Page 1

Data sheet

Pressure transmitter for marine applications

DST P30M

The compact high temperature pressure

transmitter is designed for use in almost all

marine applications, and offers a reliable pressure

measurement, even under harsh environmental

conditions.

The flexible pressure transmitter program covers

different output signals, absolute or gauge

(relative) versions, measuring ranges from 0 – 1

to 0 – 600 bar and a wide range of pressure and

electrical connections.

A robust design, an excellent vibration stability,

and a high degree of EMC / EMI protection

equip the pressure transmitter to meet the most

stringent marine requirements.

Running a powerful ARM-based microcontroller,

the DST P30M offers diagnostic functions and

performance features.

Features

Approvals

• Designed for use in severe maritime

environments

• Robust electronic platform for harsh electrical

environments

• Available output signals:

- 10 - 90% of supply voltage

- 4 - 20 mA

- Absolute voltage

• For media temperatures up to 125 °C

Det Norske Veritas/Germanisher Lloyd, DNV GL

LLoyds Register of Shipping, LR

Bureau Veritas; BV

Registro Italiana Navale, RINA

• A wide range of pressure and electrical

connections

• Enclosure and wetted parts of AISI 316L

• For use in Zone 2 explosive atmospheres

• Fully digitally compensated

• Diagnostic functions and scalable performance

features available

• UL approved

Nippon Kaiji Kyokai, NKK

American Bureau of Shipping, ABS

Korean Register of Shipping, KR

China Classification Society, CCS

Russian Maritime Register of Shipping, RMRS

© Danfoss | DCS | 2021.03

AI368009388819en-000101| 1

Page 2

Data sheet | Pressure transmitter for marine applications, DST P30M

Full scale (%)

01

Full scale (%)

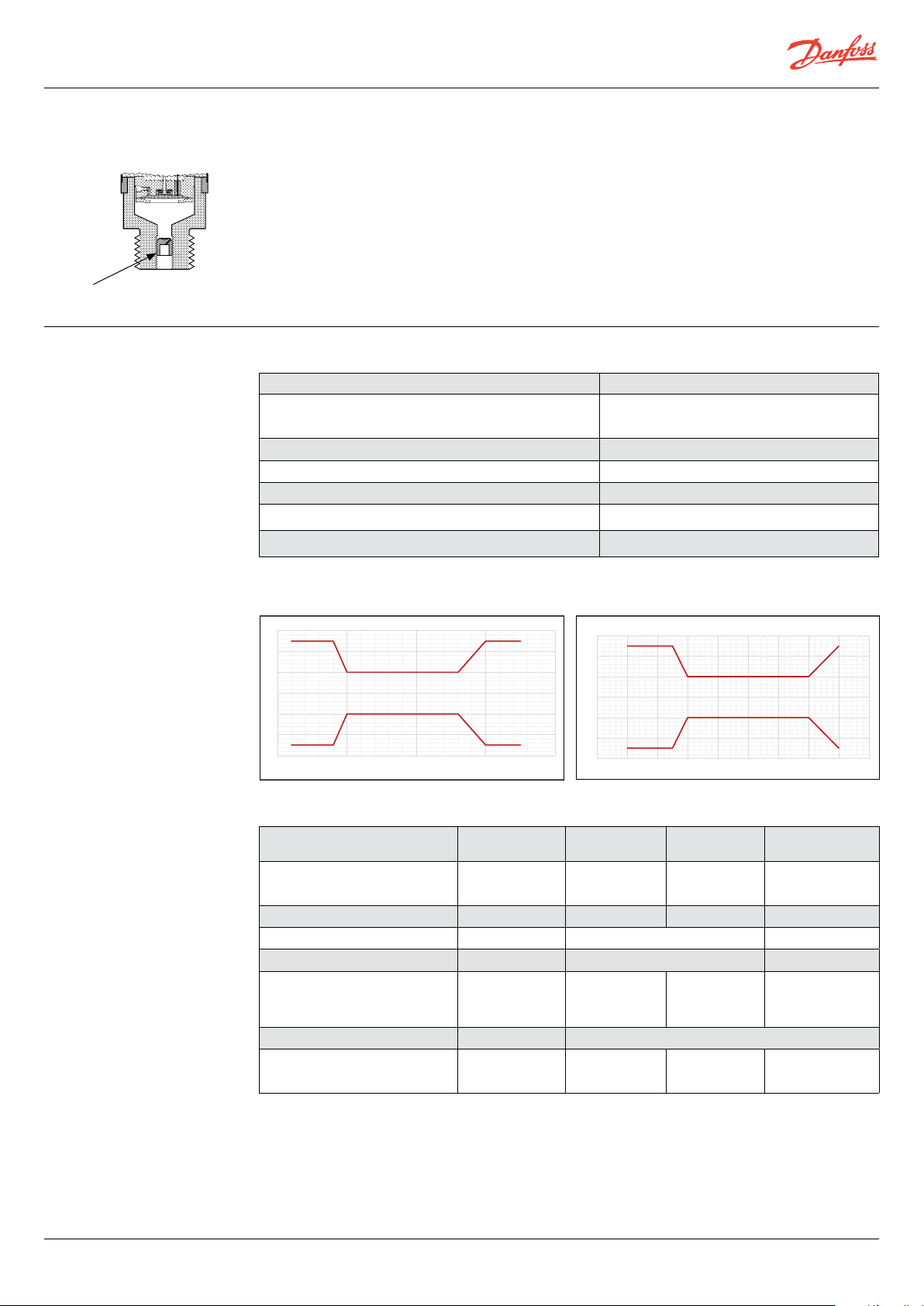

Application and media

conditions

Pulse-snubber

Technical data

Application

Cavitation, liquid hammer and pressure peaks

may occur in liquid filled hydraulic systems with

changes in flow velocity, e.g. fast closing of a

valve or pump starts and stops.

The problem may occur on the inlet and outlet

side, even at rather low operating pressures.

Media condition

Clogging of the nozzle may occur in liquids

containing particles. Mounting the transmitter

in an upright position minimizes the risk of

clogging, because the flow in the nozzle is

limited to the start-up period until the dead

volume behind the nozzle orifice is filled.

The media viscosity has only little effect on the

response time. Even at a viscosities up to

100 cSt, the response time will not exceed 4 ms.

Performance (EN 60770)

Accuracy @ 20 ºC ≤ ± 1% FS

Response time

Overload pressure (static) 6 × FS (max. 1500 bar)

Burst pressure 6 × FS (max. 2000 bar)

Power-up time < 50 ms

Durability, P: 10 – 90% FS > 10 mil. cycles

Total Error Band (TEB) Default TEB profile - see graph below

< 2 ms

Progammable fitltering available

mA version ratiometric/absolute voltage version

Danfoss

3

2

1

0

050100 150

-1

-2

-3

Temperature (°C)

60G9060

-60-40 -20020 40 60 80 10

3

2

1

0

-1

-2

-3

Temperature (°C)

Electrical specifications

Nom. output signal

(short-circuit protected)

Supply voltage [U

], polarity protected

B

4 – 20 mA 0 – 5 V, 1 – 5 V, 1– 6 V 0 – 10 V

9 – 32 V DC

(12 / 24 V DC nom.)

9 – 32 V DC

(12 / 24 V DC nom.)

(12 / 24 V DC nom.)

15 – 32 V DC

Supply – current consumption – ≤ 5 mA ≤ 8 mA < 5 mA – 5 V

Supply voltage dependency < 0.1% FS / 10 V < 0.05% FS / 10 V -

Ratiometricity - - < 0.05% FS / 4.5 - 5.5 V

0-5V: 5.75 V

Output limitation 22.4 mA

1-5V: 5.6 V

0-10V: 11.5 V ≈ supply voltage

1-6V: 6.75 V

Sink / Source – < 1 mA

10 – 90% of

supply voltage

4.5 – 5.5 V DC

(5 V DC nom.)

Danfoss

60G9059

20

2 | AI368009388819en-000101

] (load connected to 0 V) RL ≥ (UB- 9 V)/0.02 A RL ≥ 10 kΩ RL ≥ 15 kΩ RL ≥ 10 kΩ at 5 V

Load [R

L

© Danfoss | DCS | 2021.03

Page 3

Data sheet | Pressure transmitter for marine applications, DST P30M

Technical data

(continued)

Environmental conditions

Sensor operating temperature

Media temperature range -40 – 125 °C

EMC – Emission EN 61000-6-3

EMC – Immunity (Output > 1 GHz - deviation < 3%) EN 61000-6-2

Insulation resistance > 100 MΩ at 500 V DC

Vibration stability Random 7.5 g

Shock resistance Shock 500 g / 1 ms IEC 60068-2-27

Enclosure (depending on electrical connection) See page 6

4 - 20 mA -40 – 100 °C

10 - 90% of Vs & abs. voltage -40 – 125 °C

, 5 Hz – 1 kHz IEC 60068-2-64

rms

Explosive atmospheres

Zone 2 applications EN60079-0; EN60079-15

-10 ˚C < Ta < + 85 ˚C

When used in ATEX Zone 2 areas at low temperatures the cable and plug must be protected against impact

Mechanical characteristics

Wetted parts EN 10088-1; 1.4404 (AISI 316 L)

Materials

Net weight (depending on pressure connection and electrical connection) 0.2 – 0.3 kg

Enclosure EN 10088-1; 1.4404 (AISI 316 L)

Electrical connections See page 6

Pressure connections See page 5

Output and diagnostics

Pressure output signal

- Defines the measuring range of the sensor.

Output clamp levels

- Limit the pressure output signal if the

pressure rises above or falls below the normal

range.

Sensor fault signal

- Output at this level signals a sensor fault. The

fault signal setting can be high or low.

Flexible output clamping and flexible fault

signal error level to application fit available.

Contact Danfoss for detailed information and

requirements.

Self-diagnostic default levels

* programmable filtering available

Ratiometric % of

supply voltage

Zero 10% 4mA 0V 1V 1V 0V 1V

FS 90% 20mA 5V 5V 6V 10V 10V

Span 80% 16mA 5V 4V 5V 10V 9V

Output clamp level Lo 4% 3,8mA NA 0,5V 0,5V N/A 0,5V

Output clamp level Hi 99% 20,5mA 5,5V 5,5V 6,5V 11V 11V

Fault signal Lo 2% - - - - - -

Fault signal Hi - 21,5mA 5,8V 5,8V 6,8V 11,5V 11,5V

4-20mA 0-5V 1-5V 1-6V 0-10V 1-10V

© Danfoss | DCS | 2021.03

AI368009388819en-000101| 3

Page 4

Data sheet | Pressure transmitter for marine applications, DST P30M

Ordering standard

DST P30M

Type

Standard 0 0

with pulse-snubber 5 0

– –

A B 0 4

G B 0 4

A B 0 8

C D 2 8

A C 0 4

–

Gasket / O-ring material

0

No gasket

1

Gasket, Viton -20 °C – 125 °C

3

O-ring, Viton -20 °C – 125 °C

Pressure connection

G ¼ A (EN 837)

(only without pulse-snubber)

G ¼ (DIN 3852E)

G ½ A (EN 837)

G ¼ female with flange2)

¼ - 18NPT

Non-standard build-up

combinations may be selected.

However, minimum order

quantities may apply.

Please contact your local

Danfoss office for further

information or request

on other versions.

Measuring range

-1 –

-1 –

4.0 bar

10 bar

1

)

1

)

0 – 1.0 bar

0 – 1.6 bar

0 – 2.5 bar

0 – 4.0 bar

0 – 6.0 bar

0 – 10 bar

0 – 16 bar

0 – 25 bar

0 – 40 bar

0 – 60 bar

0 – 100 bar

0 – 160 bar

0 – 250 bar

0 – 400 bar

0 – 600 bar

1)

Sealed gauge only

2)

Viton gasket for flange and bolts for mounting included

* Gauge versions only available as sealed gauge versions

Preferred versions

8 6 A9

8 8 DG

1 0 A1

1 2 A6

1 4 C8

1 6

1 8 E3

2 0

2 2 Output signal

2 4 1

2 6 2 0 – 5 V

2 8 3 1 – 5 V

3 0 4 1 – 6 V

3 2 5 0 – 10 V

3 4 7 1 – 10 V

3 6

3 8

Pressure reference

1

Gauge (relative)

2

Absolute

Electrical connection

Plug (EN 175301-803-A), Pg 13.5

Cable, screened, 3 m

Plug (EN 175301-803-A), Pg 9

Plug (EN 175301-803-A), Pg 11

Bayonet plug; ISO 15170-A1-3.2-Sn

Cable, screened, 2 m

F4

* EN 60947-5-2, M12 x 1, male excl. female plug

4 – 20 mA

6 Ratiometric, 10 – 90%

4 | AI368009388819en-000101

© Danfoss | DCS | 2021.03

Page 5

Data sheet | Pressure transmitter for marine applications, DST P30M

39.5

34

oss

93Z273

39.5

38

s

93Z274

Dimensions/Combinations

Type code: A1 A6 A9 F4 / DG E3 C8

EN 175301-803-A,

Pg 9

EN 175301-803-A,

Pg 11

EN 175301-803-A,

Pg 13.5

Cable screened ship,

2 m / 3 m

EN 60947-5-2, M12 1,

male excl. female plug

ISO 15170-A1-3.2-Sn, excl

female plug, Bayonet plug

Danf

Danfos

Cartridge design

Block design

G¼ Pressure port

G ¼ A

(EN 837)

G ¼

(DIN 3852-E)

G ½ A

(EN 837)

¼ - 18 NPT G ¼ A female with flange

Type code AB04 GB04 AB08 AC 04 CD28

Recommended

1

torque

)

1

) Depends of different parameters such as gasket material, mating material, thread lubrication and pressure level

30 – 35 Nm 30 – 35 Nm 30 – 35 Nm

2 - 3 turns after

finger tightened

–

© Danfoss | DCS | 2021.03

AI368009388819en-000101| 5

Page 6

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Electrical connections

Type code, See page 5 A1 / A6 / A9 DG F4 E3 C8

Ambient temperature,

4 – 20 mA output

Ambient temperature,

ratiometric output

Enclosure

(IP protection fulfilled together

with mating connector)

Material

Electrical connection,

4 – 20 mA

output (2 wire)

Electrical connection,

ratiometric output

1)

Common

EN 175301-803-A,

Pg 9/11/13.5

Cable screened ship,

3 m

Cable screened ship

2m

EN 60947-5-2

M12 x 1; 4-pin

ISO 15170-A1-3.2-Sn

-40 – 100 °C -30 – 100 °C -30 – 100°C -25 – 90 °C -40 – 100 °C

-40 – 125 °C -30 – 125 °C -30 – 125 °C -25 – 90 °C -40 – 125 °C

IP65 IP67 IP67 IP67 IP67

Glass filled

polyamid, PA 6.6

Pin 1: + supply

Pin 2: ÷ supply

Pin 3: not used

Black wire: + supply

Blue wire: ÷ supply

Brown wire: not used

Screen: Connected

to MBS enclosure

RTFRO with PE

shrinkage tubing

Polylefin cable with

PE Shrinkage tubing

Brown wire: + supply

Black wire: ÷ supply

Red wire: not used

Orange: not used

Screen: not connected

Pin 1: + supply

Pin 2: not used

Pin 3: not used

Pin 4:÷ supply

Nickel plated

brass, CuZn/Ni

polyester PBT

Pin 1: + supply

Pin 2: ÷ supply

Pin 3: not used

Pin 4: not used

to MBS enclosure

Earth: Connected

to MBS enclosure

Pin 1: + supply

Pin 2: ÷ supply

Pin 3: + output

Black wire: + supply

1

)

Blue wire: ÷ supply

Brown wire: + output

Screen: Connected

to MBS enclosure

Red wire: + Supply

1)

Black wire: ÷ Supply

Brown wire: +Output

Orange: Not used

Screen: Not connected

Pin 1: + supply

Pin 2: not used

1)

Pin 3: + output

Pin 4: ÷ supply/

common

Pin 1: + supply

Pin 2: ÷ supply

Pin 3: not used

Pin 4: +output

to MBS enclosure

Earth: Connected

to MBS enclosure

Bayonet

Glass filled

1)

© Danfoss | DCS | 2021.03

AI368009388819en-000101

Loading...

Loading...