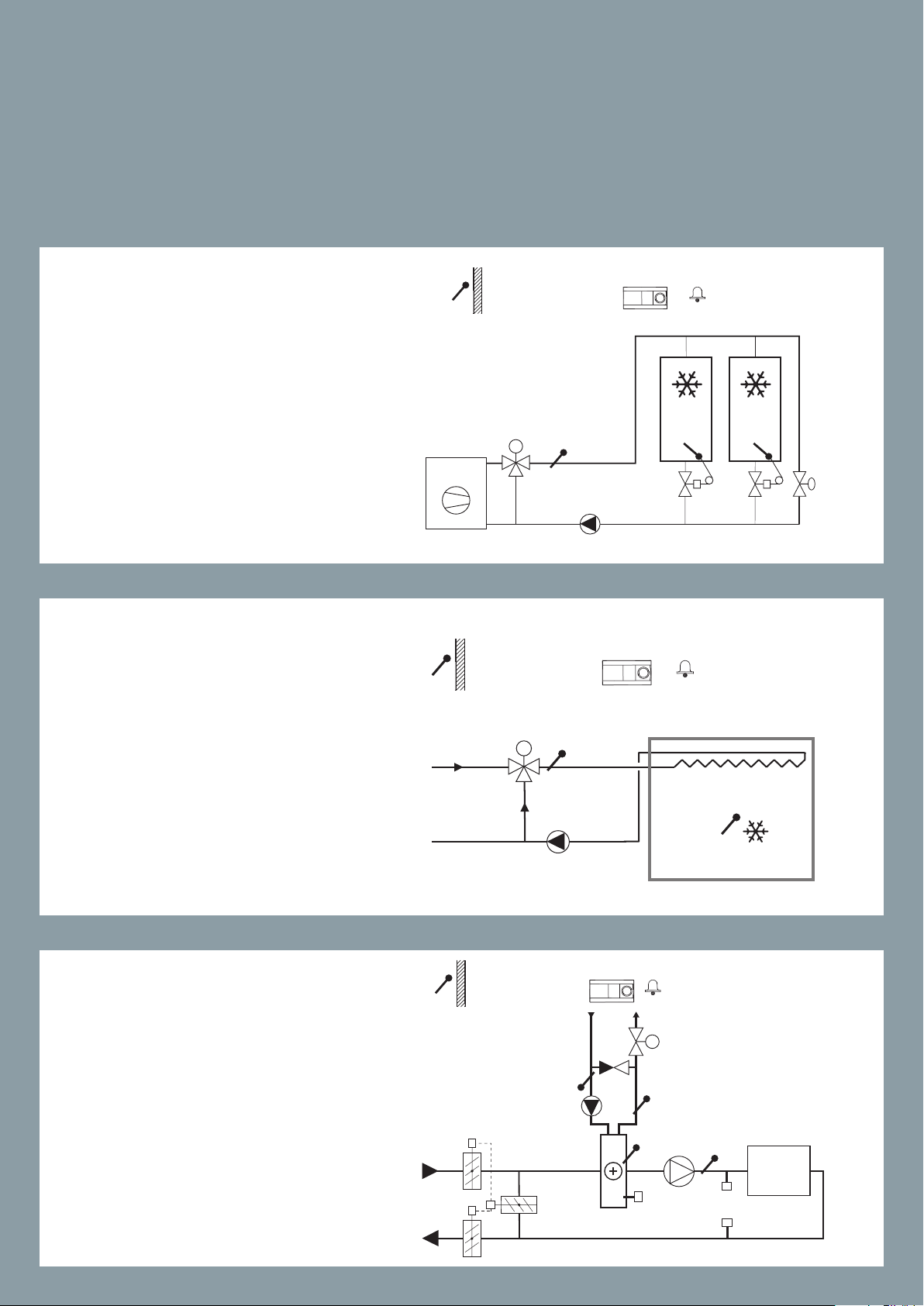

ECL Comfort 210/296/310 Application A214/A314

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A214.1

Example d

Cooling system with constant ow

temperature control.

A214.1

S1

M2

M2

S3

ECL 210 / 296 / 310

S3

A1

A1

Danfoss

Danfoss

87H2117.13

Example e

Cooling system in ceiling and constant room temperature control in

for example a wine cellar.

A214.2

Example a

Ventilation system with heating and

constant duct temperature control.

P2

F1

ECL 210 / 296 / 310

S3

X3

A1

S6

S7

S5

M1

F1

S8S8S8

S4

S4

Danfoss

87H2118.12

18

18

A214.2

S1

ECL 210 / 296 / 310

F1

ECL 210 / 296 / 310

S1

87H2120.12

S1

87H2121.12

ECL 210 / 296 / 310

Example b

Heating of a swimming pool, constant water temperature control.

M1

S5

S3

S4

A1

Danfoss

87H2119.12

A214.3

Example a

Ventilation system with heating and

constant room temperature control.

A214.3

P2

X3

A1

S6

S7

M1

S5

F1

A1

F1 F1

S4

S8S8S8

S3

Danfoss

S4

Danfoss

Example b

Ventilation system (fan coils) with

heating and constant room temperature control.

M1

S3

X3

S5

19

19

S1

87H2122.12

ECL 210 / 296 / 310

87H2123.12

ECL 210 / 296 / 310

ECL Comfort 210/296/310 Application A214/A314

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A214.4

Example a

Ventilation system with heating,

cooling and constant duct temperature control.

A214.4

Example b

Ventilation system with heating, passive cooling (outside air) and constant duct temperature control.

S1

P2

P2

M2

X3

S3

S3

X3

S6

S7

S5

M1

A1

S6

S7

S5

M1

A1

F1

F1

Danfoss

M2

S4

S8S8S8

Danfoss

S4

S8S8S8

20

20

A214.5

S1

ECL 210 / 296 / 310

87H2125.13

ECL 210 / 296 / 310

S1

ECL 210 / 296 / 310

A1

Danfoss

87H2124.12

Example a

Ventilation system with heating, cooling and constant room temperature

control.

A214.5

Example b

Ventilation system with heating, passive cooling (outside air) and constant room temperature control.

S1

P2

P2

M2

X3

X3

S6

S7

S5

M1

A1

S6

S7

S5

M1

M2

F1

S3

S8S8S8

S3

F1

S8S8S8

S4

Danfoss

S4

A214.5

Example c

Ventilation system with heating, crossow heat exchanger control and constant room temperature control.

P2

M2

X3

A1

S5

S6

S7

M1

Danfoss

87H2134.12

S3

F1

S8S8S8

S4

21

21

ECL Comfort 210/296/310 Application A214/A314

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A214.6

Example a

Heating system with 3-port mixing

valve

A214.6

Example b

Heating system with heat exchanger

22

22

A314.1

S1

87H2133.12

S1

ECL 310

87H2127.12

ECL 310

+ ECA 32

A1

M1

S2

Danfoss

Example a

Ventilation system with heating, passive cooling (outside air) and constant

duct temperature control. Analog controlled passive cooling (M2).

A314.1

Example b

Ventilation system with heating, cooling and constant duct temperature

control. Analog controlled cooling

(M2).

P2

P2

S3

X3

M2

S3

X3

A

ECL 310

+ ECA 32

M1

S5

S6

S7

S6

S7

S5

A1

F1

S4

S8S8S8

S2

M2

A

F1

S4

S8S8S8

Danfoss

87H2128.12

A314.2

Example a

Ventilation system with heating, passive cooling (outside air) and constant

room temperature control. Analog

controlled passive cooling (M2).

S1

P2

M2

S2

S6

S7

S5

A1

M1

F1

S3

S8S8S8

+ ECA 32

X3

A

S4

Danfoss

23

23

S1

ECL 310

S1

87H2132.12

ECL 310

S1

87H2131.12

ECL Comfort 210/296/310 Application A214/A314

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A314.2

Example b

Ventilation system with heating,

cooling and constant room temperature control. Analog controlled cooling (M2).

A314.3

P2

S10

X3

S6

S7

M1

S5

+ ECA 32

+ ECA 32

A1

A1

M1

S2

M2

A

F1

S3

S8S8S8

S2

S4

Danfoss

87H2135.12

Danfoss

Example a

Ventilation system with heating and

constant room temperature control.

Analog controlled fan speed (V1)

based on outdoor wind speed.

A314.3

Example b

Ventilation system with heating and

constant room temperature control.

Analog controlled air curtain (V1)

speed based on outdoor wind speed.

A1

S6

S7

S6

S5

S7

S5

F1 / V1

M1

F1

S8S8S8

S2

S3

S8S8S8

S3

S4

Danfoss

V1

A

S4

X3

P2

ECL 310

+ ECA 32

S10

X3

P2

24

24

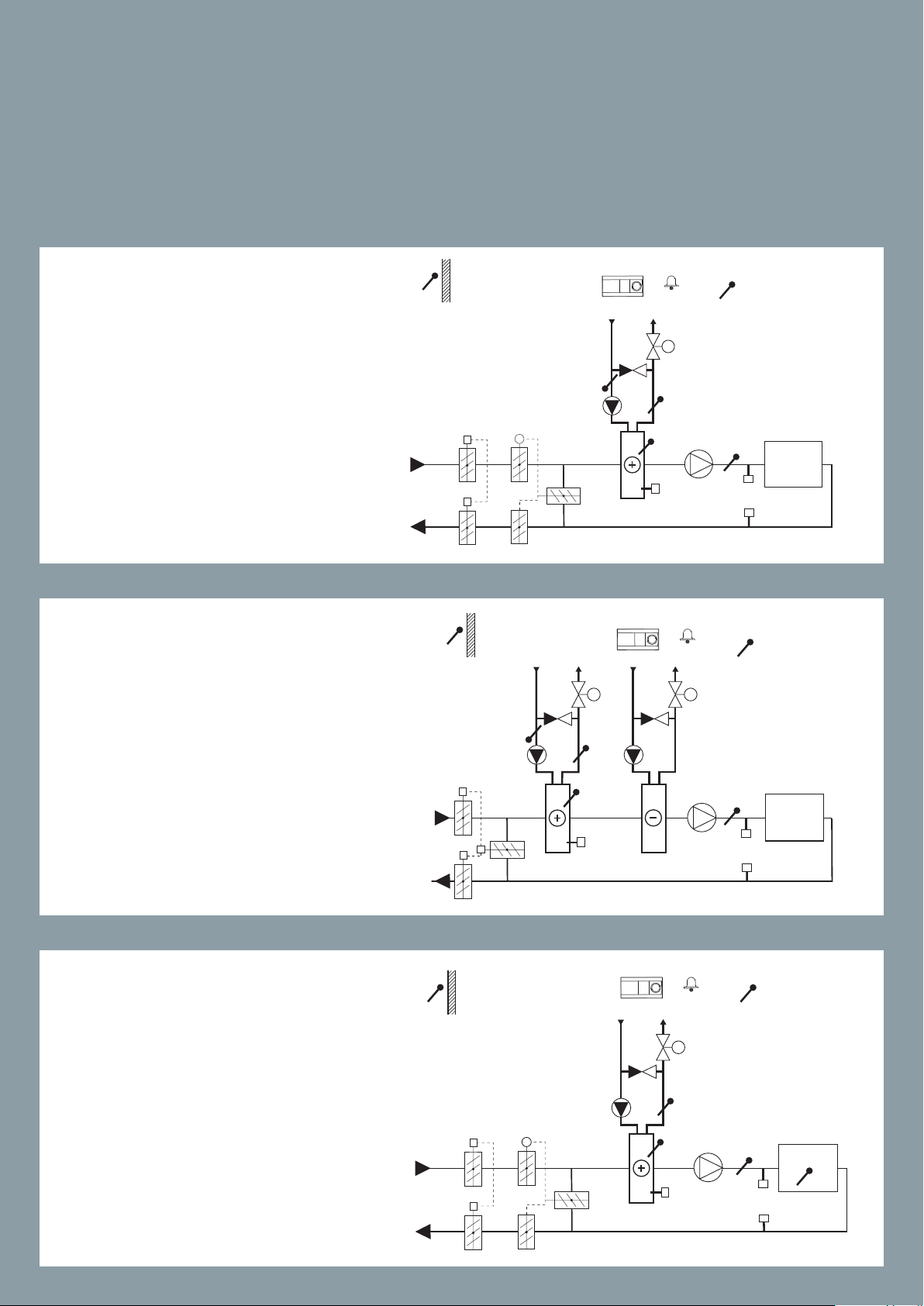

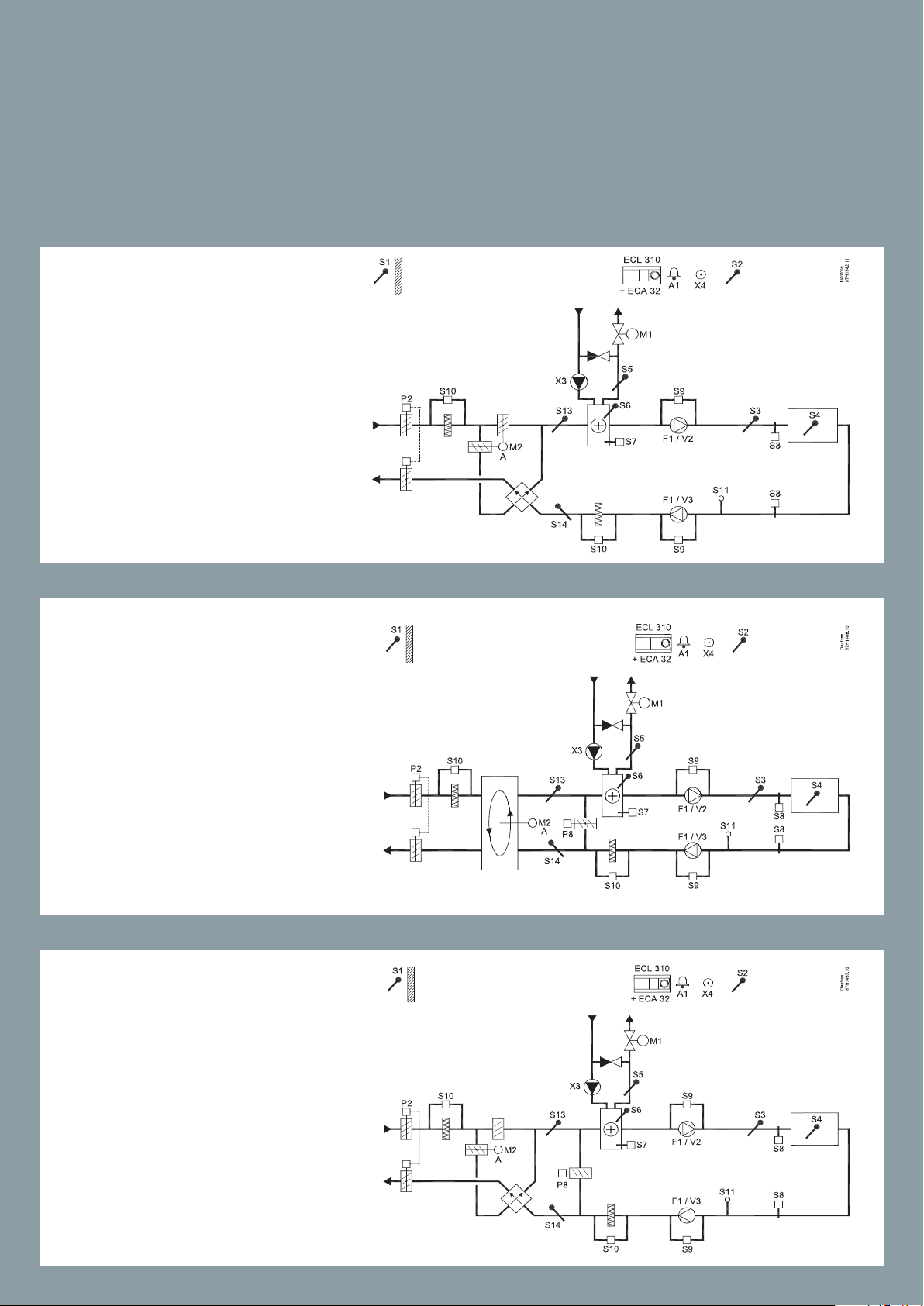

A314.4

Example a

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in relation to

pressures. Analog controlled speed

of rotary heat exchanger (M2) for

heat recover y.

A314.4

Example b

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in relation to

pressures. Analog controlled damper

(M2) for heat recovery by means of a

cross heat exchanger.

A314.4

Example c

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in relation to

pressures. Analog controlled speed

of rotary heat exchanger (M2) for heat

recovery. Control of Night damper P8

for reduced ventialtion during saving

periods.

25

25

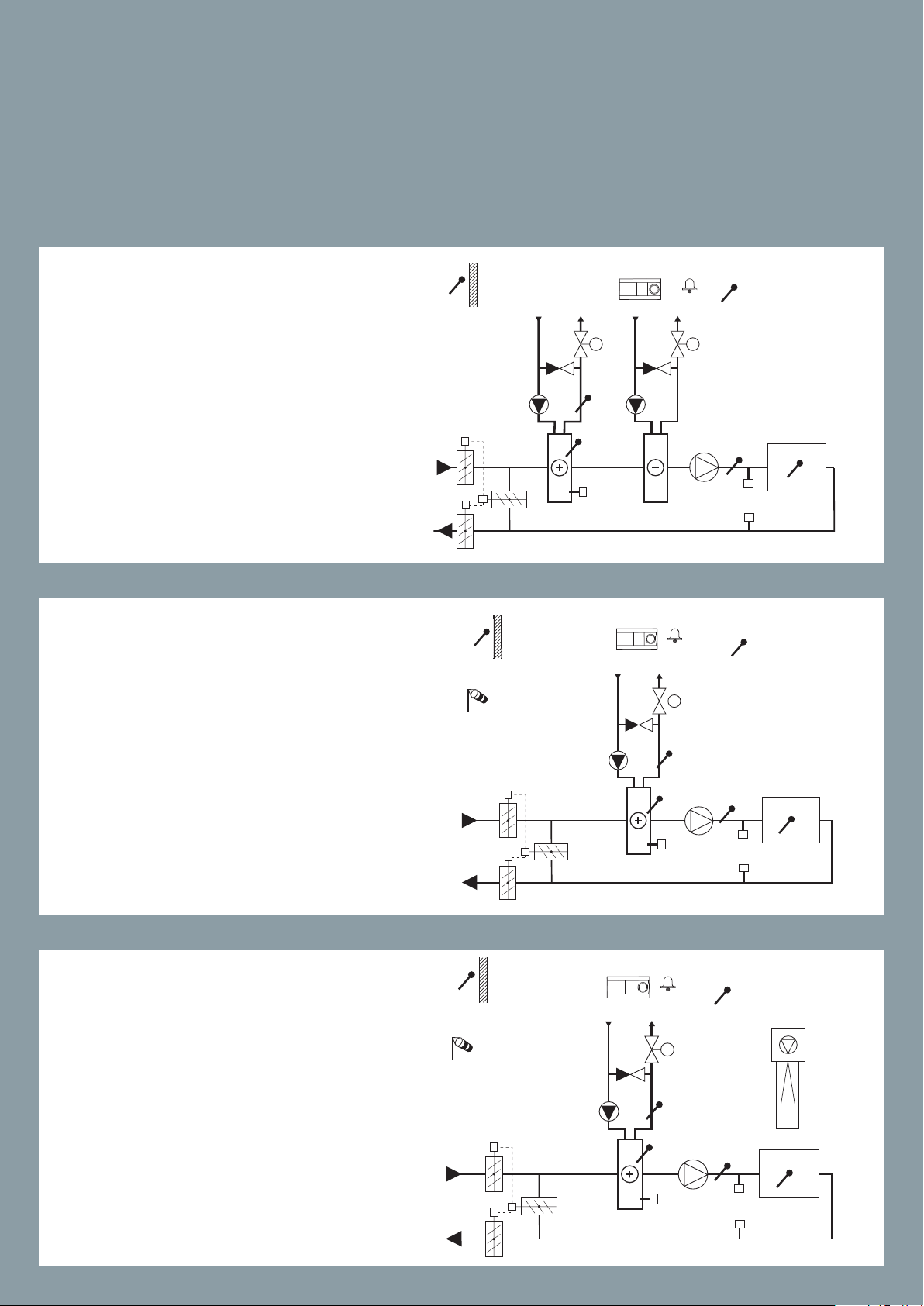

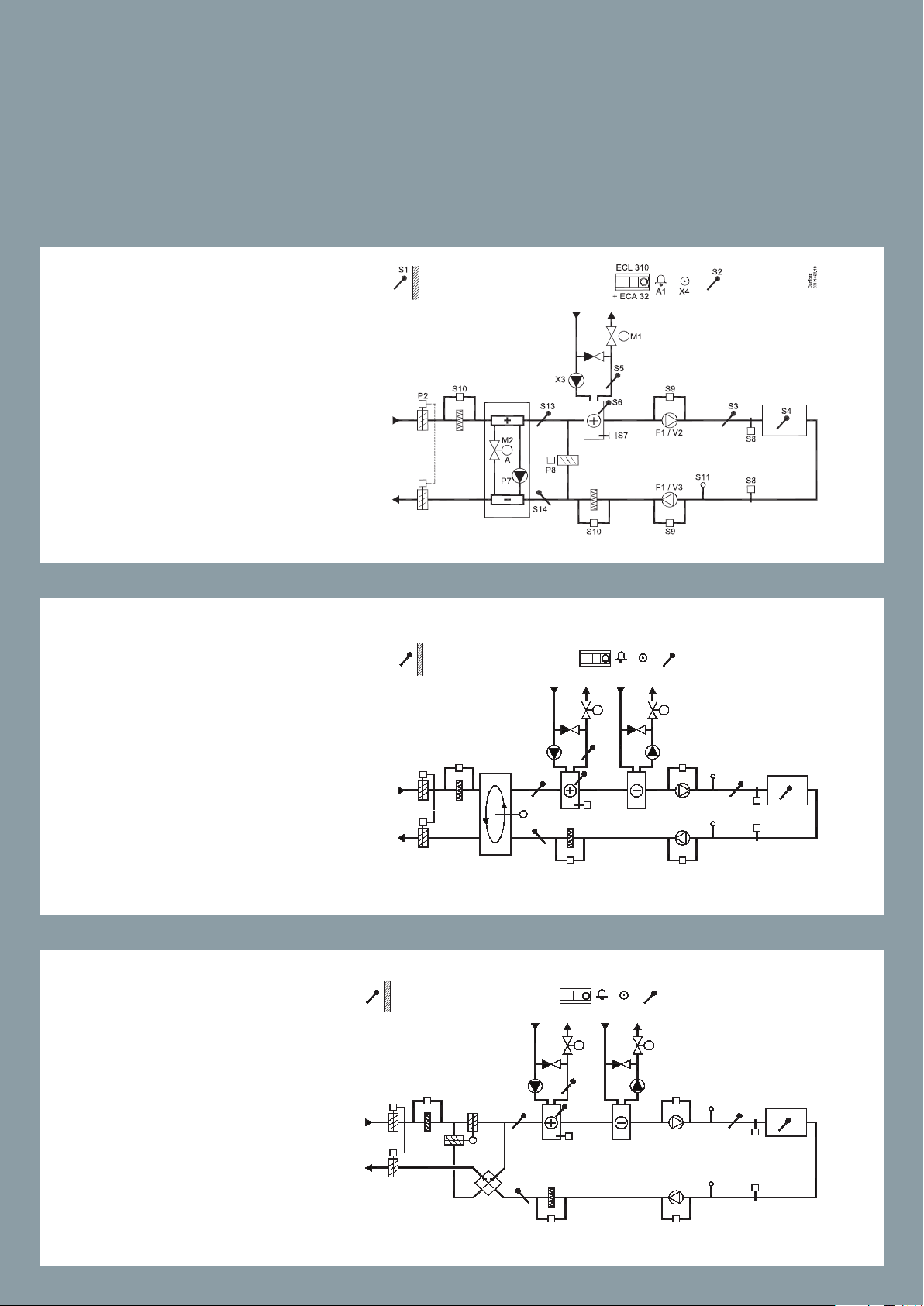

ECL Comfort 210/296/310 Application A214/A314

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A314.4

Example d

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in relation to

pressures. Analog controlled damper

(M2) for heat recovery by means of

a cross heat exchanger. Control of

Night damper P8 for reduced ventilation during saving periods.

A314.4

Example e

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in relation to

pressures. Analog controlled valve

(M2) for heat recovery by means of a

Fluid battery. Control of Night damper P8 for reduced ventilation during

saving periods.

A314.5

Example a

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in re lation to

air quality (CO2). Analog controlled

speed of rotary heat exchanger (M2)

for heat recovery.

26

26

A314.5

Example b

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in re lation to

air quality (CO2). Analog controlled

damper (M2) for heat recovery by

means of a cross heat exchanger.

A314.5

Example c

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in re lation to

air quality (CO2). Analog controlled

speed of rotary heat exchanger (M2)

for heat recovery. Control of Night

damper P8 for reduced ventilation

during saving periods.

A314.5

Example d

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in re lation to

air quality (CO2). Analog controlled

damper (M2) for heat recovery by

means of a cross heat exchanger. Control of Night damper P8 for reduced

ventilation during saving periods.

27

27

27

87H1343.11

Danfoss

S1

S2

A1 X4

P2

ECL 310

+ ECA 32

S10

M2

S13

S14

A

X3

M1

S5

S6

S7

S10

S9

F1 / V2

S12

S3

S8

S8

S4

S9

F1 / V3

S11

M3

X5

87H1344.11

Danfoss

S1

S2

A1

X4

P2

ECL 310

+ ECA 32

S10

S13

S14

X3

M1

S5

S6

S7

S10

S9

F1 / V2

S12

S3

S8

S8

S4

M2

A

S9

F1 / V3

M3

S11

X5

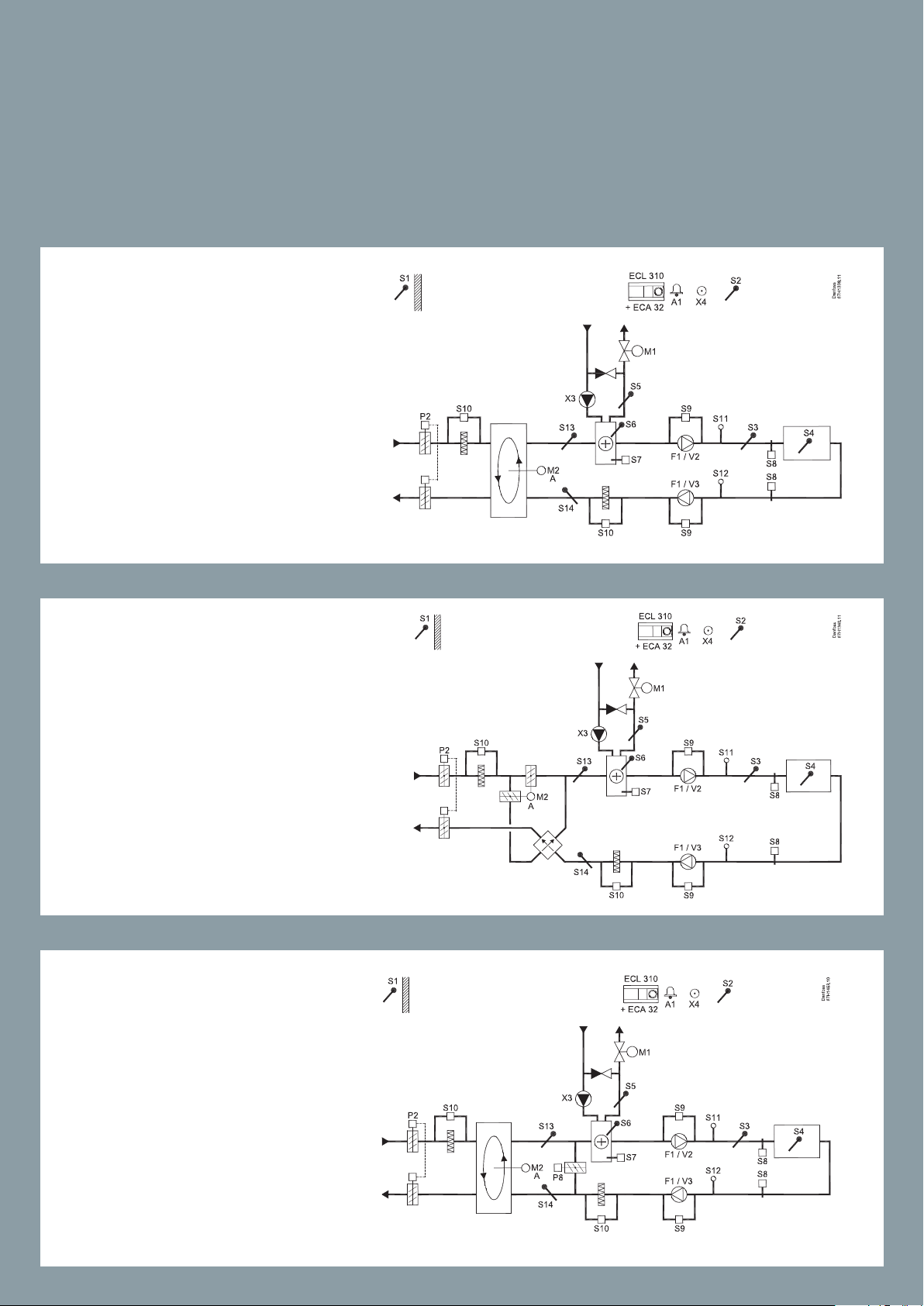

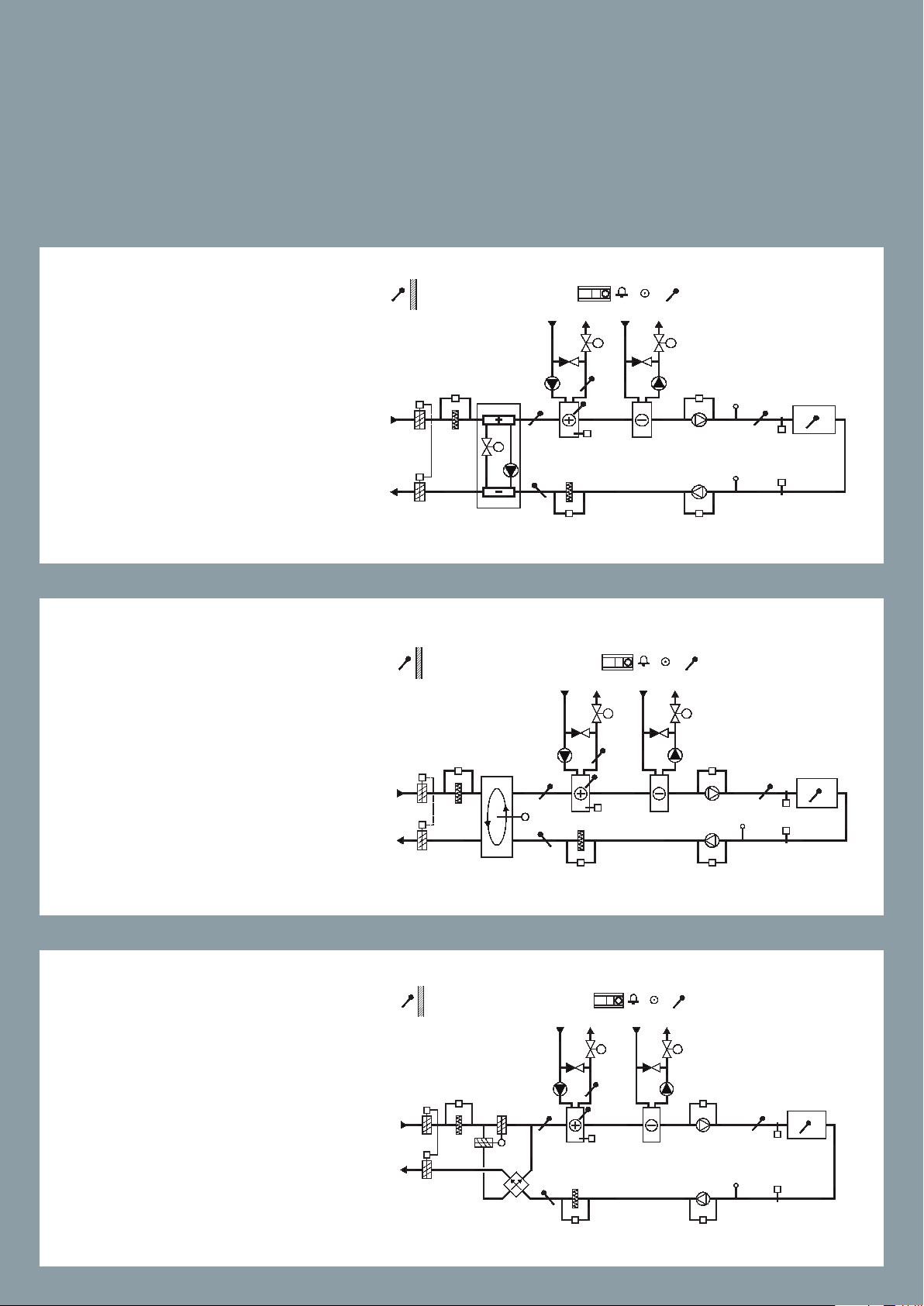

ECL Comfort 210/296/310 Application A214/A314

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A314.5

Example e

Ventilation system with heating, passive cooling (outside air) and room

temperature control. Analog controlled speed of fans in re lation to air

quality (CO2). Analog controlled valve

(M2) for heat recovery by means of a

Fluid battery. Control of Night damper P8 for reduced ventilation during

saving periods.

A314.6

Example a

Ventilation system with heating,

cooling and room temperature control. Analog controlled speed of fans

in relation to pressures. Analog controlled speed of rotary heat exchanger (M2) for heat recovery.

A314.6

Example b

Ventilation system with heating,

cooling and room temperature control. Analog controlled speed of fans

in relation to pressures. Analog controlled damper (M2) for heat recovery

by means of a cross heat exchanger.

28

28

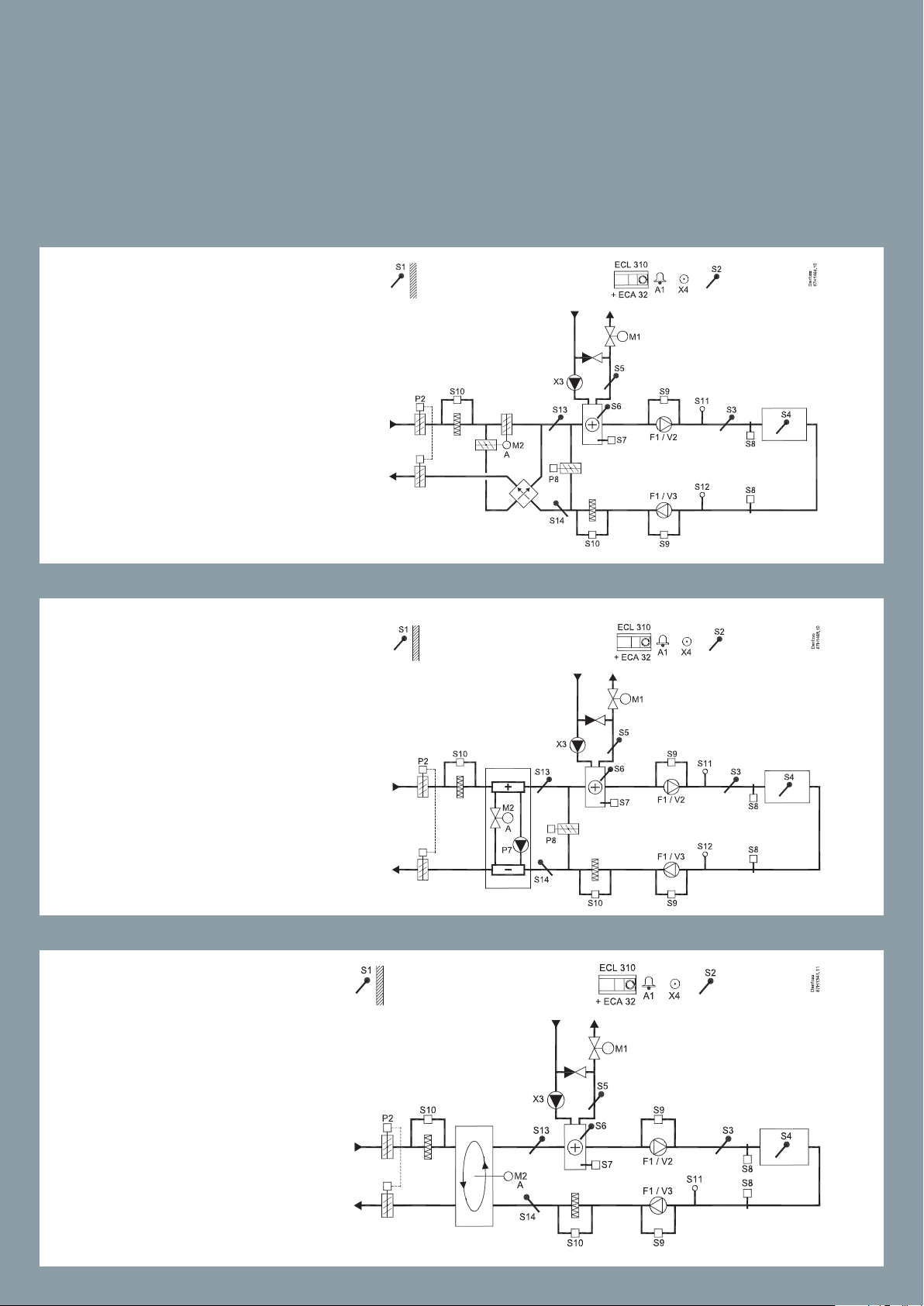

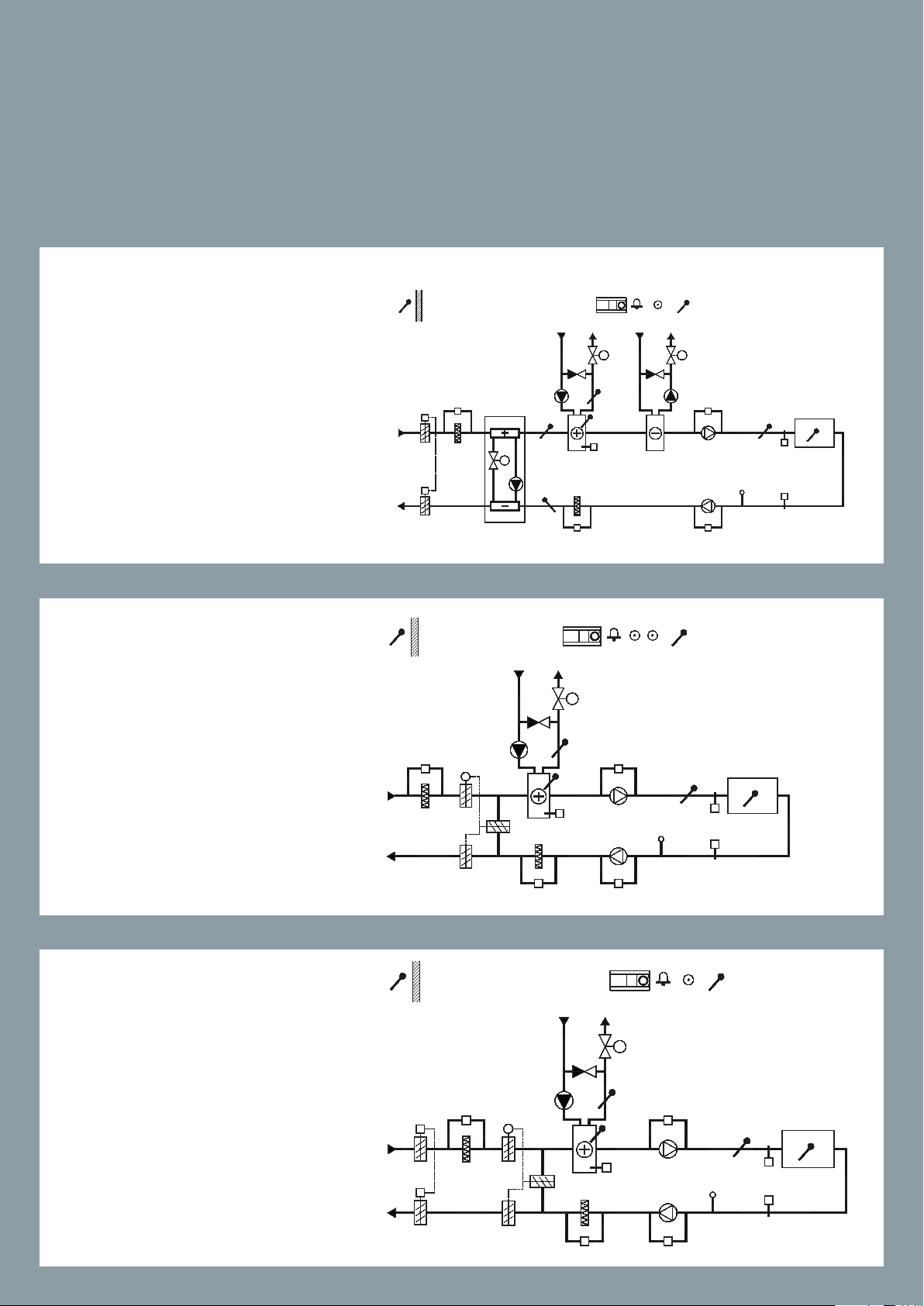

A314.6

87H1469.10

Danfoss

S1

S2

A1 X4

P2

ECL 310

+ ECA 32

S10

S13

S14

X3

M1

S5

S6

S7

S10

S9

F1 / V2

S12

S3

S8

S8

S4

S9

F1 / V3

M3

S11

X5

P7

M2

A

Example c

Ventilation system with heating, cooling and room temperature control.

Analog controlled speed of fans in relation to pressures. Analog controlled

valve (M2) for heat recovery by means

of a Fluid battery.

S10

S10

ECL 310

+ ECA 32

S5

S6

S7

ECL 310

+ ECA 32

M1

S5

S6

S7

S2

A1 X4

M1

A1

M3

X5

X4

X5

S9

S3

F1 / V2

F1 / V3

S9

S2

M3

S9

F1 / V2

S11

F1 / V3

S9

S11

S8

S8

S3

S8

S8

87H1345.11

Danfoss

S4

87H1346.11

Danfoss

S4

29

29

29

A314.7

Example a

Ventilation system with heating, cool-

S1

S10

P2

X3

S13

ing and room temperature control.

Analog con trolled speed of fans in re-

M2

A

lation to air quality (CO2). Analog controlled speed of rotary heat exchanger

S14

(M2) for heat recovery.

S1

A314.7

S10

P2

X3

S13

M2

A

S14

Example b

Ventilation system with heating, cooling and room temperature control.

Analog con trolled speed of fans in relation to air quality (CO2). Analog controlled damper (M2) for heat recovery

by means of a cross heat exchanger.

87H1471.11

Danfoss

S1

S2

A1

X4

M2

ECL 310

+ ECA 32

S10

X3

M1

S5

S6

S7

S10

S9

F1 / V2

S11

S3

S8

S8

S4

S9

F1 / V3

A

P2

S1

ECL 310

S9

ECL Comfort 210/296/310 Application A214/A314

Multi purpose application. Temperature control of, for example, ventilation

systems with heating or cooling or a combination of these. Weather based

compensation, return temperature limitation, frost and re protection. Optional analog control of cross-ow or rotary heat exchanger.

Alarm function related to duct / ow temperature, re and frost.

A314.7

Example c

Ventilation system with heating, cooling and room temperature control.

Analog con trolled speed of fans in relation to air quality (CO2). Analog controlled valve (M2) for heat recovery by

means of a Fluid battery.

A314.9

S10

ECL 310

+ ECA 32

M1

S5

S6

S7

S2

A1

X4

M3

X5

S9

F1 / V2

F1 / V3

S9

S11

S3

S8

S8

87H1470.10

Danfoss

S4

S1

S10

P2

X3

S13

M2

A

P7

S14

Example a

Ventilation system with heating and

room temperature control. Analog

controlled speed of fans in relation to

air quality (CO2).

S2

87H1472.11

X4

A314.9

Example b

Ventilation system with heating and

room temperature control. Analog

con trolled speed of fans in re lation to

air quality (CO2). ON-OFF control of

damper P2.

30

30

M2

X3

A

S10

P2

+ ECA 32

S6

S10

A1

M1

S5

S9

S3

F1 / V2

S7

F1 / V3

S11

S8

S8

Danfoss

S4

S1

87H2068.13

87H2069.13

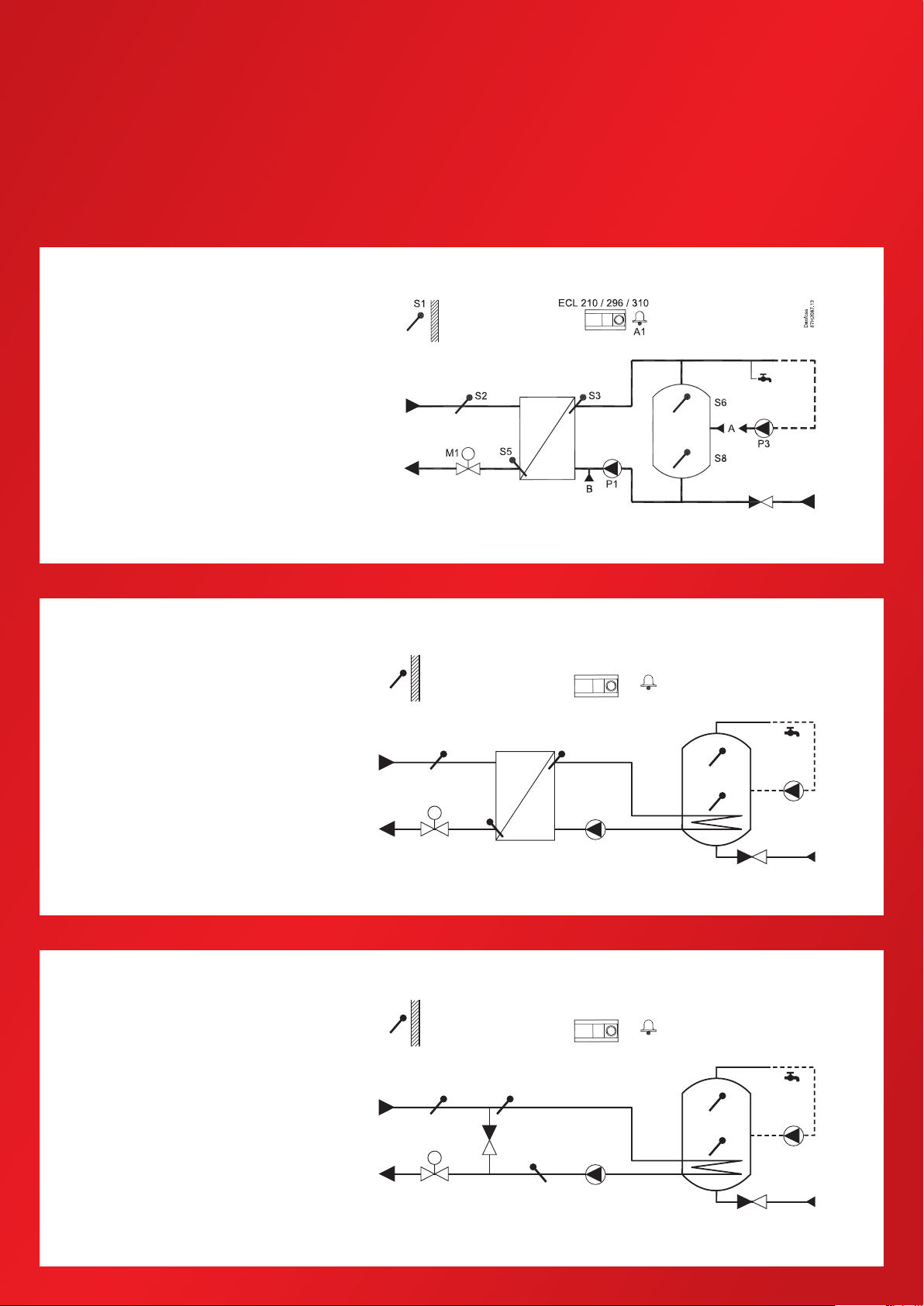

ECL Comfort 210/296/310 Application A217/A317

Advanced temperature control of DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Optional temperature

control of DHW heating temperature.

Alarm function related to ow temperature.

A217.1 / A317.1

Example a

Indirectly connected DHW charging system. DHW circulation through

DHW tank (A) or heat exchanger (B).

A217.1 / A317.1

Example b

Indirectly connected DHW heating

system.

A217.1 / A317.1

S1

M1

M1

ECL 210 / 296 / 310

A1

S2

S5

S2

S3

S3

P1

ECL 210 / 296 / 310

S5

S6

S8

A1

S6

S8

Danfoss

P3

Danfoss

P3

Example c

Directly connected DHW heating

system.

P1

31

31

S1

87H2071.13

ECL 210 / 296 / 310

S1

ECL 210 / 296 / 310

ECL Comfort 210 Application A217

Advanced temperature control of DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Optional temperature

control of DHW heating temperature.

Alarm function related to ow temperature.

A217.1 / A317.1

Example d

Directly connected DHW heating

system.

A217.2 / A317.2

Example a

Indirectly connected DHW charging

system with controlled heating temperature. DHW circulation through

DHW tank (A) or heat exchanger (B).

A217.2 / A317.2

Example b

Indirectly connected DHW charging

system with controlled heating temperature. DHW circulation through

DHW tank (A) or heat exchanger (B).

S2 S3

M1

M1

S2 S3

S5

S5

P1

P1

S4

P3

P3

Danfoss

Danfoss

87H2072.13

A1

S4

B

P2

A1

B

P2

S6

A

S8

S6

A

S8

32

32

A217. 3

Example a

Indirectly connected DHW heating

system. DHW circulation through heat

exchanger.

A217. 3

Example b

Indirectly connected DHW heating

system. DHW heating on demand via

ow switch (S8).

33

33

ECL Comfort 210 Application A217

Advanced temperature control of DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Optional temperature

control of DHW heating temperature.

Alarm function related to ow temperature.

A217. 3

Example c

Indirectly connected DHW heating

system. DHW circulation through

heat exchanger.

A217. 3

Example d

Directly heated DHW tank. DHW

circulation through DHW tank.

34

34

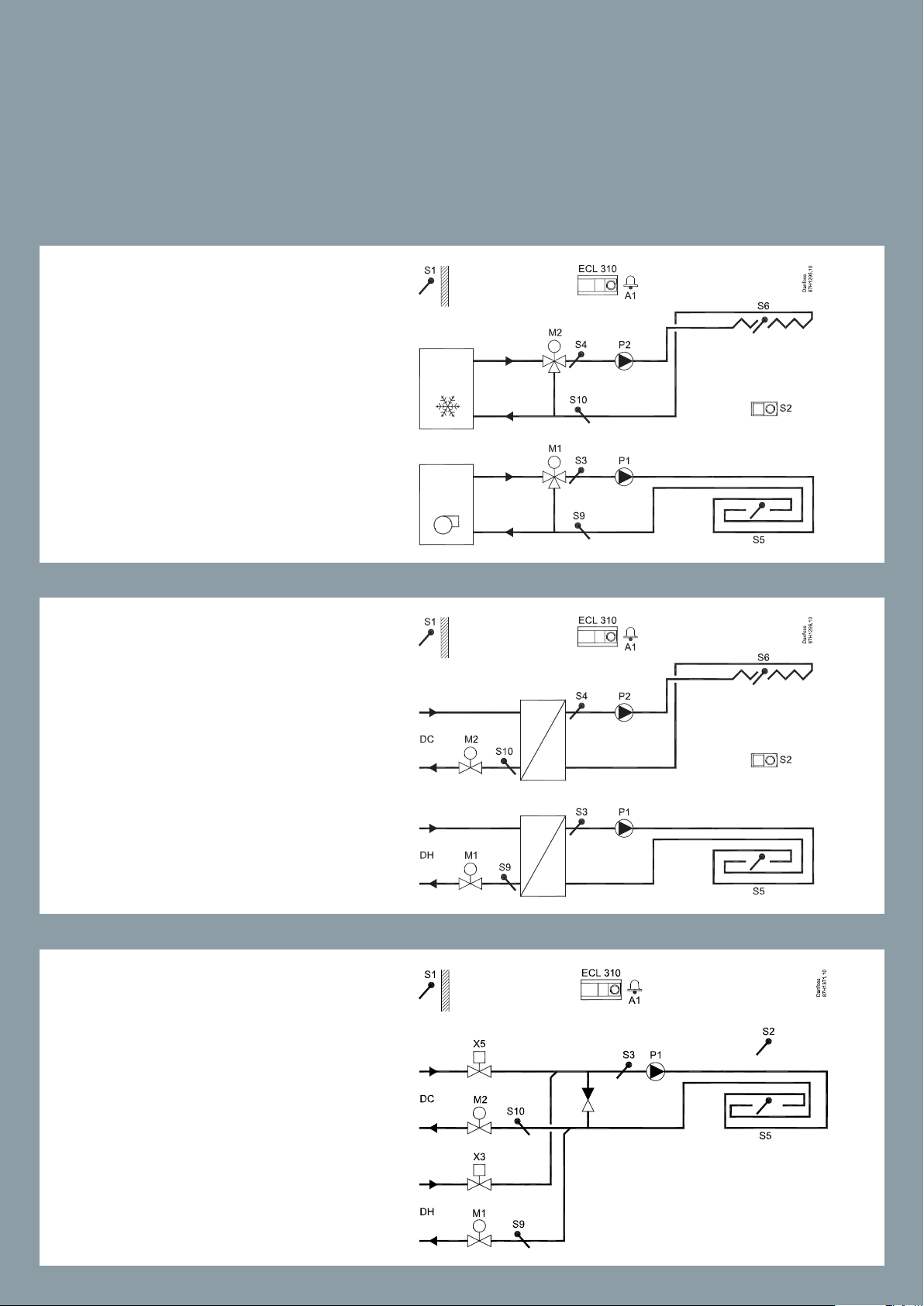

ECL Comfort 210/296/310 Application A230

Heating – Application A230.1

Weather compensated control of ow temperature in a heating circuit. Room

temperature and wind speed compensation. Sliding return temperature limitation. Alarm function related to ow temperature.

A230.1

Example a

Indirectly connected heating system

(typically district heating).

A230.1

Example b

Directly connected heating system.

A230.1

Example c

Boiler heating system with 3–port

valve.

35

35

ECL Comfort 210/296/310 Application A230

Cooling – Application A230.2

Control of ow temperature in a cooling circuit. Room and weather compensation. Return

temperature limitation.

A230.1

Example d

Boiler heating system with 4–port rotary valve.

A230.2

Example a

Indirectly connected cooling system

(typically district cooling).

A230.2

Example b

Directly connected cooling system.

36

36

A230.2

Example c

Indirectly connected cooling system,

constant ow on cooling supply side.

A230.2

Example d

Two circulation pumps in shifted

control, controlled by schedule 2.

37

37

ECL Comfort 210/296/310 Application A230

Heating – Application A230.4

Weather compensated control of ow temperature in a heating circuit. Room temperature compensation. Sliding return

temperature limitation. Power / ow limitation. Alarm function related to ow temperature.

Monitoring of temperatures in self-acting controlled DHW circuit.

A230.4

Example a

Indirectly connected heating system

(tipically district heating). Monitoring

of pressure and DHW temperatures.

A230.4

Example b

Indirectly connected heating system

(tipically district heating). Monitoring

of pressure and DHW temperatures.

Scheduled DHW circulation.

A230.4

Example c

Directly connected heating system

(tipically district heating). Monitoring

of pressure and DHW temperatures.

38

38

A230.4

Example d

Directly connected heating system

(tipically district heating). Monitoring

of pressure and DHW temperatures.

39

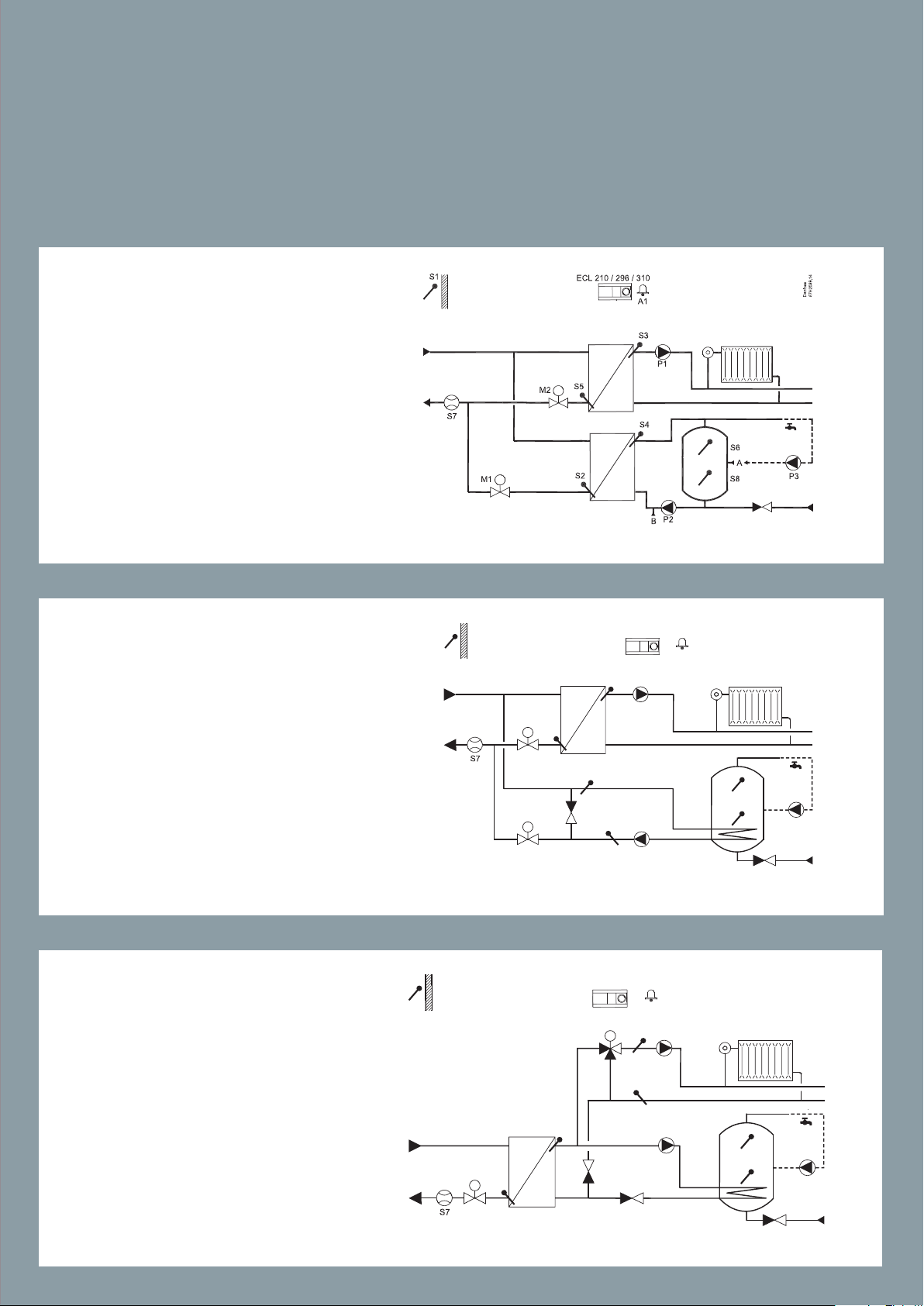

ECL Comfort 210/296/310 Application A231/A331

Weather compensated control of ow temperature in a heating circuit. Sliding return

temperature limitation. Control of one or two circulation pumps. Optional control of

ow temperature related to supply temperature. Rell water function.

Alarm function related to ow temperature, pressure and circulation pumps operation.

Additional function in A331: Control of one or two pumps for rell water function.

A231.1

Example a

Indirectly connected heating system

with two-pump control and rell water function.

A231.2

Example a

Indirectly connected heating system

with two-pump control and rell

water function (supply temperature

measurement gives further control /

limitation possibilities).

40

40

40

A331.1

Example a

Indirectly connected heating system with two-pump control and

rell water function.

A331.2

Example a

Indirectly connected heating system

with two-pump control and rell

water function (supply temperature

measurement gives further control /

limitation possibilities).

41

41

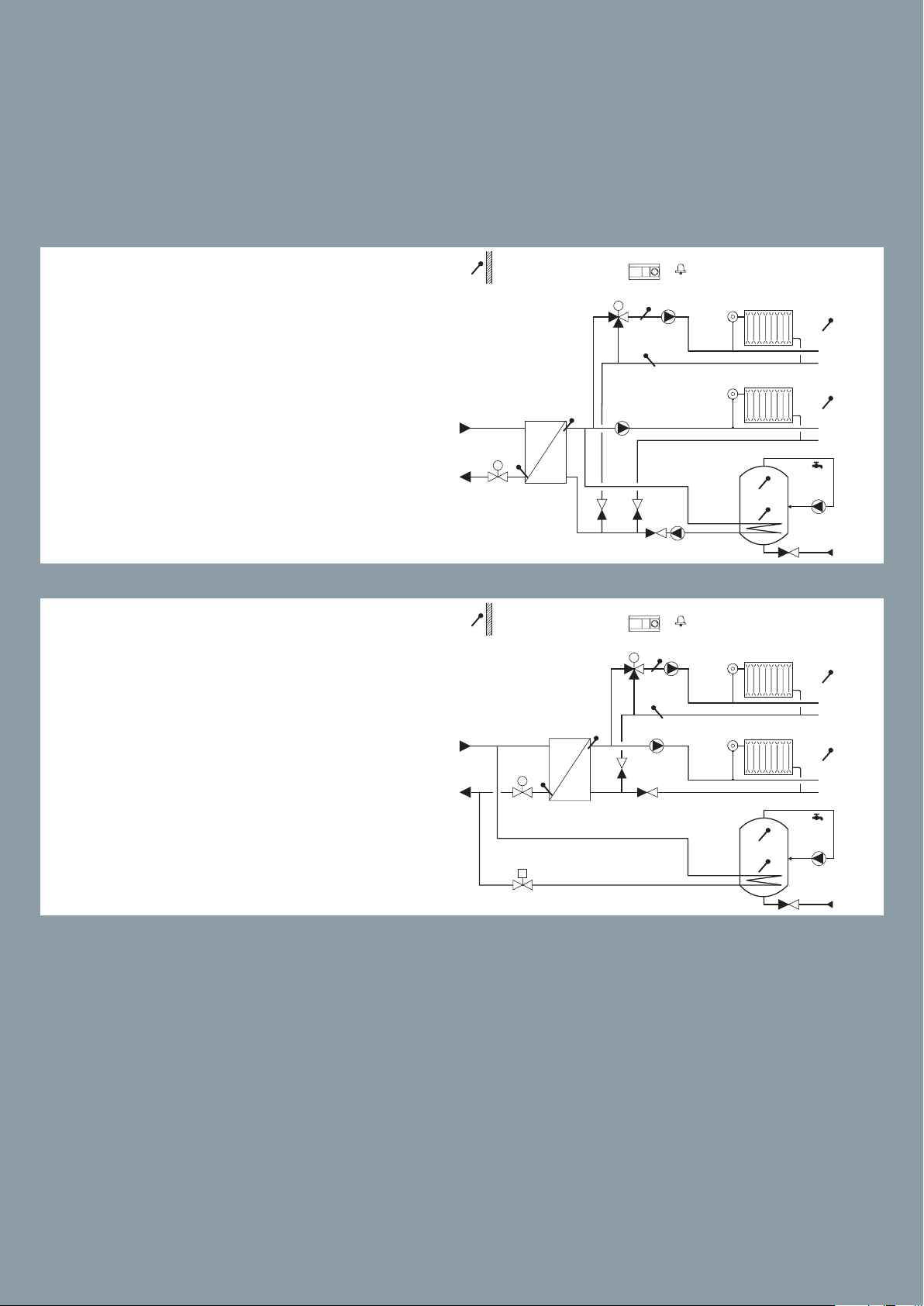

ECL Comfort 210/296/310 Application A232/A332

Weather compensated ow temperature control of heating / cooling circuit(s). Automatic change-over between heating and cooling. Circulation pump control. Dew point

(cooling mode only) and surface temperature compensation. Return temperature limitation.

A232.1

Example a

Control of ow temperature (heating

in oor / cooling in ceiling) in relation

to outdoor, room and dew point temperature.

A232.1

Example b

Control of ow temperature (heating /

cooling) in oor in relation to outdoor,

room and dew point temperature.

A232.1

Example c

Control of ow temperature (heating /

cooling) to a fan-coil in relation to outdoor, room and dew point temperature.

42

42

A232.1

Example d

Control of ow temperature (heating /

cooling) to a fan-coil in relation to outdoor, room and dew point temperature. Heating source: District heating.

Cooling source: Cooling machine.

A232.1

Example e

Control of ow temperature (heating /

cooling) in relation to outdoor, room

and dew point temperature. Heating /

cooling sources: District heating / district cooling.

A332.1

Example a

Control of ow temperature (heating

in oor / cooling in ceiling) in relation

to outdoor, room and dew point temperature. Optional return temperature limitation.

43

43

ECL Comfort 210/296/310 Application A232/A332

Weather compensated ow temperature control of heating / cooling circuit(s). Automatic change-over between heating and cooling. Circulation pump control. Dew point

(cooling mode only) and surface temperature compensation. Return temperature limitation.

A332.2

Example a

Separated control of ow temperatures for heating / cooling in

relation to outdoor, room and dew

point temperature. Optional return temperature limitations.

A332.2

Example b

District heating / cooling based

control of ow temperatures for

heating / cooling in relation to

outdoor, room and dew point

temperature. Optional return temperature limitations.

A332.2

Example c

Direct connected heating / cooling based control of ow temperatures for common heating / cooling circuit. Control in relation to

outdoor and room temperature.

Optional surface and return temperature limitations.

44

44

A332.2

Example d

Indirect connected heating / cooling based control of ow temperatures for common heating / cooling circuit. Control in relation to

outdoor and room temperature.

Optional sur face and return temperature limi tations.

A332.3

Example a

Separated control of ow temperatures in heating and cooling

circuits. Control in relation to outdoor and / or room temperature.

Optional sur face and return temperature limi tations.

Indirectly connected DHW system

with ow switch for DHW heating

on demand.

45

45

45

ECL 310

ECL Comfort 210/296/310 Application A232/A332

Weather compensated ow temperature control of heating / cooling circuit(s). Automatic change-over between heating and cooling. Circulation pump control. Dew

point (cooling mode only) and surface temperature compensation. Return temperature limitation.

A332.3

Example b

Separated control of ow temperatures in heating and cooling circuits.

Control in relation to outdoor and /

or room temperature. Optional surface and return temperature limitations.

Indirectly connected DHW system

with ow switch for DHW heating on

demand.

A332.4

Example a

Control of ow temperature (heating

in oor / cooling in ceiling) in relation

to outdoor, room and dew point temperature. Optional return and surface

temperature limitation. Override

functionalities for heating and cooling modes.

A1

M1

S3

P1

X3

X2

S10

M2

S8

S7

S9

S5

DanfossS187H1496.10

S6

S2

46

46

ECL Comfort 210/296/310 Application A237/A337

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Possibility for DHW priority.

Alarm function related to ow temperatures.

A237.1 / A337.1

Example a

Indirectly connected system and secondarily connected DHW tank with internal heat exchanger (optional DHW

priority).

A237.1 / A337.1

Example b

Indirectly connected system and secondarily connected DHW tank with internal heat exchanger (DHW priority).

A237.1 / A337.1

Example c

Indirectly connected system and

primarily connected DHW tank with

internal heat exchanger (optional

DHW priority).

47

47

ECL Comfort 210/296/310 Application A237/A337

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Possibility for DHW priority.

Alarm function related to ow temperatures.

A237.1 / A337.1

Example d

Directly connected system and

DHW tank with internal heat exchanger (optional DHW priority).

A237.2 / A337.2

Example a

Indirectly connected system and secondarily connected DHW charging

system (optional DHW priority).

A237.2 / A337.2

Example b

Indirectly connected system and secondarily connected DHW charging

system (DHW priority).

48

48

87H2053.15

S1

ECL 210 / 296 / 310

ECL Comfort 210/296/310 Application A247/A347

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Possibility for sliding DHW priority.

Alarm function related to ow temperatures.

A247.1

Example a

Indirectly connected heating system

and DHW charging system (optional

DHW priority).

Room temperature can be achieved

by an ECA 30.

A247.1

S1

M2

S5

ECL 210 / 296 / 310

S3

P1

A1

Danfoss

Example b

Indirectly connected heating system

and directly connected DHW tank

heating system. (Pre-controlled circuit

M1

and optional DHW priority).

Room temperature can be achieved

by an ECA 30.

A247.1

S4

S2

P2

A1

M2

S3

P1

S5

S6

S8

P3

Danfoss

87H2054.15

Example c

Indirectly connected heating and

DHW system (optional DHW priority).

Room temperature can be achieved

by an ECA 30.

49

S4

M1

S2

P2

S6

S8

P3

49

49

S1

87H2055.15

ECL 210 / 296 / 310

S1

87H2056.15

ECL 210 / 296 / 310

ECL Comfort 210/296/310 Application A247/A347

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Possibility for sliding DHW priority.

Alarm function related to ow temperatures.

A247. 2

Example a

Indirectly connected heating system

and DHW tank charging system with

pre-controlled charging temperature.

Room temperature can be achieved

by an ECA 30.

A247. 2

Danfoss

P1

S5

Example b

Indirectly connected heating system and DHW system. The DHW

tank charging has pre-controlled

charging temperature.

Room temperature can be achieved

by an ECA 30.

S3

M2

S2

M1

S4

P2

B

P4

S6

A

P3

S8

Danfoss

A247. 2

M2

S3

Example c

Indirectly connected heating system

S4

S5

and DHW system. The DHW tank

charging has pre-controlled charging

temperature. Optional DHW priority.

M1

S2

P2

Room temperature can be achieved

by an ECA 30.

P1

S6

A

P3

S8

B

P4

50

50

50

A247. 3

S1

87H1394.12

ECL 210 / 296 / 310

S1

87H1395.11

ECL 210 / 296 / 310

Example a

Indirectly connected heating system

and DHW charging system. The DHW

tank charging system has controlled

heating and charging temperature

and optional DHW priority.

Room temperature can be achieved

by an ECA 30.

A247. 3

Example b

Indirectly connected heating and

DHW charging system. The DHW tank

charging has controlled heating and

charging temperature and optional

DHW priority.

Room temperature can be achieved

P1

S5

S3

M2

S2

M1

S4

P2

S7

B

P4

S6

A

S8

Danfoss

P3

by an ECA 30.

A247. 3

M2

S3

P1

S5

Danfoss

Example c

Indirectly connected heating and

DHW charging system. The DHW tank

charging has optional DHW priority.

Room temperature can be achieved

by an ECA 30.

51

S4

M1

S2

P2

S7

B

P4

S6

A

P3

S8

51

51

87H2057.11

S7

S1

87H1474.10

ECL 310

S7

ECL Comfort 210/296/310 Application A247/A347

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Possibility for sliding DHW priority.

Alarm function related to ow temperatures.

A347.1

Example a

Indirectly connected heating system

and DHW charging system (optional

DHW priority).

A347.1

S1

M2

S5

M1

S2

S1

M2

S5

ECL 310

A1

S3

P1

S4

B

P2

ECL 310

A1

S3

P1

S6

A

S8

Danfoss

P3

S7

Danfoss

87H1473.10

Example b

S4

S6

Indirectly connected and controlled

heating sys tem. Controlled heating

temperature for DHW tank and optional DHW priority.

A347.1

Example c

Indirectly connected and controlled

heating sys tem. Controlled heating

M1

M1

S2

S2

P2

A1

M2

S3

P1

S5

S4

P2

S8

P3

Danfoss

S6

S8

P3

temperature for DHW tank and optional DHW priority.

52

52

52

A347. 2

S1

87H1475.11

ECL 310

S7

Example a

Indirectly connected heating system

and DHW system. The DHW tank

charging has direct connected and

pre-controlled charging temperature. Optional DHW priority.

A347. 2

Example b

Indirectly connected heating system

and DHW system. The DHW tank

charging has pre-controlled charging

A1

P1

S5

S3

M2

S2

M1

S4

P2

S9

B

P4

S6

A

S8

Danfoss

P3

temperature.

53

53

S1

87H1476.11

ECL 310

S7

S7

ECL Comfort 210/296/310 Application A247/A347

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Temperature control in DHW circuit with storage tank, directly heated or charging system. Return temperature limitation. Possibility for sliding DHW priority.

Alarm function related to ow temperatures.

A347. 2

Example c

Indirectly connected heating system

and DHW system. The DHW tank

charging has pre-controlled charging

temperature. Optional DHW priority.

A347. 3

A1

M2

S3

P1

S5

S4

M1

S2

S1

M2

P2

S3

S5

ECL 310

P1

S9

B

P4

A1

S6

A

S8

Danfoss

P3

Danfoss

87H1517.10

Example a

Indirectly connected heating system

and DHW charging system (optional

DHW priority).

S8 monitors DHW circulation return.

M1

S2

S4

B

P2

S6

S8

A

S8

P3

54

54

ECL Comfort 210/296/310 Application A260

Weather compensated control of ow temperature in two heating circuits.

Room temperature compensation and sliding return temperature limitation.

Circuits independent in parallel or circuit 2 after circuit 1.

Alarm function related to ow temperatures.

A260.1

Example a

Indirectly connected heating systems

(typically district heating). Circuit 2 is

oor heating.

A260.1

Example b

Indirectly connected heating systems

(typically district heating).

S7 is pulse based ow or energy meter.

A260.1

Example c

Indirectly connected heating systems

(typically district heating).

S7 is pulse based ow or energy meter.

55

55

ECL Comfort 210/296/310 Application A260

Weather compensated control of ow temperature in two heating circuits.

Room temperature compensation and sliding return temperature limitation.

Circuits independent in parallel or circuit 2 after circuit 1.

Alarm function related to ow temperatures.

A260.1

Example d

Indirectly connected heating systems

(typically district heating). Circuit 2 (as

sub-circuit) is oor heating.

A260.1

Example e

Directly connected heating systems

(boiler-based). Circuit 2 is oor heating.

A260.1

Example f

Directly connected heating systems

(boiler-based).

56

56

ECL Comfort 210/296/310 Application A266

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Flow temperature control in DHW circuit. Return temperature limitation. Sliding

DHW priority possibility. Optional DHW temperature control related to DHW ow

detection.

Alarm function related to ow temperatures.

A266.1

Example a

Indirectly connected heating and DHW

system (typically district heating).

S7 is pulse based ow or energy meter.

A266.1

Example b

Directly connected heating and

indirectly connected DHW system.

S7 is pulse based ow or energy meter.

A266.1

S1

M2

ECL 210 / 296 / 310

S5

S2

A1

S3

P2

Danfoss

87H2144.14

Example c

Indirectly connected heating system and

directly connected DHW tank heating.

S7 is pulse based ow or energy meter.

S7

S4

M1

S6

P1

57

57

ECL Comfort 210/296/310 Application A266

Weather compensated control of ow temperature in heating circuit. Room temperature compensation and sliding return temperature limitation.

Flow temperature control in DHW circuit. Return temperature limitation. Sliding

DHW priority possibility. Optional DHW temperature control related to DHW ow

detection.

Alarm function related to ow temperatures.

A266.2

Example a

Indirectly connected heating and DHW

system with ow switch.

S7 is pulse based ow or energy meter

A266.9

Example a

Indirectly connected heating and DHW

system with pressure transmitter and

universal alarm switch.

A266.10

Example a

Indirectly connected heating and DHW

system.

Secondary side return temperatures

monitoring and universal alarm switch.

S7 is pulse based ow or energy meter.

Flow / energy limitation is optional.

58

58

58

ECL 210 / 296 / 310

S1

ECL 210 / 296 / 310

S1

87H2165.12

ECL 210 / 296 / 310

S1

ECL Comfort 210/296/310 Application A275/A375

Weather compensated flow temperature control of 1-stage boiler based heating systems. One direct heating circuit and one mixing circuit. Circulation pumps control, room temperature control and sliding return

temperature limitation.

Temperature control of DHW storage tank with internal heat exchanger. Frost protection and alarm function.

The A275 application key contains applications related to ECL Comfort 310 for increased functionalities (multiple boiler stages).

A275.1

Danfoss

A1

S3

S7

87H2163.13

Example a

Boiler ON / OFF control for a heating

circuit.

* = Automatic by-pass valve.

A275.1

Example b

Boiler ON/OFF control for a heating circuit. The boiler circuit is

equipped with a low loss header.

* = Automatic by-pass valve.

P1

S5

B1

S3

P1

S5

B1

*

A1

*

1

Danfoss

87H2164.12

S7

1

A1

A275.2

S3

P1

S5

B1

*

Danfoss

S7

1

Example a

Boiler ON / OFF control for a heating

and a DHW circuit. Optional DHW

priority.

* = Automatic by-pass valve.

P3

S6

2

59

59

87H2166.12

ECL 210 / 296 / 310

87H2168.12

ECL 210 / 296 / 310

S1

87H2167.12

ECL 210 / 296 / 310

S1

ECL Comfort 210/296/310 Application A275/A375

Weather compensated flow temperature control of 1-stage boiler based heating systems. One direct heating circuit and one mixing circuit. Circulation pumps control, room temperature control and sliding return

temperature limitation.

Temperature control of DHW storage tank with internal heat exchanger. Frost protection and alarm function.

The A275 application key contains applications related to ECL Comfort 310 for increased functionalities (multiple boiler stages).

S1

Danfoss

S7

1

A275.2

A1

S3

P1

S5

B1

*

Example b

Boiler ON / OFF control for a heating and a DHW circuit. DHW priority.

* = Automatic by-pass valve.

A275.2

Example c

Boiler ON / OFF control for a heating

and a DHW circuit. Optional DHW priority. The boiler circuit is equipped

with a low loss header.

* = Automatic by-pass valve.

P3/M1

A1

S3

P1

*

S5

B1

P3

S6

2

Danfoss

S7

1

S6

2

A1

A275.2

Example d

S3

P1

S5

B1

*

Danfoss

S7

1

Boiler ON / OFF control for a heating and a DHW circuit. DHW

priority. The boiler circuit is

equipped with a low loss header.

P3/M1

S6

2

* = Automatic by-pass valve.

60

60

A275.3

87H2169.13

ECL 210 / 296 / 310

87H2170.13

ECL 210 / 296 / 310

S1

87H2171.13

ECL 210 / 296 / 310

S1

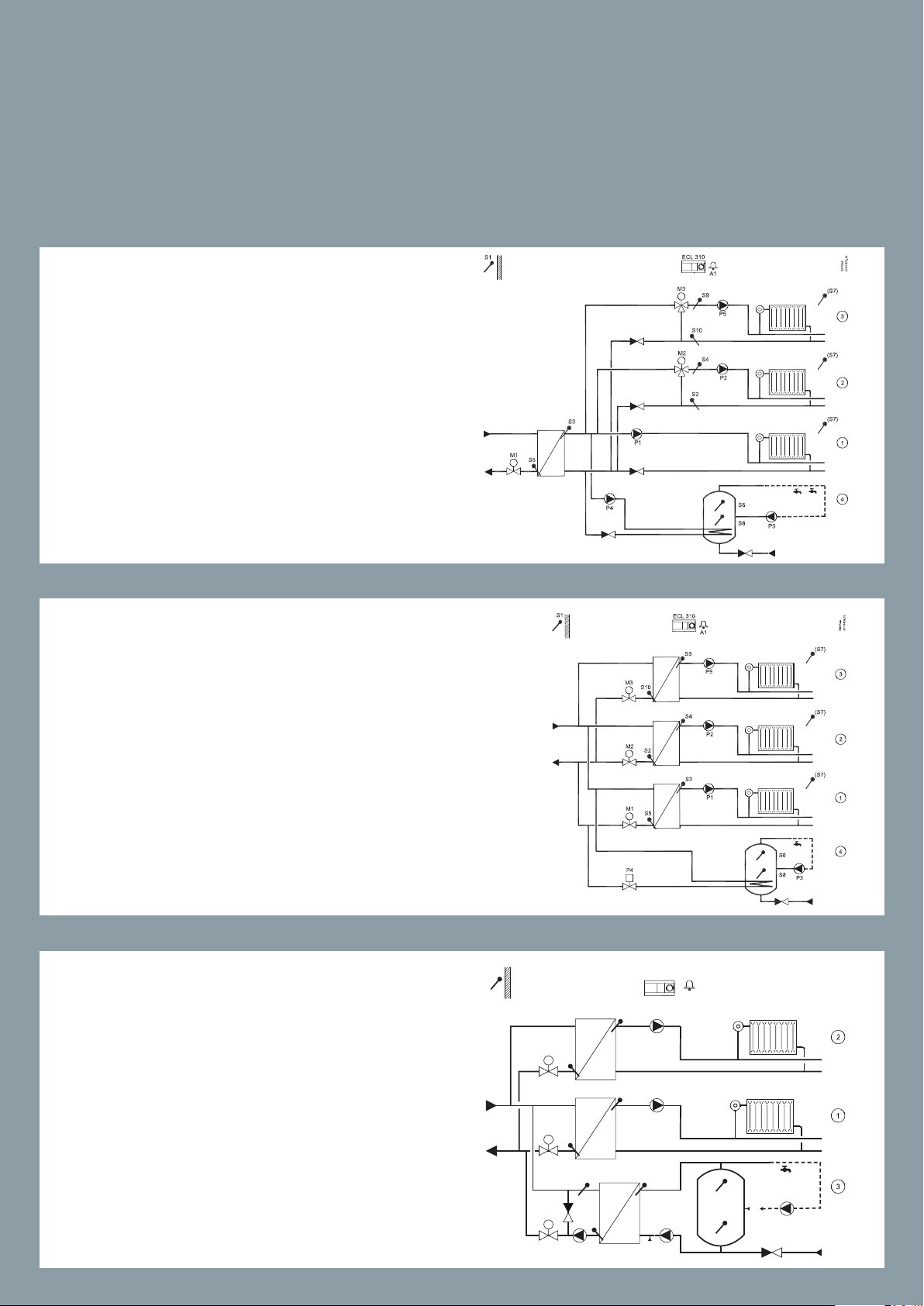

Example a

I Boiler ON / OFF control for a direct

heating circuit (1), a mixing circuit (2)

and a DHW circuit (3). Optional DHW

priority.

* = Automatic by-pass valve.

A275.3

Example b

Boiler ON / OFF control for a direct

heating circuit (1), a mixing circuit

(2) and a DHW circuit (3). Partly DHW

priority.

* = Automatic by-pass valve.

S1

M2

S4

P4

S3

S5

B1

S3

P1

S5

B1

P3/M1

S2

P1

*

S6

P3

M2

S4

P4

S2

*

S6

Danfoss

S8

2

S7

1

3

Danfoss

S8

2

S7

1

3

Danfoss

A275.3

Example c

S3

S5

B1

Boiler ON / OFF control for a direct

heating circuit (1), a mixing circuit (2)

and a DHW circuit (3). DHW priority.

P1

P3/M1

M2

S4

P4

S2

*

S8

2

S7

1

S6

3

* = Automatic by-pass valve.

61

61

87H2172.13

ECL 210 / 296 / 310

S1

87H2173.13

ECL 210 / 296 / 310

S1

87H2174.13

ECL Comfort 210/296/310 Application A275/A375

Weather compensated flow temperature control of 1-stage boiler based heating systems. One direct heating circuit and one mixing circuit. Circulation pumps control, room temperature control and sliding return

temperature limitation.

Temperature control of DHW storage tank with internal heat exchanger. Frost protection and alarm function.

The A275 application key contains applications related to ECL Comfort 310 for increased functionalities (multiple boiler stages).

Danfoss

A275.3

Example d

Boiler ON / OFF control for a direct

heating circuit (1), a mixing circuit (2)

and a DHW circuit (3). Optional DHW

priority. The mixing circuit (2) is controlled by means of a 4-port mixing

valve.

* = Automatic by-pass valve.

S3

S5

B1

S4

M2

P4

S2

P1

*

P3

S8

2

S7

1

S6

3

Danfoss

A275.3

Example e

Boiler ON / OFF control for a direct

heating circuit (1), a mixing circuit (2)

and a DHW circuit (3). Optional DHW

priority. The boiler circuit is equipped

S3

S5

B1

M2

S4

P4

S2

P1

*

S8

2

S7

1

S6

3

with a low loss header.

* = Automatic by-pass valve.

S1

ECL 210 / 296 / 310

P3

Danfoss

A275.3

S3

S5

M2

S4

P4

S2

S8

2

Example f

Boiler ON / OFF control, a mixing circuit control and a DHW circuit control. Optional DHW priority.

* = Automatic by-pass valve.

62

62

B1

S6

3

P3

A275.3

87H2175.13

ECL 210 / 296 / 310

S1

87H2176.10

ECL 310

S1

①

B1

87H2178.10

ECL 310

S1

①