Page 1

Data sheet

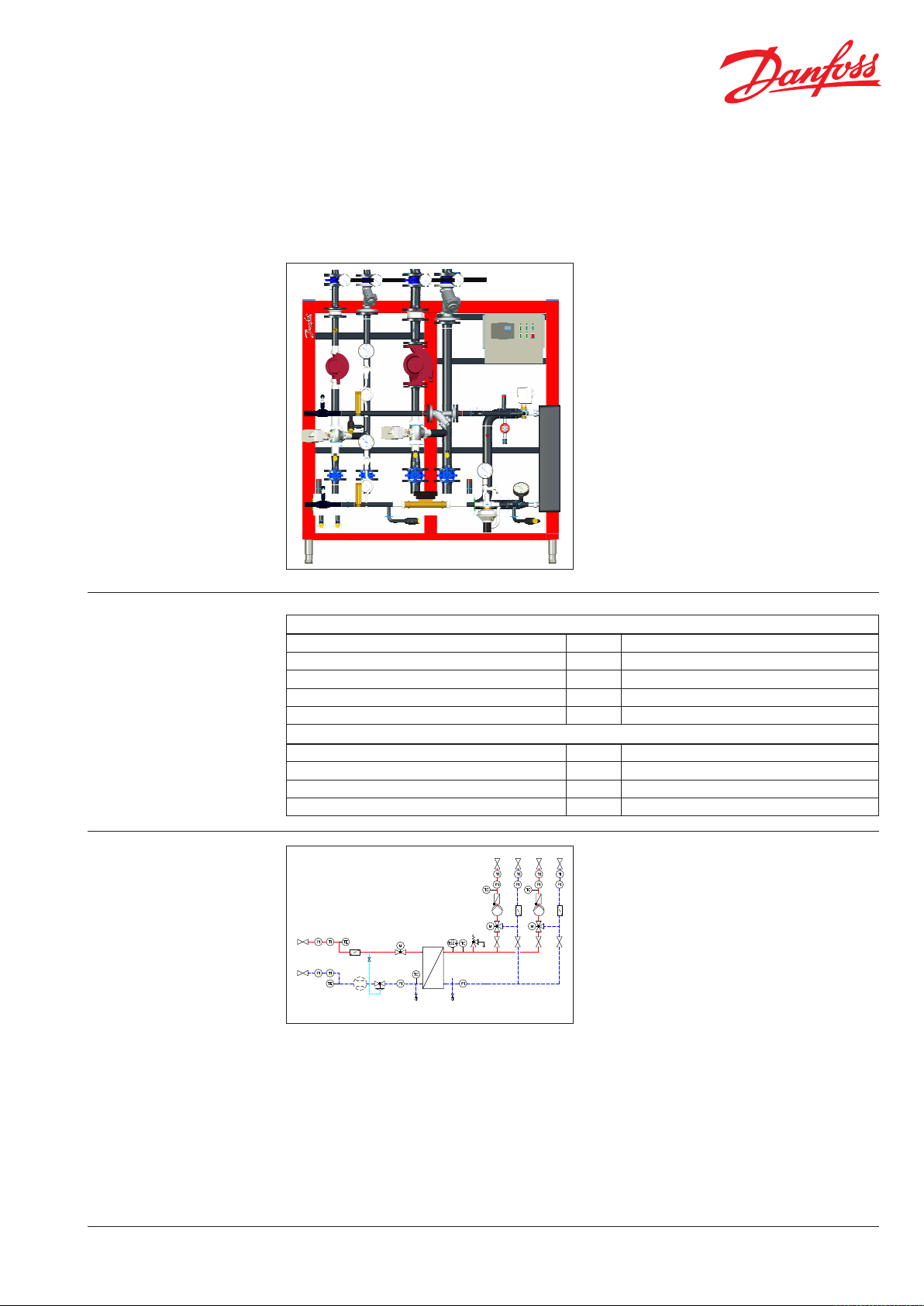

Welded District Heating Stations

Type DSE-I1B (two secondary heating circuits)

General description and

application

Maximum operating

parameters

District heating transfer stations provide the

link between district heating suppliers

and customers’ systems.

They incorporate the necessary equipment to

tailor the supplied heat to the needs of the object

premises as specied in the heating supply contract.

In this they need to comply with all applicable

standards and with the supplier’s technical

connection conditions.

Indirect connections (in which district heating

and in-house systems are hydraulically isolated)

incorporate components to separate the systems

(heat exchanger), to limit the ow volume to that

specied in the contract, regulate the secondary

supply temperature and measure the energy

consumption.

The system described here is a standard type in

which the secondary incorporates two regulatory /

heating circuits.

Primary

Maximum permissible supply temperature, primary

Maximum permissible operating pressure, primary PZP 25 or 16 bar (g)

Rated pressure, primary PN 25 or 16

Maximum permissible pressure dierential, primary

Maximum permissible ow volume, primary VZP 9.0 m

TVP 150 °C

DPP 20 bar (-kvs=8 m3/h) / 16 bar (kvs=12.5-20 m3/h)

3

/h for w <= 1.2 m/s

Secondary

Maximum permissible supply temperature, secondary

Maximum permissible operating pressure, secondary PZS 10 bar or depending on the safety valve

Rated pressure, secondary PN 10

Maximum permissible ow volume, secondar y VZS 25.0 m

TVS 110 °C

3

/h for w <= 1.2 m/s

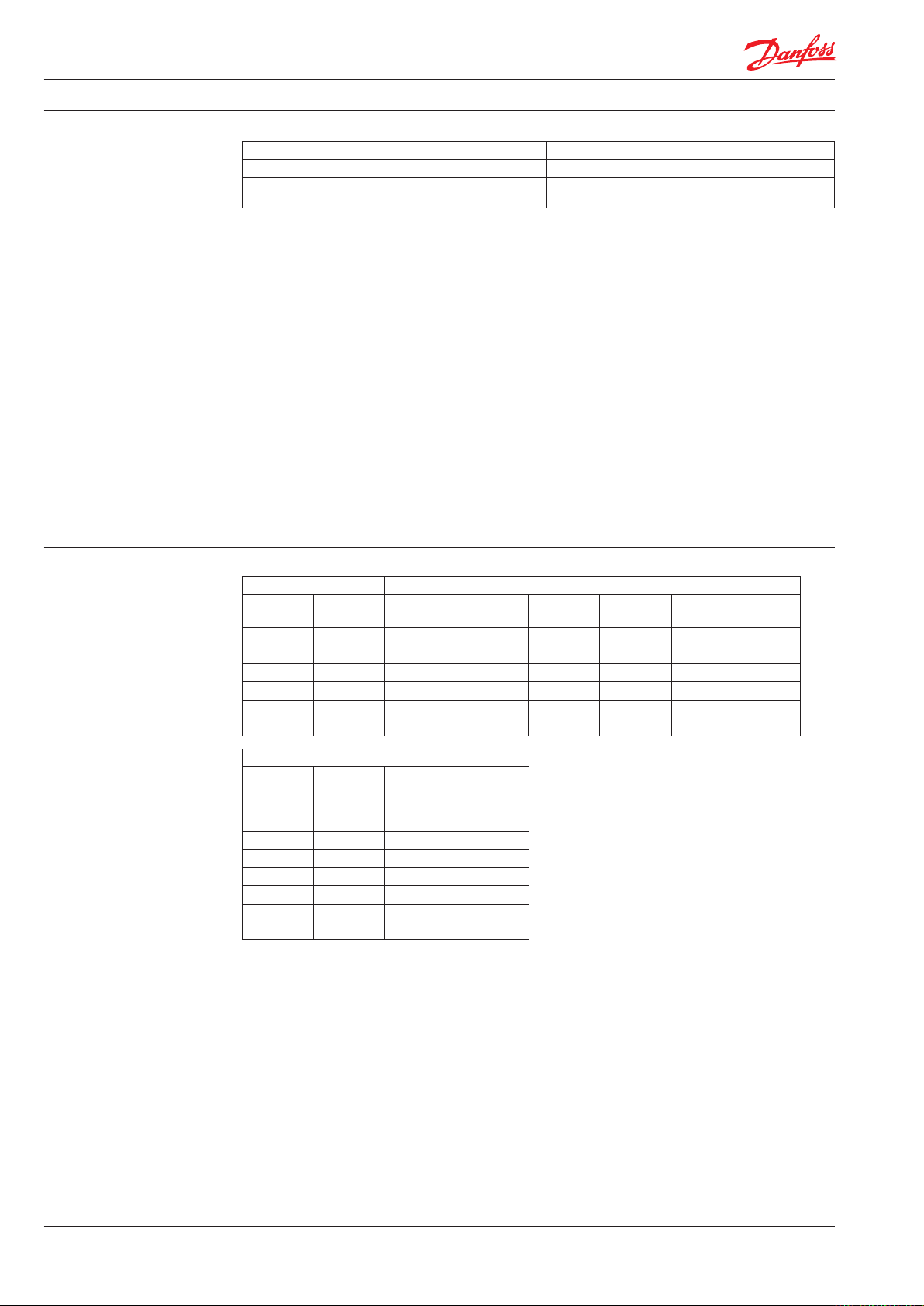

Circuit diagram

DEN-SMT/PL

0211

0212

0411

0412

0421

0522

0532

0450

0451

02310111

0122

0132

1211 1212

0422

0450

0451

02320112

0521

0531

0251 0252

0121

0430

0400

0431

0401

0200

0220

0430

0400

0431

0401

0020

0021

0010

0011

0510

0511

0430

0431

0270 0280

0012

0033

0030

0040

0131

0520

0530

0100

0560

0561

MAG

0440

0441

Options

Instead of the 0020/0030 the system can also

incorporate a combined ow/temperature

regulator (combo-valve), which can be installed

in the supply or return line as desired.

VD.HE.E2.02 © Danfoss 05/2012

Legend

0200/21x Shut-o device for primary/secondary

121x Shut-o device for secondary distributor

0430/431 Manometer with shut-o valve

0400/401 Thermometer with immersion sleeve

0220/23x Dirt trap / strainer

0040 Fitting piece for energy meter

0020 Motor regulator valve

0021 Electrical actuator

0030 Pressure dierential and ow regulator

0033 Needle valve

0270 High-pressure drain valve

0510/511 Return temperature limiter

0010-12 Heat exchanger with insulation

0560/561 Safety thermostat

052x/53x Supply temperature sensor

0100 Safety valve

0280 Drain valve

044x/045x Manometer with shut-o valve

MAG Pressure retention connector

041x/42x Thermometer with immersion sleeve

011x Circulation pump

025x Non-return valve

012x/013x Mixing valve with electrical actuator

1

Page 2

Data sheet Welded District Heating Stations Type DSE-I1B (two secondary heating circuits)

Materials

Function

Technical data

Pipes and pipe ttings, anges P235GH-TC1, C22.8

Heat exchanger 1.4404 with Cu brazing compound

Fittings CuSn5Pb5Zn5-C (RG-5), ST37.0,

Hot water drawn from the pipeline of the local or

district heating supply company is fed into the

station at an appropriate temperature and pressure,

EN-GJS-400-18-LT (GGG40.3)

The cooled heating water then ows back to the

local or district heating supply company via the

primary return pipe.

which may be higher in winter than in summer.

A pump in the secondary circuit of the in-house

In the primary supply line this hot water will

generally ow through a shut-o valve and

a dirt trap / strainer.

Depending on the system design and the

stipulations of the heating provider, both the

supply and return lines will normally incorporate

system then circulates the hot water to the heating

surfaces or other consumers (e.g. ventilators,

domestic hot-water systems, etc.).

Additional heating circuits incorporate valves to

regulate the secondary temperatures to suit the

specic parameters of the heating circuit.

a thermometer and a manometer to register the

temperature and pressure.

There will also be regulatory equipment in the

supply or return lines of the primary as specied

by the requirements and the circuit design.

Primary Secondary (largest heating circuit)

max. V

p

DN

20 1.8 40 6,0 32-120 16.0 55

25 2.5 50 9,0 40-120 25.0 50

32 3.5 50 10,0 50-120 40.0 65

40 5.7 65 15,0 50-120 40.0 55

50 7.3 80 20,0 65-120 63.0 50

65 9.0 80 25,0 65-120 63.0 30

[m3/h]

DN max.

max. Vp

[m3/h]

Pump

MAGNA

(*)

Mixer valve

[m3/h]

k

vs

Residual delivery head

[kPa]

Primary control valve (20/30) / EM (40)

Dimen-

k

DN

20 .. 4.0 .. 2.5 1 x 190

25 6.3 3.5 ⁄ x 260

32 8.0 3.5 ⁄ x 260

40 12.5 6 ⁄ x 260

50 16.0 10 2 x 300

65 20.0 10 2 x 300

Types:

0020/21 VM2/AMV10/13/20/23 (*) other pumps on request

0030 AVPQ or AVPB 0121/31 VRG/AMV435 or VF3/AMV55

0020/21 AVQM/AMV10/13/20/23(SL)

(alternative)

vs

[m3/h]

QN

sions

G [‘’] * L

[mm]

2

VD.HE.E2.02 © Danfoss 05/2012

DEN-SMT/PL

Page 3

Data sheet Welded District Heating Stations Type DSE-I1B (two secondary heating circuits)

Dimensions

Dimensions

sec.DN

pr. DN

pr.

TWE

(max.)

20 - 40 1600 1600 750 ~ 790 1500 1660 557 410 210

25 - 50 1600 1600 750 750 1520 1715 557 410 210

32 - 50 1600 1770 800 ~ 870 1430 1865 688 440 200

40 - 65 1600 1855 800 ~ 920 1430 1865 672 440 200

50 - 80 1800 2110 900 ~ 1075 1520 1995 744 520 240

65 - 80 1800 2160 900 ~ 1110 1520 1995 748 520 240

* Dependi ng on the number of plates in the h eat exchanger

f the foot can be ad justed between: 105 … 160 mm

Width Depth Height Distance

b B t T* h H p w s

Example of performance

Primary

[m3/h]

V

p

Secondary

V

[m3/h] 0100

p

0010

Type

1.8 5.9 R1-3 bar XB30 170

2.4 8.0 R1/2-5 bar XB51H 230

3.0 10.0 R1/2-5 bar XB51H 285

4.6 15.0 R1/2-5 bar XB51H 430

6.1 20.1 R1/2-5 bar XB51H 575

7.4 24.5 R1/2-5 bar XB51H 700

Q

[kW]

p

Regulation Data sheets ECL 110/210/310System will generally incorporate one or more

electronic heating controllers, depending on the

requirements and/or application.

Dimensioning example:

primary 130 -> 47 °C / secondary: 45 -> 70 °C

Optionally on left or right

DEN-SMT/PLDEN-SMT/PL

VD.HE.E2.02 © Danfoss 05/2012

3

Page 4

Data sheet Welded District Heating Stations Type DSE-I1B (two secondary heating circuits)

DN25 pipe

Energy meter tting

Number of sensors

Sensor installation

Design with threaded joints (e.g.)

R ½" X G ¾" x 110 mm = QN … 1.5

R ¾" X G 1" x 130 mm = QN 2.5

R ¾" X G 1" x 190 mm = QN … 3.0

R 1" X G ⁄" x 260 mm = QN 3.5 / 6.0

R 1 ½” X G 2" x 300 mm = QN 10.0

Other (e.g. riser/down pipe meter):

R: " x G: " x mm

One sensor:

Variant: Installed directly M10*1 (with no sleeve):

QN … 6.0

(only PN16!)

A A

GFW sensor 27.5 mm (possible only in DN20 and 25)

B

AGFW sensor 38.0 mm (possible only in DN20 and 25)

Variant: Immersion sleeve R ½" x … 37.0 mm: QN … 2.5

C Installed in a DN20 T-piece (26.9 mm)

Design with anges (e.g.)

DN20 x 190 mm = QN … 3,0

DN25 x 260 mm = QN 3,5 / 6,0

DN40 x 300 mm = QN 10,0

DN50 x 270 mm = QN 15,0

DN65 x 300 mm = QN 25,0

DN80 x 300 mm = QN 40,0

DN100 x 360 mm = QN 60 / 100

Other (e.g. riser/down pipe meter):

DN: x mm

Two sensors

:

PN 16 25

D Installed in a DN25 pipe (33.7 mm) 90° truncated

Variant: Immersion sleeve R ½" x … 150 mm: QN … 15.0

E Installed in a T-piece, at-sealing, minimum

necessary / maximum possible sleeve length:

DN min. L in [mm] max. L in [mm]

20 44,0 155,0

25 53,0 155,0

32 63,0 155,0

40 73,0 155,0

50 80,0 155,0

Variant: Immersion sleeve R ½" x xxx mm: QN 15.0 …

F Installed in a DN50 pipe ... (60.3 ... mm) 90° truncated

Sleeve length LH (specify precisely!):

(sleeve / sensor may be inside the insulation)

DN20...DN50 pipes

mm

DN... pipe

Danfoss GmbH Fernwärme- und Regelungstechnik · Kolumbusstraβe 14 · D-22113 Hamburg

Tel.: +49 (0) 40/73 67 51-0 · Fax: +49 (0) 69/8902 466 400 · info-hh@danfoss.com · www.fernwaerme.danfoss.de

4

VD.HE.E2.02 © Danfoss 05/2012

Produce d by Danfoss A/S © 05/2012

Loading...

Loading...