Danfoss DrivePro Spare Parts Fact sheet

TÜV Rheinland Energie und Umwelt GmbH

TÜV Rheinland

Energie und Umwelt GmbH

Am Grauen Stein

D-51105 Köln

Managing Director:

Amtsgericht Köln HRB 56171

Telefon:

Telefax:

+49 2 21 / 8 06 - 5200

+49 2 21 / 8 06 - 1349

Marcus Staude

S 221 2014 S4.docx

Report no. S 221 2014 S4

Testing of oil pressure atomizing nozzles

in accordance with DIN EN 293

Danfoss A/S

Test Centre for Energy Appliances

This report may only be published and forwarded to third parties in its complete, unabridged form. The publication or

dissemination of extracts, summaries, appraisals or any other adaptation and alterations, in particular for advertising

The test results presented in this report refer solely to the test object stated as described on page 2. The report does not

represent a general statement about the serial production of the test object and gives not an authorization for use of a

purposes, is only permissible with the prior written permission of TÜV Rheinland.

TÜV Rheinland test- / certification mark.

Publication of page 2 is permitted.

TÜV Rheinland Energie und Umwelt GmbH

Order No. 21225968

page 2 / 22

Report No. S 221 2014 S4

Manufacturer / Contractor:

Danfoss A/S

Nordborgvej 81

6430 Nordborg - Denmark

Product:

Oil pressure atomizing nozzles

Type designation:

0,40 / 0,50 / 0,60 USgal/h

Test subject:

Functional requirements of EN 293

Technical data:

Nominal throughput

Index angle

0,40 / 0,50 / 0,60 USgal/h

45° / 60° / 80°

Solid / hollow cone

Test requirements:

EN 293:1992, subclause 6.4 and 6.6

Test cause:

Comparison test of various types of nozzles

Dated in Cologne,

9th December 2014

432/rw

Test Centre for Energy Appliances

DIN- and DVGW-test laboratory

Review

Head of test centre

Dirk Wilczek

Dipl.-Ing. W. Rückwart

Test Centre for Energy Appliances

Functional test

Oil pressure atomizing nozzles, EN 293:1992

TÜV Rheinland Energie und Umwelt GmbH

Order No. 21225968

page 3 / 22

Report No. S 221 2014 S4

Test Centre for Energy Appliances

Content

1. Task, Cause of Test 4

2. Description of Test subject 5

3. Approval Test 5

3.1 Procurement of nozzles 5

3.2 Inspection of test laboratory 5

3.3 Practical test 6

3.3.1 Throughput test 6

3.3.2 Spray distribution test 13

4 Summary 21

TÜV Rheinland Energie und Umwelt GmbH

Order No. 21225968

page 4 / 22

Report No. S 221 2014 S4

Test Centre for Energy Appliances

1. Task, Cause of Test

TÜV Rheinland, as an independent and impartial test institution, has been commissioned by

the company Danfoss to examine 45 oil pressure atomizing nozzles in respect to precision

and quality as these are important aspects to ensure well running burners with low oil usage

and pollution. Representative samples from various manufacturers shall be tested in

accordance with the standard DIN EN 293 for nominal throughput and spray distribution.

The manufacturers Fluidics, OEG, Steinen, Danfoss, Monarch and Delavan have been

selected with the aim of including such makes of nozzle in the analysis which are

commercially available. The nozzle types and brands selected for the tests are perceived to

be some of the most common / relevant in the residential burner markets.

The lower performance range of the nozzles of 0.4 US Gal/h to 0.6 US Gal/h was selected as

it makes the highest demands on the production accuracy.

ln advance to the tests a test program was developed which represents the basis for

execution thereof. The laboratory of the company Danfoss in Nordborg was used for the

practical execution of the nozzle tests.

The test program comprises the following activities:

• Neutral procurement of a total of 270 nozzles by TÜV Rheinland from various different

retailers in Germany and France in accordance with the test program. 9 types of

nozzle of each of the manufacturers stated above were procured and 5 of each type of

nozzle were procured.

• Inspection of the test equipment in the test laboratory of the company Danfoss,

Nordborg in respect of the suitability for the designated testing in accordance with the

test standard

• Flow metering of all 270 nozzles at reference conditions in accordance with the test

basis, carried out on the test rig of the company Danfoss (DIN EN 293, point 6.4)

• Symmetry measurement with the sector patternator for a selected spectrum of types of

nozzle, carried out on the test rig of the company Danfoss (DIN EN 293, point 6.6)

The process sequence of the examination as well as the measurement results are to be

depicted in the report in such a manner that clearly shows whether the test standard is

complied with.

TÜV Rheinland Energie und Umwelt GmbH

Order No. 21225968

page 5 / 22

Report No. S 221 2014 S4

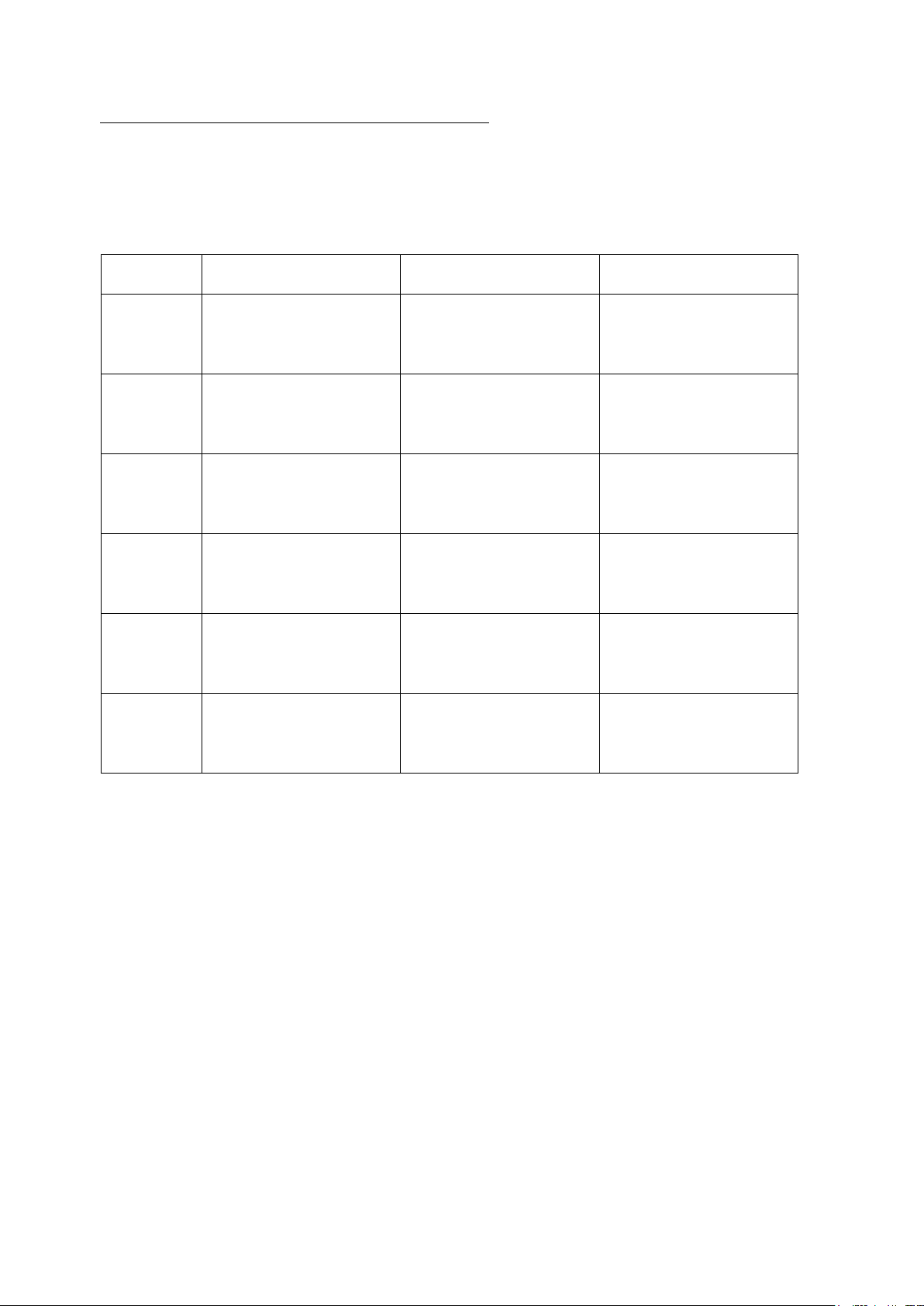

0.40

USgal/h

0.50

USgal/h

0.60

USgal/h

Fluidics

60°SF

45°SF

45°SF

80°HF

60°SF

60°SF

60°HF

60°HF

80°HF

OEG

60°S

45°S

45°S

80°H

60°S

60°S

60°H

60°H

80°H

Steinen

60°ST

45°ST

45°S

80°HT

60°ST

60°S

60°HT

60°H

80°H

Danfoss

60°S

45°S

45°S

80°H

60°S

60°S

60°H

60°H

80°H

Monarch

60°R

45°R

45°R

80°R *)

60°R

60°R

60°NS

60°NS

80°NS

Delavan

60°B

45°B

45°B

80°A

60°B

60°B

60°A

60°A

80°A

Test Centre for Energy Appliances

2. Description of Test subject

The following nozzles were subjected to the test. 5 samples of each nozzle type were

subjected to the throughput test and 3 samples were subjected to the spray distribution test.

*) sample NS was not available on the market – throughput was tested with type R

3. Approval Test

(The practical tests were performed in the laboratory of Danfoss A/S in Nordborg from 25th to 29th August 2014)

3.1 Procurement of nozzles

The nozzles were randomly purchased at wholesalers in Germany and France in a ratio of

4:1. The wholesalers were selected by TÜV Rheinland and represent standard suppliers for

the market.

3.2 Inspection of test laboratory

The test laboratory of Danfoss is located in the burner components factory and used for

production quality tests since about 50 years.

The environmental conditions are standard conditions for working places (clean air, normal

temperature of 20 +/- 5 °C).

The testing equipment is calibrated according to the Quality procedures of Danfoss under IOS

9001-certification. Calibration data were checked in advance to the tests. The following

equipment was in use for the test

TÜV Rheinland Energie und Umwelt GmbH

Order No. 21225968

page 6 / 22

Report No. S 221 2014 S4

Test Centre for Energy Appliances

Throughput test:

- Pressure: 0…30 bar; device no. 94471

- Temperature: 10…50°C; device no 79710

Control measurement for density correction:

- Weight: 0…2000g; device no. 30160

- Time: 0…60 min; device no. 92122

Spray distribution test:

- Pressure: 0…20 bar; device no. 30050

- Temperature: 0…100°C; device no. 77730

- Distance fixture: 64mm; device no. 91136

- Centre fixture: device no. 076793

The test assembly was found in accordance with the requirements of EN 293.

3.3 Practical test

The practical tests were performed by Mr. Preben Nørskov under witness of Mr. Wolf

Rückwart (permanently present during the tests).

Time schedule:

25.08.2014 - inspection of laboratory

- start of throughput measurements

- start of spray distribution test

26.08.2014 - completion of throughput measurements

- ongoing spray distribution test

27.08.2014 - verification of calibration data for measuring equipment

- ongoing spray distribution test

- exploitation and processing of data

28.08.2014 - ongoing spray distribution test

- exploitation and processing of data

29.08.2014 - additional throughput measurements (OEG nozzles)

- completion of spray distribution test

- exploitation and processing of data

3.3.1 Throughput test

The throughput test was performed by mass flow method under following conditions:

- oil temperature: 20°C

- oil pressure: 10 bar

- oil density: 799 kg/cm³

- oil viscosity: 3,36 cSt

Tolerances according to EN 293 were considered.

For calculation under reference conditions with a density of 840 kg/cm³ a correction factor of

1,0279 was used. The measurement system was validated with reference nozzles in advance

to the tests.

5 samples of each of the following types were subjected to the throughput test:

TÜV Rheinland Energie und Umwelt GmbH

Order No. 21225968

page 7 / 22

Report No. S 221 2014 S4

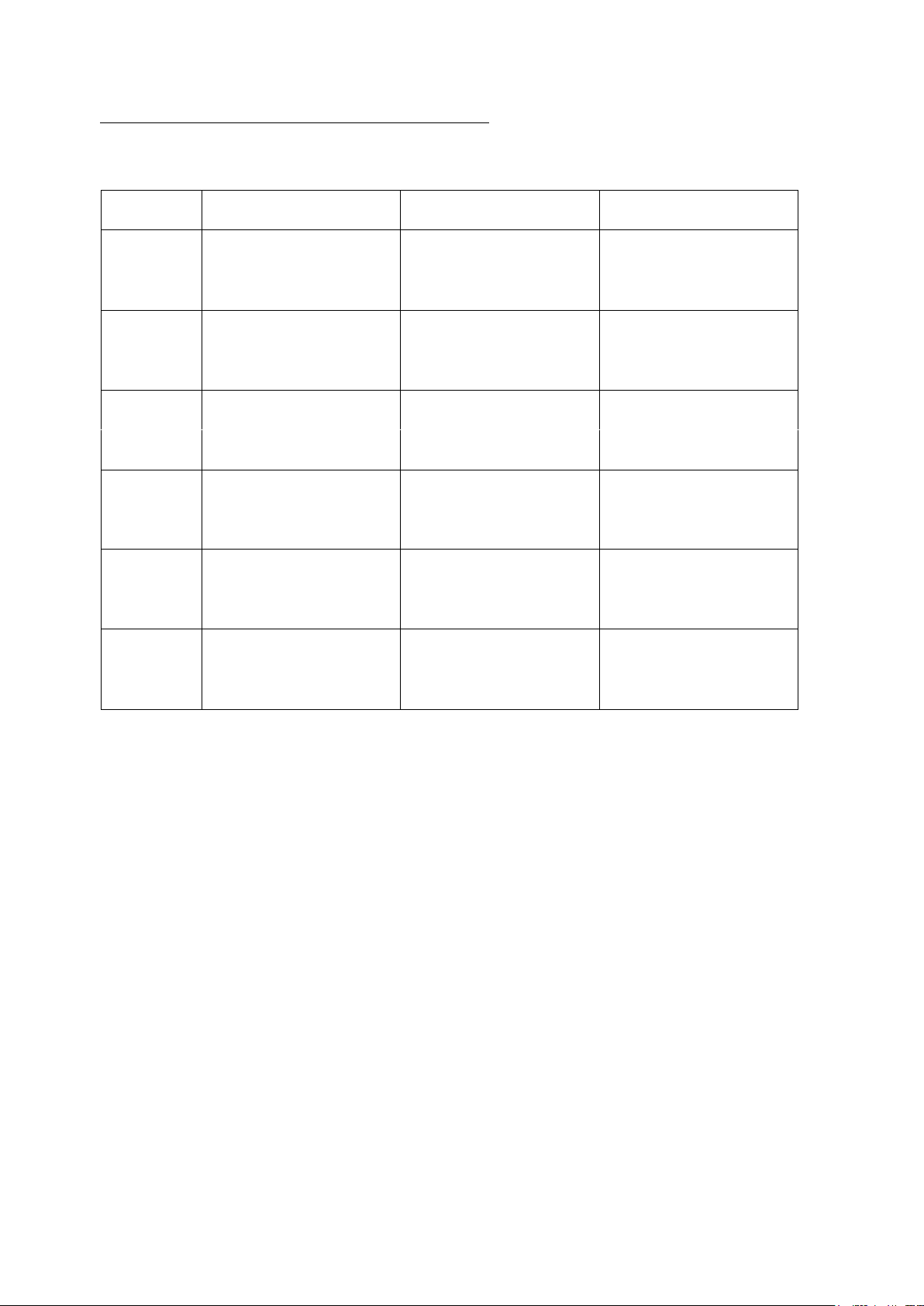

0.40

USgal/h

0.50

USgal/h

0.60

USgal/h

Fluidics

60°SF

45°SF

45°SF

80°HF

60°SF

60°SF

60°HF

60°HF

80°HF

OEG

60°S

45°S

45°S

80°H

60°S

60°S

60°H

60°H

80°H

Steinen

60°ST

**) 45°ST

**) 45°S

80°HT

60°ST

**) 60°S

60°HT

60°H

**)

80°H

**)

Danfoss

60°S

45°S

45°S

80°H

60°S

60°S

60°H

60°H

80°H

Monarch

60°R

45°R

45°R

80°R *)

60°R

60°R

60°NS

60°NS

80°NS

Delavan

60°B

45°B

45°B

80°A

60°B

60°B

60°A

60°A

80°A

Test Centre for Energy Appliances

*) sample NS was not available on the market – throughput was tested with type R

**) due to missing quantity only 4 samples were available and tested

Loading...

Loading...