Page 1

Data Sheet

Rotary position sensor

Type DST X520

For mobile hydraulic applications

The Danfoss DST X520 rotary position sensors

without shaft are designed for use in mobile

hydraulic applications.

Danfoss DST X520 series uses contactless Hall

technology with measurement ranges up to

360°. The Sensors designed for o-highway

applications and resistant to shock and

vibrations and with high electromagnetic

compatibility.

They are E1 approved for on-highway

applications. They comes with either analogue,

CANopen or SAE J1939 output.

Single and redundant sensor types are

available, making the complete portfolio

suitable for safetycritical applications.

Features

• Contactless Hall technology for almost

innite sensor life time

• Single or Redundant ranges up to 360°

(±180°)

• Output: Analogue, CANopen or SAE J1939

• Linearity: < ± 0.5% FS

• Resolution:

◦ 12 bit (analog)

◦ 14 bit (CANopen/SAE J1939)

• IP protection level IP67 - IP69K with female

mating connector

• High quality 10 mm SmCo Magnet

AI301440445780en-000701

Page 2

Measuring range

CAN

±180° (360 °C)

Analogue

Programmable ± 15 °C

Linearity

≤ ± 0.5% FS

Resolution and speed of rotation

12 bit (analog output)

120 rpm max.

14 bit (CANopen/SAE J1939 output)

Durability

No wear through the use of permanent external magnet

Electrical connections

AMP Superseal 6p 282108, Cable or cable + M12

Output signal

CANopen / SAE J1939, Ratiometric 10-90% of Vs,

0.5–4.5 V DC, 0 –10 V DC or 4–20 mA

Supply voltage

CANopen/J1939, 0.5–4.5 V DC, 4–20 mA: 9–36 V DC

0 – 10 V DC, 11–36 V DC Ratiometric: 10-90% of Vs: 5 V DC

Current consumption

Analogue: < 10 mA / pr. channel

(no load)

CANopen/J1939: < 15 mA

(no load)

MTTFd [Years]

CANopen/J1939: 336

Analogue: 406 (Single Channel)

Operating temperature range

-40 – 85 °C

Thermal drift temperature

< 50 ppm/°C

EMC

Emission

EN 55011 and CISPR 25

Immunity

EN 61236-3-2 and ISO 11452-2

Transient on supply lines

ISO 7637-2

Bulk current injection

ISO 11452-4

Vibration stability

Sinusoidal

20 g, 10 Hz – 2,000 kHz

IEC 60068-2-6

Shock resistance

Impulsive on 3 axes

50 g, 11 ms

IEC 60068-2-27

IP protection

AMP Superseal: IP67 - IP69K

with female mating connect

Cable: IP69K

Cable + M12: IP67

Materials

Enclosure

PBT (Polybutylene terephthalate)

Net weight

0.036 kg

Rotary position sensor, type DST X520

Product specication

Technical data

Table 1: Performance

Table 2: Electrical specications

Table 3: Environmental conditions

Table 4: Mechanical characteristics

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 2

Page 3

CLAMP LOW

-

15° 0° +

15°

… [IN STEPS DI 15°] 0° …

20mA

CLAMP LOW

A

12mA4

mA

CLAMP HIGH

4.5 V

2.5 V

0.5 V

10 V

5 V

0 V

B

C

-30° 0°

-180°0°+180°

A3

A1A

2

CLAMP LOW

-

15° 0° +

15°

… [IN STEPS DI 15°] 0° …

20mA

CLAMP LOW

A

12mA4

mA

CLAMP HIGH

4.5 V

2.5 V

0.5 V

10 V

5 V

0 V

B

C

-30° 0°

+30

°

-180°0°+180°

A

3

A1A

2

CLAMP LOW

20mA

CLAMP LOW

Output 1 - Output 2

Both times CW

A

12

mA

4

mA

CLAMP HIGH

4.5 V

2.5

V

0.5 V

10 V

5 V

0 V

B

C

-180°0°+180°

A3

A

1

A

2

CLAMP LOW

20mA

CLAMP LOW

A

12

mA

4

mA

CLAMP HIGH

4.5 V

2.5 V

0.5 V

10 V

5

V

0 V

B

C

-180°0°+180°

A3

A

1

A

2

CLAMP LOW

20mA

CLAMP LOW

12

mA

4

mA

CLAMP HIGH

4.5 V

2.5 V

0.5 V

10 V

5

V

0 V

A3

A

1

A

2

CLAMP LOW

≤ ≥

20mA

CLAMP LOW

12

mA

4

mA

CLAMP HIGH

4.5 V

2.5 V

0.5 V

10 V

5 V

0

V

A3

A

1

A

2

+30°

Output 1 - CW

Clockwise CW single

Direction of rotation 1

Redundant direction of rotation 1

Redundant direction of rotation 3

Redundant direction of rotation 2

Redundant direction of rotation 4

Counterclockwise CCW single

Direction of rotation 2

Output 1 - Output 2

Both times CCW

Output 2 - CCWOutput 1 - CW Output 2 - CWOutput 1 - CCW

Rotary position sensor, type DST X520

Sensor output graph

Load conditions

+0.5 V DC – 4.5 V DC output with power 9 – 36 V DC and +0 – 10 V DC output with power 11 – 36 V DC: it is

recommended a load resistance > 100 KΩ

+0.5 V DC – 4.5 V DC output with power +5 V DC: it is recommended a load resistance > 10 KΩ

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 3

Page 4

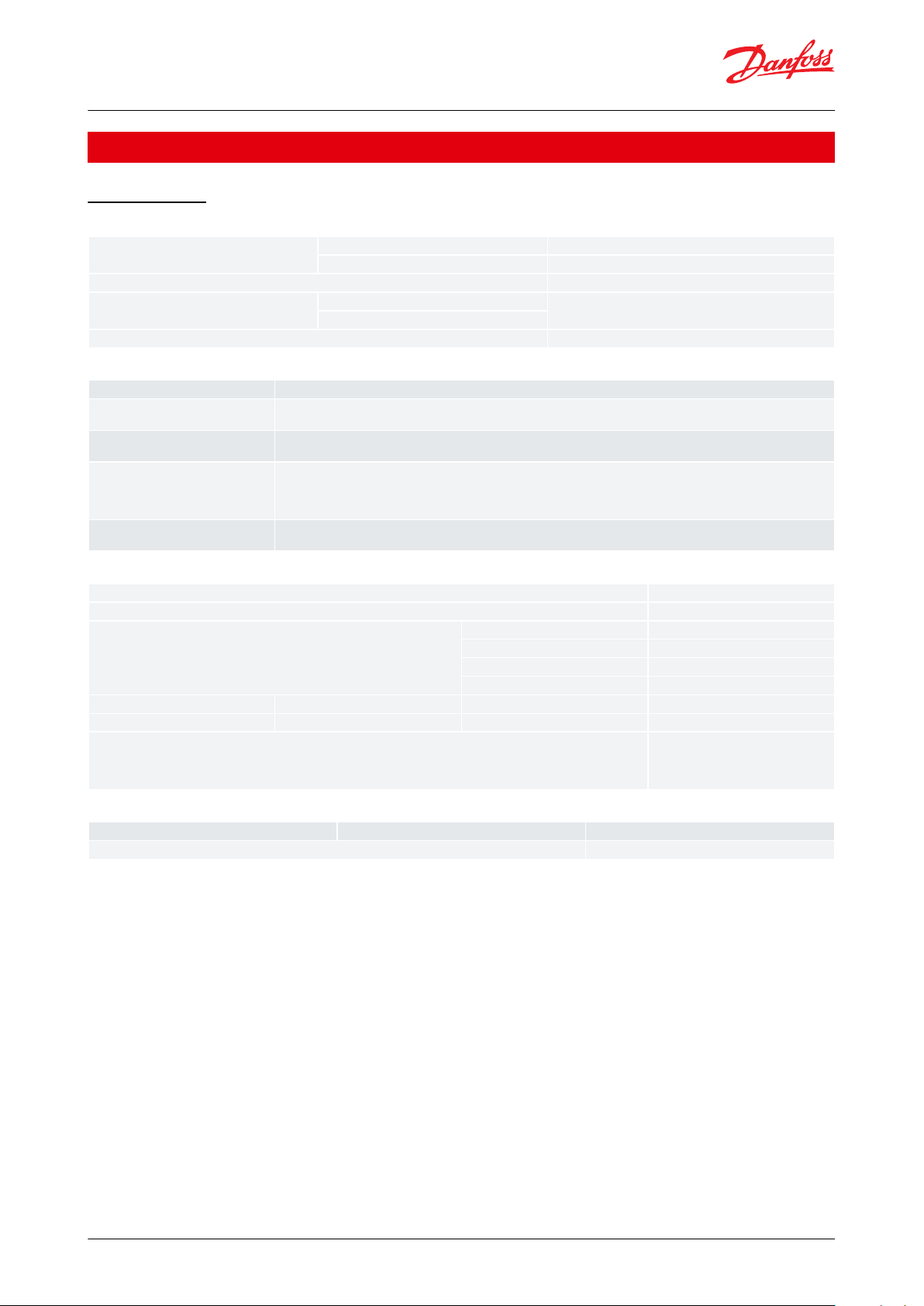

AMP version

Cable version

41

32±0.20

=24.4=

22.6

±0.20

27.1

18.7 18.7

31.7

16.3

3x Ø4.2

-0.05

0

-0.05

0

Ø 8.3

Ø 7

33

10

48.8

12.9 2 - 7mm

Z AXIS

AIR GAP

<1º

Axis X-Y offset

Max Ø 2mm tolerance zone axis

prosition magnet. Note each offset

from the axis misalignment or

magnetic will increase the non-

linearity.

Axis X-Y offset

Max Ø 2mm tolerance zone axis

prosition magnet. Note each offset

from the axis misalignment or

magnetic will increase the non-

linearity.

Z AXIS

AIR GAP

2 - 7mm

<1º

65.4

17.2

14.2

41

32 ±0.20

=24.4=

27.1

18.7

38.3

3x Ø4.2

22.6

43.8

Rotary position sensor, type DST X520

+4 – 20 mA output with power 9 - 15 V DC: maximum load resistance is 200 Ω

+4 – 20 mA output with power 15 – 36 V DC: maximum load resistance is 500 Ω

Dimensions

Figure 1: AMP and Cable version

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 4

Page 5

5

±0.05

15

13

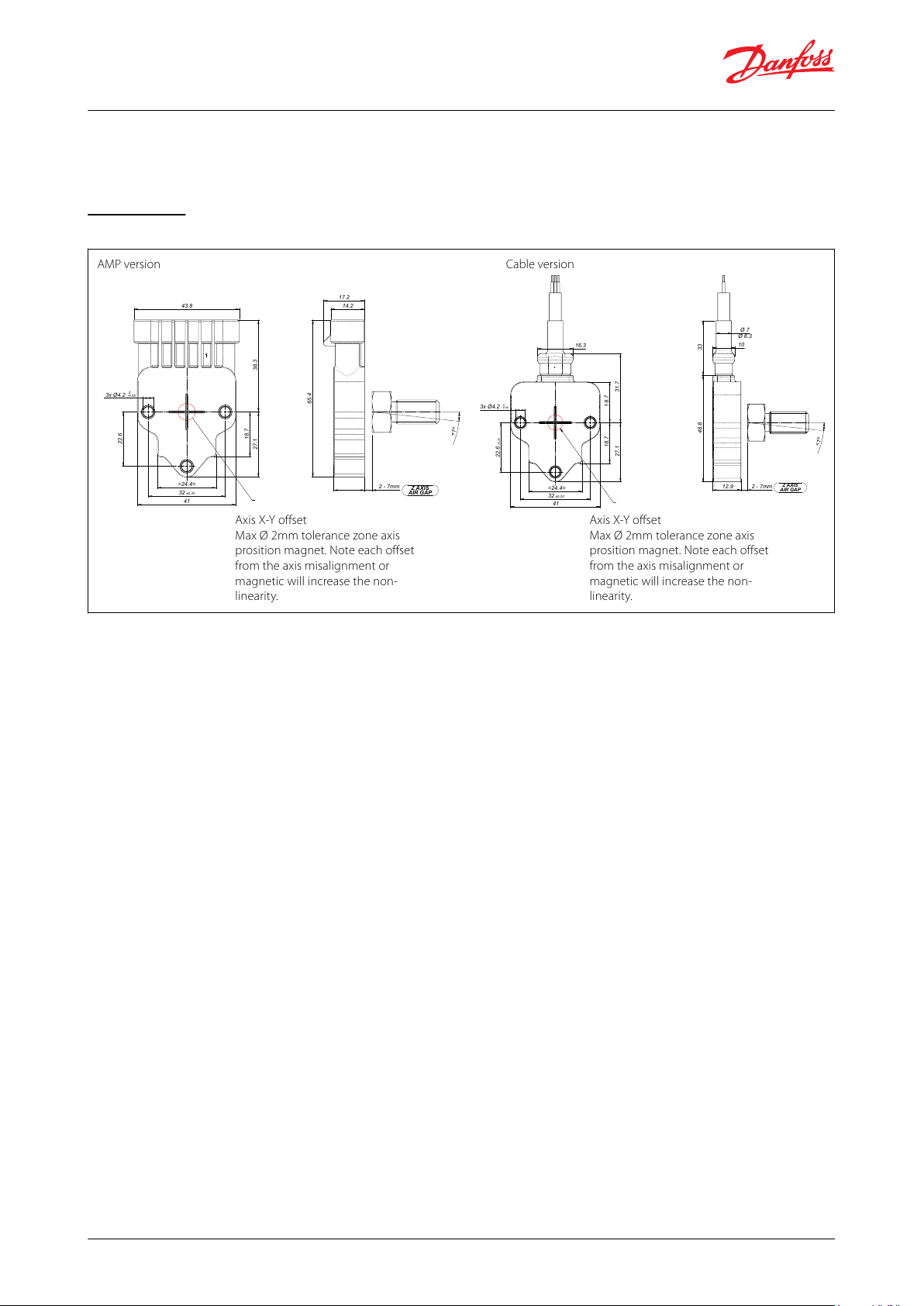

PKIT384 Shaft kit + magnet D15 M10 Hexagonal Accessory “A”

Air gap 2-7 mm axis offset Ø4 mm

PKIT389 Shaft kit to insert+ magnet D15 - Accessory “B”

Air gap 2-7 mm axis offset Ø4 mm

PKIT384 Shaft kit + magnet D15 M10 Hexagonal - Accessory “C”

Air gap 2-7 mm axis offset Ø4 mm

Ø

±0.05

±0.05

17

12

20

3

5

8

-

0

0.05

1

Ø

Ø

M10x1

20

28

CH 17

Rotary position sensor, type DST X520

Magnets models

Figure 2: Accessories

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 5

Page 6

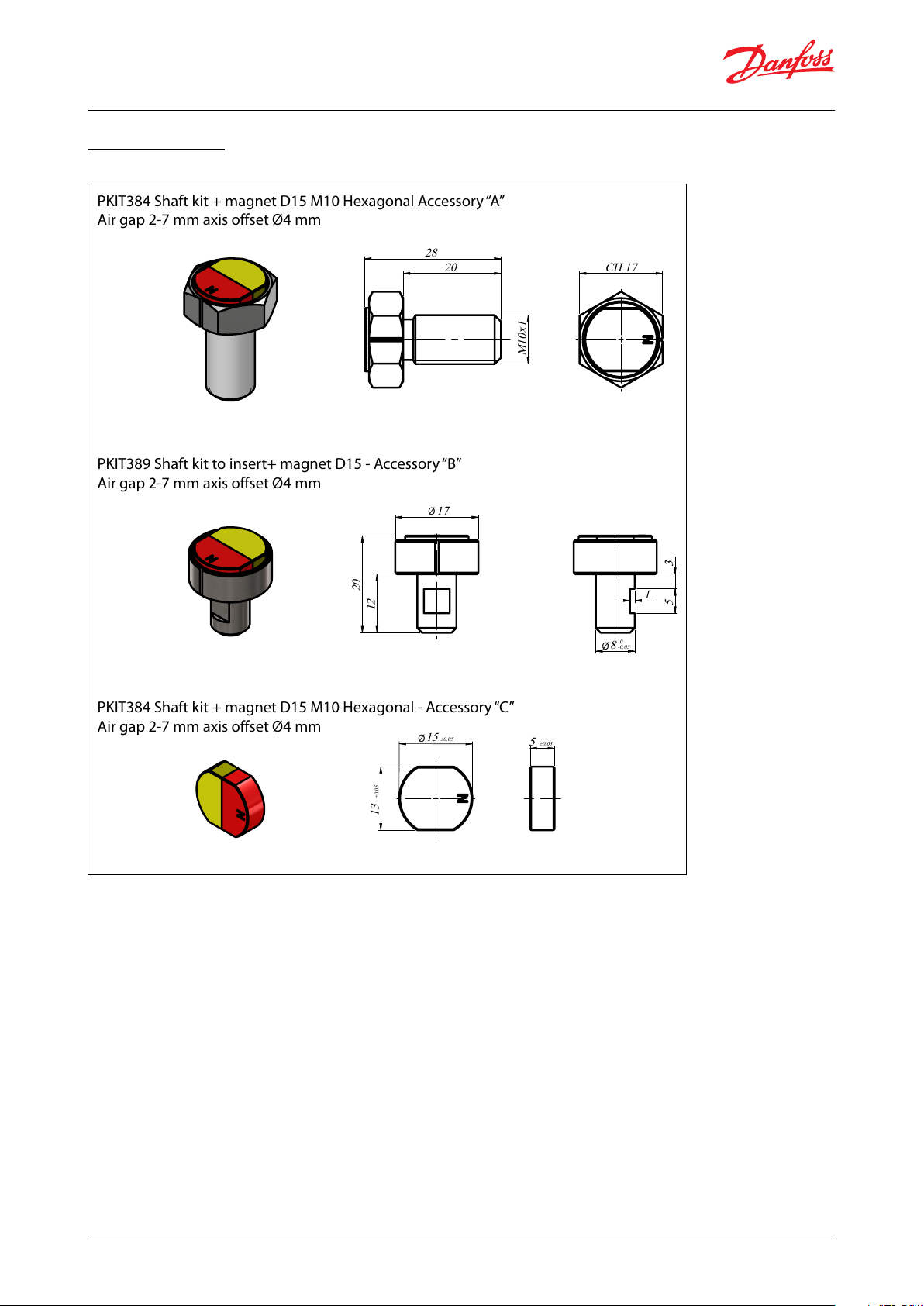

Zero angular position of 0°

The output increases for

versions CCW

Metal insert

Max. torque: 2.5 Nm

The output increases for

versions CW

X AXIS

Y AXIS

A

C

Ref.

CW output

CWW output

A

0.5 V DC

4.5 V DC

B

Zero angular position of 0°

Zero angular position of 0°

C

4.5 V DC

0.5 V DC

Rotary position sensor, type DST X520

Electrical connections

Figure 3: AMP version, angular positions

Table 5: General data

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 6

Page 7

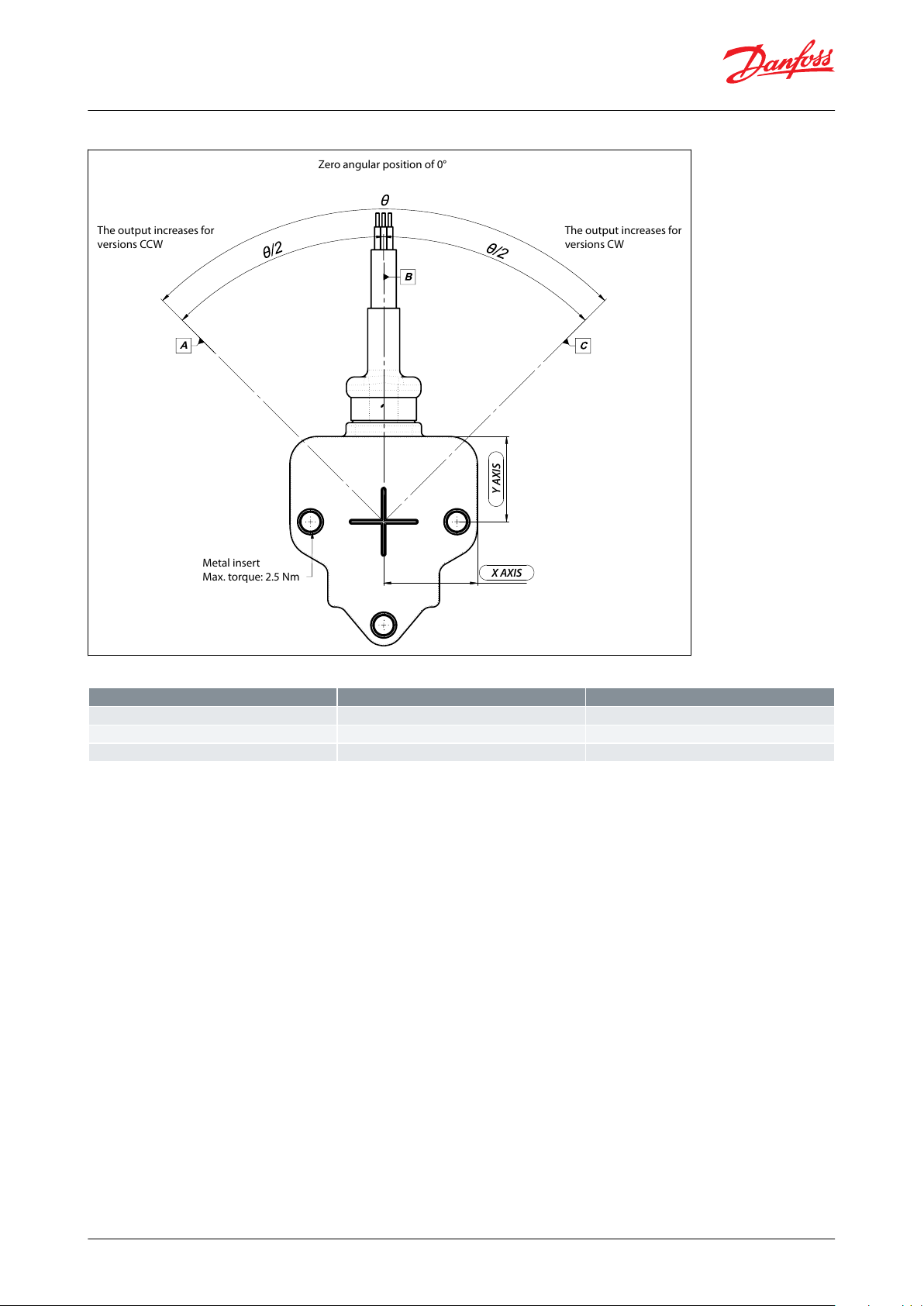

A

Zero angular position of 0°

The output increases for

versions CCW

Metal insert

Max. torque: 2.5 Nm

The output increases for

versions CW

X AXIS

Y AXIS

Ref.

CW output

CWW output

A

0.5 V DC

4.5 V DC

B

Zero angular position of 0°

Zero angular position of 0°

C

4.5 V DC

0.5 V DC

Rotary position sensor, type DST X520

Figure 4: Cable version, angular positions

Table 6: General data

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 7

Page 8

1234561

23456

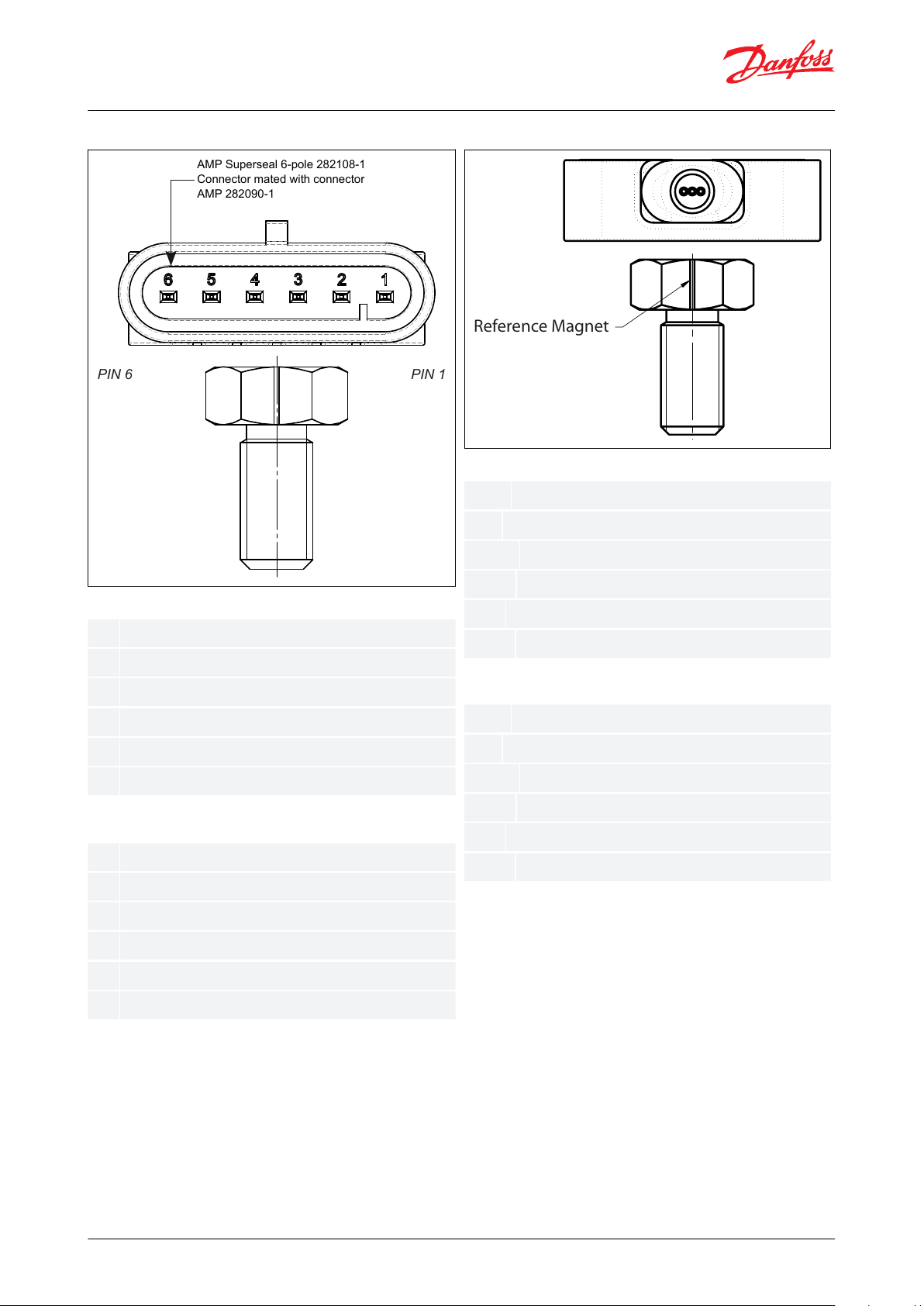

PIN 6 PIN 1

AMP Superseal 6-pole 282108-1

Connector mated with connector

AMP 282090-1

Ground 1

+ Supply 1

Output 1

Ground 2

+ Supply 2

Output 2

OV (GND)

+ Vs (+9 - 36 V DC)

GND

GND

CAN-L

CAN-H

Black:

Red:

Yellow:

Green:

Blue:

White:

Black:

Red:

Yellow:

Green:

Blue:

White:

Reference Magnet

Ground 1

+ Supply 1

Output 1

Ground 2

+ Supply 2

Output 2

Ground 1

+ Supply 1

NCNCCAN-L

CAN-H

Rotary position sensor, type DST X520

Figure 5: AMP version, connections

Figure 6: Cable version, connections

Connections

Connections

Connections - CAN/J 1939

Connections - CAN/J 1939

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 8

Page 9

12345

PUR sheath Ø 4.4

(single output)

M12 5 pin

male connector

Ground 1

+ Supply 1

Output 1

NC

NC

Rotary position sensor, type DST X520

Figure 7: Cable + M12 version, connections

Connections

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 9

Page 10

Type

Output signal

Cogurations

Code no.

DST X520 incl. PKIT magnet

5 V Ratiometric

±180° Clockwise CW

098G1500

5 V Ratiometric

±180° CounterclokwiseCCW/CH2 clockwise CW

098G1501

36 V CANopen

±180° Clockwise CW

098G1502

36 V SAE J1939

±180° Clockwise CW

098G1503

Electrical connections

AMP Superseal 6P connector

A

Cable (specify cabel length)

F

Circuit type

Single Analog and half redundant CANopen/ J1939

S

Redundant Analog

R

Angle/Channel 1 (output for single channel)

(Analog output A1-A2-A3 programmable in steps of ±15°) (CAN/J 1939 = 180)

xxx

Angle/Channel 2 (redundant/half redundant)

Analog output = same as Channel 1 and (CAN/J 1939 = 000)

xxx

Supply voltage

+5Vdc (only for A1 output)

L

+9…+36Vdc (see output signal for right supply voltage)

H

Output type

+0.5…+4.5V DC output (available with supply L = ratiometric output and with supply H = 0.5...4.5V output)

A1

0...+10Vdc output (powered at +11..36V DC

A2

4...20mA output (powered at +9...36V DC)

A3

CANopen output (powered at +9...36V DC) (available in single version with +/-180° measurement range)

C1

SAE J1939 (powered at +9...36V DC) (available in single version with +/-180° measurement range)

C2

Rotation direction

Clockwise CW (single) Both clockwise CW (redundant or CAN/J1939

1

Counterclockwise CCW (single) Both counterclockwise CCW (redundant or CAN/J1939

2

CHANNEL 1 clockwise CW and CHANNEL 2 counterclockwise CCW (redundant version or CAN/J1939)

3

CHANNEL 1 counterclockwise CCW and CHANNEL 2 clockwise CW (redundant version or CAN/J1939)

4

Cable

Single cable without connector (always “0” in case of DST X520 A version)

0

Cable + M12, 5-pin male overprinted connector

1

Reserved

00

Linearity curve

No linearity curve attached

0

Linearity curve to be attached

L

Standard

033

Rotary position sensor, type DST X520

Ordering

Ordering type

Table 7: DST X520, ordering

Ordering code - on request

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 10

Page 11

Accessories

No accessories

X

Shaft kit + magnet D 15 M10 hexagonal (PKIT 384) (Standard)

A

Shaft kit to insert + magnet D 15 (PKIT 389)

B

Kit magnet Ø15 (PKIT 418)

C

Cable length

100 mm

01

200 mm

02

500 mm051 m102 m

20

Other length on request

-

A

AMP Superseal 6p

S

Half redundant CAN/J 1939

180

±180°

000

000H+9 - +36 Vdc

C1

CANopen

4

Channel 1: Counterclockwise CCW

Channel 2: Clockwise CW

0

No cable

00

Reserved

0

No linearity curve

033

Standard

A

Magnet PKIT384

00

Not dened (only cable version)

Rotary position sensor, type DST X520

Example of ordering: DST X520-AS180000HC14000 0033A00

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 11

Page 12

Document name

Document type

Document topic

Approval authority

098R0008

EU Declaration

EMCD/ROHS

Danfoss

Rotary position sensor, type DST X520

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: Declarations

Approvals and Conformity

• CE

• RoHS

• E1 approval

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 12

Page 13

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI301440445780en-000701 | 13

Loading...

Loading...