Page 1

User’s Guide

ECL 2000

11-99 EY.65.H4.02

Page 2

Page 3

User’s Guide

ECL 2000

Danfoss A/S

EY.65.H4.02

Page 4

ECL 2000

EY.65.H4.02

ii

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in

this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss

A/S. All rights reserved.

This manual replaces the ECL 2000 User’s Guide of April 1999.

Danfoss A/S ID: EY.65.H4.02

DK-6430 Nordborg Date: November 1999

Denmark

Phone: +45 74 88 22 22

Copyright 1999 Danfoss A/S. All Rights Reserved

Page 5

Contents

EY.65.H4.02

iii

TABLE OF CONTENTS

1. INTRODUCTION 1

1.1 What Is In This Guide? 1

1.2 Getting Started With the ECL 2000 1

2. INTRODUCING THE ECL 2000 3

2.1 What is the ECL 2000? 3

2.2 Operating Modes 3

2.3 Circuit Functions 4

2.4 Time Programming 4

2.5 Other Functions 4

3. OPERATING THE ECL 2000 5

3.1 The Front Panel 5

3.2 Front Panel Push-buttons 6

3.3 Display Icons 7

4. DAY-TO-DAY OPERATION 9

4.1 About This Chapter 9

4.2 System Overview 10

4.3 Selecting a Circuit. Viewing Circuit Status 12

4.4 Changing Comfort and Night Setback Temperature Settings 14

4.5 Changing the Operating Mode 15

5. TIME PROGRAMMING 16

5.1 Extending the Comfort or Night Setback Period 16

5.2 Setting the 7-Day Plan 17

5.3 Setting the Holiday Plan 18

6. ENTERING THE ACCESS CODE 20

7. WEATHER COMPENSATION CURVES 21

7.1 Adjusting the Flow Temperature Curve 22

7.2 Adjusting the Return Temperature Curve 23

8. CONFIGURING THE ECL 2000 25

8.1 Starting the ECL 2000 for the First Time 25

8.2 ECL 2000 Types 25

8.3 Selecting an Application 26

8.4 Configuring Inputs and Outputs 27

8.4.1 Operating Configuration Pictures 27

8.4.2 Sensor Inputs 30

8.4.3 LON Inputs 32

8.4.4 Relay Output 33

8.5 Overview of ECL 2000 Applications 34

9. MANUAL OVERRIDE 36

Page 6

Contents

EY.65.H4.02

iv

10. SERVICE SETTINGS 38

10.1 Operating Service Menus 39

10.2 Heat Circuit Functions 41

10.2.1 Building Settings 41

Optimizer 42

10.2.2 Pump/Valve Settings 45

10.2.3 PI Constant Settings 47

10.2.4 Limiter 48

10.3 Hot-water Circuit Functions 51

10.3.1 Hot Water Settings 52

10.3.2 Pump/Valve Settings 56

10.3.3 PI Constant Settings 58

10.3.4 Limiter 59

10.4 Common Functions 62

10.4.1 Set Clock 64

10.4.2 Alarm Status 65

10.4.3 Alarm Setup 66

10.4.4 Log Today, Log Yesterday 67

10.4.5 Override 68

10.4.6 Communication 70

10.4.7 Sensors 71

10.4.8 Degree Days 72

10.4.9 Access Code 72

10.4.10 Energy Consumption 73

10.4.11 Language 74

10.4.12 Version 74

APPENDIX A. DISPLAY CHARTS 75

A.1 Setting the Operating Mode 75

A.2 System Overview. Selecting a Circuit. Viewing Circuit Status 76

A.3 Time Programming 77

A.4 Weather Compensation Curves 78

A.5 Configuring the ECL 2000 79

A.6 Manual Override 80

APPENDIX B. SERVICE MENUS 81

B.1 Heat Circuit Menus 81

B.2 Hot-Water Service Menus 82

B.3 Common Function Menus 83

APPENDIX C. LOG DISPLAYS 87

GLOSSARY 89

REFERENCES 93

INDEX 95

Page 7

Introduction

EY.65.H4.02

1

1. INTRODUCTION

1.1 What Is In This Guide?

This Guide is for the ECL 2000 district heating temperature controller. The purpose

of the Guide is to describe the functionality of the ECL 2000 and to enable users to

operate the controller from the front panel.

Chapter 2-7 provide information regarding the day-to-day usage of the controller.

Chapter 8-10 provide information intended for project and service engineers, for

example about configuring the ECL 2000 and using service menus to modify the setup

of the controller. Appendix A contains a number of charts providing an overview of

the ECL 2000’s display pictures. Appendix B provides a similar listing of the ECL

2000’s service menus. Appendix C provides a list of the data displayed in the ECL

2000’s Log pictures. At the end of the Guide, you find a glossary, a list of references

and an index.

1.2 Getting Started With the ECL 2000

Instructions for installing the ECL 2000 are provided in the ECL 2000 Installation

Guide (ref. [2]). After the controller has been installed, it must be configured. This

step consists of selecting an application (i.e. a system type) and, if the selected

application allows this, configuring inputs and outputs. Instructions for this start on

page 25 of this Guide.

Page 8

Introduction

EY.65.H4.02

2

This page is intentionally left blank

Page 9

Introducing the ECL 2000

EY.65.H4.02

3

2. INTRODUCING THE ECL 2000

2.1 What is the ECL 2000?

The ECL 2000 is a micro-processor based controller used for temperature control and

regulation in district heating systems and for mixing control in boiler systems.

The controller can be used for weather compensation and control in the following

types of systems:

• Two parallel district heating circuits

• Two heat circuits and one hot-water circuit

• Two separate weather compensated heat circuits

• Two heat circuits combined with hot-water tank control.

Two types of ECL 2000 are available with different input/output configurations.

ECL 2000 Type 1 is supplied with 14 pre-programmed applications (i.e. 14 standard

system setups). Type 2 has 17 pre-programmed applications. The ECL 2000’s built-in

applications cover a wide variety of commonly used central heating configurations.

See page 25 for further information.

2.2 Operating Modes

The controller can operate in 4 different modes:

• Automatic

• Comfort

• Night setback

• Stand-by.

In Automatic mode, the controller alternates between two temperature setpoints: comfort and night setback. The flow temperature of a heat circuit and the hot-water temperature are kept at either comfort or night setback temperature, according to a userdefined 7-day plan.

In Comfort mode, flow and hot-water temperatures are maintained at daytime level.

In Night setback mode, the plant is maintained at night setback temperature, which is

normally lower than the comfort temperature.

Note:

The controller can be in night setback mode even during the daytime, for example

over the week-end.

In Stand-by mode, heating is off, but the plant is frost-protected at 6 °C.

Page 10

Introducing the ECL 2000

EY.65.H4.02

4

2.3 Circuit Functions

Heat circuit functionality includes weather compensation of flow temperature according to outdoor temperature, sun intensity and wind velocity, outdoor temperature

dependant return temperature limiting, PI control of valve motors, as well as an

optimizer facility that will save energy by calculating optimum pre-heat and cooling

times for the plant. If a room temperature sensor is fitted, the optimizer is adaptive.

Hot-water circuit facilities include PI control of valve motors, return temperature limiting and an anti-bacteria function.

The ECL 2000 has a built-in timer function with a year clock, which can be used to

switch on and off an external device according to a 7-day, 24-hour program.

2.4 Time Programming

The ECL 2000’s time programming facility lets you set up an individual 7-day, 24hour program for each of the circuits being controlled.

The ‘party function’ allows the ECL 2000 to override the 24-hour program and keep

one or more circuits at comfort temperature for a prolonged period of time, for example until later in the evening than normally. The economy function lets the ECL 2000

keep the plant at night setback temperature longer than normally.

You can also pre-program a holiday period during which the controller will follow a

different 24-hour schedule than under normal conditions.

2.5 Other Functions

The controller includes a Manual Override facility that disables all automatic control,

allowing for manual control of circuit components (pumps and valve motors).

The controller’s alarm system lets you define conditions that will cause an alarm. You

can monitor the alarm status by displaying the controller’s alarm log and one relay

output can be defined as an alarm output.

The ECL 2000 also includes facilities for logging measured data and displaying this

graphically, as well as for calculating degree days.

LON (Local Operating Network) communication is available as an option. This facility enables the ECL 2000 to communicate via LON with other ECL 2000 controllers

and devices such as heatmeters.

Page 11

Operating the ECL 2000

EY.65.H4.02

5

3. OPERATING THE ECL 2000

A few basic principles determine the way the ECL 2000 is operated – these principles

apply to all ECL 2000 functions. This section gives a brief introduction to these principles.

Detailed descriptions of the various ECL 2000 functions are given from page 9. For

an overview of navigating through ECL 2000 pictures, see the charts in Appendix A,

page 75.

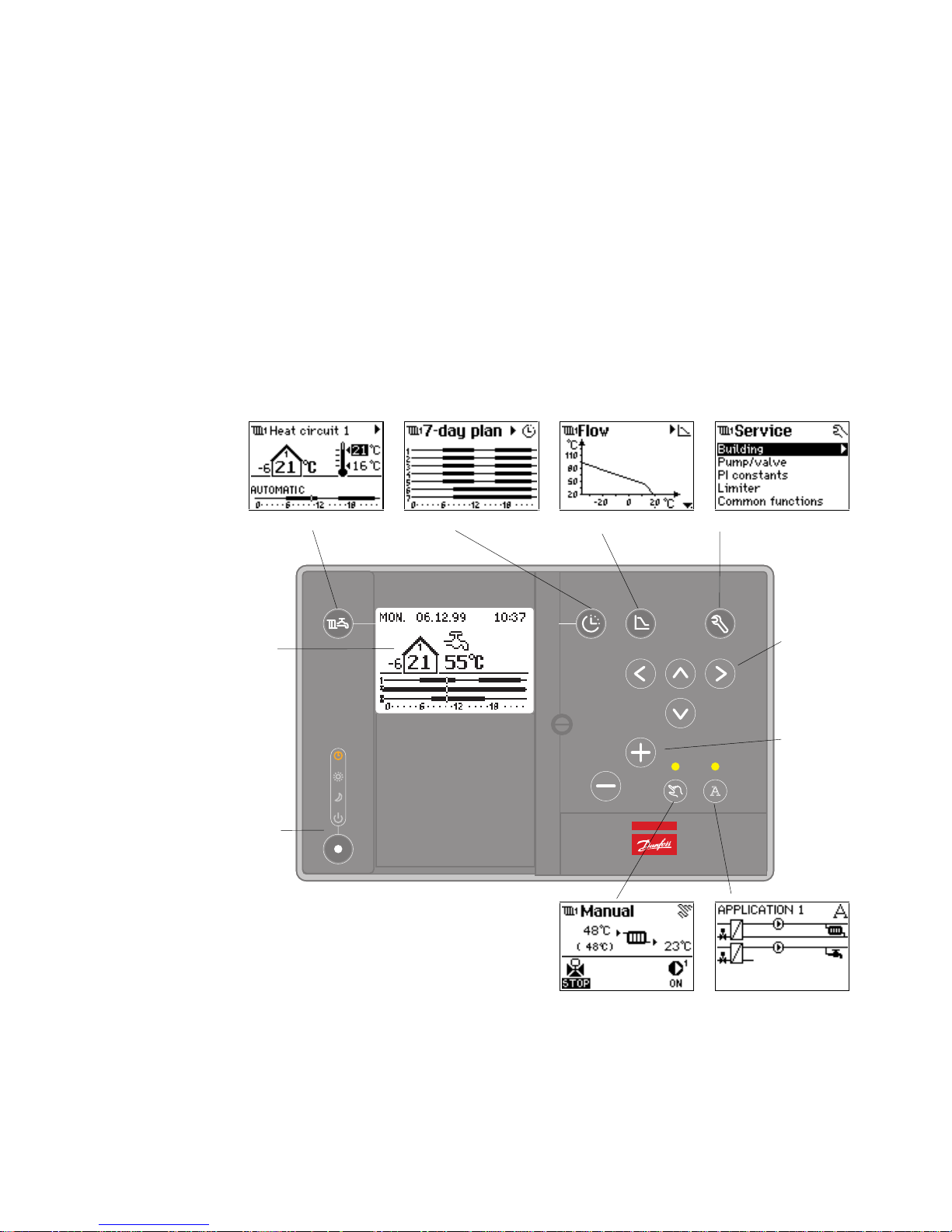

3.1 The Front Panel

Select circuit 7-day plan and holiday

plan

Weather compensation

curves

Service settings

LCD display

Operating mode

Go to next

picture/

Move cursor

Change setting

Manual override Application

Figure 1. ECL 2000 front panel push buttons

Page 12

Operating the ECL 2000

EY.65.H4.02

6

3.2 Front Panel Push-buttons

The following push-buttons operate independently of all other functions:

Push-button Function

Circuit

Selects a circuit, that is, a heat circuit, a hot-water circuit or a timer.

When you press the push-button, the display switches from the System

Overview picture to the picture of the first circuit, to the next circuit,

etc. and finally back to the System Overview again.

See page 12.

Mode

Changes the operating mode of the controller. The ECL 2000 can operate in 4 different modes: Automatic, Comfort, Night setback and Standby.

See page 15.

The function buttons activate 5 main functions: Setting time programs, adjusting

weather compensation curves, changing service settings, operating the plant manually

and selecting an application. These are:

Push-button Function

7-day plan and holiday plan

Lets you modify the controller’s 7-day plan, set up a holiday period and

a 24-hour program to follow during the holiday period.

See page 17.

Weather compensation curves

Allows you to modify the weather compensation curves used by the

ECL 2000 to control flow and return temperatures in a heat circuit.

See page 21.

Service settings

Activates the ECL 2000’s service menus. The service menus allow you

to change settings for the circuits controlled by the ECL 2000 and to

monitor actual values of plant variables.

See page 38.

Manual override

Enables manual operation of individual components in the plant.

See page 36.

Application

Lets you select an application, which is a standard system setup

See page 26.

Page 13

Operating the ECL 2000

EY.65.H4.02

7

Exit The general principle of the ECL 2000 is as follows: Once you have pressed one of

these push-buttons and activated the corresponding function, you exit the function by

pressing the same button once more. There are minor exceptions to this rule – these

are indicated in the appropriate sections of this User’s Guide. When you exit a function, any modifications you have performed are saved.

The remaining front panel buttons perform the functions outlined in the table below:

Push-button Function

Change the display to the next/previous picture in a series, for example

in the System Overview or the Circuit Status.

Move the cursor within a picture.

Increases the value of a setting, for example a temperature setpoint.

Reduces the value of a setting.

!

Note:

Before being allowed to modify a setting, you may be prompted to enter an access

code. See page 20 for instructions.

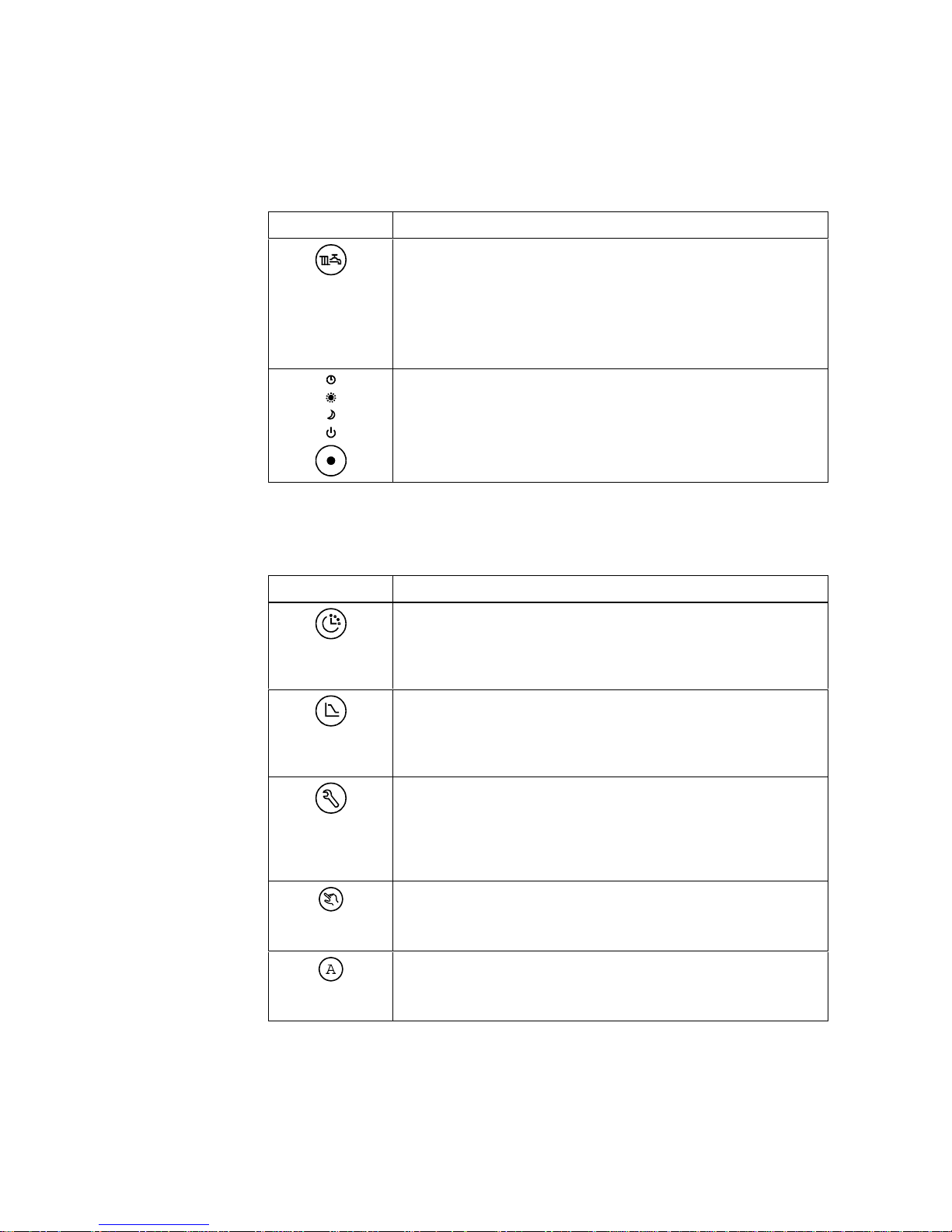

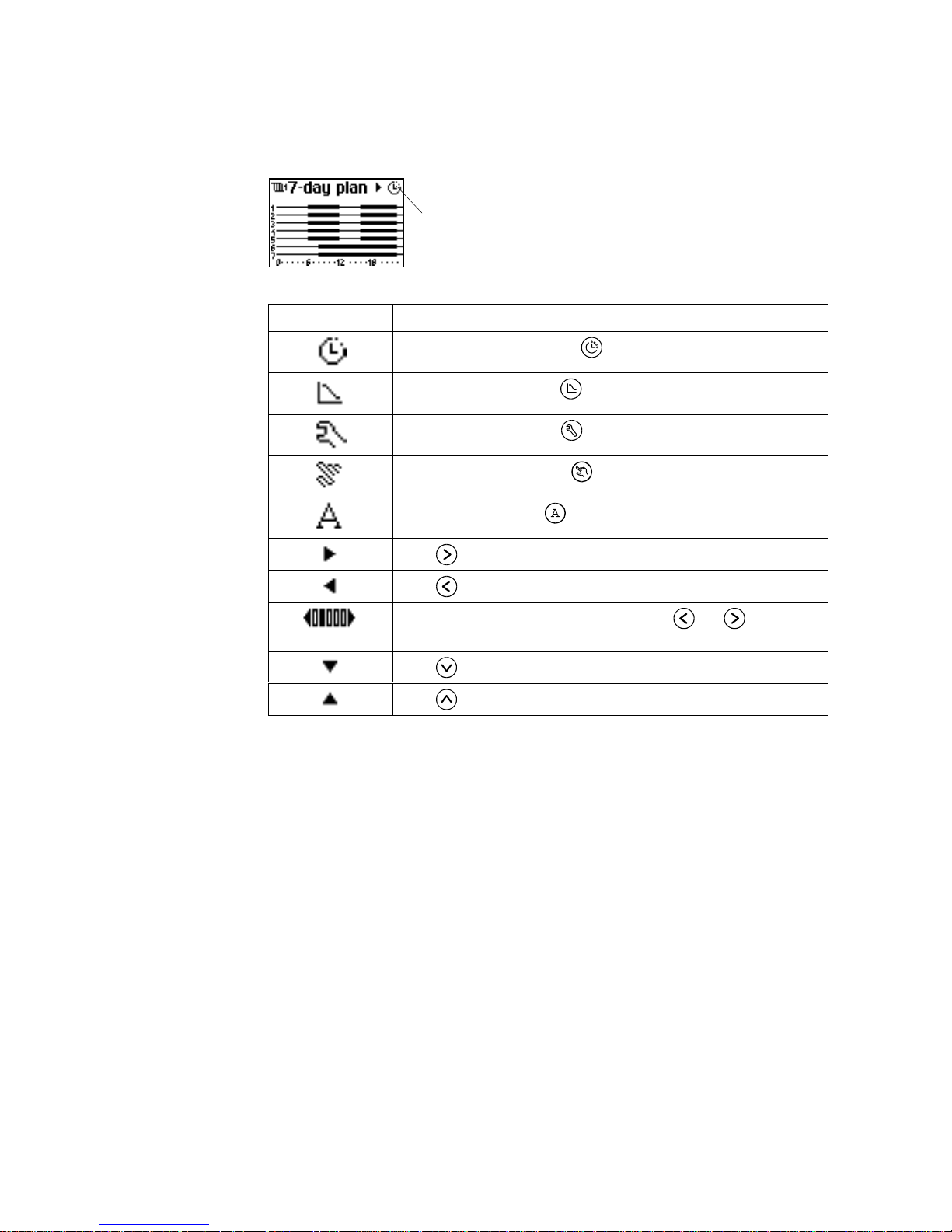

3.3 Display Icons

The ECL 2000’s displays are provided with a number of

icons to help you navigate through the pictures. The

following icons appear in the upper left corner of the

display:

Icon Indicates

Data for heat circuit no. 1 is being displayed.

Data for heat circuit no. 2 is being displayed.

Data for the hot-water circuit is being displayed.

Data for the timer function is being displayed.

Settings concerning al l circuits: Common Functions in service menus.

Icon

Page 14

Operating the ECL 2000

EY.65.H4.02

8

Icons displayed on the right-hand side of the display:

Icon Indicates

Time programming is active – was pressed.

Curve adjusting is active – was pressed.

Service menus are active – was pressed.

Manual operation is active – was pressed.

System setup is active – was pressed.

Press to access next picture.

Press to access previous picture.

Picture no. 2 of 5 is currently displayed. Press and to access

other pictures.

Press to display more settings.

Press to display more settings.

Icon

Page 15

Day-to-Day Operation

EY.65.H4.02

9

4. DAY-TO-DAY OPERATION

4.1 About This Chapter

This chapter is intended for the daily user of the ECL 2000. It describes the functions

which are used during normal day-to-day operation of the ECL 2000. Instructions are

provided for:

• Getting an overview of the plant and looking at individual circuits in the system

• Setting the ECL 2000’s operating mode

• Viewing status information

• Changing temperature setpoints.

Page 16

Day-to-Day Operation

EY.65.H4.02

10

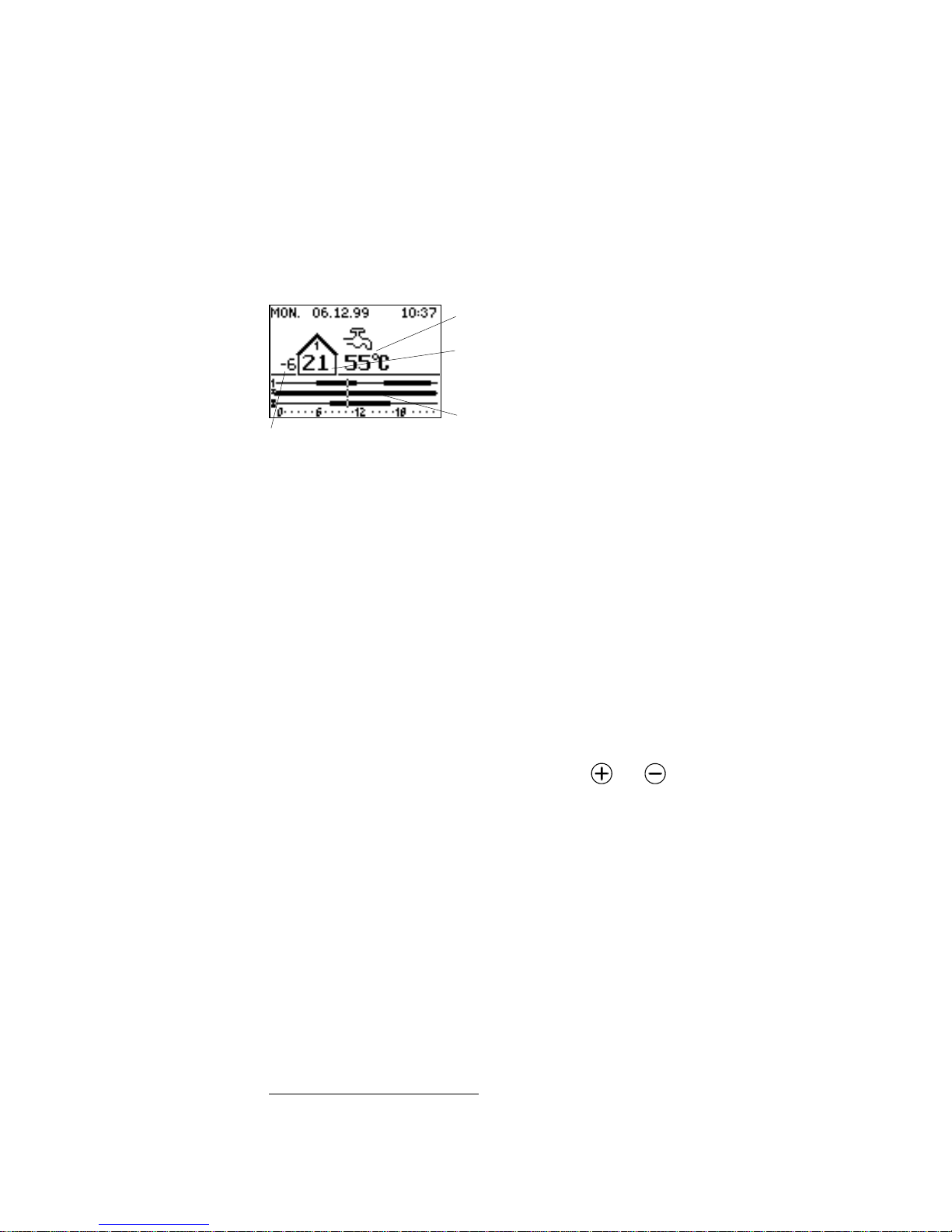

4.2 System Overview

The System Overview is the ECL 2000’s main picture. When the ECL 2000 is

powered on, the System Overview appears in the display after the self-test has been

completed

1

. During normal operation, whenever no front panel push-button is

operated for a 10 minute period, the ECL 2000 automatically reverts to the System

Overview.

System Overview

Actual outdoor temperature

Actual hot-water temperature

Room temperature. If the plant has more than one heat

circuit, the room temperature is displayed individually

for each heat circuit.

24-hour program for all circuits. This 24-hour program

indicates that heat circuit 1 should be maintained at

comfort temperature from 06:00 to 12:00 and from

16:00 to 23:00. Outside these periods, the circuit is

maintained at night setback temperature. The hot water

is kept at comfort temperature constantly.

The System Overview shows the total setup of the plant. This means that the picture

looks slightly different, according to the application that was selected when the

controller was configured.

Timer

The heating system in this example consists of one heat circuit and one hot-water

circuit. In addition to these, the system also includes a timer, which you can see from

third line of the 24-hour program. When this function is enabled, a set of outputs on

the controller is used to switch on and off some external device, that is, the ECL 2000

is used as a timer to control this other device. See also page 33.

Display contrast

If the temperature in the room where the ECL 2000 is installed is very high, this may

affect the contrast of the controller’s LCD display.

1. In the System Overview picture, use

and to adjust the display

contrast.

1

See page 25 for information on what to do when powering on the ECL 2000 for the first time.

Page 17

Day-to-Day Operation

EY.65.H4.02

11

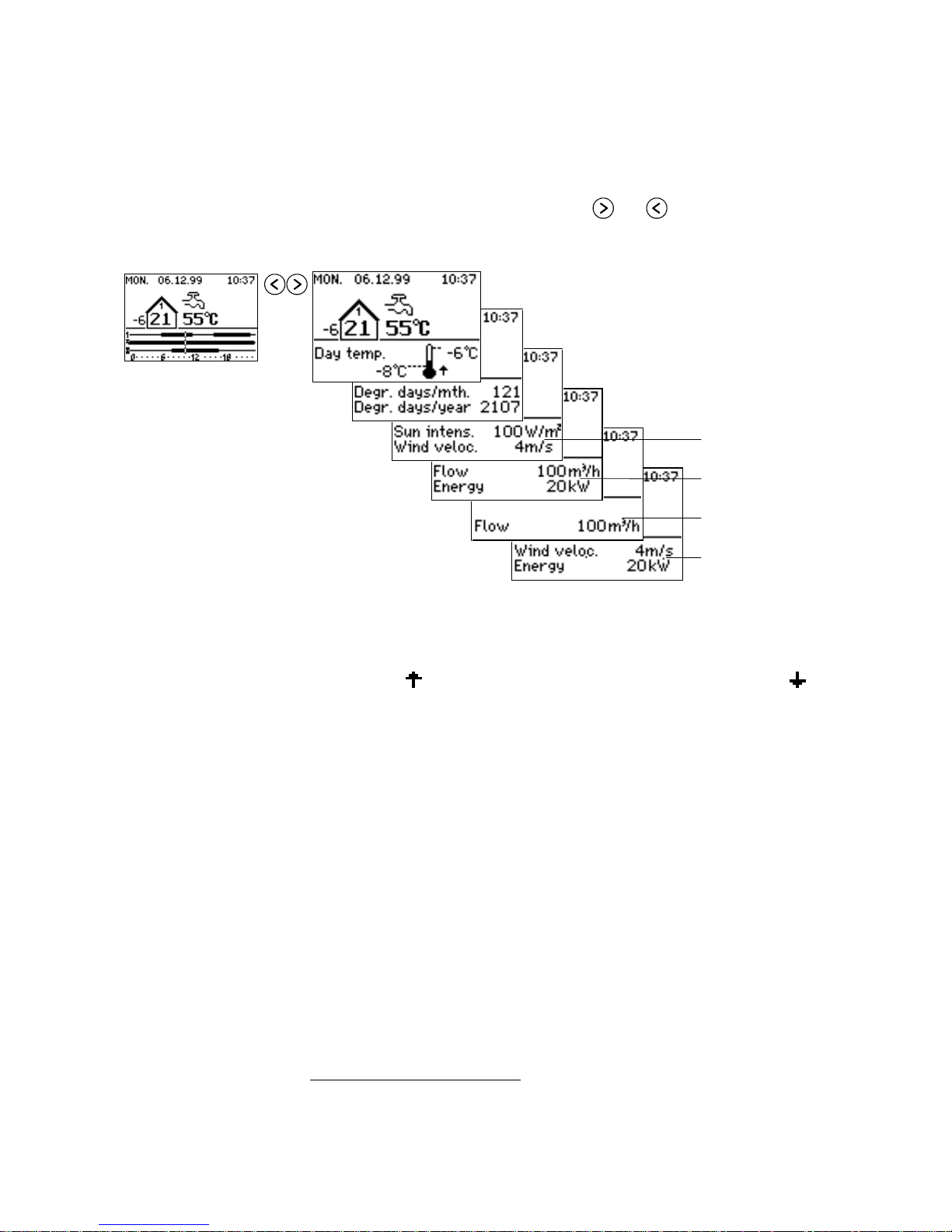

System status

To view status information for the entire plant:

1. From the System Overview, use

and

to display further information.

See illustration below.

Depending on the selected application and the sensors connected to the system, the

following status information can be available:

2

Day temperature

This picture displays the highest and lowest outdoor temperature measured since

midnight. The

symbol indicates that the actual temperature is rising. A indicates

that the temperature is falling.

Degree days

The number of degree days calculated since the first day of the current month and the

number of degree days calculated since the change of season.

3

The following status information is only available when the appropriate sensors are

connected to the ECL 2000:

Sun intensity

Actual value of sun intensity.

Wind velocity

Actual wind velocity.

Water Flow

Actual value of water flow.

Energy

Actual value of energy consumption.

Other

Actual reading from a user-defined sensor connected to the controller.

2

See page 27 for information on configuring the ECL 2000’s sensor inputs and LON inputs

3

By default, the season for degree day calculation starts on 1. June

Sensor S8 and S9

Sensor S10 and S11

(ECL 2000 Type 2 only)

Sensor L1 and L2

(LON option installed)

Sensor L3 and L4

(LON option installed)

Page 18

Day-to-Day Operation

EY.65.H4.02

12

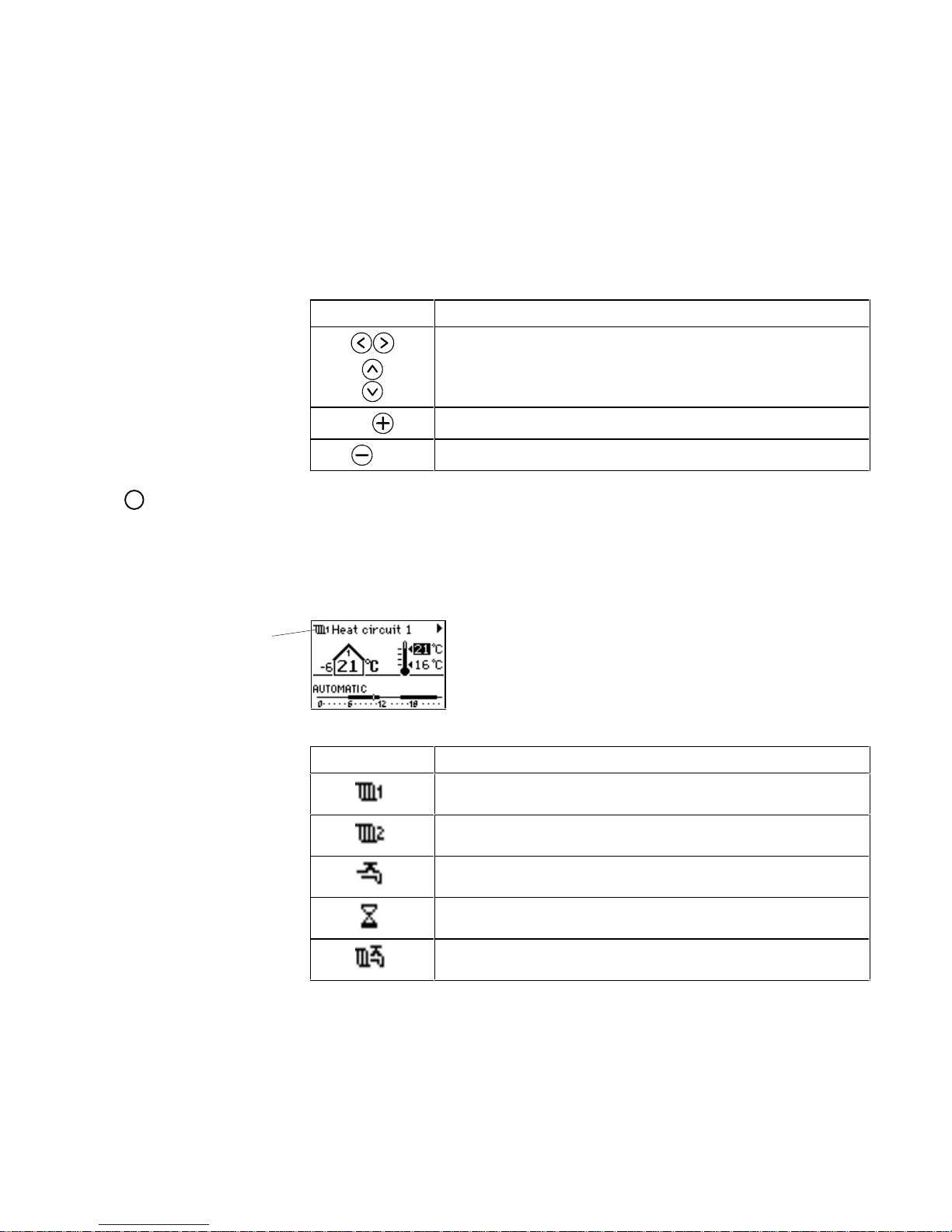

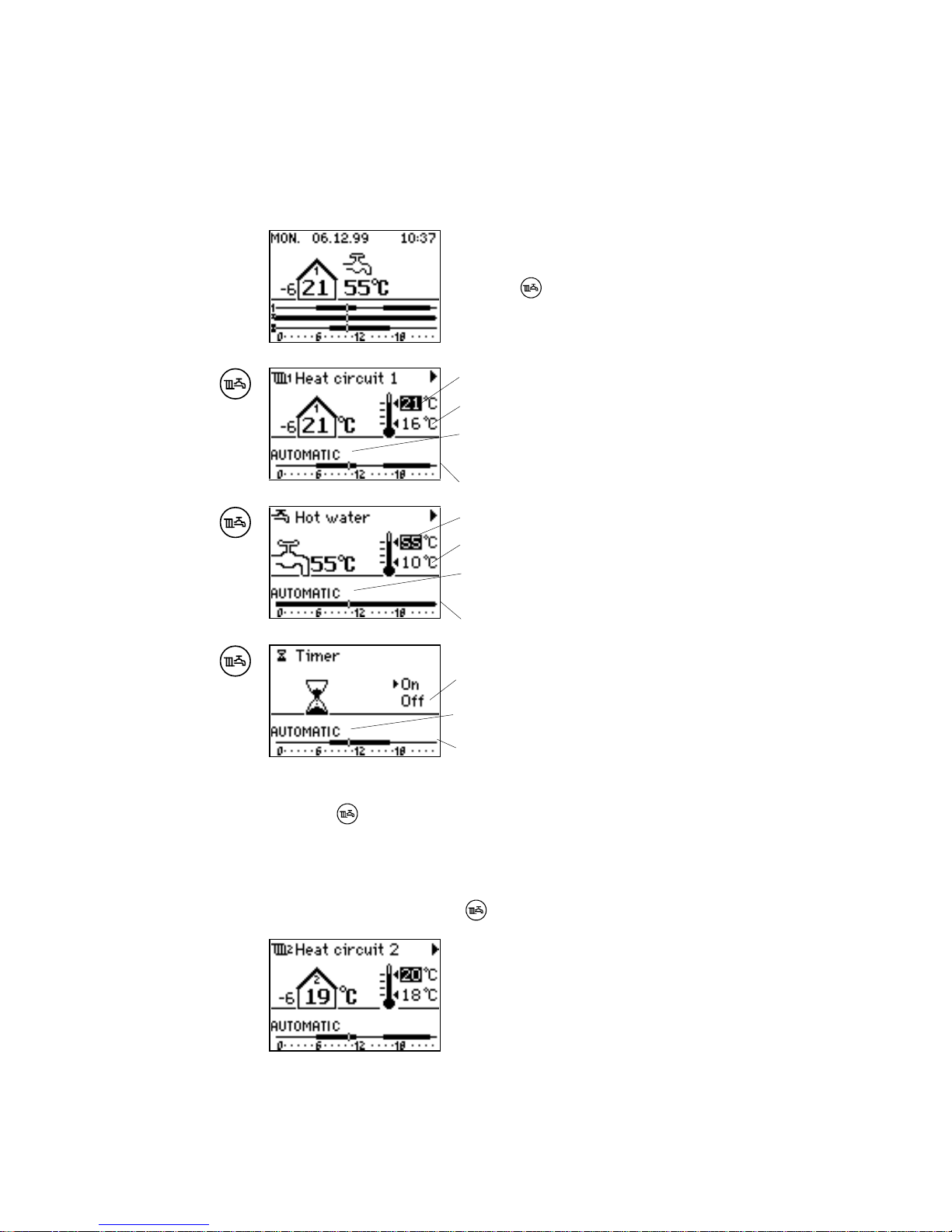

4.3 Selecting a Circuit. Viewing Circuit Status

This section tells you how to select an individual circuit in the plant and display status

data for this circuit.

In the System Overview picture or in one of the System

Status pictures (see page 10-11):

1. Press

to display the next circuit in the plant.

Comfort temperature setpoint

Night setback temperature setpoint

Operating mode of the circuit: Automatic, Comfort,

Night setback or Stand-by. See page 3

24-hour program

Comfort temperature setpoint

Night setback temperature setpoint

Operating mode of the circuit: Automatic, Comfort,

Night setback or Stand-by

24-hour program

Current status of timer

Operating mode of the timer

24-hour program

To return to the System Overview:

2. Press

again.

Whenever you wish to change the setup or view data for one circuit separately, you

start by selecting the circuit. This function is active in most of the ECL 2000’s pictures. For example, while setting the operating mode for one circuit, you can switch

to the next circuit by pressing

.

Several of the ECL 2000’s built-in applications include

two heat circuits. When a second heat circuit is part of

the application, this circuit has a picture associated with

it that is very similar to the picture for Heat circuit 1.

Page 19

Day-to-Day Operation

EY.65.H4.02

13

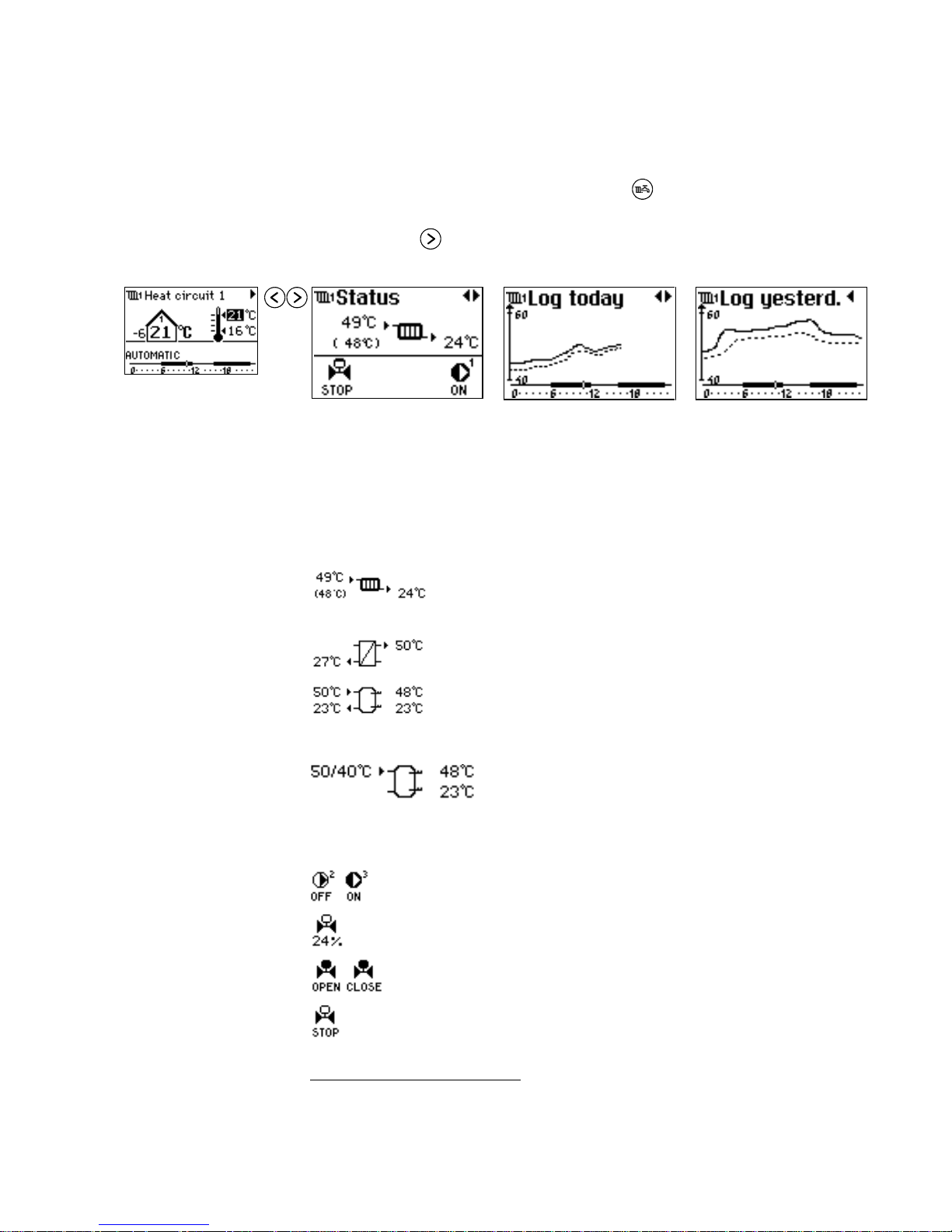

View Status

To view status information for one circuit:

1. In the System Overview picture, press

until you see the picture of the

appropriate circuit.

2. Press

to display status information for the circuit, once more to display

today’s log, and again to display yesterday’s log.

The status of individual

components of the selected circuit. The symbols used in the picture are

explained below.

Today’s log. The fully

drawn curve shows variations in flow temperature.

The dotted curve indicates

the return temperature.

4

Yesterday’s log. The fully

drawn curve shows the

flow temperature, the

dotted curve shows the

return temperature.

4

Temperature readings

The following temperature information is available in Status pictures, depending on

the selected application and the type of circuit:

5

Actual (49 °C) and reference flow temperature (calculated, 48 °C), return temperature (24 °C) for a radiator

heating system.

Primary return temperature and secondary flow temperature for a circuit that includes a heat exchanger.

Charging (50 °C) and return temperature (23 °C), upper

tank temperature (48 °C) and lower tank temperature

(23 °C) for a circuit that includes a hot-water storage

tank.

Flow temperature (50/40 °C) measured by two sensors

in a circuit that includes a hot-water storage tank.

Pump and valve status

The following pump and valve information can be available in Status pictures, depending on the application and the type of circuit.

Pump status: Pump no. 2 is currently off while pump

no. 3 is operating.

Valve status: Valve 24 % open.

Valve motor status: Valve moving in the open-

ing/closing direction, respectively.

Valve motor status: Valve is not moving.

4

See Appendix C, page 87 for a complete list of the data displayed in Log pictures

5

A blank reading indicates that the sensor is not connected or that there is a sensor error

Page 20

Day-to-Day Operation

EY.65.H4.02

14

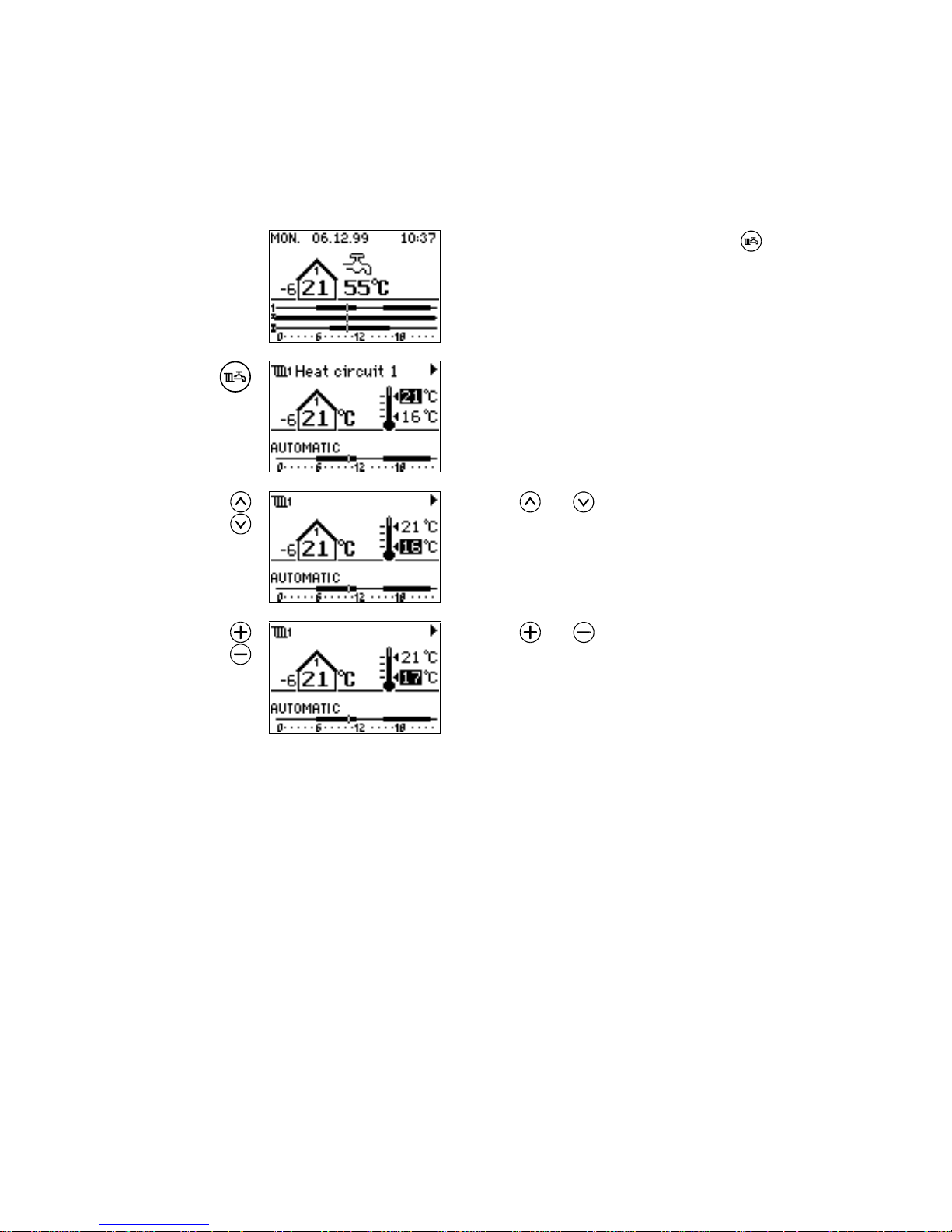

4.4 Changing Comfort and Night Setback Temperature Settings

This page tells you how to change the comfort and night setback temperature settings

for a heat circuit or a hot-water service.

1. In the System Overview picture, press to dis-

play the picture of the desired circuit.

In the Circuit picture in this example, the comfort temperature is highlighted, indicating that this setting is

selected.

2. Use and to select the temperature setting

that should be changed – the comfort temperature

or the night setback temperature.

3. Use and to change the temperature setting.

Page 21

Day-to-Day Operation

EY.65.H4.02

15

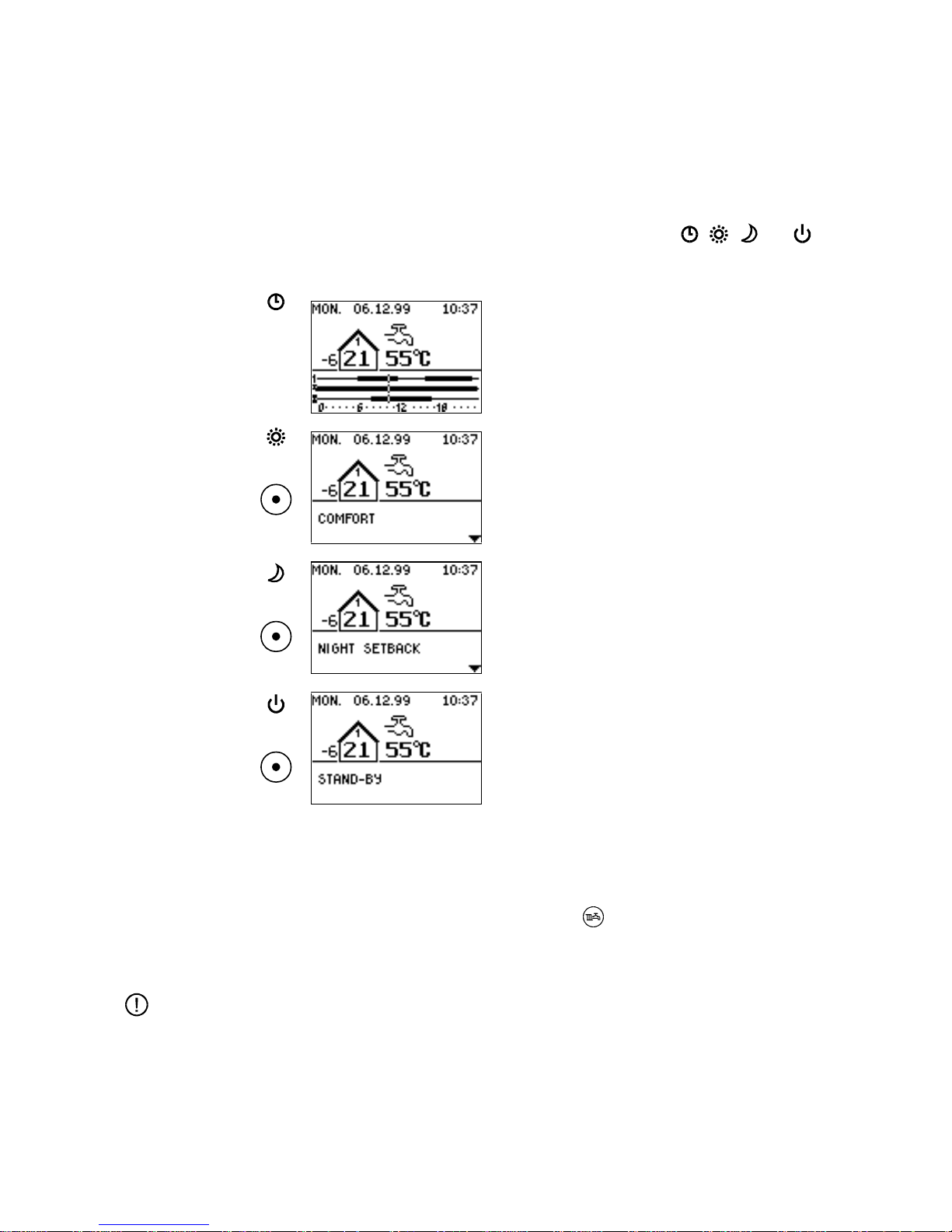

4.5 Changing the Operating Mode

Changing the operating

mode for all circuits

The ECL 2000 can operate in 4 modes. Use the Mode push-button on the front panel

to change the controller’s operating mode.

Above the Mode push-button, there are 4 LED symbols:

, ,

and

. When

you select an operating mode, the symbol corresponding to the selected mode lights

up.

Automatic

The controller switches between comfort and night setback temperature as specified in the 7-day plan.

Page 17 tells you how to modify the plan.

Comfort

The controller maintains comfort temperature for all

circuits.

Night setback

The controller maintains night setback temperature constantly in all circuits.

Stand-by

Temperature control is stopped but the system is frostprotected at 6 °C.

By pressing the Mode button once more, all three circuits are set in Automatic mode.

Changing the operating

mode for one circuit

Alternatively, you can change the operating mode for each of the system’s circuits

individually:

1. In the System Overview, press

to select the circuit you wish to work

with.

2. Use the Mode push-button to select the desired operating mode.

Note:

If the system includes a timer circuit, this circuit will be set in Night Setback mode

when Stand-by is selected, that is, the timer output will be constantly off.

Page 22

Time Programming

EY.65.H4.02

16

5. TIME PROGRAMMING

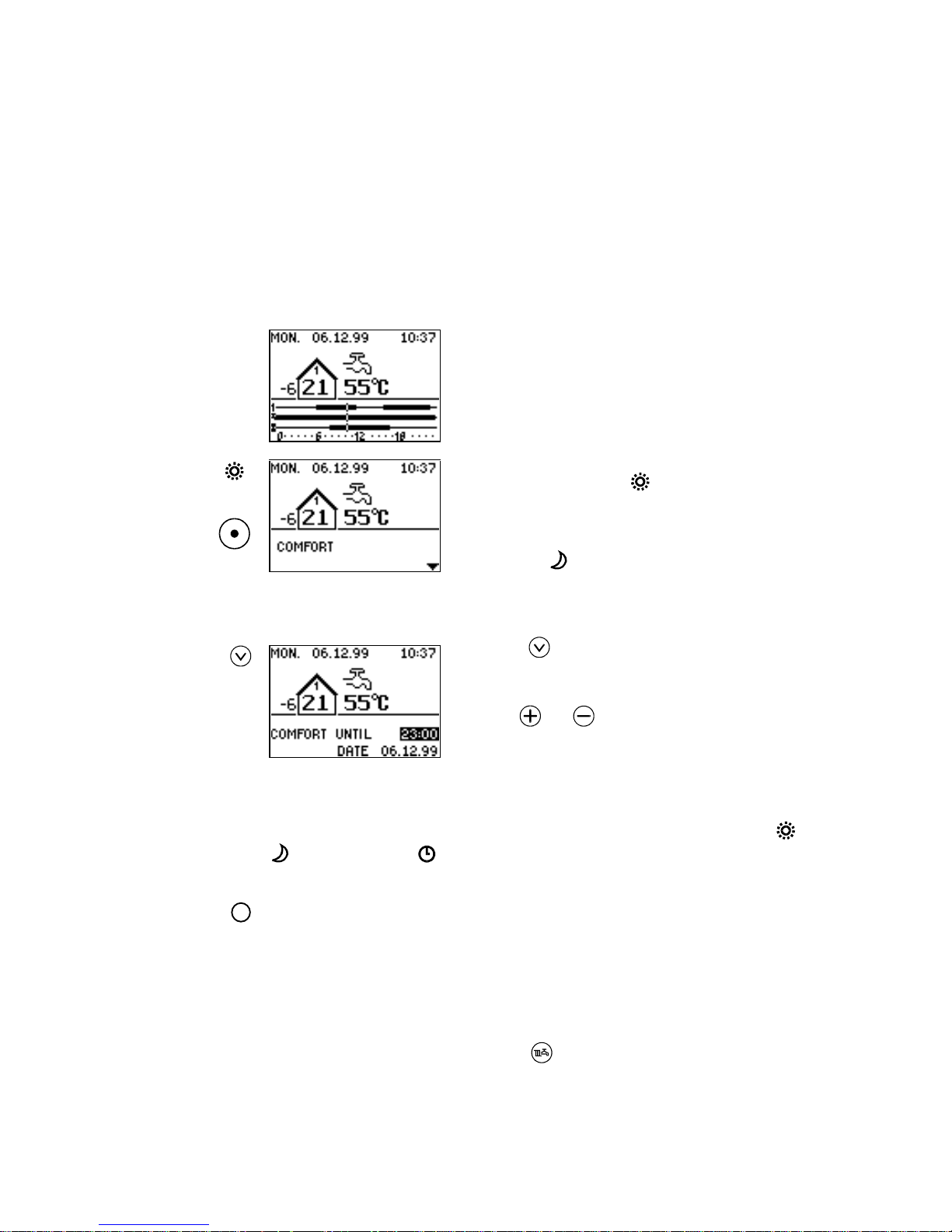

5.1 Extending the Comfort or Night Setback Period

The ECL 2000 offers two functions allowing you to override the controller’s 24-hour

program. The party function extends the comfort temperature period while the

economy function extends the night setback period.

You can extend the comfort or night setback period for

the whole plant or separately for one circuit. To change

the setting for the whole plant:

1. Start in the System Overview picture.

2. To extend the comfort period, press the Mode

push-button until the

symbol lights up.

Or:

3. To extend the night setback period, press Mode

until the

symbol lights up.

The example on this page illustrates how the comfort

period is extended.

4. Press to set the stopping time and date, i.e. the

time when the controller will revert to the normal

24-hour program.

5. Use

and to adjust the stopping time in 30-

minute steps.

The stopping date is adjusted automatically if the stopping time exceeds midnight.

When you use this function to extend the comfort or night setback period, the

or

stays lit, while the is flashing to indicate that the controller will automatically

revert to its normal 24-hour program at the specified stopping time.

!

Note:

When the party function is active, the controller maintains comfort temperature from

the current time until the specified stopping time. Any night setback periods programmed in this interval are disregarded. Likewise, the economy function keeps the

system at night setback temperature constantly until the specified stopping time.

To extend the comfort or night setback period for a single circuit:

1. Select the circuit by pressing

, and proceed from step 2. above.

Page 23

Time Programming

EY.65.H4.02

17

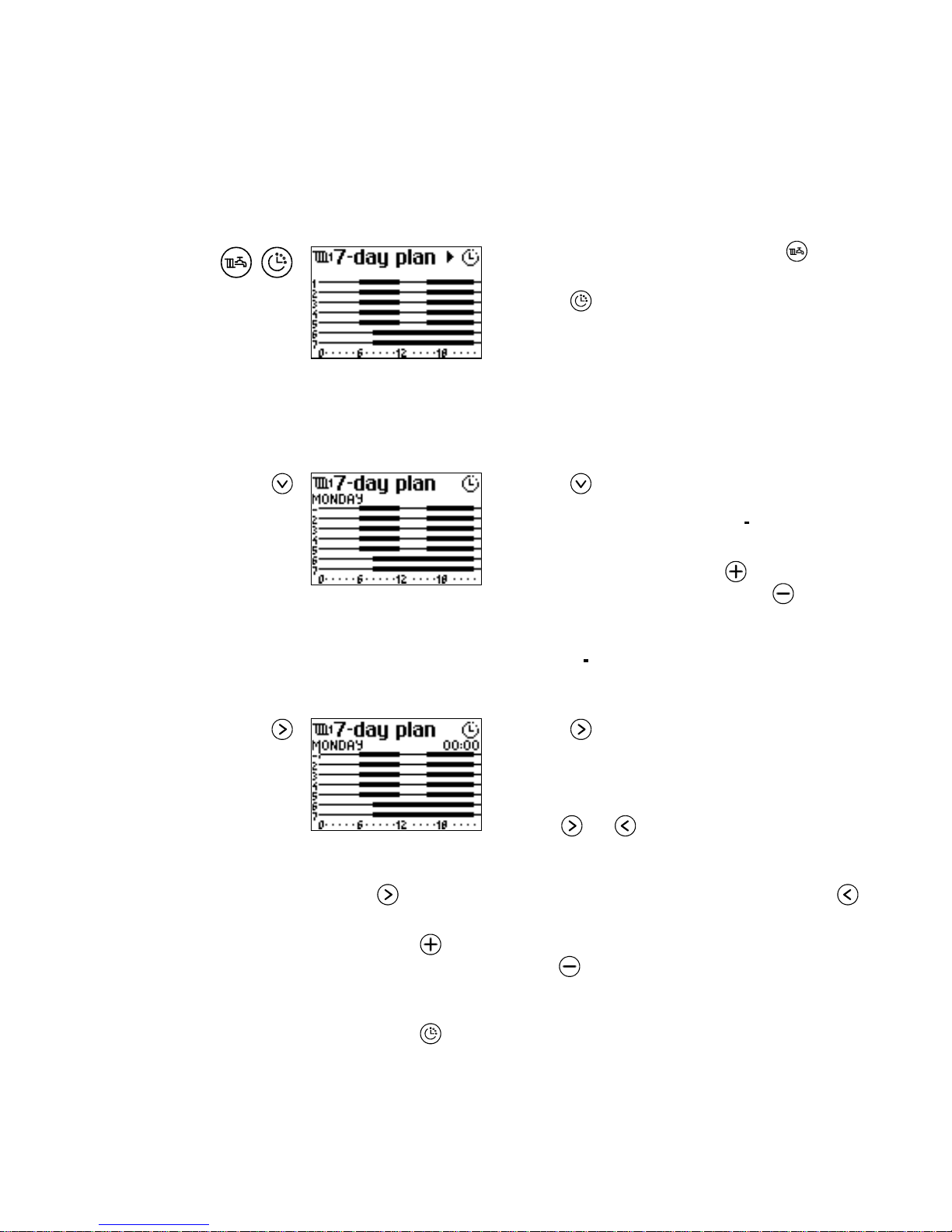

5.2 Setting the 7-Day Plan

The ECL 2000’s 7-day plan is active when the controller is in Automatic mode (see

page 15). The 7-day plan determines when comfort temperature will be maintained in

the system, and when night setback temperature will be maintained.

,

1. In the System Overview picture, press to

display the picture of the circuit.

2. Press

to display the current 7-day plan for the

selected circuit.

In the 7-day plan, the numbers 1-7 indicate the days from Monday to Sunday. A thin

time line indicates when night setback temperature should be maintained, and a thick

line indicates when comfort temperature should be maintained.

Now select a day or group of days for which the 24-hour program will be changed:

3. Press until the name of the first day appears

(Monday in this example). Note that the day’s

number is replaced by a cursor (

).

4. If you wish to select a group of days (for example

Monday through Friday), use

to add the cur-

rently selected day to the group. Use

to remove

the selected day from the group.

When a group of days is selected, the numbers of the days are highlighted while the

currently selected day is indicated by the

cursor.

Now set the 24-hour program for the selected day or group of days:

5. Press .

A cursor appears in the time line that represents the 24-

hour program for the selected day(s). The time of day

corresponding to the cursor position is displayed.

6. Use

and to move the cursor to the time of

day at which you wish to modify the plan.

If the plan includes changes from comfort to night setback temperature and vice

versa, the

push-button moves the cursor forward to the next change of mode.

always moves the cursor backwards in 15-minute steps.

7. Press

to select comfort temperature for the currently selected 15-

minute time interval. Press

to select night setback temperature.

Exit

To exit the 7-day plan:

1. Press

.

Page 24

Time Programming

EY.65.H4.02

18

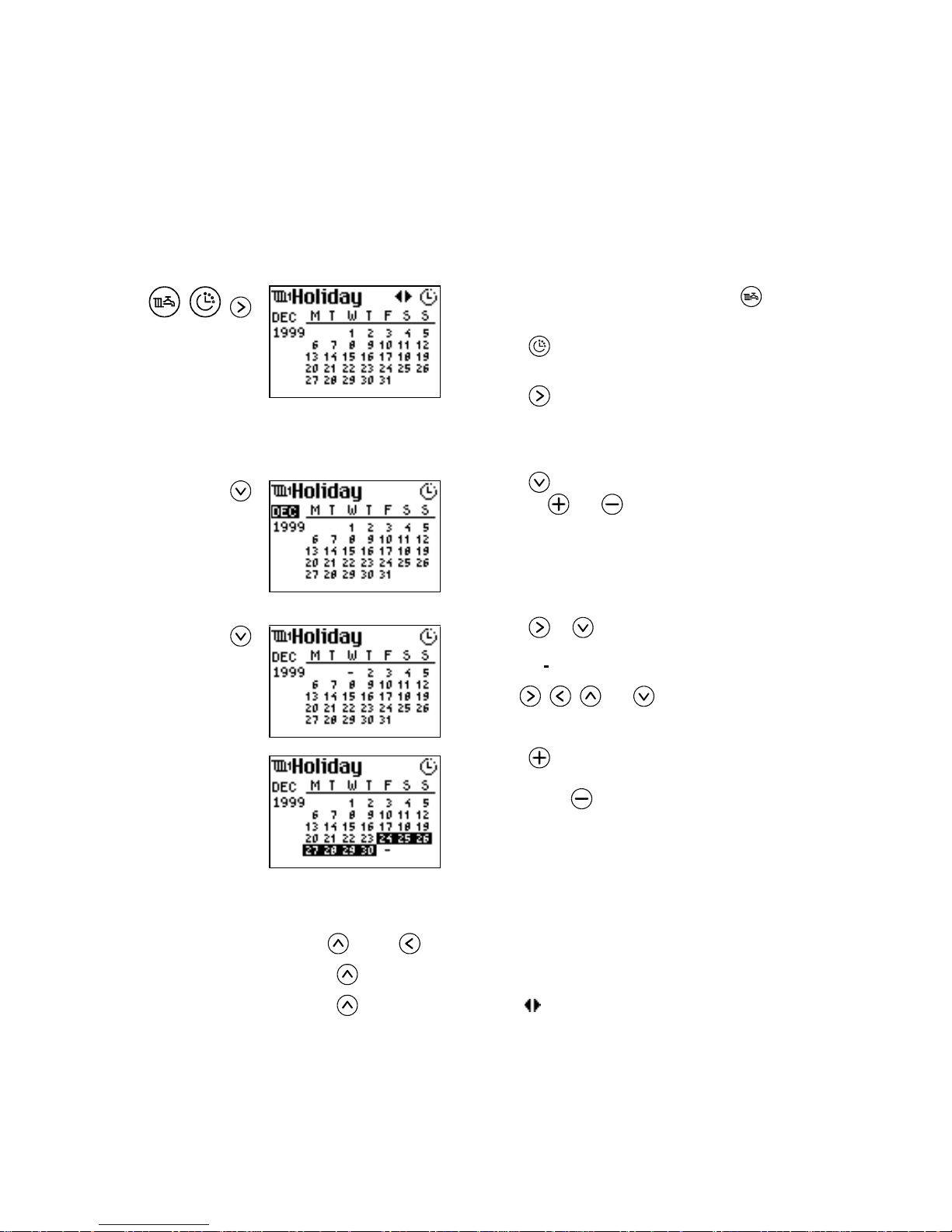

5.3 Setting the Holiday Plan

The ECL 2000’s Holiday Plan enables you to set up a special 24-hour program which

will be active for a limited number of days (the holiday period) which you select from

a calendar.

You set up the holiday plan for one circuit at a time:

, ,

1. In the System Overview picture, press until the

appropriate circuit picture appears.

2. Press

to display the 7-day plan. Details of this

picture are given on page 17.

3. Press

to display the Holiday picture.

The first thing to do is to set up the holiday period. First

select the month:

4. Press to highlight the name of the month, and

then use

and to change the holiday month.

The year changes automatically when the month

changes from Dec to Jan.

Now proceed to select the days of the holiday period:

5. Press or to move the cursor to the first day

of the selected month. The date is replaced by a

cursor (

).

6. Use

, , and to move the cursor to the

first day to be included in the holiday period.

7. Press to add the currently selected day to the

holiday period. The selected days are highlighted.

By pressing

, you remove the selected day from

the highlighted period.

The next step is to set up a 24-hour program for the holiday period. But first, you

must exit this part of the Holiday Plan facility:

8. Use

and/or to move the cursor back to the first date of the month.

9. Press

to move the cursor back to the name of the month.

10. Press

once more to display the symbol at the top right corner of the dis-

play.

See next page for further instructions.

Page 25

Time Programming

EY.65.H4.02

19

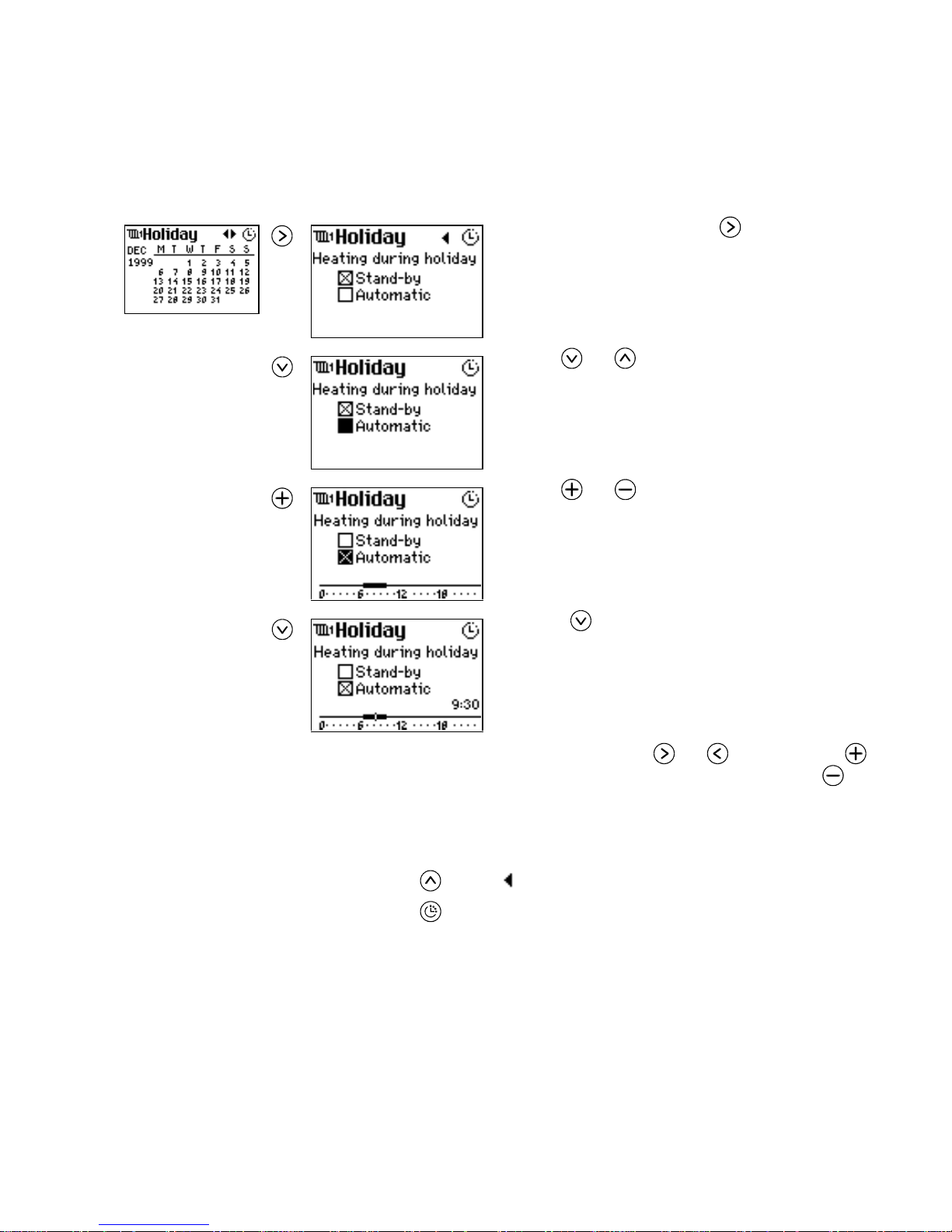

After setting up the holiday period, you are now ready to enter the 24-hour program

that the controller should follow during this period:

11. In the Holiday picture, press .

The ECL 2000 displays this picture, which allows you

to select an operating mode for the holiday. The X indicates the currently selected mode (Stand-by in the example).

12. Use

and

to move the cursor between Stand-

by and Automatic.

13. Use and to select or deselect an operating

mode (see page 3 for information about ECL

2000’s operating modes).

When you select Automatic, a time line appears at the

bottom of the display.

14. Press to move the cursor to the time line.

The time of day corresponding to the cursor position is

displayed.

Now you can set the 24-hour program for the holiday

period in the same way as you set a 24-hour program for

the normal 7-day plan:

and move the cursor,

selects comfort temperature (thick time line) and

selects night setback temperature (thin line). See page

17 for more detailed instructions.

Exit

To exit the holiday plan facility:

1. Press

until the symbol appears at the top right corner.

2. Press

.

Page 26

Entering the Access Code

EY.65.H4.02

20

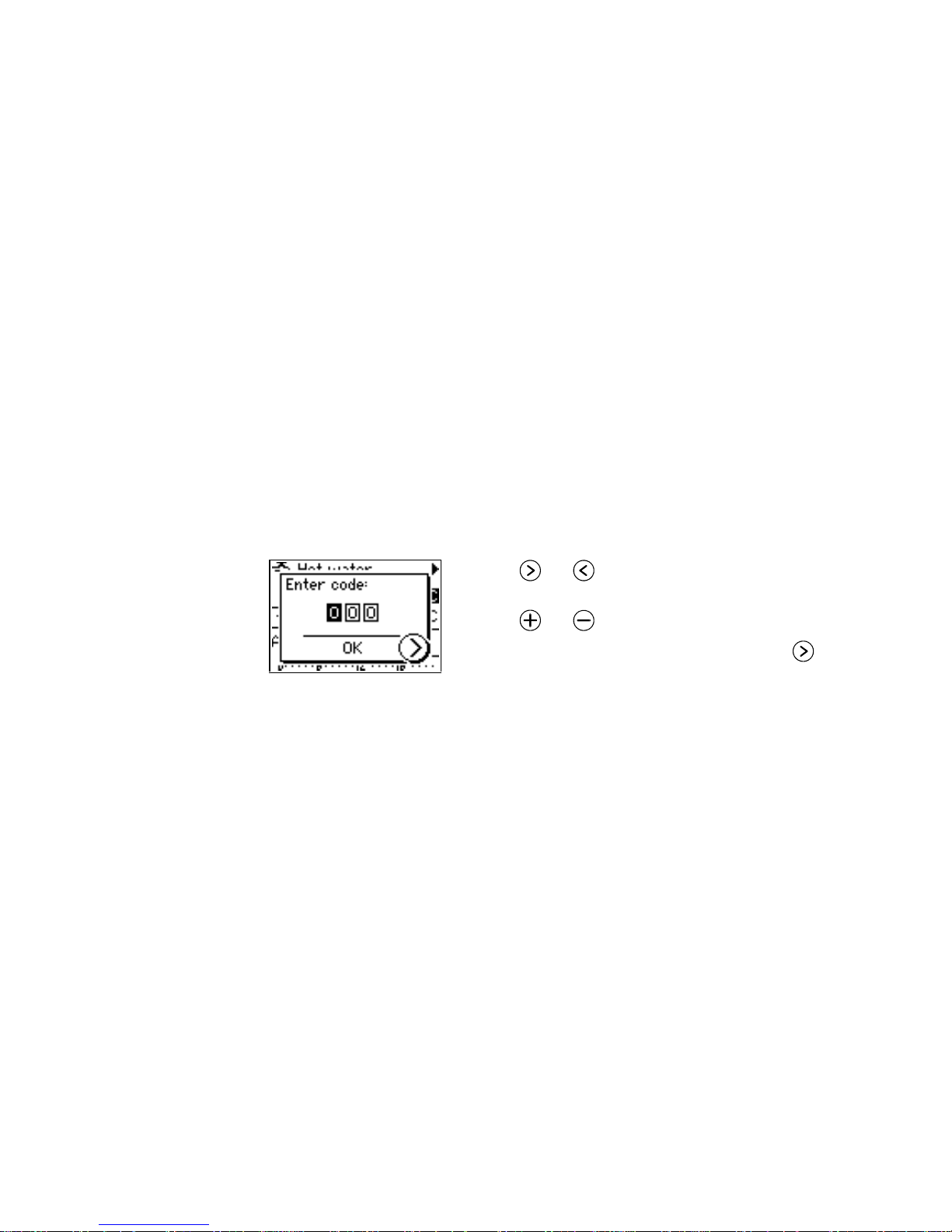

6. ENTERING THE ACCESS CODE

The ECL 2000 always allows the user to display any parameter or setting. However,

the controller can be set up to prompt the user to enter an access code before he or she

is allowed to modify a setting. The controller has 2 levels of access codes:

• The service level code gives authorization to modify all settings of the ECL 2000.

This code is required to select a different application (see page 26), to configure

inputs and outputs (see page 27) and to modify the controller’s service settings

(see chapter 10, page 38).

• By entering the user level code, you are authorized to modify all settings that do

not require the service level code. These settings are the ones that may need

changing during normal day-to-day operation, for example a temperature setpoint

or the 7-day plan.

See page 72 for instructions on activating and modifying the access code.

When you attempt to modify a setting, a pop-up similar to the one shown below appears:

1. Use and to move the cursor from one digit

to another.

2. Use

and to change the digits.

3. When you have entered the access code, press

.

The Access Code pop-up disappears. If you entered the

correct access code, you can now complete the operation you were about to perform.

When no front panel push-button has been operated for a 10 minute period, you must

enter the access code again before being allowed to modify any settings.

Page 27

Weather Compens at i on Curves

EY.65.H4.02

21

7. WEATHER COMPENSATION CURVES

Weather compensation means that the ECL 2000 regulates the heat circuit temperature in accordance with the outdoor temperature.

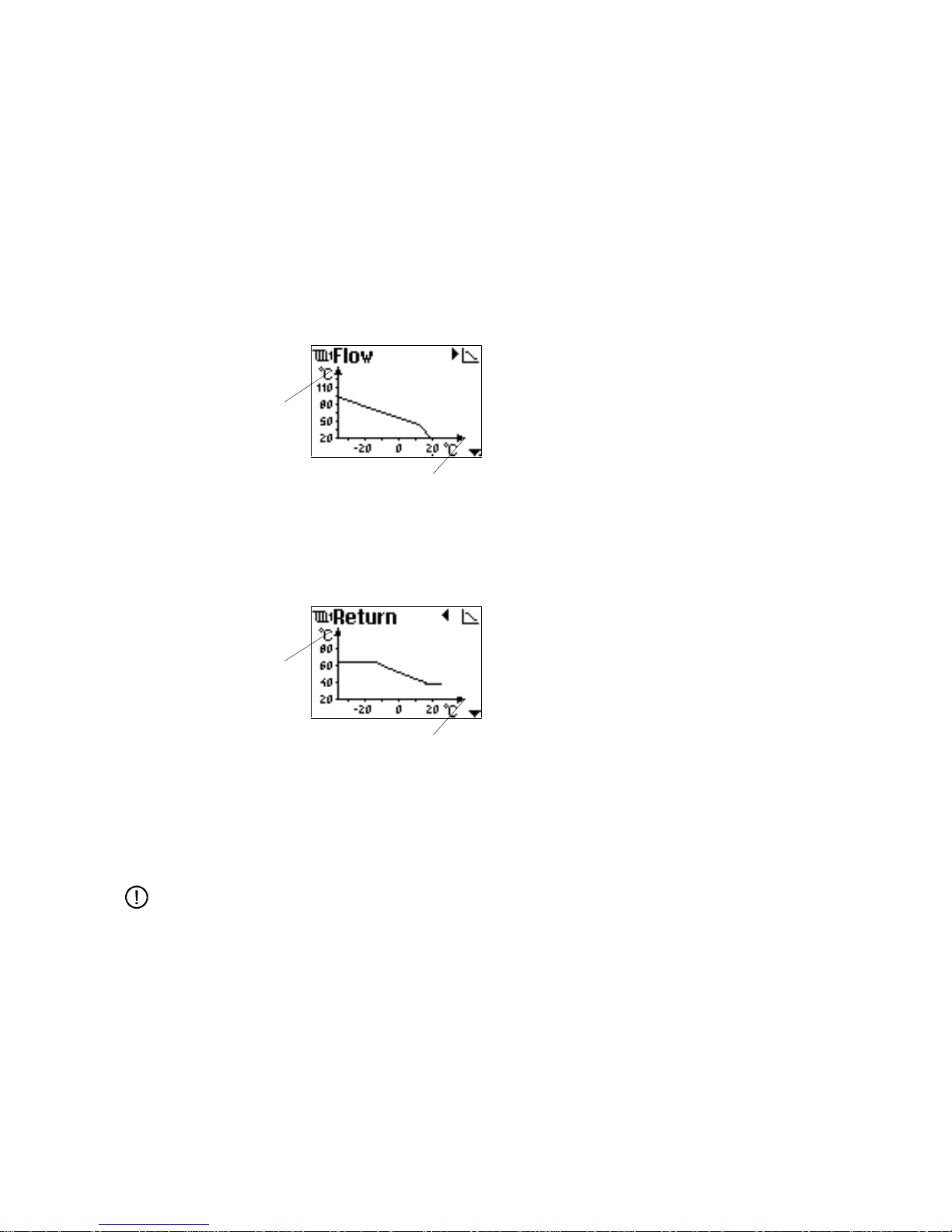

Weather compensation is controlled by two user-definable curves:

• A flow temperature curve

• A return temperature curve.

Flow temperature curve

Outdoor temperature

The flow temperature curve shows the reference flow

temperature in the heat circuit as a function of the outdoor temperature. By modifying this curve, you determine what the flow temperature should be for various

values of the outdoor temperature.

At low outdoor temperatures, you will normally want a

higher flow temperature, as shown in the curve to the

left.

You can set up maximum and minimum values for the

reference flow temperature. This is explained on

page 22.

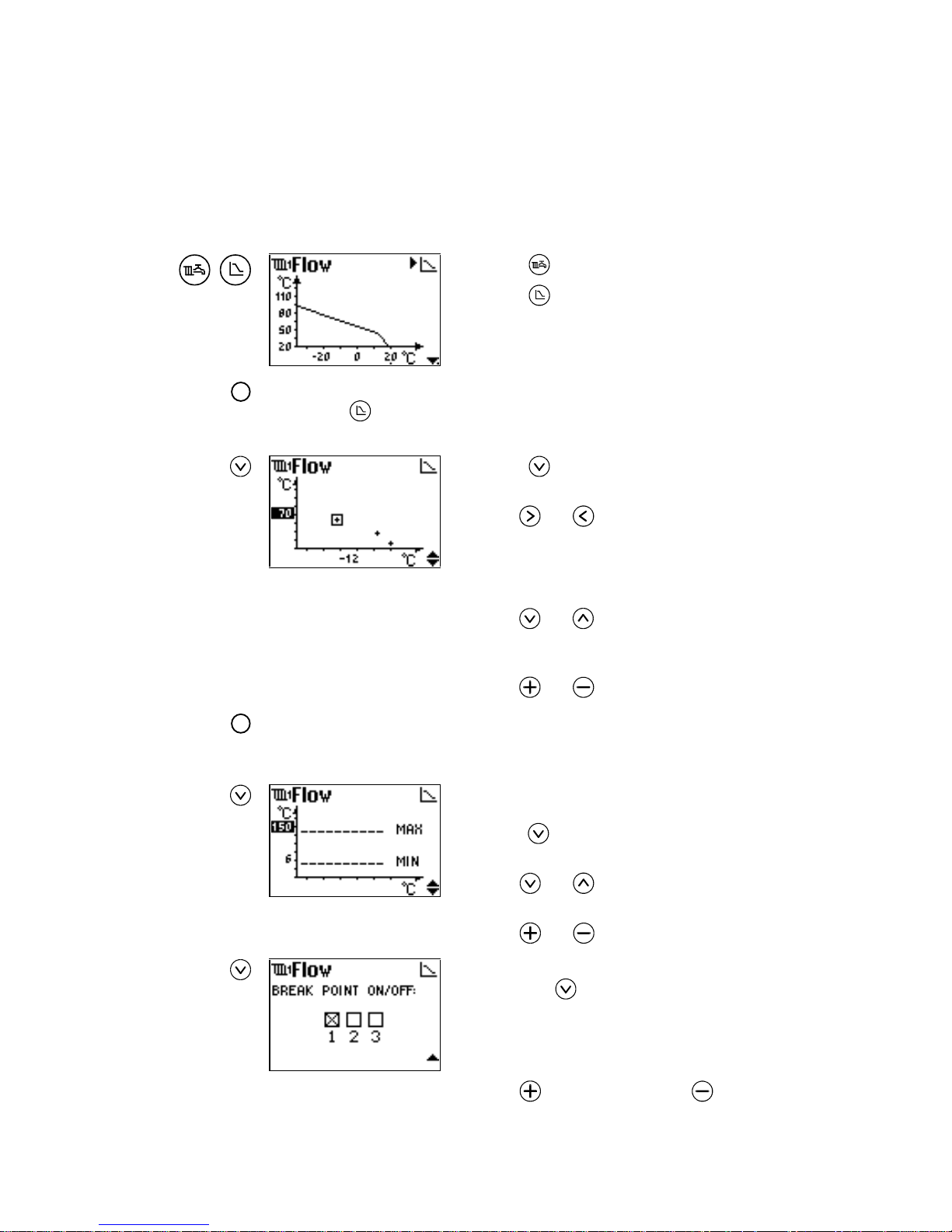

Return temperature

curve

Outdoor temperature

The return temperature curve controls return temperature limiting in accordance with the outdoor temperature. The curve shows the acceptable return temperature

as a function of the outdoor temperature.

Normally, a low outdoor temperature means that a

higher return temperature will be allowed. This is also

the case with the curve shown to the left.

For further information on return temperature limiting,

see page 47 and 48 (heat circuit) and page 58 and 59

(hot-water circuit).

The following pages provide instructions for setting up the curves.

Note:

The setting of the flow and return temperature curve is essential for the functioning of

the ECL 2000. Therefore, it is important to check that the resulting curve is reasonable in relation to the controlled system.

Reference flow

temperature

Return temperature limit

Page 28

Weather Compens at i on Curves

EY.65.H4.02

22

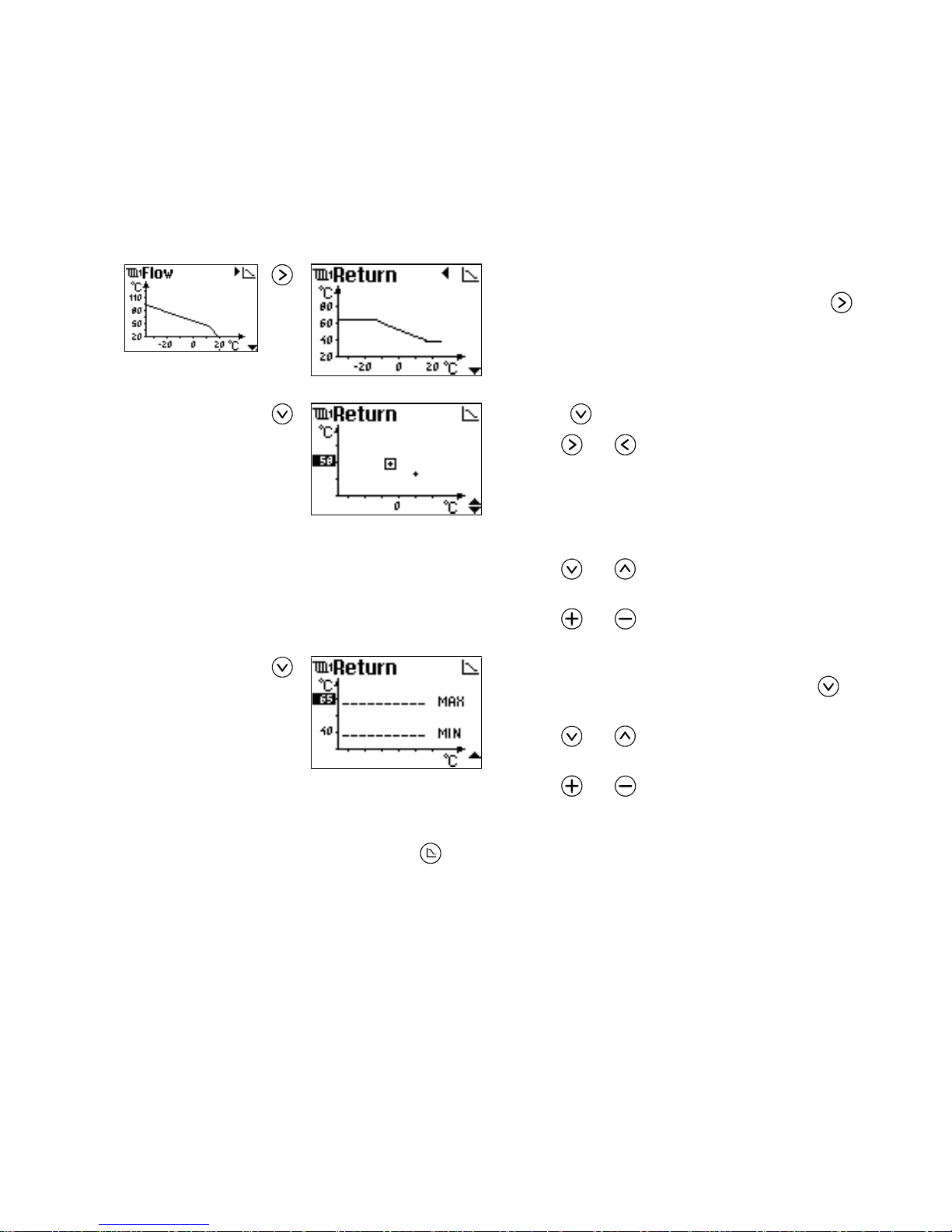

7.1 Adjusting the Flow Temperature Curve

The weather compensation curve for the flow temperature can be modified by setting:

A maximum and minimum value, 2 curve endpoints and, in addition to these, 3 break

points. Together, these parameters define the shape of the curve.

,

1. Press to select the desired heat circuit.

2. Press

to display the flow temperature curve.

!

Note:

If you press

while a hot-water circuit is selected, the ECL 2000 displays a pop-up

informing you that this facility is not available for hot-water circuits.

Moving curve

points

3. Press to display the currently defined curve

points.

4. Use

and to move the cursor to the point you

wish to modify.

The flow temperature (y co-ordinate) of the selected

point is highlighted to indicate that it can be modified.

5. Use

and to select either the flow temperature (y co-ordinate) or the outdoor temperature (x

co-ordinate) of the point.

6. Use

and to adjust the selected value.

!

Note:

If two curve points are placed in the same position, one point is automatically removed.

Setting maximum

and minimum values

7. Ensure that the outdoor temperature of a point is

selected (x co-ordinate value highlighted), and

press to display maximum and minimum val-

ues.

8. Use

and to select either the maximum or

minimum setting.

9. Use

and to adjust the selected setting.

Adding and removing curve

points

10. Ensure that the curve’s minimum value is selected,

and press

to display break points.

The checked box indicates the number of break points

that are currently active (in this example, 1 break point

is active – in addition to the two curve endpoints).

11. Use

to add a breakpoint or to remove one.

Page 29

Weather Compens at i on Curves

EY.65.H4.02

23

7.2 Adjusting the Return Temperature Curve

You modify the return temperature curve in the same way as when adjusting the flow

temperature curve (see page 22). However, for the return temperature curve, you can

only set two curve points. The curve can have no further break points.

To display the return temperature curve:

1. In the Flow Temperature Curve picture, press

.

Moving curve

points

2. Press to display the curve points.

3. Use

and to move the cursor to the point you

wish to modify.

The y co-ordinate value (the return temperature) of the

selected point is highlighted to indicate that it can be

modified.

4. Use

and to select either the y or x co-

ordinate (outdoor temperature) of the point.

5. Use

and to adjust the selected value.

Setting maximum

and minimum values

6. Ensure that the x co-ordinate of a point is selected

(x co-ordinate value highlighted), and press

to

display maximum and minimum values.

7. Use

and to select either the maximum or

minimum setting.

8. Use

and to adjust the selected setting.

Exit

To exit temperature curve editing:

1. Press

.

Page 30

Weather Compens at i on Curves

EY.65.H4.02

24

This page is intentionally left blank

Page 31

Configuring the ECL 2000

EY.65.H4.02

25

8. CONFIGURING THE ECL 2000

This section tells you how to begin using the ECL 2000 after it has been installed. The

ECL 2000 Installation Guide (ref. [2]) provides full details about the installation and

configuration of the ECL 2000.

8.1 Starting the ECL 2000 for the First Time

When the ECL 2000 is powered on, the controller displays the Danfoss logo.

The ECL 2000 is supplied with up to 17 different pre-programmed applications (see

below), accommodating a wide variety of plant configurations. Before the ECL 2000

is operational, you must select the application that matches your plant best. Once you

have selected an application, you have the possibility of customizing one or more

system parameters.

If the ECL 2000 has already been programmed with a pre-selected application, the

System Overview replaces the logo picture after a moment.

If no application is selected, the ECL 2000 automatically displays the Application 1

picture (see page 26), allowing you to select an application. See instructions on the

following pages.

8.2 ECL 2000 Types

Two different types of ECL 2000 are available. The table below summarizes the differences between the two types (see also page 89).

Type 1 Type 2

Inputs

Pt 1000 7 7

Pt 1000, 0-10 V, pulse

or digital

24

Outputs

Relay (pump control ) 3 3

3-point control (motor

valve control)

2 –

0-10 V (motor valve

control)

–3

Page 32

Configuring the ECL 2000

EY.65.H4.02

26

Power supply

230 V AC

24 V AC

24 V AC

Pre-programmed applications

1

1 – 14 1 – 17

8.3 Selecting an Application

This section explains how to select one of the ECL 2000’s pre-programmed applications. For an overview of available applications, see page 34.

To select an application:

1. Press the front panel

button.

If no application has been selected yet, the ECL 2000

displays the picture Application 1. However, if an application has already been selected, the picture of this

application is displayed. In this case, the picture’s title

is inverted, i.e. displayed in light characters on a dark

background.

2. Use and

to browse through available appli-

cations.

Each application picture shows a diagram of the system

configuration. Refer to the ECL 2000 Installation Guide

(ref. [2]) for system diagrams offering additional detail.

When you have found the application you need:

3. Keep the

button depressed for a few seconds.

While the

button is active, the picture’s title (in the

example “APPLICATION 10”) is inverted, one character at a time, until the whole title is displayed in light

characters on a dark background.

When all the characters of the title are inverted, this

indicates that the controller is configured to use this

application.

The

symbol appears briefly, indicating that you can

access further configuration pictures. After a moment,

the controller automatically displays the first configuration picture (see next page).

1

See page 34 for an overview of ECL 2000 applications

Page 33

Configuring the ECL 2000

EY.65.H4.02

27

8.4 Configuring I nputs and Outputs

8.4.1 Operating Configuration Pictures

Depending on the type of ECL 2000 you are working with and the application you

have selected, it may be possible to customize one or more sensor inputs (S8, S9, S10

and S11) and one relay output (P3). Furthermore, if the ECL 2000 LON option is installed, you can configure four LON inputs (L1, L2, L3 and L4). This section explains

how to operate the function. The following sections give some details about possible

settings. Further information is available in the ECL 2000 Installation Guide (ref.

[2]).

When you have selected an application, you are ready to configure inputs and outputs:

1. In the Application picture (see facing page), press

to access Input

settings.

Configuring Sensor

Inputs

The first pictures in the series allow you to configure the ECL 2000’s sensor inputs.

2. Use to select the different parameters.

The arrow symbol at the top right corner of the display disappears, indicating that you

can now select and set the individual parameters of the picture.

3. Use

to modify the parameters Sensor, Circuit and Type.

4. Use

and to modify the remaining parameters.

Section 8.4.2 starting on page 30 provides an overview of the possible settings of sensor input parameters.

Note:

The sensor inputs S10 and S11 and the corresponding configuration pictures are only

available for the ECL 2000 Type 2.

Page 34

Configuring the ECL 2000

EY.65.H4.02

28

To exit a configuration picture:

5. Press

until the arrow symbol at the top right corner reappears.

6. Use

or to access other configuration pictures.

See also page 29.

Configuring LON

Inputs

A maximum of 4 sensors can be configured as input from the LON network. To access LON configuration pictures:

1. Press

in the last sensor input picture (Input S9 for the ECL 2000 Type

1 and Input S11 for the Type 2).

X

2. Use

to select the different parameters.

3. Use

to modify the parameters Sensor, Circuit and Unit.

4. Use

and to modify the parameter Poll.

Section 8.4.3 starting on page 32 gives some details about the possible settings of the

LON inputs. See also section 10.4.6 on page 70 for information on the LON address.

Configuring the Relay

Output

Some ECL 2000 applications allow you to change the function of the relay output P3.

When this is possible, you can access the Output P3 picture by pressing

in either

the last sensor picture (Input S9 or Input S11) or, if the LON option is installed, in the

Input L4 picture. This is illustrated below. Section 8.4.3 starting on page 32 gives

details about the possible settings of P3.

1. Use to select the parameter Function.

2. Use

to modify the setting.

Page 35

Configuring the ECL 2000

EY.65.H4.02

29

Save and Exit

To exit the configuration facility and save the selected settings:

1. Press

until the arrow symbol appears at the top right corner of the dis-

play.

2. Press

again.

If you have selected a different application, or if one of the parameters Sensor, Cir-

cuit or Type has been changed, the ECL 2000 is reset, which takes a few moments.

Meanwhile, the Danfoss logo is shown in the display.

Page 36

Configuring the ECL 2000

EY.65.H4.02

30

8.4.2 Sensor Inputs

This section explains the setup of the ECL 2000’s sensor inputs. See the ECL 2000

Installation Guide (ref. [2]) for further information.

Note:

It is not possible to set up two sensors with the same function (Sensor) in one circuit

(Circuit). For example, you cannot have two room temperature sensors both affecting

circuit 1. The ECL 2000 automatically excludes this and similar illegal settings.

Furthermore, not all combinations of settings (e.g. Sensor and Type) are allowed. The

ECL 2000 keeps track of this and only allows you to select valid settings.

Sensor This setting tells the ECL 2000 what is measured by means of the sensor connected to

this input. The setting can have the following values:

Value Description

Room temp.

Room temperature

Sun intens.

Sun intensity

Wind veloc.

Wind velocity

Flow

Water flow

Energy

Energy measurement

Clock func.

An external timer is connected to the input. Overrides the normal program set up for the circuit. When the timer input is OFF (0), the circuit

is in Automatic mode. When the timer input is ON (1), the circuit is in

Comfort mode

Other

Universal limiter

None

No function

Circuit This parameter determines which circuit is affected by the sensor.

Value Description

None

No circuits affected

Circuit 1

Heat circuit 1

Circuit 2

Heat circuit 2

Hot water

Hot-water circuit

Circuit 1+2

Circuits 1 and 2

All circuits

All heat and hot-water circuits in the system

Page 37

Configuring the ECL 2000

EY.65.H4.02

31

Type This setting indicates what type of sensor is connected. The following sensor types

are supported:

Value Description

Pt 1000

Temperature dependent resistance: 1000

at 0 °C

ESMF

Remote control device with a built-in Pt 1000 room temperature sensor

Pulse

Pulse count

0–10 V

The sensor delivers a voltage in the range 0-10 V

Digital

Digital input

Amplific., Offset Amplification, Offset.

For a 0–10 V sensor, the ECL 2000 must convert the input voltage received from the

sensor into the correct value, using the correct unit of measurement. The parameters

Amplific. (amplification) and Offset are used to perform this calculation. Their func-

tion is illustrated in Figure 2.

Offset

Value [m/s, l/h, ...]

Value = Amplification * Input + Offset

Input signal [V]

Figure 2. Amplification and Offset

Scaling, Interval These parameters are used to convert the number of pulses received from a pulse in-

put into the correct value and unit of measurement. See the ECL 2000 Installation

Guide (ref. [2]) for details on these parameters.

Page 38

Configuring the ECL 2000

EY.65.H4.02

32

8.4.3 LON Inputs

The parameters of the LON input configuration pictures can assume the values described in the following.

Sensor This setting tells the ECL 2000 what is being measured by means of the LON sensor.

Value Description

Outd. temp.

Outdoor temperature

Note:

When Outd. temp. is selected, the ECL 2000 uses the LON sensor to

measure outdoor temperature. Any outdoor temperature sensor connected

directly to the ECL 2000 (typically via sensor input S3) is disabled

Flow

Water flow

Wind veloc.

Wind velocity

Energy Energy measurement. When Energy is selected, values for the accumu-

lated energy are automatically collected from the same device

None

The LON input is not used, i.e. no input is taken from the LON network

Circuit This parameter determines which circuit is influenced by the collected data.

Value Description

None

No circuits affected

Circuit 1

Heat circuit 1

Circuit 2

Heat circuit 2

Hot water

Hot-water circuit

Circuit 1+2

Circuits 1 and 2

All circuits

All heat and hot-water circuits in the system

Poll This parameter determines how often the ECL 2000 will poll the LON sensor.

Value Description

X s The number of seconds between sensor polls. For example, if Poll is set

to 25 s, the ECL 2000 reads the actual value from the sensor every 25

seconds

Poll can be set to values in the range 5 – 60 s for all sensor types. After

an external device has been polled 3 times without having anwered, this is

considered a sensor fault

Page 39

Configuring the ECL 2000

EY.65.H4.02

33

Unit The Unit parameter is available when Sensor is set to Flow or to Energy. When Sen-

sor is set to Flow, the Unit parameter can be set as follows:

Value Description

l/h

Water flow is being measured in liter per hour

m3/h

Water flow is being measured in m

3

per hour

Note:

When the flow unit is set to l/h, there is a risk of an overflow error if the measured

water flow exceeds 1024 l/h. This will lead to a blank flow reading on the

ECL 2000’s display. See the Technical Manual for the ECL 2000 LON Option (ref.

[4]).

When Sensor is set to Energy, the Unit parameter can be set as follows:

Value Description

kW

Energy is being measured in kW. When this setting is active, the accumulated energy is measured in MWh

MW

Energy is being measured in MW. When this setting is active, the accumulated energy is measured in GWh

Note:

When the energy unit is set to kW, there is a risk of an overflow error if the measured

energy (power consumption) exceeds 1024 kW. This will lead to a blank energy

reading on the ECL 2000’s display. See the Technical Manual for the ECL 2000 LON

Option (ref. [4]).

8.4.4 Relay Output

For some applications, you can also customize the ECL 2000’s relay output P3.

Function The relay output parameter Function can be set to the following values:

Value Description

Pump 3

The output controls a pump. This is the default setup for some applications

Timer

When this value is selected, one of the controller’s circuits is dedicated to

a timer function. The output is set to ON and OFF in accordance with the

7-day plan for the timer circuit. See also page 10.

Alarm

The relay output is used as an alarm indication, i.e. the output is set to

ON and OFF in accordance with the ECL 2000’s Alarm Setup (see page

66).

Page 40

Configuring the ECL 2000

EY.65.H4.02

34

8.5 Overview of ECL 2000 Applications

Heat circuit and hot-water circuit with indirect control

via heat exchanger.

Heat circuit and hot-water circuit with direct control of

storage tank.

Common primary heat exchanger for a heat circuit and a

hot-water circuit with indirect control of storage tank.

Common primary heat exchanger for a heat circuit with

a mixing valve and a hot-water circuit with indirect

control of storage tank.

Heat circuit and hot-water circuit with indirect control

of storage tank.

Common primary heat exchanger for a heat circuit and a

hot-water circuit with indirect tank charging system.

Common primary heat exchanger for a heat circuit with

mixing valve and a hot-water circuit with indirect tank

charging system.

Common primary heat exchanger for a heat circuit and a

hot-water circuit with mixing valve and indirect tank

charging system.

Page 41

Configuring the ECL 2000

EY.65.H4.02

35

Two separate heat circuits.

Two separate heat circuits and a hot-water circuit with

direct control of storage tank.

One separate heat circuit. In addition to this, a common

primary heat exchanger supplying one heat circuit and

one hot-water circuit with indirect control.

Two heat circuits with common heat exchanger. One

heat circuit has a mixing valve.

Two interdependent heat circuits and a hot-water circuit

with direct control of storage tank.

Common primary heat exchanger for one heat circuit

with mixing valve, one heat circuit without and a hotwater circuit with indirect control of storage tank.

Two heat circuits with common heat exchanger, where

one circuit has a mixing valve. Hot-water circuit with

indirect control via heat exchanger.

Note: This application requires ECL 2000 type 2.

Two separate heat circuits. Hot-water circuit with indirect control via heat exchanger.

Note: This application requires ECL 2000 type 2.

Two separate heat circuits. Hot-water circuit with indirect control of storage tank.

Note: This application requires ECL 2000 type 2.

Page 42

Manual Override

EY.65.H4.02

36

9. MANUAL OVERRIDE

When the ECL 2000’s Manual Override function is active, you can control system

components, circulation pumps and valve motors from the ECL 2000’s front panel.

,

1. Press to select the circuit that you wish to con-

trol manually.

2. Press

to activate manual control.

The LED above the

button lights up and all four

LED’s indicating the controller’s operating mode are

switched off. The controller displays a picture showing

the pumps and valves of the selected circuit, as well as

status information.

!

Note:

While the Manual Override function is active, automatic control of all circuits in the

plant is disabled. Automatic control is disabled, as long as the LED above the

is

lit.

While Manual Override is active, frost-protection of the plant is disabled.

3. Press

and to select the pump or valve you wish to operate (see

facing page).

The text below the selected component is highlighted to indicate the selection.

4. Press

and to operate the device. These buttons work as indicated in

the table below.

Push-button Pump Motor valve

Pump is set toONMotor valve OPENs while button is pressed. After the but-

ton has been kept depressed for about 5 seconds, the valve

will move continuously towards the open position until the

button is pressed again

Pump is set to

OFF

Motor valve CLOSEs while button is pressed. After the

button has been kept depressed for about 5 seconds, the

valve will move continuously towards the closed position

until the button is pressed again

Note:

If a motor valve is moving when

is pressed, it will continue running. You can stop

the valve by pressing

or

.

It is not possible to control a timer circuit manually.

Page 43

Manual Override

EY.65.H4.02

37

To display today’s and yesterday’s logs for the selected circuit:

1. In the Manual picture, press

to display today’s log and once more to

see yesterday’s log.

The circuit’s last component is selected. The

symbol indicates that you

can proceed to the next

picture (today’s log) by

pressing

.

Today’s log. The fully

drawn curve indicates the

flow temperature, the

dotted curve shows the

return temperature.

1

Yesterday’s log.

The ECL 2000 keeps logs of the temperature measured by all connected sensors. You

can display these logs from the Common Functions service menu. See page 67.

Exit

To exit Manual Override and revert to automatic control of the plant:

3. Press

again.

1

See Appendix C, page 87 for a complete list of the data displayed in Log pictures

Page 44

Service Settings

EY.65.H4.02

38

10. SERVICE SETTINGS

The ECL 2000’s service menus provide facilities for displaying and modifying:

• Heat circuit settings

• Hot-water circuit settings

• Settings concerning the overall operation of the ECL 2000, for example the cur-

rent date and time. These are called Common Functions.

The options that are available in service menus depend on the application that is selected and the setup of the system. This chapter describes all service menu options

that can be available in a ECL 2000. Please disregard any explanations of parameters

not available in your particular system.

Select menu item/

setting

Next/previous picture

See also the service menu overview in Appendix B. The overview shows all available

service pictures and options.

Page 45

Service Settings

EY.65.H4.02

39

10.1 Operating Service Menus

Accessing service menus The diagram on the facing page illustrates how the ECL 2000’s service menus are

operated. To access service menus for a heat circuit or a hot-water circuit:

1. Press

to select the desired circuit.

2. Press

to activate the service menu.

The controller displays the service menu for the circuit you selected. In the diagram

on the facing page, heat circuit 1 was selected prior to pressing

.

To access the Common functions service menu directly (see page 62):

1. In the System Overview picture, press

.

Operating service menus In all service menus,

and are used to select menu items. Selected menu items

are highlighted. If, for example, you wish to view and modify pump and motor valve

settings:

1. Press to select Pump/valve.

Each menu item has a number of setting pictures associated with it. How many, depends on the selected application (see page 26) and the type of controller you are

working with. You use

and to access these pictures:

2. Press

to access the first Pump/valve setting picture.

The ECL 2000 now displays the first set of parameters for pumps and valves in circuit

no. 1. The symbol in the upper right-hand corner of the display indicates the number

of pictures available and which one of these is currently displayed. In the diagram, the

symbol indicates that there are a total of 3 setting pictures, that the first one of these is

currently displayed and that you can access the next setting picture by pressing

.

To select a parameter, you use

and . The selected setting is highlighted. To

change the value of the selected parameter:

3. Press

or .

For the currently selected parameter, the line at the bottom of the picture indicates:

Current setting

Previous setting

Maximum limit

Minimum limit

Factory settin g

Figure 3. The line at the bottom of a service setting picture

Page 46

Service Settings

EY.65.H4.02

40

To exit a service setting picture:

4. Press

once to return to the service menu, and once more to exit the service

menu.

All changes you have made are saved automatically.

Page 47

Service Settings

EY.65.H4.02

41

10.2 Heat Circuit Functions

This section describes the parameters that can be set up for a heat circuit via the

service menus.

This picture is the service menu for a heat circuit. Heat

circuit functions are divided into 4 groups corresponding to the menu items: Building, Pump/valve, PI con-

stants and Limiter. See the overview diagram on page

38.

Each menu item gives access to a number of setting pictures allowing you to view and

modify various parameters for the heat circuit. The number of pictures and parameters

available depends on the type of controller you are working with and the application

you have selected (see page 26 for information about ECL 2000 applications).

This section describes all parameters that can be set for a heat circuit. Please disregard

the descriptions of any parameters not available in your specific system setup.

Instructions for operating the ECL 2000’s service menus are provided on page 39.

10.2.1 Building Settings

This section describes the parameters you can set in pictures under the Building menu

item.

Summer cut-off The summer cut-off function makes the controller close down the heat circuit.

Display text Parameter Default value,

range

Description

Outdoor temp.

Outdoor temperature

Default value:

18 °C

Range:

10-30 °C

When the outdoor temperature reaches

this value, summer cut-off is activated,

and the heat circuit it closed down

Room temp.

Room temperature

Default value:

24 °C

Range:

10-30 °C

When the room temperature reaches this

level, summer cut-off is activated

Note:

By default, the circulation pump of the heat circuit is switched off when the calcu-

lated flow temperature drops below 20 °C. See page 45.

Page 48

Service Settings

EY.65.H4.02

42

The diagram in Figure 4 illustrates the summer cut-off function. When the measured

outdoor or room temperature exceeds the setpoint (Outdoor temp. or Room temp.

setting) by 0.5 K, the flow temperature is reduced. The night setback level is main-

tained until the filtered outdoor/room temperature drops below the setpoint – 0.5 K.

See page 71 for information on setting parameters for calculating the filtered temperature.

[Hours]

Plant switched off

Filtered temperature

Temperature

Measured temperature

Time

} 1K

°C

20

18

16

Figure 4. The summer cut-off function

Optimizer

The purpose of the ECL 2000’s Optimizer function is to help run the plant in the most

economic manner possible. The Optimizer offers functions for:

• Calculating the optimum starting time in order for room temperature to reach the

desired level (the comfort temperature) at the time defined in the 7-day plan.

• Calculating how much ahead of time the system can be switched to night setback

temperature, making sure, however, that the room temperature does not drop by

more than 1 K before the pre-programmed night-setback time.

• Selecting the optimum method for pre-heating the system.

Settings for the optimizer are described on the following pages.

By default, the Optimizer functions are disabled. This has been accomplished by setting the parameters Pre-heat period: Max. limit and Cooling period: Max. limit to

0 hours. The Optimizer functions can be enabled by changing these settings as indicated on page 43. Optimizer heating and cooling can be enabled/disabled separately.

Page 49

Service Settings

EY.65.H4.02

43

Pre-heat period This is the function that allows the controller to calculate the optimum starting time. If

the system is equipped with a room temperature sensor, this function is adaptive.

If no room temperature sensor is connected, the controller estimates the room temperature as a function of the actual outdoor temperature and the default pre-heat period entered by the operator (see below). Furthermore, if the system has been on night

setback for a long period, the controller increases the length of the pre-heat period. In

this way, the controller is able to compensate for fluctuations in outdoor temperature

and accumulated heat in buildings.

Display text Parameter Default value,

range

Description

Default

Default preheat period

Default value:

23 hours

Range:

0-24 hours

As default, you must enter a pre-heat

period that you estimate is suitable given

the following conditions:

• Outdoor temperature 0 °C

• Actual room temperature 5 °C

• Comfort temperature setting 20 °C

• Flow temperature 80 °C during the

heating perio d

Max. limit

Maxi mum preheat period

Default value:

0 hours

Range:

0-24 hours

The maximum pre-heat period the system

is allowed to calculate and use. Change

this setting to enable the optimizer function

Calculated

Calculated

pre-heat period

Range:

0-24 hours

The pre-heat period calculated by the

controller using the actual outdoor temperature. This parameter is read-only and

cannot be set

Cooling period These settings enable the controller to calculate the cooling period, i.e. how soon the

plant can be switched to night setback temperature while still ensuring that the room

temperature only drops by 1 K before the pre-programmed night setback time.

Display text Parameter Default value,

range

Description

Default

Default cooling period

Default value:

1 hour

Range:

0-24 hours

You must enter a default cooling period

corresponding to the following conditions:

• Outdoor temperature 0 °C

• Actual room temperature 20 °C

• Room temperature reduction = 1 K

Max. limit

Maximum

cooling period

Default value:

0 hours

Range:

0-24 hours

The maximum cooling period the system

is allowed to calculate and use. Change

this setting to enable the optimizer function

Calculated

Calculated

cooling period

Range:

0-24 hours

The cooling period calculated by the

controller using the actual outdoor temperature. This parameter is read-only and

cannot be set

Page 50

Service Settings

EY.65.H4.02

44

Pre-heat method This function enables the controller to determine the flow temperature level during

the pre-heat period. It is possible to:

• Use the boost function, which increases the flow temperature by a user-defined

percentage. The purpose is to reach comfort room temperature sooner, that is, reduce the duration of the pre-heat period.

• Use the slope function, which increases the flow temperature gradually. The aim

is to avoid an unnecessary sudden load of the district heating network and also to

prevent the return temperature from getting too high.

Note:

When Slope time is set, the gradual increase of the flow temperature level is applied

even if the Optimizer function is disabled.

Display text Parameter Default value,

range

Description

Boost factor

Default value:

0 %

Range:

0-100 %

The percentage by which the flow temperature should be increased during the

pre-heat period

Slope time

Default value:

0 min.

Range:

0-200 min.

The length of the time interval during

which the flow temperature should be

increased gradually to its comfort level

Night setback disable This function disables night setback when the outdoor temperature drops below a

user-defined limit.

Display text Parameter Default value,

range

Description

Disable at

Default value:

–15 °C

Range:

OFF,

–29 - 15 °C

When Disable at is set to a temperature,

night setback is disabled when the actual

outdoor temperature is below this limit.

When the outdoor temperature lies in the

interval between 15 °C and the Disable

at temperature setti ng, night setback is

gradually reduced

When Disable at is set to OFF, night

setback is never disabled

Page 51

Service Settings

EY.65.H4.02

45

10.2.2 Pump/Valve Settings

This section describes the parameters you can set in pictures under the Pump/valve

menu item.

Pump The following parameters can be set for pump operation:

Display text Parameter Default value,

range

Description

Overrun

Pump overrun

period

Default value:

3 min.

Range:

0-30 min.

The number of minutes the pump will

continue to run after the calculated flow

temperature setpoint has dropped below

20 °C. After this, the pump will be

stopped

Exercise

Pump exercise Default value:

ON

Range:

ON, OFF

When the pump has been stopped for 72

hours, pump exercise will take place,

provided that this parameter is ON. This

means that at 12:00 (noon), the pump

will be started and run for 1 minute

Night stop

Default value:

OFF

Range:

ON, OFF

During the night setback period, it is

generally desirable to stop the pump, or

at least reduce the number of revolutions.

When a normal pump is used, the parameter is set to OFF. In this case, the

controller stops the pump when the calculated flow temperature drops below

20 °C.

The ON setting is used for pumps with

control of the differential pressure across

the pump. This type of pump has a separate input that can be used to instruct the

pump to reduce its number of revolutions.

When the Night stop parameter is set to

ON, the ECL 2000 sends a STOP signal

to the pump as soon as a night setback

period starts, thus causing the pump to

reduce its number of revolutions, regardless of other pump control criteria.

For further information about the connection and use of this type of pump, see

the ECL 2000 Technical Manual

(ref. [3])

Motor valve The following parameters can be set for the motor valve in the heat circuit:

Display text Parameter Default value,

range

Description

Stroke

Default value:

16 mm

Range:

1-50 mm

Stroke of the valve motor

Page 52

Service Settings

EY.65.H4.02

46

Display text Parameter Default value,

range

Description

Run time

1 mm

Running time

1 mm

Default value:

8 seconds

Range:

1-99 seconds

The time required for the spindle of the

motor valve to move 1 mm

Exercise

Valve exercise Default value:

OFF

Range:

ON, OFF

When the valve motor has not been running for 72 hours, valve exercise will

take place, provided that this parameter

is ON. This means that at 12:00 (noon),

the gear motor will be started and the

valve will be activated for 3 minutes in

the opening direction and 3 minutes in

the closing direction

Flow cut-off Depending on the type of ECL 2000 and the type of application you have selected, it

is possible to customize 1 or more sensor inputs (see page 27). If one of these inputs is

used to measure the water flow, the controller can be set up to close the valve if the

flow in the system falls below a user-defined limit.

The following settings are related to flow cut-off caused by measured flow data:

Display text Parameter Default value,

range

Description

Cut-off time

Default value:

0 min.

Range:

0-30 min.

The period during which the valve is

closed

Min. flow

Minimum flow Default value:

0.0 l/h

Range:

0.0-999 l/h or

0.0-999 m

3

/h

If the water flow in the system is below

this limit, the valve is closed

The range and unit depend on the selected application and flow sensor

Alternatively, if one of the user-definable inputs is set up as a digital input, this signal

can be used to activate flow cut-off. In this case, the valve is closed when the input is

short-circuited. For such a configuration, only the cut-off time can be set.

In more detail, the flow cut-off function works as follows:

1. The ECL 2000 detects that the condition for activating flow cut-off is present.

2. The ECL 2000 waits for 5 minutes before closing the valve.

3. The valve remains closed for the period of time specified in Cut-off time.

4. The valve is reopened and the ECL 2000 checks whether the flow cut-off condi-

tion is still present.

5. If this is the case, the valve is closed after a delay of 5 minutes. If the flow cut-off

condition is no longer present, the valve remains open.

Page 53

Service Settings

EY.65.H4.02

47

10.2.3 PI Constant Settings

This section describes the parameters you can set in pictures under the PI Constant

menu item.

Flow temp. control This group of settings determine how the flow temperature is controlled. The follow-

ing parameters can be set:

Display text Parameter Default value,

range

Description

Neutr. zone

Neutral zone Default value:

3 K

Range:

0-9 K

When the flow temperature lies within

the neutral zone, the valve motor is not

activated

P-band

Proportional

band

Default value:

70 K

Range:

1-99 K

Indicates the amplification in the control

loop. If the flow temperature deviates

from the reference temperature, the motor will be positioned proportionally to

the temperature deviation and the proportional band setting

Integr. time

Integration

time

Default value:

20 seconds

Range:

0-999 seconds

In case of a constant control error signal,

the motor will have moved by an amount

equal to that caused by the P-band after

the integration time has elapsed

When the integration time is set to 0, the

integral action is disabled

Return temp. limiter

The controller can be set up to adjust the flow temperature if the actual return temperature either:

• Rises above the return temperature setpoint (maximum limiting)

or

• Falls below the return temperature setpoint (minimum limiting).

The return temperature setpoint is calculated from the return temperature curve (see

page 23).

The following parameters can be set for this control function (see also page 48):

Display text Parameter Default value,

range

Description

Amplification

Default value:

– 0.3 K

Range:

– 25.0 - 25.0

K

Amplification for return limiter

Integr. time

Integration

time

Default value:

30 min.

Range:

0-200 min.

Integration time

Page 54

Service Settings

EY.65.H4.02

48

Room influence These settings determine how the room temperature should influence flow tempera-

ture control. They are only applicable when a room sensor is connected in the heat

circuit.

Display text Parameter Default value,

range

Description

Max. amplific.

Maximum

amplification

Default value:

0.0 K

Range:

– 25.0 - 25.0

K

If the room temperature exceeds the

room temperature setpoint, the flow temperature in the heat circuit will be reduced according to the Max. amplific.

setting

Min. amplific.

Minimum amplification

Default value:

0.0 K

Range:

– 25.0 - 25.0

K

If the room temperature falls below the

room temperature setpoint, the flow temperature in the heat circuit will be increased according to the Min. amplific.

setting

Adaptive

Default value:

OFF

Range:

ON, OFF

When the setting is ON, the flow temperature is adjusted according to variations of the room temperature over a

period of time

!

Note:

When this setting is ON, the Max. am-

plific. and Min. amplific. settings should

be symmetrical with respect to 0, for

example, Max. amplific. = –3 K and

Min. amplific. = + 3 K

10.2.4 Limiter

This section describes the parameters you can set in pictures under the Limiter menu

item.

Return temperature The following settings affect the return temperature limiter. See also page 47.

Display text Parameter Default value,

range

Description

Type

Type of limitation

Default value:

MAX

Range:

MIN, MAX

Type of return temperature limitation

used: maximum or minimum. The flow