Page 1

Product Sheet

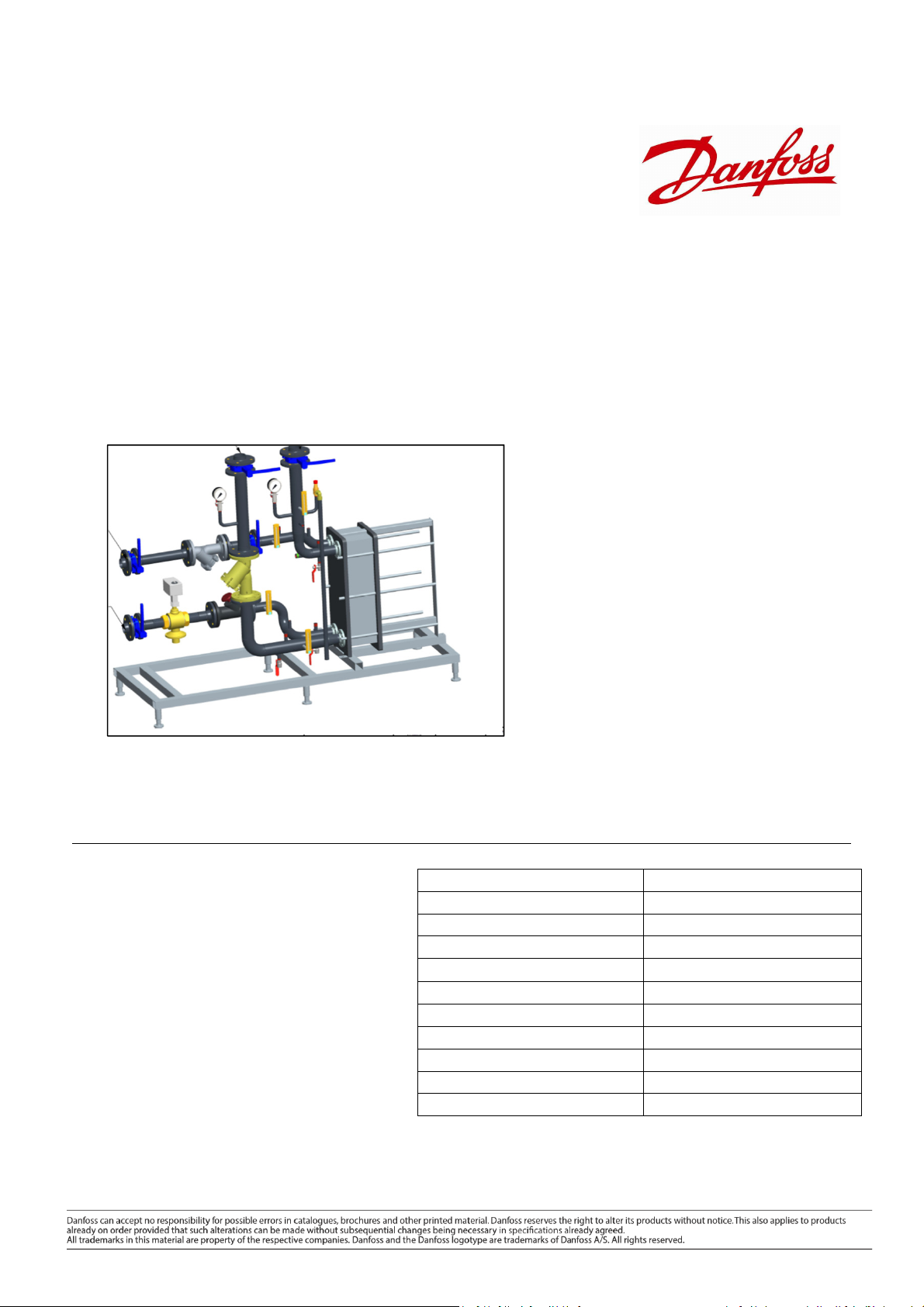

Flexible Heat Exchanger Stations

Type DSE

General description and

application

Typical Uses

• District heating building connections

• Commercial building hydronic separation

• Tall building pressure breakers

Heat exchanger stations are designed for hydronic separation of

LTHW and CHW systems. Suitable for district energy connections,

commercial buildings, and renewable applications, the stations

come complete with all relevant items to enable heat transfer,

balance, control, and service of the primary to secondary system

connection.

The stations can be installed individually, or in parallel as duty/duty

or duty /standby supplies. PN25 versions are available on request for

use as tall building or high pressure system breakers.

The stations include:

-A heat exchanger to transfer the energy between systems

-A controller which can provide individual heat exchanger control,

be linked to control multiple units, and be connected to a building

management system over-ride

-Pressure independent control valve for flow and motorised control

in a dynamic pressure system

-An MID approved ultrasonic energy meter for measurement,

monitoring, and billing accurate consumption data

-A commissioning valve for measurement of flow

-A secondary side safety valve

-Primary and secondary strainers

-Ball or butterfly isolation valves

The stations are factory tested to the pressure equipment directive

(PED)

General Operating Parameters

*other parameters are available on request

Please note, this is a generic specification and not necessarily related to your project. For exact specification, please refer to the bill of materials, and specification pages for your project.

Station Details

Station Details

Station DetailsStation Details

Pipework Sizes DN40-200

Maximum permissible supply temperature 95 ºC

PN Rating 16 Bar

Flow Rate Range 0.83 l/s to 40 l/s

Maximum Differential Pressure (Primary) 4 Bar

Safety Valve Rating (secondary) 6 Bar standard (higher upon request)

Pipes and pipe fittings, flanges P235GH-TC1, C22.8, CuS

Heat Exchanger 1.4404 with CU brazing compound

Insulation PU-Hardfoam, black, λ =0.027 W/mK

Page 2

Product Sheet Standard Heat Exchanger Stations Type DSE

LTHW ∆T

kW LTHW

Capacity

∆T

Function

The heat is drawn from the primary heat source, commonly a boiler, district heating supply, or CHP, through the

isolation valve, strainer, balancing valve, and heat exchanger, then back via the return pipe to the primary heat

source.

On the secondary side of the stations, the flow enters and passes through the isolation valve and strainer, to the

heat exchanger, where is gains energy to supply the building with heat or cooling water. A safety valve is located

on the secondary flow to ensure an excess of pressure is not experienced on the secondary system. This can be

provided with the required opening pressure.

A pressure independent control valve balances and limits flow through the pipework, to achieve the required

secondary outlet temperature. The flow control is independent of pressure fluctuations in the system and the

motorised valve element has full authority control at all load conditions.

The energy meter is positioned on the return, with two sensors, one on the flow, one on the return. The energy

meter measures the volumetric flow rate, and the difference in temperature between flow and return, to calculate

the energy used by the connection. The meter is supplied with an m-bus output to feed the energy usage to the

building management system or meter reading system

The controller senses the secondary return temperature, and modulates the control valve to achieve the desired

secondary flow temperature. An outdoor sensor can be added to provide weather compensation. A number of

applications can be provided by one controller, with an application key supplied with the station to control the

station as per the application.

The station is provided with fully isolation provided by ball or fully lugged butterfly valves, temperature and

pressure gauges, test points, and drain points.

Station Flow Rate and Capacities

Capacity

Pipework Size Code Connection

DN40 DSE1 MAXI IG 40-040 1.1/2" BSP threaded 2.05 0.82 172 258 52 85 kPa 41 kPa

DN50 DSE1 MAXI IG 50-050 2" BSP threaded 3.50 1.4 294 441 88 91 kPa 45 kPa

DN65 DSE1 LARGE IT 65-65 2.1/2" PN16 Flanged 5.50 2.2 462 692 138 92 kPa 41 kPa

DN80 DSE1 LARGE IT 80-80 3" PN16 Flanged 7.50 3 629 944 189 82 kPa 39 kPa

DN100 DSE1 LARGE IT 100-100 4" PN16 Flanged 10.00 4 839 1259 252 81 kPa 39 kPa

DN125-1 DSE1 LARGE IT 125-125-15ls 5" PN16 Flanged 15.00 6 1259 1888 378 82 kPa 38 kPa

DN125-2 DSE1 LARGE IT 125-125-20ls 5" PN16 Flanged 20.75 8.3 1741 2612 522 84 kPa 41 kPa

DN125-3 DSE1 LARGE IT 125-125-25ls 5" PN16 Flanged 25.00 10 2098 3147 629 89 kPa 43 kPa

DN150 DSE1 LARGE IT 150-150 6" PN16 Flanged 30.00 12 2517 3776 755 84 kPa 40 kPa

DN200 DSE1 LARGE IT 200-200 8" PN16 Flanged 40.00 16 3357 5035 1007 80 kPa 39 kPa

Notes *1-These figures are primary duty at the max design flow rate and the ∆T described

Notes *2-These figures are at maximum capacity, with a heat exchanger selected to lose 30 kPa. If you require a lower pressure loss please discuss this

with your Danfoss representative

Max Design

Flow Rate (l/s)

Min

Design

Flow Rate

(l/s)

kW

20

(*1)

Capacity

∆T 30

(*1)

kW

CHW

(*1)

6

Max Primary

Station ∆P

(*2)

Secondary

Station ∆P

Max

(*2)

Please note, this is a generic specification and not necessarily related to your project. For exact specification, please refer to the bill of materials, and specification pages for your project.

Page 3

Product Sheet Standard Heat Exchanger Stations Type DSE

16 Bar

16 Bar

16 Bar

16 Bar

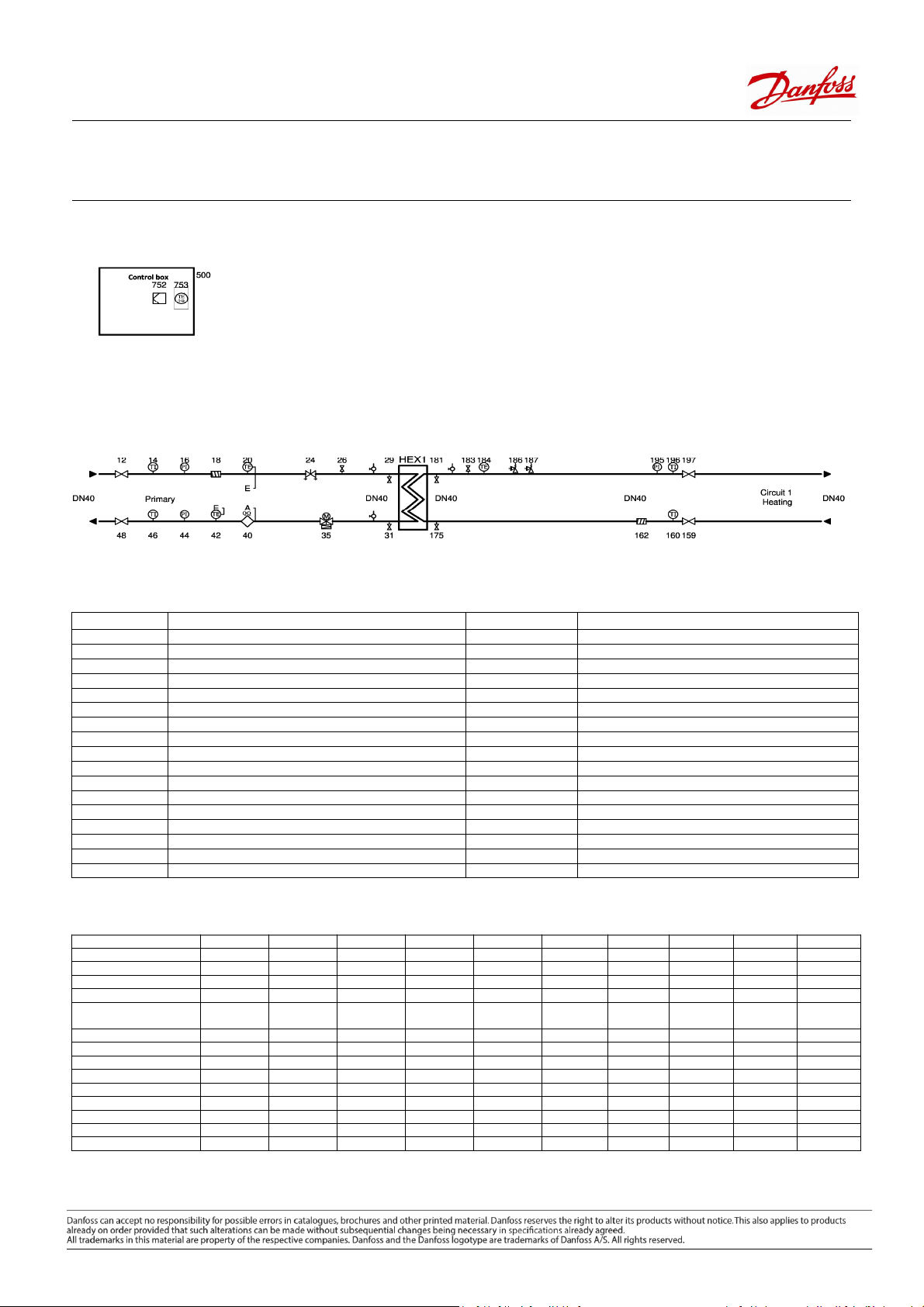

Unit Schematic

Key Components

Position Type Position Type

500 Control box 159 Isolation Valve

1 Heat exchanger 160 Pocket for thermometer sensor

12 Isolation Valve 160 Temperature Gauge

14 Temperature Gauge 175 Secondary Flow Drain Point

16 Pressure Gauge 181 Secondary Return Drain Point

18 Strainer 183 Air vent

20 Sensor for energy meter 184 Immersion Sensor

24 Hydronic Balancing valve 186 Safety valve

26 Air vent 187 Safety valve

29 Primary Flow Drain Point 195 Pressure Gauge

31 Primary Return Drain Point 196 Temperature Gauge

35 Pressure Independent Control Valve 197 Isolation Valve

40 Ultrasonic Energy meter 752 ECL controller

42 Sensor for energy meter

44 Pressure Gauge

46 Temperature Gauge

48 Isolation Valve

Component Types

Component type DN40 DN50 DN65 DN80 DN100 DN125-1 DN125-2 DN125-3 DN150 DN200

Max Flow Rate l/s 2.05 3.5 5.5 7.5 10 15 20.75 25 30 40

Heat Exchanger (See note 1) XG XG XG XG XG XG XG XG XG XG

Controller ECL 210 ECL 210 ECL 210 ECL 210 ECL 210 ECL 210 ECL 210 ECL 210 ECL 210 ECL 210

Energy Meter Sonometer 30 Sonometer 30 Sonometer 31 Sonometer 31 Sonometer 31 Sonometer 31 602 Ultraflow 602 Ultraflow 602 Ultraflow 602 Ultraflow

Pressure Independent

Control Valve

Strainers FVF FVF FVF FVF FVF FVF FVF FVF FVF FVF

Balancing Valve MSV-BD MSV-BD MSV-F2 MSV-F2 MSV-F2 MSV-F2 MSV-F2 MSV-F2 MSV-F2 MSV-F2

Temperature Sensor ESMU 100 ESMU 100 ESMU 100 ESMU 100 ESMU 100 ESMU 100 ESMU 100 ESMU 100 ESMU 100 ESMU 100

Safety Valve SYR 1915 SYR 1915 SYR 2115 SYR 2115 SYR 2115 SYR 2115 SYR 2115 SYR 2115 SYR 2115 SYR 2115

Isolation Valves IVR 954 IVR 954 VFY-LH VFY-LH VFY-LH VFY-LH VFY-LH VFY-LH VFY-LG VFY-LG

Temperature Gauges TDL 150 TDL 150 TDL 150 TDL 150 TDL 150 TDL 150 TDL 150 TDL 150 TDL 150 TDL 150

Pressure Gauges M80 0-16 Bar M80 0-16 Bar M80 0-16 Bar M80 0-16 Bar M80 0-16 Bar M80 0-16 Bar M80 0-

Air Vent Manual Manual Manual Manual Manual Manual Manual Manual Manual Manual

Drain Points IVR 954 IVR 954 IVR 954 IVR 954 IVR 954 IVR 954 IVR 954 IVR 954 IVR 954 IVR 954

Note 1-The heat exchanger selections will vary depending on duty requirement and temperature requirements

ABQM ABQM ABQM ABQM ABQM ABQM ABQM ABQM ABQM ABQM

M80 0-

M80 0-

M80 0-

Please note, this is a generic specification and not necessarily related to your project. For exact specification, please refer to the bill of materials, and specification pages for your project.

Page 4

Product Sheet Standard Heat Exchanger Stations Type DSE

Unit Components

The heat exchanger stations come skid mounted, pressure tested to PED standards, pre-wired, and ready to install. This datasheet is for standard

units which can be amended as per your requirements.

Heat Exchanger Data

Danfoss heat exchangers are specially selected to match your design application. Where

possible, Danfoss offer Micro Plate Heat Exchangers which are a revolutionary

technology, characterized by their unique plate pattern. MPHE’s enable heat to be

transferred more efficiently than any previous model of heat exchanger. The exchangers

come with specially manufactured insulation to reduce energy loss.

Technical Data:

Max working pressure: 16 Bar

Pressure Test Standard: (PED) 97/23/EC

Min Working Temperature: -10 ºC

Max Working Temperature: 150 ºC

Materials:

Plate: Stainless steel EN1.4404 (AISI316L) & EN 1.4301 (AISI 304)

Gasket Type: Glue free

Gasket Material: EPDM

Controller

Danfoss stations can be supplied complete with an in-built controller, within a specially

manufactured control panel. The panel features an ECL 210 controller and a pump

output, 3ph, for up to 2x pumps with motors 400 W-4 kW.

The ECL 210 controller, senses the temperature using the ESMU 100 temperature sensor,

and modulates the pressure independent control valve, to achieve the desired secondary

flow temperature.

The unit is supplied, pre-wired to the sensor and actuator. An ESMT outdoor sensor is

included to enable weather compensation.

The controller application is determined using an application key and will be supplied

with a key, suitable for the project application. Master/slave configurations are available.

Ultrasonic Energy Meter

An MID, ultrasonic energy meter can be provided with the station. This provides billing

accurate measurement of the energy the station uses. Accurate to +- 1%, the Sonometer

30 and 31, provide a high dynamic range of 1:100 (qi:qp) and can be used with glycol

mixtures. The meters are suitable for LTHW and CHW.

The meters come with m-bus protocol communication outputs to enable them to be

linked to an automatic meter reading or building management system

DN125+ stations come with 602 ultraflow meters.

Please note, this is a generic specification and not necessarily related to your project. For exact specification, please refer to the bill of materials, and specification pages for your project.

Page 5

Product Sheet Standard Heat Exchanger Stations Type DSE

Pressure Independent Control Valve

Danfoss AB-QM pressure independent control valves, are a world leading technology in

the world of balancing and motorised control valves. Recognised as being the ideal

solution for balance and control in variable flow systems, they feature a pressure

controller, built into a high authority control valve, to combine balancing and control into

a single valve.

Commissioning the valve is simple, with setting ring located at the valve neck, the desired

flow rate is calculated as a percentage of the valve flow capacity. This percentage is set,

and the valve commissioned in seconds

The valve is supplied with a pre-wired AMV 435 actuator, which is linked back to the

controller.

Strainer

Danfoss FVF strainers are designed for heating, district heating and cooling systems.

The strainer removes and retains foreign particles like welding beads, swarf, sand, and

any other items carried by the medium.

The strainer protects the sensitive items in the station such as the control valve, energy

meter and heat exchangers.

A ball valve can be attached to the strainer, to enable quick and simple removal of

particles from the system.

Balancing Valve

The stations can feature a manual balancing valve, for flow measurement and gives the

potential for a double regulating function.

DN40 and 50 stations feature an MSV-BD, variable orifice double regulating valve, with

360º rotating test points and an additional drain point

DN65+stations have MSV-F2 type balancing valves, with position indicator, locking

function and an integrated stroke limiter

Safety Valves

Two safety valves can be provided on the secondary flow, to ensure over-pressure on the

secondary circuit does not damage key components. The setting of the valves should be

specified at the time of order.

Isolation Valves

DN40 and DN50 stations are provided with BSP internal threaded isolation valves, type

IVR 954.

DN65-125 stations are provided with Danfoss VFY-LH manual butterfly valves. These are

fully lugged and provided with polyamid coated discs and stainless shafts

DN150-200 stations are provided with Danfoss VFY-LG gear operated, fully lugged

butterfly valves

Please note, this is a generic specification and not necessarily related to your project. For exact specification, please refer to the bill of materials, and specification pages for your project.

Page 6

Product Sheet Standard Heat Exchanger Stations Type DSE

Example Applications

Single DN65 District Heating Connection

2x DN50 Stations connected in a Duty/Standby arrangement

Page 7

Datasheet Standard Heat Exchanger Stations Type DSE

Additional Key Technical Information

Component Type DN40 DN50 D N65 DN80 D N100 DN125-1 DN125-2 DN125-3 DN150 DN200

Isolating Valve kVs

Isolating Valve Operation Hand Operated Hand Operated Hand Operated Hand Operated Hand Operated Hand Operated Hand Operated Hand Operated Gear Operated Gear Operated

Controller Supply Voltage 230V 230V 230V 230V 230V 230V 230V 230V 230V 230V

Pump Output 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW 3ph 0.4-4.0kW

Temperature Gauge Range 0-120 °C 0-120 °C 0-120 °C 0-120 °C 0-120 °C 0-120 °C 0-120 °C 0-120 °C 0-120 °C 0-120 °C

Pressure Gauge Range 0-16 Bar 0-16 Bar 0-16 Bar 0-16 Bar 0-16 Bar 0-16 Bar 0-16 Bar 0-16 Bar 0-16 Bar 0-16 Bar

Balancing Valve kVs 26 40 93.4 122.3 200 304.4 304.4 304.4 400.8 685.6

Drain Point Size mm 15 15 15 15 20 25 25 25 25 25

Drain Point Flow Rate l/s @1.2

Bar ∆P

Energy Meter Nominal Flow

m3/h

Energy Meter Min Flow m3/h 0.1 0.15 0.25 0.4 0.6 0.6 1 1 1.5 1.5

Pressure Independent Control

Valve Nominal Flow m3/h

Pressure Independent Control

Valve Min Flow rate Setting

m3/h

Actuator Control Signal 3-point 3-point 3-point 3-point 3-point 3-point 3-point 3-point 3-point 3-point

Safety Valve Size 3/4" 1" 1.1/4" 1.1/4" 1.1/4" 1.1/4" 1.1/4" 1.1/4" 1.1/4" 1.1/4"

Safety Valve Max Setting 5 Bar 5 Bar 10 Bar 10 Bar 10 Bar 10 Bar 10 Bar 10 Bar 10 Bar 10 Bar

Safety Valve Capacity (each)

m3/h @ max setting

Strainer kVs 33 54 95 140 201 340 340 340 526 870

Strainer mesh size mm 0.87 0.87 0.87 1.18 1.18 1.18 1.18 1.18 1.18 1.18

6 6 6 6 13.7 18.2 18.2 18.2 18.2 18.2

10 15 25 40 60 60 100 100 150 150

7.5 12.5 20 28 38 90 90 90 145 145

3 5 8 11.2 15.2 36 36 36 58 58

3 3 15 15 15 15 15 15 15 15

Station Commissioning

The stations are supplied with minimal commissioning requirement. It is not a requirement for a Danfoss representative to commission the station. A

representative will be able to advise on the commissioning process, and it is expected that the installer will commission the station.

Full commissioning instructions are available.

Maintenance

It is necessary to check and maintain the substation on a regular basis in order to keep it in good operating condition.

A general maintenance inspection of equipment should take place at least twice per year, with a full service inspection at least once per year.

Please note, this is a generic specification and not necessarily related to your project. For exact specification, please refer to the bill of materials, and specification pages for your project.

Loading...

Loading...