Data sheet

DSA HOME

Wall Mounted Station

General description and

application

Maximum operating

parameters

Danfoss district heating substations provide the

link between district heating suppliers and customer installations. They contain all the necessary

equipment to adjust the heat supplied for the

needs of the object premises as specied in the

heating supply contract. In this respect they must

comply with all applicable standards and with

the supplier’s technical connection conditions.

Indirect connections (in which district heating

and in-house systems are hydraulically isolated)

incorporate components that separate the systems (heat exchanger), limit the ow volume to

that specied in the contract, regulate the secondary supply temperature and measure energy

consumption.

The DSA HOME is designed for use in high-parameter district heating networks. It is suitable for

heating single family houses. It is an alternative

solution to oil or gas boilers. The DSA HOME is

prepared for heating or heating and domestic

hot water applications. Its wall-mounted construction saves space needed for installation and

servicing.

Primary

Maximum permissible supply temperature, primary 130 °C

Maximum permissible operating pressure, primary 14,4 bar(g)

Rated pressure, primary PN16

Secondary Heating

Maximum permissible temperature, secondary 100°C

Maximum permissible operating pressure, secondary 6 bar(g)

Minimum required pressure (static), water supply 1.0 bar(g)

Secondary Domestic Hot Water

Maximum permissible temperature, secondary 90°C

Maximum permissible operating pressure, secondary 10 bar(g)

Minimum required pressure (static), water supply 1.0 bar(g)

Materials

© Danfoss | YYYY.MM

Pipes, ttings, anges, valves (primary side) P235GH, EN-JL 1040 (GG25), CuSn5Pb5Zn5-C (RG-5)

Pipes, ttings, anges, valves (heating side) P235GH, EN-JL 1040 (GG25), CuSn5Pb5Zn5-C (RG-5)

Pipes, ttings, anges, valves (DHW side) 1.4301, 1.4404, brass (DZR type), bronze

Heat exchanger 1.4404 with Cu solder

Insulation PU foam λ=0.035 W/mK (heat exchanger)

PU foam λ=0.0281 W/mK (primary piping)

AI00000000en-US0102 | 1

Data sheet DSA HOME - Wall Mounted Station

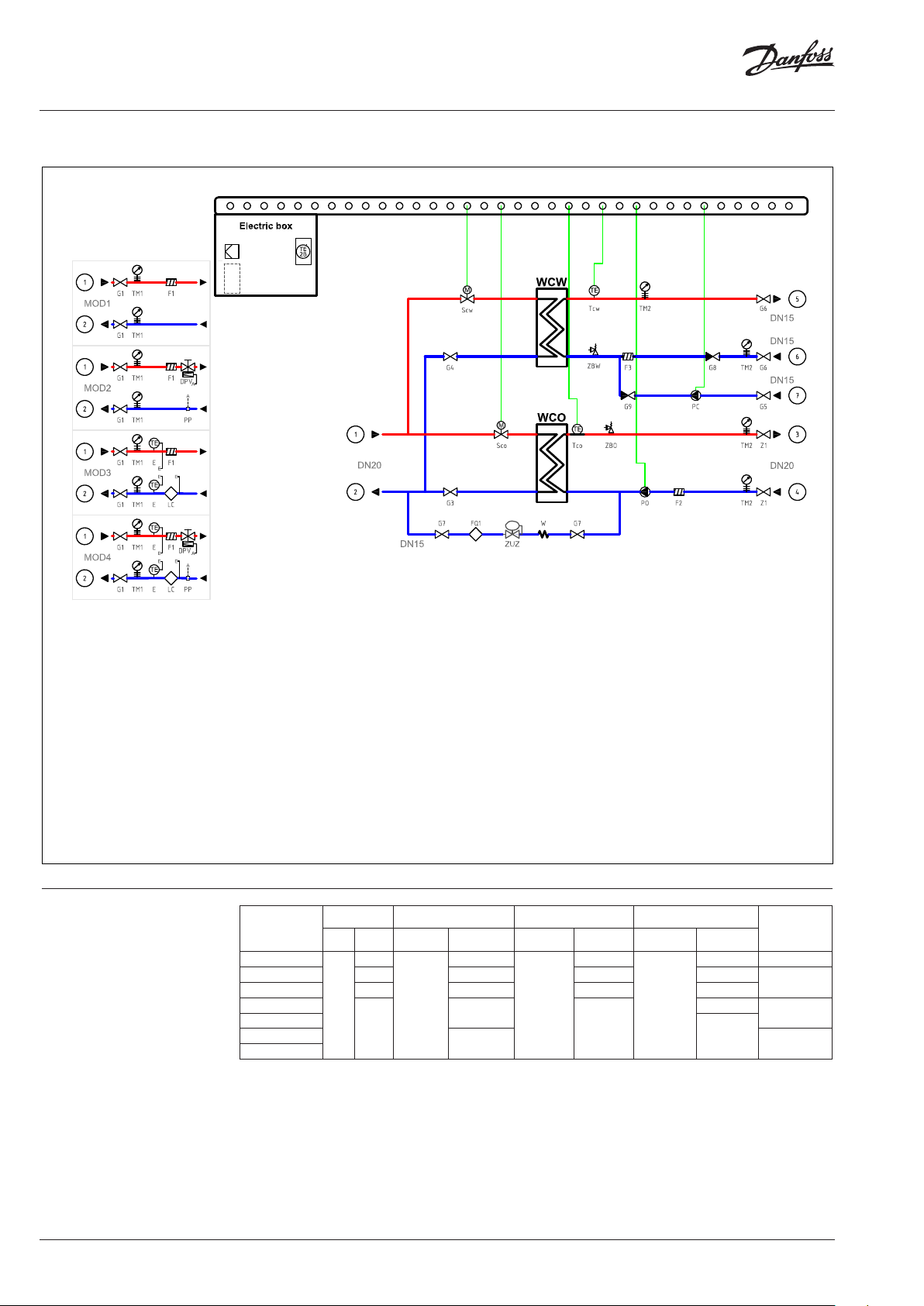

Circuit diagram

Technical data

G3, G4 Shut-o valve

Scw Control valve DHW

Sco Control valve HE

Z1 Shut-o valve

TM2 Thermomanometer

F2 Strainer

PO Heating pump

Tco Temp. sensor HE

ZBO Safety valve HE

Tcw Temp. sensor DHW

G6 Shut-o valve

G9 Check valve

ZBW Safety valve DHW

Typ e

DSA HOME 1F-1

DSA HOME 1F-2

DSA HOME 1F-3

DSA HOME 2F-1

DSA HOME 2F-2

DSA HOME 2F-3

DSA HOME 2F-4

* Maximum capacity is determined by temperature, allowable pressure drops and local regulations.

Capacity [kW]* Control valve Heat exchanger

HE

DHW HE DHW HE DHW HE DHW

–

– – – –

– – – –

40

VS 2

DN15 / 1,0

AVTQ 15 / 1,6

DN15/2,5

25

F3 Strainer

G5 Shut-o valve

G8 Check valve

PC Circulation pump

G7 Shut-o valve

FQ1 Watermeter

ZUZ Relling valve

W Elastic Hose

G1 Shut-o valve

TM1 Thermomanometer

F1 Strainer

DPV dP controller

LC Heatmeter

–

XB06L-1-16

VM 2

XB06H-1-20

–

Pump

UPM3AUTO

15-70

–

–

UPM3

DHW 15-20

Controller

ECL110

ECL310

ECL110

ECL310

2 | © Danfoss | 2017.10

VD.MG.L1.02

Data sheet DSA HOME - Wall Mounted Station

Function The DSA HOME platform can be used for various

applications such as heating or heating with

domestic hot water based on customer request

and the needed application(s). The wall-mounted

construction allows easy access to all components

for maintenance and servicing purposes. Standard

assembly accessories signicantly reduce the time

needed to place the substation on the wall.

Heat transfer between the district heating network and the building installation is achieved by

way of a micro plate heat exchanger, which

ensures better heat transfer, higher energy eciency and reduced pressure loss. In addition to

Dimensions

Typ e

DSA HOME 1F-1

DSA HOME 1F-2

DSA HOME 1F-3

DSA HOME 2F-1

DSA HOME 2F-2

DSA HOME 2F-3

Primary

DN20 DN20

Connection size

HE DHW CIR Height Width Depth

– –

– –

– –

DN15

DN15

DSA HOME 2F-4

the standard controller functions, the ECL310

oers easy remote access via an internet page

with data logging possibilities and energy optimisation functions such as weather compensation

and auto-tuning (adaptive settings for domestic

hot water parameters). For customer which are

not required advanced functionality of ECL310,

there are available DSA HOME with ECL110 which

oers basic functionality of substation.

The primary modules allow for the upgrading of

the compact module with an additional dierential pressure controller, measuring devices, strainers or a heat meter to full all of the supplier’s

technical connection requirements.

Mass

External dimensions

[kg]

24

–

810 mm

500 mm

350 mm

35 800 mm

8

max. 810

9

1

2 4 5

3

8

9

max. 350max. 800

8 Primary Supply

9 Primary Return

4 Heating Supply

5 Heating Return

2 Domestic Hot Water

1 Domestic Cold Water

3 Circulation

VD.MG.L1.02

© Danfoss | 2017.10 | 3

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet DSA HOME - Wall Mounted Station

Accessories Primary module, may include:

- Shut-o valves

- Dierential pressure regulator

- Strainer

- Energy meter

- Temperature measurement

- Pressure measurement

Sheet metal cabinet

Drain valve

Conguration The DSA HOME is a standard product, which

allows only for small modications, such as:

- changing type and kvs for primar y control valve

- changing actuator types

- changing opening pressure of safety valve

- increase volume of expansion tank

Contact the sales sta responsible for additional

details and a quotation for the DSA HOME.

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

4 | © Danfoss | DHS-SMT/PL | 2017.10

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VD.MG.L1.02

Loading...

Loading...