Page 1

Data Sheet

Pressure transmitters

Type DST P40M

Harsh environment marine application

The P40M pressure transmitter has been

designed specic for pressure monitoring of

marine applications such as Ballast water

treatment systems, Exhaust gas scrubbers,

Desalination and Sea water cooling systems

where high corrosion resistance and longevity

are essential for the continued operation of

auxiliary & propulsion systems onboard the

vessel.

The enclosure of the pressure transmitter is

machined out from a single piece of Titanium

to eliminate any structural weaknesses.

Titanium is exceptionally resistant to a broad

range of acids and alkalis, as well as Sodium

Chloride and polluted waters. Titanium’s

corrosion resistance together with its low

density, high strength and erosion resistance,

make this pressure transmitter ideal for

numerous chemical processing and marine

uses.

The pressure sensing element is made from

ceramic Al2O3 96% which has excellent

chemical immunity and is suitable for nearly all

aggressive media. The pressure transmitter

works following the piezo resistive principle

and the Wheatstone bridge is screen printed

directly on one side of the ceramic diaphragm

by means of Thick Film technology

AI366043639180en-000402

Page 2

Pressure transmitters, type DST P40M

Features

• Designed for use in corrosive industrial environments such as desalination systems, medical industry, chemical

processing, chlorate containing liquids, hydro-carbon processing, etc.

• Enclosure Titanium grade 2

• Temperature compensated

• Reverse polarity protected

• Gauge (relative)

• Wetted parts: Titanium & Ceramic

• Ceramic Al2O3 96%

• High linearity and low hysteresis value

• RoHS compliance

© Danfoss | Climate Solutions | 2021.06 AI366043639180en-000402 | 2

Page 3

Specications

Values

Transmitter type

DST P40M

Accuracy (incl. non-linearity, hysteresis and repeatability)

< ± 1% FS (typ.) @ ambient temperature

Compensated temperature range

0 – 80 °C

Total error band within compensated temperature range

± 1.5% FS (typ.)

Output type

4 – 20 mA

Pressure reference

Gauge

Supply voltage range

9 – 32 V DC

Rise time (10 – 90%)

< 5 ms

Overload pressure

2 x FS

Burst pressure

2.5 x FS

Durability

P:10-90%FS > 10 mio cycles

Media temperature range

-15 – 85 °C

Ambient temperature range

Depending on electrical connection see Electrical connections

Storage temperature range

-40 – 105 °C

Load [RL]

RL≤(UB-8V)/0,02A

EMC – Emission

EN 61000-6-3

EMC – Immunity

EN 61000-6-2

Vibration stability

Sinusoidal

15.9 mm-pp, 5 Hz – 25 Hz

IEC 60068-2-6

20 g, 25 Hz – 2 kHz

Shock resistance

Shock

100 g / 1 ms

IEC 60068-2-27

0 – 4 bar

Gauge

0 – 6 bar

Gauge

0 – 10 bar

Gauge

0 – 16 bar

Gauge

0 – 25 bar

Gauge

0 – 100 bar

Sealed gauge

Type code

A0: Male

A1: Pg 9

A6: Pg 11

A9: Pg 13.5

EN 175301-803-A, Pg 9

Ambient temperature

-25 - 85 °C

Enclosure (IP protection

fullled together with mating connector)

IP65

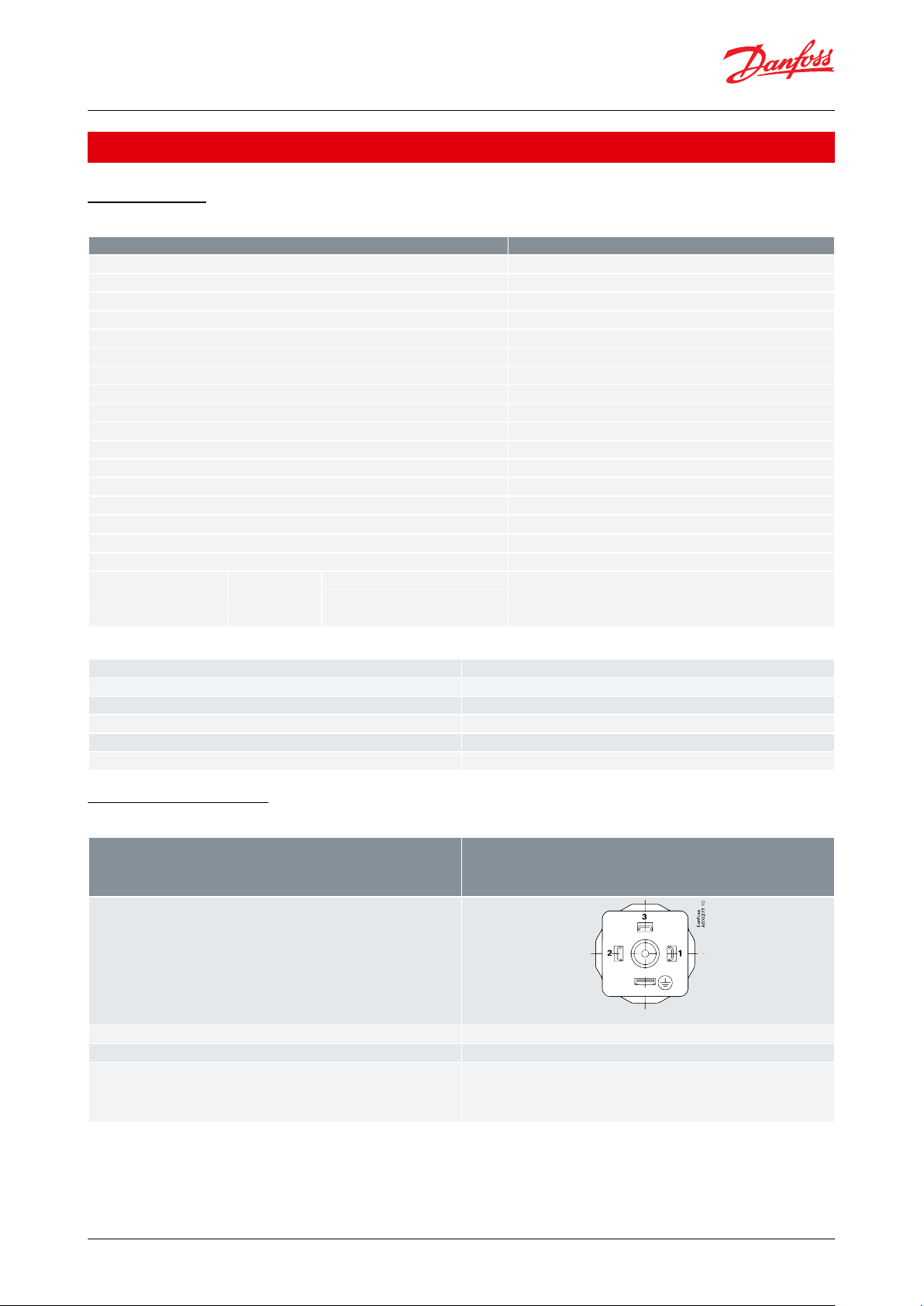

Electrical connection, 4 – 20 mA output (2 wire)

Pin 1: + supply

Pin 2: ÷ supply

Pin 3: not used

Pin 4: Ground connection to sensor house

Pressure transmitters, type DST P40M

Product specication

Technical data

Table 1: Technical specications

Table 2: Pressure range

Electrical connections

Table 3: Electrical connections

© Danfoss | Climate Solutions | 2021.06 AI366043639180en-000402 | 3

Page 4

Type code

A1A6A9

Connector

Danfoss

93Z276

34.8 ± 2

~39

EN 175301-803-A, Pg 9

Danfoss

93Z276

34.8 ± 2

~39

EN 175301-803-A, Pg 11

Danfoss

60G254

44

71

EN 175301-803-A, Pg 13.5

Hex 27h13

13 ± 0.3

Ø37.5 ± 0.3

Ø30.6 ± 0.3

48.6 ± 0.2

Danfoss

93Z275

Connection Types

Type

G

1

⁄4”; ISO 1179-2

G

1

⁄2"; ISO 1179-2

Gasket

FKM

FKM

Type code

GB04

GB08

Recommended torque

(1)

30 – 35 Nm

30 – 35 Nm

Pressure transmitters, type DST P40M

Dimensions / Combinations

Table 4: Dimensions and combinations of connector and connection types

(1)

(1)

© Danfoss | Climate Solutions | 2021.06 AI366043639180en-000402 | 4

Depends on dierent parameters such as gasket material, mating material, thread lubrication and pressure level

Depends on dierent parameters such as gasket material, mating material, thread lubrication and pressure level

Page 5

DST P40M-

– –

0

No Gasket

1

Gasket (ISO 1179-2) FKM

Measuring range

GB0 4

G ¼" (ISO 1179-2)

GB0 8

G½" (ISO 1179-2)

0 –

4.0 bar

1 6

0 –

6.0 bar

1 8

0 –

10 bar

2 0

0 –

16 bar

2 2

A0

No female plug (EN 175301-803)

0 –

25 bar

2 4

A1

Plug (EN 175301-803-A) Pg 9

0 –

100 bar

3 0

A6

Plug (EN 175301-803-A) Pg 11

A9

Plug (EN 175301-803-A) Pg 13,5

1

4 – 20 mA

Pressure reference

Gauge (relative) 1

Danfoss

93Z277

Pressure transmitters, type DST P40M

Ordering

Ordering standard

Non-standard build-up combinations may be selected. However, minimum order quantities may apply.

Please contact your local Danfoss oce for further information or request on other versions.

© Danfoss | Climate Solutions | 2021.06 AI366043639180en-000402 | 5

Page 6

File name

Document type

Document topic

Approvals Authority

MRA000003B

Approval Certicate

Marine classication (EU RO) MUTUAL

RECOGNITION CERTIFICATE

DNV

DLN34014-AE005

Approval Certicate

Marine classication

Korean Register

CPH04967-AE014

Approval Certicate

Marine classication

Korean Register

21A003

Approval Certicate

Marine classication

NKK-Approval Certicate

Marine classication

CCS (Pending)

Pressure transmitters, type DST P40M

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

© Danfoss | Climate Solutions | 2021.06 AI366043639180en-000402 | 6

Page 7

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.06 AI366043639180en-000402 | 7

Loading...

Loading...