Page 1

Data sheet

Modular pressure transmitters for harsh environments

DST P500, DST P507 and DST P550

The P500 / P507 / P550 utilizes the thin film

strain gauge sensing technology, incorporating

an hermetically sealed design with no

internal sealing required. Designed for harsh

environments, a rugged 304 stainless

steel housing surrounds the P500 / P507 / P550

transducer.

The P500 / P507 /P550 small, compact design as

well as its low overall weight makes it ideal for

applications with spacing and weight limitations.

This easy-to-use sensor is media resistant,

which allows it to be used for a broad range

of liquid and gaseous media. It can be used at

high operating temperatures and has internal

temperature compensation.

Highly reliable, the P500 / P507 / P550 provides

accurate, high pressure measurements every

time.

P507 is suitable in applications where cleanliness

is a must. All transmitter parts in contact with

the medium meet the cleanliness requirements

according to the ISO 15001 standard.

P550 with integrated pulse-snubber is suitable in

applications with severe medium influences like

cavitation, liquid hammer or pressure peaks.

Features

Approvals

© Danfoss | DCS (im) | 2018.11

• Designed for use in harsh industrial

environments

• For media and ambient temperatures from

-30° – 120 °C

• Reverse polarity protected

• Excellent shock and vibration performance

• Outstanding long-term stability and

repeatability

CE Compliance:

EMC directive 2014/30/EU, EN61000-6-2:2005

and EN61326-1:2006

• Compact and light-weight design

• Hermetically sealed to the application

• RoHS conformity

Other:

2011/65/EU ROHS Directive

UL - E494625

EAC

IC.PD.P21.5C.02 | 1

Page 2

Data sheet | Modular pressure transmitters for harsh environments, DST P500, DST P507 and DST P550

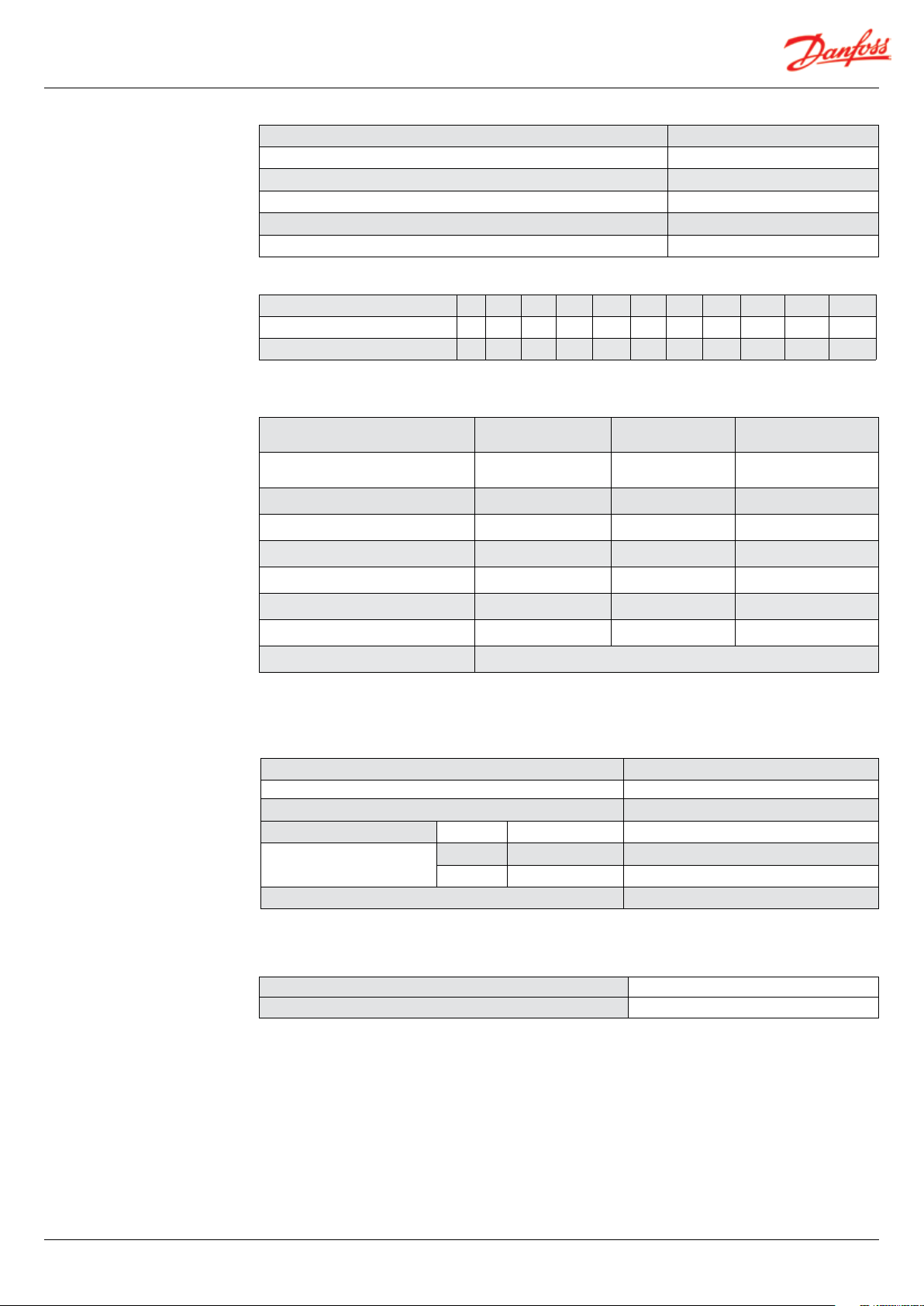

Technical data

Performance (EN 60770)

Accuracy @ 25 °C (incl. non-linearity, hysteresis and non-repeatability) ± 0.5% FS

Non-linearity BFSL (conformity) ≤ ± 0.2% FS

Thermal zero point shift ≤ 0.2% FS / 10° K @ 0-80 °C

Thermal span shift ≤ 0.2% FS / 10° K @ 0-80 °C

Non-repeatability ≤ ± 0.1% FS

Durability, P: 10 – 90% FS > 10 × 10

Overload and burst pressure

Nominal pressure [bar] 6 10 16 25 40 60 100 160 250 400 600

Overload pressure 12 20 32 50 80 120 200 320 375 600 900

Burst pressure 60 100 160 200 320 480 600 960 1000 1600 2400

Electrical specifications

Nom. output signal

(short-circuit protected)

4 – 20 mA

0.5-4.5 V DC

Ratiometric

6

cycles

0-5 V DC/0-10 V DC

Supply voltage [U

], polarity protected

B

8 – 30 V DC

5 V DC ± 0.25 V 8-30/14-30 V DC

Supply – power consumption ≤ 600 mW ≤ 25 mW ≤ 600 mW

Overvoltage protection min. 33 V DC min. 6 V DC min. 33 V DC

Short-circuit protection N/A Yes

1)

Yes

1)

Insulation voltage 500 V DC 500 V DC 500 V DC

Reverse polarity protection Yes

Load ≤ (V

- 8 V DC)/0.02 A[Ω] ≥ 4.7 kΩ ≥ 4.7 kΩ

sup

2)

Yes

2)

Yes

2)

Response time ≤5 ms max. to 63% of FS pressure with step change on input

1)

for min. 3 intervals at 5 minutes each

2)

for min. 10 sec. on assigned pins

Environmental conditions

Media temperature range -30 – 120 °C

Ambient temperature range -30 – 100 °C

Storage temperature -30 – 100 °C

Vibration stability Random 20 PSD IEC 60068-2-64

Shock resistance

Enclosure (depending on electrical connection) IP 65 or IP 67, depending on electrical connection

Shock 25 g IEC 60068-2-27

Free fall 1 m IEC 60068-2-3-1

2 | IC.PD.P21.5C.02

Mechanical characteristics

Materials 304 stainless steel (1.4301 / 1.4307)

Net weight (depending on pressure connection) <0.05 kg

© Danfoss | DCS (im) | 2018.11

Page 3

Data sheet | Modular pressure transmitters for harsh environments, DST P500, DST P507 and DST P550

Ordering

DST P 5 – –

Standard ··············································

Cleanliness according to ISO 15001

With pulse-snubber ·························

00

07

50

Measuring range

0 – 6 bar ······························································-···

0 – 10 bar ·································································

0 – 16 bar ·····························································-··

0 – 25 bar ······························································-·

0 – 40 bar ······························································-···

0 – 60 bar ······························································-···

0 – 100 bar ······························································-···

0 – 160 bar ······························································-···

0 – 250 bar ······························································-···

0 – 400 bar ··································································

0 – 600 bar ······························································-···

Others ······························································-··· ··· ···

Gauge (relative) ·········································································

18

20

22

24

26

28

30

32

34

36

38

99

·······

GB04

·······

AD10

·······

AD08

·······

GB06

······

99

Electrical connection

Figures refer to plug

and standard Pin figuration see page 5

·······

A0

C5

E3

1

C2

99

EN 175301-803-A - male (18 mm)

EN 175301-803-C-male (9.4 mm)

·······

·······

M12 - 4 pin

·······

Packard Metri-Pack 150

·······

Others

External Seal Ring

None

0

Fluorocarbon FKM>-20 °C (Viton)

1

9

Others

Pressure connection

G ¼ A DIN 3852-E

⁄ - 20 UNF-2B (female)

⁄ - 20 UNF-2A (male)

G ¼ A DIN 3852-A

Others, please specify

1)

2)

1)

Mating connector can be ordered, code no.: 060G0008

2)

Mating connector can be ordered, code no.: 063G0306

For other variants please contact Danfoss

1

6

2

5

9

···············

···············

···············

···············

··············

Output signal

4 – 20 mA

0.5 – 4.5 V DC Ratio Metric

0 – 5 V DC

0 –10 V DC

Others, please specify

© Danfoss | DCS (im) | 2018.11

IC.PD.P21.5C.02 | 3

Page 4

Data sheet | Modular pressure transmitters for harsh environments, DST P500, DST P507 and DST P550

Danfoss

090GU42

Danfoss

090GU43

Danfoss

090GU46

Danfoss

090GU47

Dimensions/Combinations

Type code A0 C5 C2 E3

Electrical connection 18 mm DIN 175301-803A 9.4 mm DIN 175301-803C Round Packard Metri-Pack M12

Danfoss

090GU53

Danfoss

090GU49

37

32

Type: DST P500

Datecode: XXXX

Type: DST P500

Datecode: XXXX

Danfoss

090GU44

33

Type: DST P500

Datecode: XXXX

Type: DST P500

Datecode: XXXX

Danfoss

090GU51

34

17

G¼ – DIN 3852-E

External thread

Type code

27 mm

14

⁷⁄₁₆ – 20 UNF-2A

SAE J1926-2

External thread

G¼ – DIN 3852-A

External thread

14

⁷⁄₁₆ – 20 UNF-2B

SAE J1926-1

Internal thread

GB06 AD10 AD08 GB04

Recommended torque 20 Nm 20 Nm 20 Nm 20 Nm

14

4 | IC.PD.P21.5C.02

© Danfoss | DCS (im) | 2018.11

Page 5

Data sheet | Modular pressure transmitters for harsh environments, DST P500, DST P507 and DST P550

P2

P4

P1

P3

P2 P3

P2

P3

Electrical connections

Type code E3 A0 C2 C5

P3

Danfoss

1 2

090GU45

P1

-30 – 100 °C

P2

Round Packard

Metri-Pack

Danfoss

090GU52

27

EN 175301-803-C

9.4 mm

4 – 20 mA

0.5-4.5 V DC

Ambient

Ratiometric

temperature

0-5 V DC

0-10 VDC

Enclosure (IP protection fulfilled

together

with mating connector)

P1

Danfoss

090GU50

27

P4

4 3

EN 175301-803-A,

M12, 4 pin

18 mm

IP67 IP65 IP67 IP65

Danfoss

090GU48

27

P1P4

Materials

Electrical

connection

4 – 20 mA

(2 wire)

0.5-4.5 V DC

Ratiometric

0-5 V DC,

0-10 V DC

Tin plated on Nickel,

Nylon 66, 40% Glass

Pin1: + supply

Pin 2: not used

Pin 3:÷ supply

Pin 4: not used

Pin 1: + supply

Pin 2: not used

Pin 3: + output

Pin 4: ÷ common

Pin 1: + supply

Pin 2: not used

Pin 3: + output

Pin 4: ÷ common

Tin plated on Nickel,

Nylon 66, 40% Glass

Pin 1: + supply

Pin 2: ÷ supply

Pin 3: not used

Pin 4: not used

Pin 1: + supply

Pin 2: + output

Pin 3: ÷ common

Pin 4: not used

Pin 1: + supply

Pin 2: + output

Pin 3: ÷ common

Pin 4: not used

Tin plated on Nickel,

Zytel 33% Glass

Pin1: ÷ supply

Pin 2: + supply

Pin 3: not used

Pin 1 ÷ common

Pin 2: + supply

Pin 3: + output

Pin 1 ÷ common

Pin 2: + supply

Pin 3: + output

Tin plated on Nickel,

Nylon 66, 40% Glass

Pin 1: + supply

Pin 2: ÷ supply

Pin 3: not used

Pin 4: not used

Pin 1: + supply

Pin 2: + output

Pin 3: ÷ common

Pin 4: not used

Pin 1: + supply

Pin 2: + output

Pin 3: ÷ common

Pin 4: not used

© Danfoss | DCS (im) | 2018.11

IC.PD.P21.5C.02 | 5

Page 6

© Danfoss | DCS (im) | 2018.11 IC.PD.P21.5C.04 | 6

Loading...

Loading...