Page 1

Operation guide

Pressure transmitter

CAN SAE J1939

DST P92C

ia.danfoss.com

Page 2

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

Table of contents

1. General Information

Contents

1. General information................................................................................................................................... 2

1.1 Contact........................................................................................................................................................... 2

1.2 General............................................................................................................................................................ 2

1.3 CAN Interface................................................................................................................................................ 3

2. Specifications............................................................................................................................................... 3

3. J1939 communication.............................................................................................................................. 3

3.1 Introduction................................................................................................................................................. 3

3.2 Supported PGN’s and SPN’s.................................................................................................................... 4

3.3 PGN of Danfoss........................................................................................................................................... 10

3.4 Definitions..................................................................................................................................................... 11

3.4.1 PGN.................................................................................................................................................................. 11

3.4.2 SPN.................................................................................................................................................................. 11

3.5 Overview of the slot for pressure sensors......................................................................................... 11

3.6 Additionally, Danfoss specific ............................................................................................................... 12

3.7 References.................................................................................................................................................... 12

1.1 Contact

Danfoss A/S

Industrial Automation

DK-6430 Nordborg

Denmark

www.ia.danfoss.com

E-mail: technical support_IA@danfoss.com

1.2 General

The pressure transmitter DST P92C measures the

physical quantity pressure. The range depends on

the sensor which is used in the transmitter and

is 25–800 bar. The measured value is transmitted

on the CAN-Bus with the J1939 protocol. The

transmitter takes 1000 samples per second, does

filtering and converts the raw value into the

output format.

The CAN 2.0B interface is able to run up to

a speed of 1 Mbit/sec with 11-bit and 29-bit

identifiers.

1.3 CAN Interface

The device includes a Full CAN controller

specified to CAN 2.0B. The physical layer of the

2-wire interface is specified according to ISO

11898. The wires are protected against shortcircuit. By adjusting the rise and fall times of the

CAN signals, the noise emission is minimized.

The bus termination resistor is not included in

the device.

2 | © Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799

Page 3

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

5

3

2

Danfoss

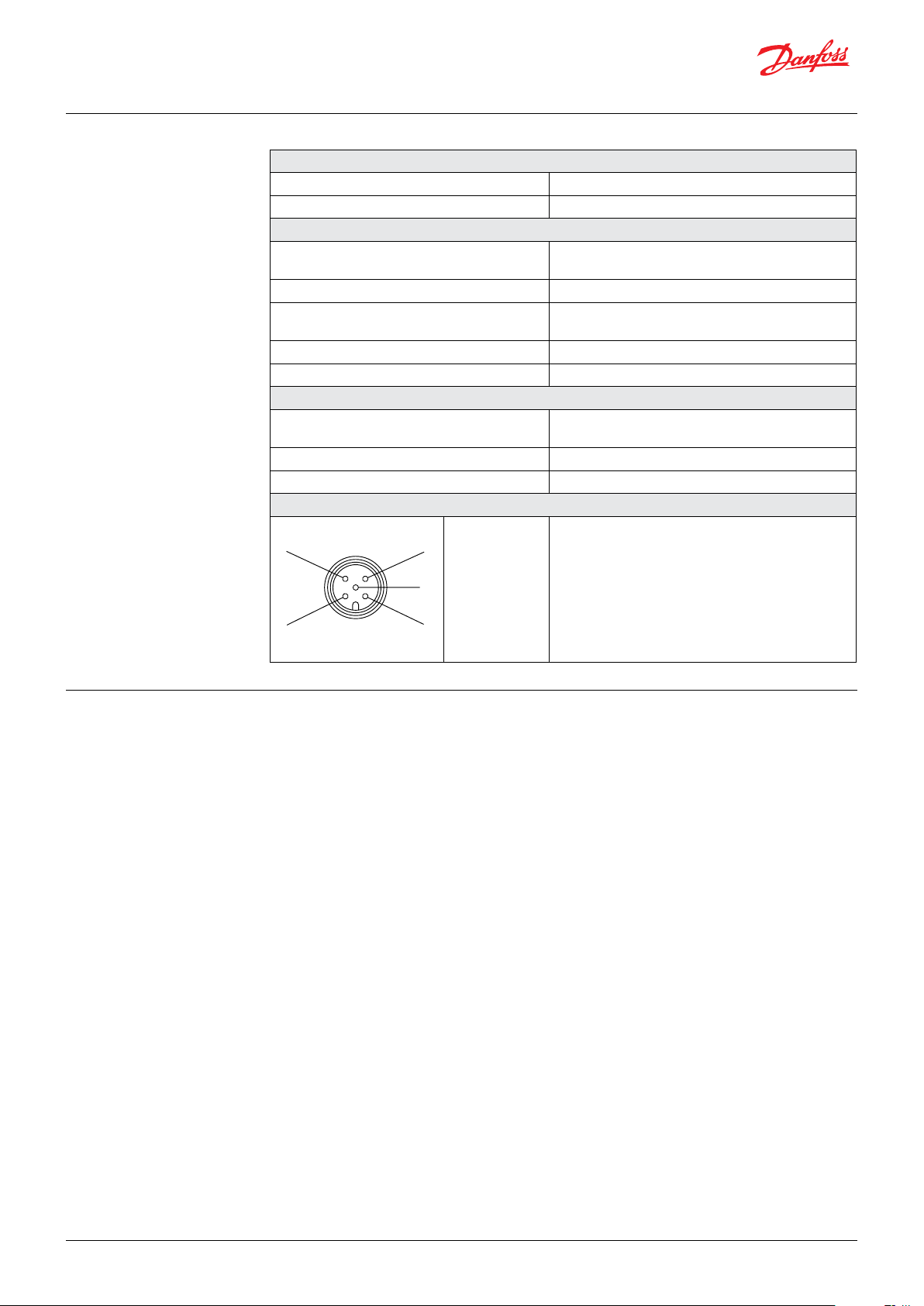

2. Specifications

Electrical specifications

Supply voltage 9 – 36 V DC protected against reverse polarity

Current consumption at U

= 24 V DC I < 50 mA typical, IMAX < 100 mA

S

CAN Interface

Physical layer

2-wire interface, 5 V level according to ISO 11898

Protected against short-circuit

Bit rate 250 kBit/s

Signal rise time

Bit rate < 125 kbit/s 12 V/µs (without bus)

Bit rate ≥ 125 kbit/s > 24 V/µs (without bus)

Bus termination External

Protokoll SAE J1939

Environment

EMC

EN 61000-6-2

EN 61000-6-4

Operating temperature -40 – 125 °C

Media temperature -40 – 150 °C

M12 connector Pin Assignment (CiA DR303-1)

4

A78G09

1

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

CAN shield, PE

+U

, +24 V DC

B

GND, 0 V

CAN_H, CAN+

CAN_L, CAN-

3. J1939 Communication

3.1 Introduction

The Society of Automotive Engineers (SAE)

developed the 1939 standard to be the

preferred CAN for equipment used in industries

ranging from agriculture, construction, and fire/

rescue to forestry, materials handling as well as

on and off-highway vehicles. It is a high-level

protocol that defines how communication

between nodes (modules) occurs on the bus.

The 1939 network is a specific communication

system, supporting specific sets of applications

and a specific industry, rather than being

generalized.

Any electronic control unit (ECU) using J1939

is permitted to transmit a message on the

network when the bus is idle. Every message

includes a 29-bit identifier, which defines the

message priority, what data is contained within

the 8-byte data array that follows the identifier,

and which ECU sent the message.

© Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799 | 3

Page 4

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

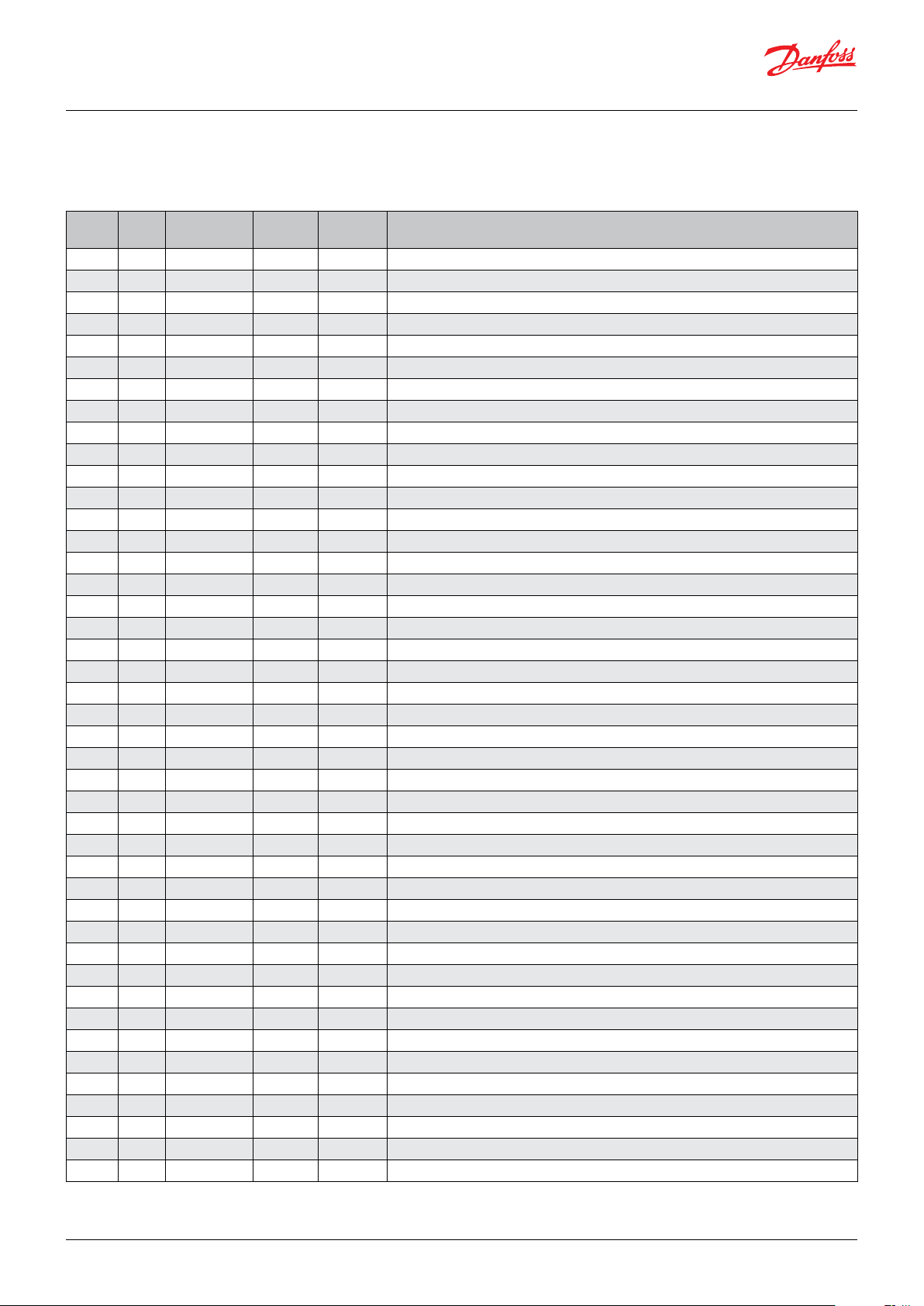

3.2 Supported PGN’s and SPN’s

PGN’s of SAE J1939

PGN SPN TTR [ms]

61448 1762 50 1-2 SAEpr08 Hydraulic Pressure

61448 6707 50 4-5 SAEpr20 Hydraulik Intake Pressure

61448 6708 50 6-7 SAEpr08 Hydraulic Discharge Pressure Set Point

61475 4334 50 6 SAEpr13 Aftertreatment 1 Diesel Exhaust Fluid Doser 1 Absolute Pressure

61478 4387 50 6 SAEpr13 Aftertreatment 2 Diesel Exhaust Fluid Doser 1 Absolute Pressure

61538 6583 10 1-2 SAEpr22 Tranmission Hydrostatic Loop 1 Pressure

61538 6584 10 3-4 SAEpr22 Tranmission Hydrostatic Loop 2 Pressure

64557 6787 500 1-2 SAEpr03 LNG Tank 1 Vapor Pressure

64557 6788 500 3-4 SAEpr03 LNG Tank 2 Vapor Pressure

64559 7350 1000 4 SAEpr13 Fire Suppression Compressed Air Foam System Air Pressure

64563 7100 500 1-2 SAEpr12 Engine Injector Metering Rail 1 Desired Pressure

64563 7101 500 3-4 SAEpr12 Engine Injector Metering Rail 2 Desired Pressure

64564 7096 500 1-2 SAEpr12 Engine Injector Metering Rail 1 Pressure 1 (Extended Range)

64564 7097 500 3-4 SAEpr12 Engine Injector Metering Rail 1 Pressure 2 (Extended Range)

64564 7098 500 5-6 SAEpr12 Engine Injector Metering Rail 2 Pressure 1 (Extended Range)

64564 7099 500 7-8 SAEpr12 Engine Injector Metering Rail 2 Pressure 2 (Extended Range)

64569 7067 500 1-2 SAEpr06 Plant Gaseous Fuel Supply Outlet Pressure

64569 7068 500 3-4 SAEpr06 Plant Inert Gas Supply Outlet Pressure

64570 7063 500 1-2 SAEpr06 Engine Gaseous Fuel Supply Pressure 2

64570 7064 500 3-4 SAEpr06 Gaseous Fuel Supply Unit Intake Pressure

64570 7065 500 5-6 SAEpr06 Gaseous Fuel Supply Shutoff Valve 1 Intake Pressure

64570 7066 500 7-8 SAEpr06 Gaseous Fuel Supply Shutoff Valve 2 Intake Pressure

64576 7019 500 4-5 SAEpr08 Engine Fuel 2 Pump Hydraulic Pressure

64577 7021 500 1-2 SAEpr08 Engine Fuel 2 Injector Metering Rail 1 Pressure

64577 7022 500 3-4 SAEpr08 Engine Fuel 2 Injector Metering Rail 2 Pressure

64577 7513 500 7-8 SAEpr08 Engine Fuel 2 Injector Metering Rail 1 Pressure 2

64578 6988 10000 2-3 SAEpr22 Time Pressure (Extended Range)

64578 6989 10000 4-5 SAEpr22 Required Tire Pressure

64579 6980 on request 2-3 SAEpr22 Cold Inflation Pressure

64589 6876 500 1 SAEpr10 Aftertreatment 2 Diesel Exhaust Fluid Dosing Pressure

64590 6875 500 1 SAEpr10 Aftertreatment 1 Diesel Exhaust Fluid Dosing Pressure

64590 7459 500 2 SAEpr13 Aftertreatment 1 Diesel Exhaust Fluid Doser 2 Absolute Pressure

64595 6837 500 4 SAEpr10 Gas Leakage Detection 1 Pressure

64595 6838 500 5 SAEpr10 Gas Leakage Detection 2 Pressure

64595 6839 500 6 SAEpr10 Gas Leakage Detection 3 Pressure

64600 6811 1000 1 SAEpr10 Engine Turbocharger 2 Lube Oil Pressure

64600 6812 1000 2 SAEpr10 Engine Turbocharger 3 Lube Oil Pressure

64600 6813 1000 3 SAEpr10 Engine Turbocharger 4 Lube Oil Pressure

64655 6646 100 1 SAEpr09 Engine Gaseous Fuel Supply Pressure (Extended Range)

64656 6589 500 1-2 SAEpr09 Engine Injector Metering Rail 1 Pressure 1

64656 6590 500 3-4 SAEpr09 Engine Injector Metering Rail 1 Pressure 2

64656 6591 500 5-6 SAEpr09 Engine Injector Metering Rail 2 Pressure 1

64656 6592 500 7-8 SAEpr09 Engine Injector Metering Rail 2 Pressure 2

Data

Position

Slot SPN Name

4 | © Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799

Page 5

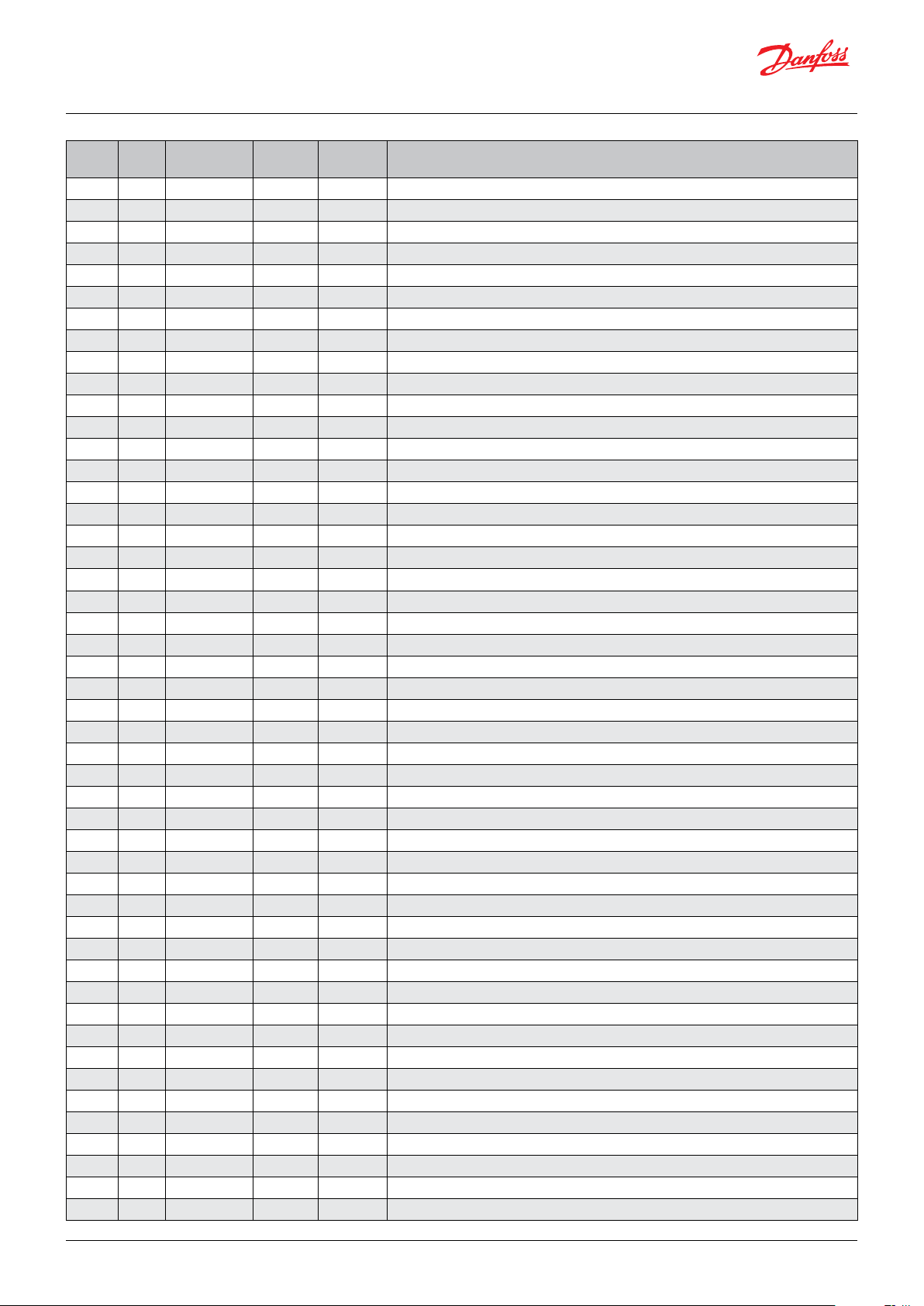

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

PGN SPN TTR [ms]

64659 6571 on request 1-2 SAEpr03 Engine Main Chamber Fuel Absolute Pressure

64659 6572 on request 3-4 SAEpr03 Engine Main Chamber Fuel Desired Absolute Pressure

64659 6573 on request 5-6 SAEpr03 Engine Prechamber Fuel Absolute Pressure

64659 6574 on request 7-8 SAEpr03 Engine Prechamber Fuel Desired Absolute Pressure

64662 6384 100 1-2 SAEpr04 Engine Exhaust Pressure 1 (Extended Range)

64662 7470 100 3-4 SAEpr03 Engine Pre-Filter Oil Pressure (High Resolution/Extended Range)

64671 6321 1000 1-2 SAEpr01 Engine Oil Filter Differential Pressure (Extended Range)

64705 5927 1000 1 SAEpr14 Transmission Clutch 2 Pressure

64733 5590 500 1-2 SAEpr03 Aftertreatment 2 Secondary Air Absolute Pressure

64734 5589 500 1-2 SAEpr03 Aftertreatment 1 Secondary Air Absolute Pressure

64735 5578 500 1 SAEpr10 Engine Fuel Delivery Absolute Pressure

64735 5579 500 2 SAEpr10 Engine Filtered Fuel Delivery Pressure

64735 5580 500 3 SAEpr10 Engine Filtered Fuel Delivery Absolute Pressure

64735 6816 500 5 SAEpr17 Engine Fuel Return Pressure

64735 7472 500 8 SAEpr11 Engine Fuel Supply Pump Intake Absolute Pressure (Extended Range)

64739 5541 100 1 SAEpr07 Engine Turbocharger 1 Turbine Outlet Pressure

64739 5542 100 2 SAEpr07 Engine Turbocharger 1 Turbine Desired Outlet Pressure

64739 5544 100 4 SAEpr07 Engine Turbocharger 2 Turbine Outlet Pressure

64739 5545 100 5 SAEpr07 Engine Turbocharger 2 Turbine Desired Outlet Pressure

64751 5430 500 1-2 SAEpr03 Engine Exhaust Gas Recirculation 1 Intake Absolute Pressure

64751 5431 500 3-4 SAEpr03 Engine Exhaust Gas Recirculation 1 Outlet Absolute Pressure (High Resolution)

64751 7468 500 5-6 SAEpr03 Engine Oil Pressure (High Resolution/Extended Range)

64751 7469 500 7-8 SAEpr03 Engine Fuel Delivery Pressure (High Resolution/Extended Range)

64752 5417 500 1 SAEpr07 Engine Fuel Filter (Suction Side) Intake Absolute Pressure

64752 7395 500 4-5 SAEpr03 Fuel Tank Transfer Pump Pressure

64765 5313 100 5-6 SAEpr09 Commanded Engine Fuel Rail Pressure

64765 5314 100 7-8 SAEpr09 Commanded Engine Fuel Injection Control Pressure

64766 5259 on request 3-4 SAEpr06 Engine Exhaust Gas Recirculation 2 Cooler Intake Gas Absolute Pressure

64768 5252 500 1-2 SAEpr01 Engine Exhaust Gas Recirculation 2 Differential Pressure

64768 5253 500 3 SAEpr07 Engine Exhaust Gas Recirculation 2 Intake Pressure

64768 5254 500 4-5 SAEpr03 Engine Exhaust Gas Recirculation 2 Outlet Absolute Pressure

64768 5429 500 6-7 SAEpr03 Engine Exhaust Gas Recirculation 2 Intake Absolute Pressure

64768 5708 500 8 SAEpr07 Engine Coolant Pressure 2

64799 4773 500 5-6 SAEpr06 Aftertreatment 2 Diesel Oxidation Catalyst Differential Pressure

64800 4767 500 5-6 SAEpr03 Aftertreatment 1 Diesel Oxidation Catalyst Differential Pressure

64801 4761 500 SAEpr03 Aftertreatment 2 Gas Oxidation Catalyst Differential Pressure

64802 4755 500 5-6 SAEpr03 Aftertreatment 1 Gas Oxidation Catalyst Differential Pressure

64817 1707 1000 5-6 SAEpr06 Hydraulic Fan 2 Motor Pressure

64825 4411 500 1-2 SAEpr03 Aftertreatment 2 SCR Differential Pressure

64825 6587 500 4-5 SAEpr18 Aftertreatment 2 SCR Intake Pressure

64825 6798 500 6-7 SAEpr03 Aftertreatment 2 SCR Intake Absolute Pressure

64827 4388 500 1 SAEpr13 Aftertreatment 2 SCR Dosing Air Assist Absolute Pressure

64831 4358 500 1-2 SAEpr03 Aftertreatment 1 SCR Differential Pressure

64831 6586 500 4-5 SAEpr18 Aftertreatment 1 SCR Intake Pressure

64831 6797 500 6-7 SAEpr03 Aftertreatment 1 SCR Intake Absolute Pressure

64833 4335 500 1 SAEpr13 Aftertreatment 1 SCR Dosing Air Assist Absolute Pressure

64836 4303 500 1-2 SAEpr03 Aftertreatment 2 Fuel Pressure 2

64837 4297 500 5-6 SAEpr03 Aftertreatment 2 Three Way Catalyst Differential Pressure

Data

Position

Slot SPN Name

© Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799 | 5

Page 6

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

PGN SPN TTR [ms]

64838 4291 500 5-6 SAEpr03 Aftertreatment 1 Three Way Catalyst Differential Pressure

64869 4077 500 1-2 SAEpr03 Aftertreatment 1 Fuel Pressure 2

64876 3833 500 1-2 SAEpr01 Aftertreatment 2 Secondary Air Differential Pressure

64876 3838 500 7-8 SAEpr03 Aftertreatment 2 Secondary Air Pressure

64877 3830 500 1-2 SAEpr01 Aftertreatment 1 Secondary Air Differential Pressure

64877 3837 500 7-8 SAEpr03 Aftertreatment 1 Secondary Air Pressure

64879 4751 on request 5-6 SAEpr06 Engine Exhaust Gas Recirculation 1 Cooler Intake Absolute Pressure

64900 3640 500 1-2 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #17

64900 3641 500 3-4 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #18

64900 3642 500 5-6 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #19

64900 3643 500 7-8 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #20

64901 3636 500 1-2 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #13

64901 3637 500 3-4 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #14

64901 3638 500 5-6 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #15

64901 3639 500 7-8 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #16

64902 3632 500 1-2 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #9

64902 3633 500 3-4 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #10

64902 3634 500 5-6 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #11

64902 3635 500 7-8 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #12

64903 3628 500 1-2 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #5

64903 3629 500 3-4 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #6

64903 3630 500 5-6 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #7

64903 3631 500 7-8 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #8

64904 3624 500 1-2 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #1

64904 3625 500 3-4 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #2

64904 3626 500 5-6 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #3

64904 3627 500 7-8 SAEpr03 Engine Intake Valve Actuation Oil Pressure for Cylinder #4

64907 3611 500 1-2 SAEpr03 Aftertreatment 2 Diesel Particulate Filter Intake Pressure

64907 3612 500 3-4 SAEpr03 Aftertreatment 2 Diesel Particulate Filter Outlet Pressure

64908 3609 500 1-2 SAEpr03 Aftertreatment 1 Diesel Particulate Filter Intake Pressure

64908 3610 500 3-4 SAEpr03 Aftertreatment 1 Diesel Particulate Filter Outlet Pressure

64916 5312 100 7-8 SAEpr04 Engine Intake Manifold Commanded Pressure

64926 3499 500 1-2 SAEpr03 Aftertreatment 2 Supply Air Pressure

64926 3500 500 3-4 SAEpr03 Aftertreatment 2 Purge Air Pressure

64927 3485 500 1-2 SAEpr03 Aftertreatment 1 Aupply Air Pressure

64927 3486 500 3-4 SAEpr03 Aftertreatment 1 Purge Air Pressure

64928 3494 500 1-2 SAEpr03 Aftertreatment 2 Fuel Pressure 1

64929 3480 500 1-2 SAEpr03 Aftertreatment 1 Fuel Pressure 1

64930 3466 500 1-2 SAEpr03 Engine Fuel Valve 2 Intake Absolute Pressure

64930 3469 500 7-8 SAEpr03 Engine Fuel Valve 2 Outlet Absolute Pressure

64938 3340 500 1 SAEpr07 Engine Charge Air Cooler 1 Intake Pressure

64938 3341 500 2 SAEpr07 Engine Charge Air Cooler 2 Intake Pressure

64938 3342 500 3 SAEpr17 Engine Coolant Pump Differentieal Pressure

64938 2631 500 8 SAEpr07 Engine Charge Air Cooler Outlet Pressure

64943 3285 500 5-6 SAEpr03 Aftertreatment 2 Diesel Particulate Filter Differential Pressure

64946 3251 500 5-6 SAEpr03 Aftertreatment 1 Diesel Particulate Filter Differential Pressure

64953 3191 on request 2 SAEpr13 Reference Tire Pressure

64961 2948 500 1-2 SAEpr09 Engine Intake Valve Actuation System Oil Pressure

Data

Position

Slot SPN Name

6 | © Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799

Page 7

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

PGN SPN TTR [ms]

64961 3358 500 3 SAEpr07 Engine Exhaust Gas Recirculation 1 Intake Pressure

64961 4287 500 4-5 SAEpr09 Engine Exhaust Valve Actuation System Oil Pressure

64961 5019 500 6 SAEpr07 Engine Exhaust Gas Recirculation 1 Outlet Pressure

64961 5631 500 7-8 SAEpr03 Engine Throttle Valve 1 Differential Pressure

64976 2809 500 1 SAEpr02 Engine Air Filter 2 Differential Prssure

64976 2810 500 2 SAEpr02 Engine Air Filter 3 Differential Prssure

64976 2811 500 3 SAEpr02 Engine Air Filter 4 Differential Prssure

64976 3562 500 4 SAEpr07 Engine Intake Manifold #2 Pressure

64976 3563 500 5 SAEpr07 Engine Intake Manifols #1 Absolute Pressure

64976 4817 500 6-7 SAEpr03 Engine Intake Manifold 1 Absolute Pressure (High Resolution)

64976 5422 500 8 SAEpr07 Engine Intake Manifold 2 Absolute Pressure

64992 5685 1000 7-8 SAEpr03 Barometric Absolute Pressure (High Resolution)

64993 2609 1000 1 SAEpr14 Cab A/C Refrigerant Compressor Outlet Pressure

64994 2603 1000 1 SAEpr13 Pneumatic Supply Pressure Request

64994 2604 1000 2 SAEpr13 Parking and/or Trailer Air Pressure Request

64994 2605 1000 3 SAEpr13 Service Brake Air Pressure Request, Circuit #1

64994 2606 1000 4 SAEpr13 Service Brake Air Pressure Request, Circuit #2

64994 2607 1000 5 SAEpr13 Auxiliary Equipment Supply Pressure Request

64994 2608 1000 6 SAEpr13 Air Suspension Supply Pressure Request

64994 6306 1000 7 SAEpr13 Powertrain Circuit Air Supply Pressure Request

64998 2580 100 1 SAEpr15 Hydraulic Brake Pressure Circuit 1

64998 2581 100 2 SAEpr15 Hydraulic Brake Pressure Circuit 2

65112 1725 100 1-2 SAEpr03 Bellow Pressure Front Axle Left

65112 1726 100 3-4 SAEpr03 Bellow Pressure Front Axle Right

65112 1727 100 5-6 SAEpr03 Bellow Pressure Rear Axle Left

65112 1728 100 7-8 SAEpr03 Bellow Pressure Rear Axle Right

65130 1381 500 2 SAEpr07 Engine Fuel Supply Pump Intake Absolute Pressure

65130 1382 500 3 SAEpr07 Engine Fuel Filter (suction side) Differential Pressure

65130 3549 500 5 SAEpr10 Engine Oil-Filter Outlet Pressure

65130 7104 500 8 SAEpr07 Engine Fuel Supply Pump Intake Pressure

65143 136 on request 1-2 SAEpr06 Auxiliary Vacuum Pressure Reading

65143 137 on request 3-4 SAEpr06 Auxiliary Gage Pressure Reading 1

65143 138 on request 5-6 SAEpr06 Auxiliary Absolute Pressure Reading

65145 141 on request 1-2 SAEpr06 Trailer, Tag or Push Channel Tire Pressure Target

65145 142 on request 3-4 SAEpr06 Drive Channel Tire Pressure Target

65145 143 on request 5-6 SAEpr06 Steer Channel Tire Pressure Target

65146 144 on request 1-2 SAEpr06 Trailer, Tag or Push Channel Tire Pressure

65146 145 on request 3-4 SAEpr06 Drive Channel Tire Pressure

65146 146 on request 5-6 SAEpr06 Steer Channel Tire Pressure

65163 1390 on request 1-2 SAEpr03 Engine Fuel Valve 1 Intake Absolute Pressure

65163 1391 on request 3-4 SAEpr03 Engine Fuel Valve 1 Differential Pressure

65163 1392 on request 5-6 SAEpr03 Engine Air to Fuel Differential Pressure

65163 2980 on request 7-8 SAEpr03 Engine Fuel Valve 1 Outlet Absolute Pressure

65164 1387 on request 3 SAEpr14 Auxiliary Pressure #1

65163 1388 on request 4 SAEpr14 Auxiliary Pressure #2

65167 1320 1000 1-2 SAEpr06 Engine External Shutdown Air Supply Pressure

65170 1208 100 1 SAEpr10 Engine Pre-filter Oil Pressure

65170 1209 100 2-3 SAEpr01 Engine Exhaust Pressure 1

Data

Position

Slot SPN Name

© Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799 | 7

Page 8

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

PGN SPN TTR [ms]

65172 1203 500 1 SAEpr10 Engine Auxiliary Coolant Pressure

65172 2435 500 3 SAEpr07 Sea Water Pump Outlet Pressure

65172 20 500 4 SAEpr10 Engine Coolant Pressure 1 (Extended Range)

65172 7313 500 5 SAEpr10 Engine Coolant Pressure 2 (Extended Range

65174 1192 100 5 SAEpr10 Engine Turbocharger Wastegate Actuator Control Air Pressure

65177 1176 1000 1-2 SAEpr01 Engine Turbocharger 1 Compressor Intake Pressure

65177 1177 1000 3-4 SAEpr01 Engine Turbocharger 2 Compressor Intake Pressure

65177 1178 1000 5-6 SAEpr01 Engine Turbocharger 3 Compressor Intake Pressure

65177 1179 1000 7-8 SAEpr01 Engine Turbocharger 4 Compressor Intake Pressure

65179 1168 1000 1 SAEpr10 Engine Turbocharger Lube Oil Pressure 2

65188 411 1000 5-6 SAEpr01 Engine Exhaust Gas Recirculation 1 Differential Pressure

65190 1127 500 1-2 SAEpr04 Engine Turbocharger 1 Boost Pressure

65190 1128 500 3-4 SAEpr04 Engine Turbocharger 2 Boost Pressure

65190 1129 500 5-6 SAEpr04 Engine Turbocharger 3 Boost Pressure

65190 1130 500 7-8 SAEpr04 Engine Turbocharger 4 Boost Pressure

65194 1692 on request 2-3 SAEpr03 Engine Intake Manifold Desired Absolute Pressure

65197 1091 100 1 SAEpr11 Brake Application Pressure High Range, Front Axle, Left Wheel

65197 1092 100 2 SAEpr11 Brake Application Pressure High Range, Front Axle, Right Wheel

65197 1093 100 3 SAEpr11 Brake Application Pressure High Range, Rear Axle #1, Left Wheel

65197 1094 100 4 SAEpr11 Brake Application Pressure High Range, Rear Axle, Right Wheel

65197 1095 100 5 SAEpr11 Brake Application Pressure High Range, Rear Axle #2, Left Wheel

65197 1096 100 6 SAEpr11 Brake Application Pressure High Range, Rear Axle #2, Right Wheel

65197 1097 100 7 SAEpr11 Brake Application Pressure High Range, Rear Axle #3, Left Wheel

65197 1098 100 8 SAEpr11 Brake Application Pressure High Range, Rear Axle #3, Right Wheel

65198 46 1000 1 SAEpr13 Pneumatic Supply Pressure

65198 1086 1000 2 SAEpr13 Parking and/or Trailer Air Pressure

65198 1087 1000 3 SAEpr13 Servic e Brake Circuit 1 Air Pressure

65198 1088 1000 4 SAEpr13 Servic e Brake Circuit 21 Air Pressure

65198 1089 1000 5 SAEpr13 Auxiliary Equipment Supply Pressure

65198 1090 1000 6 SAEpr13 Air Suspension Supply Pressure

65198 6305 1000 8 SAEpr13 Powertrain Circuit Air Supply Pressure

65213 4211 1000 5-6 SAEpr06 Hydraulic Fan Motor Pressure

65243 164 500 1-2 SAEpr09 Engine Injection Control Pressure

65243 147 500 3-4 SAEpr09 Engine Injection Metering Rail 1 Pressure

65243 156 500 5-6 SAEpr09 Engine Injection Timing Rail 1 Pressure

65243 1349 500 7-8 SAEpr09 Engine Injection Metering Rail 2 Pressure

65245 104 1000 1 SAEpr10 Engine Turbocharger Lube Oil Pressure 1

65246 82 on request 1 SAEpr10 Engine Air Start Pressure

65246 6831 on request 2 SAEpr14 Engine Air Start Pressure (Extended Range)

65246 6832 on request 3 SAEpr10 Engine Air Stop Pressure

65263 94 500 1 SAEpr10 Engine Fuel Delivery Pressure

65263 22 500 2 SAEpr02 Engine Extended Crankcase Blow-by Pressure

65263 100 500 4 SAEpr10 Engine Oil Pressure

65263 101 500 5-6 SAEpr01 Engine Crankcase Pressure 1

65263 109 500 7 SAEpr07 Engine Coolant Pressure 1

65268 241 10000 2 SAEpr10 Tire Pressure

65269 108 1000 1 SAEpr05 Barometric Pressure

65270 81 500 1 SAEpr05 Aftertreatment 1 Diesel Particulate Filter Intake Pressure (use SPN 3609)

Data

Position

Slot SPN Name

8 | © Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799

Page 9

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

PGN SPN TTR [ms]

65270 102 500 2 SAEpr07 Engine Intake Manifold #1 Pressure

65270 106 500 4 SAEpr07 Engine Intake Air Pressure

65270 107 500 5 SAEpr02 Engine Air Filter 1 Differential Pressure

65270 112 500 8 SAEpr05 Engine Coolant Filter Differential Pressure

65272 123 1000 1 SAEpr14 Clutch Pressure

65272 126 1000 3 SAEpr07 Transmission Filter Differential Pressure

65272 127 1000 4 SAEpr14 Transmission Oil Pressure

65273 579 1000 3 SAEpr10 Drive Axle Lift Air Pressure

65273 2613 1000 5 SAEpr10 Drive Axle Lube Pressure

65273 2614 1000 8 SAEpr10 Steering Axlke Lube Pressure

65274 116 1000 1 SAEpr10 Brake Apllication Pressure

65274 117 1000 2 SAEpr10 Brake Primary Pressure

65274 118 1000 3 SAEpr10 Brake Secondary Pressure

65275 119 1000 1 SAEpr14 Hydraulic Retarder Pressure

65276 95 1000 3 SAEpr07 Engine Fuel Filter Differential Pressure

65276 99 1000 4 SAEpr05 Engine Oil Filter Differential Pressure

65276 7471 1000 8 SAEpr11 Engine Oil Filter Differential Pressure (Extended Range)

65277 159 500 2-3 SAEpr06 Engine Gaseous Fuel Supply Pressure 1

65277 6814 500 4-5 SAEpr06 Engine Gaseous Fuel Vent Pressure

65278 73 1000 1 SAEpr14 Auxiliary Pump Pressure

Data

Position

Slot SPN Name

© Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799 | 9

Page 10

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

3.3 PGNs of Danfoss

There are some additional Danfoss-specific

PGNs and SPNs to use the DST P92C with J1939

in general

PGN SPN TTR [ms]

65280 Danfoss01 100 1-2 Danfosspr01 General purpose

65281 Danfoss02 100 1-2 Danfosspr02 General purpose

65282 Danfoss03 100 1-2 Danfosspr03 General purpose

65283 Danfoss04 100 1-2 Danfosspr04 General purpose

65284 Danfoss05 100 1-2 Danfosspr05 General purpose

65285 Danfoss06 100 1-2 Danfosspr06 General purpose

65286 Danfoss07 100 1-2 Danfosspr07 General purpose

65287 Danfoss08 100 1-2 Danfosspr08 General purpose

65288 Danfoss09 100 1-2 Danfosspr09 General purpose

65289 Danfoss10 100 1-2 Danfosspr10 General purpose

65290 Danfoss11 100 1-2 Danfosspr11 General purpose

65291 Danfoss12 100 1-2 Danfosspr12 General purpose

65292 Danfoss13 100 1-2 Danfosspr13 General purpose

65293 Danfoss14 100 1-2 Danfosspr14 General purpose

65294 Danfoss15 100 1-2 Danfosspr15 General purpose

65295 Danfoss16 100 1-2 Danfosspr16 General purpose

65296 Danfoss17 100 1-2 Danfosspr17 General purpose

65297 Danfoss18 100 1-2 Danfosspr18 General purpose

65298 Danfoss19 100 1-2 Danfosspr19 General purpose

65299 Danfoss20 100 1-2 Danfosspr20 General purpose

65300 Danfoss21 100 1-2 Danfosspr21 General purpose

65301 Danfoss22 100 1-2 Danfosspr22 General purpose

65302 Danfoss23 100 1-2 Danfosspr23 General purpose

65303 Danfoss24 100 1-2 Danfosspr24 General purpose

65304 Danfoss25 100 1-2 Danfosspr25 General purpose

65305 Danfoss26 100 1-2 Danfosspr26 General purpose

65306 Danfoss27 100 1-2 Danfosspr27 General purpose

65307 Danfoss28 100 1-2 Danfosspr28 General purpose

65308 Danfoss29 100 1-2 Danfosspr29 General purpose

65309 Danfoss30 100 1-2 Danfosspr30 General purpose

65310 Danfoss31 100 1-2 Danfosspr31 General purpose

65311 Danfoss32 100 1-2 Danfosspr32 General purpose

Data

Position

Slot Description

10 | © Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799

Page 11

Operation guide | DST P92C Pressure transmitter CAN SAE J1939

3.4 Definitions 3. 4.1 P G N

The PGN (Parameter Group Number) uniquely

identifies the Parameter Group (PG) that

is being transmitted in the message. The

Parameter Group Number (PGN) is a part of the

29-bit identifier sent with every message.

3.5 Overview of the slots for pressure

sensors

Slot

Name

SAEpr01 Pressure kPa 1/128 kPa/bit -250 kPa – 251.99 kPa -250 kPa 2 bytes

SAEpr02 Pressure kPa 0.05 kPa/bit 0 – 12.5 kPa 0 kPa 1 byte

SAEpr03 Pressure kPa 0.1 kPa/bit 0 – 6425.5 kPa 0 kPa 2 bytes

SAEpr04 Pressure kPa 0.125 kPa/bit

SAEpr05 Pressure kPa 0.5 kPa/bit 0 – 125 kPa 0 kPa 1 byte

SAEpr06 Pressure kPa 0.5 kPa/bit 0 – 32127.5 kPa 0 kPa 2 bytes

SAEpr07 Pressure kPa 2 kPa/bit 0 – 500 kPa 0 kPa 1 byte

SAEpr08 Pressure kPa 2 kPa/bit 0 – 128510 kPa 0 kPa 2 bytes

SAEpr09 Pressure MPa 1/256 MPa/bit 0 – 251 MPa 0 kPa 2 bytes

SAEpr10 Pressure kPa 4 kPa/bit 0 – 1000 kPa 0 kPa 1 byte

SAEpr11 Pressure kPa 5 kPa/bit 0 – 1250 kPa 0 kPa 1 byte

SAEpr12 Pressure kPa 5 kPa/bit 0 – 321275 kPa 0 kPa 2 bytes

SAEpr13 Pressure kPa 8 kPa/bit 0 – 2000 kPa 0 kPa 1 byte

SAEpr14 Pressure kPa 16 kPa/bit 0 – 4000 kPa 0 kPa 1 byte

SAEpr15 Pressure kPa 100 kPa/bit 0 – 25 MPa 0 kPa 1 byte

SAEpr16 Pressure kPa 50 kPa/bit 0 – 12500 kPa 0 kPa 1 byte

SAEpr17 Pressure kPa 1.64 kPa/bit -7 – 403 kPa -7 kPa 1 byte

SAEpr18 Pressure kPa 0.1 kPa/bit -3212.7 – 3212.8 kPa -3212.7 kPa 2 bytes

SAEpr19 Pressure kPa 1/128 kPa/bit 0 – 501.9921875 kPa 0 kPa 2 bytes

SAEpr20 Pressure MPa 1/8192 MPa/bit -1 – 6.84362793 MPa -1 MPa 2 bytes

SAEpr21 Pressure MPa 1/1024 MPa/bit 0 – 62.74902344 MPa 0 MPa 2 bytes

SAEpr22 Pressure kPa 1 kPa/bit 0 – 64255 kPa 0 kPa 2 bytes

SAEpr23 Pressure kPa 10 kPa/bit -40000 – 602550 kPa -40000 kPa 2 bytes

SAEpr24 Pressure MPa 0.0035176 MPa/bit -102.0104 – 124.012988 MPa -102.0104 MPa 2 bytes

Slot Type Units Scaling Range Offset Length

0 – 8031.875 kPa

(0 – 1164.62 psi)

3.4.2 SPN

Each parameter used in the J1939 network is

described by the standard. A Suspect Parameter

Number (SPN) is a number that has been assigned

by SAE committee to a specific parameter. Each

SPN has the following detailed information

associated with it: data length (in bytes);

data type; resolution, offset; range; and a tag

(label) for reference. SPNs that share common

characteristics will be grouped into a Parameter

Group (PG) and will be transmitted to the network

using the same PGN.

0 kPa 2 bytes

© Danfoss | DCS (im) | 2018.01

IC.PS.P21.2C.02 | 520B7799 | 11

Page 12

3.6 Additionally, there are

some Danfoss specific

Slot Name Slot Type Units Scaling Range Offset Length

Danfosspr01 Pressure bar 0.4 mbar/bit 0 – 25.702 bar 0 bar 2 bytes

Danfosspr02 Pressure bar 0.75 mbar/bit 0 – 48.19125 bar 0 bar 2 bytes

Danfosspr03 Pressure bar 1.5 mbar/bit 0 – 96.3825 bar 0 bar 2 bytes

Danfosspr04 Pressure bar 4 mbar/bit 0 – 257.02 bar 0 bar 2 bytes

Danfosspr05 Pressure bar 6 mbar/bit 0 – 385.53 bar 0 bar 2 bytes

Danfosspr06 Pressure bar 10 mbar/bit 0 – 642.55 bar 0 bar 2 bytes

Danfosspr07 Pressure bar 12.5 mbar/bit 0 – 803.1875 bar 0 bar 2 bytes

Danfosspr08 Pressure psi 0.006 psi/bit 0 – 385.53 psi 0 psi 2 bytes

Danfosspr09 Pressure psi 0.01 psi/bit 0 – 642.55 psi 0 psi 2 bytes

Danfosspr10 Pressure psi 0.02 psi/bit 0 – 1285.1 psi 0 psi 2 bytes

Danfosspr11 Pressure psi 0.05 psi/bit 0 – 3212.75 psi 0 psi 2 bytes

Danfosspr12 Pressure psi 0.09 psi/bit 0 – 5782.95 psi 0 psi 2 bytes

Danfosspr13 Pressure psi 0.125 psi/bit 0 – 8031.875 psi 0 psi 2 bytes

Danfosspr14 Pressure psi 0.175 psi/bit 0 – 11244.625 psi 0 psi 2 bytes

Danfosspr15 Pressure bar 19 mbar/bit 0 – 1220.845 bar 0 bar 2 bytes

Danfosspr16 Pressure bar 32 mbar/bitt 0 – 2056.160 bar 0 bar 2 bytes

Danfosspr17 Pressure bar 47 mbar/bit 0 – 3019.985 bar 0 bar 2 bytes

Danfosspr18 Pressure psi 0.271 psi/bit 0 – 17413.105 0 psi 2 bytes

Danfosspr19 Pressure psi 0.452 psi/bit 0 – 29043.260 psi 0 psi 2 bytes

Danfosspr20 Pressure psi 0.678 psi 0 – 43564.890 psi 0 psi 2 bytes

Danfosspr21 Pressure bar 0.032 mbar/bit -1 – 1.05616 bar -1 bar 2 bytes

Danfosspr22 Pressure bar 0.18 mbar/bit -1 – 10.5659 bar -1 bar 2 bytes

Danfosspr23 Pressure bar 0.41 mbar/bit -1 – 25.34455 bar -1 bar 2 bytes

Danfosspr24 Pressure bar 0.016 mbar/bit 0 – 1.02808 bar 0 bar 2 bytes

Danfosspr25 Pressure bar 0.078 mbar/bit 0 – 5.01189 bar 0 bar 2 bytes

Danfosspr26 Pressure bar 0.16 mbar/bit 0 – 10.2808 bar 0 bar 2 bytes

Danfosspr27 Pressure psi 0.00046 psi/bit -14.5 – 15.0573 psi -14.5 psi 2 bytes

Danfosspr28 Pressure psi 0.0025 psi/bit -14.5 – 146.1375 psi -14.5 psi 2 bytes

Danfosspr29 Pressure psi 0.0063 psi/bit -14.5 – 390.3065 psi -14.5 psi 2 bytes

Danfosspr30 Pressure psi 0.0003 psi/bit 0 – 19.2765 psi 0 psi 2 bytes

Danfosspr31 Pressure psi 0.0012 psi/bit 0 – 77.106 psi 0 psi 2 bytes

Danfosspr32 Pressure psi 0.0023 psi/bit 0 – 147.7865 psi 0 psi 2 bytes

3.7 References

Danfoss A/S | Industrial Automation | Nordborgvej 81 | DK-6430 Nordborg | Denmark | www.ia.danfoss.com

© Danfoss | DCS (im) | 2018.01

ISO11783-3 Data Link Layer

J1939-71

IC.PS.P21.2C.02 | 520B7799 | 12

Loading...

Loading...