Page 1

ECL Comfort 100M

User’s Guide and Installation

ECL Comfort 100M

User’s Guide and Installation

*087R9728*

*vi7ab402*

2004.05

*087R9728*

*vi7ab402*

2004.05

Page 2

Table of contents

Page No.

User’s Guide

Temperature setting

Temperature reduction

Installation and maintenance

Table of contents

Page No.

User’s Guide

Temperature setting

Temperature reduction

Installation and maintenance

Page 3

User’s Guide

Before you start

Save energy - save money - improve your

comfort temperature

The ECL Comfort controller is designed by Danfoss for the

The advantages of the ECL Comfort controller system are

the security of your heating control and the op ti mum use

while you are out or asleep save heating costs.

The temperature programming provides comfort and

the au to mat ic pump motion program protects against

Time control of the ECL Comfort 100M controller

When an analog clock is mounted the controller can

This ensures comfortable temperatures when you are at

while you are out.

User’s Guide

Before you start

Save energy - save money - improve your

comfort temperature

The ECL Comfort controller is designed by Danfoss for the

The advantages of the ECL Comfort controller system are

the security of your heating control and the op ti mum use

while you are out or asleep save heating costs.

The temperature programming provides comfort and

the au to mat ic pump motion program protects against

Time control of the ECL Comfort 100M controller

When an analog clock is mounted the controller can

This ensures comfortable temperatures when you are at

while you are out.

Page 4

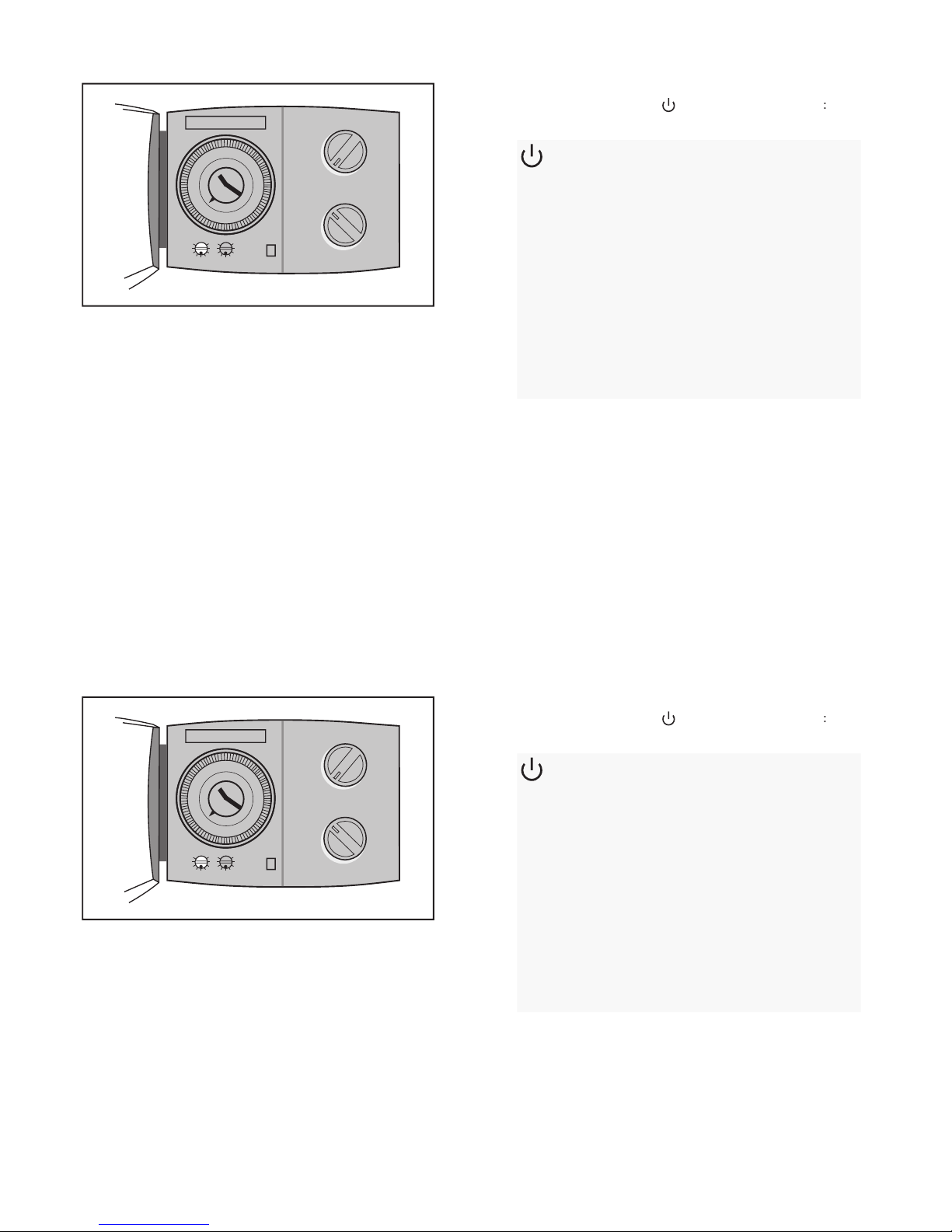

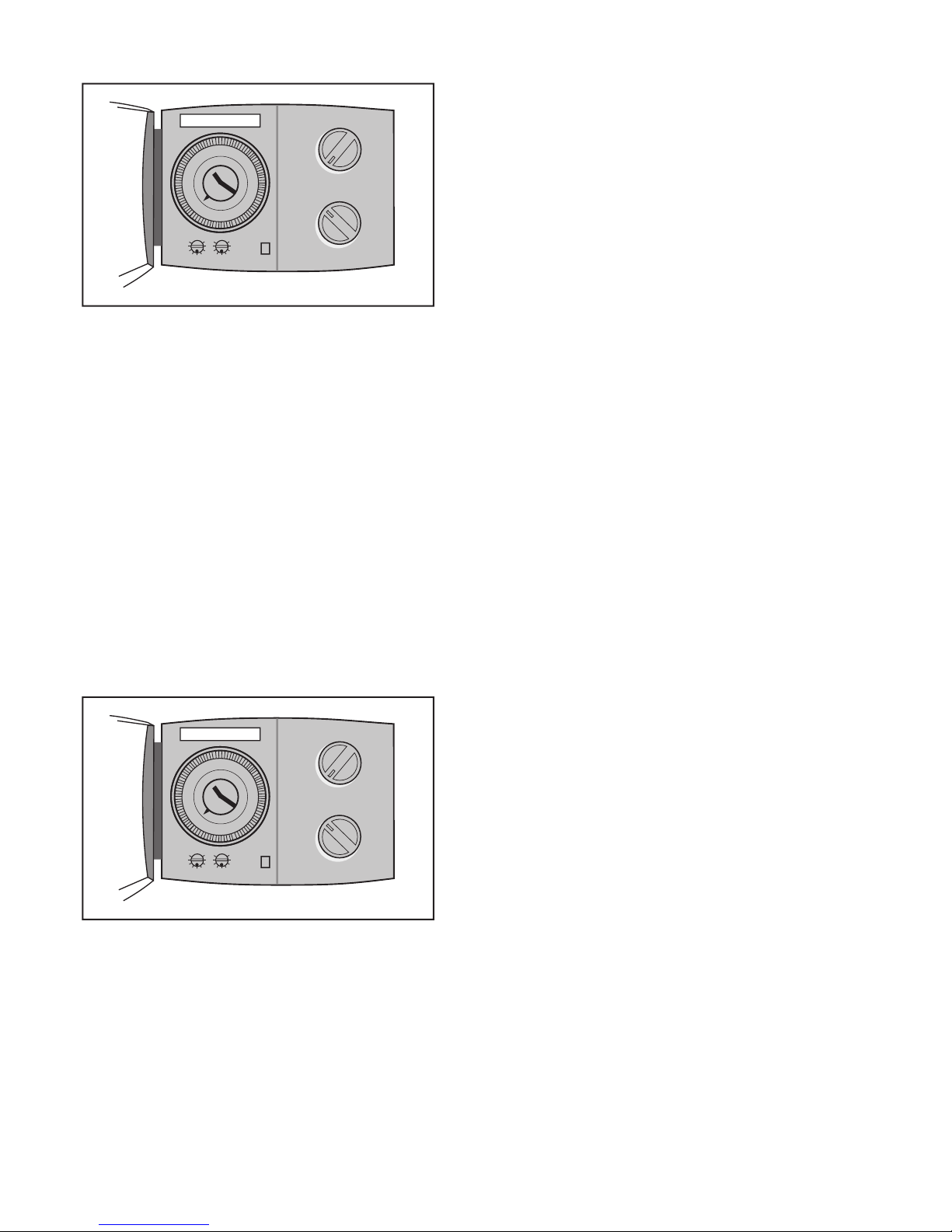

Operating the controller

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Clock (optional)

Setting the clock

Turn the minute hand to set the actual week day (7-day clock)

You will move the entire outer ring of the clock with its sliders,

just by turn ing the minute hand. Turn the minute hand until

the white ar row points at the actual week day and hour in the

Summer time setting

Individual comfort and reduced

tem per a ture periods

temperature or reduced temperature. Look at the week

the slid ers to point outwards, you set the heat ing sys tem to

Setting the clock

Operating the controller

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Clock (optional)

Setting the clock

Turn the minute hand to set the actual week day (7-day clock)

You will move the entire outer ring of the clock with its sliders,

just by turn ing the minute hand. Turn the minute hand until

the white ar row points at the actual week day and hour in the

Summer time setting

Individual comfort and reduced

tem per a ture periods

temperature or reduced temperature. Look at the week

the slid ers to point outwards, you set the heat ing sys tem to

Setting the clock

Page 5

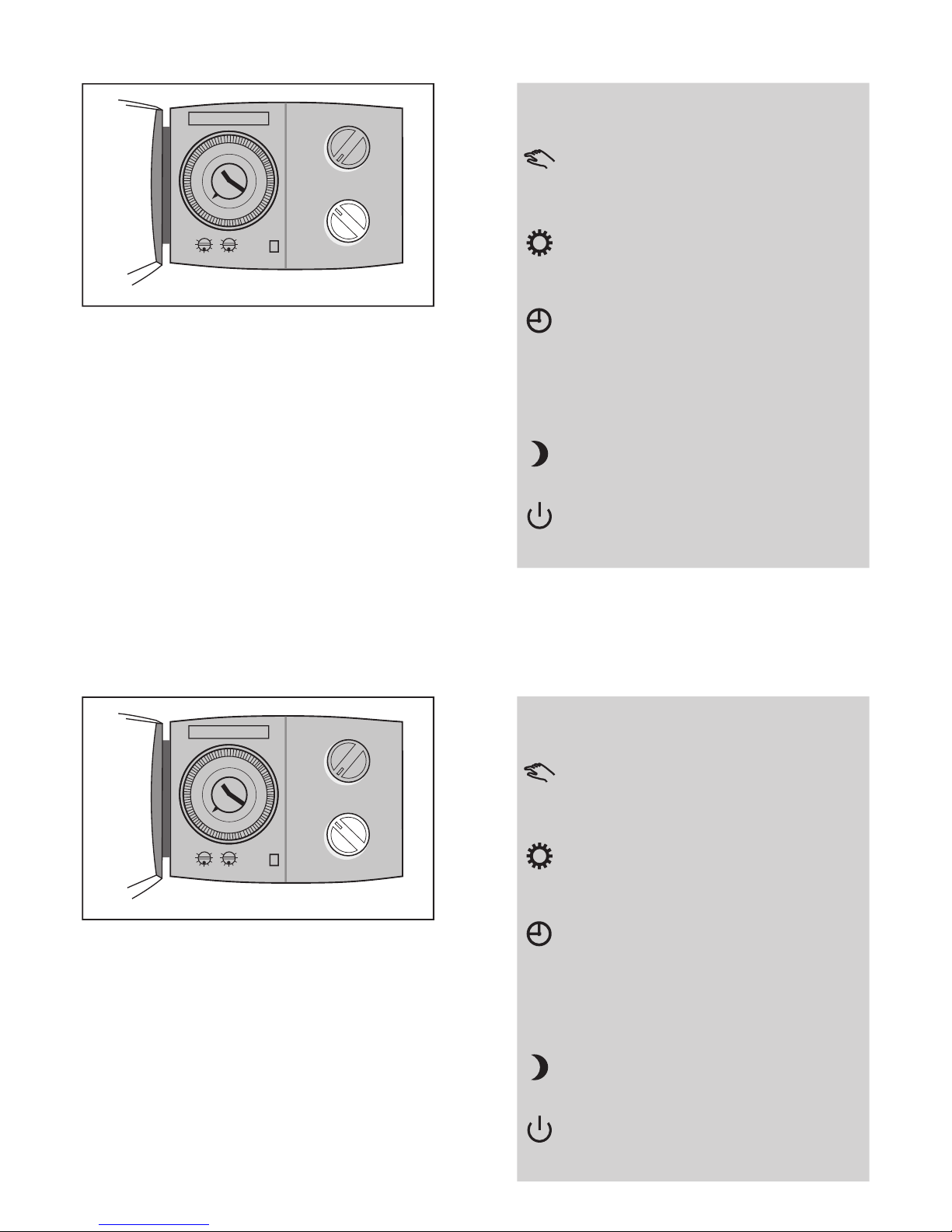

What do the symbols mean?

Controller mode

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Used only at maintenance

The system protection against frost is

The day plan

work or a late-night party.

Automatic operation.

This is the normal mode.

The tem per a ture is

The temperature is

The day plan

Heating is stopped. The system is

What do the symbols mean?

Controller mode

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Used only at maintenance

The system protection against frost is

The day plan

work or a late-night party.

Automatic operation.

This is the normal mode.

The tem per a ture is

The temperature is

The day plan

Heating is stopped. The system is

Page 6

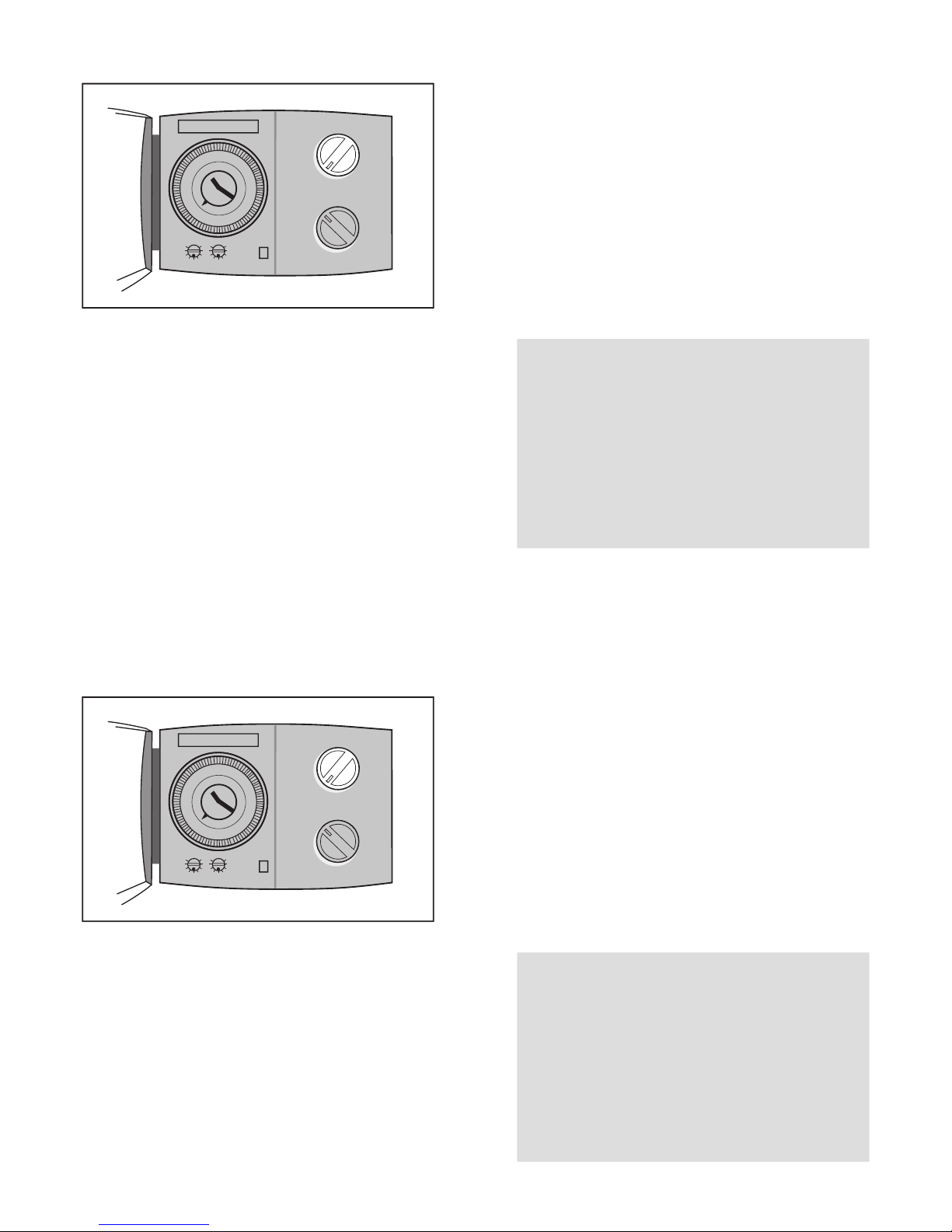

Adjustments

If the wanted comfort temperature is not reached?

Make sure that the radiator thermostat/valve is fully open in the

The rooms seem to be too cold?

Before adjusting the comfort temperature on the controller it

If you are not able to obtain the desired temperature by these

value.

Temperature setting without room sensor

(parallel displacement of the heat curve)

temperature. This cor re sponds approx. to a possible change

Temperature setting with room sensor

temperature setting button will correspond to a room

temperature of 20 °C. The room temperature can be set in a

Temperature setting

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Adjustments

If the wanted comfort temperature is not reached?

Make sure that the radiator thermostat/valve is fully open in the

The rooms seem to be too cold?

Before adjusting the comfort temperature on the controller it

If you are not able to obtain the desired temperature by these

value.

Temperature setting without room sensor

(parallel displacement of the heat curve)

temperature. This cor re sponds approx. to a possible change

Temperature setting with room sensor

temperature setting button will correspond to a room

temperature of 20 °C. The room temperature can be set in a

Temperature setting

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Page 7

Temperature reduction in reduced temperature

mode

You can choose how many degrees you want the fl ow

temperature / room temperature to be decreased in time

Temperature reduction

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

The knob (potentiometer) for the temperature reduction can

(standby),

The heating system is stopped, but still

Without room sensor: The fl ow tem per a ture is

With room sensor: The room tem per a ture is

AUTO

Variable temperature reduction

The temperature reduction is de pend ent

temperature will not be reduced if the outdoor

temperature is below -8 ºC.

Temperature reduction in reduced temperature

mode

You can choose how many degrees you want the fl ow

temperature / room temperature to be decreased in time

Temperature reduction

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

The knob (potentiometer) for the temperature reduction can

(standby),

The heating system is stopped, but still

Without room sensor: The fl ow tem per a ture is

With room sensor: The room tem per a ture is

AUTO

Variable temperature reduction

The temperature reduction is de pend ent

temperature will not be reduced if the outdoor

temperature is below -8 ºC.

Page 8

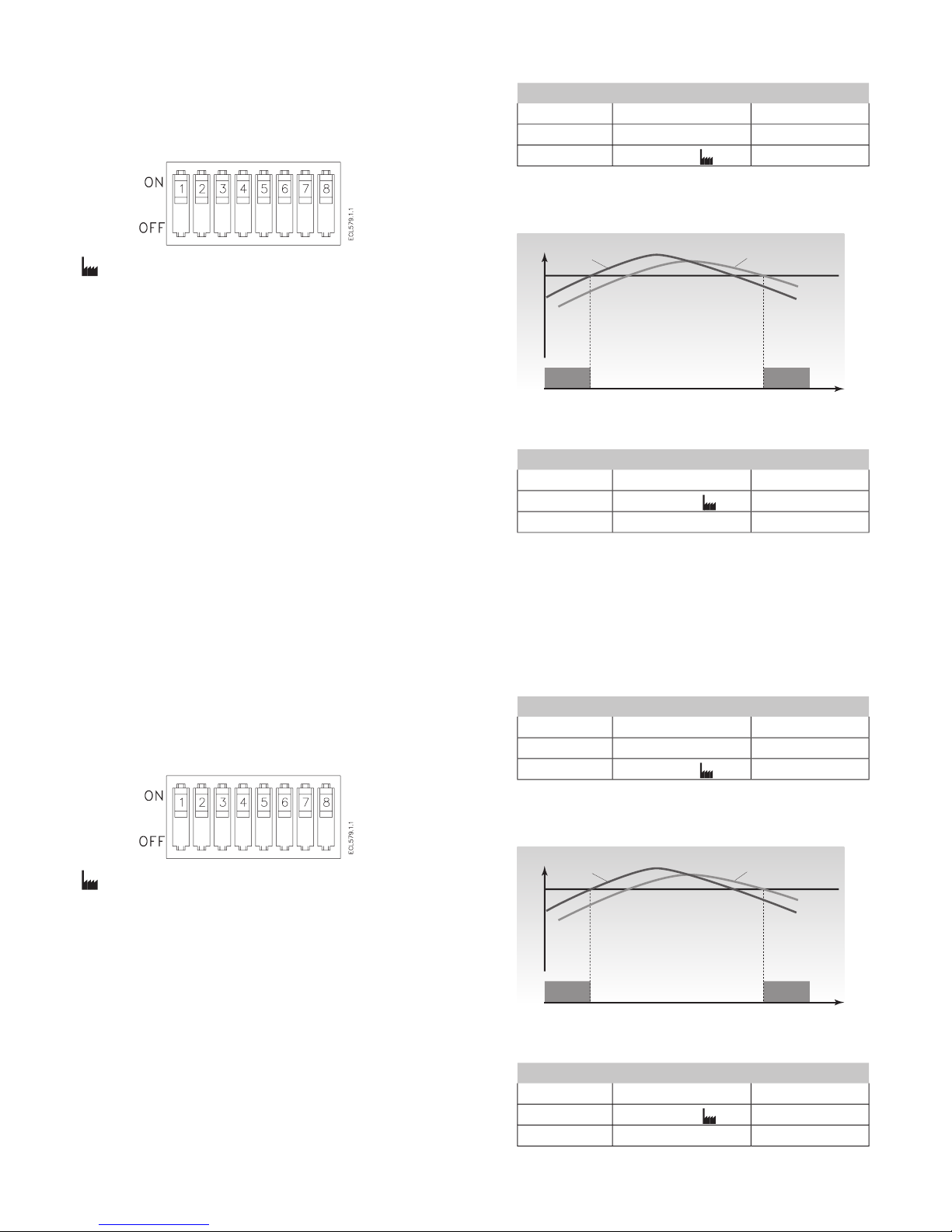

The heat curve shows the relation between the outdoor

tem per a ture and the fl ow temperature of the heating circuit.

Setting the heat curve

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

-20 -10 0 10 20-30

10

20

30

40

50

60

70

80

90

1.8

1.2

0.6

0.2

2.2

˚C

˚C

You can set the heating curve sl ope in the range from 0.2 to 2. 2. The slope

is factory set to 1.2.

*) Dimensioning temperature depend ing on the temperature normal for

your area.

The heat curve shows the relation between the outdoor

tem per a ture and the fl ow temperature of the heating circuit.

Setting the heat curve

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

-20 -10 0 10 20-30

10

20

30

40

50

60

70

80

90

1.8

1.2

0.6

0.2

2.2

˚C

˚C

You can set the heating curve sl ope in the range from 0.2 to 2. 2. The slope

is factory set to 1.2.

*) Dimensioning temperature depend ing on the temperature normal for

your area.

Page 9

Controller settings on the rear side

To make the controller ready for operation, you must

18 ˚C

Temp

Heatin g

Actual T

out

Accumul ated T

out

Time

Heatin g OFF

Heatin g

The accumulated T

out

The heating cut-out function helps you save energy. Set the

: Factory setting

Your setting

10 ºC

35 ºC

Your setting

18 ºC

Controller settings on the rear side

To make the controller ready for operation, you must

18 ˚C

Temp

Heatin g

Actual T

out

Accumul ated T

out

Time

Heatin g OFF

Heatin g

The accumulated T

out

The heating cut-out function helps you save energy. Set the

: Factory setting

Your setting

10 ºC

35 ºC

Your setting

18 ºC

Page 10

The running time of the motorized valve is the time it takes

the valve to move from closed to fully open position.

Valve stroke

(mm) X

(sec./mm) =

time.

Your setting

120 sec.

Your setting

45 ºC

90 ºC

Your setting

Thermo actuator

Gear motor

Your

0

built-in

The running time of the motorized valve is the time it takes

the valve to move from closed to fully open position.

Valve stroke

(mm) X

(sec./mm) =

time.

Your setting

120 sec.

Your setting

45 ºC

90 ºC

Your setting

Thermo actuator

Gear motor

Your

0

built-in

4

Page 11

Installation and maintenance

Before you start

Save energy - save money - improve your

comfort temperature

The ECL Comfort controller is designed by Danfoss for

tem per a ture con trol of heating systems.

The ECL Comfort ensures you of the following;

reduce costs and ensure optimum use of energy

resources.

circulation pump against blocking.

Installation and maintenance

Before you start

Save energy - save money - improve your

comfort temperature

The ECL Comfort controller is designed by Danfoss for

tem per a ture con trol of heating systems.

The ECL Comfort ensures you of the following;

reduce costs and ensure optimum use of energy

resources.

circulation pump against blocking.

Page 12

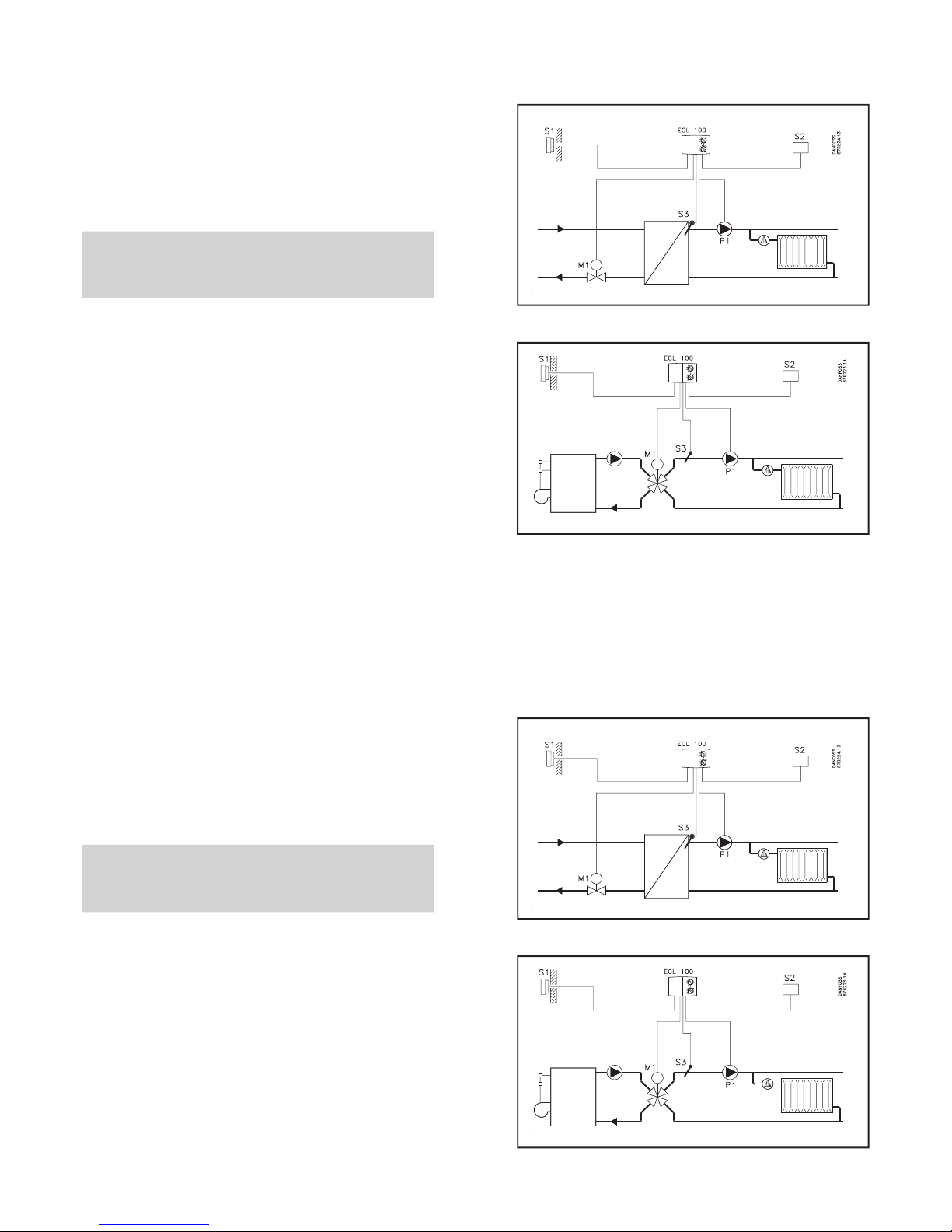

Identifying the system type

The ECL Comfort controller is capable of controlling diff erent

frequently used systems, fi nd the diagram with the best

Identifying the system type

The ECL Comfort controller is capable of controlling diff erent

frequently used systems, fi nd the diagram with the best

Page 13

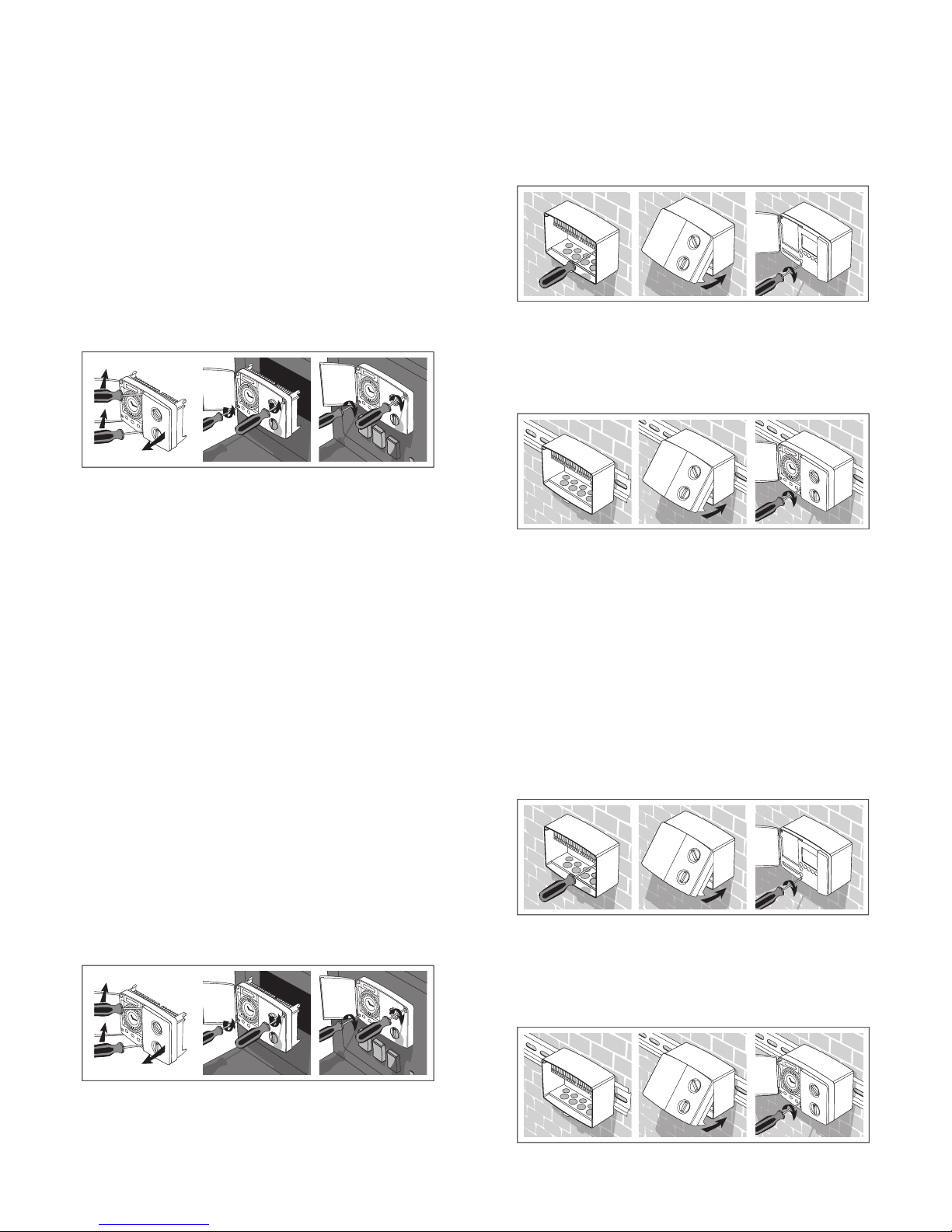

You should mount the ECL Comfort controller for easy

Mounting the controller

Mounting in a panel

The panel plate thickness must not exceed 3 mm. Prepare

fi x it with the two locks which are placed diagonally in the

two corners of the controller.

Mounting on a wall

Mounting on a DIN rail

You should mount the ECL Comfort controller for easy

Mounting the controller

Mounting in a panel

The panel plate thickness must not exceed 3 mm. Prepare

fi x it with the two locks which are placed diagonally in the

two corners of the controller.

Mounting on a wall

Mounting on a DIN rail

Page 14

Outdoor temperature sensor

(ESMT type)

The outdoor sensor should be mounted on the north side

Flow temperature sensor

(ESMU, ESM-11 or ESMC types)

with heat exchanger, Danfoss recommends the ESMU-type

to be inserted into the exchanger fl ow outlet. Make sure

that the surface of the pipe is clean where the sen sor is to be

Placing the tem per a ture sensor types

Room temperature sensor

(ESM-10, ECA 60 and 61 remote controls)

temperature is to be controlled. Do not place it on outside

walls or close to radiators, windows or doors.

Valid for ESM-11: Do not move the sensor after it has been

fastened in order to avoid damage to the sensor element.

Outdoor temperature sensor

(ESMT type)

The outdoor sensor should be mounted on the north side

Flow temperature sensor

(ESMU, ESM-11 or ESMC types)

with heat exchanger, Danfoss recommends the ESMU-type

to be inserted into the exchanger fl ow outlet. Make sure

that the surface of the pipe is clean where the sen sor is to be

Placing the tem per a ture sensor types

Room temperature sensor

(ESM-10, ECA 60 and 61 remote controls)

temperature is to be controlled. Do not place it on outside

walls or close to radiators, windows or doors.

Valid for ESM-11: Do not move the sensor after it has been

fastened in order to avoid damage to the sensor element.

Page 15

Electrical connections 230 V a.c.

Electrical connections 24 V a.c.

Terminal

Voltage supply 230 V a.c.

Voltage supply 230 V a.c.

Gear motor - open 0.2 VA 230 V a.c.

4

Gear motor - close

alt.: ABV thermo actuator

0.2 VA 230 V a.c.

heating circuit

4(2)A 230 V a.c.

Terminal

Voltage supply 24 V a.c.

Voltage supply 24 V a.c.

Gear motor - open 1A 24 V a.c.

4

Gear motor - close

alt.: ABV thermo actuator

1A 24 V a.c.

24 V a.c. supply for M1

Relay for circulation

pump

4(2) A 24 V a.c.

24 V a.c. supply for K1

Electrical connections 230 V a.c.

Electrical connections 24 V a.c.

Terminal

Voltage supply 230 V a.c.

Voltage supply 230 V a.c.

Gear motor - open 0.2 VA 230 V a.c.

4

Gear motor - close

alt.: ABV thermo actuator

0.2 VA 230 V a.c.

heating circuit

4(2)A 230 V a.c.

Terminal

Voltage supply 24 V a.c.

Voltage supply 24 V a.c.

Gear motor - open 1A 24 V a.c.

4

Gear motor - close

alt.: ABV thermo actuator

1A 24 V a.c.

24 V a.c. supply for M1

Relay for circulation

pump

4(2) A 24 V a.c.

24 V a.c. supply for K1

Page 16

Electrical connections - sensors

2

Total cable length: Max. 50 m (sensors and bus).

LED indication

Function test

The LED indicator shows wheth er the 100M is in

Control status

,

the indicator lights.

The fl ow temperature is in the neutral zone

The fl ow temperature

The fl ow

temperature is above the neutral zone. The motor closes

the valve.

The indication does not follow the signals.

Test of controller and sensors

Turn the function switch in position

. After about fi ve

The controller is defective or the fl ow

temperature sen sor is not mount ed.

The number of

The controller is defective.

Terminal

Type

Room sensor (S2) ESM-10

Flow sensor (S3) ESMU/ESM-11/ESMC

Electrical connections - sensors

Total cable length: Max. 50 m (sensors and bus).

LED indication

Function test

The LED indicator shows wheth er the 100M is in

Control status

,

the indicator lights.

The fl ow temperature is in the neutral zone

The fl ow temperature

The fl ow

temperature is above the neutral zone. The motor closes

the valve.

The indication does not follow the signals.

Test of controller and sensors

Turn the function switch in position

. After about fi ve

The controller is defective or the fl ow

temperature sen sor is not mount ed.

The number of

The controller is defective.

Terminal

Type

Room sensor (S2) ESM-10

Flow sensor (S3) ESMU/ESM-11/ESMC

Page 17

Check list

Is the ECL Comfort controller ready for use?

Controller settings on the rear side.

✐

Check list

Is the ECL Comfort controller ready for use?

Controller settings on the rear side.

✐

You can check the turning direction of the

feel ing whether the temperature of the actual pipe

The LED indicator shows whether the 100M is

You can check the turning direction of the

feel ing whether the temperature of the actual pipe

The LED indicator shows whether the 100M is

Page 18

Communication

The ECL Comfort controller can be connected to

Master / slave systems

The controller which is physically connected with the out door

temperature demand can be sent to the master. The master

Communication

The ECL Comfort controller can be connected to

Master / slave systems

The controller which is physically connected with the out door

temperature demand can be sent to the master. The master

Page 19

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Power back-up for your ECL Comfort controller

To ensure power back-up there is a battery placed above the

Power back-up

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

1

8

1

2

6

12

3

6

9

Power back-up for your ECL Comfort controller

To ensure power back-up there is a battery placed above the

Power back-up

Page 20

The circuit for heating the room/building.

the Pt 1000 ohm type. The resistance is 1000 ohms at 0 °C and

The temperature measured with the room sensor. The room

temperature can be controlled only when the sensor is

Weather compensation

temperature into consideration for heat ing con trol.

This control is based on a user defi nable heat curve which

Defi nitions

Actual flow temperature

The temperature that is measured in the fl ow at any

time.

The temperature maintained in the heating or hot water

The circuit for heating the room/building.

the Pt 1000 ohm type. The resistance is 1000 ohms at 0 °C and

The temperature measured with the room sensor. The room

temperature can be controlled only when the sensor is

Weather compensation

temperature into consideration for heat ing con trol.

This control is based on a user defi nable heat curve which

Defi nitions

Actual flow temperature

The temperature that is measured in the fl ow at any

time.

The temperature maintained in the heating or hot water

Page 21

Loading...

Loading...