Data Sheet

DSA WALL – Wall Mounted Station

General description and

application

Maximum operating

parameters

Danfoss district heating substations provide the

link between district heating suppliers and customer installations. They contain all the necessary

equipment to adjust the heat supplied for the

needs of the object premises as specied in the

heating supply contract. In this respect they must

comply with all applicable standards and with the

supplier’s technical connec tion conditions. Indirect

connections (in which district heating and in -house

systems are hydraulically isolated) incorporate

components that separate the systems (heat

exchanger), limit the ow volume to that specied

in the contract, regulate the secondary supply temperature and measure energy consumption.

The DSA WALL is designed for use in high-parameter district heating network s. It is suitable for heating single and multifamily homes, and commercial

and industrial buildings. It oers an alternative

solution to oil or gas boilers. The DSA WALL is prepared for heating, domestic hot water and oor

heating applications. Its wall-mounted construction allows for the space saving needed for installation and servicing.

Primary

Maximum permissible supply temperature, primary 130 °C

Maximum permissible operating pressure, primary 14,4 ba r(g)

Rated pressure, primary PN16

Secondary Heating

Maximum permissible temperature, secondary 100 °C

Maximum permissible operating pressure, secondary 6 bar(g)

Minimum required pressure (static), water supply 1.0 bar(g)

Secondary Domestic Hot Water

Maximum permissible temperature, secondary 90°C

Maximum permissible operating pressure, secondary 10 bar(g)

Minimum required pressure (static), water supply 1.0 bar(g)

Materials

DEN -SMT/ PL

Pipes, ttings, anges, valves (primary side) P235GH, EN-JL 1040 (GG25), CuSn5Pb5Zn5-C (RG-5)

Pipes, ttings, anges, valves (heating side) P235GH, EN-JL 1040 (GG25), CuSn5Pb5Zn5-C (RG-5)

Pipes, ttings, anges, valves (DHW side) 1.4301, 1.4404, brass (DZR type), bronze

Heat exchanger 1.4404 with Cu solder

Insulation EPP foam λ=0.037 W/mK (heat exchanger)

PU foam λ=0.029 W/mK (primary piping)

VD.IQ.P1.02 © Danfoss 11/2014

1

Data Sheet DSA WALL – Wall Mounted Station

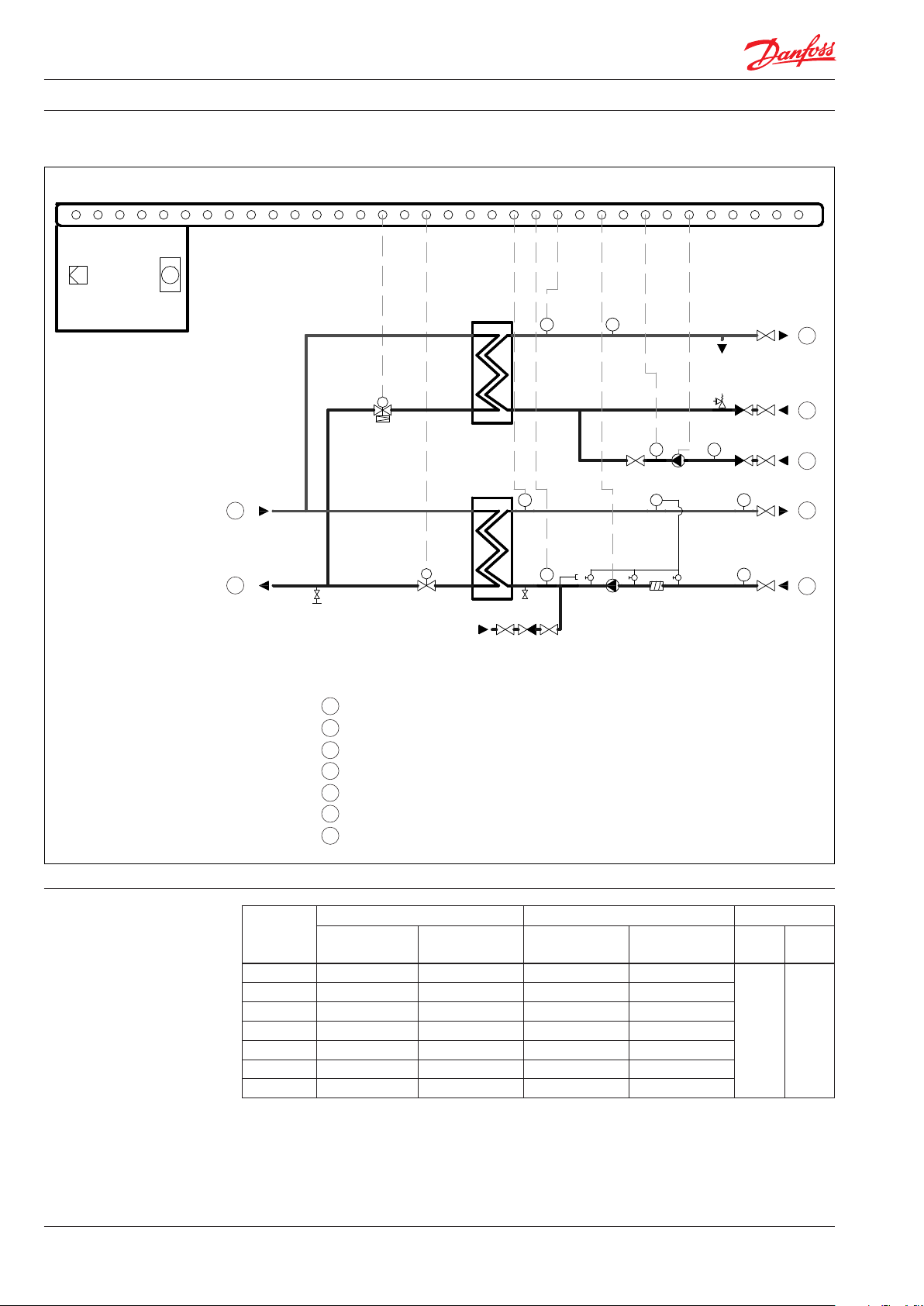

Circuit diagram

Electric box

TE

2B

750

M1 Combi valve

M2 Control valve

49 Drain valve

S4 Temperature sensor

380 Thermometer

387 Shut o valve

345 Supply valve

762 Pump valve

769 Thermometer

P1 Circulation pump

S6 Temperature sensor

767 Shut o valve

S3 Temperature sensor

187 Multipoint pressure measurment

191,165 Thermometer

192,164 Shut o valve

169 Strain er

P2 Heating pump

S2 Temperature sensor

175 D r ain

721 Relling valve

S1

DN20

M

M1

8

DN32 DN32

DN25

M

9

49 M2

8 Primary Supply

9 Primary Return

4 Heating Supply

5 Heating Return

2 Domestic Hot Water

1 Domestic Cold Water

3 Circulation

DHW

HE

TE

S3

175

A 721

TE

S4 380 A

TE

S2

TI

TE

S6

767

PI

187

169

P2

2

387

DN25

1

345

TI

769P1

DN20

762

TI

191 192

TI

3

4

5

165

164

Technical data

2

Typ e

HE/DHW

90 / 80

120 / 80

150 / 80

90 / 120

120 / 120

150 / 120

145 / 120

1) Reference temperatures: HE – 100/63/60/80 °C, DHW – 65/22/10/55 °C. Pressure drop: HE – 20/20 kPa, DHW – 20/20 kPa

2) Reference temperatures: HE – 100/63/60/80 °C, DHW – 65/22/10/55 °C. Pressure drop: HE – 30/15 kPa, DHW – 20/20 kPa

VD.IQ.P1.02 © Danfoss 11/2014

VM2+AMV10

1

1

1

1

1

1

2

Control valve Heat exchanger Pump

HE

DHW

AVQM+AMV30

HE DHW HE DHW

DN15/1.6 DN15/4.0/0.2 XB 37L-1-26 XB37H -1-26

DN15/ 2.5 DN15/4.0/0.2 XB 37L-1- 40 XB37H -1-26

DN15/ 2.5 DN15/4.0/0.2 XB 37L-1- 60 XB37H -1-26

DN15/1.6 DN20/6.3/0.2 XB37 L-1-2 6 XB37H-1-36

DN15/ 2.5 DN20/6.3/0.2 X B 37L-1- 40 XB37H-1-36

DN15/ 2.5 DN20/6.3/0.2 X B 37L-1- 60 XB37H-1-36

DN15/ 2.5 DN20/6.3/0.2 X B37L-1-80 XB37H-1-36

Magna 3 25-100

UPS 25-60 N

DEN -SMT/ PL

Data Sheet DSA WALL – Wall Mounted Station

Function The DSA WALL platform can be used for various

applications such as heating, domestic hot water

and / or oor heating. Due to its modular construction and exibility, it is possible to deliver

a1-, 2- or 3-circuit station based on customer

request and the needed application(s). The wallmounted construction allows easy access to all

components for maintenance and servicing purposes. Standard assembly support signicantly

reduces the time needed to place the substation

on the wall. An additional frame (accessory list)

allows for placing the substation in the centre of

the substation room.

Dimensions

Typ e

HE / DHW

DH (8 & 9) HE (4 & 5) DHW Height Width Depth

Pipe diameter

90 / 80 kW DN25 DN32 DN25 69

120 / 80 kW DN32 DN32 DN25 73

150 / 80 kW DN32 DN32 DN25 77

90 / 120 kW DN25 DN32 DN25 81

120 / 120 kW DN32 DN32 DN25 85

150 / 120 kW DN32 DN32 DN25 89

145 / 120 kW DN32 DN32 DN25 91

Heat transfer bet ween the district heating network

and the building installation is achieved by way of

a micro plate heat exchanger, which ensures better

heat transfer, higher energy eciency and reduced

pressure loss. In addition to the standard controller

functions, the ECL310 oers easy remote access via

an internet page with data logging possibilities

and energy optimisation functions such as weather

compensation and auto-tuning (adaptive settings

for domestic hot water parameters).

The primary modules allow for the upgrading of

the compact module with an additional dierential

pressure controller, measuring devices, strainers

or a heat meter to full all of the supplier’s technical connection requirements.

Weight

External dimension

[kg]

118 5 mm 800 mm 575 mm

420

446

118 5

120

208

280

575

1 2 4

8

9

3

0 40

0

246 674

800

5

8

479

820

251

9

800

120

8 Primary Supply

9 Primary Return

4 Heating Supply

5 Heating Return

2 Domestic Hot Water

1 Domestic Cold Water

3 Circulation

DEN -SMT/ PL

VD.IQ.P1.02 © Danfoss 11/2014

3

Data Sheet DSA WALL – Wall Mounted Station

Accessories Primary module may include:

- Shut-o valves

- Dierential pressure regulator

- Strainer

- Energy meter

- Temperature measurement

- Pressure measurement

Frame for stand-alone assembly, allowing for

placement of the DSA WALL in the centre of the

technical room.

Conguration The DSA WALL’s exibility of construction makes

it possible to order a substation with additional

components and dierent capacities depending

on requested features and requirements, such as:

Primary side

- Shut-o valves

- Temperature sensors

- Drain valves

Heating

- Additional temperature sensors

- Thermostat

- Pressure measurement

- Temperature maesurement

- Drain valve

Domestic hot water

- Additional temperature sensors

- Thermostat

- Pressure measurement

- Temperature measurement

- Drain valve

- Water meter

Contact the sales sta responsible for additional

details and a quotation for the DSA WALL.

4

VD.IQ.P1.02

Produce d by Danfoss A/S © 11/2014

Loading...

Loading...