Page 1

GB

Installation And User Instructions

Devimat™ Warm Floor System

Installation Instructions

User Guide

Trouble Shooter

1

Page 2

Existing Floor

Wooden Floors

Concrete Floors

In all above situations, the fl oor temperature must be controlled with a DEVI fl oor sensor and

™

550 thermostat/timer, or Devireg™ 130 thermostat.

Devireg

Maximum load per m

100 W/m

150 W/m

2

2

2

INSTALLATION: KEY POINTS

•

Before laying the mat the fl oor sensor (in controller box) MUST be installed. The

sensor is fi tted into a tube (in mat box) which should be laid 20-30cm across

the fl oor under the mat between a cable loop.

• Before laying check the continuity of the cable, it should match the Ohm rating

™

on the Devimat

label with a tolerance of -5 to +10% and check the insulation

resistance which should read infi nity.

• To install the mat simply cut and turn the mat. The heating cable must NOT be

cut or subjected to strain around the area of the coupling, only the blue and

black cables can be cut to suit.

• When installing more than one mat, all ‘cold tails’ (blue/black wires) must be taken

back to the connection point/controller, DO NOT wire one mat to another.

• After laying the adhesive the heating mat must be checked once again for continuity and insulation resistance, then connected by an authorised electrician.

• The blue central core is NEUTRAL and the black central core is LIVE. The outer

surrounding copper wire is the earth screen and should be connected to earth.

™

• A fl exible adhesive is required when installing the devimat

product.

• Installation on new concrete fl oors should not be carried out for approxi-

mately 30 days to ensure thorough drying out.

Devimat™ specifi cations

Cable

Type

Voltage

Effect

Dimension (W x H)

Cold tails

DTIF

Twin conductor with screen

230 V AC

100 W/m² to 150 W/m²

460 mm x 3 - 3.5 mm

4.0 m, 1.0 mm² plus screen

Connections

Live - Black

Neutral - Blue

Earth - Screen

2

Page 3

Installing the Devimat

1. Draw up a plan of the room and

calculate the free fl oor area.

Use the plan to work out how to

lay the mat evenly across the

fl oor and show the location of the

cold tail (where the mat starts),

fl oor sensor and connection box.

The Devimat

obstructions and close fl oor fi tting objects like pipes,

baths and cupboards. It is acceptable to lay the

devimat under suspended cupboards and wash

basins.

2. Mark the positions of the fl oor fi tting objects that

will be installed once the fl oor is fi nished, so

when laying the mat these can be avoided.

3. Each mat is supplied with a piece of 10mm

fl exible tubing (only one tube is required for each

thermostat), this is for the fl oor sensor, so that in

the unlikely event that the sensor fails, it can be

4. The existing fl oor

should be prepared as normally

required for tiling, this may

include cleaning and

removing all loose particles,

removing any sharp

protrusions that may cause

damage to the heating wire,

priming the fl oor surface and

bracing a timber fl oor with WBP

ply-for professional guidance refer to your adhesive

manufacturers recommendations.

™

should laid avoiding all fl oor

™

easily removed and

replaced without lifting the fl oor.

In some situations a small channel may have to be

made in the fl oor to accommodate the tubing. If so,

cut a channel from the thermostat position

approximately 20-30cm across the fl oor.

It is important that the

channel is positioned such

that it lays between two

heating wires and not across

them and not above heating

pipes below the fl oor. The

end of the tubing in the fl oor

is sealed with tape to prevent

adhesive entering the tube.

3

Page 4

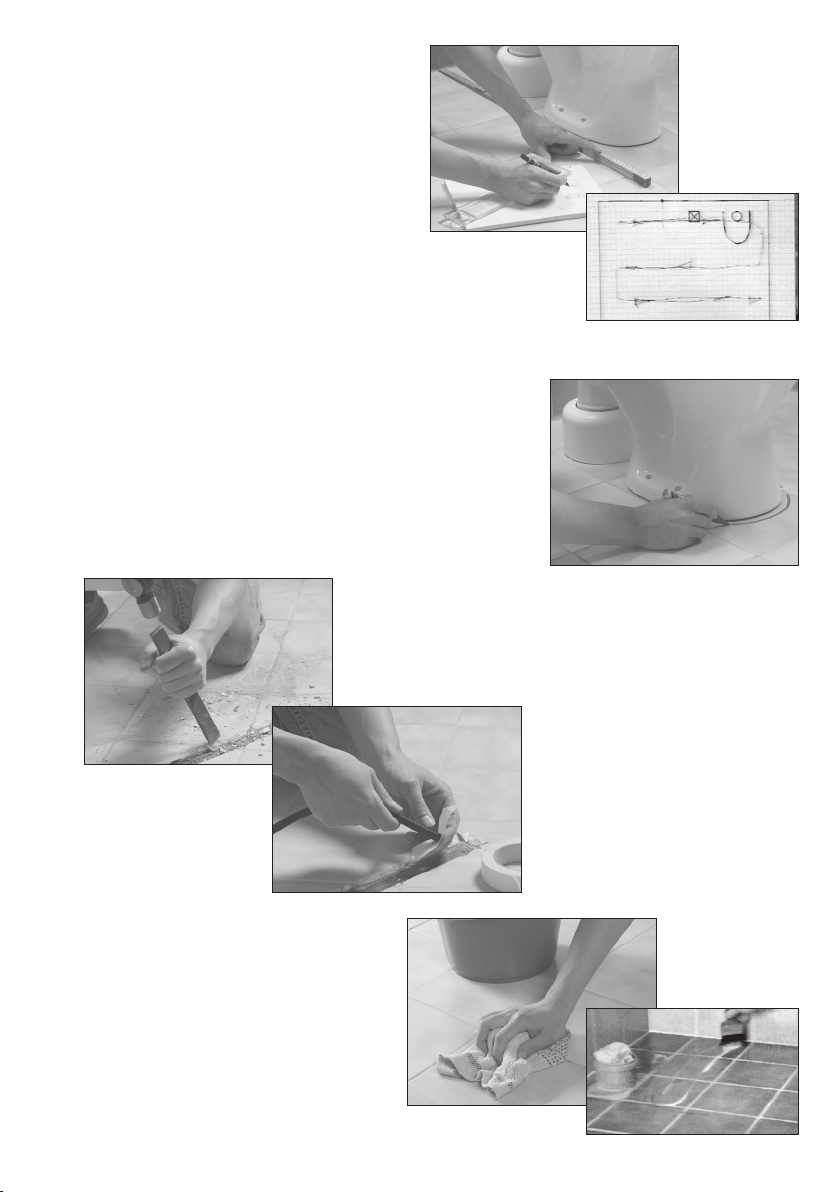

5. Before laying the mat should be tested-see page 7.

Remove the plastic outer and place the cold tail of

the mat at the connection point. The Devimat™ has

a self-adhesive backing, lay this to the fl oor and roll

the mat out, if necessary the mat can be laid with

the cable face down. In situations where the mat

has to be turned over it can be secured using

Devipins, hot glue gun (taking care not to damage

the heating cable), staple gun or double sided tape.

™

6. When the Devimat

reaches

the end of the run, simply

cut the grey mesh (NOT THE

RED CABLE) and turn the mat,

positioning the next piece

beside the fi rst. When cutting

and turning the mat ensure there is a 50mm

gap between the cable loops. To avoid risk

of damage at later stage do not lay the mat

where objects will be put onto or fi xed to the

fl oor.

7. If required, the cable can be removed from

the mesh and loops formed manually, but ensure

the cables are spaced the same distance as those

on the mat.

• The devimat™ must NOT be installed

across two or more rooms

• The heating cables (RED CABLE) must

not touch or cross each other.

• The heating cables (RED CABLE) must

not be CUT.

• All the red heating cable must be within

the fl oor.

4

Page 5

8. The mat should be tested-see page 7.

The mat can now be covered in one of two methods Concrete and wooden fl oors using fl exible tile adhesives

Working with a width of devimat at a time, apply

fl exible tile adhesive through the mat with a rubber

back trowel or similar so that the heating cable is

covered, making sure that there are no air pockets.

Another layer of adhesive can then be applied

carefully using a suitable notched trowel to comb

the adhesive before applying the tiles.

Concrete and wooden fl oors using self-levelling compounds

An alternative method is to cover the devimat with a suitable self levelling/

latex type compound. This product will fi nd its own level giving you a fl at

surface to then apply a layer of fl exible tile adhesive using a suitable notched

trowel to comb the adhesive before applying the tiles.

The mat should be tested-see page 7.

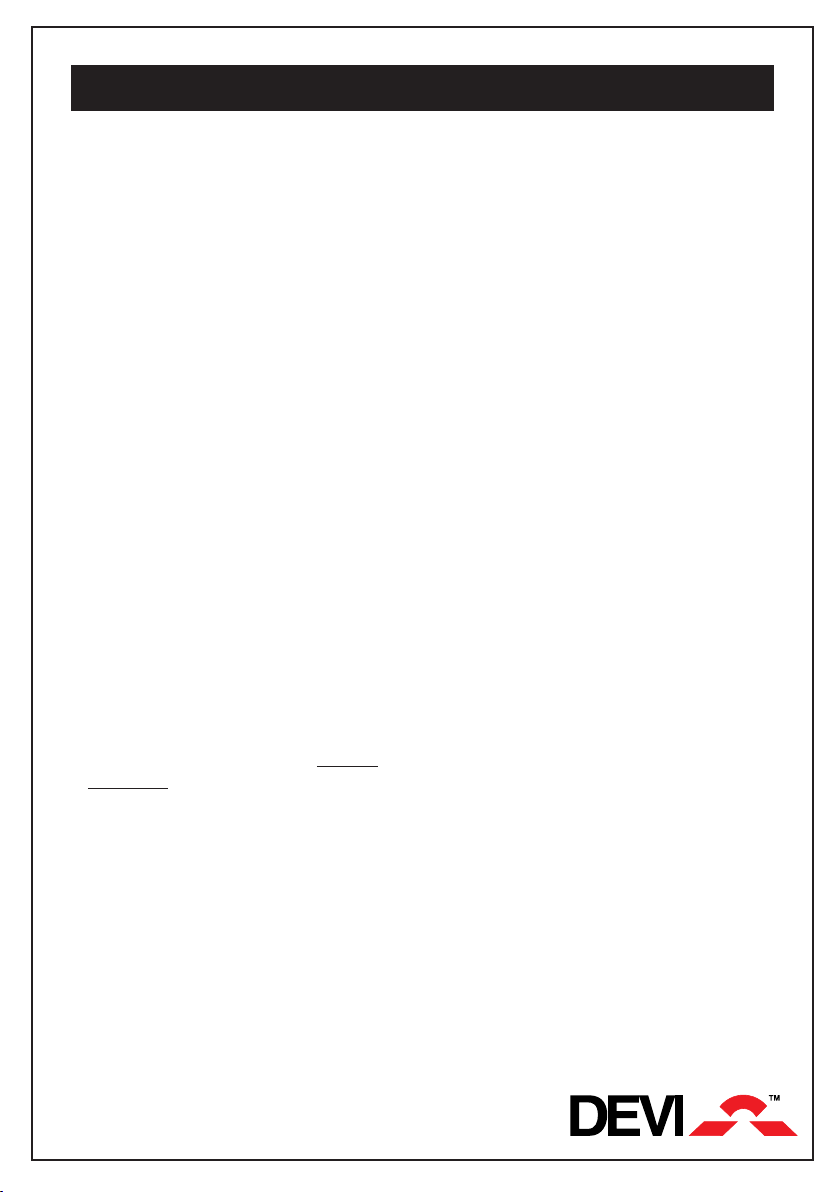

Installing the Devimat™ on concrete

fl oors

Ceramic tiles

Devimat

Floor sensor

Existing or new screeded fl oor

™

Tiling adhesive

Installing the Devimat™ on

timber fl oors

Ceramic tiles

Tiling adhesive

Wood joist

15 mm plywood bracing

screwed at 200 mm centres

with 0.5-1.0 mm gaps

between

Devimat

Floor sensor

T & G fl oor boards

Seal all sides and

edges of plywood

™

Flooring note:

Whichever fl oor covering is being used with the Devimat system, it must be

covered with a latex/adhesive covering before the fl oor fi nish is laid, the

suitability of which should be checked for use with underfl oor heating with the

manufacturer. If using Devimat beneath wood laminate fl ooring, you must only

use the thin foam type sound-deadening layer, this must not exceed 3mm.

5

Page 6

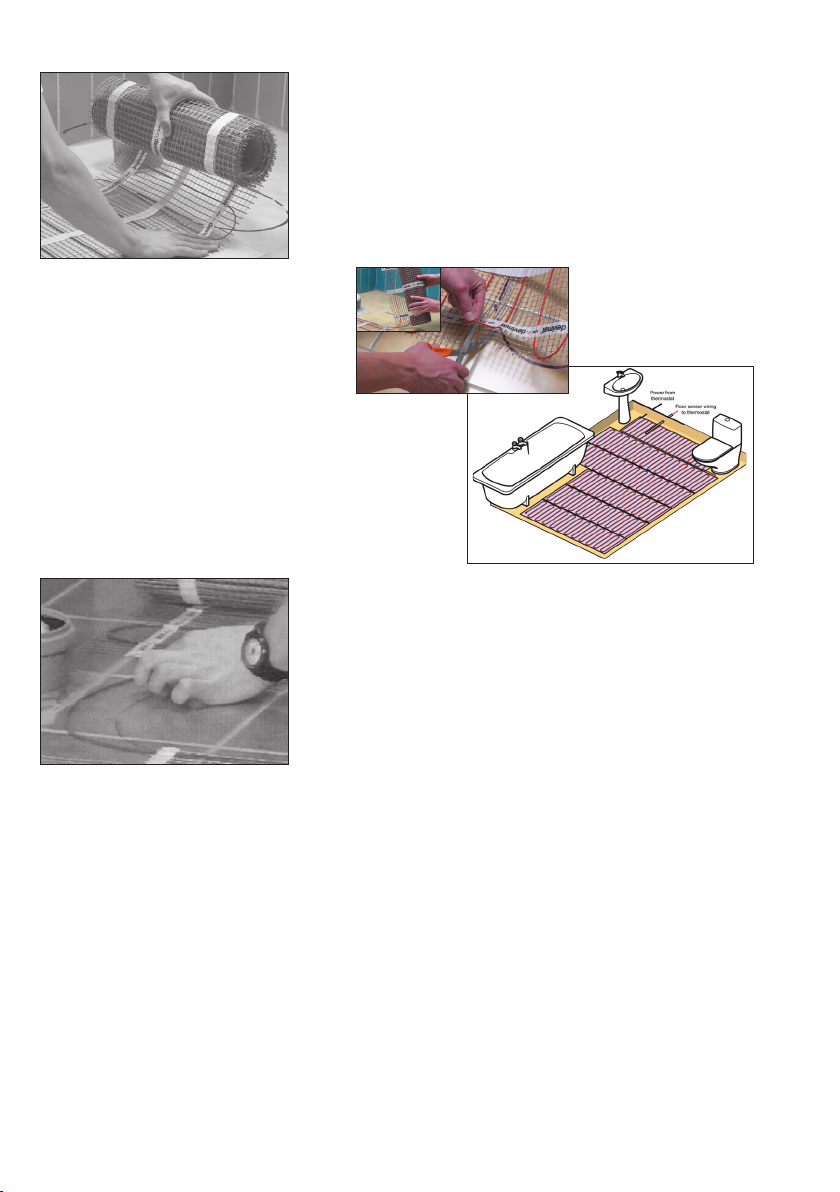

Wiring and controlling the devimat

A qualifi ed electrician must connect the heating mat, in accordance with the

current wiring regulations BS 7671.

It is recommended that the Devimat™ be connected via a 30mA RCD (residual

current device). Wiring regulations state that the thermostat should be located

away from sources of water, i.e. outside the bathroom. As the thermostat is

sensing fl oor temperature, the control unit can be located at any level from the

fl oor. ONLY the cold tail(s) of the Devimat™ and the black fl oor sensor should be

leading from the fl oor to the thermostat position.

The Devimat™ must be controller using either a Devireg™ 130 or a Devireg™ 550,

both of which use a fl oor sensor to monitor the fl oor temperature.

Both thermostats have a switching limit of 16 amps (35m2 of Devimat™ on timber

fl oors or 23m2 of Devimat™ on concrete fl oors) if above these limits a contactor

or multiple controllers should be used.

Wiring the Devireg™ 130-see instructions enclosed with the Devireg™ 130.

Wiring the Devireg™ 550-see the instructions below:

Wiring The Devireg™ 550

The sensor cable, heating mat and electricity supply can now be connected.

Five simple steps to connecting your controller are:

1. The mains voltage is connected to the terminals marked (Mains L & N).

L = Live

N = Neutral

2. The devimat™ is connected via terminals L and N where :

Blue Cable Central Core = Neutral

Black Cable Central Core = Live

3. The screening around the black and blue wires of the devimat™

should be connected to the earth terminal within the

electrical box, in accordance with the electricity

regulations.

4. The sensor must be connected to the terminals

marked NTC. This cable can be shortened as

required and connected either way round.

5. The ‘Network’ terminal is not used.

6

Page 7

Installation complete

Following installation the Warranty

Certifi cate on the back of this user

guide should be fi lled in.

The Devimat™ system should not be

turned on until the adhesive and tile

grout has completely dried, then once

dried it can be turned on gradually

over a 48 hour period.

No close fi tting objects should be laid

or fi xed to the warm fl oor area, for

example thick mats or beanbags.

Testing

At each stage of the installation it is recommended that the heating mat is tested

for the following:

Continuity- This checks that the heating cable (blue and black wires) are intact

and have the correct resistance. The resistance is checked with a multimeter

and the reading should match the resistance rating on the label on the cold tail of

the Devimat™ with a tolerance of -5 to +10%. Ensure your multimeter is capable

of reading values between 28-550 ohms.

Insulation- This checks that the earth screen around the heating cable has not

been damaged and shorted to the heating cables. The test can be made with a

multimeter and can be done by testing the path between the blue cable and the

earth screen and the black cable and the earth screen, both should read infi nity.

7

Page 8

Setting up your Devireg™ 550 programmable

thermostat with your devimat

If the thermostat is displaying ‘CODE’, initially you will ONLY be presented with step 1 and

step 4, set these as described below.

Once you have either completed steps 1 and 4, or the controller is displaying something other than

‘CODE’, you must press and hold the button until the word ‘CODE’ is displayed and follow the steps

below:

Step 1-Setup code

Step 2-Operating mode

Step 3-Temperature

readout

Step 4-Sensor selection

Step 5-Maximum fl oor

temperature selection

Step 6-Off periods

Rotate button to select code 0044 and then press

button once.

Rotate button to select ‘ALO’ and then press

button.

Rotate button to select °C and then press button.

Rotate button to select ‘FS’ to activate the fl oor

sensor, then press button (not rFs or rs).

At ‘nt’ rotate button to select either of the following temperature selection maximum fl oor

temperatures, then press button.

Tiles on timber based fl oors 29°C

Tiles on concrete based fl oors 40°C

Timber covered fl oors (parquet etc.) 27°C

‘LO’ should be displayed, you should rotate dial

to select -30°C, then press button.

™

system

0044

FS

29ºC

LO -30ºC

Step 7-Clock display

Step 8-Save settings

(If the controller is now displaying ‘CODE’, disconnect the power to the controller and then reconnect)

Now you can set the time and day on the controller.

Step 9-Setting of clock

*If any steps are skipped, hold button until word ‘CODE’ is displayed to reset controller and start

again at step 1.

Rotate button to select clock display as either 24

hours or 12 hours AM/PM.

Press button once.

Press and hold button until is displayed in bottom

left corner. The display now shows the time and day

(number 1 represents Monday, number 7 is Sunday).

Rotate the dial to show the correct time and day of the

week and then press the button to save the correct time

setting.

24 12

8

Page 9

Finally you can now set how you wish the controller to operate.

You can operate the controller in either Manual or Timer Mode, by pressing the button you can

toggle between these two modes.

Manual

Mode

Timer

Mode

Step 10

Step 11

Step 12

Step 13

Step 14

In this mode the temperature set on the display is maintained 24

hours a day, i.e. no timing facility and therefore no ‘ ‘ displayed.

Whilst in manual mode, if you rotate the dial to level 1.0 then turn

the dial further anti-clockwise, the thermostat will switch off and

display ‘OFF’.

On the timer program, the controller switches on and off as programmed. With this mode you tell the controller at what time of day

you want a warm fl oor and then using its intelligence,the controller

learns how long your fl oor takes to warm up.

Enter timer

mode

Select fi rst day

First start time

First end time

Continue

Press and hold button until is displayed in

bottom right corner.

Rotate button to display the fi rst day you wish to

program and then press button.

Rotate button to indicate the start of the fi rst time

period when you want a warm fl oor (i.e. 06:00) and

then press the button.

Rotate button to highlight duration of fi rst warm

fl oor period, then press button to indicate the end

of fi rst time period (i.e. 07:30).

Rotate button to indicate next warm fl oor start time,

press the button, rotate to the end of the period

and press button again. Continue this through the

whole week.

5.0

5.0

1 2 3 4 5 6 7

06:00

1

07:30

1

22:30

1

Step 15

Step 16

Save program

Set fl oor level

To save programs, press and hold the button to

return to the normal display. By pressing the button

once you can now toggle between manual and

timer modes.

The button now controls the heat level of your

™

Devimat

to the required heat level on a range from 110, level 10 being the maximum fl oor heat.

The displayed heat level is what the controller

will provide at the times programmed. It is

recommended that you initially set to level 5, then

adjust to suit.

system. The controller can be adjusted

9

5.0

Page 10

Devimat™ Trouble Shooter

Should you experience any problems with the Devimat™ not warming the fl oor, before

calling DEVI, the following tests should be carried out:

No.

1

Check for a 230V supply to the thermostat on terminals 1 and 2.

2

Rotate thermostat dial to position 10

and test for a 230V output on terminals 3 and 4. This may take a few

minutes to switch on.

3

Turn off power to thermostat and test

resistance of fl oor sensor.

4

Turn off power to thermostat and test

resistance of the devimat™.

5

Turn off power to thermostat and

ensure there is no continuity between

the conductors and the earth screen.

Test

Expected Outcome

230V

230V

10-20k, depending on

temperature of fl oor.

27-550, depending on

mat size (see mat label).

No continuity.

Action

If no voltage present, connect supply.

Firstly, check resistance of fl oor sensor

fi rst (step 3). If fl oor sensor is normal,

the thermostat is faulty-contact your

supplier.

If sensor is faulty, call your supplier for

replacement.

If mat is faulty, the mat has been damaged, contact your supplier.

If there is continuity between the

conductor and screen, the mat has

been damaged, contact your supplier.

Devireg™ 550 Controller Trouble Shooter

If the outer ring on the Devireg™ 550 controller is fl ashing you have a fault, note the small

number at the bottom of the display and follow the procedures below:

Devireg™ 550 controller

indicating error No. 2.

Devireg™ 550 controller

indicating error No. 3.

Devireg™ 550 controller

indicating error No. 4.

Devireg

indicating error No. 5.

Devireg

indicating error No. 6.

Devireg™ 550 controller

indicating error No. 7.

Devireg™ 550 controller

not working at all.

Fault

™

550 controller

™

550 controller

Unit Confi gured as a Master,but

can detect another master unit

Unit Confi gured as a Slave, but

cannot detect another master unit

The thermostat is over heating

Sensor fault-fl oor sensor short-cir-

cuit

Sensor fault-fl oor sensor open-cir-

cuit

Clock not adjusted

No power

Wiring incorrect or Faulty unit

Possible Cause

Only one unit may be confi gured as a master-

see 550 programming instructions.

Only one unit may be confi gured as a master-

see 550 programming instructions.

Let the thermostat cool down and check the

wiring.

Check the fl oor sensor wiring and check for a

resistance reading of 10K - 24K Ohms.

Check the fl oor sensor wiring and check for a

resistance reading of 10K - 24K Ohms.

Set the clock.

See devimat™ Trouble Shooter above.

IF AT ANY POINT THE CONTROLLER IS NOT FUNCTIONING CORRECTLY PLEASE

TURN OFF THE POWER AND RESET THE CONTROLLER.

Solution

10

Page 11

The DEVI Warranty:

You have purchased a Deviheat™

system, which we are certain will

improve your home comfort and

economy.

Deviheat™ provides complete

heating solutions with Devifl ex™

heating cables or Devimat™ heating

mats, Devireg™ thermostats and

Devifast fi tting bands.

If, however, contrary to all

expectations, a problem should occur

with your heating system, we at DEVI,

with manufacturing units in Denmark,

are, as European Union suppliers,

subject to general product liability

rules, as stated in Directive 85/374/

CEE, and all relevant national laws

which imply that:

DEVI provides a warranty for

Devifl ex

™

heating cables and

Devimat™ heating mats for a 10 year

period and all other DEVI products

for a 2 year period against defects in

material and production.

The guarantee is granted on the

condition that the WARRANTY

CERTIFICATE overleaf is fi lled out

properly in accordance with

instructions and that the defect is

inspected by, or presented to, DEVI or

their authorised DEVI distributor.

Please note that the wording of the

WARRANTY CERTIFICATE must

be provided in English with the ISO

code for your country in the upper left

corner of the front page of the

installation instructions in order to

release the warranty.

The obligation of DEVI will be to

repair or supply a new unit, free of

charge to the customer, DEVI are not

responsible for secondary charges

linked to repairing the unit. In case of

defective Devireg

™

thermostats, DEVI

reserves the right to repair the unit

free of charge and without

unreasonable delay to the customer.

The DEVI warranty does not cover

installations made by unauthorised

electricians, or faults caused by

incorrect designs supplied by others,

misuse, damage caused by others, or

incorrect installation or any

subsequent damage that may occur.

If DEVI is required to inspect or

repair any defects caused by any of

the above, then all work will be fully

chargeable.

The DEVI warranty is void, if

pay-ment of the equipment is in

default.

At all times, we at DEVI will respond

honestly, effi ciently and promptly to all

queries and reasonable requests from

our customers.

The above mentioned warranty

concerns product liability whereas

matters in relation to legislation on

sale of goods shall be referred to

national law.

N.B. Unit means DEVI installed

equipment.

11

Page 12

Warranty Certificate

The DEVI Warranty is granted to:

Name:

Address:

Phone:

Postal code:

Please Observe!

In order to obtain the DEVI Warranty, the following must be carefully

devimat™ layout contractor:

Mat length:

Stock code:

Application:

Concrete floor Tiles Parquet

Wooden floor Vinyl Carpet

Supplier Stamp:

filled in. See other conditions on the overleaf.

Lay-out date:

Installation date:Electrical Installation by:

Watt:

DEVI A/S, HQ

Phone +45 76 424700

Fax +45 76 424703

DEVI United Kingdom

Phone 01359 242400

Fax 01359 242525

DEVI Ireland

Phone 01 460 2622

Fax 01 460 2633

08090215 · Revision 1, dated 01/03/04

DEVI New Zealand

Phone 33 48 00 70

Fax 33 48 00 67

12

Loading...

Loading...