Installation Guide

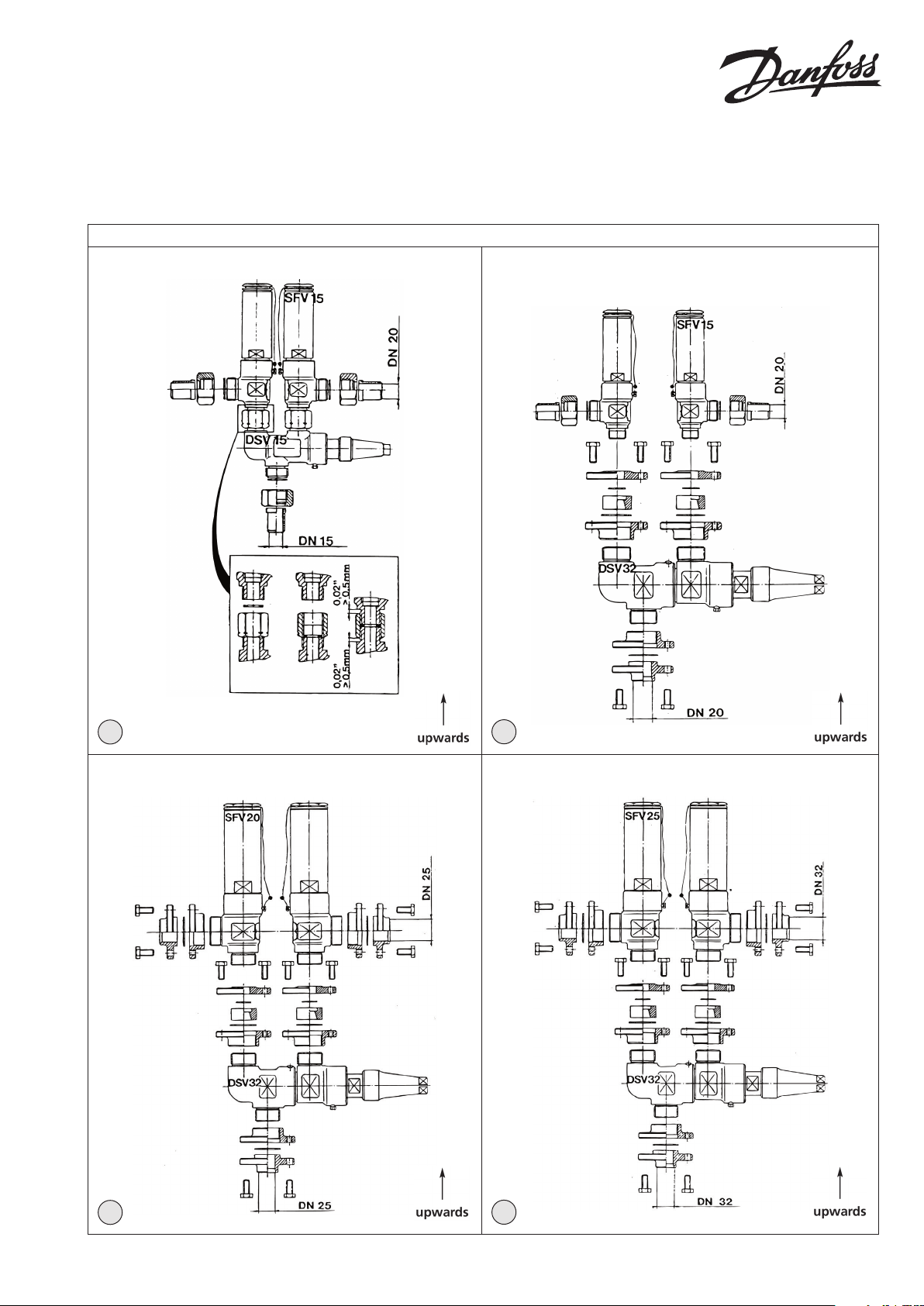

Change-over valves

DSV 15-32

Installation

DSV 15 ND + SFV 15

2516 +172

DSV 32 FND + SFV 15

2516 +172

1a

1b

DSV 32 FD + SFV 20 DSV 32 FD + SFV 25

1c

© Danfoss A/S (MWA), 2015-02 DKRCI.PI.IE0.B3.02 / 520H4694 1

1d

DSV 15

SFV 15

DSV 32

SFV 20-25

2

3a

3b

ENGLISH

Installation

Refrigerants

Applicable to HCFC, HFC, R717(Ammonia)

and R744 (CO2).

Flammable hydrocarbons are not

recommended. The valve is only

recommended for use with safety valves

type SFV. For further information please

contact Danfoss.

Temperature range

DSV: –50/+100°C (–58/+212°F)

Pressure range

The valves are designed for a max. working

pressure of 25 bar g (363 psi g).

Installation

Applied in connection with safety valves

(SFVs) installation instruction for safety

valves must be followed.

DSV and the two safety valves are to be

mounted as indicated on g. 1.

IMPORTANT:

THE INLET/OUTLET PIPE DIMENSIONS

MUST NOT BE SMALLER THAN THOSE OF

THE SAFETY VALVES.

The valve is designed to withstand a high

internal pressure. However, the piping

system should be designed to avoid liquid

traps and reduce the risk of hydraulic

pressure caused by thermal expansion. It

must be ensured that the valve is protected

from pressure transients like “liquid

hammer” in the system.

Welding

If welding ttings are applied, these should

be dismounted during the welding process

(g. 2).

Only materials and welding methods,

compatible with the ange material, must

be welded to the ange.

Avoid welding debris and dirt in the

threads of the housing and the pipes.

Assembly

Remove welding slag and dirt from tubes

and housing before the valve is mounted.

Mount the valve as shown in g. 1.

Operating Instructions

When the spindle is turned clockwise (g.

3a) the inlet socket C is connected to outlet

B. When the spindle is turned anticlockwise

(g. 3b) the inlet socket C is connected to

outlet A.

Colours and identication

The DSV valves are painted with a red oxide

primer in the factory. The external surface

of the valve housing must be prevented

against corrosion with a suitable protective

coating after installation and assembly.

In cases of doubt, please contact Danfoss.

Danfoss accepts no responsibility for

errors and omissions. Danfoss Industrial

Refrigeration reserves the right to make

changes to products and specications

without prior notice.

2 DKRCI.PI.IE0.B3.02 / 520H4694 © Danfoss A/S (MWA), 2015-02

Loading...

Loading...