Page 1

Data sheet

ECL Comfort 110

230 V a.c. and 24 V a.c.

Description and application

ECL Comfort 110 The ECL Comfort 110 is a universal 1-circuit

controller for use in district heating substations

and district heating systems as well as boilerbased systems.

The product is an electronic controller for

• weather compensated flow temperature

control (heating)

• constant temperature control (for example

Domestic Hot Water, DHW)

• constant temperature control (DHW on

demand)

In heating applications the ECL Comfort 110 can

be integrated with the Danfoss Link™ solution

via the DLG interface for use in single-family

applications.

The controller is designed for easy installation:

one cable, one connector.

The ECL Comfort 110 controller has a customdesigned display with backlight. For a quick

overview, the display readouts are based on

graphic symbols as well as text in various

languages.

The controller has triac outputs for motorized

control valve and relay outputs for pump

control.

It is possible to connect up to 4 temperature

sensors (Pt 1000 types) and it has 1 input for

override.

The ECL Comfort 110 controller can be used as

master or slave in ECL 100, ECL 110, ECL 200,

ECL 300 and ECL 301 systems.

It is prepared for mounting on a DIN rail, a wall

or in a panel.

ECL Comfort 110 works with a limited range of

Danfoss actuators. See list.

© Danfoss | 2018.08

VD.KT.C11.02 | 1

Page 2

Data sheet ECL Comfort 110

Ordering Controllers

Typ e Designation Code no.

ECL Comfort 110 Universal hardware - 230 V a.c. Base part included 08 7B1261

ECL Comfort 110 Universal hardware - 24 V a.c. Base par t included 087B12 51

ECL Comfort 110 with week

schedule

ECL Comfort 110 with week

schedule

Panel mounting kit For ECL Comfor t 110 08 7B1249

Literature

Typ e Designation Code no.

Instructions, appl. 116 User guide and quick guide (English) 087B 8151

Instructions, appl. 130 User guide and quick guide (English) 087B8152

All other language versions are available on our website.

Go to http://www.danfoss.com.

In the ‘Service and support’ menu search for ‘ECL 110’ and select Documentation > Documents >

Heating > your language

Pt 1000 temperature sensors

Typ e Designation Code No.

ESMT Outdoor temperature sensor 08 4N1012

ESM-10 Room temperature sensor 087 B116 4

ESM -11 Surface sensor 087 B116 5

ES MB-12 Universal sensor 087 B118 4

ESMC Surface sensor incl. 2 m cable 087N0011

ESMU -100 Immersion sensor, 100 mm, copper 087 B118 0

ESM U-250 Immersion sensor, 250 mm, copper 0 87B 1181

ESMU -100 Immersion sensor, 100 mm, stainless steel 087 B118 2

ESM U-250 Immersion sensor, 250 mm, stainless steel 087 B118 3

Universal hardware - 230 V a.c. Base part included 087B1262

Universal hardware - 24 V a.c. Base par t included 087 B1252

User guide and quick guide (Danish) 087B 8153

User guide and quick guide (Swedish) 087B 8155

User guide and quick guide (Danish) 08 7B815 4

User guide and quick guide (Swedish) 087B 8156

Accessories, ECL 110 related

Typ e Designation Code no.

EC A 11 0* Week schedule for ECL Comfort 110 (chip card) 08 7B124 8

DLG** Interface with power supply for system integration of ECL 110

*

The ECA 110 is a supple ment to the ECL Comfort 110 versions

without a week schedule, e .g., the code nos. 087B1261 and

and Danfoss Link™. Mounting Guide / Instructions are

supplied with the product.

**

The CC panel of the Danfoss Link™ system has to be a

Mk III v. 3.2.0 or newer.

087H3241

087B1251 (see page 1). With the ECA 110 it will be possible

to set personal schedules in terms of start and stop times

of the system and thereby optimize the energy supply.

Accessories, temperature sensor related

Pocket Immersion, stainless steel 100 mm, for ESMU-100, Cu (087B1180) 087 B119 0

Pocket Immersion, stainless steel 250 mm, for ESMU-250, Cu (087B1181) 087 B1191

Pocket Immersion, stainless steel 100 mm, for ESMB -12, (087B1184) 087 B1192

Pocket Immersion, stainless steel 250 mm, for ESMB-12, (087B1184) 087B1193

2 | © Danfoss | 2018.08

VD.KT.C11.02

Page 3

Data sheet ECL Comfort 110

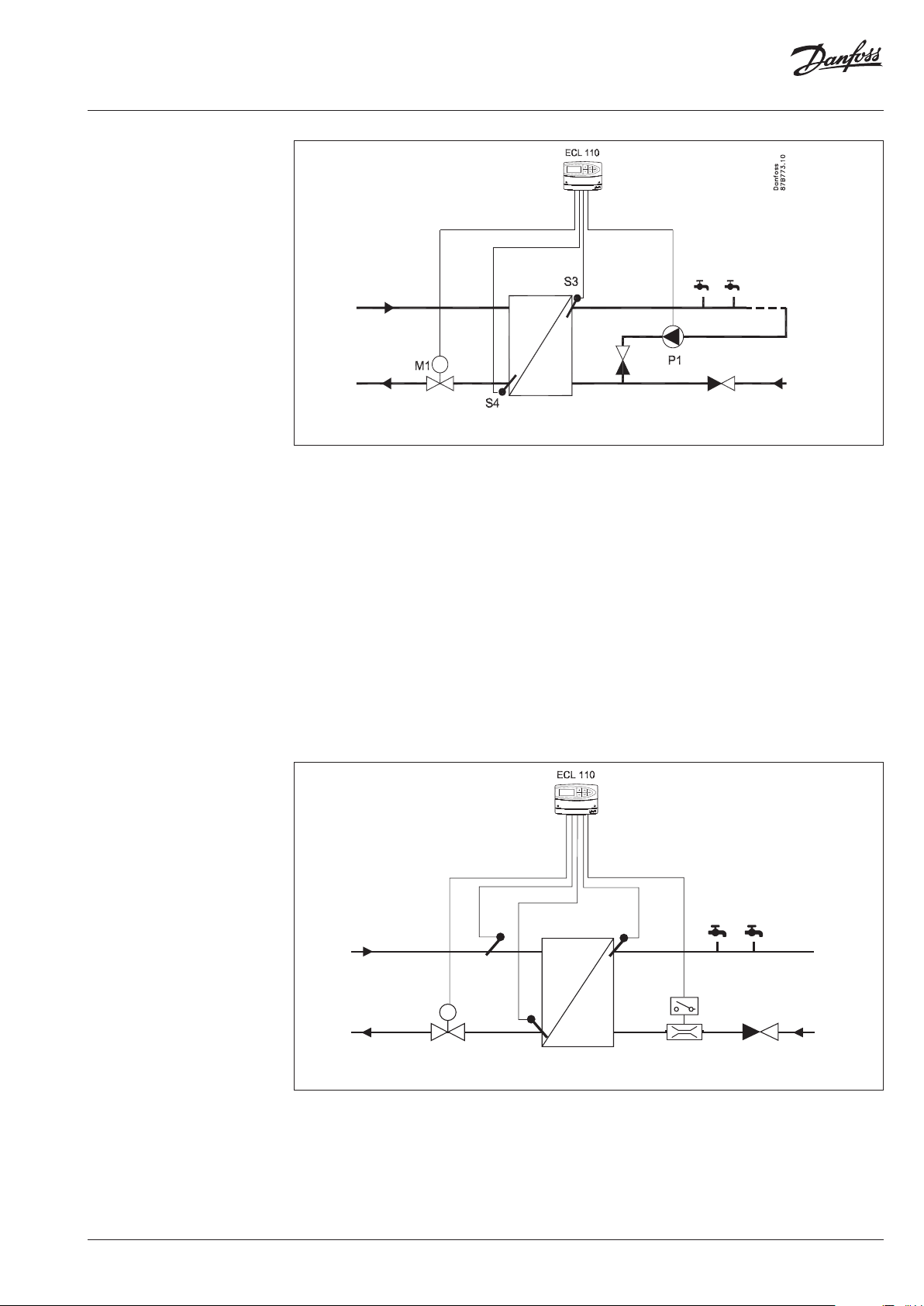

Domestic hot water (DHW)

(Application 116)

Application 116, example 1

Constant DHW temperature control with heat e xchanger

Basic principles Constant DHW temperature control with heat

exchanger or storage tank

Application 116, example 2:

Typically, the flow temperature is adjusted

according to the desired flow temperature.

• Adjustment of DHW temperature

If the measured DHW temperature is lower

than the desired temperature, the motorized

control valve is opened gradually and vice

versa.

S2

• Return temperature limitation

The return temperature to the district

heating supply should not be too high. If so,

the desired flow temperature can be

adjusted (typically to a lower value) thus

resulting in a gradual closing of the

motorized control valve. In boiler-based

heating supply the return temperature

should not be too low (same adjustment

procedure as above).

• Circulation pump control

The circulation pump is ON when the desired

DHW temperature is higher than a userdefined value (factory setting: 20 °C).

Danfoss

87H2156.10

S3

VD.KT.C11.02

M1

DHW temperature control at DHW demand, detected by flow switch FS

S4

FS

© Danfoss | 2018.08 | 3

Page 4

Data sheet ECL Comfort 110

Basic principles Desired DHW temperature, for example 55 °C, is

controlled as long as a flow is detected by flow

switch FS.

The temperature at S2 corrects the set

Proportional band (Xp) in order to achieve stable

control at different supply temperatures.

Key functions Flow temperature control

• Return temperature limitation

The controller automatically changes the

desired flow temperature to obtain an

acceptable return temperature when the

return temperature falls below or gets higher

than the set value. The return temperature

influence factor is set in the ECL 110.

Optimization

• Auto tuning

A function for automatically setting the

proportional band (Xp) and integration time

const ant ( Tn).

Heating

(Application 130)

When no DHW flow is detected, the ECL 110 can

maintain a minimum supply temperature at S2.

DHW circulation temperature, for example 55 °C,

can be maintained.

Safety functions

• Frost protection

The controller automatically switches the

circulation pump ON when the flow

temperature is lower than a user-defined

value (factory setting: 10 °C).

• Motor protection

The controller prevents unstable

temperature control thus resulting in a

longer life of the motorized control valve and

actuator.

• Pump exercise

Exercise of the pump to avoid blocking in

periods without heat demand.

Application 130 examples

District heating circuit with heat exchanger

4 | © Danfoss | 2018.08

Boiler-based heating circuit

VD.KT.C11.02

Page 5

Data sheet ECL Comfort 110

Basic principles Control of district heating circuits with or without

heat exchanger and for boiler-based heating

circuits

Application with

Danfoss Link™

Typically, the flow temperature is adjusted

according to the desired room temperature.

The desired room temperature (Comfort and

Setback) can be determined by the week

schedule.

• Adjustment of flow temperature

The desired flow temperature is calculated in

the ECL Comfort controller, based on the

outdoor temperature. The lower the outdoor

temperature, the higher the desired flow

temperature.

The heat curve (relationship between outdoor

temperature and desired flow temperature) is

set by means of a slope value. Max. / min.

limitation of the desired flow temperature can

be set.

The motorized control valve is opened gradually

when the flow temperature is lower than the

desired flow temperature and vice versa.

• Return temperature limitation

The return temperature to the district heating

supply should not be too high. If so, the desired

flow temperature can be adjusted (typically to

a lower value) thus resulting in a gradual closing

of the motorized control valve. In boiler-based

heating supply the return temperature should

not be too low (same adjustment procedure as

above).

• Room temperature limitation

If the measured room temperature does not

equal the desired room temperature, the

desired flow temperature can be adjusted.

• Circulation pump control

The circulation pump is ON when the desired

flow temperature is higher than a user-defined

value (factory setting: 20 °C ) or the outdoor

temperature is lower than a user-defined value

(factory setting: 2 °C).

• The heating cut-out function can switch OFF

the heating and stop the circulation pump at

high outdoor temperatures.

living connect®

Danfoss

87H1559.10

ECL Comfort 110

DLG

Danfoss Link™ CC

Mk III v. 3.2.0 +

By system integration of ECL Comfort 110

and Danfoss Link™ via the DLG interface the

following is achieved:

• Heating is ON whenever there is a demand

• Heating is operated from only one interface

• Heating comfort is achieved with the lowest

energy consumption

• Outdoor temperature is shown in the

Danfoss Link™ panel.

Danfoss Link™ HC

VD.KT.C11.02

© Danfoss | 2018.08 | 5

Page 6

Data sheet ECL Comfort 110

General data

Wiring - 230 V a.c.

Ambient temperature 0 - 55 °C

Storage temperature -40 - + 70 °C

Enclosure DIN rail, wall or panel

Sensor type Pt 1000 (1000 Ω 0 °C)

Min. backup time for time and date 36 hours

Backup of settings and data Flash memor y

Date and time The built-in Real Time Clock gives automatic Summer / Winter time

Grade of enclosure IP 41 DIN 40050

- marking

in accordance with the standards

Languages, integrated and selectable in ECL 110 (alphabetic order) Danish, English, Estonian, Finnish, German, Latvian,

changeover.

EMC (ElectroMagnetic Compatibility Directive)

LVD (Low Voltage Directive)

RoHS (Restriction of Hazardous Substances Directive)

Lithuanian, Polish, Russian and Swedish.

Wiring - 24 V a.c.

* Connections for safety thermostat

Supply voltage 230 V a.c. - 50 Hz

Voltage range 207 to 244 V a.c. (IEC 60038)

Power consumption 3 VA

Load on relay 1 outputs 4 (2) A - 230 V a.c.

Load on triac outputs 15 VA @ 230 V a.c.

* Connections for safety thermostat

Supply voltage 24 V a.c. - 50 Hz

Voltage range 21.6 to 26.4 V a.c. (IEC 60038)

Power consumption 3 VA

Load on relay 2 outputs 4 (2) A - 230 V a.c.

Load on triac outputs 15 VA @ 24 V a.c.

Recommended actuator

types

6 | © Danfoss | 2018.08

Types (Danfoss): Remarks:

ABV series Thermo -hydraulic, ON- OFF controlled; for seated valves

AMB 100 series Gear-motor, 3-point controlled; for rotating valves

AMV 10 / 20 / 30 series Gear-motor 3-point controlled; for seated valves

AMV 100 series Gear-motor 3-point controlled; for seated valves

VD.KT.C11.02

Page 7

Data sheet ECL Comfort 110

Operation

Menu navigation

Adjust temperatures and values.

Switch between menu lines.

Select / return.

2 sec.

Return to daily user menu.

Temp.

5 sec.

Mode

‘Weekday’

Date - time

Flow temp.

Room T limit

Return T limit

Optimize

Control

param.

VD.KT.C11.02

Application

Service

© Danfoss | 2018.08 | 7

Page 8

Data sheet ECL Comfort 110

Dimensions

Cut-out for mounting Mounting in a panel (panel mounting kit,

code no.: 087B1249).

The panel thickness must not exceed 5 mm.

Additional documentation for ECL Comfort 110 is available on http://heating.danfoss.com/

8 | © Danfoss | DHS-SMT/DK | 2018.08

VD.KT.C11.02

Loading...

Loading...