Page 1

Operation guide

Temperature transmitter

CAN SAE J1939

DST T92C

ia.danfoss.com

Page 2

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

Table of contents

1. General Information

Contents

1. General information................................................................................................................................... 2

1.1 Contact........................................................................................................................................................... 2

1.2 General............................................................................................................................................................ 2

1.3 CAN Interface................................................................................................................................................ 3

2. Specifications............................................................................................................................................... 3

3. J1939 communication.............................................................................................................................. 3

3.1 Introduction................................................................................................................................................. 3

3.2 Supported PGN’s and SPN’s.................................................................................................................... 4

3.3 Definitions..................................................................................................................................................... 9

3.3.1 PGN.................................................................................................................................................................. 9

3.3.2 SPN.................................................................................................................................................................. 9

3.4 Overview of the slot for pressure sensors......................................................................................... 10

3.5 References.................................................................................................................................................... 10

1.1 Contact

Danfoss A/S

Industrial Automation

DK-6430 Nordborg

Denmark

www.ia.danfoss.com

E-mail: technical support_IA@danfoss.com

1.2 General

The temperature transmitter DST T92C measures

the physical quantity temperature. The range is

-40 – 150 °C for the medium. The measured value

is transmitted on the CAN-Bus with the J1939

protocol. The transmitter takes 107 samples per

second, does filtering and converts the raw value

into the output format.

The CAN 2.0B interface is able to run up to a

speed of 1 Mbit/sec.

The device supports Diagnostic Message 1 (DM1,

PGN 0xFECA, active diagnostic trouble codes,

automatically send every second), Diagnostic

Message 2 (DM2, PGN 0xFECB, previously

active diagnostic trouble codes) and Diagnostic

Message 3 (DM3, PGN 0xFECC, diagnostic data

clear/reset for previously active DTCs). Also the

DST T92C CAN SAE J1939 firmware supports

static node addressing as well as dynamically

address claiming.

1.3 CAN Interface

The device includes a Full CAN controller

specified to CAN 2.0B. The physical layer of

the 2-wire interface is specified according to

ISO 11898. The wires are protected against

short-circuit. By adjusting the rise and fall

times of the CAN signals, the noise emission is

minimized to meet the EMC requirements. The

bus termination resistor is not included in the

device.

2 | © Danfoss | DCS (im) | 2018.01

Furthermore the device can easily configured

with a configuration vector (PGN 0xEF00) by

the customer if needed. An example dbc-file

with a default configuration to use with “Vector

CANdb++ Editor” is available on request.

IC.PS.P30.B1.02 | 520B8401

Page 3

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

2. Specifications

Electrical specifications

Supply voltage 9 – 36 V DC protected against reverse polarity

Current consumption at U

= 24 V DC I < 50 mA typical, I

S

< 100 mA

MAX

CAN Interface

Physical layer

2-wire interface, 5 V level according to ISO 11898

Protected against short-circuit

Bit rate 250 kBit/s (max. 1 Mbit/sec prossible)

Signal rise time

Bit rate < 125 kbit/s 12 V/µs (without bus)

Bit rate ≥ 125 kbit/s > 24 V/µs (without bus)

Bus termination External

Protocol SAE J1939

Environment

EMC EN 61326-1:2013

Operating temperature -40 – 125 °C

Media temperature -40 – 150 °C

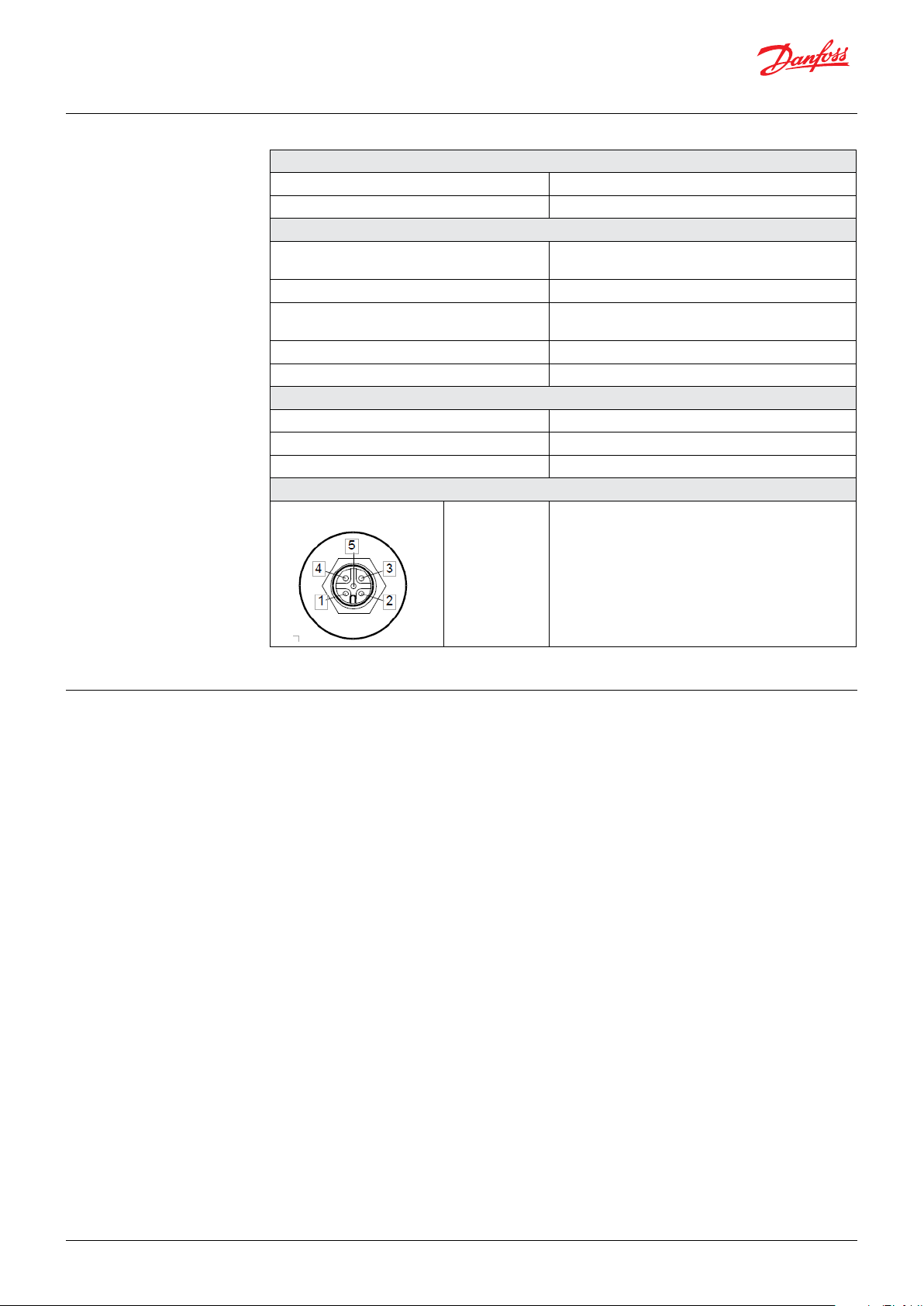

M12 connector Pin Assignment (CiA DR303-1)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

CAN shield, PE

+U

, +24 V DC

B

GND, 0 V

CAN_H, CAN+

CAN_L, CAN-

3. J1939 Communication

3.1 Introduction

The Society of Automotive Engineers (SAE)

developed the 1939 standard to be the

preferred CAN for equipment used in industries

ranging from agriculture, construction, and fire/

rescue to forestry, materials handling as well as

on and off-highway vehicles. It is a high-level

protocol that defines how communication

between nodes (modules) occurs on the bus.

The 1939 network is a specific communication

system, supporting specific sets of applications

and a specific industry, rather than being

generalized.

Any electronic control unit (ECU) using J1939

is permitted to transmit a message on the

network when the bus is idle. Every message

includes a 29-bit identifier, which defines the

message priority, what data is contained within

the 8-byte data array that follows the identifier,

and which ECU sent the message.

© Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401 3

Page 4

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

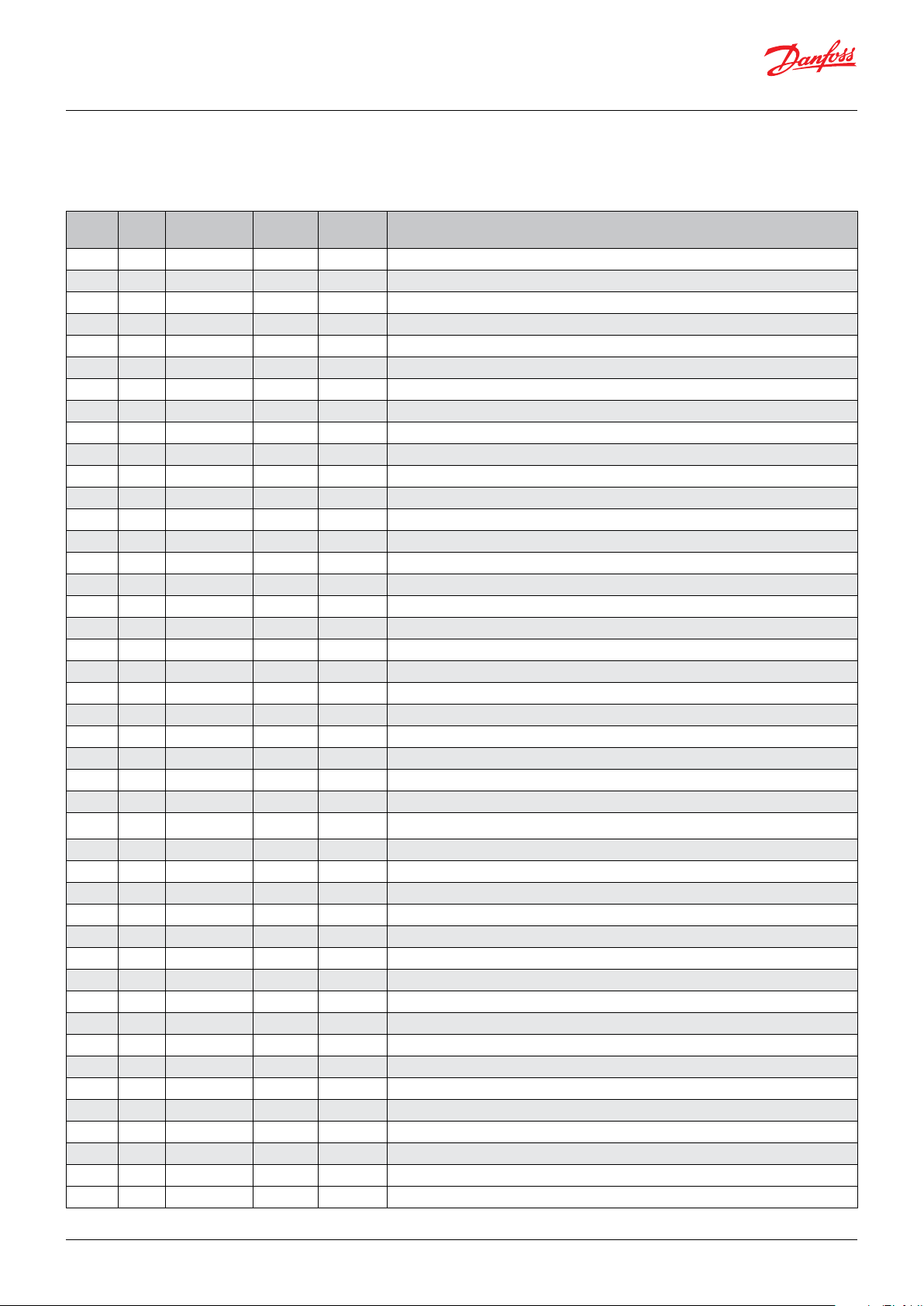

3.2 Supported PGN’s and SPN’s

PGN’s of SAE J1939

PGN SPN TTR [ms]

61495 6313 100 2 SAEtp01 Engine Turbocharger Compressor Blowoff Actuator 1 Temperature

61649 7090 100 2 SAEtp01 Engine Cylinder Head Bypass Actuator 1 Temperature

64548 7574 1000 2 SAEtp01 Aftertreatment 2 Diesel Exhaust Fluid Tank Temperature 2

64549 7572 1000 2 SAEtp01 Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature 2

64550 7529 1000 1 SAEtp01 Aftertreatment 2 Diesel Exhaust Fluid Controller Temperature

64550 7535 1000 2 SAEtp01 Aftertreatment 2 Diesel Exhaust Fluid Controller 2 Temperature

64551 5480 1000 1 SAEtp01 Aftertreatment 1 Diesel Exhaust Fluid Controller 1 Temperature

64551 7528 1000 2 SAEtp01 Aftertreatment 1 Diesel Exhaust Fluid Controller 2 Temperature

64557 7514 500 5 SAEtp01 Engine Fuel 2 Injector Metering Rail 1 Temperature 2

64571 7059 1000 1 SAEtp01 Engine End Bearing 17 Temperature

64571 7060 1000 2 SAEtp01 Engine End Bearing 18 Temperature

64571 7061 1000 3 SAEtp01 Engine End Bearing 19 Temperature

64571 7062 1000 4 SAEtp01 Engine End Bearing 20 Temperature

64572 7051 1000 1 SAEtp01 Engine End Bearing 9 Temperature

64572 7052 1000 2 SAEtp01 Engine End Bearing 10 Temperature

64572 7053 1000 3 SAEtp01 Engine End Bearing 11 Temperature

64572 7054 1000 4 SAEtp01 Engine End Bearing 12 Temperature

64572 7055 1000 5 SAEtp01 Engine End Bearing 13 Temperature

64572 7056 1000 6 SAEtp01 Engine End Bearing 14 Temperature

64572 7057 1000 7 SAEtp01 Engine End Bearing 15 Temperature

64572 7058 1000 8 SAEtp01 Engine End Bearing 16 Temperature

64573 7043 1000 1 SAEtp01 Engine End Bearing 1 Temperature

64573 7044 1000 2 SAEtp01 Engine End Bearing 2 Temperature

64573 7045 1000 3 SAEtp01 Engine End Bearing 3 Temperature

64573 7046 1000 4 SAEtp01 Engine End Bearing 4 Temperature

64573 7047 1000 5 SAEtp01 Engine End Bearing 5 Temperature

64573 7048 1000 6 SAEtp01 Engine End Bearing 6 Temperature

Data

Position

Slot SPN Name

64573 7049 1000 7 SAEtp01 Engine End Bearing 7 Temperature

64573 7050 1000 8 SAEtp01 Engine End Bearing 8 Temperature

64577 7023 500 5 SAEtp01 Engine Fuel 2 Injector Metering Rail 1 Temperature

64577 7024 500 6 SAEtp01 Engine Fuel 2 Injector Metering Rail 2 Temperature

64579 6984 On request 7 SAEtp01 O ver Temperature

64590 7460 500 3 SAEtp01 Aftertreatment 1 Diesel Exhaust Fluid Doser 2 Temperature

64651 6780 200 3-4 SAEtp01 Aftertreatment 1 Particulate Sensor Temperature

64655 6610 100 2 SAEtp01 Engine Fuel Vaporizer 1 Discharge Temperature

64655 6815 100 3 SAEtp01 Gaseous Fuel Accumulator Temperature

64689 6214 100 1 SAEtp01 Engine Ignition Control Module 1 Temperature

64689 6215 100 2 SAEtp01 Engine Ignition Control Module 2 Temperature

64705 5938 1000 2 SAEtp01 Transmission Oil Transmission Cooler Outlet Temperature

64708 5864 500 1-2 SAEtp01 Aftertreatment 2 SCR <intermediate Temperature

64709 5862 500 1-2 SAEtp01 Aftertreatment 1 SCR <intermediate Temperature

64713 6783 100 1 SAEtp01 Engine Throttle Valve 1 Temperature

64713 5784 100 2 SAEtp01 Engine Throttle Valve 2 Temperature

64713 5785 100 3 SAEtp01 Engine Fuel Valve 1 Temperature

4 | © Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401

Page 5

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

PGN SPN TTR [ms]

64713 5786 100 4 SAEtp01 Engine Fuel Valve 2 Temperature

64713 5787 100 5 SAEtp01 Engine Turbocharger Wastegate Actuator 2 Temperature

64713 7314 100 6 SAEtp01 Engine Fuel Rack Supply Temperature

64714 5775 100 2 SAEtp01 Engine Exhaust Gas Recirculation 2 Actuator 1 Temperature

64714 5779 100 5 SAEtp01 Engine Exhaust Gas Recirculation 2 Actuator 2 Temperature

64715 5765 100 2 SAEtp01 Engine Exhaust Gas Recirculation 1 Actuator 1 Temperature

64715 5769 100 5 SAEtp01 Engine Exhaust Gas Recirculation 1 Actuator 2 Temperature

64736 5501 100 1-2 SAEtp02 Aftertreatment 1 Diesel Particulate Filter Intake Temperature Set Point

64738 5561 1000 3 SAEtp01 Supplement Fan Controller ECU Temperature

64740 5540 30000 7-8 SAEtp02 Engine Fuel Temperature (High Resolution)

64741 5536 30000 7-8 SAEtp02 Hydraulic Oil Temperature (High Resolution)

64749 5315 500 1-2 SAEtp02 Aftertreatment 2 Warm Up Diesel Oxidation Catalyst Intake Temperature

64749 5316 500 3-4 SAEtp02 Aftertreatment 2 Warm Up Diesel Oxidation Catalys Outlet Temperature

64753 5788 100 6 SAEtp01 Engine Turbocharger Wastegate Actuator 1 Temperature

64753 5790 100 8 SAEtp01 Engine Exhaust Pressure Actuator 1 Temperature

64755 5791 100 5 SAEtp01 Engine Turbocharger Compressor Bypass Actuator 1 Temperature

64755 5792 100 6 SAEtp01 Engine Turbocharger Compressor Bypass Actuator 2 Temperature

64756 5289 1000 1-2 SAEtp02 Engine Charge Air Cooler 2 Intake Temperature

64756 5290 1000 3-4 SAEtp02 Engine Charge Air Cooler 2 Outlet Temperature

64756 5291 1000 5-6 SAEtp02 Engine Charge Air Cooler 2 Ambient Air Temperature

64757 5286 1000 1-2 SAEtp02 Engine Charge Air Cooler 2 Precooler Intake Temperature

64757 5287 1000 3-4 SAEtp02 Engine Charge Air Cooler 2 Precooler Outlet Temperature

64758 5283 1000 1-2 SAEtp02 Engine Charge Air Cooler 1 Intake Temperature

64758 5284 1000 3-4 SAEtp02 Engine Charge Air Cooler 1 Ambient Air Temperature

64759 5280 1000 1-2 SAEtp02 Engine Charge Air Cooler 1 Precooler Intake Temperature

64759 5281 1000 3-4 SAEtp02 Engine Charge Air Cooler 1 Precooler Outlet Temperature

64766 5258 On request 1-2 SAEtp02 Engine Exhaust Gas Recirculation 2 Cooler Intake Temperature

64767 5255 1000 1-2 SAEtp02 Engine Exhaust Gas Recirculation 2 Temperature

64767 5256 1000 3-4 SAEtp02 Engine Exhaust Gas Recirculation 2 Mixer Intake Temperature

64769 5148 500 4 SAEtp01 Low Voltage Disconnect Temperature

64776 5925 30000 7-8 SAEtp02 Engine Oil Temperature 3

64794 4809 500 1-2 SAEtp02 Aftertreatment 1 Warm Up Diesel Oxidation Catalyst Intake Temperature

64794 4810 500 3-4 SAEtp02 Aftertreatment 1 Warm Up Diesel Oxidation Catalyst Outlet Temperature

64795 5570 1000 8 SAEtp01 Diesel Particulate Filter 2 Soot Sensor ECU Internal Temperature

64796 5569 1000 8 SAEtp01 Diesel Particulate Filter 1 Soot Sensor ECU Internal Temperature

64797 4779 On request 1-2 SAEtp02 Aftertreament 1 Three Way Catalyst Differential Temperature

64797 4780 On request 3-4 SAEtp02 Aftertreatment 2 Three Way Catalyst Differential Temperature

64798 4777 On request 1-2 SAEtp02 Aftertreatment 1 Gas Oxidation Catalyst Differential Temperature

64798 4778 On request 3-4 SAEtp02 Aftertreatment 2 Gas Oxidation Catalyst Differential Temperature

64799 4771 500 1-2 SAEtp02 Aftertreatment 2 Diesel Oxidation Catalyst Intake Temperature

64799 4772 500 3-4 SAEtp02 Aftertreatment 2 Diesel Oxidation Catalyst Outlet Temperature

64800 4765 500 1-2 SAEtp02 Aftertreatment 1 Diesel Oxidation Catalyst Intake Temperature

64800 4766 500 3-4 SAEtp02 Aftertreatment 1 Diesel Oxidation Catalyst Outlet Temperature

64801 4759 500 1-2 SAEtp02 Aftertreatment 2 Gas Oxidation Catalyst Intake Temperature

64801 4760 500 3-4 SAEtp02 Aftertreatment 2 Gas Oxidation Catalyst Outlet Temperature

64802 4753 500 1-2 SAEtp02 Aftertreatment 1 Gas Oxidation Catalyst Intake Temperature

64802 4754 500 3-4 SAEtp02 Aftertreatment 1 Gas Oxidation Catalyst Outlet Temperature

64820 4434 1000 2 SAEtp01 Aftertreatment 2 Diesel Exhaust Fluid Quick Thaw Temperature

Data

Position

Slot SPN Name

© Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401 5

Page 6

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

PGN SPN TTR [ms]

64821 4427 1000 2 SAEtp01 Aftertreatment 2 Diesel Exhaust Fluid Tank Temperature

64822 4420 1000 1 SAEtp01 Aftertreatment 2 Diesel Exhaust Fluid Temperature 2

64824 4413 500 1-2 SAEtp02 Aftertreatment 2 SCR Intake Temperature

64824 4415 500 4-5 SAEtp02 Aftertreatment 2 SCR Outlet Temperature

64827 4390 500 3 SAEtp01 Aftertreatment 2 Diesel Exhaust Fluid Doser 1 Temperature

64829 4368 1000 2 SAEtp01 Aftertreatment 1 Diesel Exhaust Fluid Quick Thaw Temperature

64830 4360 500 1-2 SAEtp02 Aftertreatment 1 SCR Intake Temperature

64830 4363 500 4-5 SAEtp02 Aftertreatment 1 SCR Outlet Temperature

64831 4337 500 3 SAEtp01 Aftertreatment 1 Diesel Exhaust Fluid Doser 1 Temperature

64837 4295 500 1-2 SAEtp02 Aftertreatment 2 Three Way Catalyst Intake Temperature

64837 4296 500 3-4 SAEtp02 Aftertreatment 2 Three Way Catalyst Outlet Temperature

64838 4289 500 1-2 SAEtp02 Aftertreatment 1 Three Way Catalyst Intake Temperature

64838 4290 500 3-4 SAEtp02 Aftertreatment 1 Three Way Catalyst Outlet Temperature

64849 4199 1000 2 SAEtp01 Desired Aftercooler Coolant Intake Temperature

64850 4196 1000 2 SAEtp01 Desired Engine Coolant Pump Outlet Temperature

64851 4151 500 1-2 SAEtp02 Engine Exhaust Bank Temperature Average

64851 4153 500 3-4 SAEtp02 Engine Exhaust Bank 1 Temperature Average

64851 4152 500 5-6 SAEtp02 Engine Exhaust Bank 2 Temperature Average

64869 5456 500 6 SAEtp01 Aftertreatment 1 Hydrocarbon Doser Intake Fuel Temperature

64870 4076 1000 1 SAEtp01 Engine Coolant Tempera5ture 2

64870 4193 1000 2 SAEtp01 Engine Coolant Pump Outlet Temperature

64870 4288 1000 4-5 SAEtp02 Engine Exhaust Valve Actuation System Oil Temperature

64870 5020 1000 5-7 SAEtp02 Engine Exhaust Gas Recirculation 1 Mixer Intake Temperature

64870 6209 1000 8 SAEtp01 Engine Coolant Temperature 3

64876 3834 500 3-4 SAEtp02 Aftertreatment 2 Secondary Air Temperature

64877 3831 500 3-4 SAEtp02 Aftertreatment 1 Secondary Air Temperature

64879 4750 On request 3-4 SAEtp02 Engine Exhaust Gas Recirculation 1 Cooler Intake Temperature

64917 3823 1000 2-3 SAEtp02 Transmission Torque Converter Oil Outlet Temperature

64917 5913 1000 5-6 SAEtp02 Transmission Oil Temperature 2

64919 2775 1000 1 SAEtp01 Engine Fuel Supply Temperature

64919 2776 1000 2 SAEtp01 Engine Fuel Return Temperature

64923 3515 1000 1 SAEtp01 Aftertreatmwent 1 Diesel Exhaust Fluid Temperature 2

63930 3468 500 5 SAEtp01 Engine Fuel Temperature 2

64943 3283 500 1-2 SAEtp02 Aftertreatment 2 Exhaust Temperature 2

64943 3284 500 3-4 SAEtp02 Aftertreatment 2 Diesel Particulate Filter Intermediate Temperature

64944 3279 500 1-2 SAEtp02 Aftertreatment 2 Exhaust Temperature 3

64944 3280 500 3-4 SAEtp02 Aftertreatment 2 Diesel Particulate Filter Outlet Temperature

64945 3275 500 1-2 SAEtp02 Aftertreatment 2 Exhaust Temperature 1

64945 3276 500 3-4 SAEtp02 Aftertreatment 2 Diesel Particulate Filter Intake Temperature

64946 3249 500 1-2 SAEtp02 Aftertreatment 1 Exhaust Temperature 2

64946 3250 500 3-4 SAEtp02 Aftertreatment 1 Diesel Particulate Filter Intermediate Temperature

64947 3245 500 1-2 SAEtp02 Aftertreatment 1 Exhaust Remperature 3

64947 3246 500 3-4 SAEtp02 Aftertreatment 1 Diesel Particulate Filter Outlet Temperature

64948 3241 500 1-2 SAEtp02 Aftertreatment 1 Exhaust Temperature 1

64948 3242 500 3-4 SAEtp02 Aftertreatment 1 Diesel Particulate Filter Intake Temperature

64979 2916 1000 1-2 SAEtp02 Engine Turbocharger 1 Compressor outlet Temperature

64979 2799 1000 3-4 SAEtp02 Engine Turbocharger 2 Compressor Outlet Temperature

64979 2800 1000 5-6 SAEtp02 Engine Turbocharger 3 Compressor Outlet Temperature

Data

Position

Slot SPN Name

6 | © Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401

Page 7

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

PGN SPN TTR [ms]

64979 2801 1000 7-8 SAEtp02 Engine Turbocharger 4 Compressor Outlet Temperature

64981 2789 On request 1-2 SAEtp02 Engine Turbocharger 1 Calculated Turbine Intake Temperature

64981 2790 On reuest 3-4 SAEtp02 Engine Turbocharger 1 Calculated Turbine Outlet Temperature

64992 5581 1000 5-6 SAEtp02 Calculated Ambient Air Temperature

65031 2433 500 1-2 SAEtp02 Engine Exhaust Manifold Bank 2 Temperature 1

65031 2434 500 3-4 SAEtp02 Engine Exhaust Manifold Bank 1 Temperature 1

65031 5969 500 5-6 SAEtp02 Engine Exhaust Manifold Bank 2 Temperature 2

65031 5970 500 7-8 SAEtp02 Engine Exhaust Manifold Bank 1 Temperature 2

65104 1800 1000 1 SAEtp01 SLI Battery 1 Temperature

65104 1801 1000 2 SAEtp01 SLI Battery 2 Temperature

65104 2779 1000 3 SAEtp01 SLI Battery 3 Temperature

65104 2780 1000 4 SAEtp01 SLI Battery 4 Temperature

65110 3031 1000 2 SAEtp01 Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature

65128 1638 1000 1 SAEtp01 Hydraulic Temperature

65129 1636 1000 1-2 SAEtp02 Engine Intake Mainfold 1 Temperature (High Resolution)

65129 1637 1000 3-4 SAEtp02 Engine Coolant Temperature (High Resolution)

65129 2986 1000 5-6 SAEtp02 Engine Intake Valve Actuation System Oil Temperature

65129 2630 1000 7-8 SAEtp02 Engine Charge Air Cooler 1 outlet Temperature

65133 1687 1000 1 SAEtp01 Auxiliary Heater Output Coolant Temperature

65133 1688 1000 2 SAEtp01 Auxiliary Heater Input Air Temperature

65164 441 On request 1 SAEtp01 Auxiliary Temperature 1

65164 442 On request 2 SAEtp01 Auxiliary Temperature 2

65172 1212 500 2 SAEtp01 Engine Auxiliary Coolant Temperature

65175 1184 1000 1-2 SAEtp02 Engine Turbocharger 1 Turbine Outlet Temperature

65175 1185 1000 3-4 SAEtp02 Engine Turbocharger 2 Turbine Outlet Temperature

65175 1186 1000 5-6 SAEtp02 Engine Turbocharger 3 Turbine Outlet Temperature

65175 1187 1000 7-8 SAEtp02 Engine Turbocharger 4 Turbine Outlet Temperature

65176 1180 1000 1-2 SAEtp02 Engine Turbocharger 1 Turbine Intake Temperature

65176 1181 1000 3-4 SAEtp02 Engine Turbocharger 2 Turbine Intake Temperature

65176 1182 1000 5-6 SAEtp02 Engine Turbocharger 3 Turbine Intake Temperature

65176 1183 1000 7-8 SAEtp02 Engine Turbocharger 4 Turbine Intake Temperature

65178 1172 1000 1-2 SAEtp02 Engine Turbocharger 1 Compressor Intake Temperature

65178 1173 1000 3-4 SAEtp02 Engine Turbocharger 2 Compressor Intake Temperature

65178 1174 1000 5-5 SAEtp02 Engine Turbocharger 3 Compressor Intake Temperature

65178 1175 1000 7-8 SAEtp02 Engine Turbocharger 4 Compressor Intake Temperature

65180 1165 1000 1-2 SAEtp02 Engine Main Bearing 9 Temperature

65180 1166 1000 3-4 SAEtp02 Engine Main Bearing 10 Temperature

65180 1167 1000 5-6 SAEtp02 Engine Main Bearing 11 Temperature

65180 6830 1000 7-8 SAEtp02 Engine Main Bearing 12 Temperature

65181 1161 1000 1-2 SAEtp02 Engine Main Bearing 5 Temperature

65181 1162 1000 3-4 SAEtp02 Engine Main Bearing 6 Temperature

65181 1163 1000 5-6 SAEtp02 Engine Main Bearing 7 Temperature

65181 1164 1000 7-8 SAEtp02 Engine Main Bearing 8 Temperature

65182 1157 1000 1-2 SAEtp02 Engine Main Bearing 1 Temperature

65182 1158 1000 3-4 SAEtp02 Engine Main Bearing 2 Temperature

65182 1159 1000 5-6 SAEtp02 Engine Main Bearing 3 Temperature

65182 1160 1000 7-8 SAEtp02 Engine Main Bearing 4 Temperature

65183 1153 1000 1-2 SAEtp02 Engine Exhaust Gas Port 17 Tempeature

Data

Position

Slot SPN Name

© Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401 7

Page 8

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

PGN SPN TTR [ms]

65183 1154 1000 3-4 SAEtp02 Engine Exhaust Gas Port 18 Temperature

65183 1155 1000 5-6 SAEtp02 Engine Exhaust Gas Port 19 Temperature

65183 1156 1000 7-2 SAEtp02 Engine Exhaust Gas Port 20 Temperature

65184 1149 1000 1-2 SAEtp02 Engine Exhaust Gas Port 13 Temperature

65184 1150 1000 3-4 SAEtp02 Engine Exhaust Gas Port 14 Temperature

65184 1151 1000 5-6 SAEtp02 Engine Exhaust Gas Port 15 Temperature

65184 1152 1000 7-8 SAEtp02 Engine Exhaust Gas Port 16 Temperature

65185 1145 1000 1-2 SAEtp02 Engine Exhaust Gas Port 9 Temperature

65185 1146 1000 3-4 SAEtp02 Engine Exhaust Gas Port 10 Temperature

65185 1147 1000 5-6 SAEtp02 Engine Exhaust Gas Port 11 Temperature

65185 1148 1000 7-8 SAEtp02 Engine Exhaust Gas Port 12 Temperature

65186 1141 1000 1-2 SAEtp02 Engine Exhaust Gas Port 5 Temperature

65186 1142 1000 3-4 SAEtp02 Engine Exhaust Gas Port 6 Temperature

65186 1143 1000 5-6 SAEtp02 Engine Exhaust Gas Port 7 Temperature

65186 1144 1000 7-8 SAEtp02 Engine Exhaust Gas Port 8 Temperature

65187 1137 1000 1-2 SAEtp02 Engine Exhaust Gas Port 1 Temperature

65187 1138 1000 3-4 SAEtp02 Engine Exhaust Gas Port 2 Temperature

65187 1139 1000 5-6 SAEtp02 Engine Exhaust Gas Port 3 Temperature

65187 1140 1000 7-8 SAEtp02 Engine Exhaust Gas Port 4 Temperature

65188 1135 1000 1-2 SAEtp02 Engine Oil Temperature 2

65188 1136 1000 3-4 SAEtp02 Engine ECU Temperature

65188 412 1000 7-8 SAEtp02 Engine Exhaust Gas Recirculation 1 Temperature

65189 1131 1000 1 SAEtp01 Engine Intake Manifold 2 Temperature

65189 1132 1000 2 SAEtp01 Engine Intake Manifold 3 Temperature

65189 1133 1000 3 SAEtp01 Engine Intake Manifold 4 Temperature

65189 1802 1000 4 SAEtp01 Engine Intake Manifold 5 Temperature

65189 1803 1000 5 SAEtp01 Engine Intake Manifold 6 Temperature

65191 1122 1000 1 SAEtp01 Engine Alternator Bearing 1 Temperature

65191 1123 1000 2 SAEtp01 Engine Alternator Bearing 2 Temperature

65191 1124 1000 3 SAEtp01 Engine Alternator Winding 1 Temperature

65191 1125 1000 4 SAEtp01 Engine Alternator Winding 2 Temperature

65191 1126 1000 5 SAEtp01 Engine Alternator Winding 3 Temperature

65262 110 1000 1 SAEtp01 Engine Coolant Temperature

65262 174 1000 2 SAEtp01 Engine Fuel Temperature 1

65262 175 1000 3-4 SAEtp02 Engine Oil Temperature 1

65262 176 1000 5-6 SAEtp02 Engine Turbocharger Oil Temperature

65262 52 1000 SAEtp01 Engine Intercooler Temperature

65264 90 100 1 SAEtp01 Power Takeoff Oil Temperature

65268 242 10000 3-4 SAEtp02 Tire Temperature

65269 170 1000 2-3 SAEtp02 Cab Interior Temperature

65269 171 1000 4-5 SAEtp02 Ambient Air Temperature

65269 172 1000 6 SAEtp01 Engine Intake Air Temperature

65269 79 1000 7-8 SAEtp02 Road Surface Temperature

65270 105 500 3 SAEtp01 Engine Intake Manifold 1 Temperature

65270 173 500 6-7 SAEtp02 Engine Exhaust Temperature

65272 177 1000 5-6 SAEtp02 Transmission Oil Temperature 1

65273 75 1000 1 SAEtp01 Steering Axle Temperature

65273 578 1000 4 SAEtp01 Drive Axle Temperature

Data

Position

Slot SPN Name

8 | © Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401

Page 9

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

PGN SPN TTR [ms]

65275 120 1000 2 SAEtp01 Hydraulic Retarder Oil Temperature

65275 5656 1000 4 SAEtp01 Retarder Coolant Outlet Temperature

65276 169 1000 5-6 SAEtp02 argo Ambient Temperature

65277 7020 500 6 SAEtp01 LNG Vaporizer Coolant Outlet Temperature

Data

Position

Slot SPN Name

3.3 Definitions 3.3.1 PGN

The PGN (Parameter Group Number) uniquely

identifies the Parameter Group (PG) that

is being transmitted in the message. The

Parameter Group Number (PGN) is a part of the

29-bit identifier sent with every message.

3.3.2 SPN

Each parameter used in the J1939 network is

described by the standard. A Suspect Parameter

Number (SPN) is a number that has been assigned

by SAE committee to a specific parameter. Each

SPN has the following detailed information

associated with it: data length (in bytes);

data type; resolution, offset; range; and a tag

(label) for reference. SPNs that share common

characteristics will be grouped into a Parameter

Group (PG) and will be transmitted to the network

using the same PGN.

3.4 Overview of the slots for temperature

sensors

Slot

Name

Slot Type Scaling Range Offset Length

SAEtp01 Temperature 1 °C/bit -40 – 210 °C -40 °Ca 1 byte

SAEpr02 Temperature 0.03125 °C/bit -273 – 1734.96875 °C -273 °C 2 bytes

SAEtp04 Temperature 1/128 °C/bit -2373 – 228.9921875 °C -273 °C 2 bytes

SLOT is the acronym for Scaling, Limit, Offset and

Transfer function. The following SAE SLOTs are

supported by the device.

Additionally, the scaling, limit and offset can be

completely free configured by using a customer

specific PGN. Only the data length is limited to 1,

2 or 4 bytes.

For example, a default Danfoss-specific SLOT was

defined, which perfectly fits the complete

DST T92C CAN media temperature operational

range:

Slot Name Slot Type Scaling Range Offset Length

Danfosstp01 Temperature 0.003 °C/bit -40 – 150 °C -40 °Ca 2 bytes

3.5 References

© Danfoss | DCS (im) | 2018.01

ISO11783-3 Data Link Layer

J1939-71

IC.PS.P30.B1.02 | 520B8401 9

Page 10

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

10 | © Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401

Page 11

Operation guide | DST T92C Temperature transmitter CAN SAE J1939

© Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B8401 11

Page 12

Danfoss A/S

Industrial Automation

Nordborgvej 81

DK-6430 Nordborg

Denmark

www.ia.danfoss.com

© Danfoss | DCS (im) | 2018.01

IC.PS.P30.B1.02 | 520B9401 | 12

Loading...

Loading...