User guide for Coolselector®2. Not for use as a design guide.

Always remember that selection software is only as good as the person using it.

2019-06-04 | Version 1.03

Coolselector®2 User Guide

Coolselector®2 User Guide

2

Contents

1 Installing Coolselector®2 ............................................................................................................... 3

2 Check for latest version................................................................................................................. 3

3 Country and language settings ..................................................................................................... 4

4 How to find out what is new in Coolselector®2 ............................................................................ 5

5 Basic component selection ........................................................................................................... 6

6 Changing the refrigerant ............................................................................................................... 8

7 Description of operating conditions ............................................................................................. 9

8 Different screen segments .......................................................................................................... 10

9 Check the calculations details ..................................................................................................... 11

10 Adding a new tab ...................................................................................................................... 12

11 Saving your project ................................................................................................................... 13

12 Loading a saved project ............................................................................................................ 13

13 Selection of components in series ............................................................................................ 14

14 Compressor selection................................................................................................................ 18

15 Understanding superheat ......................................................................................................... 20

16 Electronic controller selection .................................................................................................. 21

17 Creating a report ....................................................................................................................... 22

18 Selecting a code number ........................................................................................................... 25

19 Bill of materials ......................................................................................................................... 27

20 Customization – units and conversions .................................................................................... 29

21 Customization – change application ......................................................................................... 30

22 Customization – columns in selection table ............................................................................. 31

23 Customization – user interface ................................................................................................. 32

24 Customization - preferences ..................................................................................................... 35

25 Advanced settings – calculation and selection criteria ............................................................. 38

26 Advanced settings – custom unit system.................................................................................. 40

Coolselector®2 User Guide

1 Installing Coolselector®2

In order to get Coolselector®2 up and running, if you have not done so already, you can

download and install Coolselector®2 from http://coolselector.danfoss.com.

Coolselector®2 is free to use and runs on all Windows PCs.

If you are running a mac or other non-Windows PC, you can access Coolselector®2 online from

http://coolselectoronline.danfoss.com.

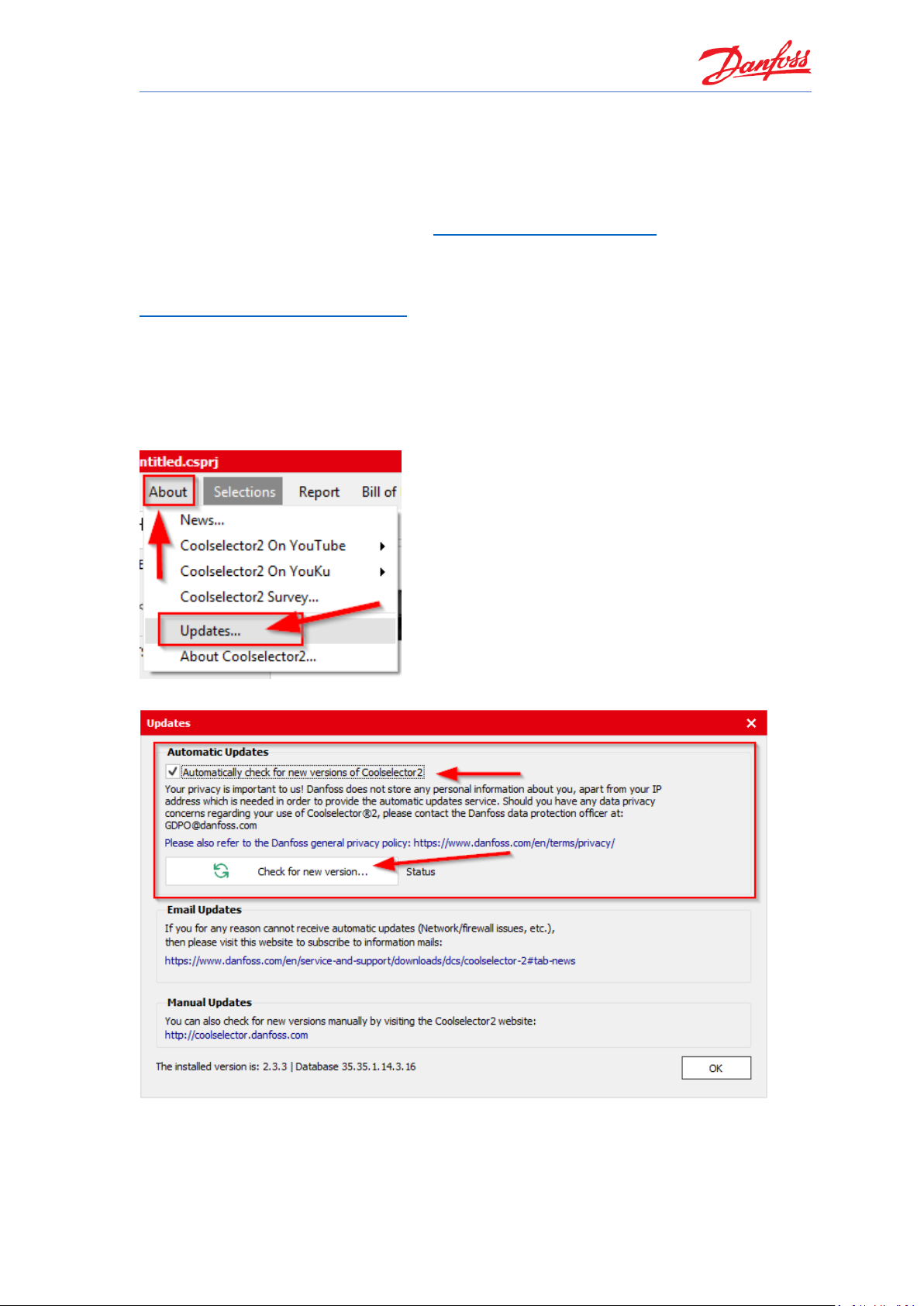

2 Check for latest version

Before you start using the standard PC version of Coolselector®2, please make sure you have the

latest version, by going to the “About | Updates” menu:

Once you see the Updates screen, click on the “Check for new version” button:

Note that, if you cannot update automatically (i.e. due to your company policies), it is possible to

subscribe to an email service which will notify you whenever a new version is released.

Coolselector®2 User Guide

4

Once you have clicked the button, Coolselector®2 will notify you if there is a newer version

available. If that is the case, you can install the new version directly from the prompt.

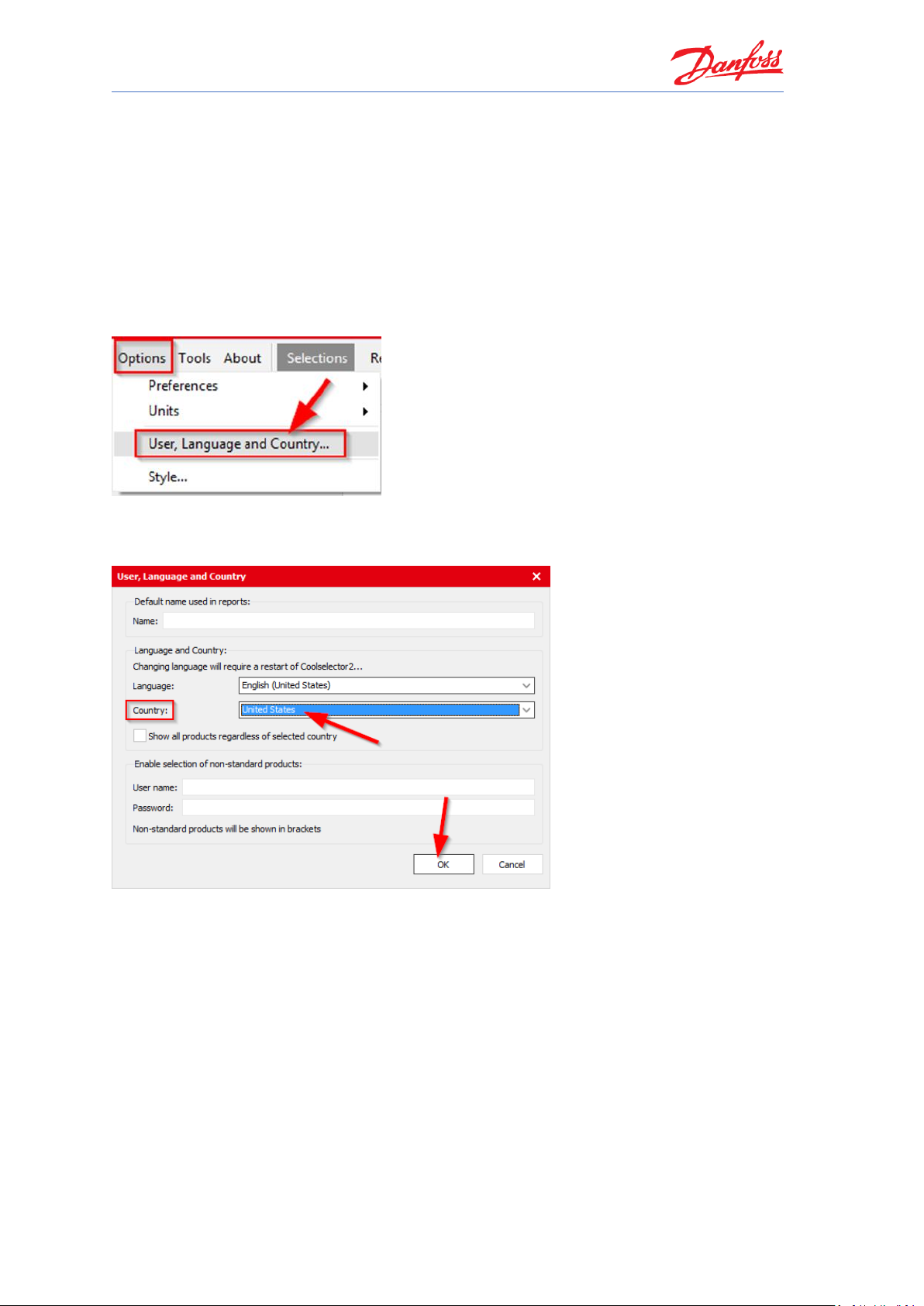

3 Country and language settings

Before first use, please also ensure you have set the country and language based on your

preferences.

You can set the preferences for country and language in “Options | User, Language, Country”

menu:

As an example, you can change your country to ‘USA’ as in the following example;

From the drop down, set your country to ‘United States’ and click OK:

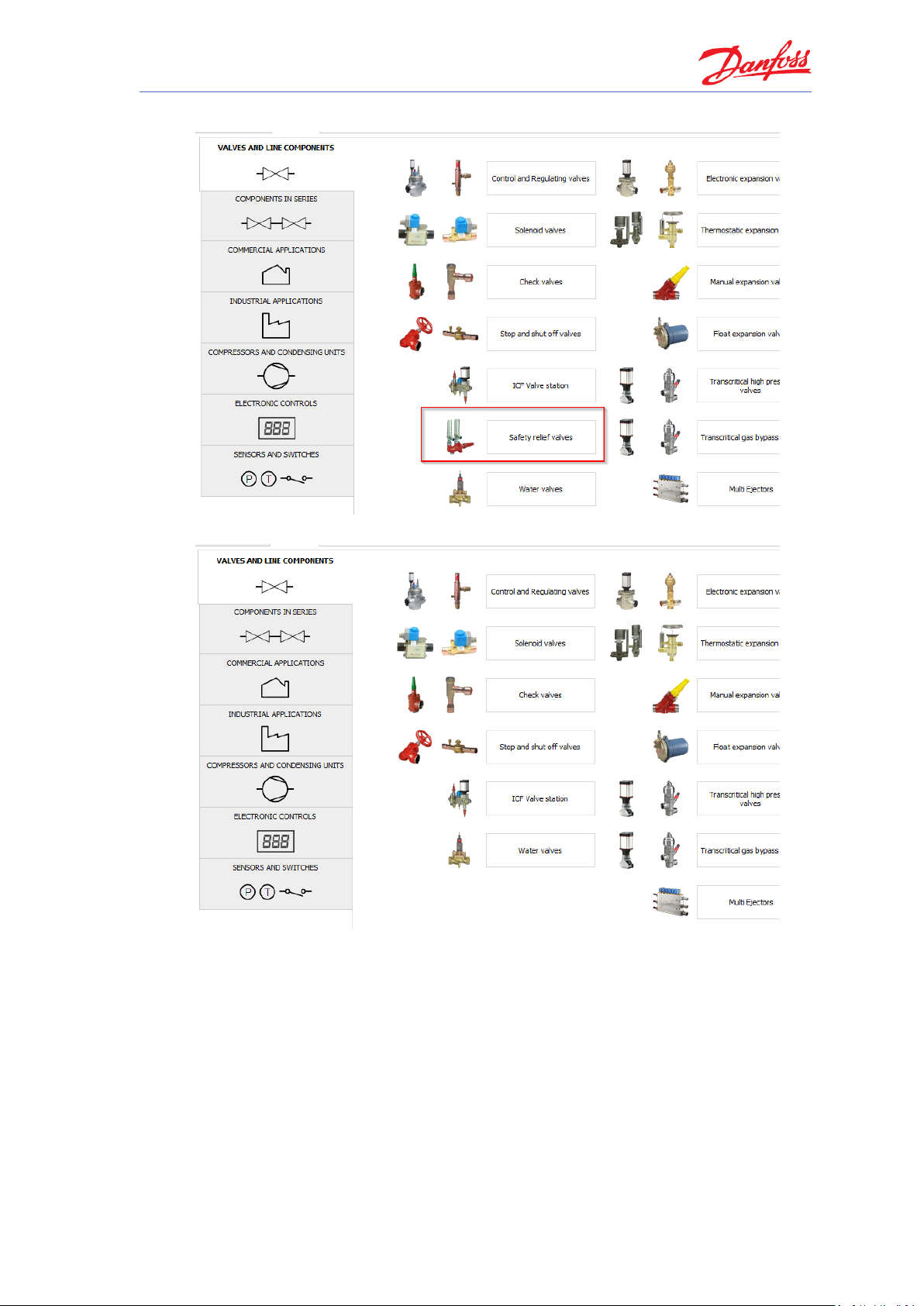

When you change your country to USA, you will see that the available components in “Valves

and Line Components” have changed. You will no longer be able to select “Safety relief valves” –

the reason being that Danfoss does not sell safety valves for the US market (this might change in

the future).

The important thing to note here is that Coolselector®2 will use your country setting to display

as relevant as possible information to you (this is even more pronounced for condensing units,

where each unit has a specific sales region).

On the next page, you will find some examples of this:

Coolselector®2 User Guide

1. Country = Denmark (or any other EU country as an example):

2. Country = United States:

Do not forget to change the settings back to your preferred ones (i.e. your own country).

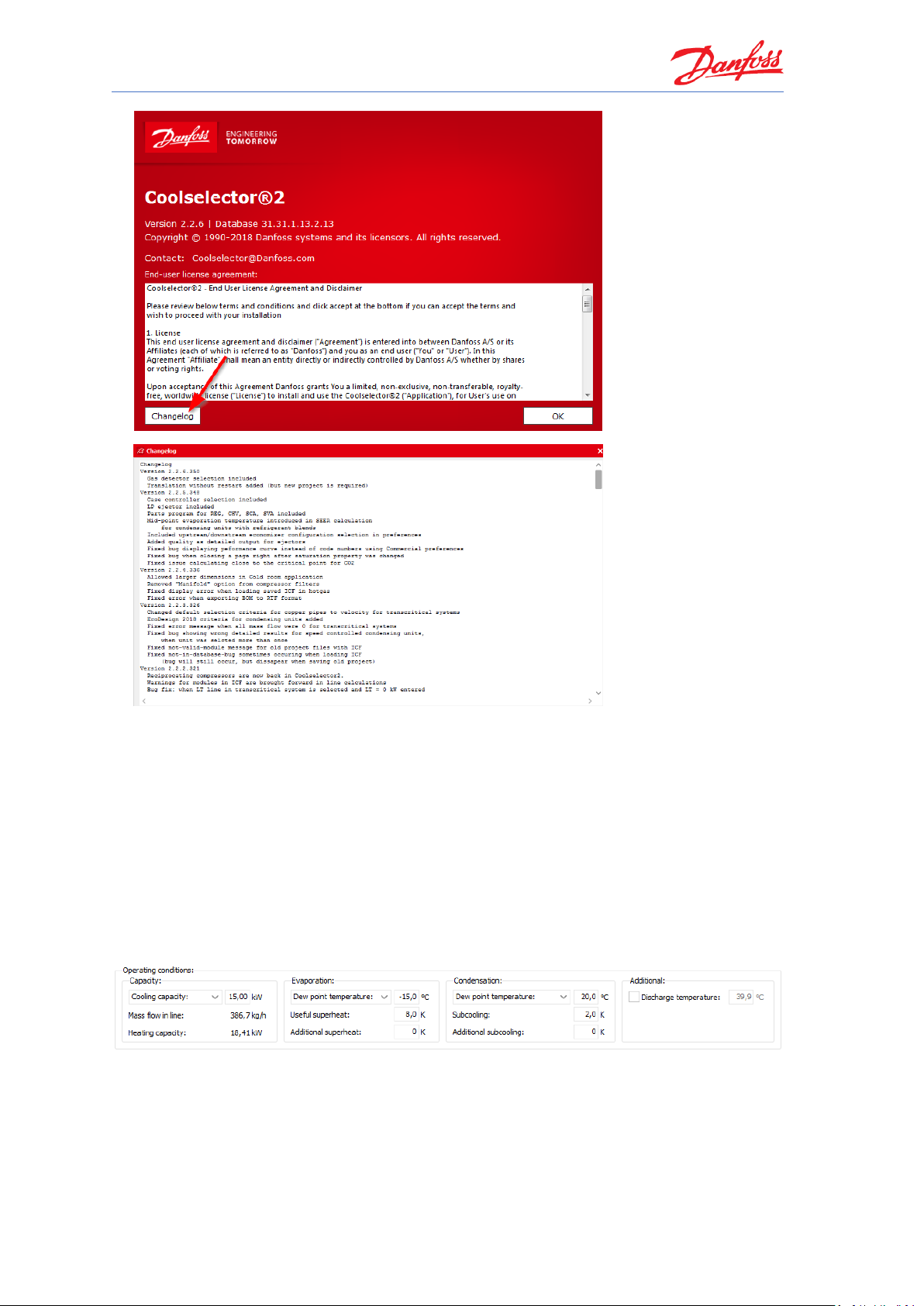

4 How to find out what is new in Coolselector®2

To see the latest changes in Coolselector®2, go to the “About | About Coolselector2” menu and

click the <Changelog> button:

Coolselector®2 User Guide

6

’

Also, check out the “About | News” menu item for new product releases.

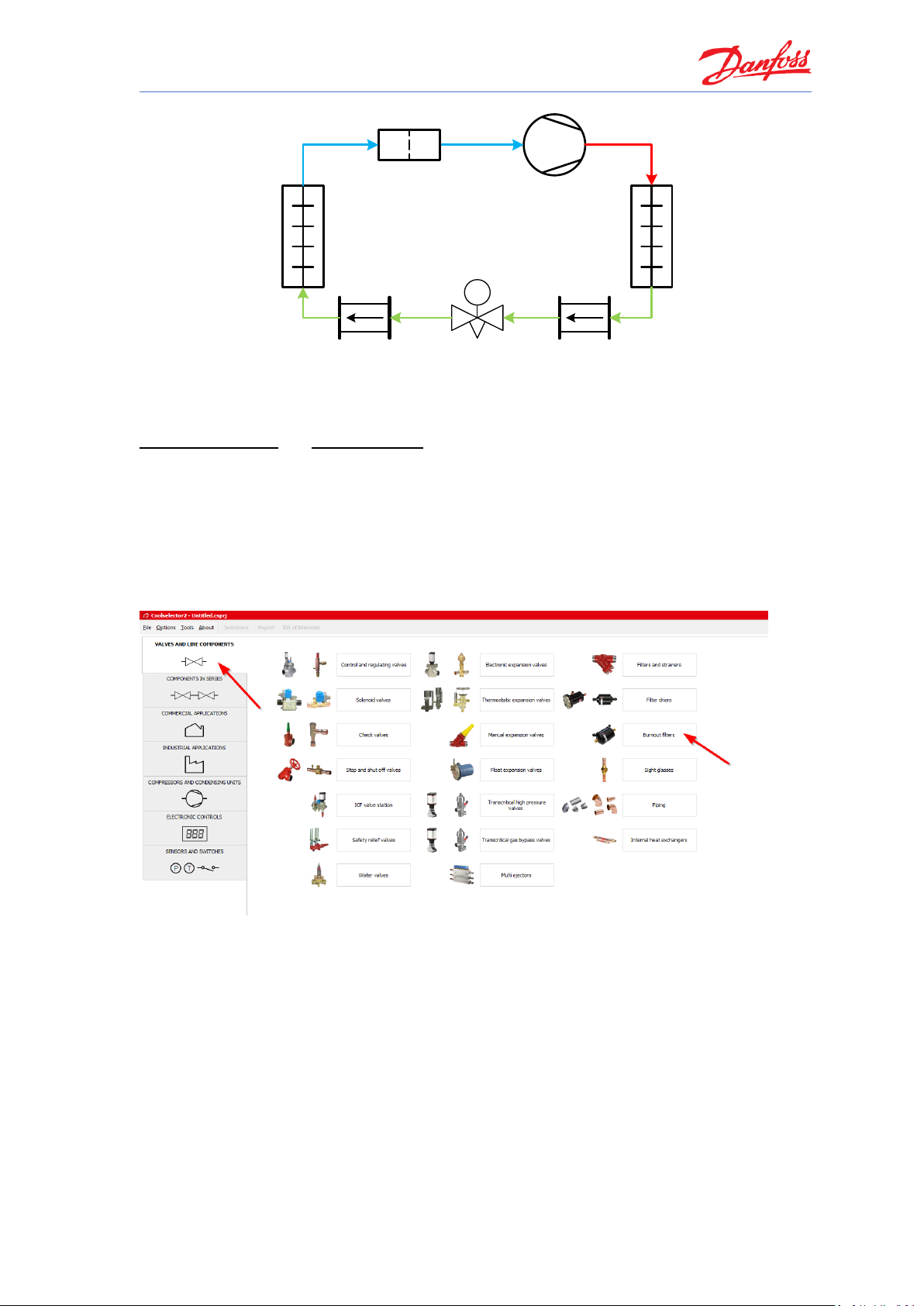

5 Basic component selection

In the following part of this user guide, we will go through creating a project in which we try

selection and calculation for a few components in a very simplified refrigeration cycle as it can

be seen in the following graph and properties snippet. We will also discuss how to customize the

project with your own name, how to get bill of materials and how to generate a report for this

project. Make sure your preferences choice is set to “’all applications’ in “Options | Preferences

| All applications” (refer to chapter 21 if in doubt how you do this).

System Properties 1

Coolselector®2 User Guide

TC

DCR-DA

Speed 12±3 m/s

Refrigerant R404A

Copper DIN-EN 10 m

Speed 0,9±0,2 m/s

Copper DIN-EN 1 m

Speed 15±3 m/s

AKV

Load 80%

Condenser

Evaporator

Cycle Diagram 1

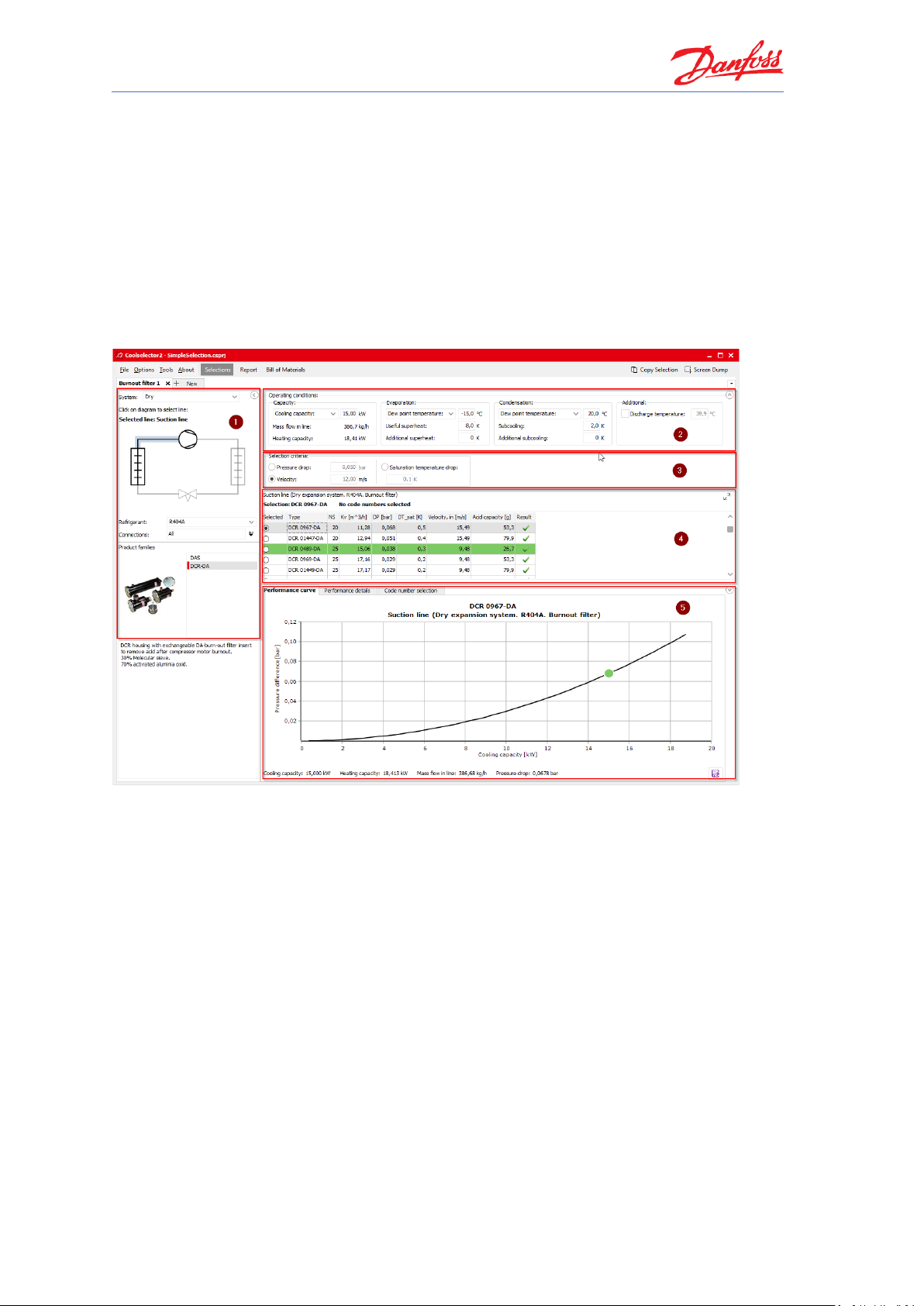

For the following explanations on basic component selection, we will use the information in

System Properties 1 and Cycle Diagram 1 above.

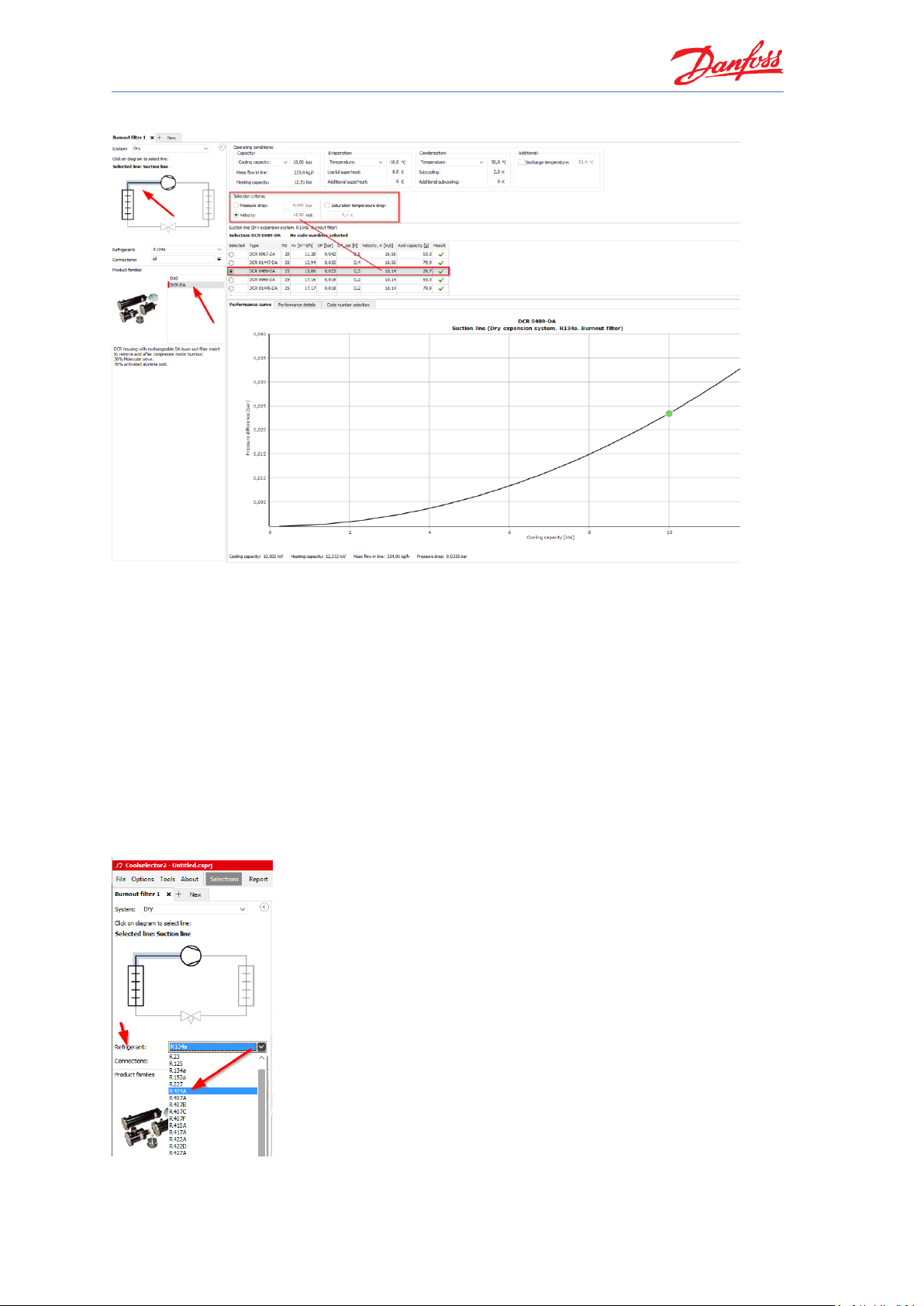

First, and to give you an overview of the “Valves and Line Components” part of Coolselector®2,

we will start by selecting a DCA-DA burnout filter for the suction line in a dry system with the

default operating conditions.

To do this, open Coolselector®2. Upon doing so, you will find that the program starts on the tab

for ‘Valves and Line Components’. From this screen, among the different component

functionalities, we will choose “Burnout filters”.

Coolselector®2 creates a dry system by default, and we then select the suction line and then

click on the DCR-DA in the product families. You will see the list of valid products and the best

Coolselector®2 User Guide

8

one matching the selection criteria as depicted in the snippet below:

Here you can also see the other parameters for the filter in the table, such as acid capacity, as

well as the pressure-drop as a function of changing the cooling capacity and keeping the other

parameters constant.

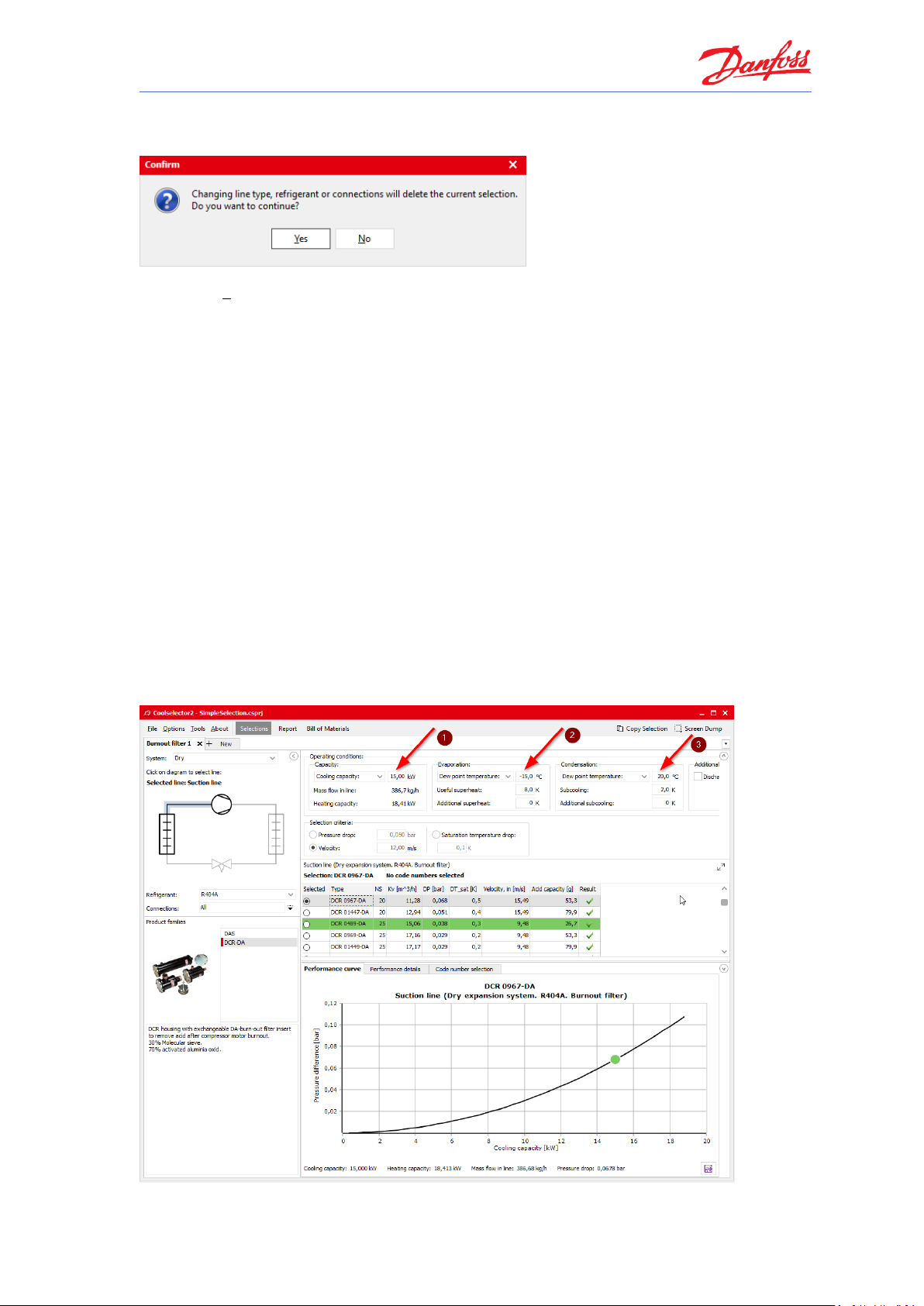

6 Changing the refrigerant

Coolselector®2 also allows you to change the refrigerant during product selection.

In our previous example we selected a DCR-DA using the standard settings (the default

refrigerant for DCR-DA is R134a). Now, let us try to change this to R404A.

Change the refrigerant by choosing R404A in the drop down ‘Refrigerant’ on the left-hand side:

Coolselector®2 User Guide

You may notice, that when you change the refrigerant, Coolselector®2 asks for a confirmation,

as this change means you are creating a new selection procedure.

By clicking “Yes”, a new selection will be made.

Please note that the ‘evaporation temperature’ and ‘condenser temperature’ are now changed

to ‘dew point temperature’. This is due to the fact that R404A is a glide-refrigerant and hence

there is reference required for the evaporator and condenser temperatures.

The current suggestion from Coolselector®2 for a best match to the operating conditions is “DCR

0967-DA”, which is different from the suggestion made by the exact same properties in the

system running with R134a; this is of course due to the different properties of the two

refrigerants.

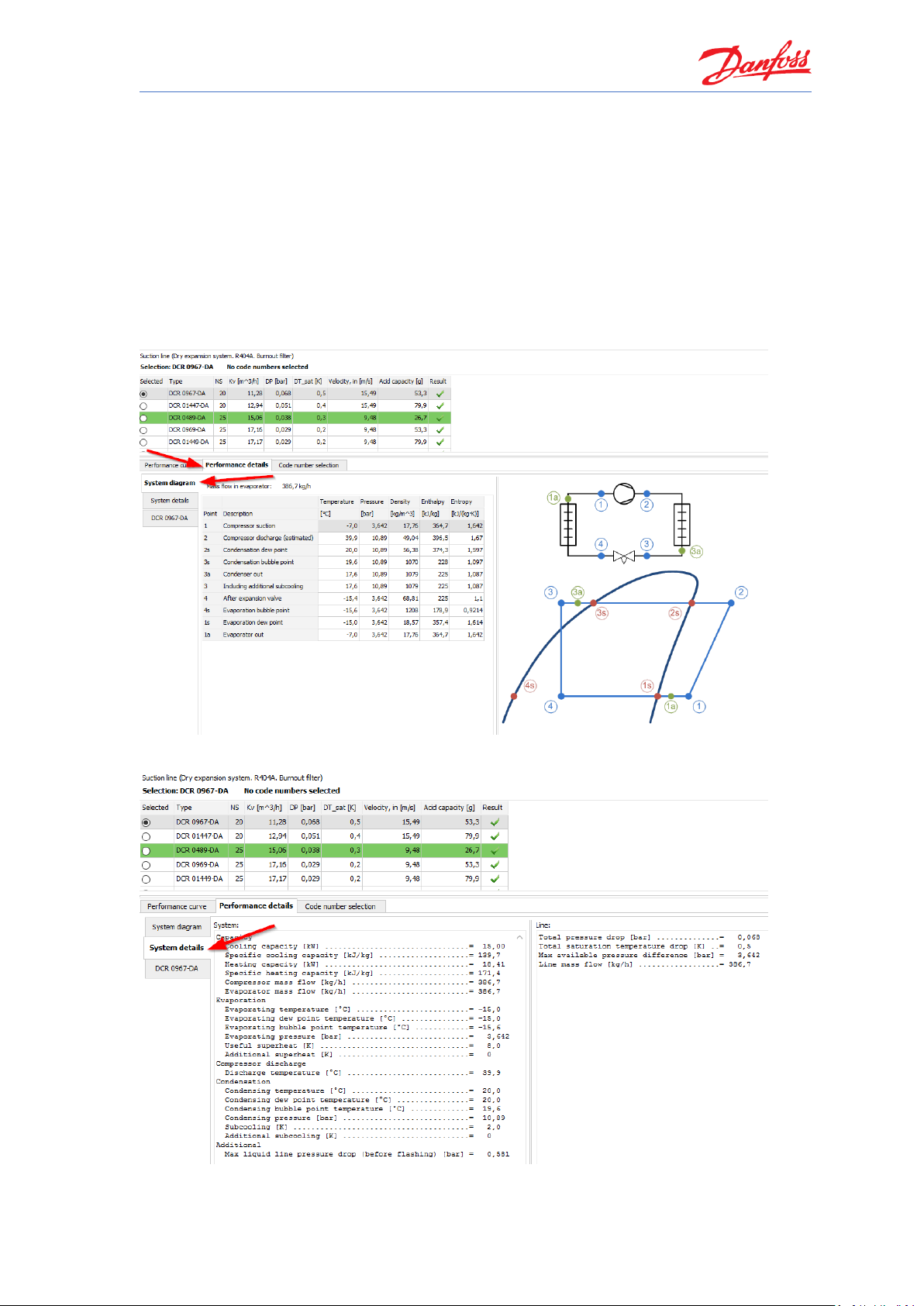

7 Description of operating conditions

Using our examples with selection of a DCR-DA using the standard Coolselector®2 settings, but

with refrigerant R404A, we now try to adjust the cooling capacity, and dew point temperatures

for evaporation and condensation, respectively.

Increasing the capacity would increase the mass flow in line and hence the speed in the

component which results in a larger component. Decreasing the evaporation temperature

increases the mass flow-rate as the cycle COP would be lower. Decreasing the condensation

temperature has the opposite effect, which is the cause of the changes in the suggestion.

Coolselector®2 User Guide

10

Changing the system properties as shown in the snippet above, means that Coolselector®2 now

suggests the “DCR 0489-DA” as the best match instead of the previous “DCR 0967-DA”.

These are merely some examples to show you that the Coolselector®2 suggestion can change

and is easily affected by even small changes to the system properties.

8 Different screen segments

In the calculation and selection interface of Coolselector®2, you will find that the screen is

separated in to five different segments:

1. Segment “1” is dedicated to the application criteria for your selection. These criteria

include, but are not exclusive to, system type, line, refrigerant, connection type, and

product family.

2. Segment “2” is where you insert your system operating conditions, such as cooling

capacity, evaporation and condensation temperature, and useful superheat. These

operating conditions have significant impact on the calculations and a lack of due care

when filling them in might lead to inapplicable results. Whereas great care has been

taken to set meaningful default conditions, there is no guarantee that these will mirror

the operating conditions for your system design.

3. Segment “3” is dedicated to the product selection criteria for the suggestion to be made

in the next segment based on your inputs in functionality criteria and operating

conditions segments.

4. In segment “4” you will find the selection table. In this area you will see the options

matching the functionality criteria and operating conditions that you specified in the

selected family. For each calculation, Coolselector®2 has a ‘suggestion’ which remains

highlighted in green based on your input in the product selection criteria input. The

selection table also includes some of the most relevant information for the product.

Coolselector®2 User Guide

5. In segment “5”, you will find the performance details and information about the chosen

product from the previous segment. This information updates as you choose other

products from the list.

9 Check the calculations details

After making any calculation and/or selection within Coolselector®2, you can click on the

“performance details” tab, and check the system diagram calculations, system details and the

performance of the selected product from the list in the corresponding tabs.

System diagram and different points calculations:

System calculation details:

Coolselector®2 User Guide

12

Product performance details:

Notice that the performance details are presented for the selected product only. You can click

on any of the products in the list and see the calculations for the selected product.

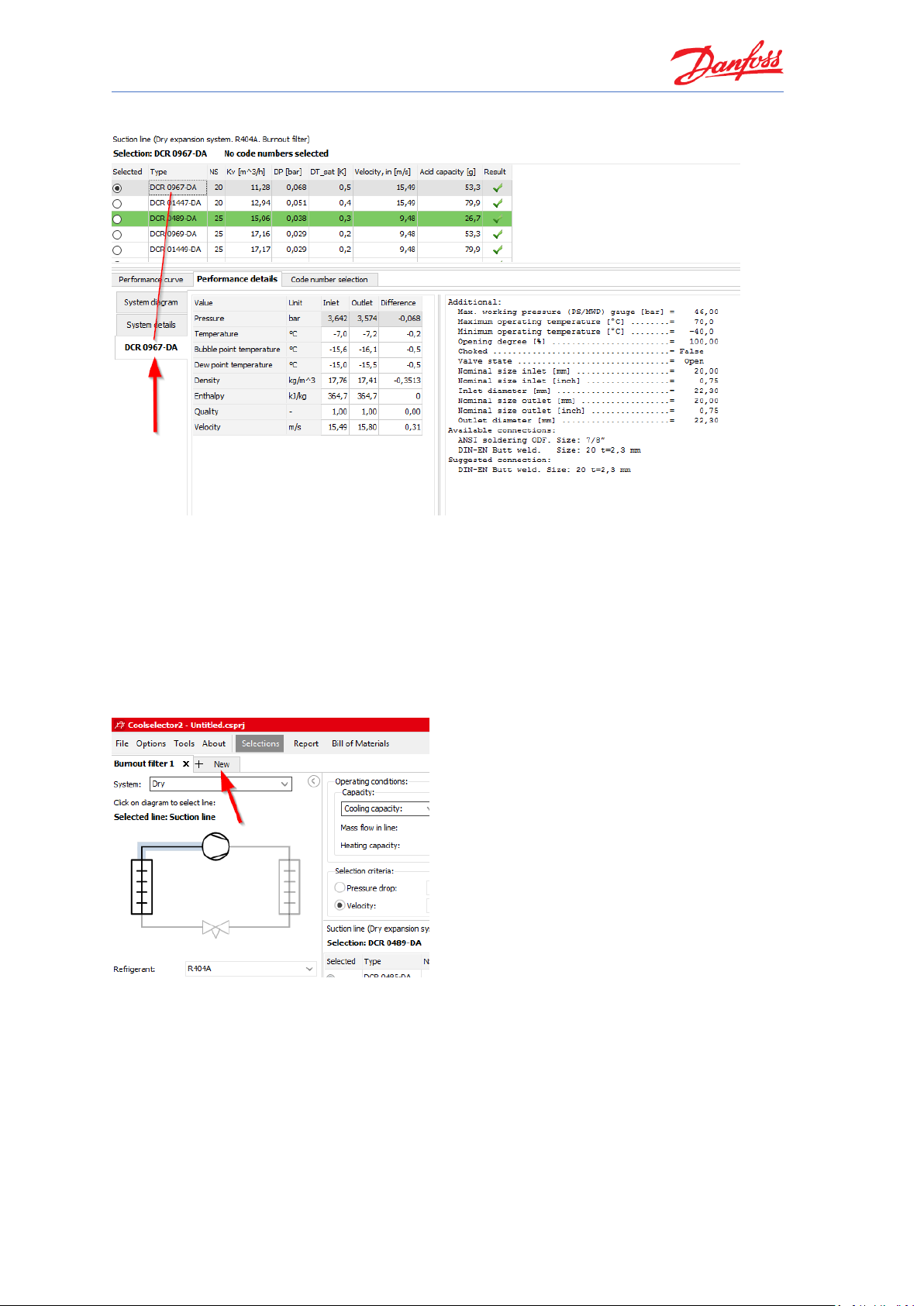

10 Adding a new tab

You can add a new tab for any new selection by clicking the “+ New” tab on the top next to your

existing tabs:

NB! Note that Coolselector®2 keeps your operating conditions for the system based on your

selection in the previous tab.

Coolselector®2 User Guide

11 Saving your project

To save the project, open File | Save Project… or click “Ctrl+S” on the keyboard. You will then be

asked for the name and the location of your project:

You can also use the “Save Project As…” option to save it with a different name or “Save and

Send…” option to save and send it to a customer or a colleague.

12 Loading a saved project

You can load the previously saved project from the menu “File | Open Project”… or by clicking

“Ctrl+O” on the keyboard.

Coolselector®2 User Guide

14

13 Selection of components in series

To calculate on components in series, first, create a new tab and select the option “Components

in Series” and then the liquid line in a dry system:

Now you need to add the components to the line. To do so, first you need to select the

functionality you would like to add to the line, and then double click on the family or drag the

family and drop it in the location that you need it.

Coolselector®2 User Guide

Add a Copper pipe with DIN-EN connection to the line and set its length to one meter:

Now you need the AKV electronic expansion valve:

Notice that Coolselector®2 automatically added a “Copper expander DIN-EN 15 × 18” between

the two components. The software recognizes the material of the piping as well as the

connection sizes and standard between two components. When two connections do not match,

it adds the required expander/reducer between the two componets for common cases, or

informs you in the row shown by the blue triangle and you can fix the connection problem

manually by adding an expander/reducer from the proper family in the piping function.

Coolselector®2 User Guide

16

Now the pipe after the expansion valve:

As can be seen, there are no warnings in the selected pipe, since the expansion is happening

entirely in the expansion valve.

It is also interesting to notice that the load for the AKV valve has increased. This is due to the fact

that the added pipes after the valve increase the pressure drop and hence the opening load of

the valve increases. Additionally, as can be seen, the target criteria for the pipe suggestion after

the expansion valve are clearly different to the one before the expansion valve.

Correct selection of an AKV valve or any other pulse modulated valve requires extra care, so

please be sure to pay close attention to your selection criteria, before making your selection.

The benefit of using components in series, is that in this case, Coolselector®2 calculates

components one after another. Furthermore, you can see the collective effect on the

performance curve for the components in the liquid line and the need for an expander/reducer

if you want to select the suggested components. The detailed calculation of each component

with the right inlet condition as shown by numbers 1-5 on the snippet can also be extracted.

Coolselector®2 User Guide

Note that if you need to replace components in the line, you can do so by simply dragging the

component to the preferred position and dropping it there.

The suggestions for components in series calculation use the default selection targets and values

in Coolselector®2. However, if you want to select another component from the same family, you

can do so by clicking on the icon of the component in the line and choosing the preferred one in

the pop-up menu. In this case, as a good design practice, it is better to avoid having a reducer

after the expansion valve. To do so, you can simply remove the reducer using the close sign on

the top right-hand side of the reducer and select the size of the pipe which fits the expansion

valve outlet:

You can see the share of each component on the pressure drop on top of the calculation details.

As you can see, the connections fit and, furthermore, the pressure drop after the expansion

valve is reduced significantly and is happening correctly in the AKV valve. You can also see the

relevant calculation details such as min and max capacity in the details.

Coolselector®2 User Guide

18

14 Compressor selection

To select a compressor for a system, we will use the following requirements:

1. Application: Refrigeration

2. Power supply: 50 Hz

3. Refrigerant: R404A

4. All compressor types.

5. Fixed speed

To begin selection, create a new tab and choose the option “Compressors and condensing

units”. Then select “Compressors”.

Check the operating conditions are set to:

Set the application criteria as they were specified in the beginning of this section:

1. Application: Refrigeration

2. Power supply: 50 Hz

3. Refrigerant: R404A

4. All compressor types.

5. Fixed speed

Coolselector®2 User Guide

Coolselector®2 now suggests MLZ058T4 as the best possible match:

The suggested compressor can achieve the requirement for this cycle and match the demand.

You can check that in the last column which indicates the match of the compressor to the given

operating conditions.

You can check the details about the compressors in the list on the performance tab in the

product performance and information segment. To check the COP at the working conditions,

choose the performance tab, then select the COP. Now you can check the COP for the

Coolselector®2 User Guide

20

compressor on working conditions:

You can also check the COP at this exact working condition in the selection segment:

15 Understanding superheat

Some superheat is required for the refrigerant at the compressor inlet to ensure avoidance of

liquid droplets in the compressor.

The useful superheat is the superheat inside the evaporator which contributes to the cooling

capacity. However, a very high useful superheat decreases the evaporator efficiency as well as

the density at the evaporator outlet which results in higher compressor consumption. This value

is set to 8 K by default in Coolselector®2.

Additional superheat happens after the evaporator in the suction line. A longer length of the

suction line would result in a higher additional superheat. This is set to zero by default as it is

highly affected by the length and size of the suction line which is not provided to Coolselector®2.

However, you should try to provide an accurate value or estimation for a good selection.

If you change the additional superheat to 5 K, the suggested compressor in Coolselector®2 will

change to MLZ058T2, which allows a slightly higher volumetric flow rate to support the given

cooling capacity.

The reason is that increasing the useful superheat would result in decrease of density after the

suction line at the compressor inlet. The mass flow rate required for the cooling capacity would

be the same (you can check that in the performance details tab), but a lower density means a

higher volumetric flow rate which results in demand for a slightly larger compressor. Another

important aspect regarding additional superheat is the discharge temperature which can be

affected significantly and would affect selection of components in the discharge line, as well as

compressors or condensing units.

Hence providing additional superheat correctly is important for proper selection and suggestion.

Coolselector®2 User Guide

16 Electronic controller selection

To select a controller for our system, we will use the following requirements:

1. Expansion Valve Type: EEV AKV

2. Number of Compressors: Single compressor

3. Communication: MOD bus

To begin selection, create a new tab and choose the option “electronic controls”. Then select

“case controllers”:

If you apply the requirements in the selection criteria segment, Coolselector®2 will suggest the

controllers that can satisfy the requirements:

Coolselector®2 User Guide

22

You can add additional criteria such as the “Dual case sections” requirement in the

“Refrigeration System” section:

As is evident from above, Coolselector®2 suggests the AK-CC 550B as the best matched

alternative for the given selection criteria.

17 Creating a report

Now, after going through the selections and calculation phase, we will create a report.

View the report by clicking on “Report” in the menu bar of Coolselector®2. This opens the report

section:

Coolselector®2 User Guide

The segment for the project information will be blank if you did not enter this information

before (in the settings). You can fill this in and modify the report to suit your requirements, the

following steps will show you how.

To add your name to Coolselector®2, open “Options | User, Language and Country

…” and then add your name and click “OK”

Now your name should be on the report preview section. You can also add a project

name. After that, click “Update” to update the report preview:

You can add/remove included information in the report. To do so, click on the “+”

sign beside each list to see the available options, or click on the “Collapse all”

Coolselector®2 User Guide

24

button. Add the required fields and click update and check the result. Note that

each list belongs to one tab on your “Selections” section:

Coolselector®2 User Guide

Click the “PDF” button at the top of the report preview to export your report as a

PDF. You have multiple options for your exported PDF, such as printing specific

pages in the report, adding extra information, or securing your pdf file with a

password. Investigate those options for further details.

You will then be asked for the name and the location of the document and you can

click “save”. If you selected the option “Open after export”, the report will then

automatically open.

18 Selecting a code number

Coolselector®2 will enable you to select the relevant code numbers for the selected products.

Depending on the product type, this code number can be accessed/modified differently.

If you are currently in the ‘report’ (following section 17), first, go to the “Selections” section by

clicking on the “Selections” button in the menu bar (see “1” in the snippet below).

Next, go to any open tab (in this case “Burnout filter 1” – see “2” in the snippet below) and

select the tab for code number selection (“3” in the snippet below). Then select the proper

casing and filters. E.g. in an example with a burnout filter, we would like to have the DIN

connection casing with copper connection to match our installation and a pack of 8 filter cores:

Coolselector®2 User Guide

26

Then go to the tab for liquid-line calculation and select the code number for the AKV valve. E.g.

we select the one with DIN-EN connection again to match our selection:

Now, for the compressor code number you need to go the “Information” tab, where you can

select the code number and also see other information about the compressor, including the

Coolselector®2 User Guide

spare parts available for the compressor:

And for the case controller the code number is just visible after you click on your selected

controller:

19 Bill of materials

After you have selected the relevant code numbers for the products in your Coolselector®2

project, you can check out the bill of materials. You just need to click on the “Bill of Materials”

button in the menu bar:

Coolselector®2 User Guide

28

To include the piping, you just need to click on the option “include piping”:

To export the bill of materials as an Excel file, click on the “Excel” button at the top of the bill of

materials preview. Then specify the destination and the name for the exported file:

Coolselector®2 User Guide

20 Customization – units and conversions

To convert all units in Coolselector®2 from the default international units to e.g. American or SI

units is very simple. To change the unit system to e.g. American units, you simply need to select

it in “Options | Units | American”:

Coolselector®2 User Guide

30

You can also select the “Tools | Show operating conditions” menu and see the equivalent of

operating conditions in different unit systems:

21 Customization – change application

Coolselector®2 allows you to customize your product view to either ‘all applications’,

‘commercial applications’ or ‘industrial applications’ respectively.

You can set the preferred application to e.g. commercial applications in “Options | Preferences |

Commercial applications”:

You will notice that following this change, the “new” tab interface has changed in the order as

well as the available options. This is to provide a better overview for you.

You can see that, following the change to ‘commercial applications’, some of the options which

are more specific to industrial applications such as “ICF valve station” are now no longer part of

Coolselector®2 User Guide

the “new” tab interface:

22 Customization – columns in selection table

You can modify which columns you see in your selection table and change the order for the

calculations and selections made in the “Valve and Line Components” option as well as

“Compressors”. To do so, right click on the table header and select “Manage Columns…”. This is

step 1 and 2 in the following snippet:

To remove the columns e.g. after the “Mass flow”, you can simply uncheck them in

the list as shown by step 3.

Coolselector®2 User Guide

32

To replace “Heating” with “COP cooling”, you should click on Heating and then click

on the top arrow as shown by steps 4 and 5.

Then you can click OK to update the table. Coolselector®2 will remember your

modifications next time you run it and you can always go back to the default table by

clicking on default in “Manage Columns…”:

23 Customization – user interface

Coolselector®2 allows you to resize different segments or minimize the segments to see the

information more clearly. Coolselector®2 will remember previous modifications, but sizes will

reset to default when you start Coolselector®2 again.

You can minimize the “Operating conditions” segment by clicking on the button at

the top right-hand side of the segment:

Coolselector®2 User Guide

To resize any of the segments, you can click and drag on the border in order to see

information more easily:

Coolselector®2 User Guide

34

After setting the general criteria and operating conditions and the product

suggestion criteria, sometimes it is handy to expand the segments for the selection

table and product performance and information to fullscreen. You can do that by

clicking on the expand button in the top right-hand corner of the selection table:

Coolselector®2 User Guide

24 Customization - preferences

The settings we discuss in this part of the user guide do not need to be modified in most cases,

as we, in the Coolselector®2 team, constantly try to optimize the default preferences based on

our customer requirements.

To create custom preferences, use “Options | Preferences | Edit preferences…”:

You will see the “Preferences” window. On top you have the different preferences which are

customizable.

You can select “Dry expansion systems” among the options for the “Default system” and

add/remove options for your selection and calculations among the product pages as well as

control their sorting order within the interface:

Coolselector®2 User Guide

36

Next, you can go to the “Operating conditions” tab by clicking on the top bar and changing the

default operating conditions:

You can also go to the “Valves and Line Components” tab and select the type of components you

would like to see for your selections/calculations and the families in each functionality, as well as

connection sizes and some more options:

In the tab for compressors and condensing units, you will find the relevant settings for those

products. You can choose which products to see and even see the rating conditions and create

Coolselector®2 User Guide

custom ones. You can also set the limits to those you prefer:

If you click the “OK” button to apply your settings, Coolselector®2 will ask you to name your

preferences and save them. Coolselector®2 will keep the default settings intact so you can

always go back to the predefined preferences easily:

Coolselector®2 User Guide

38

Next time you open Coolselector®2, it will keep your preferences and you can see that in

the list of the preferences. You can come back to this menu and edit, rename or delete

your preferences at any time.

You can also see that the new tab menu has changed based on your new preferences.

On the top right-hand side of the window you will be able to see the recent projects and

load them easily.

25 Advanced settings – calculation and selection criteria

Please note that changing the following settings can affect the results of the selection or

calculation process and lack of due care can have a negative effect on the suggestions and

default calculations. However, the advanced settings enable you to customize and improve your

experience and even modify the calculations if you find it necessary.

Coolselector®2 User Guide

The default values for the calculations can be changed in “Valves and Line Components |

Advanced | Default values” in the preferences window:

The selection criteria for all the components supported by Coolselector®2 can be found in

“Valves and Line Components | Advanced | Selection critera”:

Coolselector®2 User Guide

40

26 Advanced settings – custom unit system

To create a custom unit system, you need to go to “Options | Units | Custom…”. Then you will

find the unit used for each of the default unit systems and you can create your own:

By clicking OK, you will be asked to save your custom unit system and give it a name. It will then

appear on the list of unit systems similar to your custom preferences.

Coolselector®2 User Guide

│ │2019.06

Loading...

Loading...