Page 1

Data Sheet

DSP MINI

a Danfoss Platform for Flensburg Secondary Network

General description and

application

The DSP MINI is designed for use in district heating

networks, suitable for heating and for providing

DHW for single family houses. It provides an alternative solution to an oil or gas boiler. The DSP MINI

is designed for heating, do mestic hot water and floor

heating. The wall- mounted construction saves space

which is needed for installation and service.

The DSP MINI is designed as a wall -mounted sta tion.

Each station is equipped with micro plate heat

exchangers for DHW and optional for heating manufactured by Danfoss, which significantly increase

substation performance and lifetime. All components are placed at the front of the station, which

makes it very easy to access them during maintenance or servicing. The mounting bracket significantly reduces the time required to mount the substation to the wall. The connections are predefined

and allow installers to prepare installation before

station is available on the site, which reduces the

time between deliver y and startup. Piping prepared

with automatic welding machines ensures th e highest possible welding quality.

DSP MINI is equipped with high quality Danfoss

components, which are tested, approved and optimized for safe and reliable operation:

• ECL Comfort 310 controller

• Motorized control valves

• AVTB self-acting temperature controller

• AVPB-F Differential pressure controller with flow

limitation

• Brazed MicroPlate™ Heat exchanger, XB06

• Primary side polyurethane insulation according

50% ENEV 2013

• Metal box with door

Operating parameters

Materials

Primary side

Maximum temperature 95°C

Maximum pressure 10 bar (g)

Connection DN 20 / Rp ¾”

Heating

Maximum temperature* 95°C

Maximum pressure* 10 bar (g)

Connection DN 20 / Rp ¾”

Domestic Hot Water

Maximum temperature 95°C

Maximum pressure 10 bar (g)

Connection DN 20 / Rp ¾”

Max dimensions (mm)

Width ⁄ Height ⁄ Depth 770 / 1000 / 330 mm

Weight (incl. packing) max. 80 kg

* In case of floor heating with heat exchanger the maximum

temperature is 50 °C and the maximum pressure is 3 bar(g)

Pipes, fittings, valves (primary side) P235GH, CuSn5ZnPb (Rg5), Red bronze (Rg5), brass MS58 (nickel plated)

Pipes, fittings, valves (heating side) P235GH , EN - GJL-150 (GG15)

Pipes, fittings, valves (DHW side) 1.4404, 1.4301, CW617N

Heat exchanger 1.4404 with Cu brazed

Insulation (heat exchanger) PU foam (λ=0.035 W/mK)

Insulation (piping primary side) PU foam (λ<0.025 W/mK)

© Danfoss | 2020.01

AI246186498258en-010202 | 1

Page 2

Data Sheet DSP MINI a Danfoss Platform for Flensburg Secondary Network

Circuit diagram

2

1

3

2

3

1

TIPI

18

TIPI

18

Approval number

FL-S-DL37-U-D-17/11

2

3

1

TIPI

18

4

3xDN 5xDN

5

6

4

15

10

7

15

2

PI

3

4

17

11

21

22

17

ECL

310

A230

13

25

15

16

23

16

15

12

2

3

1

TIPI

3xDN 5xDN

18

5

Approval number

FL-S-DL37-R-D-17/11

1 Ball valve with M10

sensor connection

2 Manometer

3 Manovalve

4 Strainer

5 Drain valve

6 Insert energy meter

7 Pressure controller AVPB-F

10

6

7

8 Control valve VM2

9 Heat exchanger

10 Shut off valve 6 mm

11 Temperature controller AVTB

12 Pump

13 Heat exchanger

14 Safety valve

15 Ball valve

15

17

PI

2

4

3

8

17

11

13

28

15

16

23

16

16 Ball valve DVGW

17 Ball valve

18 Bimetal thermometer

21 ECL

22 ECL application key

23 Safety valve

25 Temperature sensor

27 Safety temperature monitor (STW)

28 Check valve

2 | © Danfoss | 2020.01

AI246186498258en-010202

Page 3

Data Sheet DSP MINI a Danfoss Platform for Flensburg Secondary Network

21

ECL

22

2

3

1

TIPI

4

18

310

A230

25

27

15

12

2

3

1

TIPI

18

5

Approval number

FL-S-DL37-R/FB-D-17/11

2

1

3

2

3

1

TIPI

4

18

TIPI

18

5

3xDN

3xDN 5xDN

5xDN

6

6

10

7

10

4

7

15

2

PI

4

3

15

PI

2

3

17

21

22

17

17

11

ECL

310

A230

8

28

15

8

16

23

27

16

15

12

15

16

13

25

14

9

23

Approval number

FL-S-DL37-R/FB/WT-D-17/11

1 Ball valve with M10

sensor connection

2 Manometer

3 Manovalve

4 Strainer

5 Drain valve

6 Insert energy meter

7 Pressure controller AVPB-F

AI246186498258en-010202

17

8 Control valve VM2

9 Heat exchanger

10 Shut off valve 6 mm

11 Temperature controller AVTB

12 Pump

13 Heat exchanger

14 Safety valve

15 Ball valve

13

11

16 Ball valve DVGW

17 Ball valve

18 Bimetal thermometer

21 ECL

22 ECL application key

23 Safety valve

25 Temperature sensor

27 Safety temperature monitor (STW)

28 Check valve

© Danfoss | 2020.01 | 3

16

Page 4

Data Sheet DSP MINI a Danfoss Platform for Flensburg Secondary Network

2

3

1

2

3

1

Approval number

FL-S-KP-U-D-17/11

2

3

1

TIPI

18

TIPI

18

TIPI

18

4

3xDN

5xDN

10

15

2

PI

4

3

15

15

1717

5

4

6

7

21

ECL

22

310

A230

25

15

12

1

Approval number

FL-S-KP-R-D-17/11

1 Ball valve with M10

sensor connection

2 Manometer

3 Manovalve

4 Strainer

5 Drain valve

6 Insert energy meter

7 Pressure controller AVPB-F

4 | © Danfoss | 2020.01

10

2

3

TIPI

3xDN 5xDN

18

5

6

2

3

8 Control valve VM2

9 Heat exchanger

10 Shut off valve 6 mm

11 Temperature controller AVTB

12 Pump

13 Heat exchanger

14 Safety valve

15 Ball valve

15

PI

8

17

17

28

15

16 Ball valve DVGW

17 Ball valve

18 Bimetal thermometer

21 ECL

22 ECL application key

23 Safety valve

25 Temperature sensor

27 Safety temperature monitor (STW)

28 Check valve

AI246186498258en-010202

Page 5

Data Sheet DSP MINI a Danfoss Platform for Flensburg Secondary Network

21

ECL

22

2

3

1

TIPI

4

18

310

A230

25

27

15

12

2

3

1

TIPI

18

Approval number

FL-S-KP-R/FB-D-17/11

2

1

3

2

3

1

TIPI

18

TIPI

18

Approval number

FL-S-KP-R/FB/WT-D-17/11

1 Ball valve with M10

sensor connection

2 Manometer

3 Manovalve

4 Strainer

5 Drain valve

3xDN

5

4

3xDN 5xDN

5

6

6

10

PI

2

4

2

3

17

3

17

15

PI

17

5xDN

10

4

7

6 Insert energy meter

7 Pressure controller AVPB-F

8 Control valve VM2

9 Heat exchanger

10 Shut off valve 6 mm

11 Temperature controller AVTB

12 Pump

13 Heat exchanger

14 Safety valve

15

21

22

28

8

17

ECL

310

A230

8

15 Ball valve

16 Ball valve DVGW

17 Ball valve

18 Bimetal thermometer

21 ECL

22 ECL application key

23 Safety valve

25 Temperature sensor

27 Safety temperature monitor (STW)

28 Check valve

25

14

27

9

15

15

12

15

Function

AI246186498258en-010202

The DSP Mini substation is the connecting part

between the h eat supplier and the consumer of the

heating and domestic hot water.

The task of the substation is to adapt the heat condition suitable for the consumer and meet the

demand from the heat supplier and consumer.

The water is coming from the district heating utility

and is fed into the station at the appropriate pressure and temperature. This can be higher in winter

and lower in the summer. The district heating water

flows in the primary fl ow through the shut-off valves

and the strainer. Pressure gauges and thermom eters

are installed in the flow and return to detect the

pressure and temperature.

Depending on the variant, the connection of the

secondary side (heating) is carried out directly or

indirectly (via heat exchanger).

Furthermore, on the primary side, in the flow circuit

we have a control valve, depending on the variant,

control valves are used to adapt the heat condi tions

(secondary temperature) by controling the flow of

district heating water. The input s are comming from

using our Danfoss ECL Comfort 310 controller with

weather compensating function.

The district heating water then flows back to the

district heating supply via the primary return

through the shut-off valves and the strainer. On the

primary side, high tem perature connections for radi

ator heating or similar are used depending on the

application selected.

In the secondary circuit, a circulating pump distributes the heating water to the heating devices, this

is available depending on the application.

If the application selected has domestic hot water

production included, this is connected to the primary side and is prepare via a heat exchanger and

with a self-acting control valve.

To limit the flow of primary district heating water,

a flow limiter with integrated differential pressure

control is provided in the return of th e primary side,

here the maximum flow from the contract can be

adjusted. To measure the energy consumed, an

insert for a heat meter is available and M10 connections are provided in the primary side ball valves.

© Danfoss | 2020.01 | 5

-

Page 6

Data Sheet DSP MINI a Danfoss Platform for Flensburg Secondary Network

205

305

395

485

575

530

128

173

Capacity, weight and dimensions

Code Description

Typ e

Capacity

[kW]

Heat exchanger Pipe diameter

HE DHW HE DHW DH HE DHW kPa

146G0000

1

146G0001

2

146G0002

3

146G0003

4

5

146G0004

146G0005

6

146G0006

7

146G0007

8

* Calculated with 15 deg ΔT (40/65 °C)

** Calculated with 10 deg ΔT (25/35 °C)

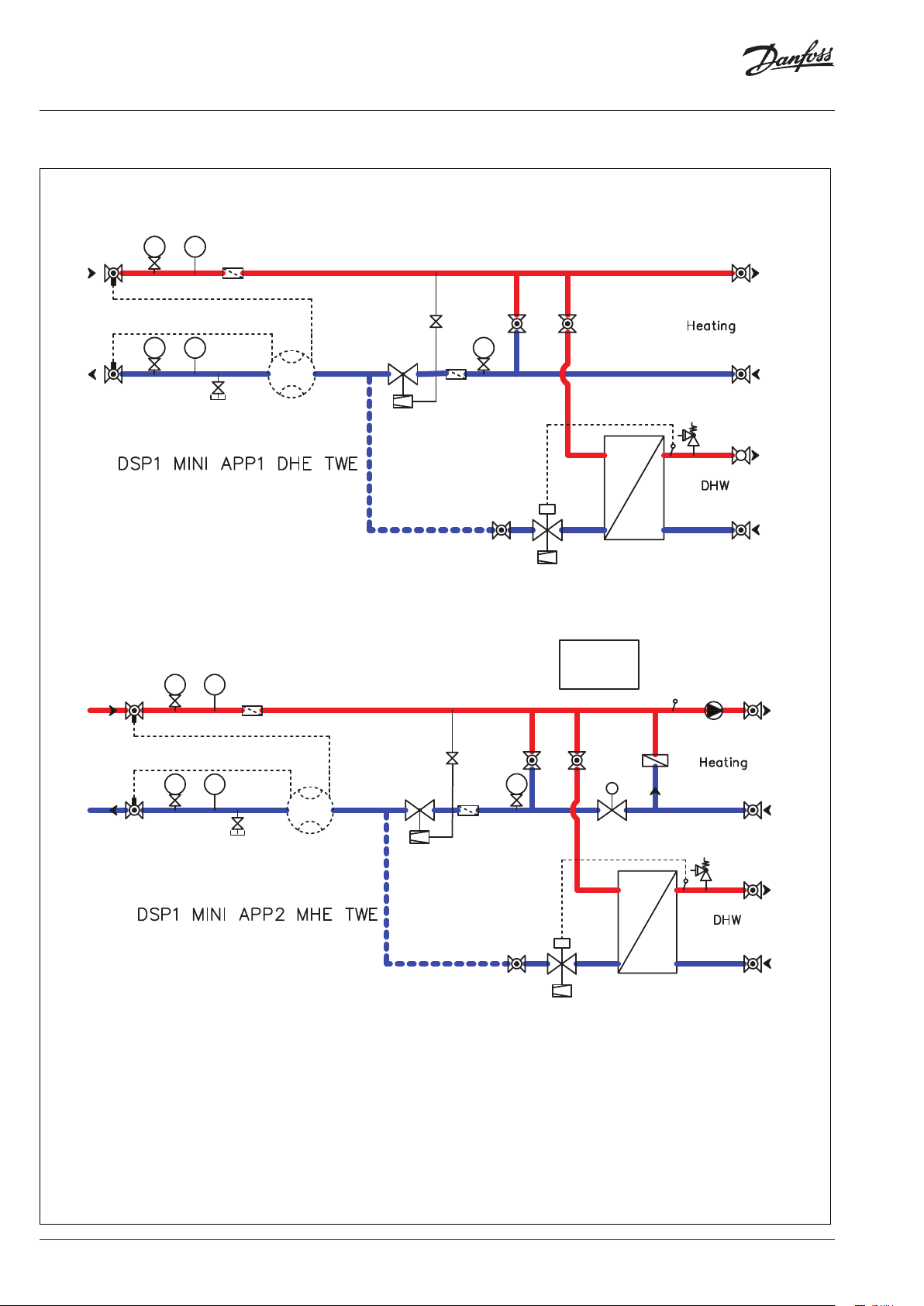

DSP1 MINI APP1 DHE TWE 14*

DSP1 MINI APP2 MHE TWE 14*

DSP1 MINI APP3 FBH TWE 10* *

DSP2 MINI APP4 FBH TWE 10* *

37***

37***

37***

37***

n/a XB06H+-1-30

n/a XB06H+-1-30 65 66* FL-S-DL37-R-D-17/11

n/a XB06H+-1-30 65 65** FL-S-DL37-R/FB-D-17/11

XB06L-1-10 XB06H+-1-30 70 55**

DSP0 MINI APP5 DHE – 14* – n/a n/a 50 18**** FL-S-KP-U-D-17/11

DSP0 MINI APP6 MHE – 14* – n/a n/a 55 66* FL-S-KP-R-D-17/11

DSP0 MINI APP7 FBH – 10** – n/a n/a 55 65** FL-S-KP-R/FB-D-17/11

DSP1 MINI APP8 FBH – 10** – XB0 6L-1-10 n/a 60 55** FL-S-KP-R/FB/WT-D-17/11

*** Calculated with 40 deg ΔT (10/50 °C)

**** No pump is available in this application

DSP 1 MINI APP1 DHE TWE

Typ e No. of hex Application no Type of heating Type of DHW

MINI APP1 DHE = Direct heating TWE = Instantaneus

MINI APP2 FBH = Floor heating – = Connections

MINI APP3 MHE = Mixing heating

MINI APP4

MINI APP5

MINI APP6

MINI APP7

MINI APP8

DN 20 / R p ¾”

Max

(kg)

Heating Dp

available

approval number

Weight

60 18**** FL-S-DL37-U-D-17/11

FL-S-DL37-R/FB/WT-D-17/11

95

83

72

0

0

45

90

766

755

908

Configuration Contact the sales staff responsible for additional

details and a quotation for the DSP MINI.

290

Radiator heating return

Radiator heating supply

Drain valve

Primary out

Primary in

998

MAG

Heating return

Heating supply

Domestic hot water

Drain pipes

Cold water

6 | © Danfoss | DHS-SMDBT/PL | 2020.01

AI246186498258en-010202

Loading...

Loading...