Operation guide

Rotary position sensors

CANopen output

DST X510 and DST X520

ia.danfoss.com

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

Table of contents

Contents

1. General information..............................................................................................................................................2

1.1 Contact........................................................................................................................................................... 2

1.2 General............................................................................................................................................................ 2

1.3 Abbreviations................................................................................................................................................ 3

2. Electrical connections............................................................................................................................... 4

2.1 Deutsch version with shaft...................................................................................................................... 4

2.2 AMP Supersxeal with shaft...................................................................................................................... 5

2.3 AMP Superseal without shaft................................................................................................................. 6

2.4 Cable without shaft.................................................................................................................................... 7

2.5 Functional Block......................................................................................................................................... 8

3. Network Management............................................................................................................................. 8

4. Baud rate............................................................................-........................................................................... 9

5. Node-ID and Resolution........................................................................................................................... 9

6. Parameter settings...................................................................................................................................... 9

7. Restore defalut parameters..................................................................................................................... 10

8. Restore default parameters..................................................................................................................... 10

9. Error handling.............................................................................................................................................. 10

10. SDO communication................................................................................................................................. 11

11. PDO communication and Angle calculation..................................................................................... 11

12. CANopen features summary................................................................................................................... 15

13. Communication examples................................................................................................................... 19

1. General Information

1.1 Contact

Danfoss A/S

Industrial Automation

DK-6430 Nordborg

Denmark

www.ia.danfoss.com

E-mail: IA-Sensorglobaltechnicalsupport@danfoss.com

1.2 General

The document describes the standard CANopen

implementations created. It is addressed to

CANopen system integrators and to CANopen

device designers who already know the

content of standards designed by C.i.A. (CAN in

Automation).

2 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

1.3 Abbreviations and terms

Abbreviation/term Denition

CAN

CAL

CMS

COB

COB-ID

D1 - D8

DLC

ISO

NMT

PDO

RXSDO

SDO

TXPDO

TXSDO

Controller Area Network

Describes a serial communication bys that implements the “physical” level

1 and the “data link” level 2 of the ISO/OSI reference model.

CAN Application Layer

Describes implementation of the CAN in level 7 “application” of the ISO/

OSI reference model form which CANopen derives.

CAN Message Specication

CAL service element. Denes the CAN Apllication Layer for the various

industrial applications.

Communication Object

Unit of transport of data in a CAN network (aCAN message). A maximum

of 2,048 COBs may be present i a CAN network, each of which may

transport from 0 to a maximum of 8 bytes.

COB Identier

Identifying element of a CAN message. The identier determines the

priority of a COB in case of multiple messages in the network.

Data from 1 to 8

Number of data bytes in the data eld of a CAN message.

Data Length Code

Number of data bytes transmitted in a single frame.

International Standard Organization

International authority providing standards for various merchandise

sectors.

Network Management

CAL service element. Describes how to congure, initialize, manage errors

in a CAN network.

Process Data Object

Process data communication objects (with high priority).

Receive SDO

SDO objects received from the remote device.

Service Data Object

Service data communication objects (with low priority). The value of this

data is contained in the “Objects Dictionary” of each device in the CAN

network.

Transmit PDO

PDO objects transmitted by the remote device.

Transmit SDO

SDO objects transmitted by the remote device.

© Danfoss | DCS (im) | 2019.10

NOTE:

The numbers followed by the suffix “h” represent a hexadecimal value, with suffix “b” a

binary value, and with suffix “d” a decimal value.

The value is decimal unless specified otherwise.

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 3

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

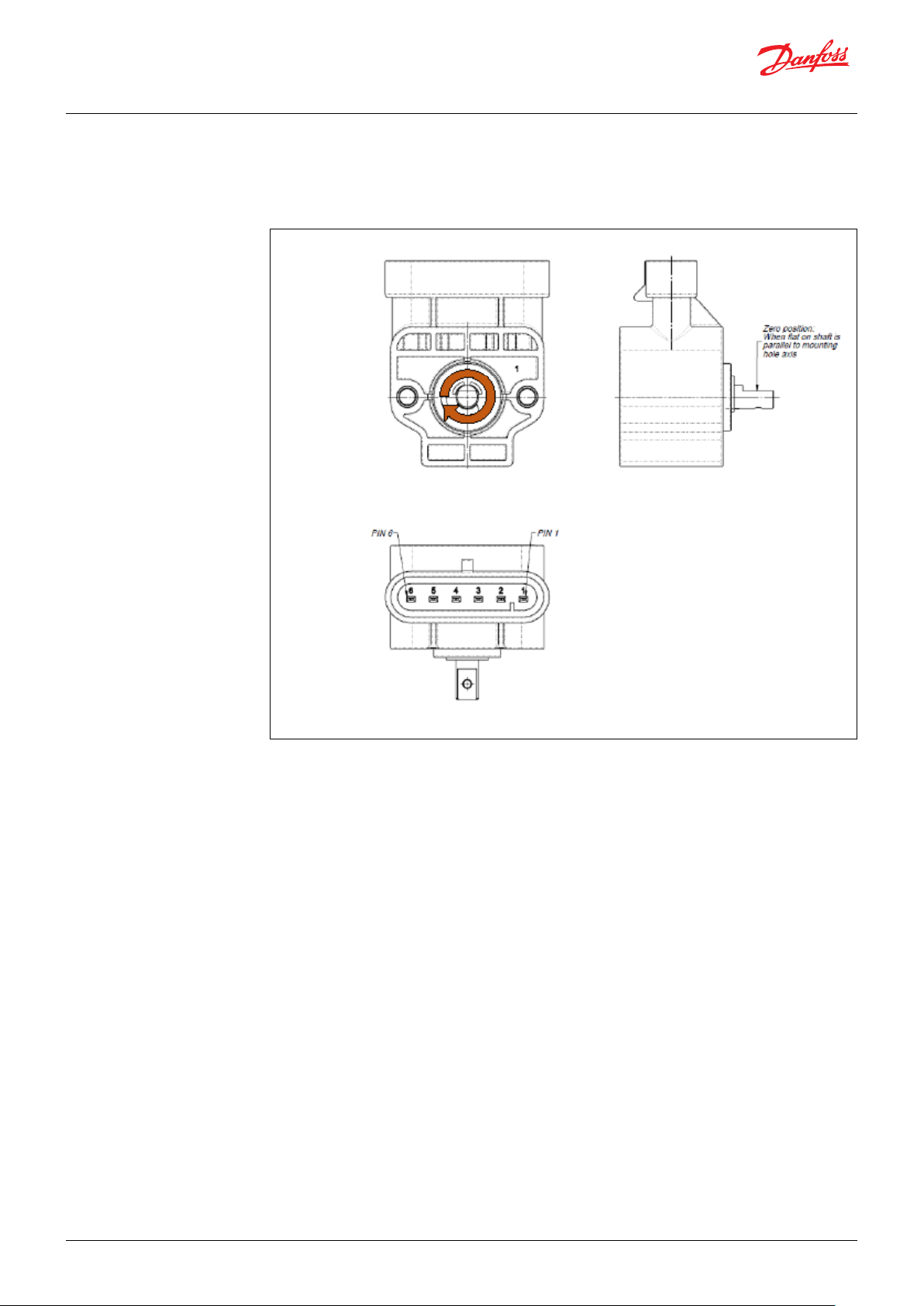

2. Electrical Connections 2.1 Deutsch version with shaft

CONNECTIONS

1.: OV (GND)

2.: + VS (+9 - +36 VDC)

3.: NC

4.: NC

5.: CAN-L

6.: CAN-H

NOTE:

Please make sure that the CANbus is terminated.

The impedance measured between CAN-H and

CAN-L must be 60 ohm that means the cable

must be connected to a 120 ohm resistor on each

ends of the bus line. Internally the tranducer is

not terminated with the resistor of 120 ohm.

Do not confuse the signal lines of the CAN bus,

otherwise communication with the transducer is

impossible.

4 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

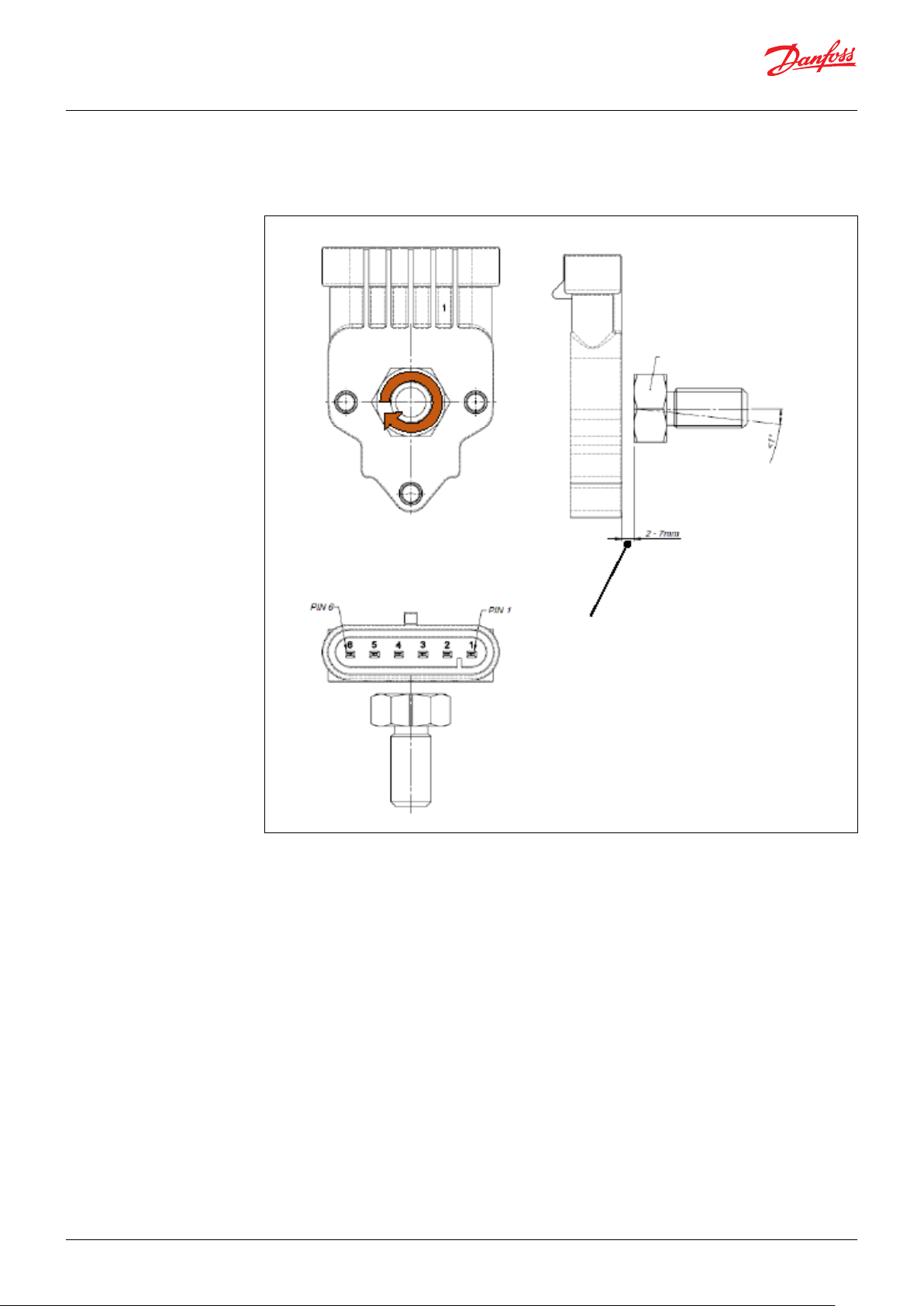

2.2 AMP version with shaft

NOTE:

Please make sure that the CANbus is terminated.

The impedance measured between CAN-H and

CAN-L must be 60 ohm that means the cable

must be connected to a 120 ohm resistor on each

ends of the bus line. Internally the tranducer is

not terminated with the resistor of 120 ohm.

Do not confuse the signal lines of the CAN bus,

otherwise communication with the transducer is

impossible.

CONNECTIONS

1.: OV (GND)

2.: + VS (+9 - +36 VDC)

3.: NC

4.: NC

5.: CAN-L

6.: CAN-H

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 5

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

2.3 AMP Superseal version without shaft

M10 CH17 Magnet

< Suggested less than 1°

Air gab

NOTE:

Please make sure that the CANbus is terminated.

The impedance measured between CAN-H and

CAN-L must be 60 ohm that means the cable

must be connected to a 120 ohm resistor on each

ends of the bus line. Internally the tranducer is

not terminated with the resistor of 120 ohm.

Do not confuse the signal lines of the CAN bus,

otherwise communication with the transducer is

impossible.

CONNECTIONS

1.: OV (GND)

2.: + VS (+9 - +36 VDC)

3.: NC

4.: NC

5.: CAN-L

6.: CAN-H

6 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

2.4 Cable version without shaft

NOTE:

Make sure that the CANbus is terminated. The

inpedance measured between CAN-H and

CAN-L mus be 60 ohm that means the cable

must b e connected to a 120 ohm resistor

on each end of the bus line. Internally the

transducer is not terminated with resistor of

120 ohm. Do not confuse the signal lines of the

CANbus, otherwise communication with the

transducer is impossible.

CONNECTIONS

Black: GROUND

Red: + SUPPLY 1

Yellow: NC

Green: NC

Blue: CAN-L

White: CAN-H

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 7

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

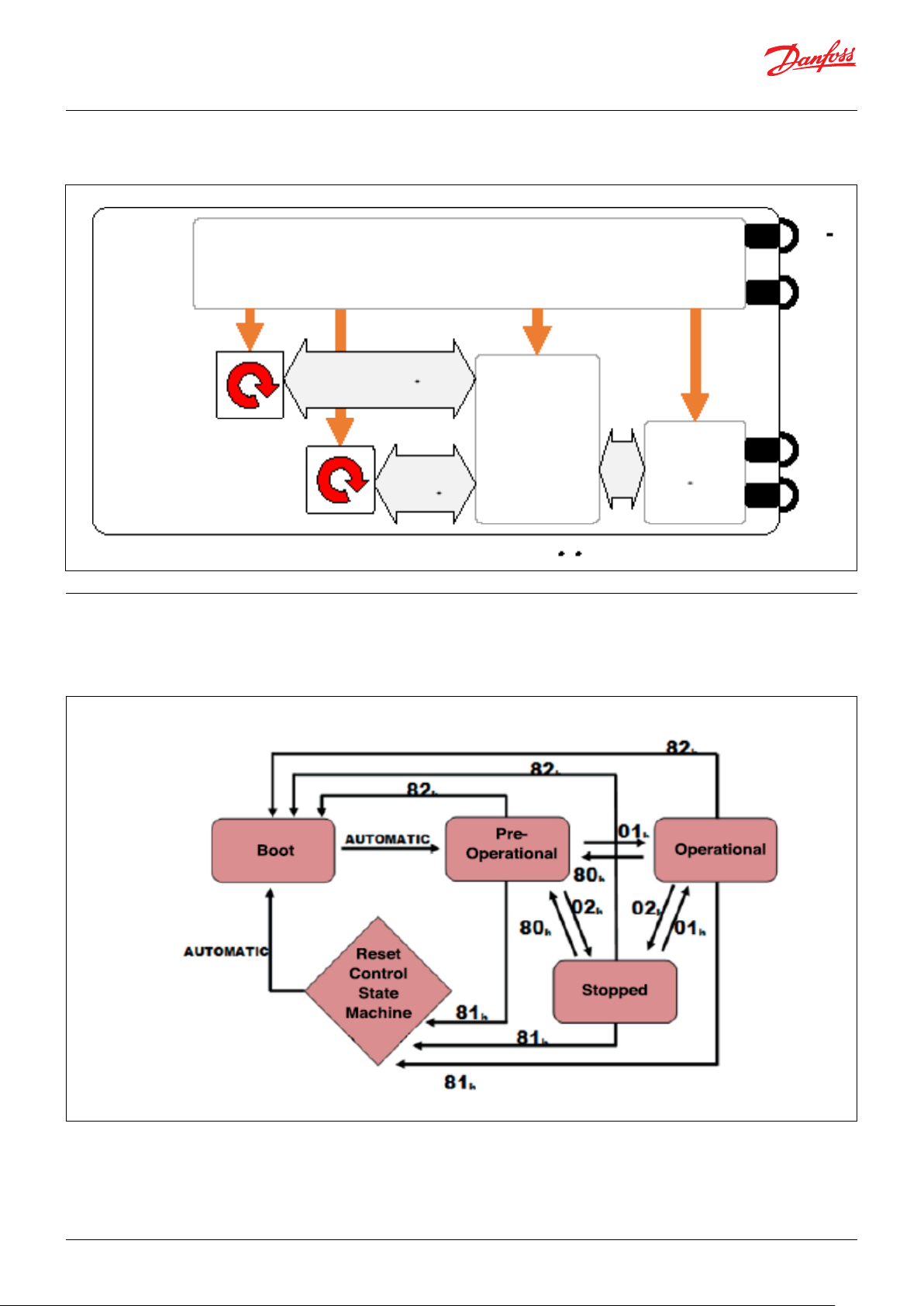

2.5 Functional Block

Power Management

+ Vs

GND

Angle 1 (CCW)

Hall- CHIP 1

Angle 2(CW)

Hall- CHIP 2

3. Network Management

(NMT)

Data & Diagnostic

Main

Controller

Data &

Diagnostic

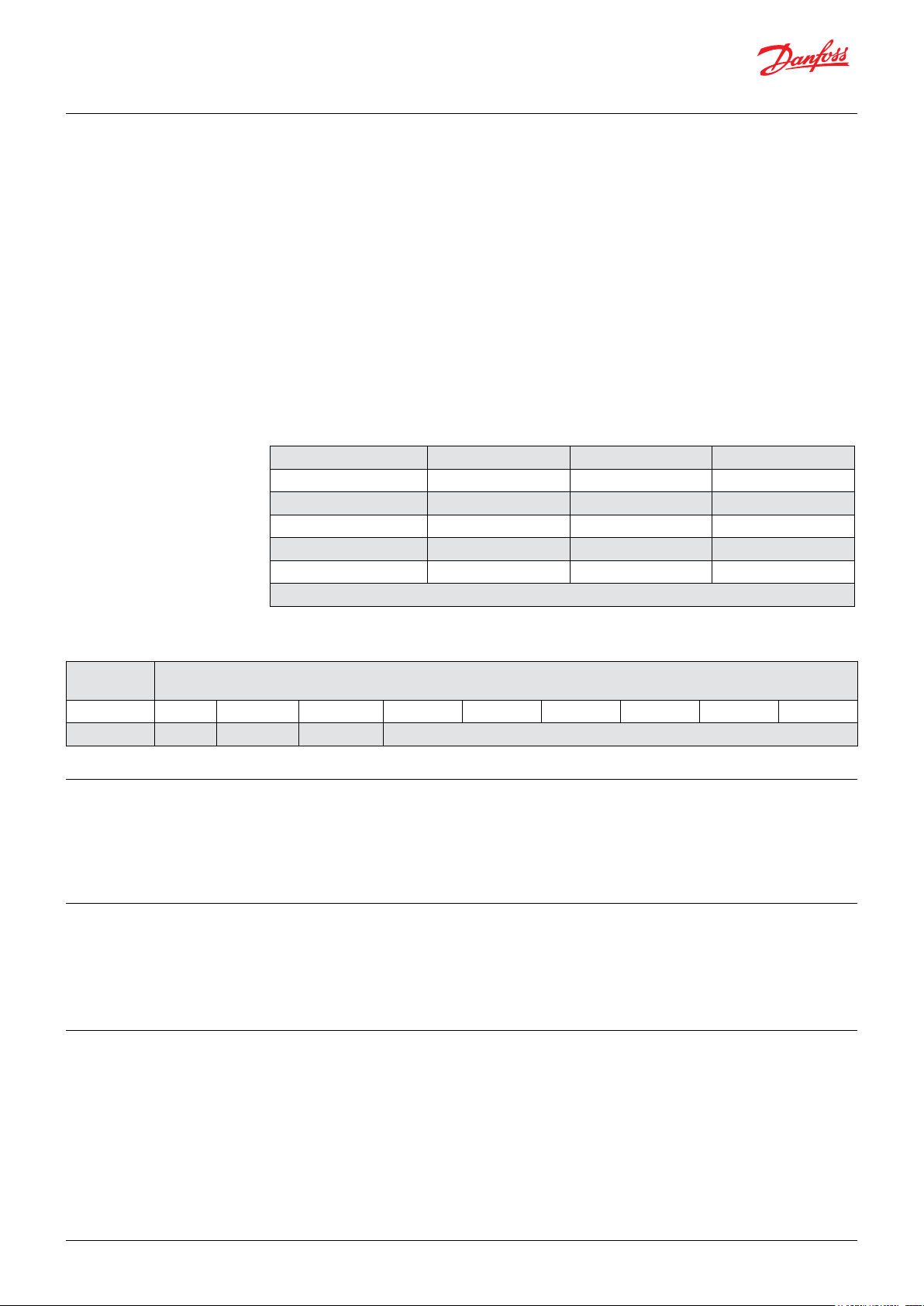

The device supports CANopen network

management functionality NMT Slave

(Minimum Boot Up).

CAN

Transceiver

4. Baud rate4. Baud rate4. Baud rate

CAN-H

CAN-L

8 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Every CANopen device contains an

international Network Management server that

communicates with an external NMT master.

One device in a network, generally the host,

may act as the NMT master.

Through NMT messages, each CANopen device’s

network management server controls state

changes within its built-in Communication

State Machine.

This is independent from each node’s

operational state machine, which is device

dependant and described in Control State

Machine.

NMT Message COOB-ID Data Byte 1 Data Byte 2

Start Remote Node 0 01h Node-ID*

Stop Remote Node 0 02h Node-ID*

Pre-operational State 0 80h Node-ID*

Reset Node 0 81h Node-ID*

Reset Communica<tion 0 82h Node-ID*

* Node-ID = Drive address (from 1 to 7Fh)

It is important to distinguish a CANopen

device’s operational state machine from its

Communication State Machine.

CANopen sensors and I/O modules, for example,

have completely dierent operational state

machines than servo drives. The “Communication

State Machine” in all CANopen devices, however,

is identical as specied by the DS301.

NMT messages have the highest priority. The 5

NMT messages that control the Communication

State Machine each contain 2 date bytes that

identify the node number and a command to that

node’s state machine.

Table 1 shows the 5 NMT messages surpported,

and Table 2 shows the correct message for

sending these messages.

Table 1

Arbitration

Field

COB-ID RTR Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

000h 0 See table 1 See table 2 These bytes are not sent

4. Baud rate

5. Baud rate

6. Parameter settings

Baud rate can be congurable via Layer Setting

Services and Protocol (LSS) and via SDO

communication (index 0x5999).

The default Baud rate is 250kbit/s.

Node-ID can be congurable via Layer Setting

Services and Protocol (LSS) and via SDO

communication (index 0x5999).

This parameters are called LSS parameters

(marking LSS-PARA).

The resolution can be congurable by using

manufacturing specic objec 0x2100.

All object dictionary parameters (object with

marking PARA) can be saved in a special

section of the internal EEPROM and secured

by checksum calculation.

The special LSS parameters (objects with

marking LL-PARA), also part of the objec

dictionary, will be also saved in a special

section of the internal EEPROM and secured

by checksum calculation.

Date Field

Important Note:

Changing this parameter can disturb the network!

Use the service only if one device is connected to the

network!

The default Node-ID is 7F.

The default resolution is 0.1°.

Important note:

Changing this parameter can disturb the network!

Use the service only if one device is

the network!

Due to the internal architecture of the

microcontroller the parameter write cycles are

limited to 100,000 cycles.

connected to

Table 2

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 9

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

7. Restore default

parameters

8. Restore default

parameters

9. Error handling

All object dictionary parameters (objects with

marking PARA) can be restored to factory default

values via SDO communication (index

0x1011).

The heartbeat mechanism for this device

isestablished through cyclic transmission of

the heartbeat message done by the heartbeat

producer.

One or more devices in the network are aware

of this heartbeat message. If the herartbeat

cycle fails from the heartbeat producer the local

application on the heartbeat consumer will be

informed about that event.

Heartbeat Message

COB-ID Byte 0

700 + Node-ID Content NMT State

Principle

Emergency messages (EMCY) shall be triggered

by internal errors on device and they are

assigned the highest possible priority to ensure

that they get access to the bus without delay

(EMCY Producer). By default, the EMCY contains

the error eld with pre-dened error numbers

and additional information.

Error Behavior (object 0x4000)

If a serious device failure is detected the object

0x4000 species, to which state the module shall

be set:

=: Pre-operational

1: Mo state change (default)

2: Stopped

The implementation of either guarding or

heartbeat is mandatory.

The device supports Heartbeat Producer

functionality.

The producer heartbeat time is dened in object

0x1017.

EMCY Message

The EMCY COB-ID is dened in object 0x1014.

The EMCY message consists of 8 bytes.

It contains an emergency error code, the

contents of object 0x1001 and 5 byte of

manufacturer specic error code. The device

uses only the 1st byte as manufacturer specic

error code. When a failure ccurs, the reading

of the angular position from the failed channel

presents an out-of-range value, i.e. 0xFFFF.

10 | © Danfoss | DCS (im) | 2019.10

Supported Manufacturer Specic Error Codes (object 0x4001)

Error code Description

0000 0000 No error

0000 0001 Angle 1 sensor chip error

0000 0010 Angle 2 sensor chip error

0000 0100 Angle mismatch (Angle 1 vs Angle 2) error, object 0x2103

NOT IMPLEMENTED

0001 0000 Program checksum error

0100 0000 LSS Parameter checksum error

1000 0000 Magnetic eld too high/low

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

10. SDO communication

COB-ID DLC Byte 1 Byte 2 Byte 3 Byted 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data Data Data Data

COB-ID DLC Byte 1 Byte 2 Byte 3 Byted 4 Byte 5 Byte 6 Byte 7 Byte 8

5807+Node-ID 8 RES Index Sub-Index Data Data Data Data

The device fulls the SDO Server functionality.

Witi Service Data Object (S.D.O.) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data typ SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

Structure of SDO-answer by the Slave

Write Access, Data Transfer form Host to Slave

Each access to object dictionary is checked

by the slave for validity. Any write access to

nonexistent objects, to read - only objects or

with a non-corresponding data format are

rejected and answered with a corresponding

error message.

CMD determines the direction of data transfer and

the size of the data object:

23 hex Sending of 4-byte data

(bytes 5 - 8 contian a 32 bit value)

2B hex Sending of 2-byte data

(bytes 5, 6 contain a 16-bit value

2F hex Sending of 1-byte data

(byte 5 contians an 8-bit value)

Read Access, Data Transfer form Slave to Host

Any read access to non-existing objects is

answered with an error message.

CMD determines the direction of data transfer:

40 hex read access (in any case)

The Slave answers:

RES Response of the slave:

42 hex Bytes used by node when replying to

read command with 4 or less data

43 hex Bytes 5 - 8 contain a 32-bit value

4B hex Bytes 5, 6 contain a 16-bit value

4F hex Byte 5 contains an 8-bit value

80 hex Error

11. PDO communication

and Angle calculation

Byte Byte 1 Byte 2 Byte 3 Byte 4

ANGLE 1

Description

object

(0x2110.1)

High-Byte

The Slave answers:

RES response of the slave:

60 hex Data sent successfully

80 hex Error

Transmit PDO #0

This PDO transmits asynchronously the

position value of the angle sensor. Default

transmission rate is 100 ms. The Tx PDO#0

shall be transmitted cyclically, if the cyclic

timer (object 0x1800.5) is programmed > 0.

Values between 1 ms and 65535 ms shall

be selectable by parameter settings. The Tx

PDO#0 will be transmitted by entering the

“Operational” state.

ANGLE 1

object

(0x2110.2)

Low-Byte

TxPDO# with default mapping when object 0x5001 = 0 (big endian)

ANGLE 2

object

(0x2110.3)

High-Byte

ANGLE 2

object

(0x2110.4)

Low-Byte

Byte 5

Byte 6

Byte 7

(0xFF)

Byte 8

Error Code

(object 0x4001)

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 11

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

Byte Byte 1 Byte 2 Byte 3 Byte 4

ANGLE 1

Description

Example of PDO mapping is reported in the case of Angle 1 = 0.00° and Angle 2 = 359.99°

object

(0x2110.1)

Low-Byte

TxPDO# with default mapping when object 0x5001 = 0 (little endian)

ANGLE 1

object

(0x2110.2)

High-Byte

ANGLE 2

object

(0x2110.3)

Low-Byte

ANGLE 2

object

(0x2110.4)

High-Byte

Byte 5

Byte 6

Byte 7

(0xFF)

Byte 8

Error Code

(object 0x4001)

12 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Reading resolution ± 0.1° (see manufacturing

specic object 0x2100 and example (7) at the

end of this manual)

Example of PDO mapping for:

Angle 1 = 0.-0° and Angle 2 = 359.9° (Node-ID

= 02h, resolution 0.1°, zero degree point = 0.0°,

CCW and big endian)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

182h 00h 00h 0Eh 0Fh FFh FFh FFh 00h

Angle 1:

Byte 1 MSB (00h) = 00h Byte 2 LSB (00h) = 00h

Angle 1 = 0000h to decimal 0d (resolution 0.1°)

= 0.0°

Reading resolution ± 0.01° (see

manufacturing specic object 0x2100 and

example (8) at the end of this manual)

Example of PDO mapping for:

Angle 1 = 0.-0° and Angle 2 = 359.9° (Node-ID

= 02h, resolution 0.1°, zero degree point = 0.0°,

CCW and big endian)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

182h 00h 00h 8Ch 9Fh FFh FFh FFh 00h

Angle 1:

Byte 1 MSB (00h) = 00h Byte 2 LSB (00h) = 00h

Angle 1 = 0000h to decimal 0d (resolution 0.1°)

= 0.0°

Example of PDO mapping is reported in the case of Angle 1 =270.0° and Angle 2 = 90.0°

Angle 2:

Byte 3 MSB (00h) = 0Eh Byte 4 LSB (00h) = 0Fh

Angle 2 = 0E0Fh to decimal 3599d (resolution

0.1°) = 359.9°

Angle 2:

Byte 3 MSB (00h) = 0Ch Byte 4 LSB (00h) = 9Fh

Angle 2 = 8C9Fh to decimal 35999d (resolution

0.1°) = 359.9°

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 13

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

Reading resolution ± 0.1° (see manufacturing

specic object 0x2100 and example (7) at the

end of this manual)

Example of PDO mapping for:

Angle 1 = 270.-0° and Angle 2 = 90.0° (Node-ID

= 02h, resolution 0.1°, zero degree point = 0.0°,

CCW and big endian)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

182h 0Ah 8Ch 03h 84h FFh FFh FFh 00h

Angle 1:

Byte 1 MSB (00h) = 0Ah Byte 2 LSB (00h) = 8Ch

Angle 1 = 0A8Ch to decimal 0d (resolution 0.1°)

= 270.0°

Reading resolution ± 0.01° (see

manufacturing specic object 0x2100 and

example (8) at the end of this manual)

Example of PDO mapping for:

Angle 1 = 270.-0° and Angle 2 = 90.0° (Node-ID

= 02h, resolution 0.1°, zero degree point = 0.0°,

CCW and big endian)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

182h 69h 78h 23h 28h FFh FFh FFh 00h

Angle 1:

Byte 1 MSB (00h) = 69h Byte 2 LSB (00h) = 78h

Angle 1 = 6978h to decimal 27000d (resolution

0.1°) 270.0°

Angle 2:

Byte 3 MSB (00h) = 03h Byte 4 LSB (00h) = 84h

Angle 2 = 0384h to decimal 900d (resolution

0.1°) = 90.0°

Angle 2:

Byte 3 MSB (00h) = 23h Byte 4 LSB (00h) = 28h

Angle 2 = 90.0°

Angle calculation for ANGLE 1 and ANGLE 2

Fig. 1 Angle computation

14 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

182h 00h 00h 0Eh 0Fh FFh FFh FFh 00h

ANGLE 1

Important note:

The two angles Angle 1 and Angle 2 are

obtained independently from each other (i.e.

in DST X510/DST X520 series contactless rotary

sensors there are two on-board HALL chips) in a

sort of redundant conguration.

12. CANopen features

summary

Sub

Index

1000h Device Prole Unsigned 32 Ro 0x00000000 No standardized device prol adapted

1001h Error Register Unsigned 8 Ro 0x00 Always ZERO

1008h

1009h

100Ah

1010h

1011h

1014h 0 Emergency ID Unsigned 32 Rw 0x80+Node-ID

1017h

1018h

Ro = the parameter can be read only

Rw = the parameter can be read and also written

Wo = the parameter can be written only

Index

Name Type Access Default value Comments

Manufacturer Device

Name

Manufacturer Hardware

Version

Manufacturer Software

Version

0 Number of entries Unsigned 8 Ro 1 “save” (0x65766173) to store all

1

Save all parameters Unsigned 32 Rw

0 Restore default

parameters

1 Restore all parameters Unsigned 32 Rw

0

Producer time/Heart beat Unsigned 16 Rw 0

0 Identity object Unsigned 8 Ro 4

1 Vendor ID Unsigned 32 Ro 0x0000093

2 Product code Unsigned 32 Ro 0x0000064

3 Revision number Unsigned 32 Ro 0x0000001

4 Serial number Unsigned 32 Ro 0x0000000

Communication Prole

The parameters which are critical for

communication are determined in the

Communication prole.

This area is common for all CANopen devices.

ANGLE 2

String Ro “GRA” or “GRN”

String Ro “1.00”

String Ro “1.14”

Unsigned 8 Ro

Rewfer to Danfoss data sheet:

GRA: DST X510 contactless rotary

sensor with shaft

GRN: DST X520 Contactless rotary

sensor without shaft

parameters (objects with marking

PARA)

“load” (0x64616F6C) to restore all

parameters (objects with PARA and

LSS-PARA)

Min. = 0 & Max. = 65536 with unit =

1ms; If 0: NOT USED

Refer to Vendor ID: 0x0000093

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 15

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

Index

1200h

1800h

1A00h

Sub

Index

Name Type Access Default value Comments

SDO Server Parameter

0 Number of entries Unsigned 8 Ro 2

1 COB-ID Client to Server (Tx) Unsigned 32 Ro 0x600+Node-ID

2 COB-ID Server to Server (tx) Unsigned 32 Ro 0x580+Node-ID

0 1

st

Transmit PDO Parameter Unsigned 8 Ro

Default value

Ro

Comments Ro

1 COB-ID Unsigned 32 Ro 180h + Node-ID Comments 180h, Node-ID

2 Transmission Type Unsigned 8 Rw 253 Asynchronous transmission

3 Inhibit Time Unsigned 16 Ro 0 Min. = 0 & Max. = 65535

4 Reserved // // 14 Min. 14 Max. 14 with unit 1 ms

5 Timer Unsigned 16 Rw 100 Min. = 4 & Max. = 65535

TxPDO Mapping Parameter

0 Number of entries Unsigned 8 Ro 8

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 4

st

Mapped Object Unsigned 32 Ro 0x21100108

nd

Mapped Object Unsigned 32 Ro 0x21100208

rd

Mapped Object Unsigned 32 Ro 0x21100308

th

Mapped Object Unsigned 32 Ro 0x21100408

th

Mapped Object Unsigned 32 Ro 0x21100508

th

Mapped Object Unsigned 32 Ro 0x21100608

th

Mapped Object Unsigned 32 Ro 0x21100708

th

Mapped Object Unsigned 32 Ro 0x40010008

Objects:

0x2110.1

0x2110.2

0x2110.3

0x2110.4

0x2110.5

0x2110.6

0x2110.7

0x4001.0

2 Angle 2 Zero degree point Unsigned 16 Ro 0

Ro = the parameter can be read only

Rw = the parameter can be read and also written

Wo = the parameter can be written only

16 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Manufacturer Specic Prole Objects

In this section you will nd the manufacturer

specic prole indices for transducers.

Index Sub

Index

2000h 0 Number of entries Unsigned 8 Ro 2 Angle sensor 1 and Angle sensor 2 in a single

1 Angle 1 Sensor Value Unsigned 16 Ro 0

2 Angle 2 Sensor Value Unsigned 16 Ro 0

2001h 0 Number of entries Unsigned 8 Ro 2 Min. = 0 & Max. = 255

1 Angle 1 FILTER Unsigned 8 Rw 0

2 Angle 2 FILTER Unsigned 8 Rw 0

0 Number of entries Unsigned 8 Ro 3

1 Angle 1 Process data Unsigned 16 Ro 0 Angle 1 Process data

2 Angle 2 Process data Unsigned 16 Ro 0 Angle 2 Process data

3

2100h 0 Number of entries Unsigned 8 Ro 2 The Angle 1 and 2:

1 Angle 1 Resolution Unsigned 16 Rw 100

2 Angle 2 Resolution Unsigned 16 Rw 100

2101h 0 Number of entries Unsigned 8 Ro 2 Angle 1 & 2 Zero Degree Point have to be in

1

2102h 0 Number of entries Unsigned 8 Ro 2 0: CCW

1 Angle 1 Unsigned 8 Rw X

2 Angle 2 Unsigned 8 Rw X

2103h Angle maximum

2110h 0 Number of entries Unsigned 8 Ro 4

1

2

3

4

Name Type Access Default

Angle Value

Angle Filter Function

Angle Sensor Process Data

Angle 1 & 2 Process

data

Angle 1 Zero degree

point

dierence

Angle 1 Output

Value Byte 0

Angle 1 Output

Value Byte 1

Angle 1 Output

Value Byte 0

Angle 1 Output

Value Byte 0

Unsigned 32 Ro 0

Angle Resolution

Angle Zero Degree Point

Unsigned 16 Ro 0

Angle Clockwise

Angle 1 and Angle 2 Values

Unsigned 8 0

Unsigned 8 0

Unsigned 8 0

Unsigned 8 0

value

0

Comments

chip with 360° fullscale and a resolution of

about 0.022°/bit

Min. = 0 & Max. = 16383

0: Not used

NOT IMPLEMENTED

Angle 1 & 2 Process data sent at the same time

Resolution accepted values are:

1000d: 1° bit; 100d: 0.1° bit; 22d: 0.01° bit

(14 bits eective resolution 0.02°)

relationg with the maximum allowed degree

Min. = 0 & Max. = 16383

1: CW

According to the ordering code

NOT IMPLEMENTED

Unit: 0x2100

MSB when PDO coding Big Endian

(Index 0x500) is used Min.= 0 & Max. = 255

Unit: 0x2100

MSB when PDO coding Big Endian

(Index 0x500) is used Min.= 0 & Max. = 255

Unit: 0x2100

MSB when PDO coding Big Endian

(Index 0x500) is used Min.= 0 & Max. = 255

Unit: 0x2100

MSB when PDO coding Big Endian

(Index 0x500) is used Min.= 0 & Max. = 255

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 17

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

Index Sub

Index

4000h Error

4001h

5000h Automatic NMT

5001h

5999h 0 Number of entries Unsigned 8 Ro 3

1 Baud rate - LSS-PARA Unsigned 16 Rw 250

2 Node-ID - LSS-PARA Unsigned 8 Rw 2

3 Store - LSS-PARA Unsigned 32 Wo

Ro = the parameter can be read only

Rw = the parameter can be read and also written

Wo = the parameter can be written only

Name Type Access Default

Angle Value

Behavior - PARA

Error code Unsigned 8 Ro 0

Start after Power-on

- PARA

PDO coding standard

used - PARA

Unsigned 8 Rw 1

Unsigned 8 Rw 1

Undesigned Rw 0

LSS Parameter

value

Comments

0: Pre-operational, 1: No state change

2: Stopped; Min. = 0 & Max. = 255

0000 0000 No error

0000 0001 Angle 1 sensor chip error

0000 0010 Angle 2 sensor chip error

0000 0100 Angle mismatch (Angle 1 vs Angle 2)

error, object 0x2103 NOT IMPLEMEMTED

0001 0000 Program checksum error

0100 0000 LSS Parameter checksum error

1000 0000 Magnetic elsd too high/low

0: Not activated

1: Little endian

Min. = 0 & Max. = 1

0: Big endian

1: Little Endian

Min. = 0 & Max. = 1

Possible values:

50 kbit/s

125 kbit/s

250 kbit/s

500 kbit/s

800 kbit/s

1000 kbit/s

Min. = 50 & Max. = 1000

IMPORTANT: use this service only if one device

is connected to the network

Min. = 1 & Max. = 127

IMPORTANT: use this service only if one device

is connected to the network

“Save” (0x65766173) to store all LSS parameters

(object with marking LSS-PARA)

IMPORTANT: use this service only if one device

is connected to the network

I

18 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

13. Communication

examples

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

Example 1: How to change the Baud Rate

Setting from 250 kbaud to 500 kbaud

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bith value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

Write (in the example the Node-ID = 0x03)

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 99h 59h 01h F4h 01h 00h 00h

5999h LSS Parameter

0 Number of entries Unsigned 8 Ro 3

Possible values:

50 kbit/s

125 kbit/s

250 kbit/s

Baud rate -

1

LSS-PARA

2 Node-ID - LSS-PARA Unsigned 8 Rw 2

3 Store - LSS-PARA IUnsigned 32 Wo

Unsigned 16 Rw 500

500 kbit/s

800 kbit/s

1000 kbit/s

Min. = 50 & Max. = 1000

IMPORTANT: use this service only if one device is

connected to the network

Min. = 1 & Max. = 127

IMPORTANT: use this service only if one device is

connected to the network

“Save” (0x65766173) to store all LSS parameters

(object with marking LSS-PARA)

IMPORTANT: use this service only if one device is

connected to the network

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 19

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

The supported baudrate are listed in the

following table:

Byte 5 Byte 6 Baudrate

32h 00h 50 Kbaud

7Dh 00h 125 Kbaud

FAh 00h 250 Kbaud

F4h 01h 500 Kbaud

20h 03h 800 Kbaud

E8h 03h 1Mbaud

The answer after successful storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 99h 59h 01h 00h 00h 00h 00h

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 99h 59h 03h 73h 61h 76h 65h

Note: save command is given by sending the code:

73h 61h 76h 65h

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 99h 59h 03h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

20 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Example 2: How to change the ID-Node from

0x03h (3d) to 0x06h (6d)

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

Write (in the example the Node-ID = 0x03)

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 99h 59h 02h F4h 06h 00h 00h

5999h LSS Parameter

0 Number of entries Unsigned 8 Ro 3

Possible values:

50 kbit/s

125 kbit/s

250 kbit/s

Baud rate -

1

LSS-PARA

2 Node-ID - LSS-PARA Unsigned 8 Rw 6

3 Store - LSS-PARA IUnsigned 32 Wo

Unsigned 16 Rw 250

500 kbit/s

800 kbit/s

1000 kbit/s

Min. = 50 & Max. = 1000

IMPORTANT: use this service only if one device is

connected to the network

Min. = 1 & Max. = 127

IMPORTANT: use this service only if one device is

connected to the network

“Save” (0x65766173) to store all LSS parameters

(object with marking LSS-PARA)

IMPORTANT: use this service only if one device is

connected to the network

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 21

Operation guide | DST X510 and DST X520 Rotary position sensors CANopen

To supported Node-ID are 0x01 to 0x7F

The answer after successful storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 99h 59h 02h 00h 00h 00h 00h

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 99h 59h 03h 73h 61h 76h 65h

Note: save command is given by sending the code:

73h 61h 76h 65h

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 99h 59h 03h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

22 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Example 3: How to activate an automatic NMT

Start after Power ON (the PDO will be send

automatically after power ON)

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

Write (in the example the Node-ID = 0x03)

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Fh 00h 50h 00h 01h 00h 00h 00h

Object:

5000h

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 10h 10h 01h 73h 61h 76h 65h

73h 61h 76h 65h

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 10h 10h 01h 00h 00h 00h 00h

Automatic NMT Start

after Power-On - PARA

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

Unsigned 8 Rw 1

Note: save command is given by sending the code:

0: Not activated

1: Activated

Min. = 0 & Max. = 1

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 23

Operation guide | DST X510 and DST X520 Rotary position sensors SAE J1939

Example 4: How to change the PDO rate (time

interval) from 100 ms to 20 ms

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

Write (in the example the Node-ID = 0x03)

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 00h 18h 05h 14h 00h 00h 00h

Object:

0

1 COB-ID Unsigned 32 Ro 180h+Node-ID

1800h

2 Transmission Type Unsigned 8 Rw 254 PAsynchronous transmission

3 Inhibit Time Unsigned 16 Ro 0 Min. = 0 & Max. = 65535 with unit = 1 ms

4 Reserved // //

5 Timer Unsigned 16 Rw 20 Min. = 4 & Max. = 65535 with unit = 1 ms

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 00h 18h 05h 00h 00h 00h 00h

1st Transmit PDO

Parameter

The answer after succesful storing you will receive is:

Unsigned 8 Ro

24 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 10h 10h 01h 73h 61h 76h 65h

Note: save command is given by sending the code:

73h 61h 76h 65h

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 10h 10h 01h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 25

Operation guide | DST X510 and DST X520 Rotary position sensors SAE J1939

Example 5: How to set the ZERO degree point

to Angle 1 (example with resolution ±0.1°)

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

Write (in the example the Node-ID = 0x03)

If the actual value of the Angle 1 is 02h 65 h =

0265 h = 613 d = 61.3° with the aim to move the

Angle 1 to ZERO add to Byte 5 and Byte 6 the

values below:

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 01h 21h 01h 65h 02h 00h 00h

Object:

Angle ZERO

Degree Point

The Angle 1 and Angle 2 ZERO Degree Point

have to be in relation with the mas. allowed

degree

Min. = 0 & Max. = 16383

2101h

0 Number of entries Unsigned 8 Ro 2

1

2

Angle 1 ZERO

Degree Point

Angle 2 ZERO

Degree Point

Unsigned 16 Rw 613

Unsigned 16 Rw 0

The answer after succesful storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 01h 21h 01h 00h 00h 00h 00h

26 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 10h 10h 01h 73h 61h 76h 65h

Note: save command is given by sending the code:

73h 61h 76h 65h

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 10h 10h 01h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 27

Operation guide | DST X510 and DST X520 Rotary position sensors SAE J1939

Example 6: How to set the ZERO degree point

to Angle 2 (example with resolution ±0.1°)

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

Write (in the example the Node-ID = 0x03)

If the actual value of the Angle 1 is 02h 65 h =

0265 h = 613 d = 61.3° with the aim to move the

Angle 2 to ZERO add to Byte 5 and Byte 6 the

values below:

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 01h 21h 02h 65h 02h 00h 00h

Object:

Angle ZERO

Degree Point

The Angle 1 and Angle 2 ZERO Degree Point

have to be in relation with the mas. allowed

degree

Min. = 0 & Max. = 16383

2101h

0 Number of entries Unsigned 8 Ro 2

1

2

Angle 1 ZERO

Degree Point

Angle 2 ZERO

Degree Point

Unsigned 16 Rw 0

Unsigned 16 Rw 613

The answer after succesful storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 01h 21h 02h 00h 00h 00h 00h

28 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 10h 10h 01h 73h 61h 76h 65h

Note: save command is given by sending the code:

73h 61h 76h 65h

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 10h 10h 01h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 29

Operation guide | DST X510 and DST X520 Rotary position sensors SAE J1939

Example 7: How to set the resolution to ± 0.1°

on Angle 1 and Angle 2 (the current setting

resolution is ±0.1°)

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

With the aim to set the resolution on Angle 1 to

± 0.01° send write the PDO (in the example the

Node-ID = 0x03)

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 00h 21h 01h 64h 02h 00h 00h

Object:

2100h

Angle RESOLUTION The Angle 1 and Angle 2 Resolution

0 Number of entries Unsigned 8 Ro 2

1 Angle 1 Resolution Unsigned 16 Rw 100

2 Angle 2 Resolution Unsigned 16 Rw 22

When the aim to set the resolution on Angle 2 to

± 0.01° send write the PDO (inthe example NodeID = 0x03):

accepted values are:

1000d: 1 Deg/bit

100d: 0.1 Deg/bit

22d: 0.01 Deg/bit

(14 bits eective resolution 0.02°)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 01h 21h 02h 64h 00h 00h 00h

30 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Object:

Angle RESOLUTION The Angle 1 and Angle 2 Resolution

0 Number of entries Unsigned 8 Ro 2

2100h

1 Angle 1 Resolution Unsigned 16 Rw 100

2 Angle 2 Resolution Unsigned 16 Rw 100

The answer after succesful storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 01h 21h 01h 00h 00h 00h 00h

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 10h 10h 03h 73h 61h 76h 65h

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 10h 10h 01h 73h 61h 76h 65h

Note: save command is given by sending the code:

73h 61h 76h 65h

accepted values are:

1000d: 1 Deg/bit

100d: 0.1 Deg/bit

22d: 0.01 Deg/bit

(14 bits eective resolution 0.02°)

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 10h 10h 01h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 31

Operation guide | DST X510 and DST X520 Rotary position sensors SAE J1939

Example 8: How to set the resolution to ± 0.1°

on Angle 1 and Angle 2 (the current setting

resolution is ±0.1°)

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

With the aim to set the resolution on Angle 1 to

± 0.01° send write the PDO (in the example the

Node-ID = 0x03)

COB-ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 00h 21h 01h 16h 02h 00h 00h

Object:

2100h

Angle RESOLUTION The Angle 1 and Angle 2 Resolution

0 Number of entries Unsigned 8 Ro 2

1 Angle 1 Resolution Unsigned 16 Rw 22

2 Angle 2 Resolution Unsigned 16 Rw 100

When the aim to set the resolution on Angle 2 to

± 0.01° send write the PDO (inthe example NodeID = 0x03):

accepted values are:

1000d: 1 Deg/bit

100d: 0.1 Deg/bit

22d: 0.01 Deg/bit

(14 bits eective resolution 0.02°)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 2Bh 00h 21h 02h 16h 00h 00h 00h

32 | © Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21J2.02

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Object:

Angle RESOLUTION The Angle 1 and Angle 2 Resolution

0 Number of entries Unsigned 8 Ro 2

2100h

1 Angle 1 Resolution Unsigned 16 Rw 100

2 Angle 2 Resolution Unsigned 16 Rw 220

The answer after succesful storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 00h 21h 01h 00h 00h 00h 00h

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 00h 21h 02h 00h 00h 00h 00h

With the aim to save new Baud Rate write the “save” command as below:

Write (in the example the Node-ID = 0x03)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

603h 23h 10h 10h 01h 73h 61h 76h 65h

Note: save command is given by sending the code:

73h 61h 76h 65h

Where:

73h = ASCII code “s”

61h = ASCII code “a”

76h = ASCII code “v”

65h = ASCII code “e”

The answer after successfull storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

583h 60h 10h 10h 01h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

accepted values are:

1000d: 1 Deg/bit

100d: 0.1 Deg/bit

22d: 0.01 Deg/bit

(14 bits eective resolution 0.02°)

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 33

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

Example 9: How to send the command

RESTORE

With Service Data Object (S.D.O) the access

to entries of a device Object Dictionary is

provided. As these entries may contain data of

arbitrary size and data type SDOs can be used

to transfer multiple data sets from a client to a

server and vice versa.

Structure of SDO-request by the Master

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

600+Node-ID 8 CMD Index Sub-Index Data

CMD determines the direction of data transfer

and the size of the data object:

23 hex Sending of 4-byte data (bytes 5 - 8

contain a 32 bit value)

2B hex Sending of 2-byte data (bytes 5, 6

contain a 16-bit value)

2F hex Sending of 1-byte data (byte 5 contains

an 8-bit value)

Structure of SDO-answer by the Slave

COB-ID DLC Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

580+Node-ID 8 CMD Index Sub-Index Data

RES Response of Slave:

60 hex Data sent successfully

80 hex Error

Write (in example the Node-ID = 0x7F)

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

67Fh 23h 11h 10h 01h 6Ch 6Fh 61h 64h

Object:

1011h 1 Load all parameters Unsigned 8 Wo

The answer after successful storing you will receive is:

ID Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

5FFh 60h 11h 10h 01h 00h 00h 00h 00h

IMPORTANT NOTE:

After setting the new entries a reset must be

made so that the new entries become valid

(switch off the module for a short time).

“Load” (0x64616F6C) to restore all

parameters (objects with marking PARA and

LSS-PARA)

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 34

Operation guide | DST X510 and DST X520 Rotary position sensor CANopen

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 35

Danfoss A/S | Industrial Automation | Nordborgvej 81 | DK-6430 Nordborg | Denmark | www.ia.danfoss.com

© Danfoss | DCS (im) | 2019.10

AQ304226795410en-0001010 | IC.PS.P21.J2.02 | 36

Loading...

Loading...