Data sheet

DSE FLEX – Compact Substation

General description and

application

Maximum operating

parameters

New generation subst ation is suitable for the already

proven flexible, efficient and economical infrastructure of a low carbon cit y, a District Heating net work.

Danfoss district heating substations provides the

link between dis trict heating suppliers and customer

installations. They contain all the necessary equipment to adjust the heat supplied for the needs of

the object premises as specified in the heating

supply contract. In this respect they must comply

with all applicable st andards and with the supplier’s

technical connection conditio ns. Indirect conne ctions (in which district heating and in-house systems

are hydraulically isolated) incorporate components

that separate the systems (he at exchanger), limit the

flow volume to that specified in the contract, regulate the secondary sup ply temperature and measure

energy consumption. It is a an exclusive solution

designed to optimally fulfil specific requests and

stringent requirements for district heating. By use

of the Danfoss dimensioning program you can find

out if the application you need fits DSE FLEX. The

new generation substation is designed to be floor

mounted, is keeps the robustness and friendly /

appealing outlook of the old product with the

advantage of a lighter profile, smaller size and designed for a faster and safer transport.

Primary

Maximum permissible supply temperature, primary 135°C

Maximum permissible operating pressure, primary 14, 2 bar (g)

Rated pressure, primary PN16

Secondary Heating

Maximum permissible temperature, secondary 100°C

Maximum permissible operating pressure, secondary 6 bar(g)

Minimum required pressure (static), water supply 1.0 bar(g)

Secondary Domestic Hot Water

Maximum permissible temperature, secondary 90°C

Maximum permissible operating pressure, secondary 10 bar(g)

Minimum required pressure (static), water supply 1.0 bar(g)

Materials

© Danfoss | 2018.02

Pipes, fittings, flanges, valves (primary side) P235GH, EN-JL1040 (GGC25), CuSn5Pb5Zn5-C (RG-5),

EN-GJS-400-18-LT (GGG 40.3)

Pipes, fittings, flanges, valves (heating side) P235GH, EN-JL1040 (GGC25),

EN-GJS-400-18-LT (GGG 40.3), brass (DZR type)

Pipes, fittings, flanges, valves (DHW side) 1.4301, 1.4404, brass (DZR type),

CuZn35Pb2Al-C (CC752S)

Heat exchanger 1.4404 with Cu solder

Insulation (casted parts) EPP foam, l=0.038 W/mK

Insulation (heat exchanger) PU foam, l =0.035 W/mK

Insulation (piping) PU foam, l =0.029 W/mK

VD.JV.C2.02 | 1

Data sheet DSE FLEX – Compact substation

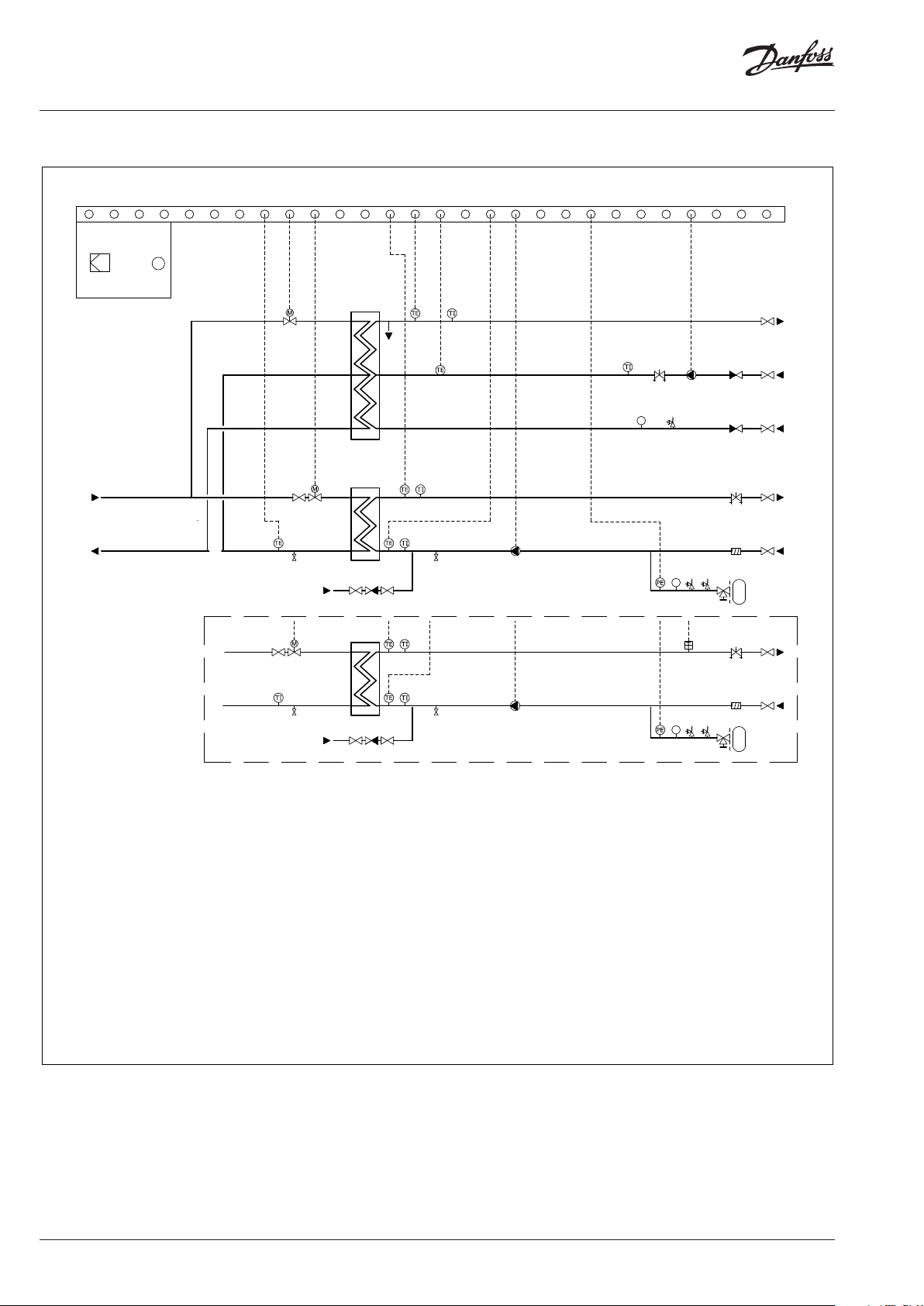

Circuit diagram

Electric box

TE

2B

750

753

95

3

445

443

A

488

474

465

430

470

472

PI

420419

468

423

411

26 Control valve HE

34 Drain valve

35 Temperature sensor

75 Ball valve

84 Drain valve

85 Thermometer

95 Control valve DHW

150, 151 Ball valve

153 Strainer

164 Balancing valve

167 Pump

171 Drain valve

174 Thermometer

175 Temperature sensor

181 Temperature sensor

175

376

365

181

174

377

364

182

171

361

167

357

164

153

813

815

PI

811

812

814

398

395

343

820

822

PI

818

819

821

430 Ball valve

443 Temperature sensor

445 Thermometer

465 Ball valve

468 Check valve

470 Pump

472 Balancing valve

474 Thermometer

488 Temperature sensor

750 Electronic controller

753 Outdoor sensor

811, 818 Pressure transmitter

812, 819 Pressure measurement

813, 814 Safety valve

815, 822 Expansion valve

150

151

PS

340

341

PS

26

1

151

35

34

720

A

75

85

84

700

A

182 Thermometer

340, 341 Ball valve

343 Strainer

357 Pump

361 Drain valve

364 Thermometer

365 Temperature sensor

376 Temperature sensor

377 Thermometer

395 Safety thermostat

398 Balancing valve

411 Ball valve

419 Pressure measurement

420 Safety valve

423 Check valve

820, 821 Safety valve

2 | © Danfoss | 2018.02

VD.JV.C2.02

Data sheet DSE FLEX – Compact substation

Function

The DSE FLEX platform can be used for various

applications such as heating, domestic hot water

and / or other water based heating system. Due

to its flexibility, it is possible to deliver a 1-, 2- or

3-circuit substation with possibility to make combinations between modules if more circuits are

required. This is based on customer requests and

the needed application(s). The construction

allows easy access to all components for maintenance and servicing purposes. Heat transfer

between the district heating network and the

building installation is achieved by way of a micro

plate heat exchanger, which ensures better heat

transfer, higher energy efficiency and reduced

pressure loss. In addition to the standard controller functions, the ECL310 offers easy remote

access via an internet page with data logging possibilities and energy optimization functions such

as weather compensation and auto-tuning (adaptive settings for domestic hot water parameters).

Dimensions

Capacity [kW] Pipe diameter External dimensions (max) Weight

Heating 1Heating

115 -4 5/

50-80

60 40 70 25 25 25 15 900 1000 1600 13 00 500 54 71 99

95 60 100 25 25 25 15 900 110 0 1600 1300 500 59 77 10 9

120 80 150 32 32 25 15 900 115 0 1700 1300 500 65 83 119

150 100 195 32 32 32 20 900 115 0 1700 1300 500 70 88 127

190 12 5 245 40 40 32 20 950 120 0 1750 1300 610 87 110 170

235 160 300 40 40 40 25 950 120 0 1750 1300 610 102 129 19 9

295 200 380 50 50 40 25 115 0 1400 19 00 1400 650 110 140 215

370 245 395 50 50 50 25 1150 140 0 190 0 1400 650 141 18 0 276

560 410 590 65 65 50 32 1200 1500 2000 150 0 650 16 4 210 322

2

115 -6 5/

60-80

70-25/

10-58

DHW

Heating 1Heating

[DN] [DN] [DN] [DN] [mm] [mm] [mm] [mm] [mm] [kg] [kg] [kg]

Cold/

warm

2

water

DHW

circulation

Length

(A1)

Length

(A2)

Length

(A3)

Height

(B)

Depth

(C)

Weight

1 circuit

Weight

2 circuits

Weight

3 circuits

These are only few examples of all the possible combinations. Depending on the customer requirements, type of heat exchangers, application, DN

combinations, etc. the dimensions may vary. Depth dimension C is considered for 2 and 3 circuit stations. Height dimension B is considered with the

electrical box in the minimum height position and the heating pump on the return line.

A1 A2 A3

B

VD.JV.C2.02

C

© Danfoss 2018.02 | 3

Data sheet DSE FLEX – Compact substation

Accessories The DSE FLEX platform is designed for Full Insu-

lation. This reduces significantly the energy loss

in the heating room.

In order to receive this accessory and also for additional details and quotations please contact the

sales responsible.

Configuration Contact the sales staff responsible for additional

details and a quotation for the DSE FLEX.

4 | © Danfoss | DHS-SMT/PL | 2018.02

VD.JV.C2.02

Loading...

Loading...