Data sheet

Welded District Heating Stations

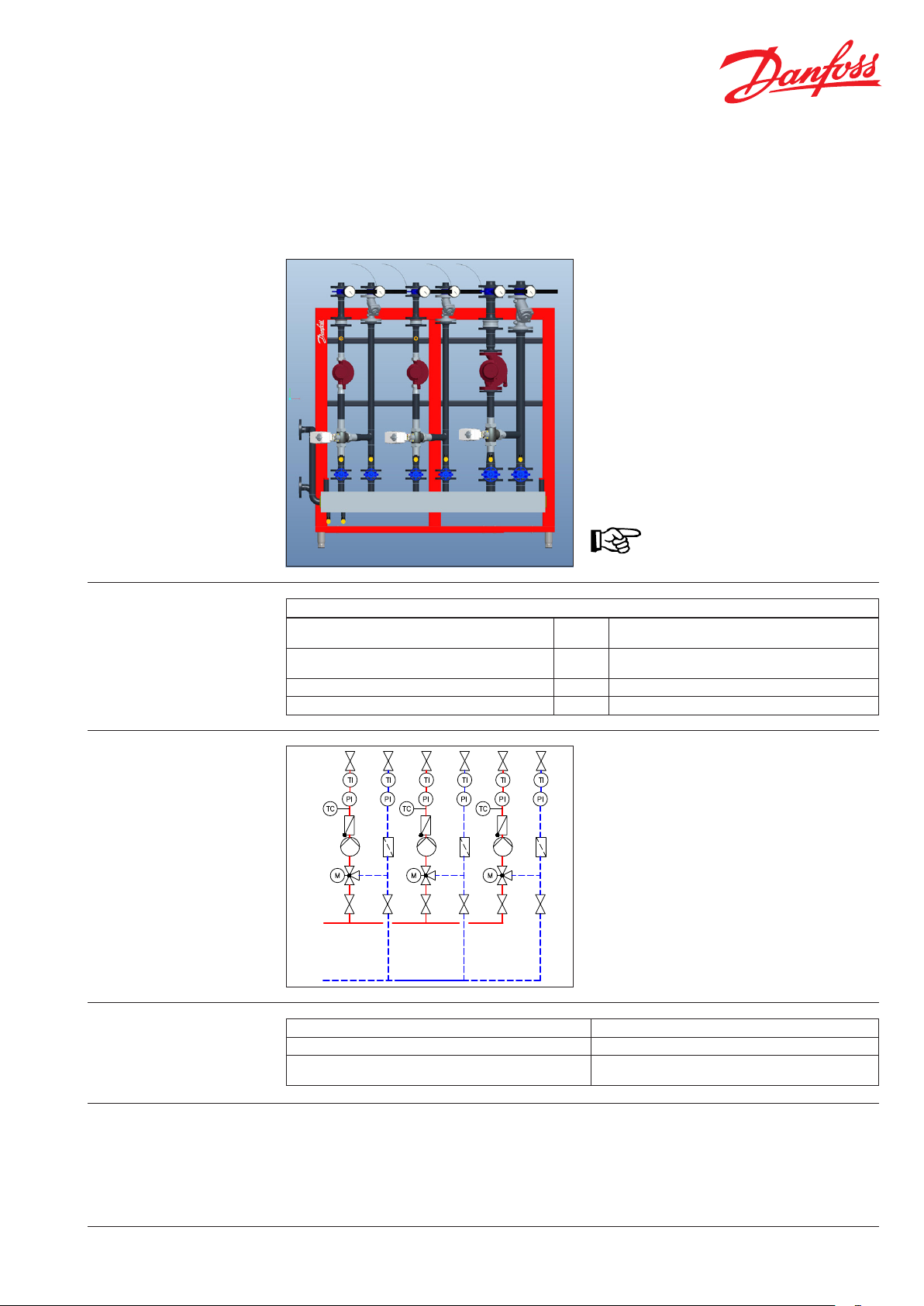

Type DSE-D00 (distributor module, three secondary circuits)

General description and

application:

Maximum operating

parameters

District heating transfer stations provide

the link between district heating suppliers

and customers’ systems.

They incorporate the necessary equipment

to tailor the supplied heat to the needs of the

object premises as specied in the heating

supply contract.

In this they need to comply with all applicable

standards and with the supplier’s technical

connection conditions.

Transfer modules for system separation are

described in a number of other data sheets

(see also types H0 and H0WP).

The system described here is a standard distributor

module for secondary readjusted heating circuits

Secondary

Maximum permissible supply temperature,

secondary

Maximum permissible operating pressure,

secondary

Rated pressure, secondary PN 10

Maximum permissible ow volume, secondar y VZS 25.0 m

TVS 110 °C

PZS 10 bar or depending on the safety valve

Data sheets type DSE-I1B

(primary DHW connection)

3

/h for w <= 1.2 m/s

.

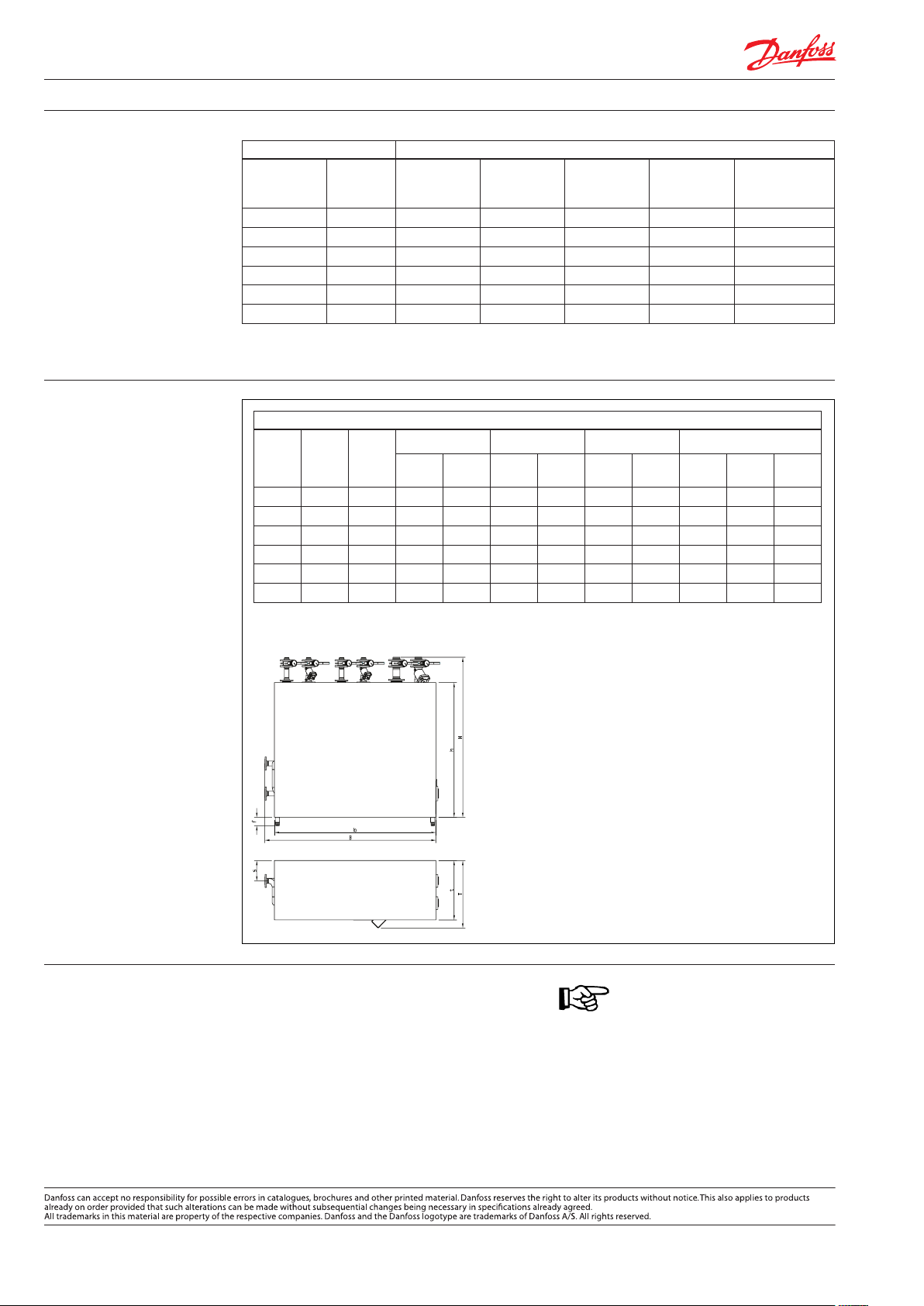

Circuit diagram: Legend

0121

0131

Materials:

Pipes and pipe ttings, anges P235GH-TC1, C22.8

0211

0411

0521

0531

0251 0252

0522

0421

0532

0450

0451

02310111

0122

0132

1211 1212

0212

0412

0422

0450

0451

02320112

0523

0533

0253

0123

0133

0213

0413

0423

0450

0451

02330113

1213

021x Shut-o device for secondary

121x Shut-o device for secondary distributor

023x Strainer

025x Non-return valve

052x/53x Supply temperature sensor

0450/451 Manometer with shut-o valve

041x/42x Thermometer with immersion sleeve

011x Circulation pump

012x/013x Mixing valve with motor

Heat exchanger 1.4404 with Cu brazing compound

Fittings CuSn5Pb5Zn5-C (RG-5), ST37.0,

EN-GJS-400-18-LT (GGG40.3)

Function:

The heated and preregulated secondary supply

water from the transfer module (e.g. H0 or H0WP)

is fed into the heating circuit distributor. The

various outputs to the attached heating circuits

For this purpose they incorporate electrical mixing

valves that ensure that the various heating circuits

receive optimal supply in accordance with the

appropriate temperature and/or timer programs.

serve to adjust the heat supplied to them

depending on their current requirements.

DEN-SMT/PL

VD.HE.G2.02 © Danfoss 06/2012

1

Data sheet Welded District Heating Stations Type DSE-D00 (distributor module, three secondary circuits)

Technical data:

Dimensions:

Distributor feed Secondary (largest possible heating circuit)

max. V

DN

p

[m3/h] DN max.

max. VS

[m3/h]

Pump

MAGNA

(*)

Mixing valve

Kvs [m3/h]

delivery head

40 6.0 40 6.0 32-120 16.0 50

50 9.0 50 9.0 40-120 25.0 45

50 10.0 65 10.0 50-120 40.0 60

65 15.0 65 15.0 50-120 40.0 50

80 20.0 80 20.0 65-120 63.0 45

80 25.0 80 25.0 65-120 63.0 25

(*) other pumps on request

012x/3x VRG/AMV435 or VF3/AMV55

Dimensions

DN

In

pr.

DHW

sec.

DN

(max.)

Width Depth Height Distance

b B t T * h H p w s

40 - 40 1600 1740 550 ~ 650 1500 1645 - - 205

50 - 50 1600 1740 550 ~ 650 1500 1680 - - 215

50 - 50 1600 1855 550 ~ 700 1500 1795 - - 230

65 - 65 1600 1875 750 750 1500 1780 - - 230

80 - 80 2060 2215 750 ~ 850 1700 2025 - - 255

80 - 80 2060 2255 750 ~ 850 1700 2025 - - 255

* Dependi ng on the number of plates in the h eat exchanger

f the foot can be ad justed between: 105 … 160 mm

Residual

[kPa]

Optionally on left or right

Regulator: Data sheets ECL 110/210/310System will generally incorporate one or more

electronic heating controllers, depending on the

requirements and/or application.

Fernwärme- und Regelungstechnik · Kolumbusstraβe 14 · D-22113 Hamburg

l.: +49 (0) 40/73 67 51-0 · Fax: +49 (0) 69/8902 466 400 · info-hh@danfoss.com · www.fernwaerme.danfoss.de

2

VD.HE.G2.02

Produce d by Danfoss A/S © 06/2 012

Loading...

Loading...