Page 1

Safety guide

Pressure transmitter SIL-2

DST P92S

ia.danfoss.com

Page 2

Safety guide | DST P92S Pressure transmitter

Table of contents

Contents

1. Introduction ................................................................................................................................................. 2

2. General information.................................................................................................................................. 3

2.1 Contact........................................................................................................................................................... 3

2.2 Used symbols and format........................................................................................................................ 3

2.3 Reference....................................................................................................................................................... 3

2.4 Abbreviations............................................................................................................................................... 4

3. Qualication test........................................................................................................................................ 5

3.1 Compliance information......................................................................................................................... 5

3.2 Electromagnetic and electrical tests................................................................................................... 5

3.3 Environmental qualication................................................................................................................... 12

4. System information................................................................................................................................... 13

4.1 Functional safety classication............................................................................................................. 13

4.2 Technical data............................................................................................................................................. 14

4.3 Technical drawings..................................................................................................................................... 16

4.4 Pin congurations...................................................................................................................................... 17

4.5 Wiring diagram............................................................................................................................................ 17

4.6 Safety functions.......................................................................................................................................... 17

4.7 Diagnosis....................................................................................................................................................... 18

5. Safety requirements.................................................................................................................................. 18

5.1 Known issues............................................................................................................................................... 19

5.2 Instructions and constraints................................................................................................................... 19

5.3 Safe state....................................................................................................................................................... 19

5.4 System............................................................................................................................................................ 20

5.5 Pressure.......................................................................................................................................................... 21

5.6 Outputs.......................................................................................................................................................... 22

5.7 Decommissioning and disposal............................................................................................................ 24

5.8 Security.......................................................................................................................................................... 24

6. Transport and storage............................................................................................................................... 24

7. Maintenance................................................................................................................................................. 24

8. Mounting....................................................................................................................................................... 24

9. Dismounting................................................................................................................................................. 25

1. Introduction This document includes system information and

safety requirements for the pressure transmitter

DST P92S, which have to be considered and

fullled within the overall safety application.

It shall be used as input for the:

• development of the overall safety

application.

• overall installation and commissioning

planning.

• overall safety validation planning.

• overall operation, maintenance and repair

planning.

2 | © Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782

Page 3

Safety guide | DST P92S Pressure transmitter

2. General information

2.1 Contact

Danfoss A/S

Industrial Automation

DK-6430 Nordborg

Denmark

www.ia.danfoss.com

E-mail: technical support_IA@danfoss.com

2.2 Used symbols and formats

REQIREMENT:

Requirement which shall be adhered

to maintain safe system operations.

RECOMMENDATION:

Recommendation on how to handle

certain aspects of requirements.

WARNING:

Warning of faults and errors during

the application development.

NOTE:

A note provides additional and

important information of the system

behavior.

2.3 Reference

No. Description

International standard IEC 61508:2010

/1/

Functional safety of electrical, electronic and programmable electronic safety-related systems

Safety standard EN ISO 13849-1:2015

/2/

Safety of machinery - Safety-related parts of control systems

/3/ Siemens standard SN 29500: Failure rates of components

EMC standard EN 61000-4-5:2005

/4/

Electromagnetic Compatibility; testing and measurement techniques - Surge immunity test

Safety standard ISO 25119:2010 / EN 16590:2014

/5/

Tractors and machinery for agriculture and forestry - Safety-related parts of constrol system

© Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782 | 3

Page 4

Safety guide | DST P92S Pressure transmitter

2.4 Abbreviations

Abbreviation Description

AgPL Agricultural Performance Level: Safety classication according to ISO 25119 / EN 16590

CCF Common Cause Failure

CRC Cyclic Redundancy Check

DC Diagnostic Coverage

DFB Digital Feedback

DTI Diagnostic Test Interval

ECU Electronic Control Unit

EEPROM Electrically Erasable Programmable ROM

EMC Electromagnetic Compatibility

FRT Fault Reaction Time

FTT Fault Tolerance Time

FS Full Scale

GND Ground

HW Hardware

I/O Input / Output

MDT Mean Downtime

MTBF Mean Time Between Failure

MTTFd Mean Time To dangerous Failure

MTTR Mean Time To Restoration

PFH Probability of dangerous Failure per Hour

PL Performance Level: Safety classication according to EN ISO 13849

PST Process Safety Time

RAM Random Access Memory

ROM Read Only Memory

SFF Safe Failure Fraction

SIL Safety Integrity Level: Safety classication according to IEC 61508

SMM Shadow Memory Module (if existing)

SN Siemens Standard

SRL Software Requirement Level

SW Software

TBD To be determined / to be dened

VCC Positive voltage supply connection

VFB Voltage Feedback

VSRC Valid Safety Relevant Conguration

4 | © Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782

Page 5

Safety guide | DST P92S Pressure transmitter

3. Qualication tests

3.1 Compliance information

Standard Description Parameter

Conformity See EU Dclaration of conformity

Certication

Requirement in accordance

to the EC type-approval of

the Kraftfahrt-Bundesamt

KBA (KraftfahrtBundesamt)

See also Functional Safety Classication on page 9

E

(KBA) - Fedral Motor tTransport

1

Authority:

All vehicle types with a 12 V

respectively 24 V - electrical

wiring and battery(-) at the

body

According UN ECE Regulation No. 10

3.2 Electromagnetic and electrical tests

Electrical Safety

Standard Test description Test parameter

Danfoss reference Supply voltage Current variant:

Operation with U

and U

= 9V DC for a duration of

min

= 32V DC

max

60 min. each.

Current

variant

x x

Ratiometric

voltage

variant

Ratiometric voltage variant:

Operation withg U

and U

= 4.5V DC for a duration

min

= 5.5 V DC

max

of 50 min. each

Danfoss reference Starting prole

switch-on

hysteresis

Overvoltage and hysteresis:

U

t = U

max

+3%

Tes

t = 5 min.

Undervoltage and hysteresis:

U

= U

Start

nom

ΔU = 0.1V

U

= U

min

switch-o

Danfoss reference Broken cable

supply lines

t at U

Interruption of supply lines:

Current variant:

U

max

U

min

switch-on

= 32V

= 9V

= 5 min.

Ratiometric voltage variant:

U

= 5.5V

max

U

= 4.5V

min

t = 60 sec.

Danfoss reference Short circuits Output signals to VCC or GND in

each case

t = 60 sec.

Danfoss reference

ISO 16750-2:

2012-11

Polarity

Protection

Change supply polarity:

t = 5 min.

Curent variant:

No current limitation of supply

necessary

x x

x x

x x

x x

© Danfoss | DCS (im) | 2020.01

Ratiometric voltage variant:

Current limiting of supply to 2A

IC.PS.P21.2A.02 | 520B7782 | 5

Page 6

Safety guide | DST P92S Pressure transmitter

Standard Test description Test parameter

Danfoss reference Current

consumption

Supply current consumption

without load:

Current variant:

I

≤ 50 mA

max

Ratiometric voltage variant:

I

≤ 20 mA

max

Danfoss reference Load test 48 hours at minimum

temperature:

12 hours without operating, 36

hours with operating U

min

and l

min

48 hours at maximum

Danfoss reference

ISO 16750-2:

2012-11

Insulation

Resistance

temperature with operation U

and I

max

Unpowered; 500V DC; 60

sec.; 50% rh; 35 °C; between

Connector pins and electric

max

conductive housing without

galvanic contact.

Insulation resistance > 10 MΩ

CE Conformity (EMC)

Standard Test Description Test Parameter Current

variant

DIN EN 61000-6-3

DIN EN 61326

DIN 61326-2-3

DIN EN 610000-4-2:2009-12

DIN EN 61326-1

Emission

Electrostatic Discharge (ESD)

Conducted emission: 150 kHz to 30 MHz

Radiated emission: 30 MHz to 1 GHz

Direct discharge:

Contact discharge:

±2 kV, ±4 kV

Air discharge:

±2 kV, ±4 kV, ±8 k

Current

variant

x x

x x

x x

x x

x x

Ratiometric

voltage

variant

Ratiometric

voltage

variant

DIN EN 61000-4-2: 2009-12

DIN EN 61326-1 Electrostatic Discharge (ESD)

DIN EN 61000-4-2: 2009-12

DIN EN 61326-1 Electrostatic Discharge (ESD)

DIN EN 61000-4-3: 2011-04

DIN EN 61326-1

DIN EN 61326-2-3

DIN EN 61000-4-4: 2013-04

DIN EN 61326-1

DIN EN 61326-2-3

Immunity

Burst

6 | © Danfoss | DCS (im) | 2020.01

10 discarges per test point

Indirect discharge:

(horizontal coupling-plate)

Contact discharge: ±2 kV; ±4 kV

15 discharges per test point

Indirect discharge:

(vertical coupling-plate)

Contact discharge: ±2 kV; ±4 kV

15 discharges per test point

Immunity radio frequency:

80 MHz to 1 GHz (10 V/m)

1.4 GHz to 2.0 GHz (3 V/m)

2.0 GHz to 2.7 GHz (1 V/m)

3 m, horizontal and vertical

Test voltage:

Supply lines: ± 2 kV

Data lines: ±1 kV

Duration: 5 min.

Pulse form: 5/50 ns

Frequency: 5 kHz

Polarity: positive and negative

x x

x x

x x

x x

IC.PS.P21.2A.02 | 520B7782

Page 7

Safety guide | DST P92S Pressure transmitter

Standard Test Description Test Parameter Current

variant

Symmetrical coupling (L-N):

Supply lines: ±0.5 kV; ±1 kV

Coupling: 2 Ω / 18 µF

DIN EN 61000-4-5: 2007-06

DIN EN 61326-1

DIN 61326-2-3

DIN EN 610000-4-6: 2014

DIN EN 61326-1

DIN EN 61326-2-3

DIN EN 61000-4-8

DIN EN 61326-1

DIN EN 61326-2-3

DIN EN 61000-4-8

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

Surge

Immunity

Power Frequency

Magnetic Fields

Power Frequency

Magnetic Fields

Unsymmetrical coupling (L-PE, N-PE, LN-PE):

Supply lines: ±0.5 kV; ±1 kV, ±2 kV

Signal lines: not required, cable length <30 m

Coupling: 12 Ω / 9 µF

Number of repeats: 5

Conducted disturbances

0.15 mHz – 80 MHz, 3 V, 80% AM sine wave 1 kHz

50 Hz / 60 Hz

30 A/m

60 sec. for each axis

50 Hz / 60 Hz

30 A/m

60 sec. for each axis

EMC (Automotive)

Standard Test Description Test Parameter Current

variant

Articial network (AN):

150 kHz to 108 MHz, 1 m, 120 kHz bandwidth class 3

Ratiometric

voltage

variant

x -

x x

x x

x x

Ratiometric

voltage

variant

x x

CISPR 25/ECE R10 Emission

ISO 11452-2: 2004-11 Immunity

ISO 11452-4: 2011-12 Immunity

ISO 7637-2: 2004-09 Emission

ISO 7637-2: 2004-09 Emission

Road vehicles, electrical

disturbance by conduction

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Antenna measurement (RE):

160 kHz to 30 MHz, 1 m, 9 kHz bandwidth class 4

30MHz to 1 GHz, 1 m, 120 kHz bandwidth class 3

1 GHz to 2.5 GHz, 1 m, 120 kHz bandwidth class 5

Absorber lined chamber:

200 MHz to 2 GHz, 200 V/m

CW, AM (1 kHz/80%), PM (577 us duration, 217 Hz

repetition rate)

BCI:

20 MHz to 400 MHz, 200 mA, AM, (1 kHz, 80%)

Transient emissions on supply cables (12 V system)

Severity level:III: +75 V, -100 V

Transient emissions on supply cables (24 V system)

Severity level III: +150 V, -450 V

Pulse 1 (12 V system): -150 V, 5000 pulses

Severity level: IV

Pulse 1 (24 V system): -600 V, 5000 pulses

Severity level: IV

Pulse 2a (12 V system): +50 V, 5000 pulses

Severity level: IV

x x

x x

x -

x -

x -

x -

x -

© Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782 | 7

Page 8

Safety guide | DST P92S Pressure transmitter

Standard Test Description Test Parameter Current

variant

Road vehicles, electrical

disturbance by conduction

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-2: 2004-09

ISO 7637-3: 2007-07 Immunity

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Road vehicles, electrical

disturbance by conduction

and coupling (data, signal), test

level 4

Test level 4 for 12 V and 24V

systems

Pulse 2a (24 V system): +50 V, 5000 pulses

Severity level: IV

Pulse 2b (12 V system): +10 V, 10 pulses

Severity level: IV

Pulse 2b (24 V system): +20 V, 10 pulses

Severity level: IV

Pulse 3a (12 V system): -150 V, 1 hour

Severity level: IV

Pulse 3a (24 V system): -200 V, 1 hour

Severity level: IV

Pulse 3b (12V system):+100 V, 1 hour

Severity level: IV

Pulse 3b (24 V system):+200 V, 1 hour

Severity level: IV

Pulse 4 (12V system):-7 V, 1 pulse

Severity level: IV

Pulse 4 (24V system):-16 V, 1 pulse

Severity level: IV

Capacitive coupling (CCC)

12 V system

test level: IV (-110 V)

Test ime: 10 min.

24 V system

Test level: IV (-150 V)

test time: 10 min.

Ratiometric

voltage

variant

x -

x -

x -

x -

x -

x -

x -

x -

x -

x x

8 | © Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782

Page 9

Safety guide | DST P92S Pressure transmitter

Standard Test Description Test Parameter Current

variant

Capacitive coupling (CCC)

12 V system

test level: IV +75 V)

ISO 7637-3: 2007-07 Immunity

ISO 7637-3: 2007-07 Immunity

ISO 7637-3: 2007-07 Immunity

CISPR 25 Emission

ISO 10605: 2008-07 Electrostatic Discharge (ESD)

Test ime: 10 min.

24 V system

Test level: IV (+150 V)

test time: 10 min.

Capacitive coupling (ICC)

12 V system

test level: IV (-110 V)

Test ime: 10 min.

24 V system

Test level: IV (-150 V)

test time: 10 min.

Capacitive coupling (ICC)

12 V system

test level: IV (+75 V)

Test ime: 10 min.

24 V system

Test level: IV (+150 V)

test time: 10 min.

Conducted emission

150 kHz to 108 MHz

Powered-up test wit direct discharge:

- contact discharge:

±2 kV, ±4 kV, ±6 kV, ±8 kV

- air discharge

±4 kV, ±8 k±15 kV

Ratiometric

voltage

variant

x x

x x

x x

x x

x x

ISO 10605: 2008-07 Electrostatic Discharge (ESD)

ISO 10605: 2008-07 Electrostatic Discharge (ESD)

ISO 10605: 2008-07 Electrostatic Discharge (ESD)

3 discharges per test point

Powered-up test wit indirect discharge:

- contact discharge:

±2 kV, ±4 kV, ±6 kV, ±8 kV

50 discharges per test point

Unpowered-up test wit direct discharge:

- contact discharge to pins and connectors:

±2 kV, ±4 kV

3 discharges per test point

Unpowered-up test wit direct discharge:

- air discharge to surface:

±4 kV, ±8 k±15 kV

3 discharges per test point

x x

x x

x x

© Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782 | 9

Page 10

Safety guide | DST P92S Pressure transmitter

EMC (Functional Safety with Normal Condition)

Standard Test Description Test Parameter Current

variant

Direct discharge:

Contact discharge:

DIN EN 61000-4-2: 2009-12

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

Electrostatic Discharge (ESD

±6 kV

Air discharge:

±2 kV, ±4 kV, ±8 kV

10 discharges per test point

Indirect discharge (Horizontal coupling-plate):

DIN EN 61000-4-2: 2009-12

DIN EN 61326-3-1

DIN EN 61326-1

Electrostatic Discharge (ESD

Contact discharge:

±6 kV

DIN EN 61326-2-3

15 discharges per test jpoint.

Indirect discharge (Vertical coupling-plate):

DIN EN 61000-4-2: 2009-12

DIN EN 61326-3-1

DIN EN 61326-1

Electrostatic Discharge (ESD

Contact discharge:

±6 kV

DIN EN 61326-2-3

15 discharges per test jpoint.

DIN EN 61000-4-3: 2011-04

DIN EN 61326-3-1

DIN EN 61326-1

Immunity

80 MHz to 1.0 GHz (20 V/m)

1.4 GHz to 2.0 GHz (10 V/m)

2.0 GHz to 2.7 GHz (3 V/m)

DIN EN 61326-2-3

DIN EN 61000-4-3: 2013-04

DIN EN 61326-3-1

DIN EN 61326-1

Burst

Supply: ±3 kV (5/50 ns, 5 kHZ)

Signal: ±2 kV (5/50 ns, 5 kHz)

DIN EN 61326-2-3

Symmetrical coupling (L-N):

Supply lines: ±0.5 kV, ±1 Kv

Coupling: 2 Ω / 18 µF

DIN EN 61000-4-5: 2007-06

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

Surge

Unsymmetrical coupling (L-PE, N-PE, L-N-PE):

Supply lines: ±0.5 kV, ±1 kV, ±2 kV

Signal lines: not required for cable length < 30 m

Coupling: 12 Ω / 9 µF

Ratiometric

voltage

variant

x x

x x

x x

x x

x x

x x

DIN EN 61000-4-6: 2014

DIN EN 61326-3-1

DIN EN 61326-1

Immunity

DIN EN 61326-2-3

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

Voltage Dips

DIN EN 61000-4-29

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

Short Interruptions

DIN EN 61000-4-29

10 | © Danfoss | DCS (im) | 2020.01

Number of repeats: 5

Conducted disturbance

0.15 MHz - 80 MHz

10 V

80% AM sine wave 1kHz

V

: 40%

dip

Td: 10 ms

Tr: 10 s

Number of repeats: 3

V

: 100%

dip

Td: 20 ms

Tr: 10 s

Number of repeats: 3

x x

x x

x x

IC.PS.P21.2A.02 | 520B7782

Page 11

Safety guide | DST P92S Pressure transmitter

EMC (Functional Safety with Fail-safe Condition)

Standard Test Description Test Parameter Current

variant

Direct discharge:

Contact discharge:

DIN EN 61000-4-2: 2009-12

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

Electrostatic Discharge (ESD

±6 kV

Air discharge:

±2 kV, ±4 kV, ±8 kV

10 discharges per test point

Indirect discharge (Horizontal coupling-plate):

DIN EN 61000-4-2: 2009-12

DIN EN 61326-3-1

DIN EN 61326-1

Electrostatic Discharge (ESD

Contact discharge:

±6 kV

DIN EN 61326-2-3

15 discharges per test jpoint.

Indirect discharge (Vertical coupling-plate):

DIN EN 61000-4-2: 2009-12

DIN EN 61326-3-1

DIN EN 61326-1

Electrostatic Discharge (ESD

Contact discharge:

±6 kV

DIN EN 61326-2-3

15 discharges per test jpoint.

DIN EN 61000-4-3: 2011-04

DIN EN 61326-3-1

DIN EN 61326-1

Immunity

80 MHz to 1.0 GHz (20 V/m)

1.4 GHz to 2.0 GHz (10 V/m)

2.0 GHz to 2.7 GHz (3 V/m)

DIN EN 61326-2-3

DIN EN 61000-4-3: 2013-04

DIN EN 61326-3-1

DIN EN 61326-1

Burst

Supply: ±3 kV (5/50 ns, 5 kHZ)

Signal: ±2 kV (5/50 ns, 5 kHz)

DIN EN 61326-2-3

Symmetrical coupling (L-N):

Supply lines: ±0.5 kV, ±1 Kv

Coupling: 2 Ω / 18 µF

DIN EN 61000-4-5: 2007-06

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

Surge

Unsymmetrical coupling (L-PE, N-PE, L-N-PE):

Supply lines: ±0.5 kV, ±1 kV, ±2 kV

Signal lines: not required for cable length < 30 m

Coupling: 12 Ω / 9 µF

Ratiometric

voltage

variant

x x

x x

x x

x x

x x

x x

DIN EN 61000-4-6: 2014

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

DIN EN 61000-4-29

DIN EN 61326-3-1

DIN EN 61326-1

DIN EN 61326-2-3

DIN EN 61000-4-29

© Danfoss | DCS (im) | 2020.01

Immunity

Voltage Dips

Short Interruptions

Number of repeats: 5

Conducted disturbance

0.15 MHz - 80 MHz

10 V

80% AM sine wave 1kHz

V

: 40%

dip

Td: 10 ms

Tr: 10 s

Number of repeats: 3

V

: 100%

dip

Td: 20 ms

Tr: 10 s

Number of repeats: 3

x x

x x

x x

IC.PS.P21.2A.02 | 520B7782 | 11

Page 12

Safety guide | DST P92S Pressure transmitter

3.3 Environmental qualication

Standard Test Description Test Parameter Current

variant

5 Hz to 2000 Hz, 20 g

5 hours for each axis,

-40 °C to + 125 °C, 2 temperature cycles per axis,

directions: ±x, ±y, ±z

1 m free fall on concrete ground, 6 axes

10 Hz to 2000 Hz, broadband random, 32 hours for

each axis,

-40 °C to +85 °C, 4 tmperature cycles per axes

See ISO 16750-3:2012-12 clause 4.1.2.7

directions: ±x, ±y, ±z

DIN EN 60068-2-6: 2008-10

DIN EN 60068-2-14: 2010-04

DIN EN 60068-2-31: 2008

ISO 16750-3: 2012-12

DIN EN 60068-2-14: 2009

DIN EN 60068-2-64: 2008

ISO 16750-3: 2012-12

Environmental testing

- Vibration (sinusoidal) with

temperature prole

Environmental testing:

Free fall

Road vehicles Environmental conditions

and testing for electrical and

electronic equipment:

Mechanical loads Random vibration - Test VII

DIN EN 60068-2-27: 2009

DIN EN 60068-2-27: 2009

DIN EN 60068-2-2: 2008-05

ISO 16750-4: 2010-4

DIN EN 60068-2-2: 2008-05

ISO 16750-4: 2010-04

IEC 60068-2-14: 2009

DIN EN 60068-2-14: 2010-04

Environmental testing:

Shock

Environmental testing:

Bump

Environmental testing:

Cold storage

Environmental testing:

Dry heat (storage)

Environmental testing:

Change of temperature Na

50 g / 11 ms, half-sine wave, 3 shocks per direction

directions: ±x, ±y, ±z

Bumo, 30 g / 6 ms, half-sine wave, 3 shocks per

direction,

directions: ±x, ±y, ±y

24 hours with -40 °C

96 hours with 85 °C

-40 °C --> +85 °C, 100 cycles, duration time 1 hour,

temperature changes 10 seconds

Ratiometric

voltage

variant

x x

x x

x x

x x

x x

x x

x x

x x

IEC 60068-2-14: 2009

DIN EN 60068-2-14: 2010-04

IEC 60068-2-14: 2009

DIN EN 60068-2-14: 2010-04

ISO 16750-4: 2010-04

IEC 60068-2-30: 2005

DIN EN 60068-2-30: 2005

DIN EN 60068-2-78: 2014-02

IEC 60068-2-60: 1996-09

ISO 16750-4: 2010-04

DIN EN 60529: 2000-09

DIN 40050-9: 1993-05

Environmental testing:

Change of temperature Na

Environmental testing:

Life test, thermal shock

Environmental testing:

Ice water shock

Environmental testing:

Damp heat cyclic

Environmental testing:

Damp heat constant

Flowing mixed gas corrosin test

IP protection classes

ISO 16750-5: 2010-04 Chemical resistance

-40 °C --> +85 °C, 10 cycles

Weibull test according ISO 16750-1: 2003

: 60 Kelvin

ΔT

prac

Frequency of temperature dierences: twice a day

Number of days in the year: 365 days

Life time: 10 years

Cycles: 10

T

85 °C

max:

Duration time: 5 min.

+25 °C to 55 °C with 93% r.h. 6 cycles (each cycle 24

hours)

21 days with 40 °C and 93% r.h.

Sulfur dioxide SO2, hydrogen sulde H2S, nitrous

oxide NO2, Chlorine CI1

IP67/IP69K,

IP6KX Dust tight according to ISO 12103-1

Arizona test dust A2 ne

Gas / petrol, diesel, cleaner solvent, antifreeze, urea,

battery uid, brake uid, engine oil, hydraulic oil

x x

x x

x x

x x

x x

x x

x x

x x

12 | © Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782

Page 13

Safety guide | DST P92S Pressure transmitter

4. System information

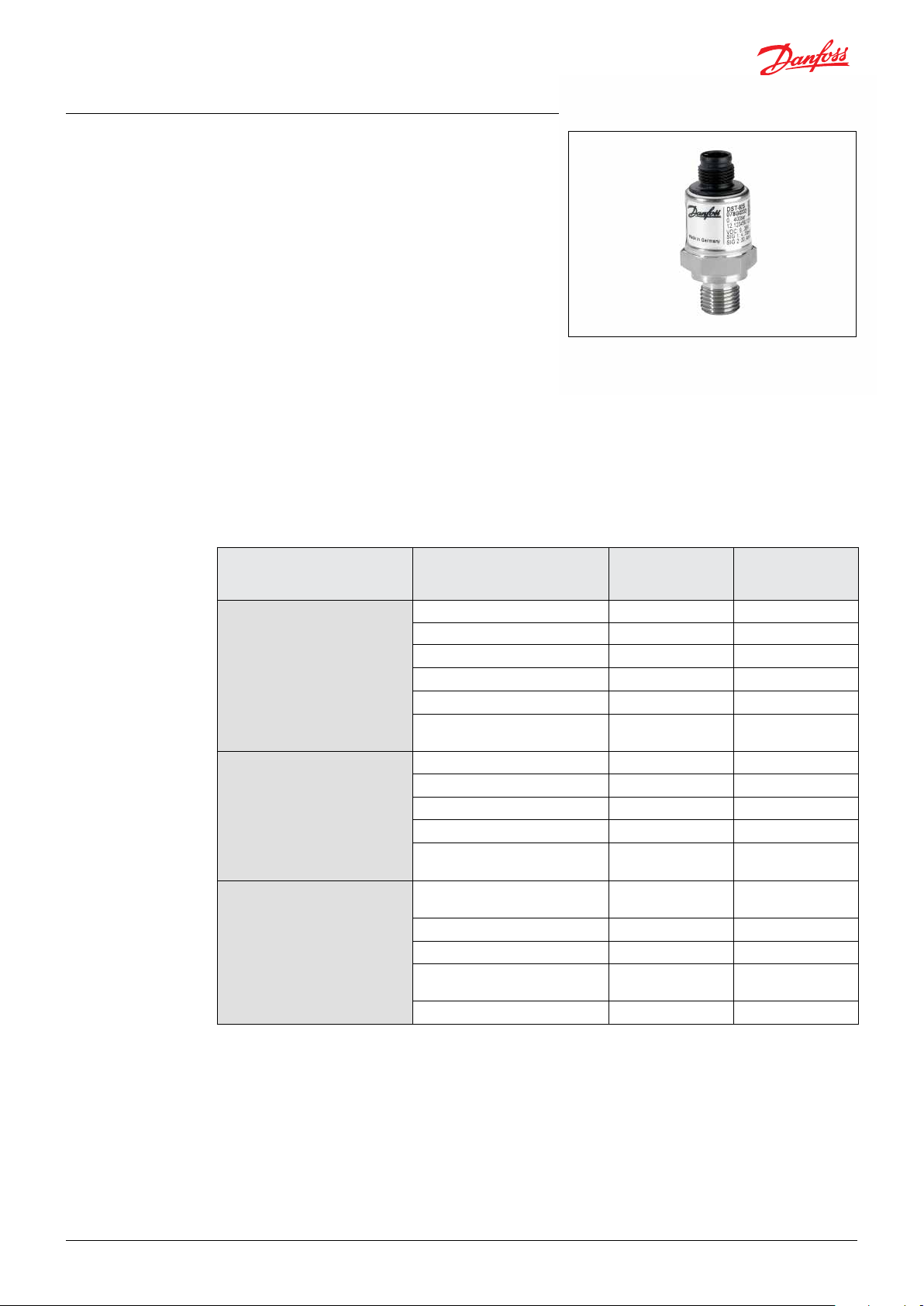

The DST P92S is designed for the operation

in working machinery and further suitable

application areas and qualied especially for use

under harsh conditions.

The pressure transmitter is a passive intelligent

sensor. Its basically function is to convert the

physical quantity “pressure” to an electrical signal.

Available output types:

Curent variant:

Current output signal. This variant provides two

opposing current outputs 4 – 20 mA and

20 – 4 mA.

Ratiometric voltage variant:

Ratiometric voltage output signal. This variant

provides two opposing ratiometric voltage

outputs 10% * VCC – 90% * C and

90% * VCC – 10% ' VCC

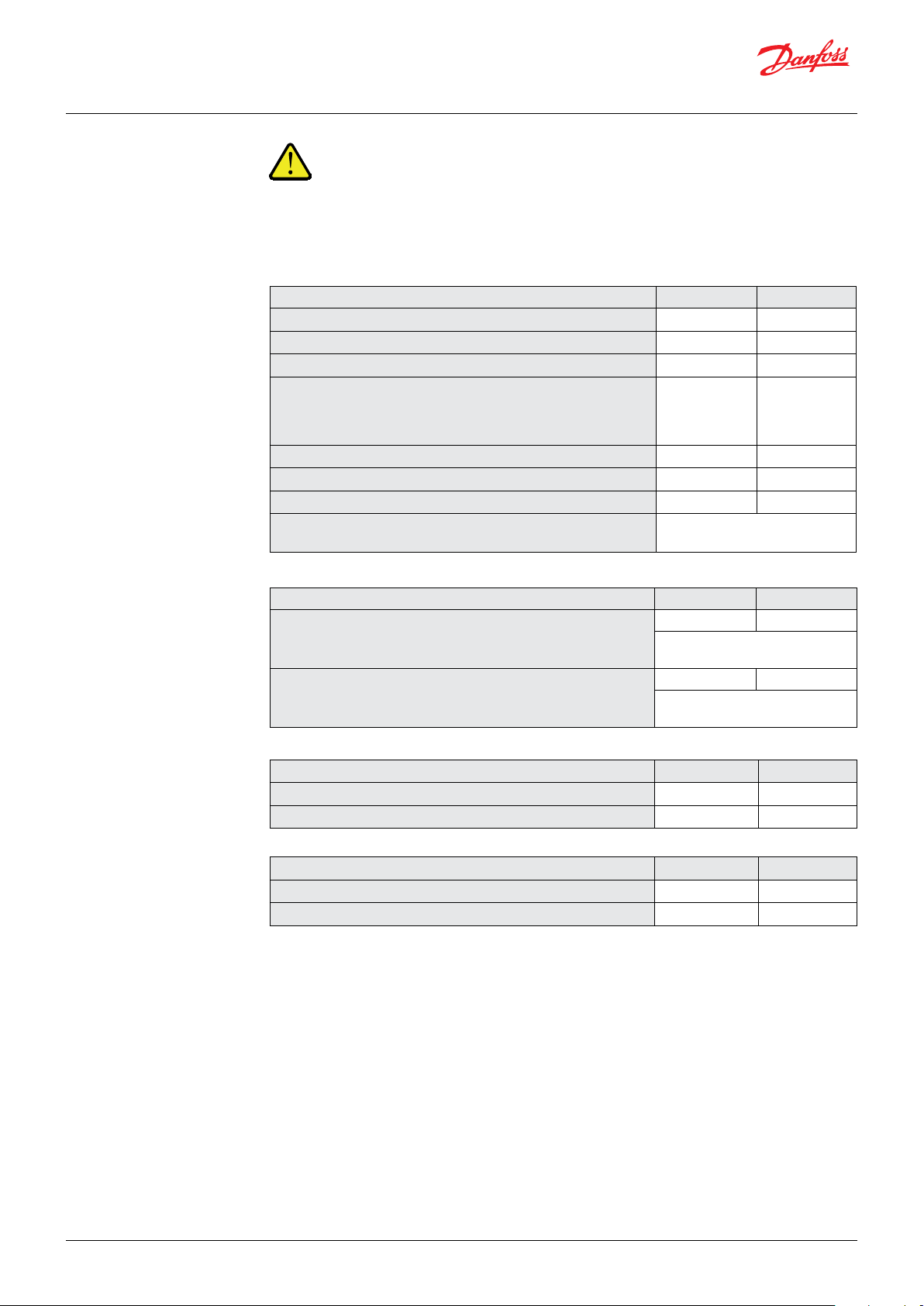

4.1 Functional safety classication

The DST P92S has the following functional safety classication and parameters:

Standard Description Parameters of

current variant

Safety Integrity Level (SIL) 2

Architecture 1oo1 (single channel) 1oo1 (single channel)

IEC 61508/1/ (see “Reference” on

page 3)

EN ISO 13849-1 /2/ (see “Reference”

on page 3)

ISO 25119/EN 16590/5/(see

“Reference” on page 3)

Hardware Failure Tolerance (HFT) 0

Safety-related subsystem Type B

Safe Failure Fraction (SFF) 95.8% *

Average frequency of dangerous

failure per hour (PFH)

Performance Level (PL) d

Category (Cat.) 2

Avg. Diagnostic Coverage (DC

Common Cause Failures (CCF) 70 points

Mean Time To dangerous

Failure (MTTFD)

Agricultural Oerformance level

(AgPL)

Category (Cat)

Avg. Diagnostic Coverage (DC

Mean Time to Dangerous

Failure (MTTFdc)

Sofware Requirement Level (SRL)

6.1 x 10-9 1/h

) 94.7% *

avg

981 years 2090 years

d d

2 2

)

94.7%* 91.0%*

avg

981 years 2090 years

Not relevant Not relevant

Parameters of the

ratiometric voltage

variant

2

0

Type B

93.1%*

4.9 x 10-9 1/h

d

2

91.0%*

70 points

* with an external monitoring according to this safety guide

© Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782 | 13

Page 14

Safety guide | DST P92S Pressure transmitter

4.2 Technical data

Pressure

Parameter Min. Max.

Nominel pressure range 0 - 10 bar 0 - 1200 bar

Overload (depending on pressure range) 50 bar 2400 bar

Installation torque of the pressure connection

Current output

Parameter Min. Max.

Current within nominal pressure range 4 mA 20 mA

Current at o-state 0 mA 2 mA

Current accuracy output SIG1 (depending on ambient temperature)

Tolerance for plausibility check current output SIG1 +

output SIG2

Current load (depending on power supply) 0 Ω 1325 Ω

Electrical protection

15 Nm

1% FS

35 Nm

2.5 % FS

Depending

on application

2.5 % FS

and ECU

tolerance: e.g.

3%FS

Short circuit protected (signal

on GND/VCC)

NOTE

• The accuracy is only guaranteed under

reference conditions (T

medium

= T

ambient

).

• The maximum current load depends on the

power supply and is calculated by R

MAX

=

(+UB - 5.5 V) / 0.02 A.

Operating area for current outputs of the current variant

14 | © Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782

Page 15

Safety guide | DST P92S Pressure transmitter

Output of ratiometric voltage variant

Parameter of the ratiometric voltage outputs

Parameter Min. Max.

Relative voltage withnin nominal pressure range

Relative voltage at o-state

Accuracy of output SIG1 (depending on ambient temperature)

Accuracy plausibility check output SIG1 + output SIG2

(depending on ambient temperature

Load Resistance

Load current

Capacitive load

Electrical protection

WARNING

If the application operates at

maximum load limit, pressures above

100% FS can not be displayed!

10%* VCC

0 V

1% FS

2.5% FS

90%* VCC

5%* VCC

2.5% FS

Depending on

application and

ECU tolerance:

e.g. 3% FS

≥ 10 kΩ

-

-

Short circuit protected

(signal on GND/VCC)

-

1.3 mA

10 nF

Power supply

Parameter Min. Max.

9 V DC 32 V DC

Current variant: Voltage supply (power supply pin VCC)

Ratiometric voltage variant: Voltage supply (power supply pin VCC)

Supply lines inverse-polarity

protected

4.5 V DC 5.5 V DC

Supply lines inverse-polarity oritec

ted with current limit of up to 2 A

General accuracy

Parameter Min. Max.

Linearity, pressure hysteresis and repeatability - 0.5% FS

Long-run stability - 0.2% FS

Timing

Parameter Min. Max.

Startup - 40 ms

Response time - 2 ms

© Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782 | 15

Page 16

Safety guide | DST P92S Pressure transmitter

Mechanical data

Component Description

Housing Welded stainless steel

Degree of protection IP67, IP69K

Electrical connection M12

Pressure connection G¼, ¼ NPT, 7/16 - 20 UNF and 9/16 - 18 UNF

Installation torque Maximum 35 Nm

Material with medium contact EN/DIN 1.4548 / FK

Material housing EN/DIN 1.4301

Material diagphragm EN/DIN 1.4548

Material connector PBT-GF30

Dimensions (W x H x D) DST P92S G¼ with M12x1 PBT: 54 x 22 x 26 mm (wrenchsize 22)

Weight DST P92S with M12x1 PBT: ca. 50 g

Operating chassis temperature

Ratiometric voltage variant

Operating chassis temperature

Current variant

DT04

DST P92S G¼ with DT04x1 PBT: 65 x 22 x 26 mm (wrenchsize 22)

-40 °C – 85 °C

Electrical connection

4.3 Technical drawings

M1¼¼2x1 , 5-pole PBT DT04, 4-pole PBT

Ø21.3

Ø21.3

G¼ ¼ NPT 7/16-20 UNF 9/16-18 UNF

Pressure connection

16 | © Danfoss | DCS (im) | 2020.01

G¼

14 NPT

7/16-20 UNF

(SAE 4)

9/16-18 UNF

(SAE 8)

IC.PS.P21.2A.02 | 520B7782

Page 17

Safety guide | DST P92S Pressure transmitter

4.4 Pin conguration

M12x1 DT04

Pin 1: VCC Power supply

Pin 2: SIG2 Inverse pressure signal output

Pin 3: GND Common ground

Pin 4: SIG1 Pressure signal output

Pin 5: - Do not connect

4.5 Wiring diagram

4.6 Safety functions

Pin 1: VCC Power supply

Pin 2: GND Common ground

Pin 2: SIG2 Inverse pressure signal output

Pin 4: SIG1 Pressure signal output

© Danfoss | DCS (im) | 2020.01

The pressure transmitter DST P92S executes following safety function:

Safety function Safety integrity Error reaction DTI

safe conversion of the measured pressure into two

proportional redundant-opposing current signals

or ratiometric voltage signals

(0..100 %FS correspond to 4..20 mA or

0..100 %FS correspond to 10% * VCC .. 90% * VCC)

IEC 61508 / SIL-2

EN ISO 13849 / PLd

ISO 25119 / AgPld

“Fail safe” 80 ms

Safety relevance:

1. Accuracy of the sum of the single current

2. Maximum conversion delay

NOTE

The outputs of the DST P92S are not

safe by temselves but in combination

with a redundant signal processing.

IC.PS.P21.2A.02 | 520B7782 | 17

Page 18

Safety guide | DST P92S Pressure transmitter

4.7 Diagnosis

5. Safety requirements

The DST P92S uses several mechanisms to

detect faults in the electronic circuit. Those are

realized in a start-up and a cyclic diagnosis.

Cyclic Diagnosis

The cyclic diagnosis is made every 30-40ms and

includes:

• testing of the temperature sensor element

Start-Up Diagnosis

The start-up diagnosis is made once after

powering the DST P92S and includes internal

tests concerning e.g. the oscillator, the

watchdog or any memory. If the start-up

• testing of the pressure sensor concerning

drift, open circuit and short circuit

• testing of the sensor signal range

If the cyclic diagnosis detects a fault, the “Fail safe”

is entered as long as the fault is pending.

diagnosis detects a fault, the “Fail safe” is

entered. The DST P92S remains in the safe state.

The following diagram shows the pressure transmitter DST P92S is a typical application

Sensor_Y_DST P92S

NOTE

Information:

Safety requirements within this manual

are characterized by an identier like

SR_DST P92S_<index>. This can be

used to trace requirements that shall

be followed through the development

process of the application.

18 | © Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782

Page 19

Safety guide | DST P92S Pressure transmitter

5.1 Known issues

5.2 Instructions and constraints

NOTE

There are no known issues for the

DST P92S

Safety standards

REQUIREMENT

SR_DST P92S_001:

The current national and international

safety regulations, laws, and standards

for the whole safety lifecycle have to be

observed.

Qualication of sta

REQUIREMENT

SR_DST P92S_002:

The pressure transmitter DST P92S must

be installed and operated by trained,

qualied personnel only. The knowledge

and the technical implementation of

the safety information provided by

this manual are imperative for a safe

installation and operation.

Method statement

REQUIREMENT

SR_DST P92S_003:

Before setting the DST P92S into

operation for an application it is

necessary to read and follow the

instructions of this safety manual.

The limits of the technical data (see

“Technical Data” item 4.2) must be

complied within the application.

Proof test interval

REQUIREMENT

SR_DST P92S_004:

A proof test interval of the pressure

transmitter DST P92S must be initiated

and controlled every 7½ years.

As the DST P92S can not be recalibrated,

it has to be replaced, if the deviations

exceed the maximum tolerances.

Troubleshooting procedures

REQUIREMENT

SR_DST P92S_005:

A faulty transmitter must be replaced

immediately. There is no maintenance or

repair procedure provided for the

DST P92S

CE Conformity

REQUIREMENT

SR_DST P92S_014:

For CD conformity the following

restrictions have to be observed:

The length of the cables, which are

connected to pressure transmitter, must

not exceed 30 m.

© Danfoss | DCS (im) | 2020.01

5.3 Fail Safe

The state fail safe of the pressure transmitter

DST P92S

Type of DST P92S Signal State fail safe M12 DT04

Current variant

Ratiometric voltage

variant

The safe state is entered when the DST P92S

recognizes a fault condition.

Both outputs go into the safe state simultaneous.

Output SIG1 Iout < 2 mA Pin 4 Pin 4

Output SIG2 Iout < 2 mA Pin 2 Pin 3

Output SIG1 Uout < 5% * VCC Pin 4 Pin 4

Output SIG2 Uout < 5% * VCC Pin 2 Pin 3

NOTE

Specication:

The maximum time between a fault

occurrence and the safe state of the

DST P92S is 80 ms.

REQUIREMENT

SR_DST P92S_006:

The fault detection cycle of the

superordinate logic system must be long

enough to detect an error reliably.

IC.PS.P21.2A.02 | 520B7782 | 19

Page 20

Safety guide | DST P92S Pressure transmitter

Example:

The following time diagram shows the DST P92S

in a typical “sensor-logic-actuator” application

e.g. with and electronic control unit.

DST P92S Operation Interval

DST P92S Safe state

Reset condition

NOTE

Specication:

If a fault condition isn’t pending

continously, the DST P92S will leave the

safe state earliest after 60 ms.

REQUIREMENT

SR_DST P92S_007:

The diagnostic test interval of the

superordinate logic system must be short

enough to detect the safe state reliably.

5.4 System

System overview

Restrictions

WARNING

The safe state may not be entered during

an over- or under-voltage condition or

during startup. Possibly occurring spikes

on the outputs have to be ignored.

REQUIREMENT

SR_DST P92S_022:

The superordinate logic system has

to consider non-functional operating

modes, which do not lead to a safe state.

20 | © Danfoss | DCS (im) | 2020.01

REQUIREMENT

SR_DST P92S_008:

Exceeding the maximum supply voltage

of the DST P92S may cause an unsafe

operation. Therefore the superordinate

logic system has to monitor the sensor

power supply.

DST P92S

REQUIREMENT

SR_DST P92S_018:

Take measures to avoid an overvoltage

condition at the DST P92S.

IC.PS.P21.2A.02 | 520B7782

Page 21

Safety guide | DST P92S Pressure transmitter

REQUIREMENT

SR_DST P92S_009:

Running the DST P92S outside its

temperature limits may cause an unsafe

operation. Therefore the superordinate

logic system has to monitor the ambient

temperature.

REQUIREMENT

SR_DST P92S_019:

There have to be taken measures to

avoid an over- or under-temperature

condition at the DST P92S.

5.5 Pressure

The pressure is measured by a welded thin-lm

capsule, which converts the physical pressure

into an electrical signal by resistor full-bridge.

An additional temperature meander makes

itpossible to compensate the signal.

Functional diagram

REQUIREMENT

SR_DST P92S_021:

The chassis, in which the DST P92S is

mounted, has to be connected to the

power supply ground, to fulll the EMC

requirements.

© Danfoss | DCS (im) | 2020.01

REQUIREMENT

SR_DST 92S_010:

Because the radius of the pressure

channel of the DST P92S is very small,

measures must be taken for the pressure

system to prevent its clogging.

REQUIREMENT

SR_DST P92S_011:

Running the DST P92S outside its

temperature limits may cause an unsafe

operation. Therefore, the superordinate

logic system has to monitor the pressure

medium temperature.

REQUIREMENT

SR_DST 92S_024:

The thread shall be made of stainless

steel and shall be free of lubricant.

RECOMMENDATION

Avoid to exceed the specied pressure

ranges of the used DSR P92S. For a

smooth operation the pressure system

should be able to provide a stable nonuctuating pressure.

The accuracy of the pressure

measurement is only guaranteed under

reference conditions, that means if

the medium temperature and the

ambient temperature is nearly the same.

Therefore measures should be taken to

eect this.

IC.PS.P21.2A.02 | 520B7782 | 21

Page 22

Safety guide | DST P92S Pressure transmitter

WARNING

A drift of the measurement cell due to an

overpressure as well as an aging-related

drift can only be detected at the pressure

limits (0 %FS, 100 %FS) of the DST P92S.

5.6 Outputs

The outputs of the DST P92S are designed as

redundant inverted signals. The inverted signals

can be used to establish a redundant signal

processing for safety-related applications.

Signal diagram

Output signal Range of current variant Range of ratiometric voltage

variant

SIG1 4 – 20 mA 10% * VCC – 90% * VCC

SIG2 20 – 4 mA 90% * VCC – 10% * VCC

90% VCC /

20 mA

SIG2

10% VCC /

4 mA

REQUIREMENT

SR_DST P92S_012:

The superordinate logic system has to

provide safety-related input pairs, which

fulll the reservations of the

DST P92S outputs (see technical data

(see “Technical Data” item 4.2).

(Especially the requirements for the

minimum and maximum loading of the

current outputs have to be observed.)

REQUIREMENT

SR_DST P92S_020:

The superordinate logic system

has to process both output signals

simultaneously and to compare them in

a meaningful way.

SIG1

REQUIREMENT

SR_DST P92S_013:

The measured pressure is always

represented by output 1. Output 2 must

only be used for the safety function,

as it is not calibrated and temperature

compensated.

REQUIREMENT

SR_DST P92S_017

The superordinate logic system has to

check, if there is a short circuit between

the DST P92S outputs. Depending on the

applications, this must be done cyclically

or at start-up.

22 | © Danfoss | DCS (im) | 2020.01

RECOMMENDATION

For signal processing the two output

values should be accumulated by

the application and be compared to

predened limits (e.g. 24 mA ± 3 %FS).

IC.PS.P21.2A.02 | 520B7782

Page 23

Safety guide | DST P92S Pressure transmitter

Outputs of ratiometric voltage variant

With the ratiometric voltage variant the supply

and outout pins of the signal conditioning are

directly connected to the connector.

Output of current variant

With the current variant the signal conditioning

is supplied via a DC/DC converter and its outputs

are used to generate the current signals.

REQUIREMENT

SR_DST P92S_015:

A ratiometric voltage value of <7.5%*VCC

or >92.5%*VCC may be the result of

a damaged DST P92S. Therefore,, the

superordinate logic system must be able

to check the current range and react on

an invalid value.

REQUIREMENT

SR_DST P92S_025:

In case of an electronic ground loss

(GND), the two output signals have no

dened level. The superordinate logic

system must perform a plausibility check

of the two output signals (See SR_DST

P92S_020 and SR_DST_P92S_017).

© Danfoss | DCS (im) | 2020.01

REQUIREMENT

SR_DST P92S_016:

A current value < 3.5 mA or > 20.5 mA

may be the result of a damaged

DST P92S. Therefore the superordinate

logic system must be able to check the

current range and react on an invalid

value.

RECOMMENDATION

To check, if there is a short circuit

between the DST P92S current outputs,

one of them could be additional loaded,

e.g. with a programmable pull-down

resistor. The other one should not

change its value.

RECOMMENDATION

If the inputs of superordinate logic

system do not provide suitable load

resistors as required in the technical

data (see “Technical Data” item 4.2 ),

an additional series resistance can

be connected to the wiring. (See

“Examples”)

IC.PS.P21.2A.02 | 520B7782 | 23

Page 24

Safety guide | DST P92S Pressure transmitter

5.7 Decommissioning and disposal 5.8 Security

NOTE

For the DST P92S there has nothing to be

considered regarding decommissioning.

The disposal of the DST P92S has to be

done according to national laws.

6. Transport and storage

7. Maintenance There is no main tenance or repair procedure

8. Mounting

Transport

Check the pressure transmitter for possible

transport damage.

Do not use damaged deivces.

provided for the DST P92S (See “Instructions

and Constraints” item 5.2).

Preconditions

• Provide an ESD suitable environment

• Provide a dry and clean environment

• The thread and all sealing faces of the

pressure transmitter must be undamaged

and clean

• Apply the force to screw the pressure

sensor only through the spanner ats

provided for this purpose

• Select a cable diameter that matches the

cable connector of the mating plug

• Protect the cable end from humidity.

Otherwise humidity can intrude into the

instrument

See Mechanical Dimensions r needed space.

WARNING

Danger of serious injury and/or damage

to the equipment, when used beyond

the specied operative range.

Ensure to select the right type of

pressure transmitter according to:

• pressure range

• measurement range

• specic measurement conditions

NOTE

For the DST P92S there has nothing to be

considered regarding security.

Storage

Store the pressure transmitter in its original

packaging.

Remove the packaging only immediately before

mounting. The packaging provides protection

during storage and transport.

Required tools

Torque wrench: Width across ats 22

How to mount

WARNING

Danger of serious injury from sudden

escaping pressurized media.

Before opening any connections, make

sure to:

• Disconnect energy source

• Prevent reconnection

• Depressurize the system, including

pressure accumulators, lower upheld

load or provide compression-resistant

support for upheld load, remove

resifual energy

• Test the system for absence of

pressure

• Prevent danger due to adjacent

systems components

1. Screw the DST P92S into your system by

hand. Do not damage the thread, otherwise

a sealing connection cannot be established.

2. Tighten the DST P92S with the torque

wrench and a maxmimal screwing-torque of

35 Nm

3. Connect the connector with opposite plug:

Make sure the sealing of the connector is

present. Make sure to latch the connector

into the opposite plug.

4. Attach the used cables for DST P92S with

a cable relief. No force must act on the

connector and cables. Do not bend the cable

with a radius smaller than 18 mm.

24 | © Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782

Page 25

Safety guide | DST P92S Pressure transmitter

9. Dismounting Preconditions

• Provide an ESD suitable environment

• The connected pressure transmitter must

be cleaned

• Apply the force to screw o the pressure

transmitter only through the spanner ats

provided for this purpose

Required tools

Wrench: Width across ats 22

How to dismount

WARNING

Danger of serious injury from sudden

escaping pressurized media.

Before opening any connections, make

sure to:

• Disconnect energy source

• Prevent reconnection

• Depressurize the system,

including pressure accumulators,

lower upheld load or provide

compression-resistant support for

upheld load, remove resifual energy

• Test the system for absence of

pressure

• Prevent danger due to adjacent

systems components

1. Make sure the system is depressurized.

2. Remove cable relief from the cables. Do not

damage the cables.

3. Disconnect the connetor from mating plug.

4. Screw of DST P92S from your system with

the wrench. Do not damage the threads.

© Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782 | 25

Page 26

Danfoss A/S

Industrial Automation

Nordborgvej 81

DK-6430 Nordborg

Denmark

www.ia.danfoss.com

© Danfoss | DCS (im) | 2020.01

IC.PS.P21.2A.02 | 520B7782 | 26

Loading...

Loading...