Page 1

Data Sheet

Pressure Transmitter

Type DST P110

For cooling applications

The Danfoss DST P110 series pressure

transmitter is designed for demanding

refrigeration, air conditioning and industrial

cooling applications, such as:

• Chillers

• Transport refrigeration

• Commercial refrigeration

• Variable speed HVAC

• Heat pumps

• Variable refrigerant ow (VRF)

Drawn from over 30 years of experience with

MEMS pressure sensing, the DST P110 oers

outstanding performance in a compact and

durable stainless-steel package.

Running a powerful ARM-based

microcontroller, the DST P110 oers diagnostic

features and scalable performance features at a

competitive price.

Features

• Hermetically sealed media interface (all

stainless steel, fully welded)

• Compatible with all refrigerants

• Industry leading accuracy over a broad

temperature range

• Compact and cost eective design for OEM

applications

• Self-diagnostics minimize warranty costs

• Enables harness fault detection

• Superior shock and vibration resistance

• High overload and burst pressure

• Robust electronics platform for harsh

electrical environments

• Low heat conduction Bi-metal solder tube

(Copper/Stainless Steel) version available.

AI277436397784en-001001

Page 2

Total error band

± 1% FS (within specied temperature range

(1)

)

Durability, P: 10%-110%

10 x 106 cycles

Burst pressure

300 bar

Overload pressure

4 x FS pressure

Response time

< 2 ms

Media temperature range

-40 – 135 °C

Ambient temperature range

-40 – 125 °C

(2)

Storage temperature range

-50 – 125 °C

Voltage supply

5 V ± 10%

Load [RL] (load connected to ground)

RL ≥ 2 kΩ at 5 V DC

Output modes

Ratiometric (10-90% Vss)

Output limiting (clamping)

Low clamp 4% Vss

High clamp 99% Vss

Over and reverse voltage

Protected to 16 V

Short circuit

Protected to 16 V

Miswiring

Protected

Diagnostic fault signal

2% Vss

EMC compatibility

EN 61000-6-3

EN 61000-6-2

ESD

IEC 61000-4-2 8 kV contact, 15 kV air

Insulation resistance

>100M Ohm at 500 V DC

Vibration resistance

16.5 g (20-2000 Hz)

EN 60068-2-64

Shock resistance

1000 g (half sinus, 1 ms)

EN 60068-2-27

Enclosure material

AISI 304L Stainless steel and PBT (30% glass reinforced)

Material with media contact

AISI 304L Stainless steel; AISI 316L Stainless steel

Weight

approx. 61 g for solder tube & 62 g for female are

Enclosure

IP 67

Pressure Transmitter, type DST P110

Product specication

Technical data

(1)

(1)

See code number table for focused accuracy ranges

See code number table for focused accuracy ranges

Table 1: Overload and burst pressure

Table 2: Environmental conditions

(2)

(2)

Contact Danfoss for higher temperatures

Contact Danfoss for higher temperatures

© Danfoss | Climate Solutions | 2021.02 AI277436397784en-001001 | 2

Page 3

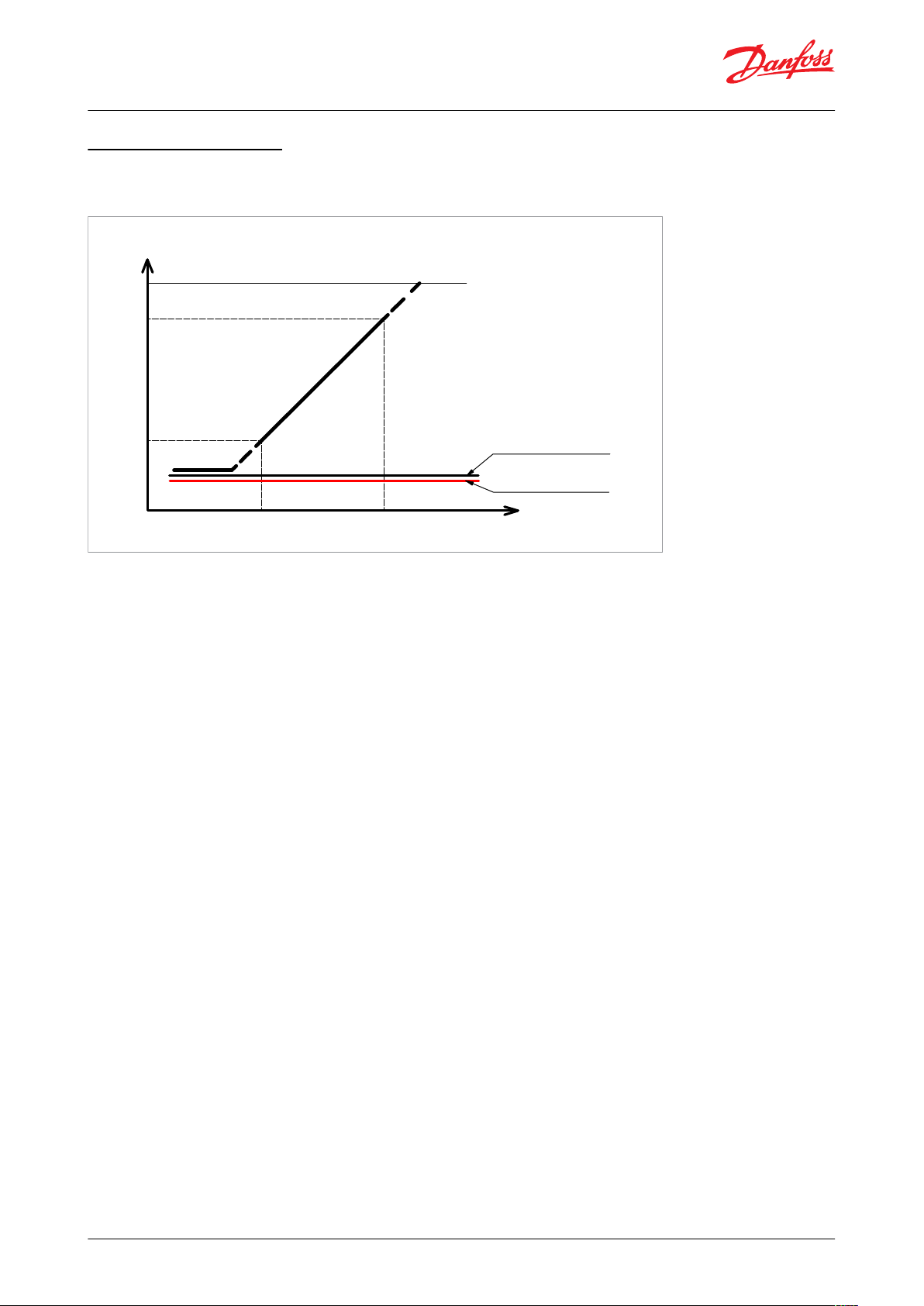

Output

[ %Vs ]

100%

90%

0%

Zero

FS

Pressure

Pressure output signal range

Clamp level 4%

10%

Fault signal 2%

Pressure Transmitter, type DST P110

Output and diagnostics

Ratiometric example

Figure 1: Output and Diagnostics

Output range

• Denes the measuring range of the sensor

Output clamp levels

• Limit the pressure output signal if the pressure rises above or falls below the normal range

Sensor fault signal

• Placed below the pressure output range. Output at this level signals a sensor fault

Harness fault detection

• Low leakage current of the sensor allows the controller to recognize harness fault conditons. (Requires a pulldown or pull-up resistor at controller interface).

If the connected controller has an internal pull up or pull down resistor at the analog channel input, then the loss of

ground or supply voltage (Vss) connection to the sensor will result in a near Vss or near ground signal voltage.

Contact Danfoss for detailed information and requirements.

© Danfoss | Climate Solutions | 2021.02 AI277436397784en-001001 | 3

Page 4

Metri-Pack 150 (Round)

Metri-Pack 150 (Round)

7/16-20 UNF

Ø17

56,1

44,1

7

4

,

8

5

4

6

,

3

5

1/4 inch

SAE female are

Solder tube

HEX 27

Pin A

Pin B

Pin C

2

7

H

E

X

Pin-plating

Tin (Sn)

Pin A: ÷Supply

Pin B: +Supply

Pin C: Output

Pressure Transmitter, type DST P110

Dimensions / Combinations

Table 3: Dimensions

Electrical connections

Table 4: Electrical connection specications

© Danfoss | Climate Solutions | 2021.02 AI277436397784en-001001 | 4

Page 5

Type

Operating range

Units

Colour code elec‐

trical connector

Focus tempera‐

ture range (1%

TEB)

Pressure port

Code no.

Code no. I-Pack

(2)

DST P110

0 – 150

psia

Green

-20 °C – 40 °C

7/16 UNF, female

(1)

075G1014

075G4003

0 – 200

psia

Green

-20 °C – 40 °C

075G1016

075G4005

0 – 400

psi sg

Black

0 °C – 80 °C

075G1019

075G4008

0 – 500

psi sg

Black

0 °C – 80 °C

075G1021

075G4010

-1 – 12

bar sg

Green

-20 °C – 40 °C

075G1013

075G4002

-1 – 34

bar sg

Black

0 °C – 80 °C

075G1018

075G4007

-1 - 49

bar sg

Black

-30 °C – 40 °C

075G1080

075G4058

0 – 10

bar sg

Green

0 °C – 80 °C

075G1012

075G4001

0 – 15

bar sg

Green

-20 °C – 40 °C

075G1085

075G4063

0 – 20

bar sg

Green

-20 °C – 40 °C

075G1015

075G4004

0 – 30

bar sg

Black

0 °C – 80 °C

075G1017

075G4006

0 – 32

bar sg

Black

0 °C – 80 °C

075G1036

075G4019

0 – 50

bar sg

Black

0 °C – 80 °C

075G1020

075G4009

0 – 10

bar

Green

-40 °C – 40 °C

Solder tube

075G1072

075G4051

0 – 30

bar

Black

0 °C – 100 °C

075G1071

075G4050

Electrical connection

Round Packard , Metri-Pack

Type

I-Pack Code no.

Qty/Box

Description

Cable with Metri-Pack 150 (Round) mating connector

060G8085

60 pcs.

0.8 m with outer sheath

Cable with Metri-Pack 150 (Round) mating connector

060g8086

60 pcs.

1.3 m with outer sheath

Cable with Metri-Pack 150 (Round) mating connector

064G0910

(1)

14 pcs.

10 m with outer sheath

Pressure Transmitter, type DST P110

Ordering

Table 5: Standard ordering type

(1)

(1)

¼” are with a deator pin

¼” are with a deator pin

(2)

(2)

I- Pack contains 60 pcs. per box for 7/16 UNF & 55 pcs. per box for solder tube

I- Pack contains 60 pcs. per box for 7/16 UNF & 55 pcs. per box for solder tube

Electrical connector colour coding:

• Black: High pressure prole

• Green: Low pressure prole

CO2 application: Sensors with an overload pressure exceeding 90bar can be used for CO2 applications - see

overload pressure specication on Table 1: Overload and burst pressure

Accessories

Table 6: Cable accessories

(1)

(1)

Multi Pack code number is 064G0950

Multi Pack code number is 064G0950

For more options and info, please go to https://store.danfoss.com/

© Danfoss | Climate Solutions | 2021.02 AI277436397784en-001001 | 5

Page 6

File name

Document type

Document topic

Approval authority

060R3142.06

Manufacturers Declaration

PED

Danfoss

075R0015.00

Manufacturers Declaration

R32 & R290 ignition statement

Danfoss

E494625

Electrical - Safety Certicate

-ULE510763

Electrical - Safety Certicate

-

UL

Pressure Transmitter, type DST P110

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 7: Certicates and declarations

Conformity

• CE marked

• RoHS compliant

• UL le for refrigeration: E31024

• UL le for Hazloc: E510763

© Danfoss | Climate Solutions | 2021.02 AI277436397784en-001001 | 6

Page 7

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI277436397784en-001001 | 7

Loading...

Loading...