Fact Sheet

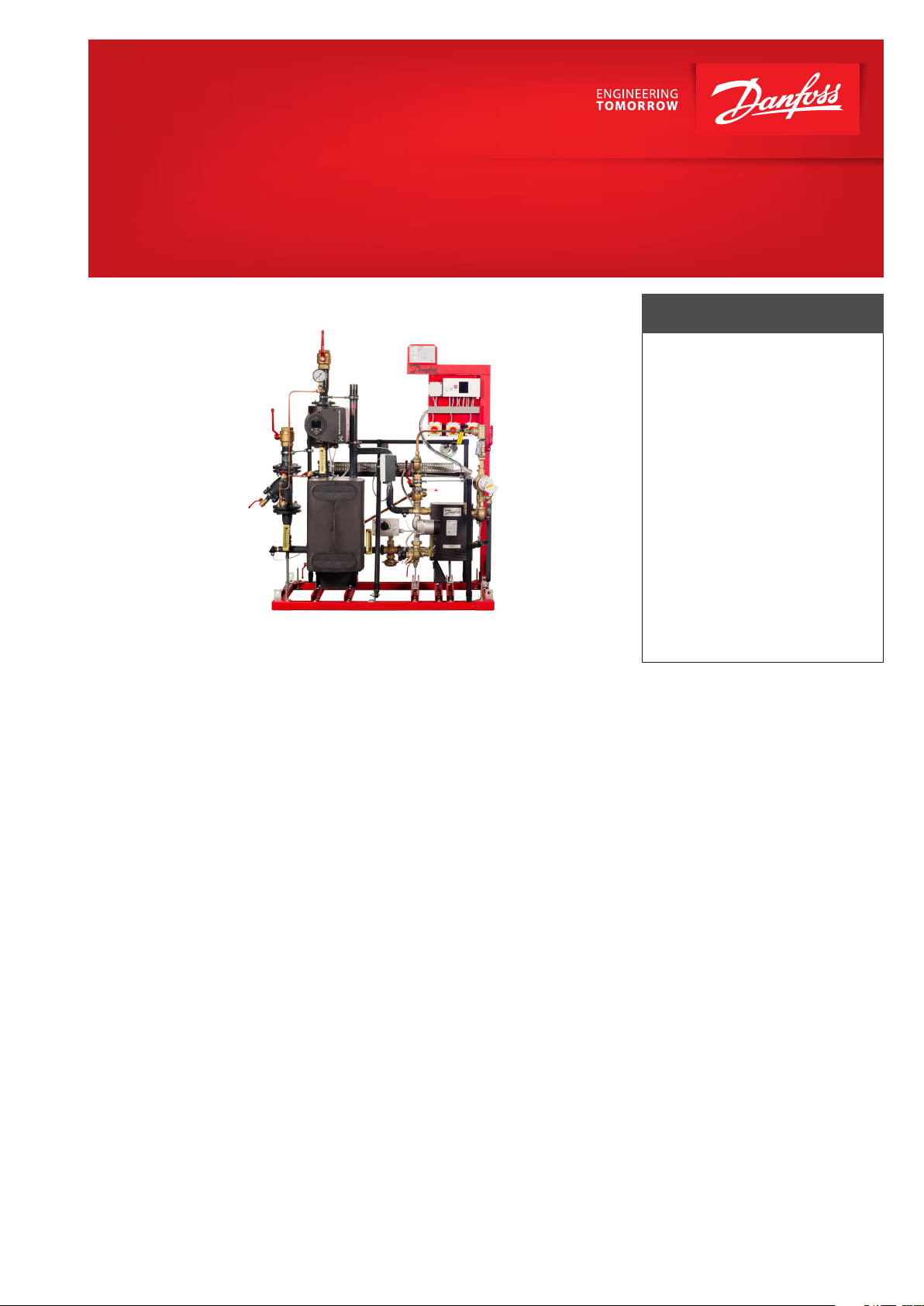

DSE FLEX

Compact substation, HE 560 kW, DHW 590 kW

Application

New generation substation is suitable

for the already proven flexible, efficient

and economical infrastructure of a low

carbon city, a District Heating network.

It is a an exclusive solution designed

to optimally fulfil specific requests and

stringent requirements for district heating. By use of the Danfoss dimensioning

program you can find out if the application you need fits DSE FLEX.

Construction

DSE FLEX is a compact substation platform designed for indirect district heating with up to 3 circuits with possibility

to make combinations between modules if more circuits are required. The

new generation substation is designed

to be floor mounted, is keeps the robustness and friendly / appealing outlook of

the old product with the advantage of a

lighter profile, smaller size and designed

for a faster and safer transport. DSE FLEX

usually does not exceed when delivered

1.5m height. However if the situation

requires the substation height can be reduced to 1.2m. (See the Hauling instructions). DSE FLEX is designed always with

the HE heat exchanger and circuit on the

left side and the DHW heat exchanger

an circuit on the right side when facing

the substation. Piping can be prepared

in the room to fit this construction

before the substation is delivered. The

reduced size of the base frame and

layout offers DSE FLEX the smallest foot

print in it’s product class. Most of the

2 circuit variants are not larger then 1

Euro Pallet. The compact size does not

minimize the access to key service components. The connections are very low

and orientated upwards, making it easy

to connect the substation in all directions. The electrical panel is mounted

always on the right side when facing

the substation. The bracket of the

electrical panel is adjustable 90 deg

in rotation and in vertical direction

up to 500 mm. The substation piping

construction is realized with automatic

welding machines to ensure the highest welding quality, the quality of this

product is further more ensured by the

GGG40.3 casted parts on Heating and

CC752S casted parts on Domestic Hot

Water. On request the substation can

be delivered with full insulation PUR.

Equipment

Danfoss substation is equipped with

various high quality components produced by Danfoss. They ensure high

comfort, high quality performance

during operation and energy saving.

FEATURES AND BENEFITS

• Compact size for an easy

transport and installation

• The adjustable feet are from

construction inside the profile

• Hauling instructions for a faster

and safer transport

• The height of the connections is very low

• Electronic controller for heating

and domestic hot water systems

with access to ECL Portal

• Advanced gasket system primary side

• Fast and reliable delivery

• Substation with high efficiency

brazed plate heat exchanger with

the new microplate technology

• Easy access to key service components

• Danfoss substations and heat exchangers

are manufactured according to

European Pressure Directive PED

The components are tested and

approved especially for DEN applications. All Danfoss components in

control loop are tuned together so the

optimum performance is guaranteed.

We mention ECL DH controller which

gives access to an online portal, a full

range of Microplate Heat Exchanger

that thanks to the unique plate design,

reduces pressure loss up to 35%, the

Danfoss pressure balanced control

valves VM and the DHW control proven solution AVQM. DSE FLEX means

flexible for your application, that is

why we allow also other components

inside this substation with out minimizing the construction and installation advantages.

Information needed

for a quotation

Heat capacities

Temperature program

Permissible pressure losses in the

heat exchangers / substation

Primary pressure difference available

Pressure losses in secondary circuits

Flow-through hot water circulation

Other information about other

required components.

heating.danfoss.com

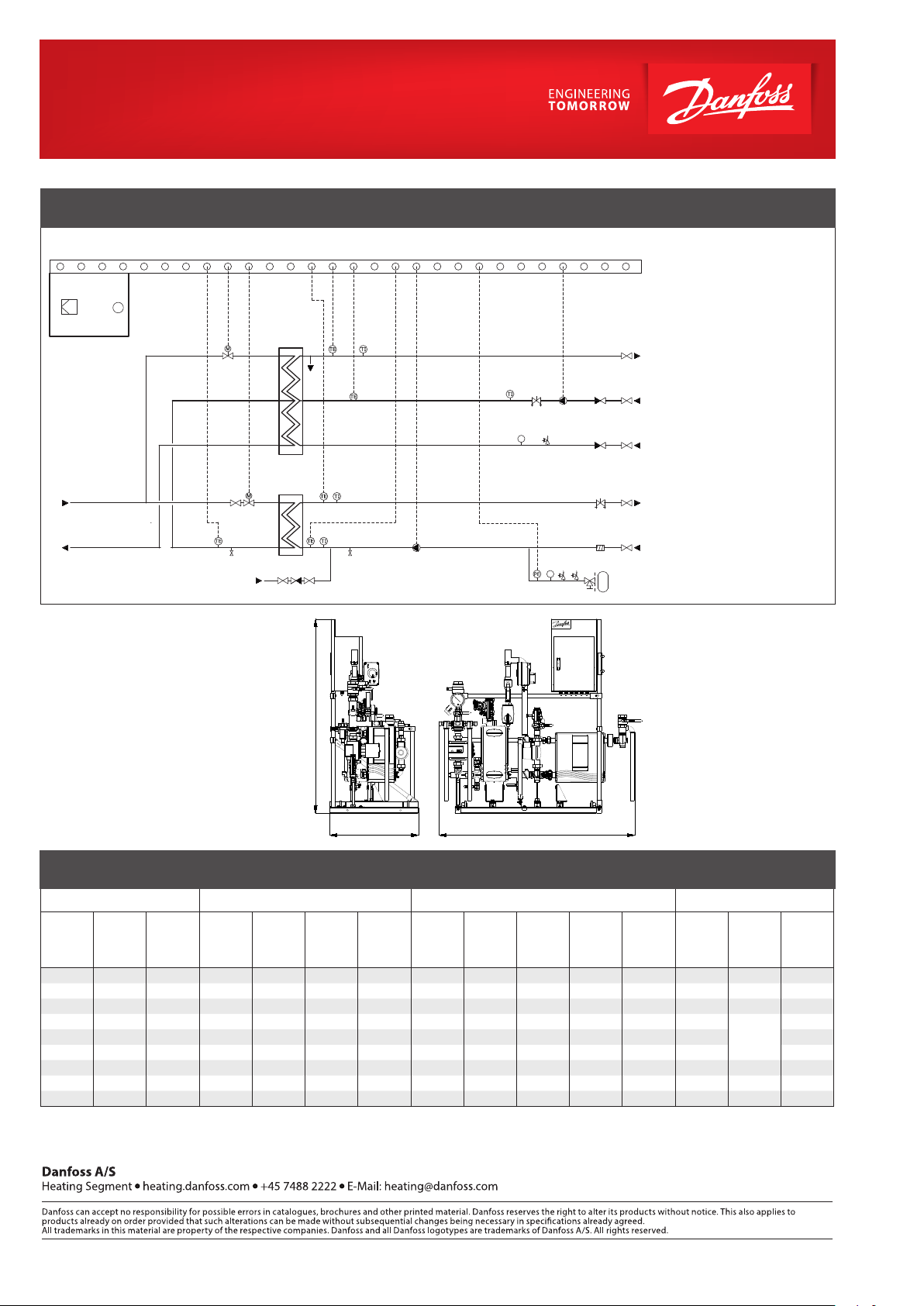

CIRCUIT DIAGRAM – EXAMPLE

Electric box

TE

750 753

2B

95

26

151

35

34

A

3

1

720

443

A

182

181

174

175

445

488

171 167

474

472 470 468

PI

420419

811 812 814

26 Control valve HE

34 Drain valve

35 Temperature sensor

95 Control valve DHW

150,151 Ball valve

153 Strainer

164 Balancing valve

167 Pump

171 Drain valve

465

430

423

411

164

150

153

815

151

PS

813

PI

174 Thermometer

175 Temperature sensor

181 Temperature sensor

182 Thermometer

411 Ball valve

419 Pressure measurement

420 Safety valve

423 Check valve

430 Ball valve

443 Temperature sensor

445 Thermometer

465 Ball valve

468 Check valve

470 Pump

472 Balancing valve

474 Thermometer

488 Temperature sensor

750 Electronic controller

753 Outdoor sensor

811 Pressure transmiter

812 Pressure measurement

813, 814 Safety valve

815 Expansion valve

820 Safety valve

Technical paremeters

Primary side

Maximum temperature: 135 °C

Nominal pressure: PN 16

Diameter: DN 25 / 50

Heating

Maximum temperature: 90 °C

Nominal pressure: PN 6

Diameter: DN 25 / 65

Domestic Hot Water

Maximum temperature: 90 °C

Nominal pressure: PN 10

(1)

(6)

(7)

B

(3)

(5)

Weight (incl. packing)

1-circuit station: max. 164 kg

2-circuit station: max. 210 kg

3-circuit station: max. 322 kg

Connections:

1. District Heating Supply

2. District Heating Return

(4)

3. Domestic Hot Water

4. Domestic Cold Water

5. Circulation

6. Heating Supply

(2)

7. Heating Return

Diameter: DN 25 / 50

Max dimensions (mm)

Width / Height / Depth (1F): 1200 / 1500 / 650 mm

Width / Height / Depth (2F): 1500 / 1500 / 650 mm

Width / Height / Depth (3F): 2000 / 1500 / 650 mm

C A2

CAPACITY, WEIGHT AND DIMENSIONS

Capacity [kW] Pipe diameter External dimensions (max) Weight

Heating 1

115 -4 3/

40 -70

Heating 2

115 -6 3/

60-80

DHW

70-20/

10-58

Heating 1

[DN]

Heating 2

[DN]

Cold/

warm

water

[DN]

60 40 70 25 25 25 15 900 1000 1600 1300 500 54 71 99

95 60 100 25 25 25 15 900 1100 1600 1300 500 59 77 109

120 80 150 32 32 25 15 900 1150 1700 1300 500 65 83 119

150 100 195 32 32 32 20 900 1150 1700 1300 500 70 88 127

190 125 245 40 40 32 20 950 1200 1750 1300 610 87 110 170

235 160 300 40 40 40 25 950 1200 1750 1300 610 102 129 199

295 200 380 50 50 40 25 1150 1400 1900 1400 650 110 140 215

370 245 395 50 50 50 25 1150 1400 1900 1400 650 141 180 276

560 410 590 65 65 50 32 1200 1500 2000 1500 650 164 210 322

These are only few examples of all the possible combinations. Depending on the customer requirements, type of heat exchangers, application, DN combinations, etc. the dimensions may vary.

Depth dimension C is considered for 2 and 3 circuit stations. Height dimension B is considered with the electrical box in the minimum height position and the heating pump on the return line.

Maximum capacity is determined by temperature, allowable pressure drops and local regulations.

DHW

circulation

[DN]

Length

(1 circuit)

[mm]

Length

(A2)

[mm]

Length

(3 circuit)

[mm]

Height

(B)

[mm]

Depth

(C)

[mm]

Weight

1 circuit

[kg]

Weight

2 circuits

[kg]

Weight

3 circuits

[kg]

© Danfoss | DHS-SMT/ PL | 2018 .02

VL.JV.F3.02

Loading...

Loading...