Page 1

Application Guide

Scroll compressors

DSF090 to DSF530

Single and manifold, 50-60 Hz - R32

www.danfoss.com

Page 2

Scroll compressors, DSF090 to DSF530 | Contents

Contents

Safety and warnings 5

Introduction 6

Product description 6

Cut Away DSF090-200 6

Cut away DSF 270-530 7

How do IDVs work? 7

Product identication 8

Name Plate 8

Nomenclature 8

Compressors serial number 9

Certicates, declarations, and approvals 10

Low voltage directive 2014/35/EU 10

Machines directive 2006/42/EC 10

Pressure equipment directive 2014/68/EU 10

Internal free volume 10

Refrigerants 11

General information 11

R32 11

Technical specication 12

50-60 Hz data, Single compressor 12

Performance data 13

R32 50-60 Hz, Single compressor 13

Tandem and trio performances 13

Sound and vibration data 14

Compressor sound radiation 14

Mechanical vibrations 15

Operating envelope data 16

Operating envelope 16

Dimensions 18

Single compressors 18

Tandem assemblies 19

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 2

Page 3

Scroll compressors, DSF090 to DSF530 | Contents

Trio assemblies 20

Mechanical connections 22

Connection details 22

Design compressor mounting 22

Design piping 26

Electrical connections 33

Wiring connections 33

Electrical specications 34

Application 39

Manage oil in the circuit 39

Manage sound and vibration 39

Manage operating envelope 40

Manage superheat 42

Manage o cycle migration 44

Power supply and electrical protection 47

Control logic 49

Reduce moisture in the system 51

Assembly line procedure 52

Commissioning 55

Dismantle and disposal 56

Packaging 57

Single pack 57

Industrial pack 57

Ordering 58

Compressor code numbers 58

Single pack 58

Industrial pack 58

Accessories and spare parts 60

Gaskets 60

Solder sleeve 60

Rotolock nut 60

Motor protection modules 60

Surface sump heaters 61

Mounting hardware 61

Lubricant 61

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 3

Page 4

Scroll compressors, DSF090 to DSF530 | Contents

Terminal boxes, covers and T-block connectors 62

Acoustic hoods 62

Miscellaneous 62

Tandem kits 62

Trio kits 63

Online support 64

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 4

Page 5

Scroll compressors, DSF090 to DSF530 | Safety and warnings

Safety and warnings

Danfoss compressors are designed and manufactured according to the state of the art and to valid European and US

regulations. Particular emphasis has been placed on safety and reliability. Related instructions are highlighted with

the following icons:

This icon indicates instructions to avoid safety risk.

This icon indicates instructions to avoid reliability risk.

The purpose of this guideline is to help customers qualify compressors in the unit. You are strongly advise to follow

these instructions. For any deviation from the guidelines, please contact Danfoss Technical Support. In any case,

Danfoss accepts no liability as a result of the improper integration of the compressor into the unit by the system

manufacturer.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 5

Page 6

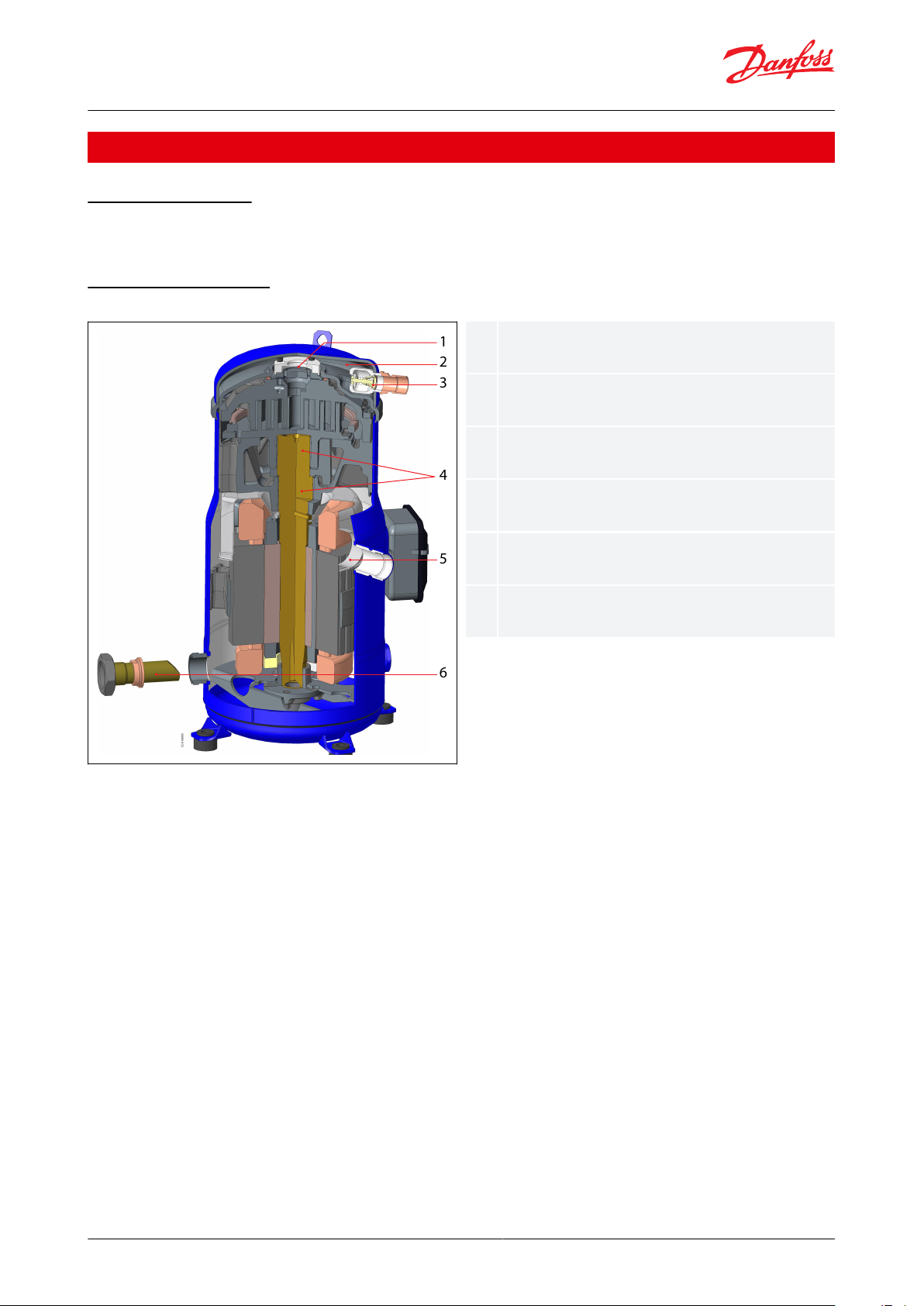

1

2

4

5

6

3

CC-000005

12345

6

Intermediate discharge valves (IDVs) increase

seasonal eciency

Heat shield lowers the heat transfer between

discharge and suction gas and the sound level

Internal Non Return Valve (INRV) prevents

excessive leak rate from high pressure side

Lead free polymer bearings improve behavior

under poor lubrication conditions

Patented motor cap for optimal motor cooling and

higher resistance to liquid slugging

Organ pipe masters oil circulation in manifold

conguration.

Scroll compressors, DSF090 to DSF530 | Introduction

Introduction

Product description

DSF series scroll compressor benet from an improved design to achieve the highest eciency and increased life

time.

Cut Away DSF090-200

Figure 1: Cut Away DSF090-200

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 6

Page 7

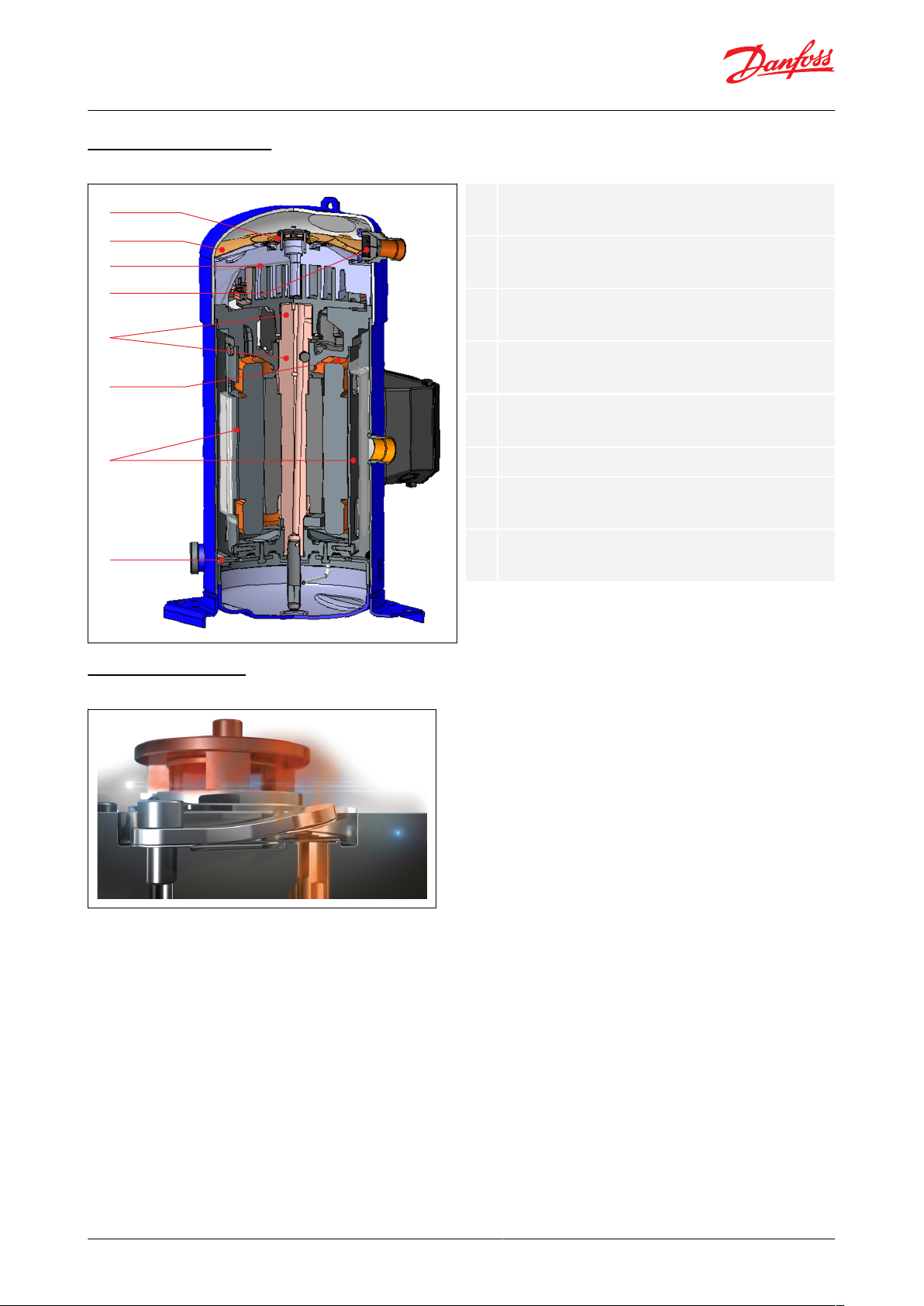

1

2

3

4

5

6

7

8

1234567

8

Intermediate discharge valves (IDVs) increase

seasonal eciency

Heat shield lowers the heat transfer between

discharge and suction gas and the sound level

Integrated discharge gas temperature protection

(DGT)

Internal Non Return Valve (INRV) prevents

excessive leak rate from high pressure side

Lead free polymer bearings improve behavior

under poor lubrication conditions

Patented motor cap for optimal motor cooling

Patented gas path ow with gas intake design

induce higher resistance to liquid slugging

Organ pipe masters oil circulation in manifold

conguration.

Scroll compressors, DSF090 to DSF530 | Introduction

Cut away DSF 270-530

Figure 2: Cut Away DSF 270-530

How do IDVs work?

Figure 3: Intermediate Discharge Valve (IDV)

Danfoss Intermediate Discharge Valves (IDVs) are located close to the discharge side of the compressor. They reduce

excessive compression of refrigerant under part-load conditions while maintaining the same cooling capacity. The

IDVs open when discharge pressure falls below the built-in optimization point. They adapt the eort of the motor to

the varying load and pressure conditions in the system, thus reducing the eort of the motor and its electrical

consumption and improving the system’s seasonal energy eciency.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 7

Page 8

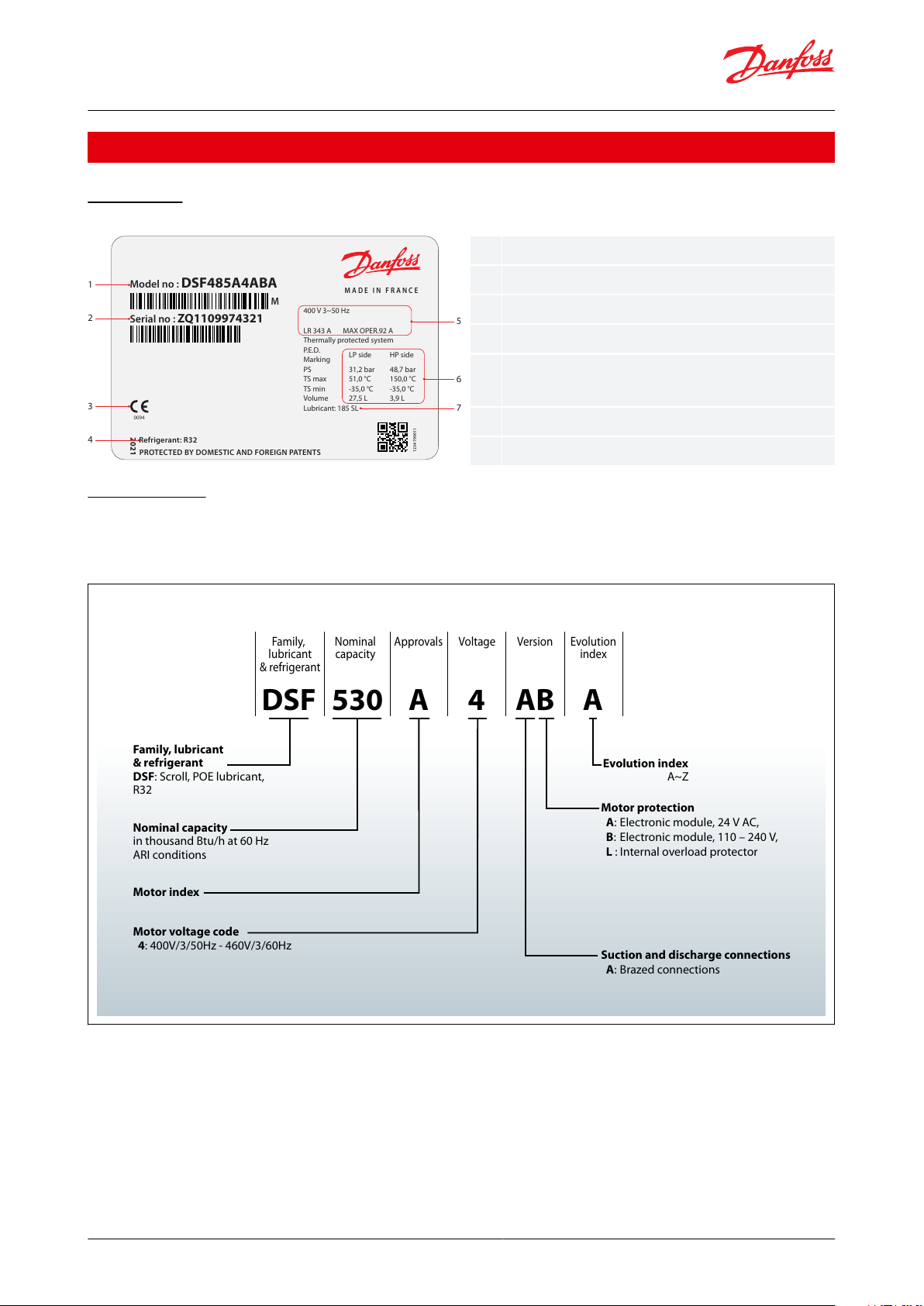

M A D E I N F R A N C E

Model no : DSF485A4ABA

Serial no : ZQ1109974321

400 V 3~50 Hz

Thermally protected system

P.E.D.

Marking

LP side HP side

PS 31,2 bar 48,7 bar

TS max 51,0 °C 150,0 °C

TS min -35,0 °C -35,0 °C

Volume 27,5 L 3,9 L

Lubricant: 185 SL

M

2021

Refrige rant: R32

12347 9901 1

PROTEC TED BY DOM ESTIC AND FOREIGN PATENTS

0094

1

5

6

7

2

3

4

LR 343 A MAX OPER.92 A

123

4567Model number

Serial number

Approvals

Refrigerant

Supply voltage, Starting current & Maximum

operating current

Housing service pressure

Factory charged lubricant

Family, lubricant

& refrigerant

DSF: Scroll, POE lubricant,

R32

Motor protection

A: Electronic module, 24 V AC,

B: Electronic module, 110 – 240 V,

L : Internal overload protector

Suction and discharge connections

A: Brazed connections

Family,

lubricant

& refrigerant

Nominal

capacity

Approvals Voltage Version Evolution

index

Evolution index

A~Z

A4DSF A AB530

Motor voltage code

4: 400V/3/50Hz - 460V/3/60Hz

Motor index

Nominal capacity

in thousand Btu/h at 60 Hz

ARI conditions

Scroll compressors, DSF090 to DSF530 | Product identication

Product identication

Name Plate

Figure 4: Name Plate

Nomenclature

Danfoss scroll compressor DSF for R32 is available as single compressor and can be assembled in tandem or trio

combinations. The example below presents the compressor nomenclature which equals the technical reference as

shown on the compressor nameplate. Code numbers for ordering are listed in section Ordering.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 8

Page 9

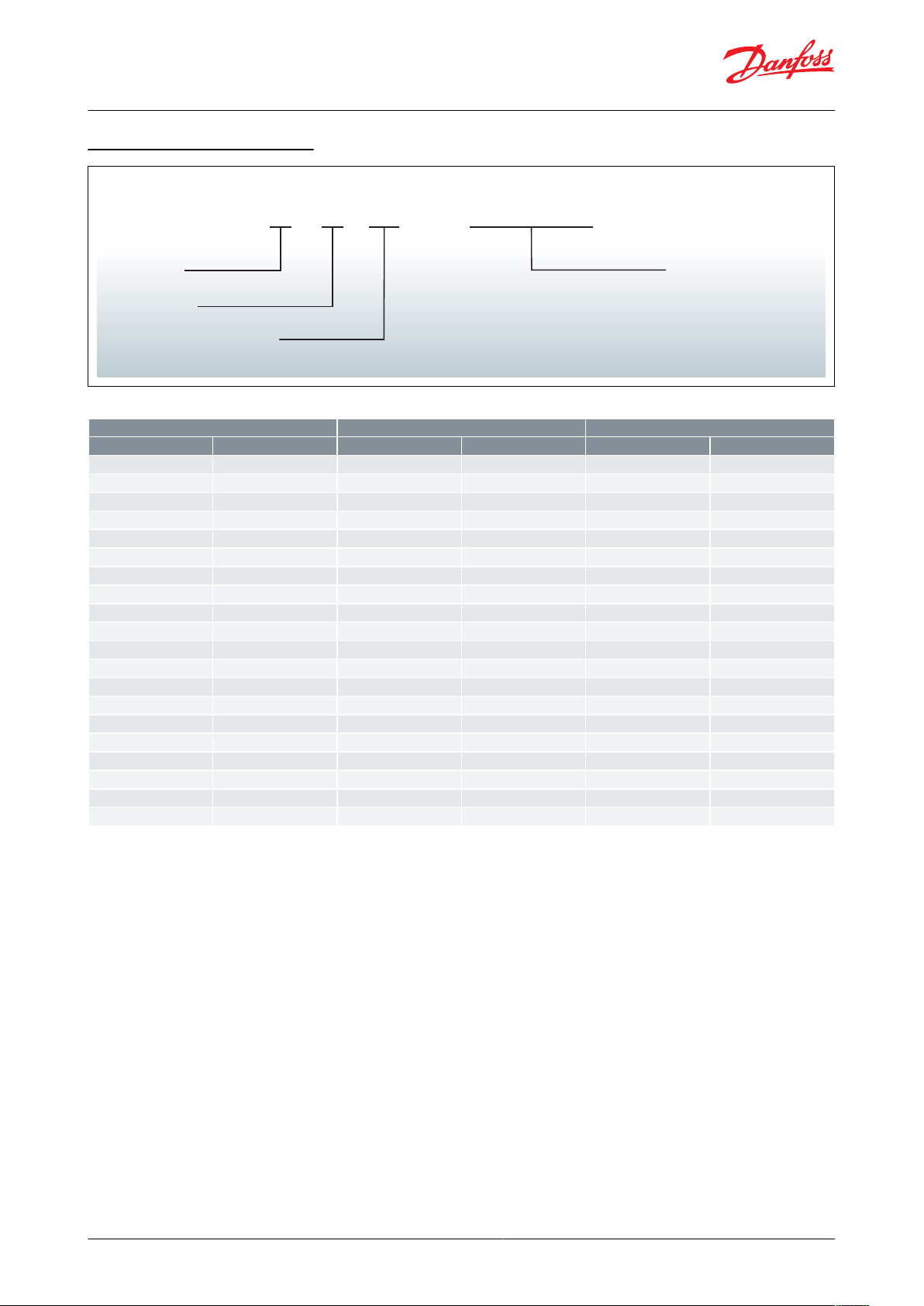

Year code 8 Digit serial number

12345678A 25B

Plant assembly line code

Month code

Year code

Month code

Plant assembly line code

Year

Code

Month

Code

Plant

Code

1990, 2010

A

January

A

Trévoux, France

11

1991, 2011

B

February

B

1992, 2012

C

March

C

1993, 2013

D

April

D

Wuqing ,China

25

1994, 2014

E

May

E

1995, 2015

F

June

F

1996, 2016

G

July

G

1997, 2017

H

August

H

1998, 2018

J

September

J

1999, 2019

K

October

K

2000, 2020

L

November

L

2001, 2021

M

December

M

2002, 2022

N

2003, 2023

P

2004, 2024

Q

2005, 2025

R

2006, 2026

S

2007, 2027

T

2008, 2028

U

2009, 2029

V

Scroll compressors, DSF090 to DSF530 | Product identication

Compressors serial number

Table 1: Serial number code legend table

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 9

Page 10

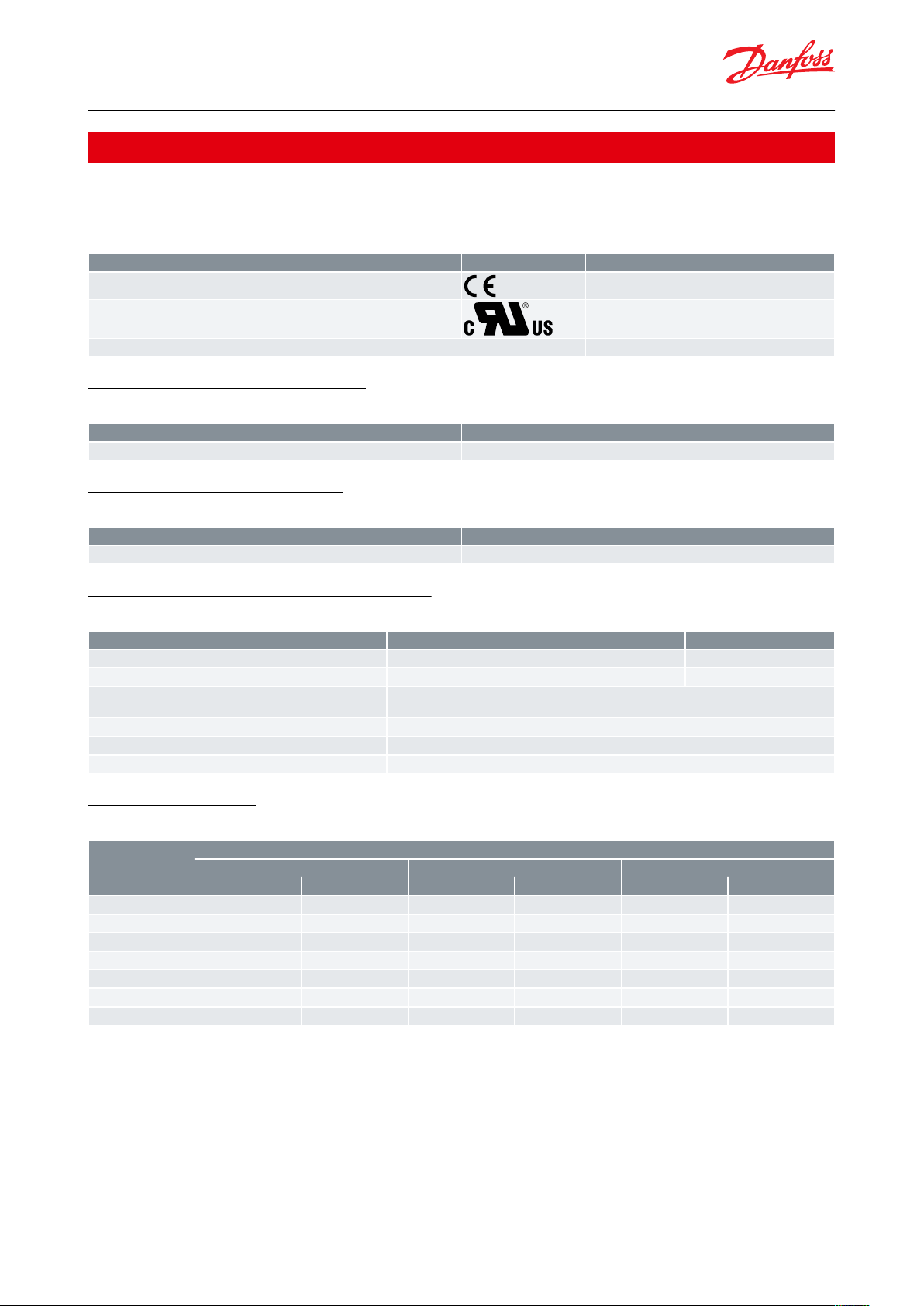

Approval and certicates

Certication logo

Models

CE0062 or CE0094 (European Directive)

All DSF models

UL (Underwriters Laboratories)

All DSF models

Other approvals / certicates

Contact Danfoss

Products

DSF models

Declaration of conformity

Contact Danfoss

Products

DSF models

Manufacturer’s declaration of incorporation

Contact Danfoss

Products

DSF090-200

DSF270-325

DSF485-530

Refrigerant

uids

Group 1

Group 1

Group 1

Category PED

III

III

IV

Maximum / Minimum temperature (Low side) - Ts

-35°C < Ts < 53°C

-31°F < Ts < 127°F

-35°C < Ts < 51°C

-31°F < Ts < 125.6°F

Maximum allowable pressure (Low side) - Ps

32.7bar(g) / 474psig

31.2 bar(g) / 452 psig

Maximum allowable pressure (High side) - Ps

48.7 bar(g) / 706 psig

Declaration of conformity

Contact Danfoss

Products

Internal free volume without oil

Low pressure side

High pressure side

Total

litre

cu.inch

litre

cu.inch

litre

cu.inch

DSF090-100

11.7

714

0.74312.4

757

DSF115-175

13.6

830

0.74314.3

873

DSF200

13.9

848

0.74314.6

891

DSF270

27.5

1678

2.9

177

30.4

1855

DSF325

27.1

1654

2.8

171

29.9

1825

DSF485

28.5

1739

3.9

238

32.4

1977

DSF530

28.5

1739

3.9

238

32.4

1977

Scroll compressors, DSF090 to DSF530 | Certicates, declarations, and approvals

Certicates, declarations, and approvals

DSF scroll compressors comply with the following approvals and certicates.

Certicates are listed on: Documentation for Commercial Compressor | Danfoss

Table 2: Approval and certicates

Low voltage directive 2014/35/EU

Table 3: Low voltage directive 2014/35/EU

Machines directive 2006/42/EC

Table 4: Machines directive 2006/42/EC

Pressure equipment directive 2014/68/EU

Table 5: Pressure equipment directive 2014/68/EU

Internal free volume

Table 6: Internal free volume

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 10

Page 11

Scroll compressors, DSF090 to DSF530 | Refrigerants

Refrigerants

General information

When choosing a refrigerant, dierent aspects must be taken into consideration:

• Legislation (now and in the future)

• Safety

• Application envelope in relation to expected running conditions

• Compressor capacity and eciency

• Compressor manufacturer recommendations & guidelines

Additional points could inuence the nal choice:

• Environmental considerations

• Standardisation of refrigerants and lubricants

• Refrigerant cost

• Refrigerant availability

R32

R32 is a pure HFC refrigerant with a zero Ozone Depletion Potential (ODP=0) and a low Global Warming Potential

(GWP: 677/AR5; 675/AR4).

R32 leads to higher discharge temperatures than R410A but it oers higher cooling capacities and better eciencies

compared to R410A.

R32 is classied A2L with low ammability properties. Please refer to European regulations and directives about the

use of refrigerant of the A2L safety group (EN378, EN60335). Outside Europe refer to the local regulation

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 11

Page 12

Model

Swept volume

Displacement (50 Hz)

(1)

Displacement (60 Hz)

(2)

Oil charge

Net weight

(3)

cm3/rev

cu.in/rev

m3/h

cu.ft/h

m3/h

cu.ft/h

dm

3

ozkglbs

DSF090

81.3

4.96

14.2

500

17.1

603

3.0

10258128

DSF100

88.4

5.39

15.4

544

18.6

657

3.0

10258128

DSF115

103.5

6.3218636

21.8

770

3.3

11364141

DSF130

116.9

7.13

20.3

717

24.6

869

3.3

11364141

DSF155

133

8.12

23.1

816

27.9

985

3.3

11367148

DSF175

151.7

9.26

26.4

932

31.9

1127

3.3

11369152

DSF200

170.3

10.39

29.6

1045

35.8

1264

3.6

123

71.5

158

DSF270

227.6

13.89

39.6

1398--

6.1

206

114

251

DSF325

276.2

16.85

48.1

1699--

6.1

206

117

258

DSF485

407.2

24.85

70.9

2502--

6.1

206

176

388

DSF530

442.6

27.01772719--

6.1

206

176

388

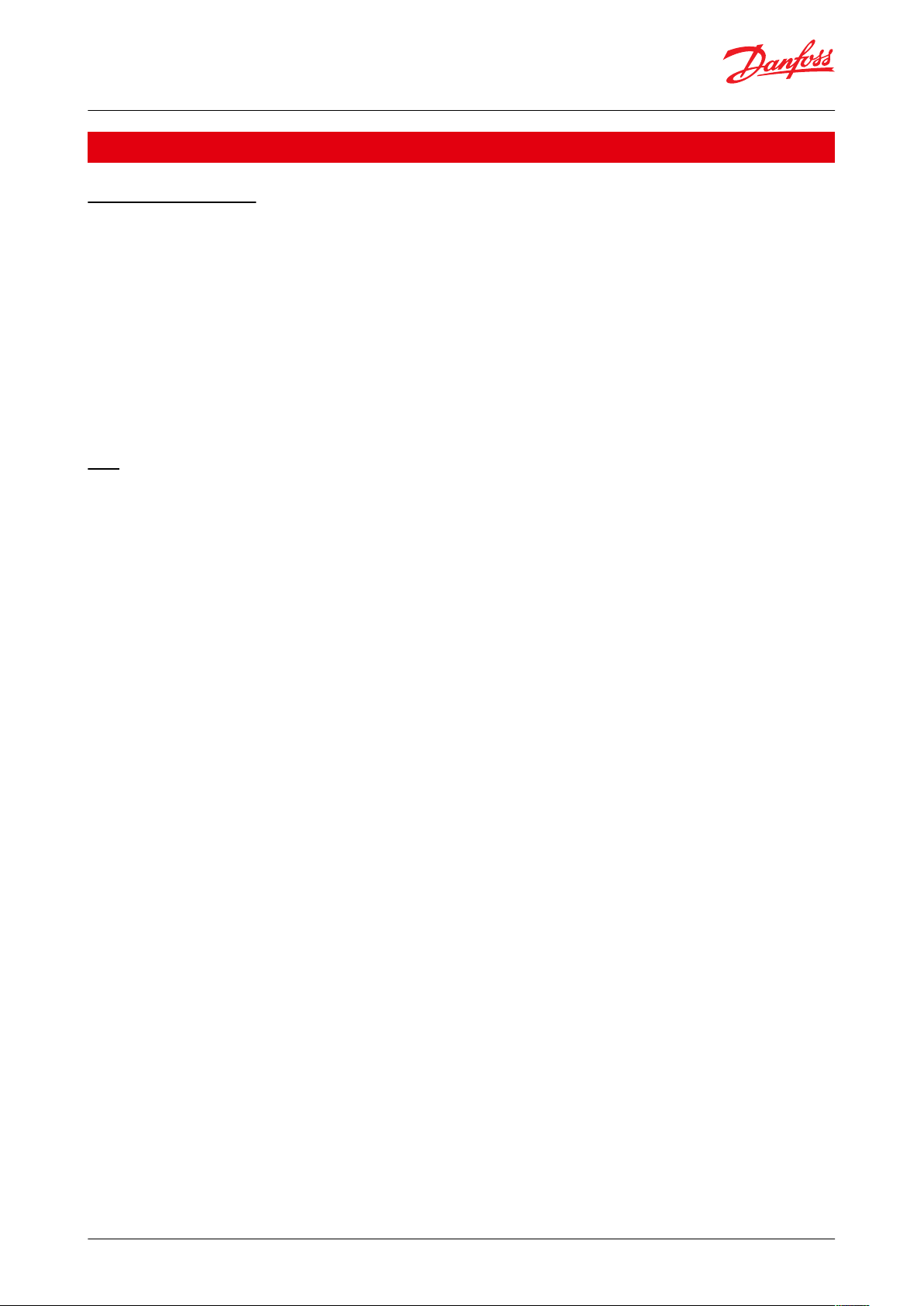

Scroll compressors, DSF090 to DSF530 | Technical specication

Technical specication

50-60 Hz data, Single compressor

Table 7: 50-60 Hz data, Single compressor

(1)

(1)

Displacement at nominal speed: 2900 rpm at 50 Hz

Displacement at nominal speed: 2900 rpm at 50 Hz

(2)

(2)

Displacement at nominal speed : 3500 rpm at 60 Hz

Displacement at nominal speed : 3500 rpm at 60 Hz

(3)

(3)

Net weight with oil charge

Net weight with oil charge

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 12

Page 13

Model

Nominal tons

60Hz

Nominal cooling capacity

Power input

COP

E.E.R.

TRWBtu/hkWW/W

Btu/h/W

50 Hz

DSF090

7.5

19958

68096

6.69

2.99

10.19

DSF100

8.5

21940

74860

7.13

3.08

10.50

DSF115

10

26349

89904

8.31

3.17

10.82

DSF130

11

29421

100384

9.19

3.20

10.93

DSF155

13

33772

115232

10.51

3.21

10.97

DSF175

15

39172

133655

12.07

3.24

11.07

DSF200

16.5

43329

147838

13.53

3.20

10.92

DSF270

-

60037

204853

17.98

3.34

11.40

DSF325

-

72501

247380

21.50

3.37

11.51

DSF485

-

107102

365443

31.67

3.38

11.54

DSF530

-

116998

399209

34.27

3.41

11.65

60 Hz

DSF090

7.5

26938

91911

8.68

3.10

10.59

DSF100

8.5

29362

100182

9.38

3.13

10.67

DSF115

10

34923

119157

10.79

3.24

11.04

DSF130

11

39465

134653

12.24

3.22

11.00

DSF155

13

45215

154273

13.82

3.27

11.16

DSF175

15

51618

176121

15.70

3.29

11.22

DSF200

16.5

57717

196932

17.63

3.27

11.17

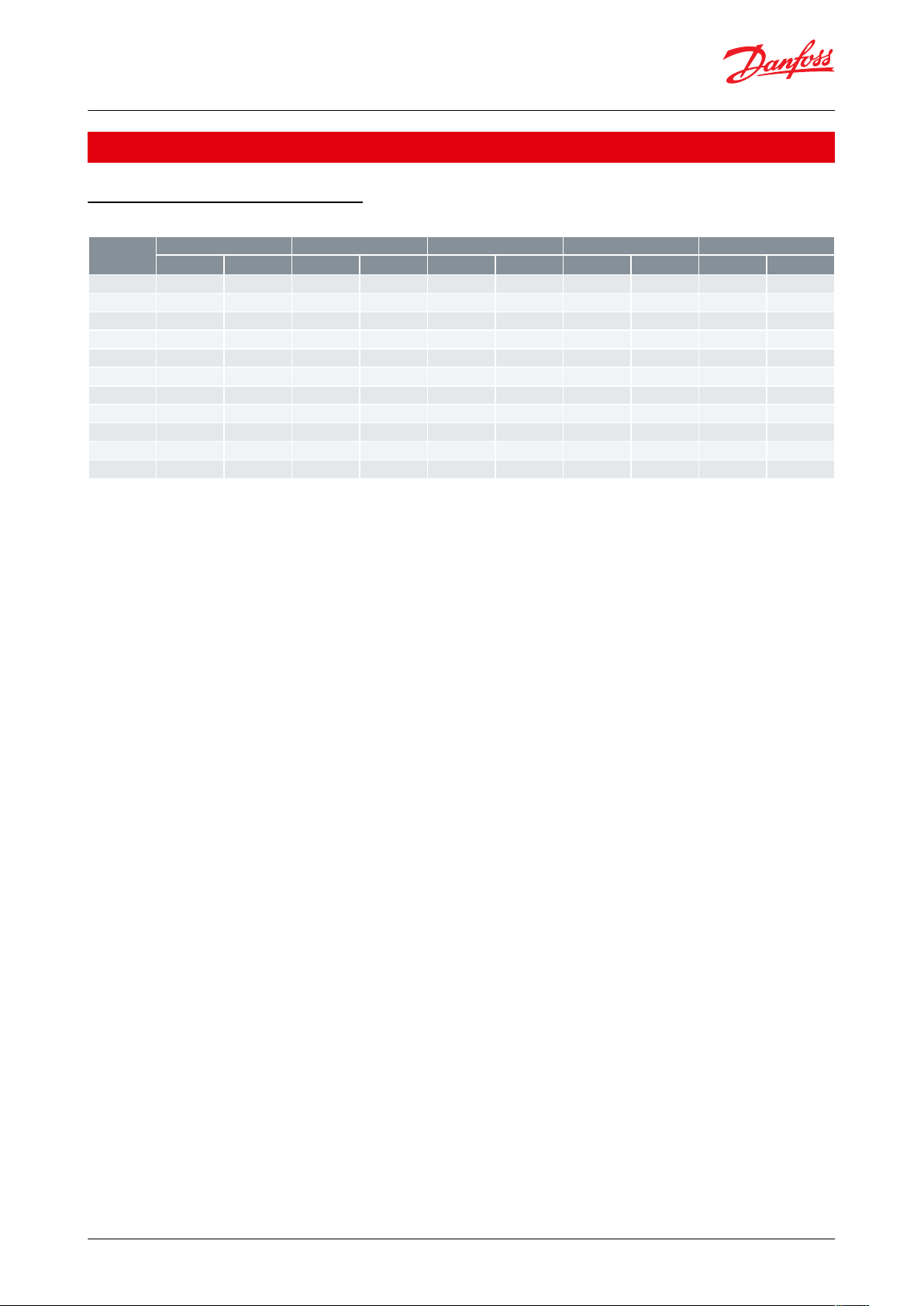

Scroll compressors, DSF090 to DSF530 | Performance data

Performance data

R32 50-60 Hz, Single compressor

Table 8: 50-60 Hz R32, Single compressor

NOTE:

TR: Ton of Refrigeration,

COP: Coecient Of Performance

EER: Energy Eciency Ratio

Standard rating conditions for 50Hz: Evaporating temperature: 5°C (41°F), Condensing temperature: 50°C (122°F),

Superheat: 10K (18°F), Subcooling: 0K (0°F)

Standard rating conditions for 60Hz: Evaporating temperature: 7.2°C (45°F), Condensing temperature: 54.4°C (130°F),

Superheat: 11.1K (20°F), Subcooling: 8.3K (15°F)

Subject to modication without prior notication.

Data given for motor code 4 compressor with above conditions

For regular updates and detailed capacities, please refer to Coolselector®2.

Tandem and trio performances

The impact of manifolding on compressor performances depends widely of the customer system itself. Therefore, it

would be unrealistic to provide data that corresponds accurately to a particular system. In rst approach, to support

compressors selection at full load, the manifold performances can be considered as the sum of capacities of the

compressors composing the manifold. For better accuracy, the customer should integrate the appropriate weighing

coecients according to his system very pressure drops and part load levels.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 13

Page 14

Compressor model

50 Hz

60 Hz

Acoustic hood code no.

Sound power, dB(A)

Attenuation, dB(A)

Sound power, dB(A)

Sound power, dB(A)

DSF09074-77--DSF10076-79--DSF115-17578-81--DSF20080-83--DSF270834--

120Z0768

DSF325834--

DSF485894--

DSF530894--

Scroll compressors, DSF090 to DSF530 | Sound and vibration data

Sound and vibration data

Typical sounds and vibrations in systems can be broken down into the following three categories:

• Sound radiation (through air)

• Mechanical vibrations (through parts and structure)

• Gas pulsation (through refrigerant)

The following sections focus on the causes and methods of mitigation for each of the above sources.

Compressor sound radiation

For sound radiating from the compressors, the emission path is air and the sound waves are travelling directly from

the machine in all directions.

Sound levels as follows:

• For compressors running alone:

Table 9: Compressor sound radiation

NOTE:

Sound power and attenuation are given at ARI conditions, measured in free space.

For compressors running simultaneously

The global sound level of “n” identical compressors is:

L

=Li+10 Log10 n

GLOBAL

Example for the trio

DSF810T = 3 × DSF270

L

=83dB(A)

DSF270

L

=83+10 Log10 3=87 . 8dB(A)

DSF810T

The global sound level of “n” dierent compressors with respectively Li sound level is:

L

GLOBAL

i = n

= 10

i = 1

log10(∑ 10

0.1

∗ Li)

Example for the tandem

DSF1180T=DSF325+DSF325+DSF530

L

DSF325

L

DSF1180T

=83dB(A),L

=10Log10(10

DSF530

=89dB(A)

0 . 1×83

+10

0 . 1×83

+10

0 . 1×89

)= 90 . 8dB(A)

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 14

Page 15

Scroll compressors, DSF090 to DSF530 | Sound and vibration data

Mechanical vibrations

A compressor generates some vibrations that propagate into the surrounding parts and structure. The vibration

level of a DSF compressor alone does not exceed 120 µm peak to peak for DSF090 to DSF200, and 154um peak to

peak for DSF270 to DSF530.. However, when system structure natural frequencies are close to running frequency,

vibrations are amplied due to resonance phenomenon.

A high vibration level is damageable for piping reliability and generates high sound levels.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 15

Page 16

Condensing temperature (°C)

Condensing temperature (°F)

Evaporating temperature (°C)

Evaporating temperature (°F)

5

10

15

20

25

30

35

40

45

50

55

60

65

70

41

0

32

50

59

68

77

86

95

104

113

122

131

140

149

158

-30-35 -25 -20 -15 -10 -5 0 5 10 15 20 25 30

-22-31 -13 -4 5 14 23 32 41 50 59 68 77 86

S.H. = 5 K (9°F)

CC-000182

S.H. = 10 K (18°F)

Condensing temperature (°C)

Condensing temperature (°F)

Evaporating temperature (°C)

Evaporating temperature (°F)

5

10

15

20

25

30

35

40

45

50

55

60

65

70

41

0

32

50

59

68

77

86

95

104

113

122

131

140

149

158

-30-35 -25 -20 -15 -10 -5 0 5 10 15 20 25 30

-22-31 -13 -4 5 14 23 32 41 50 59 68 77 86

S.H. = 5 K (9°F)

CC-000183

S.H. = 10 K (18°F)

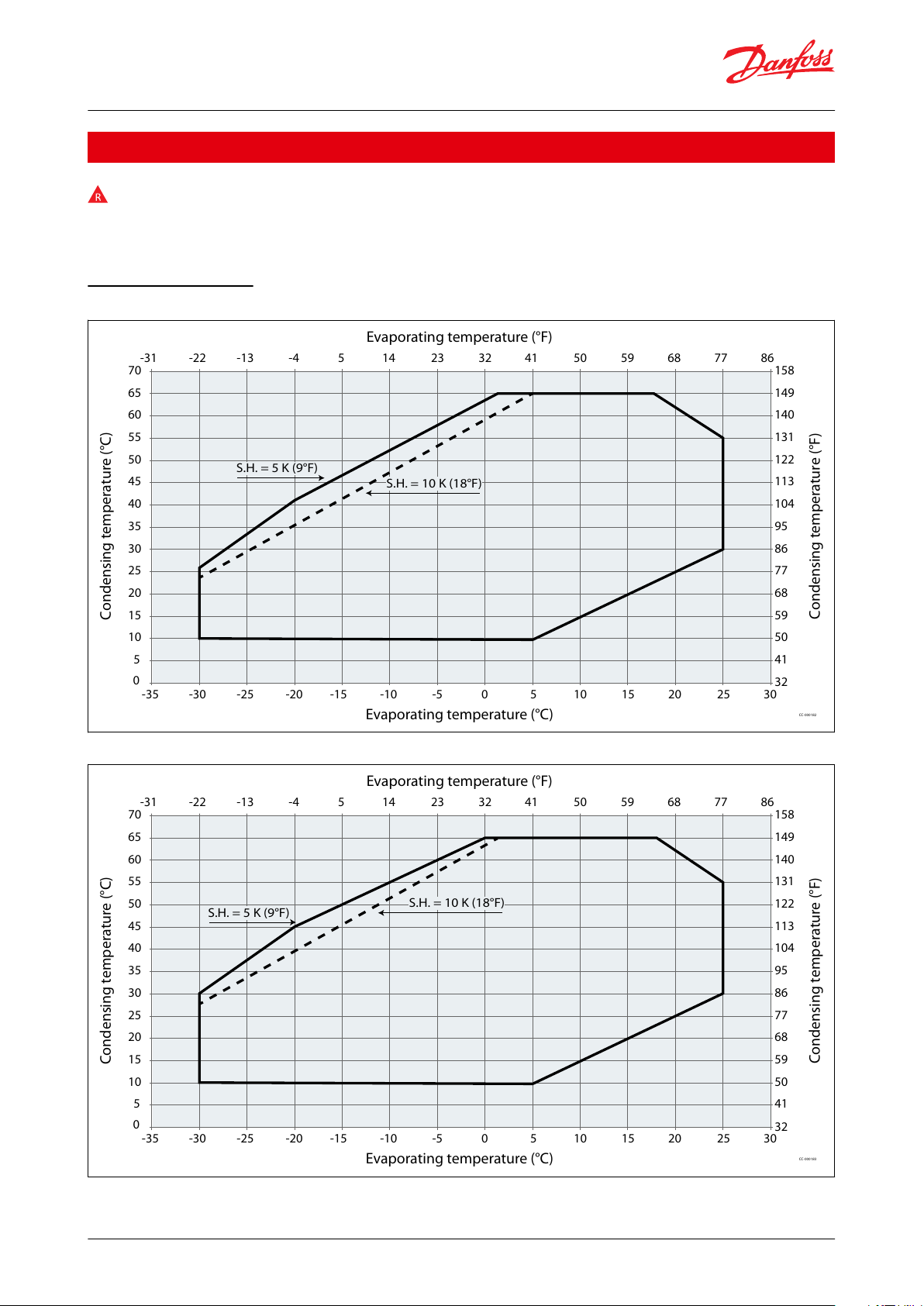

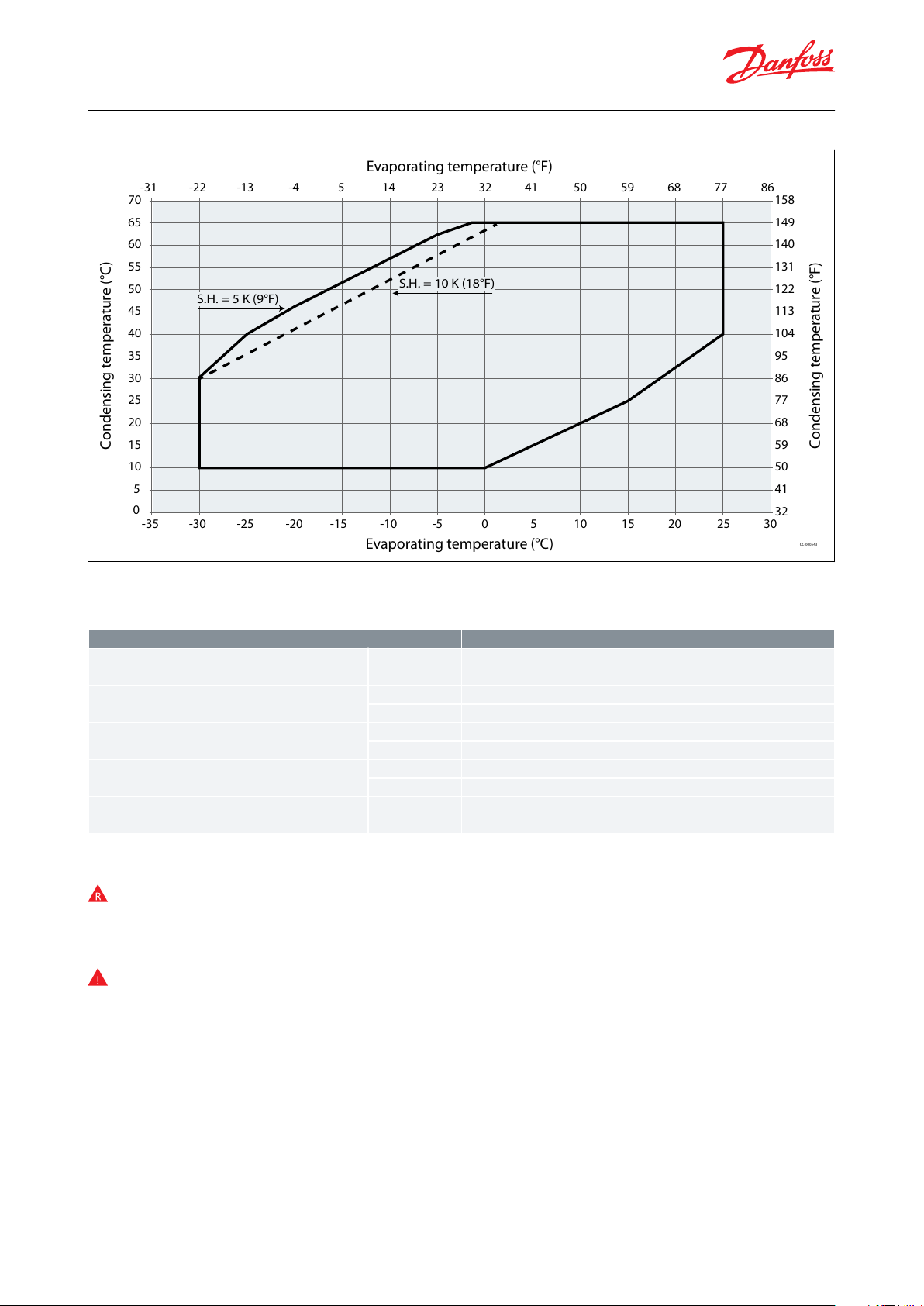

Scroll compressors, DSF090 to DSF530 | Operating envelope data

Operating envelope data

The Operating envelope data for DSF scroll compressors guarantees reliable operations of the compressor for

steady-state operation.

Steady-state operation envelope is valid for a suction superheat within 5K to 10K range at nominal Voltage.

Operating envelope

Figure 5: Operating envelope R32 DSF090 to DSF130

Figure 6: Operating envelope R32 DSF155 to DSF200

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 16

Page 17

Condensing temperature (°C)

Condensing temperature (°F)

Evaporating temperature (°C)

Evaporating temperature (°F)

5

10

15

20

25

30

35

40

45

50

55

60

65

70

41

0

32

50

59

68

77

86

95

104

113

122

131

140

149

158

-30-35 -25 -20 -15 -10 -5 0 5 10 15 20 25 30

-22-31 -13 -4 5 14 23 32 41 50 59 68 77 86

S.H. = 5 K (9°F)

CC-000543

S.H. = 10 K (18°F)

Pressure settings

R32

Working range high side

bar(g)

10 – 43

psig

145 – 624

Working range low side

bar(g)

1.7 – 15.9

psig

25 – 231

Maximum high pressure safety switch setting

bar(g)

44.4

psig

645

Minimum low pressure safety switch setting

bar(g)

1.5

psig

22

Minimum low pressure pump-down switch setting

bar(g)

1.5 bar below nominal evap. pressure with minimum of 1.7 bar(g)

psig

22 psi below nominal evap. pressure with minimum of 25 psig

Scroll compressors, DSF090 to DSF530 | Operating envelope data

Figure 7: Operating envelope R32 DSF270 to DSF530

Pressure settings

Table 10: Pressure settings

High and low pressure protection

Low-pressure (LP) and high-pressure (HP) safety switches must never be bypassed nor delayed and must stop all

the compressors.

LP switch auto restart must be limited to 5 times within 12 hours.

HP safety switch must be reset manually.

Depending on application operating envelope, you must dene HP and LP limits within operating envelope and

pressure setting table above.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 17

Page 18

Ø D

H1

Ø19.05mm

(0.75 inch)

L3

L2

190.5mm

(7.5 inch)

190.5mm

(7.5 inch)

L1

30°

H2

H

30°

CC-000055

Ø D

H

H2

H1

L1

L3

L2

8556208

H

H2

H1

Ø D

L2

L3

L1

8556199

Compressor

model

DHH1H2L1L2L3

Outline drawing no.

mm

inchmminchmminchmminchmminchmminchmminch

DSF090-100

243

9.57

485

19.09

235

9.25

451

17.76

180

7.09

230

9.06

230

9.0618560176

DSF115-175

243

9.57

542

21.34

278

10.94

509

20.04

180

7.09

230

9.06

230

9.06

8560177

DSF200

243

9.57

558

21.97

299

11.77

524

20.63

201

7.91

230

9.06

230

9.06

8560178

DSF270

320

12.6

653

25.71

302

11.87

618

24.33

427

16.81

371

14.61

371

14.61

2

8556208

DSF325

320

12.6

653

25.71

302

11.87

618

24.33

427

16.81

371

14.61

371

14.61

DSF485

333

13.11

726

28.58

302

11.87

667

26.26

429

16.89

371

14.61

371

14.61

3

8556198

DSF530

333

13.11

726

28.58

302

11.87

667

26.26

429

16.89

371

14.61

371

14.61

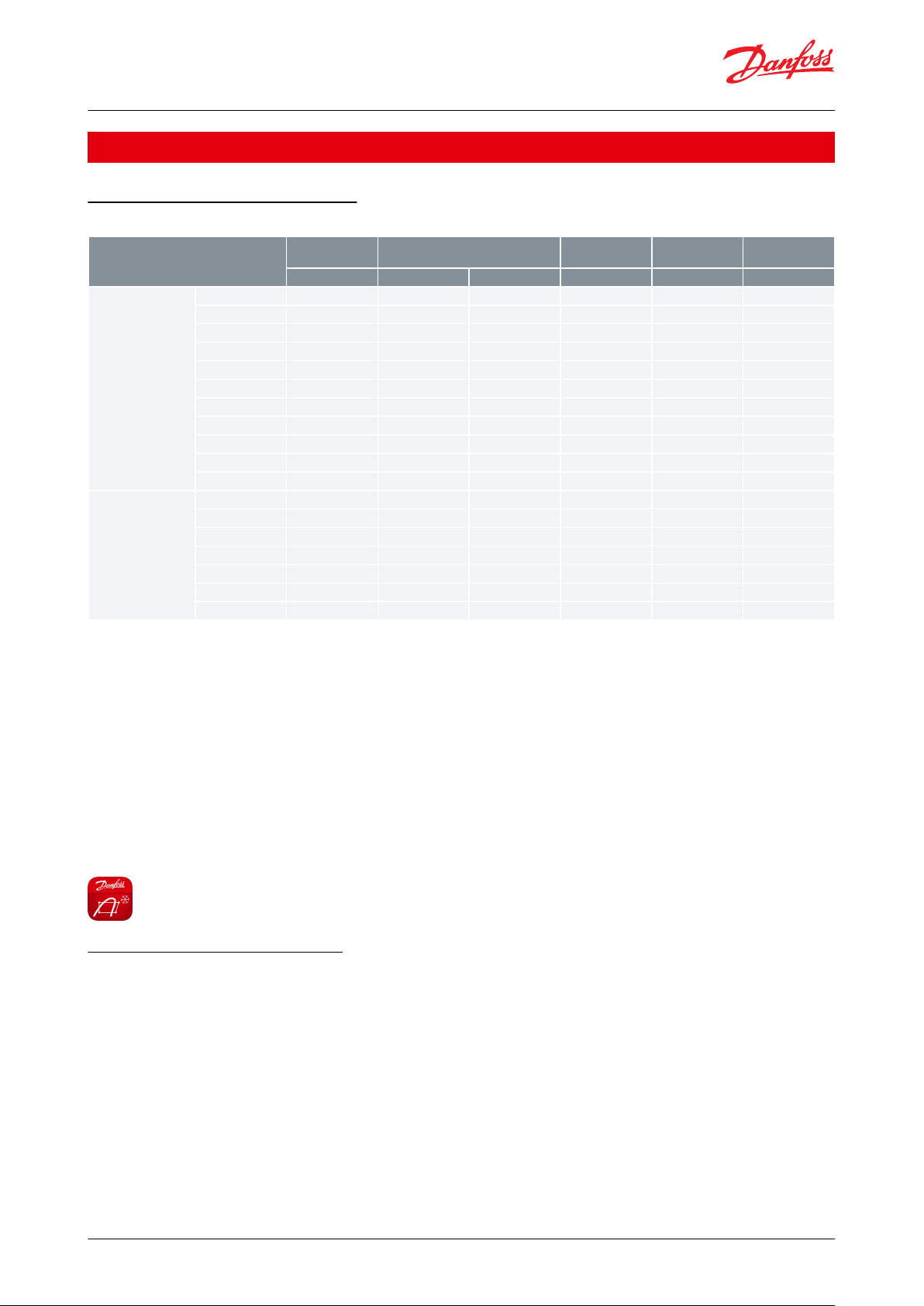

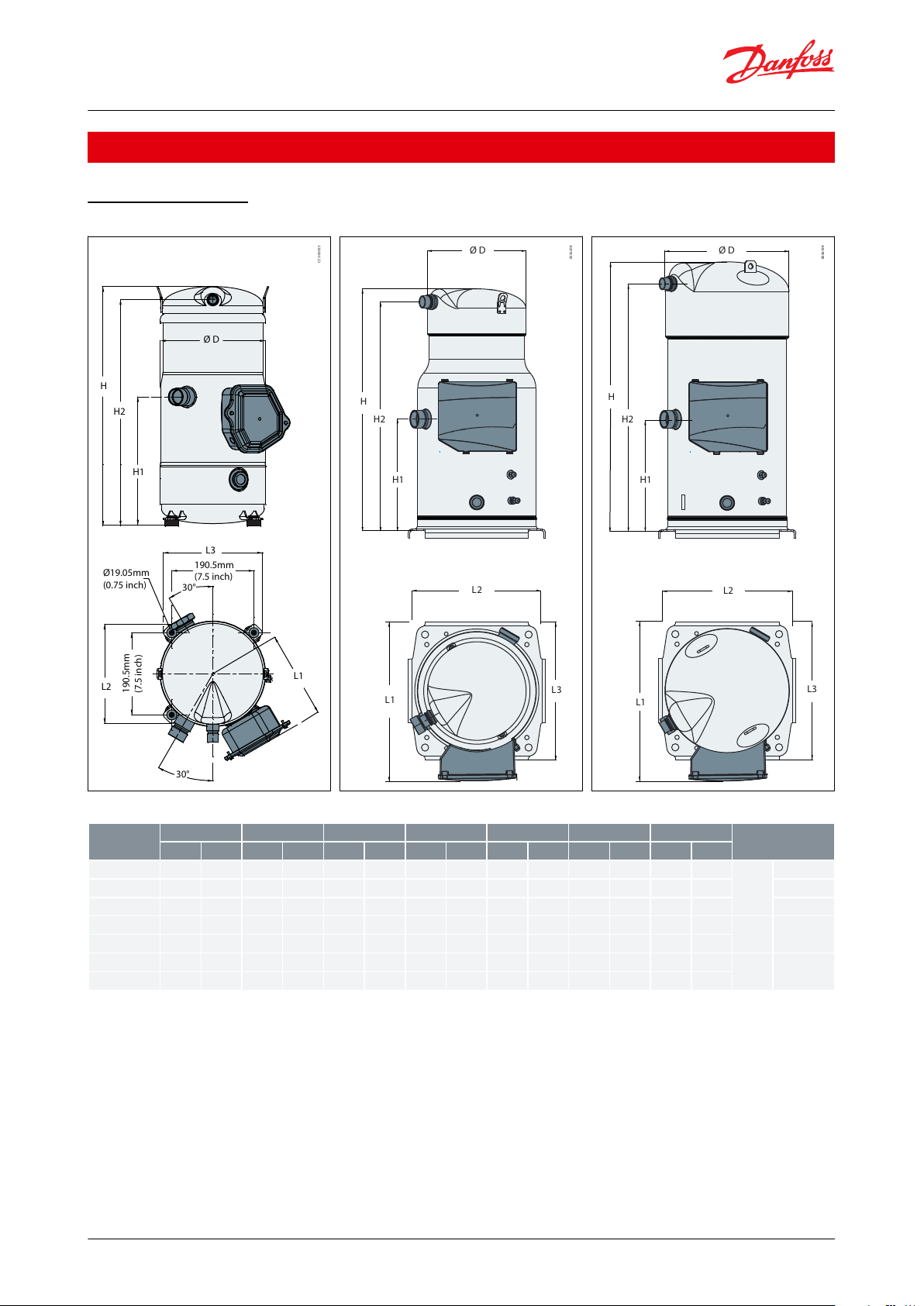

Scroll compressors, DSF090 to DSF530 | Dimensions

Dimensions

Single compressors

Figure 8: Outline drawing number 1

Figure 9: Outline drawing number 2

Figure 10: Outline drawing number 3

Table 11: Single compressor

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 18

Page 19

H

L

8556230

D

L1

H1

H

L

L1

H1

D

8556228

D

H

L

L1

H1

8556222

L1

H1

H

L

D

8556223

H1

CC-000056

L1

L

H

D

Tandem mod‐

el

Composition Cp1

+ Cp2

LDHL1H1

Outline drawing

number

mm

inchmminchmminchmminchmminch

DSF180E

DSF090+DSF090

850

33.46

384

15.12

507

19.96

240

9.45

242

9.5318560144

DSF200E

DSF100+DSF100

850

33.46

384

15.12

507

19.96

240

9.45

242

9.5318560144

DSF230E

DSF115+DSF115

850

33.46

384

15.12

565

22.24

240

9.45

242

9.5318560145

DSF260E

DSF130+DSF130

850

33.46

384

15.12

565

22.24

240

9.45

242

9.5318560145

DSF215U

DSF100+DSF115

850

33.46

386

15.20

565

22.24

240

9.45

242

9.5318560189

DSF230U

DSF100+DSF130

850

33.46

386

15.20

565

22.24

240

9.45

242

9.5318560189

DSF255U

DSF100+DSF155

850

33.46

386

15.20

565

22.24

240

9.45

242

9.5318560189

DSF275U

DSF100+DSF175

850

33.46

386

15.20

565

22.24

240

9.45

242

9.5318560189

DSF285U

DSF130+DSF155

850

33.46

386

15.20

565

22.24

240

9.45

242

9.5318560168

DSF300U

DSF100+DSF200

850

33.46

428

16.85

580

22.83

240

9.45

242

9.5318560190

DSF305U

DSF130+DSF175

850

33.46

386

15.20

565

22.24

240

9.45

242

9.5318560168

DSF310E

DSF155+DSF155

850

33.46

384

15.12

565

22.24

240

9.45

242

9.5318560145

DSF315U

DSF115+DSF200

850

33.46

428

16.85

580

22.83

240

9.45

242

9.5318560167

DSF330U

DSF155+DSF175

850

33.46

386

15.20

565

22.24

240

9.45

242

9.5318560168

DSF331U

DSF130+DSF200

850

33.46

428

16.85

580

22.83

240

9.45

242

9.5318560167

DSF350E

DSF175+DSF175

850

33.46

384

15.12

565

22.24

240

9.45

242

9.5318560145

DSF355U

DSF155+DSF200

850

33.46

428

16.85

580

22.83

240

9.45

242

9.5318560167

DSF375U

DSF175+DSF200

850

33.46

428

16.85

580

22.83

240

9.45

242

9.5318560167

DSF400E

DSF200+DSF200

850

33.46

428

16.85

580

22.83

240

9.45

242

9.5318560146

DSF400X

DSF130+DSF270

903

35.55

533

20.98

731

28.78

359

14.13

211

8.3158560169

DSF470X

DSF200+DSF270

903

35.55

533

20.98

731

28.78

359

14.13

211

8.3158560170

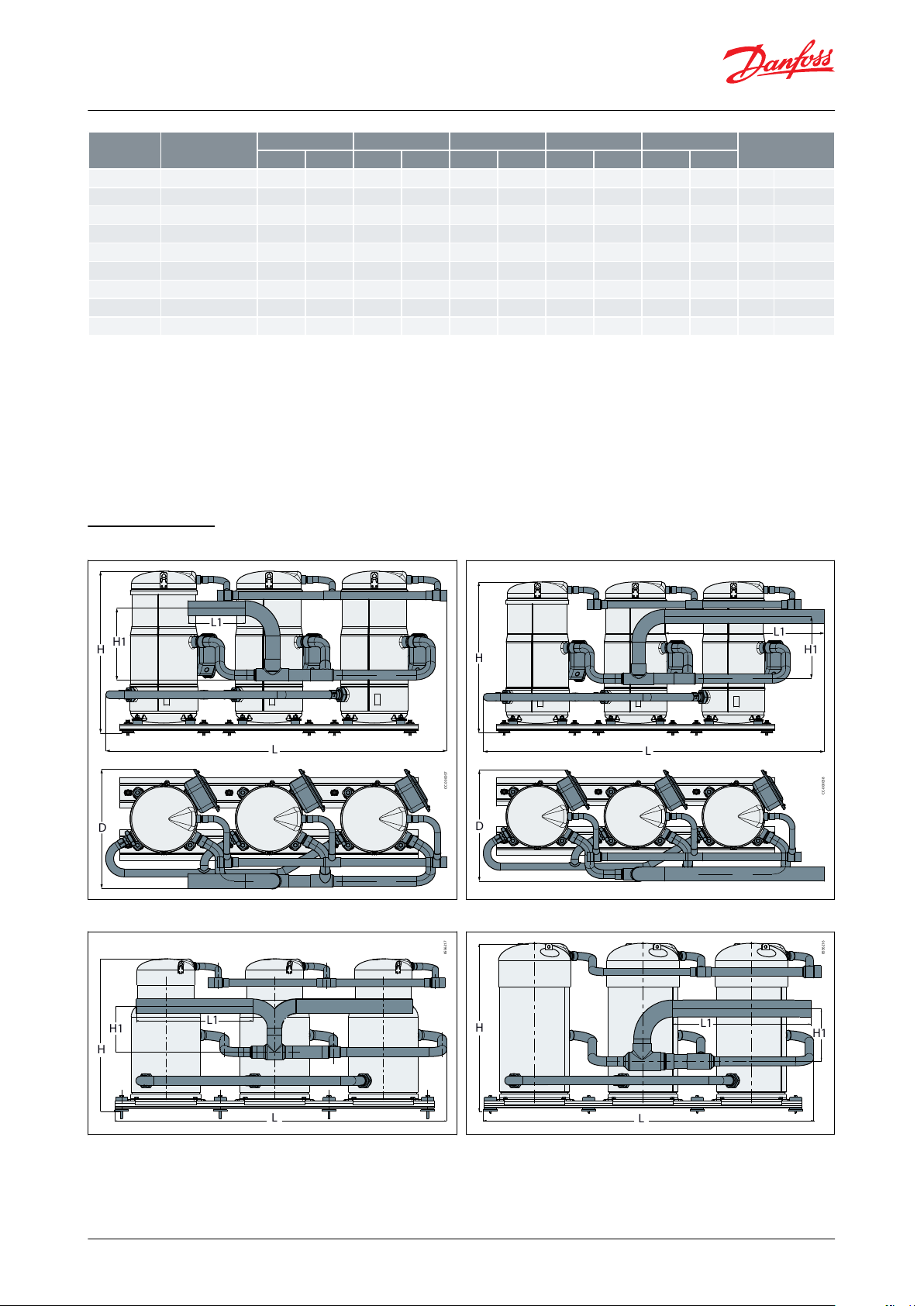

Scroll compressors, DSF090 to DSF530 | Dimensions

Tandem assemblies

Figure 11: Outline drawing number 1

Figure 14: Outline drawing number 4

Figure 12: Outline drawing number 2

Figure 15: Outline drawing number 5

Figure 13: Outline drawing number 3

Table 12: Tandem assemblies

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 19

Page 20

CC-000057

H

D

H1

L1

L

CC-000058

H

D

H1

L1

L

H1

L1

H

L

8556217

L

H1

L1

H

8556216

Tandem mod‐

el

Composition Cp1

+ Cp2

LDHL1H1

Outline drawing

number

mm

inchmminchmminchmminchmminch

DSF500X

DSF175+DSF325

903

35.55

533

20.98

731

28.78

359

14.13

211

8.3158560169

DSF525X

DSF200+DSF325

903

35.55

533

20.98

731

28.78

359

14.13

211

8.3158560170

DSF540E

DSF270+DSF270

1025

40.35

527

20.75

701

27.6

535

21.06

211

8.3128556228

DSF595U

DSF270+DSF325

1025

40.35

527

20.75

701

27.6

535

21.06

211

8.3128556228

DSF650E

DSF325+DSF325

1025

40.35

527

20.75

701

27.6

535

21.06

211

8.3128556228

DSF800U

DSF270+DSF530

1025

40.35

546

21.5

774

30.5

535

21.06

211

8.3138556207

DSF970E

DSF485+DSF485

1025

40.35

553

21.77

774

30.5

640

25.2

211

8.3148556205

DSF855U

DSF325+DSF530

1025

40.35

546

21.5

774

30.5

640

25.2

211

8.3148556220

DSF1060E

DSF530+DSF530

1025

40.35

553

21.77

774

30.5

640

25.2

211

8.3148556205

Scroll compressors, DSF090 to DSF530 | Dimensions

NOTE:

Tandems to be achieved by assembly of individual compressors.

By convention, the last letter of tandems designation have been set to help to discern easily which type of manifold

we are considering.

U : Uneven tandem

E : Even tandem

X: Crossplatfom (medium-large) tandem

Trio assemblies

Figure 16: Outline drawing number 6

Figure 18: Outline drawing number 8

Figure 17: Outline drawing number 7

Figure 19: Outline drawing number 9

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 20

Page 21

Tandem model

Composition

LDHL1H1

Outline drawing

number

mm

inchmminchmminchmminchmminch

DSF465T

3 x DSF155

1230

48.4

402

15.8

571

22.5

205

8.1

242

9.568560172

1326

52.2

402

15.8

571

22.5

622

24.5

242

9.578560172

DSF525T

3 x DSF175

1230

48.4

402

15.8

571

22.5

205

8.1

242

9.568560172

1326

52.2

402

15.8

571

22.5

622

24.5

242

9.578560172

DSF 600T

3 x DSF200

1236

48.7

433

17.0

587

23.1

205

8.1

242

9.568560171

1326

52.2

433

17.0

587

23.1

622

24.5

242

9.578560171

DSF810T

DSF270+DSF270+DSF270

1467

57.76

543

21.38

701

27.6

535 min

21.06

211

8.3188556217

DSF975T

DSF325+DSF325+DSF325

1467

57.76

543

21.38

701

27.6

536 min

21.06

211

8.3188556217

DSF1180T

DSF325+DSF325+DSF530

1467

57.76

573

22.56

774

30.5

535 min

21.06

211

8.3188556310

DSF1385T

DSF530+DSF530+DSF325

1520

59.84

573

22.56

774

30.5

640 min

25.19

244

9.6198556314

DSF1590T

DSF530+DSF530+DSF530

1520

59.84

573

22.56

774

30.5

640 min

25.19

244

9.6198556216

Scroll compressors, DSF090 to DSF530 | Dimensions

Table 13: Trio assemblies

NOTE:

Trio to be achieved by assembly of individual compressors.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 21

Page 22

CC-000167

CC-000168

Connection Details

DSF090-100

DSF115-200

DSF270-325

DSF485-530

Suction connection

Brazed 1"1/8

Brazed 1"3/8

Brazed 1"5/8

Brazed 1"5/8

Discharge connection

Brazed 7/8"

Brazed 7/8"

Brazed 1"1/8

Brazed 1"3/8

Oil sight glass

Threaded (1"1/8 – 18 UNEF)

Oil equalization connection

Rotolock 1"3/4

Rotolock 2"1/4

Oil drain connection

None

None

Female ¼" Flare incorporating a Schrader valve

Low pressure gauge port (Shrader)

Male ¼" Flare incorporating a Schrader valve

Outline drawing

112

2

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Mechanical connections

Connection details

Table 14: Connection details

Figure 20: Outline drawing 1

Figure 21: Outline drawing 2

Design compressor mounting

General requirements

Compressors used in single applications must be mounted with exible grommets.

Compressors used in parallel applications must be mounted with rigid spacers onto rails (or directly on rails

according to compressor models) and the manifold assembly must be mounted with exible grommets onto the

frame.

During operation, the maximum inclination from the vertical plane must not exceed 3 degrees.

Single requirements DSF090-200 mounting

Compressors DSF090-200 are delivered with rubber grommets and steel mounting sleeve used to isolated the

compressor from the base frame.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 22

Page 23

15 mm

(0.59 Inch)

1

2

3

4

5

6

7

cc-0048

1234567

Tightening torque 15 Nm

HM 8 bolt (4 pcs)

Lock washer (4 pcs)

Flat washer (4 pcs)

Steel mounting sleeve (4 pcs)

Rubber grommet (4 pcs)

Nut (4 pcs)

1

CC-0000001

27.5 mm

(1.08 inch)

CC-0049

2

8

3

4

5

6

7

1234567

8

Rubber grommets from kit 8156138

HM 8 bolt

Lock washer

Flat washer

Steel mounting sleeve

Rubber grommet

Nut

Compressor base plate

Scroll compressors, DSF090 to DSF530 | Mechanical connections

The grommets must be compressed until contact between the at washer and the steel mounting sleeve is

established. The required bolt size for the DSF090-200 compressors is HM8-40. This bolt must be tightened to a

torque of 15Nm.

Figure 22: Rubber grommets

Part 2, 3, 4, 5, 6 and 7 are delivered along with

compressor

Single requirements, DSF270-325-485-530 mounting

To be used in single applications, an additional accessory including exible grommets is necessary kit 8156138.

The grommets must be compressed until contact between the at washer and the steel mounting sleeve is

established. The required bolt size for the DSF compressors is HM8-55. This bolt must be tightened to a torque of 21

Nm.

Figure 23: Rubber grommets from kit 8156138

Figure 24: Rubber grommets

Manifolding requirements DSF 180E-400E and DSF285U-305U-330U mounting

The compressors must be mounted with rigid mounting spacers on rails. Rubber grommets and spacers must be

installed below the rails.

The rigid mounting spacers are included in tandem accessory kits. The rubber grommets are supplied with

compressor.

For more details about parallel mounting feet, please see parallel unit outline drawing.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 23

Page 24

2

3

4

1

CC-000002

1234Tightening torque 15Nm

Not supplied Φ8x75mm 0.31x2.95inch

Tightening torque 15Nm

4mm (0.16 inch) thickness

Supplied with the compressor

Included in manifolding kit

Not supplied

1

2

3

4

5

CC-000003

4

3

2

1

CC-000004

12345

Tightening torque 15Nm

Not supplied HM8mm 0.31 inch

Tightening torque 15 Nm

4mm (0.16 inch) Thickness

Additional rigid spacer (Refer to table below)

Supplied with the compressor

Included in manifolding kit

Not supplied

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Figure 25: DSF 180E-400E and DSF285U-305U-330U mounting

Manifolding requirements DSF 215U-230U-255U-275U-300U-315U-331U-355U-375U mounting

The compressors must be mounted with rigid mounting spacers on rails. Rubber grommets and spacers must be

installed below the rails.

The rigid mounting spacers are included in tandem accessory kits. The rubber grommets are supplied with

compressor.

Figure 26: Smaller model of tandem

Figure 27: Larger model of tandem

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 24

Page 25

1

2

3

4

CC-000009

1234Tightening torque 15Nm

Not supplied HM8mm 0.31 inch

Tightening torque 15 Nm

3mm (0.12inch) Thickness

Supplied with the compressor

Included in manifolding kit

Not supplied

1

CC-000010

4

5

2

3

7

6

5

CC-000011

Additionnal rigid spacer

Additional right spacer(to be added on the smallest compressor of the tan‐

dem)

DSF215U-230U-255U-275U-315U-331U-355U-375U

7mm

DSF300U

14mm

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Table 15: Additionnal rigid spacer

Tandem requirements DSF465T-525T-600T mounting

The compressors must be mounted with rigid mounting spacers on rails. Rubber grommets and spacers must be

installed below the rails.

The rigid mounting spacers and rubber grommets are included in tandem accessory kits.

Tandem requirements DSF400X-470X-500X-525X mounting

The large compressor, DSF270,325, is mounted with rigid spacers on the rails.

The DSF130, 175,200 compressor is xed on beams by rigid spacer, and the beams are mounted with rigid spacers

on the rails. Rubber grommets and spacers must be installed below the rails.

Figure 28: DSF270-325

Figure 29: DSF130-175-200

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 25

Page 26

2

1

3

CC-000012

123

HM 10 x 30 class 10.9, Tightening torque 50 Nm

HM 10 x 100 class 10.9, Tightening torque 50

Nm

Thickness: 5 mm (0.2 inch)

Included in tandem/trio kit

Not supplied

1234567

Tightening torque 16Nm

Not supplied Φ10mm

Tightening torque 50Nm

Tightening torque 55Nm

5mm (0.2inch) thickness

Tightening torque 15Nm

4mm (0.16inch) thickness

Supplied with the compressor

Included in manifolding kit

Not supplied

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Tandem requirements, DSF540E to DSF1590T mounting

For parallel mounting, the compressors can be mounted directly on the rails. Rubber grommets and spacers must be

installed below the rails.

These parts are included in accessories.

Figure 30: DSF540E to DSF1590T mounting

Design piping

General requirements

Proper piping practices should be employed to:

1.

Ensure adequate oil return, even under minimum load conditions (refrigerant speed, piping slopes…). For

validation tests see section Manage oil in the circuit.

2.

Avoid condensed liquid refrigerant from draining back to the compressor when stopped (discharge piping

upper loop). For validation tests see section Manage o cycle migration.

3.

Piping should be designed with adequate three-dimensional exibility to avoid excess vibration. It should not be

in contact with the surrounding structure, unless a proper tubing mount has been installed. For more

information on noise and vibration, see section Sound and vibration data.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 26

Page 27

HP

3

3

2

2

5

4 m*

4 m*

6

6

6

1

LP

4

CC-0043

123456*

Evaporator

0.5% slope

4m/s or more

8 to 12 m/s

To condenser

U-trap, as short as possible

Max.

CC-000162

HP

LP

3

1

2

123

3D exibility

Upper loop

Condenser

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Figure 31: Proper piping - Evaporator

Figure 32: Proper piping - Condenser

Tandem and Trio requirements (Static)

DSF tandem and trio use static oil balancing principle to equalize oil level between the compressors by gravity. This

is ensured by a precise suction and oil equalization piping design.

The discharge line has no impact on oil balancing. It is shown with tee, to indicate that both left and right side

discharge headers are possible.

By default, DSF tandems and trios are not factory-built.

To complete an assembly in the eld, you will need:

• Tubings, according to specic outline drawings indicated in the following table

• Manifolding accessory kit

• Compressors

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 27

Page 28

CC-000037

Included in tandem or trio accessory kit

Not supplied

Cp3

Cp2

Cp1

CC-000035

1

Cp3

Cp2

Cp1

2

CC-000036

12Cp1

Cp2

Cp3

Trio models with Right suction

Trio models with Left suction

Compressor 1

Compressor 2

Compressor 3

Tandem

model

Composition

Suction

Discharge

Oil equali‐

zation

Outline

drawing

number

Suction

from

Washer inner diameter

Washer in

suction of

Tandem kit

code no

DSF180E

DSF090+DSF090

1"5/8

1"3/8

1"1/8

8560144

Left

Not needed

120Z0634

Right

DSF200E

DSF100+DSF100

1"5/8

1"3/8

1"1/8

8560144

Left

Not needed

120Z0634

Right

DSF215U

DSF100+DSF115

1"5/8

1"3/8

1"1/8

8560189

Left

25 mm (0.98 inch)

Cp2

120Z0694

Right

26 mm (1.02 inch)

Cp2

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Suction and oil equalization piping drawings must be respected (diameters, minimum straight lengths, …).

Suction washer position

Depending on manifold conguration, it is essential to equalize the pressure of compressor sumps. Hence, a

suction washer must be added on certain compressors according to the table. Suction washers are included in

tandem or trio accessory kits as described in the illustrations.

Figure 33: Suction washer position

By convention, the compressor order (No.1, No.2 ...) is dened counting from left to right, placed on the side facing

the electrical boxes of the compressors (see example below on a trio)

Figure 34: Example of right suction

Figure 35: Example of left suction

Tandem models

Table 16: Tandem models

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 28

Page 29

Tandem

model

Composition

Suction

Discharge

Oil equali‐

zation

Outline

drawing

number

Suction

from

Washer inner diameter

Washer in

suction of

Tandem kit

code no

DSF230E

DSF115+DSF115

1"5/8

1"3/8

1"1/8

8560145

Left

Not needed

120Z0634

Right

DSF230U

DSF100+DSF130

1"5/8

1"3/8

1"1/8

8560189

Left

27mm (1.06 inch)

Cp2

120Z0694

Right

27mm (1.06 inch)

Cp2

DSF255U

DSF100+DSF155

1"5/8

1"3/8

1"1/8

8560189

Left

23 mm (0.91 inch)

Cp1

120Z0694

Right

23 mm (0.91 inch)

Cp1

DSF260E

DSF130+DSF130

1"5/8

1"3/8

1"1/8

8560145

Left

Not needed

120Z0634

Right

DSF275U

DSF100+DSF175

1"5/8

1"3/8

1"1/8

8560189

Left

21 mm (0.83 inch)

Cp1

120Z0694

Right

21 mm (0.83 inch)

Cp1

DSF285U

DSF130+DSF155

1"5/8

1"3/8

1"1/8

8560168

Left

27 mm (1.06 inch)

Cp1

120Z0692

Right

27 mm (1.06 inch)

Cp1

DSF300U

DSF100+DSF200

1"5/8

1"3/8

1"1/8

8560190

Left

20 mm (0.79 inch)

Cp1

120Z0693

Right

20 mm (0.79 inch)

Cp1

DSF305U

DSF130+DSF175

1"5/8

1"3/8

1"1/8

8560168

Left

25 mm (0.98 inch)

Cp1

120Z0692

Right

25 mm (0.98 inch)

Cp1

DSF310E

DSF155+DSF155

1"5/8

1"3/8

1"1/8

8560145

Left

Not needed

120Z0634

Right

DSF315U

DSF115+DSF200

1"5/8

1"3/8

1"1/8

8560167

Left

23 mm (0.91 inch)

Cp1

120Z0693

Right

23 mm (0.91 inch)

Cp1

DSF330U

DSF155+DSF175

1"5/8

1"3/8

1"1/8

8560168

Left

27.5 mm (1.08 inch)

Cp1

120Z0692

Right

26 mm (1.02 inch)

Cp1

DSF331U

DSF130+DSF200

1"5/8

1"3/8

1"1/8

8560167

Left

24 mm (0.94 inch)

Cp1

120Z0694

Right

24 mm (0.94 inch)

Cp1

DSF350E

DSF175+DSF175

1"5/8

1"3/8

1"1/8

8560145

Left

Not needed

120Z0634

Right

DSF355U

DSF155+DSF200

1"5/8

1"3/8

1"1/8

8560167

Left

25 mm (0.98 inch)

Cp1

120Z0694

Right

25 mm (0.98 inch)

Cp1

DSF375U

DSF175+DSF200

1"5/8

1"3/8

1"1/8

8560167

Left

27.5 mm (1.08 inch)

Cp1

120Z0694

Right

27.5 mm (1.08 inch)

Cp1

DSF400E

DSF200+DSF200

1"5/8

1"3/8

1"1/8

8560146

Left

Not needed

120Z0634

Right

DSF400X

DSF130+DSF270

2"1/8

1"3/8

1"3/8

8560169

Left

24 mm (0.94 inch)

Cp1

120Z0709

Right

25 mm (0.98 inch)

Cp1

DSF470X

DSF200+DSF270

2"1/8

1"3/8

1"3/8

8560170

Left

35.5 mm (1.4 inch)

CP2

120Z0709

Right

35.5 mm (1.4 inch)

CP2

DSF500X

DSF175+DSF325

2"1/8

1"3/8

1"3/8

8560169

Left

25 mm (0.98 inch)

Cp1

120Z0709

Right

26 mm (1.02 inch)

Cp1

DSF525X

DSF200+DSF325

2"1/8

1"3/8

1"3/8

8560170

Left

26 mm (1.02 inch)

Cp1

120Z0709

Right

26 mm (1.02 inch)

Cp1

DSF540E

DSF270+DSF270

2"1/8

1" 5/8

1" 3/8

8556228

Left

Not needed

120Z0792

Right

DSF595U

DSF270+DSF325

2"1/8

1" 5/8

1" 3/8

8556228

Left

31 mm (1.22 inch)

Cp1

120Z0796

Right

DSF650E

DSF325+DSF325

2"1/8

1" 5/8

1" 3/8

8556228

Left

Not needed

120Z0792

Right

DSF800U

DSF270+DSF530

2"1/8

1" 5/8

1" 5/8

8556207

Left

24 mm (0.94 inch)

Cp1

120Z0786

Right

DSF970E

DSF485+DSF485

2"5/8

1" 5/8

1" 5/8

8556205

Left

Not needed

120Z0785

Right

DSF855U

DSF325+DSF530

2"5/8

1" 5/8

1" 5/8

8556220

Left

27 mm (1.06 inch)

Cp1

120Z0787

Right

DSF1060E

DSF530+DSF530

2"5/8

1" 5/8

1" 5/8

8556205

Left

Not needed

120Z0785

Right

Scroll compressors, DSF090 to DSF530 | Mechanical connections

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 29

Page 30

1 2

CC-000034

12Organ pipe

Tightening torque 100Nm

Supplied with the compressor

Included in tandem kit

Trio model

Composition

Suction

Discharge

Oil equali‐

zation

Outline

drawing

number

Suction

from

Washer inner diameter

Washer in

suction of

Trio kit

code no

DSF465T

3xDSF155

2"1/8

1"3/8

1"1/8

8560172

Left

26 mm (1.02 inch)

CP1

120Z0714

25 mm (0.98 inch)

CP3

Right

26 mm (1.02 inch)

CP1

24 mm (0.94 inch)

CP3

DSF525T

3xDSF175

2"1/8

1"3/8

1"1/8

8560172

Left

26 mm (1.02 inch)

CP1

120Z0714

25 mm (0.98 inch)

CP3

Right

26 mm (1.02 inch)

CP1

25 mm (0.98 inch)

CP3

DSF600T

3xDSF200

2"1/8

1"3/8

1"1/8

8560171

Left

26 mm (1.02 inch)

CP1

120Z0714

25 mm (0.98 inch)

CP3

Right

25.5 mm (1.00 inch)

CP1

25 mm (0.98 inch)

CP3

DSF810T

DSF270+DSF270 +DSF270

2"5/8

1" 5/8

1" 5/8

8556217

Left

30 mm (1.18 inch)

Cp3

120Z0784

Right

34.5 mm (1.36 inch)

Cp1 & Cp3

120Z0794

DSF975T

DSF325+DSF325 +DSF325

2"5/8

1" 5/8

1" 5/8

8556217

Left

30 mm (1.18 inch)

Cp3

120Z0784

Right

34.5 mm (1.36 inch)

Cp1 & Cp3

120Z0794

DSF1180T

DSF325+DSF325+DSF530

2"5/8

1" 5/8

1" 5/8

8556310

Left--

120Z0790

Right

29 mm (1.14)

Cp1 & Cp2

120Z0815

DSF1385T

DSF530+DSF530+DSF325

3"1/8

1" 5/8

1" 5/8

8556314

Left

26 mm (1.02)

Cp3

120Z0814

Right

26 mm (1.02)

Cp1

120Z0815

DSF1590T

DSF530+DSF530 +DSF530

3"1/8

2" 1/8

1" 5/8

8556216

Left

33 mm (1.3 inch)

Cp2 & Cp3

120Z0793

Right

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Trio models

Table 17: Trio models

Oil equalization DSF180E-400E

The oil level is balanced by a pipe of 1"1/8 oil equalization line.

In order ensure best oil balance, the organ pipe need to be mounted inside the oil equalization port as indicated on

below picture. To connect the equalization line on rotolock connections, the organ pipe adaptor and teon gasket

are included in the tandem kit must be used.

The organ pipe needs to be installed in the direction indicated by the label attached on pipe surface, which will

ensure best oil balance.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 30

Page 31

1 2

CC-000032

3

CC-000033

123

Organ pipe

Tightening torque 100Nm

Tightening torque 145Nm

Supplied with the compressor

Included in tandem kit

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Oil equalization design DSF 400X-470X-500X-525X

The oil level is balanced by a pipe of 1"3/8 oil equalization line.

In order to ensure best oil balance, the organ pipe need to be mounted inside the DSF130, DSF175, DSF200 oil

equalization port as indicated on below picture. DSF270, DSF325 has integrated organ pipe inside the oil

equalization port.

To connect the equalization line on rotolock connections, the organ pipe, adaptor sleeves, Teon gaskets included

in the tandem accessory kit must be used.

Figure 36: For DSF130, DSF175, DSF200

Figure 37: For DSF270, DSF325

Oil equalization design DSF270-530

The oil level is balanced by a pipe of 1"3/8 or 1"5/8. To connect the equalization line on rotolock connections, the

adaptor sleeves included in the tandem or trio accessory kit must be used.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 31

Page 32

3

CC-000033

3

Tightening torque 145 Nm

Supplied with the compressor

Included in tandem kit

Scroll compressors, DSF090 to DSF530 | Mechanical connections

Figure 38: DSF270, DSF530

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 32

Page 33

4

1

2

3

CC-0031

1234Terminal box

Ø 29mm (φ1.14inch) knockout

Ø 25.5mm (φ1inch) knockout

Power supply

3

2

1

CC-0400

123

Ø 16.5mm (φ0.65inch) knockout

Ø 40.5mm (φ1.59inch) hole

Power supply

Scroll compressors, DSF090 to DSF530 | Electrical connections

Electrical connections

Wiring connections

According to compressor model, electrical power is connected to the compressor terminals either by 4.8mm (10-32)

screws or by M5 studs and nuts. In both cases the maximum tightening torque is 3 Nm.

Cable gland or similar protection component must be used on electrical box's knockouts to against accidental

contact with electrical parts inside.

DSF090-175

The terminal box is provided with a Ø 25.5mm (φ1 inch) (ISO25) and a Ø 29mm (φ1.14) (PG21) knockouts.

Figure 39: Wiring connections for DSF090-175

DSF200

The terminal box is provided with a Ø 40.5mm (φ1.59inch) hole (ISO40) for power supply and a Ø 16.5mm

(φ0.65inch) knockout (ISO16).

Figure 40: Wiring connections for DSF200

DSF270-325-485-530

The terminal box is provided with 2 triple knockouts and 1 single knockout for power supply and 4 double

knockouts for the safety control circuit.

The 3 power supply knockouts accommodate the following diameters:

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 33

Page 34

2

3

1

8

6

7

4

3

2

1

5

L1

L N S1 S2 M1M2

L2 L3

CC-0517

12345678Black

Blue

Brown

M1, M2 Control circuit

Module power supply

Sump heater

Faston 1/4" tabs

Power supply

L N S1 S2 M1 M2

L1 L2 L3

2

3

4

5

1

CC-0035

L1L2L312345Black

Blue

Brown

Phase sequence input

Internal control contact

Safety circuit

Thermistor connection

Module power

Motor voltage code

Code 4

50 Hz

Nominal voltage

400 V - 3ph

50 Hz

Voltage range

360-440V

60 Hz

Nominal voltage

460V-3ph

60 Hz

Voltage range

414-506V

Scroll compressors, DSF090 to DSF530 | Electrical connections

• Ø 50.8 mm (φ 2 inch) (UL 1"1/2 conduit) & Ø 43.7 mm (φ 1.72 inch) (UL 1"1/4 conduit) & Ø 34.5 mm (φ 1.36 inch)

(UL 1" conduit)

• Ø 40.5 mm (φ 1.59 inch) (ISO40) & Ø 32.2 mm (φ 1.27 inch) (ISO32) & Ø 25.5 mm (φ 1 inch) (ISO25)

• Ø 25.5 mm (φ 1 inch) (ISO25)

The 4 others knockouts are as follows:

• Ø 22.5 mm (φ 0.89 inch) (PG16) (UL 1/2") & Ø 16.5 mm (φ 0.65 inch) (ISO16) (x2)

• Ø 20.7 mm (φ 0.81 inch) (ISO20 or PG13.5) (x2)

Figure 41: Wiring connections for DSF270-325-485-530

Motor protection module

The motor protection modules come preinstalled within the terminal box. Phase sequence protection connections

and thermistor connections are pre-wired and should not be removed.

The module must be connected to a power supply of the appropriate voltage. The module terminals are 6.3 mm

(0.25 inch) size Faston type.

Figure 42: Motor protection module

Electrical specications

Motor voltage

Danfoss scroll compressors DSF are available in motor voltage listed below.

Table 18: Motor voltage

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 34

Page 35

Vavg

V1-2

V1-3

V2-3

Mean voltage of phases 1, 2, 3.

Voltage between phases 1 and 2.

Voltage between phases 1 and 3.

Voltage between phases 2 and 3.

Compressor models

LRA

Max. operating current

Winding resistance

AAΩ

DSF0909817

1.47

DSF1009819

1.47

DSF115

142221.05

DSF130

142241.05

DSF155

147270.92

DSF175

158300.83

DSF200

197340.83

DSF270

191440.62

DSF325

231540.52

DSF485

343830.28

DSF530

343920.28

Scroll compressors, DSF090 to DSF530 | Electrical connections

NOTE:

Voltage range: Nominal voltage ± 10%. The voltage range indicates where the compressor can run in the majority

of the application envelope. A boundary voltage supply which accumulates under specic conditions such as high

ambiance, high superheat, or map boundary conditions, may lead to a compressor trip.

Voltage imbalance

The maximum allowable voltage imbalance is 2%. Voltage imbalance causes high amperage over one or several

phases, which in turn leads to overheating and possible motor damage. Voltage imbalance is given by the formula:

% voltageimbalance =

| Vavg − V1−2 | + | Vavg − V1−3 | + | Vavg − V2−3 |

2×Vavg

×100

IP rating

The compressor terminal box according to IEC60529 is IP54 for all models when correctly sized IP54 rated cable

glands are used.

First numeral, level of protection against contact and foreign objects

5 - Dust protected

Second numeral, level of protection against water

4 - Protection against water splashing

Terminal box temperature

The temperature inside the terminal box must not exceed 70 °C (158 °F). Consequently, if the compressor is

installed in an enclosure, precautions must be taken to avoid that the temperature around the compressor and in

the terminal box would rise too much. A ventilation installation on the enclosure panels may be necessary. If not,

the electronic protection module may not operate properly. Any compressor damage related to this will not be

covered by Danfoss warranty. In the same manner, cables must be selected in a way that ensures the terminal box

temperature does not exceed 70 °C (158 °F).

Three phase electrical characteristics

Table 19: Motor voltage code 4 - 400V/3ph/50Hz, 460V/3ph/60Hz

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 35

Page 36

t

25°CtambR25°C (77°F)

R

amb

a

reference temperature = 25°C (77°F)

temperature during measurement °C (°F)

winding resistance at 25°C (77°F)

winding resistance at tamb

Coecient a = 234.5

Scroll compressors, DSF090 to DSF530 | Electrical connections

LRA (Locked Rotor Amp)

Locked Rotor Amp value is the higher average current as measured on mechanically blocked compressors tested

under nominal voltage. The LRA value can be used as a rough estimation for the starting current. However, in most

cases, the real starting current will be lower. A soft starter can be applied to reduce starting current (see section Soft

starts).

MOC (Maximum Operating Current)

The max operating current is the amperage the compressor will draw when it operates at maximum load of

operating envelope within the voltages printed on the nameplate.

MOC can be used as a basis for contactors selection.

Winding resistance

Winding resistance is the resistance between phases at 25°C (77°F) (resistance value +/- 7%). Winding resistance is

generally low and it requires adapted tools for precise measurement. Use a digital ohm-meter, a “4 wires” method

and measure under stabilised ambient temperature. Winding resistance varies strongly with winding temperature. If

the compressor is stabilised at a dierent value than 25°C (77°F), the measured resistance must be corrected using

the following formula:

R

tamb

= R

25°C(77°F)

a + t

a + t

amb

25°C(77°F)

Motor protection

DSF090 to DSF200

Compressor models DSF090 to 200 are provided with internal overload motor protection to prevent against

excessive current and temperature caused by overloading, low refrigerant ow or phase loss.

The protector is located in star point of motor and, should it be activated, will cut out all three phases. It will be reset

automatically.

While not compulsory, an additional thermal magnetic motor circuit breaker is still advisable for either alarm or

manual reset.

Then it must be set at max operating current:

• When the motor temperature is too high, then the internal protector will trip.

• When the current is too high the thermal magnetic motor circuit breaker will trip before the internal protection

therefore oering possibility of manual reset.

DSF270 to DSF530

DSF compressors are delivered with a pre-installed motor protection module inside the terminal box. This device

provides ecient and reliable protection against overheating and overloading as well as phase loss/reversal.

The motor protector comprises a control module and PTC sensors embedded in the motor winding.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 36

Page 37

*

460 ms

1s*

40 ms 460 ms40 ms

approx. 1 second

*

1s*

80 ms 920 ms

approx. 1 second

Scroll compressors, DSF090 to DSF530 | Electrical connections

The motor temperature is being constantly measured by a PTC thermistor loop connected on S1-S2 . If any

thermistor exceeds its response temperature, its resistance increases above the trip level (4.500 Ω) and the output

relay then trips – i.e. contacts M1-M2 are open. After cooling to below the response temperature (resistance < 2.750

Ω), a 5-minute time delay is activated.

After this delay has elapsed, the relay is once again pulled in – i.e. contacts M1-M2 are closed. The time delay may be

cancelled by means of resetting the mains (L-N -disconnect) for approximately 5 sec.

A red/green twin LED is visible on the module. A solid green LED denotes a fault free condition. A blinking red LED

indicates an identiable fault condition:

Figure 43: PTC Overheat

Figure 44: Delay timer active (after PTC over temp.)

While not compulsory, an additional thermal magnetic motor circuit breaker is still advisable for either alarm or

manual reset.

Then it must be set below max operating current:

• When the motor temperature is too high, then the internal PTC over temp. and module is activated.

• When the current is too high the thermal magnetic motor circuit breaker will trip before the module activate

therefore oering possibility of manual reset.

Phase sequence and reverse rotation protection

Use a phase meter to establish the phase orders and connect line phases L1, L2 and L3 to terminals T1, T2 and T3,

respectively.

DSF090 to DSF200

Compressor models DSF090 to 200 incorporates an internal reverse vent valve which will react when the

compressor is run in reverse and will allow refrigerant to circulate through a by-pass from the suction to the

discharge. Although reverse rotation is not destructive for these models, it should be corrected as soon as possible.

Repeated reverse rotation over 24 hours may have negative impact on the bearings.

Reverse rotation will be obvious to the user as soon as power is turned on: the compressor will not build up

pressure, the sound level will be abnormally high and power consumption will be minimal. If reverse rotation

symptoms occur, shut the compressor down and connect the phases to their proper terminals. If reverse rotation is

not halted, the compressor will cycle o-on the motor protection.

DSF270 to DSF530

Use a phase meter to establish the phase orders and connect line phases L1, L2 and L3 to terminals T1, T2 and T3,

respectively.

Compressor models DSF270 to 530 are delivered with an electronic module which provides protection against

phase reversal and phase loss at start-up.

The phase sequencing and phase loss monitoring functions are active during a 5-sec window 1 second after

compressor start-up (power on L1-L2-L3).

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 37

Page 38

Cp

Ph

0 1s 6s

St

CpPhSt

Compressor

Phase monitoring

start

*

760 ms*

120 ms 400 ms120 ms 120 ms

Approximate

*

1 s*

500 ms 500 ms

Approximate

Scroll compressors, DSF090 to DSF530 | Electrical connections

Figure 45: Phase sequence module logic

Should one of these parameters be incorrect, the relay would lock out (contact M1-M2 open). The red LED on the

module will show the following blink code:

Figure 46: In case of phase reverse error

Figure 47: In case of phase loss error

The lockout may be cancelled by resetting the power mains (disconnect L-N) for approximately 5 seconds.

For more detailed information see “Instructions for electronic module” AN160986418236.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 38

Page 39

1.

2.

3.

1.

2.

3.

1.

2.

Split type

Single compressor

Manifold compressors

Non split

Test No.1

Test No.1+2

Split

Test No.1+3

Test No.1+2+3

Test No.

Purpose

Test conditions

Pass criteria

Solutions

1

Check proper oil

return

A

Lowest foreseeable evaporation, and highest foreseeable condensation.

Minimum number of compressor running for 6 hours.

For reversible system, perform test in both heating and

cooling mode.

Oil level must be visible or full in the

sight glass when the compressor is

running and when all compressors of

the circuit are stopped.

Top-up with oil, generally 3% of

the total system refrigerant

charge (in weight). Above 3%

look for potential oil trap in the

system.

Integrate a function in control

logic to run all compressors simultaneously in order to boost

oil return (for more details see

section Control logic).

Oil separator can be added

2

Check oil balancing

A

Lowest foreseeable evaporation and highest foreseeable

condensation and nominal capacity condition

For tandem 2 compressors running for 6 hours, for trio,

compressor running follow the running sequence:

(1+2+3)2hrs→ (1+2)2hrs →(2+3)2hrs→(1+3)2hrs

For reversible system, perform test in both heating and

cooling mode.

Oil level must be visible or full in the

sight glass when the compressors

are running and when all compressors of the circuit are stopped

Top-up with oil, generally 3% of

the total system refrigerant

charge (in weight).

Check that manifold piping is

conform to Danfoss requirements.

Integrate a function in control

logic to stop manifold periodically in order to balance oil (for

more details see section Control

logic).

3

Oil return in split

systems

Since each installation is unique, test 1 and 2 can not

fully validate the oil return. Oil level must be checked

and adjusted at commissioning.

Oil level must be visible or full in the

sight glass when the compressor is

running and when all compressors of

the circuit are stopped.

Pay special attention to “Piping

design”

Oil separator is strongly recommended, especially in case of

part load.

Scroll compressors, DSF090 to DSF530 | Application

Application

Manage oil in the circuit

Requirement

Oil level must be visible or full in the sight glass when the compressor is running and when all compressors of

the circuit are stopped. For DSF155-200 trio models, top-up oil quantity 1L at least as mandatory.

System evaluation

Table 20: System evaluation

Test, criteria and solutions

Table 21: Test, criteria and solutions

Manage sound and vibration

Sound radiations

We can consider two means to reduce compressors sound radiations:

1.

Acoustic hoods are quick and easy to install and do not increase the overall size of the compressors. Acoustic

hoods are available from Danfoss as accessories. Refer to the tables above for sound levels, attenuation and code

numbers.

2.

Use of sound-insulation materials on the inside of unit panels is also an eective mean to reduce sound

radiation.

NOTE:

During compressor shut down, a short reverse rotation sound is generated. The duration of this sound depends on

the pressure dierence at shut down and should be less than 3 seconds. This phenomenon has no impact on

compressor reliability.

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 39

Page 40

Scroll compressors, DSF090 to DSF530 | Application

Gas pulsation

DSF has been designed and tested to ensure that gas pulsation is optimized for the most commonly encountered

air conditioning pressure ratio. Manifolded compressors are equivalents to lagged sources of gas pulsation.

Therefore, pulse level can vary during time.

Mitigations methods:

If an unacceptable level is identied, a discharge muer with the appropriate resonant volume and mass can be

installed.

Mitigation methods

Mitigations methods:

1.

To ensure minimum vibrations transmission to the structure, strictly follow Danfoss mounting requirements

(mounting feet, rails etc..). For further information on mounting requirements, please refer to section Design

compressor mounting.

2.

Ensure that there is no direct contact (without insulation) between vibrating components and structure.

3.

To avoid resonance phenomenon, pipings and frame must have natural frequencies as far as possible from

running frequency. Solutions to change natural frequencies are to work on structure stiness and mass

(brackets, metal sheet thickness or shape…).

Manage operating envelope

The Operating envelope data for DSF scroll compressors guarantees reliable operations of the compressor for

steady-state operation.

Steady-state operation envelope is valid for a suction superheat within 5K to 10K range at nominal Voltage.

Discharge temperature protection

DSF270 to DSF530 include an integrated discharge temperature protection. Excessive discharge temperature will

result in tripping of electronic module ouput relay.

This protection, eective for suction superheat above 5 – 10 K (9 – 18 °F), should be considered as a compressor

safety device and its purpose is not to ensure operation map control.

In case of basic map control by pressure switches that can not ensure totally that the compressor will remain in its

operating envelope, an additionnal external discharge protection is required. (see Figure 48: Discharge temperature

protection examples)

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 40

Page 41

3

2

1

4

CC-0056

1234Thermostat

Discharge line

Bracket

Insulation

Condensing temperature (°C)

Condensing temperature (°F)

Evaporating temperature (°C)

Evaporating temperature (°F)

5

10

15

20

25

30

35

40

45

50

55

60

65

70

41

50

59

68

77

86

95

104

113

122

131

140

149

158

-35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30

-31 -22 -13 -4 5 14 23 32 41 50 59 68 77 86

Example 2

LP2

DGT - limit

LP1

R32

Example 1

HP1

HP2

CC-000184

Scroll compressors, DSF090 to DSF530 | Application

Figure 48: Discharge temperature protection examples

Example 1 (R32, SH = 5K)

LP switch setting: LP1 = 3.9 bar (g) (-15°C), HP switch setting: HP1 =40.2 bar (g) (62°C)

Risk of operation beyond the application envelope.

DGT protection required.

Example 2(R32, SH = 5K)

LP switch setting: LP2 = 4.8 bar (g) (-10°C), HP switch setting: HP2 = 32 bar (g) (52°C)

No risk of operation beyond the application envelope.

No DGT protection required.

DSF090 to DSF200 have no integrated discharge temperature protection, an external protection is required.

This external protection device can be a thermostat or a temperature sensor. The discharge gas temperature

protection must trip the power supply when it reaches the setting point to protect the compressor from

overheating.

The discharge gas protection should be set to open at a maximum discharge gas temperature of 150°C(302°F). A

PT1000 is recommended.

The discharge gas thermostat or sensor must be attached to the discharge line within 150mm (5.91 inch) from the

compressor discharge port and must be thermally insulated and tightly xed on the pipe (see Figure 49: Discharge

Gas Temperature protection (DGT))

Figure 49: Discharge Gas Temperature protection (DGT)

© Danfoss | Climate Solutions | 2021.10 AB309735209512en-000401 | 41

Page 42

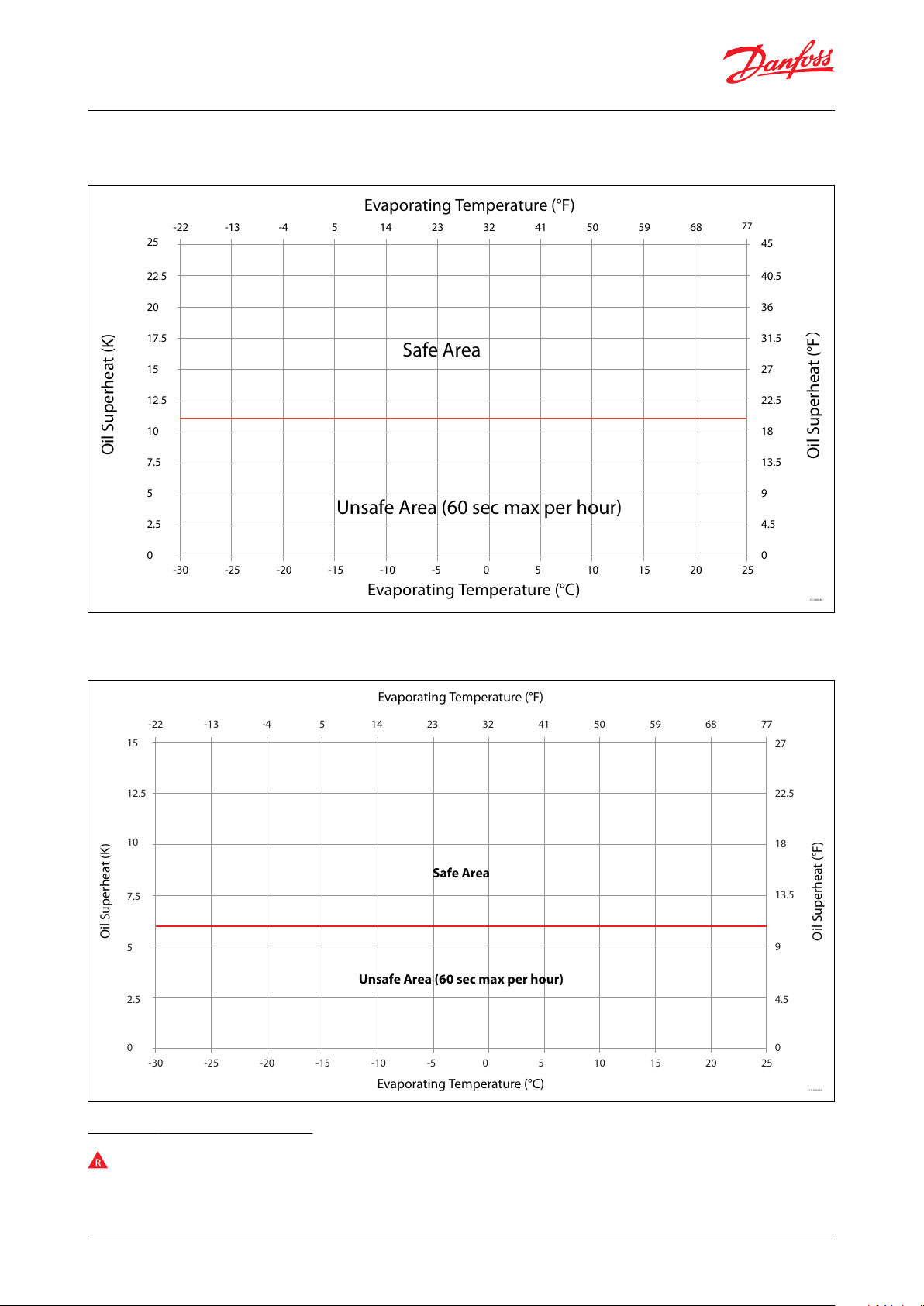

Basic

Advanced

• HP and LP switch