Page 1

Fitters’ Notes Condensing units

Contents Page

General information on operating Danfoss condensing units ....................................... 3

Equipment conguration .......................................................................... 3

Power supply and electrical equipment ........................................................ 3

Hermetic compressors ............................................................................. 4

Condensers and fans .............................................................................. 4

Stop valves ........................................................................................ 4

Receiver Pressure container ordinance ............................................................. 5

Terminal box ...................................................................................... 5

Safety pressure monitors .......................................................................... 5

Setup ............................................................................................. 5

Protective weather-proof housing .............................................................. 6

Careful installation ................................................................................ 6

Contamination and foreign particles ........................................................... 6

Doing the pipe work ........................................................................... 6

Tubing layout of the condensing units with 1-cylinder compressors

types TL, FR, NL, SC and SC-TWIN ........................................................... 6

Tubing layout of the condensing units with hermetic Maneurop®

reciprocating piston compressors, 1-2-4 cylinder ............................................ 8

Leak check .................................................................................... 8

Soldering ..................................................................................... 9

Protective gas ................................................................................. 9

Evacuating and lling ............................................................................ 10

Exceeding the max. allowable operational lling capacity and setting up outdoors .................11

General information: ......................................................................... 11

“Pump-down” .................................................................................... 13

Max. allowable temperatures ..................................................................... 14

DKRCC.PF.000.G3.02 / 520H6471

Condensing

units

1

Page 2

Notes

2

Page 3

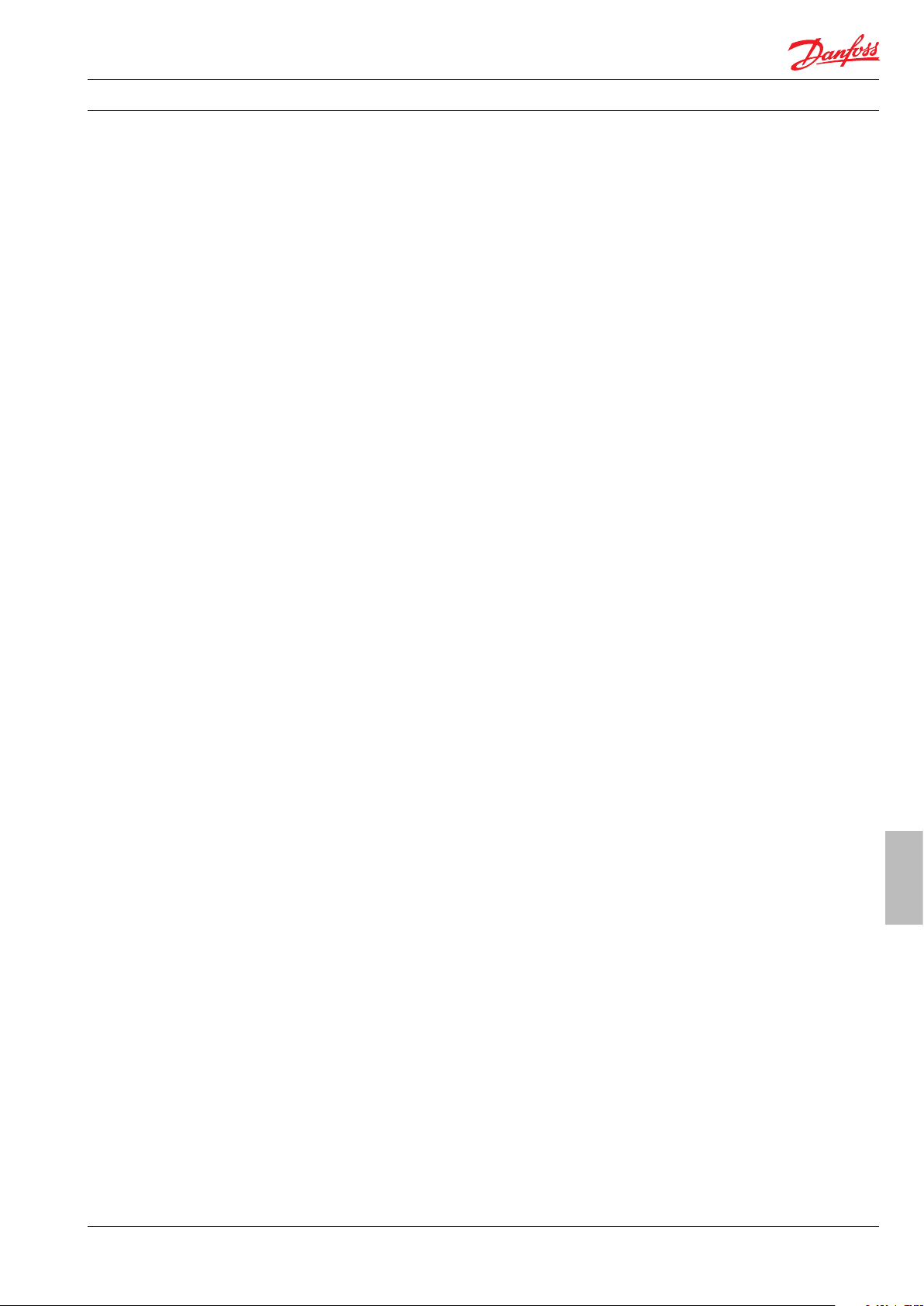

Fitters’ Notes Condensing units

General information

on operating Danfoss

condensing units

In the following you will nd general information

and practical tips for using Danfoss condensing

units. Danfoss condensing units represent

an integrated range of units with Danfoss

reciprocating piston compressors. The versions

and con gurations of this series correspond

to the requirements of the market. To give

an overview of the program, the individual

subsections are generally divided into the

various hermetic compressors mounted on the

condensing units.

Condensing units with 1-cylinder compressors

(types TL, FR, NL, GS, SC and SC-TWIN).

Condensing units with hermetic 1 -2 and 4

cylinder Maneurop® reciprocating piston

compressors MTZ, NTZ and MPZ.

Equipment con guration Danfoss condensing units are delivered with a

compressor and condenser mounted on rails

or a base plate. Terminal boxes are prewired. In

addition, stop valves, solder adaptors, collectors,

dual pressure switches and power cables with

3-pin grounded plugs complete the delivery kit.

Power supply and

electrical equipment

Condensing units with 1-cylinder compressors

(types TL, FR, NL, GS, SC and SC-TWIN)

These condensing units are equipped with

hermetic compressors and fans for 230 V 1-,

50 Hz power supply.

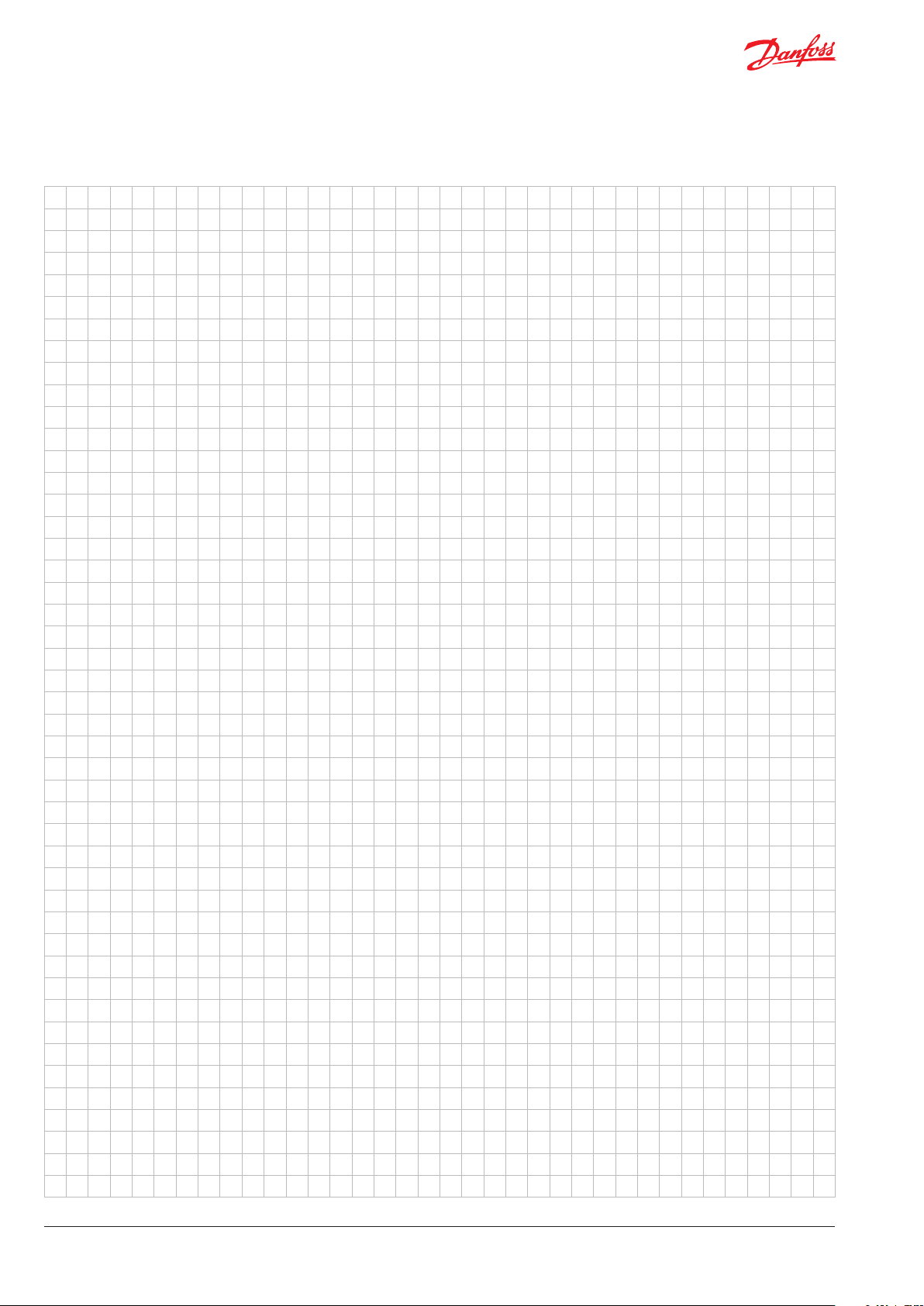

The compressors are equipped with an HST

starting device consisting of a starting relay

and a starting capacitor. The components can

also be delivered as spare parts.

The starting capacitor is designed for short

activation cycles (1.7% ED). In practice, this

means that the compressors can perform up

to 10 starts per hour with an activation duration of 6 seconds.

Please consult the corresponding Danfoss

documentation or the current price list for

details and ordering numbers. The Danfoss sales

company responsible for your area will be glad

to help you make your selection.

Condensing units with hermetic 1-2 and

4 cylinder Maneurop® reciprocating piston

compressors MTZ and NTZ.

These condensing units are equipped with

hermetic compressors and fan(s) for di erent

voltage supplies:

• 400 V-3ph-50 Hz for compressor and for

fan(s).

• 400 V-3ph-50Hz for compressor and

230 V-1ph-50Hz for fan(s) (the capacitor(s)

of the fans are included inside the electrical

box).

• 230 V-3ph-50Hz for compressor and

230 V-1ph-50Hz for fan(s) (the capacitor(s)

of the fans are included inside the electrical

box).

• 230 V-1ph-50Hz for compressor (the starting

device (capcitors, relay) is included into the

electrical box) and 230V-1ph-50Hz for fan(s)

Condensing

units

The starting current of the Maneurop® threephase compressor can be reduced through the

use of a soft starter. CI-tronic

TM

soft start, type

MCI-C is recommended for use with this type of

compressor. The starting current can be reduced

up to 40% depending on the compressor model

and the model of soft start used. The mechanical

load that occurs at start-up is also reduced,

which increases the lifespan of the internal

components.

For details on the CI-tronic

TM

MCI-C soft start,

please contact your local Danfoss dealer.

The number of compressor starts is limited

to 12 per hour in normal conditions. Pressure

equalisation is recommended when MCI-C is

used.

3DKRCC.PF.000.G3.02 / 520H6471

Page 4

Fitters’ Notes Condensing units

Hermetic compressors The hermetically sealed compressor types w,

FR, NL, GS, SC and SC TWIN have a built-in

winding protector. When the protector is

activated, a switch-o time of up to 45 minutes can

occur as the result of heat storage in the motor.

The single-phase Maneurop® compressors

MTZ and NTZ are internally protected by a

temperature/current sensing bimetallic protector,

which senses the main and start winding currents

and also the winding temperature.

The three-phase Maneurop® reciprocating piston

compressors MTZ and NTZ are equipped against

over-current and over-temperature by internal

motor protection. The motor protection is located

in the star point of the windings and opens all

3 phases simultaneously via a bimetallic disk.

After the compressor has switched o via the bimetallic disc, reactivation can take up to 3 hours.

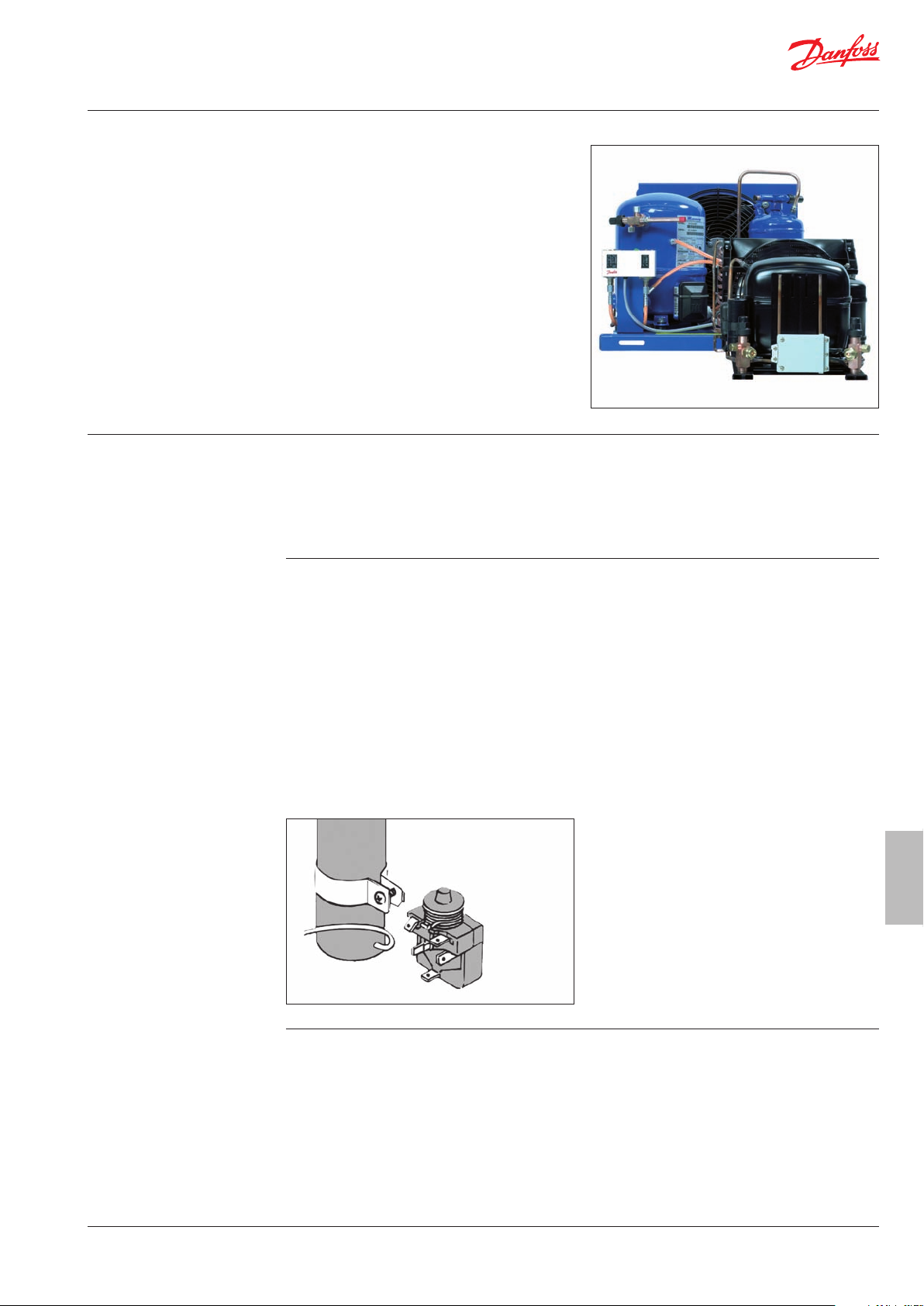

Condensers and fans Highly eective condensers allow a broader

range of usage at higher ambient temperatures.

One or two fan motors are used per condensing

unit depending on the output value.

In addition, the fans can be equipped, e.g. with

a Danfoss Saginomiya fan speed regulator, type

RGE. This allows good condensing pressure

control and reduces the noise level. The fans

are provided with self-lubricating bearings,

which ensures many years of maintenance-free

operation.

If the motor does not work, you can determine by

means of resistance measurement whether the

cause is a switched o winding protection switch

or a possible broken winding.

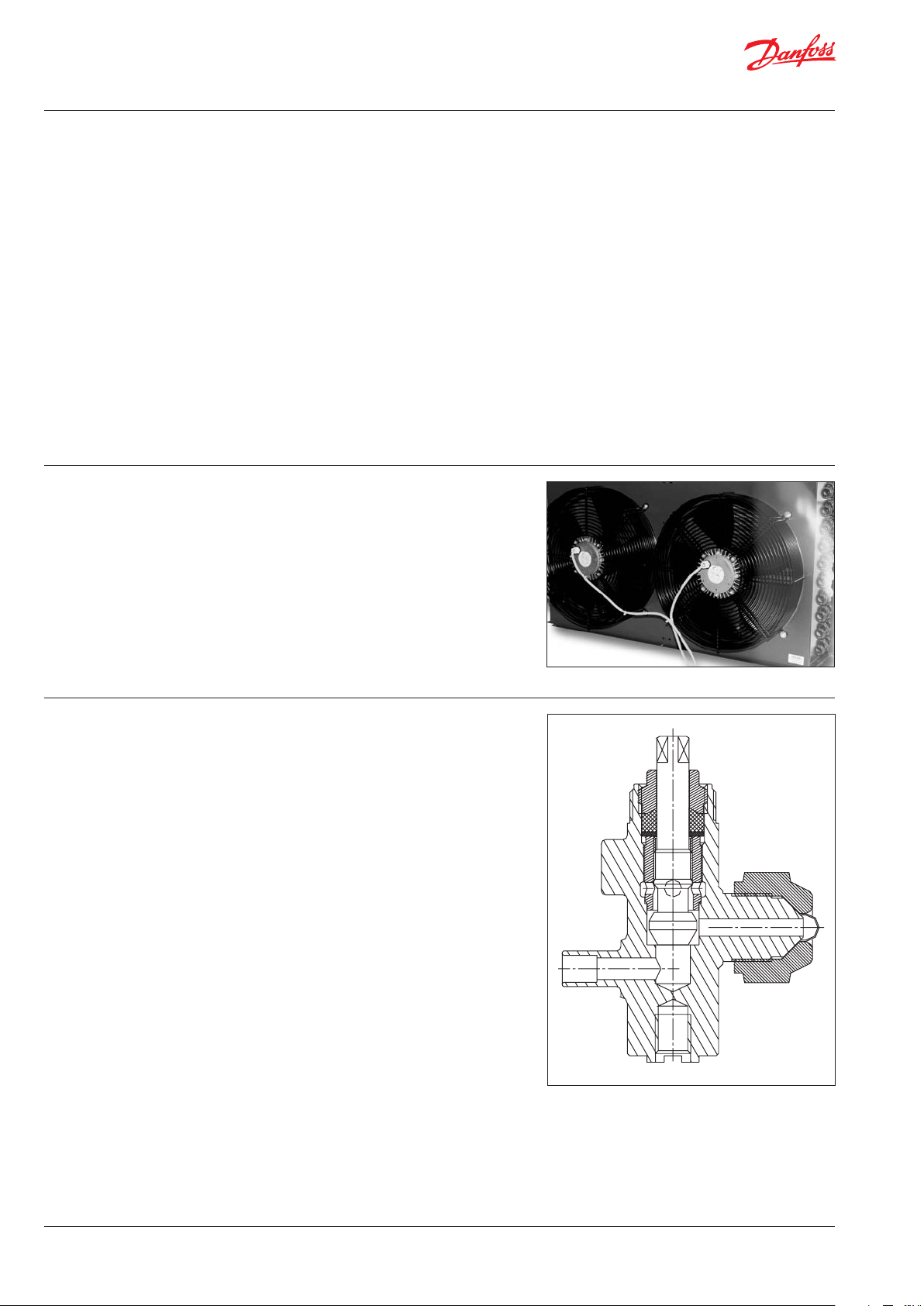

Stop valves Danfoss condensing units are provided with stop

valves on the suction and liquid side.

The stop valves of the condensing units with

the 1-cylinder compressors (types TL, FR, NL,

GS, SC and SC TWIN) are closed by turning the

spindle clockwise to te soldered piece. This opens

the ow between the pressure gauge connection

and the are connection. If you turn the spindle

counter-clockwise to the rear stop, the pressure

gauge connection is closed. The ow between

the soldered and the are connection is free. In

the centre position, the ow through the three

connections is free. The accompanying soldered

adapters help prevent are connections and to

make the system hermetic.

The stop valves of the condensing units with

Maneurop® reciprocating piston compressors

MTZ and NTZ are directly tted into the suction

and discharge rotalock ports of the compressor

and on the receiver. The suction valve is provided

with long, straight tube pieces in such a manner

that soldered connections can be carried out

without disassembling the Rotalock valve.

4 DKRCC.PF.000.G3.02 / 520H6471

Page 5

Fitters’ Notes Condensing units

Receiver Liquid receiver is standard on Danfoss

condensing units for use with expansion valves.

The expansion valve is regulating the level in

the receiver buer (the de- or increasing ow

of the refrigerant). The receivers from an internal

volume of 3 l onwards are equipped with a

Rotolock Valve.

Terminal box The Danfoss condensing units are electrically

pre-wired and equipped with a terminal box.

Thus the power supply and additional electrical

wiring can be easily tted. The terminal box of

the condensing units with Maneurop®

compressors is equipped with screw type

connector blocks for both power and controls.

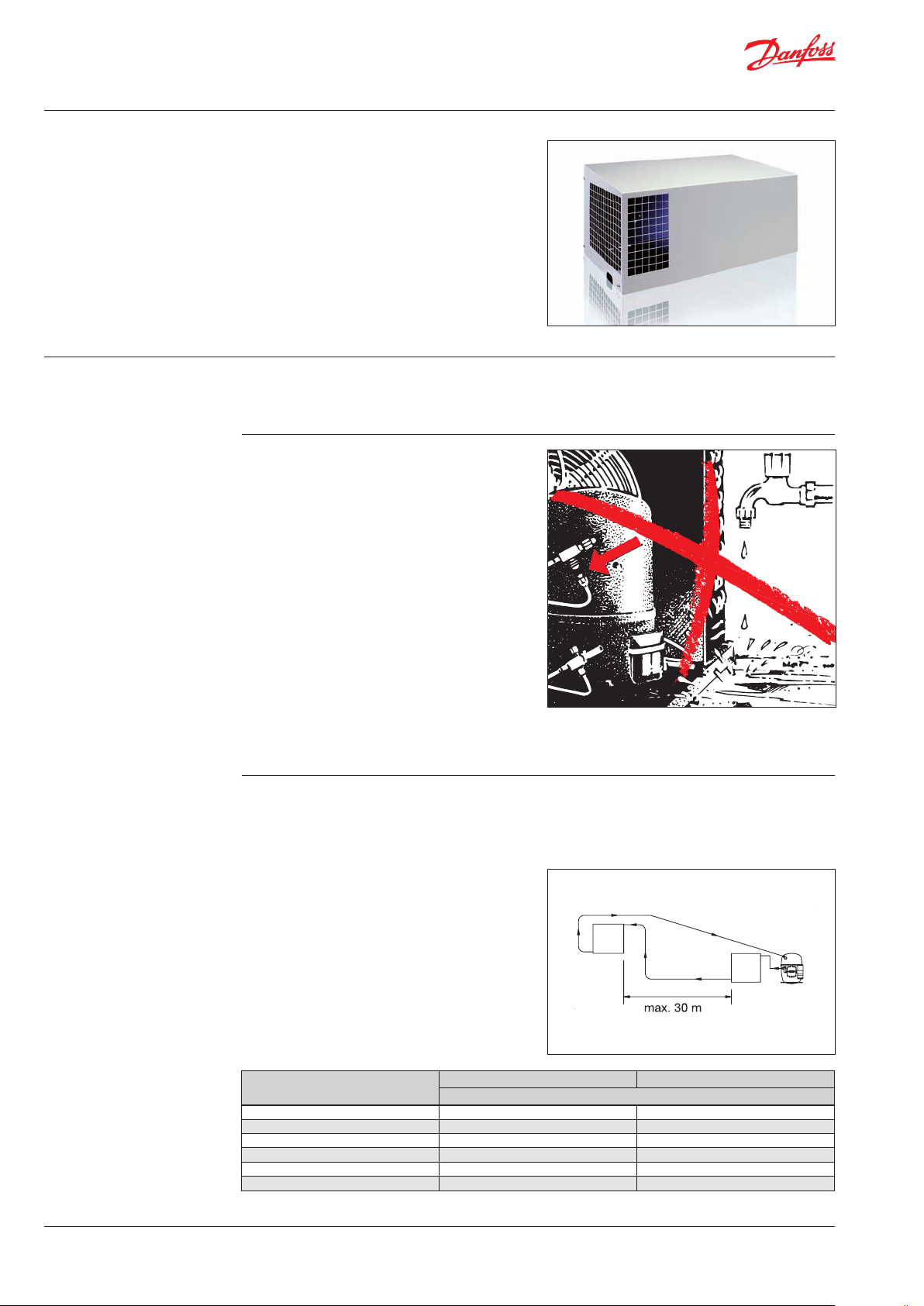

Safety pressure monitors Danfoss condensing units can be ordered

with safety pressure switches KP 17 (W, B…).

Condensing units that do not come equipped

with pressure switches from the factory must

be equipped with a pressure switch at least

the high-pressure side in systems with

thermostatic expansion valves as per EN 378.

The electrical connections of each component

(compressor, fan(s), PTC, pressure switch) are

centralised into this box. A wiring diagram is

available in the cover of the electrical box.

These terminal boxes are protected to a degree

of IP 54.

LP

Start

Stop

AB

Diff.

Setup

HP

Stop

Start

AB

Diff.

The following settings are recommended:

Refrigerant Low pressure side High pressure side

Cut in (bar) Cut o (bar) Cut in (bar) Cut o (bar)

R407C 2 1 21 25

R404A/R507 MBP 1.2 0.5 24 28

R404A/R507 LBP 1 0.1 24 28

R134a 1.2 0.4 14 18

Danfoss condensing units must be set up in a

well ventilated location.

You must ensure that there is sucient fresh air

for the condenser at the intake end.

In addition, you must ensure that no cross-ow

The ventilator motor is connected in such a way

that the air is drawn in via the condenser in the

direction of the compressor.

For optimal operation of the condensing unit,

the condenser must be cleaned regularly.

occurs between the fresh air and the exhaust air.

Condensing

units

5DKRCC.PF.000.G3.02 / 520H6471

Page 6

Fitters’ Notes Condensing units

Protective weather-proof

housing

Careful installation

Contamination and

foreign particles

Danfoss condensing units that are set up

outside must be provided with a protective

roof or with protective weather-resistant

housing. The scope of delivery includes

optional, high-quality protective weatherproof housings.

More and more commercial cooling and

air-conditioning systems are installed with

condensing units that are equipped with

Contamination and foreign particles are among

the most frequent causes that negatively impact

the reliability and lifespan of cooling systems.

During the installation, the following types of

contamination can enter the system:

Scaling during soldering (oxidations)

Flux residue from soldering

Humidity and outside gasses

Shavings and copper residues from deburring

the tubing

hermetic compressors. High demands are put

on the quality of the installation work and the

alignment of such a cooling system.

Doing the pipe work

Tubing layout of the

condensing units with

1-cylinder compressors

(types GS, TL, FR, NL, SC

and SC-TWIN)

For this reason, Danfoss recommends the

following precautions:

Use only clean and dry copper tubing and

components that satisfy standard DIN 8964.

Danfoss oers a comprehensive and integral

range of products for the necessary cooling

automation. Please contact your Danfoss

dealer for additional information.

When laying the tubing, you should try to make

the shortest and most compact pipe work

possible. Low-lying areas (oil traps), where oil

might accumulate should be avoided.

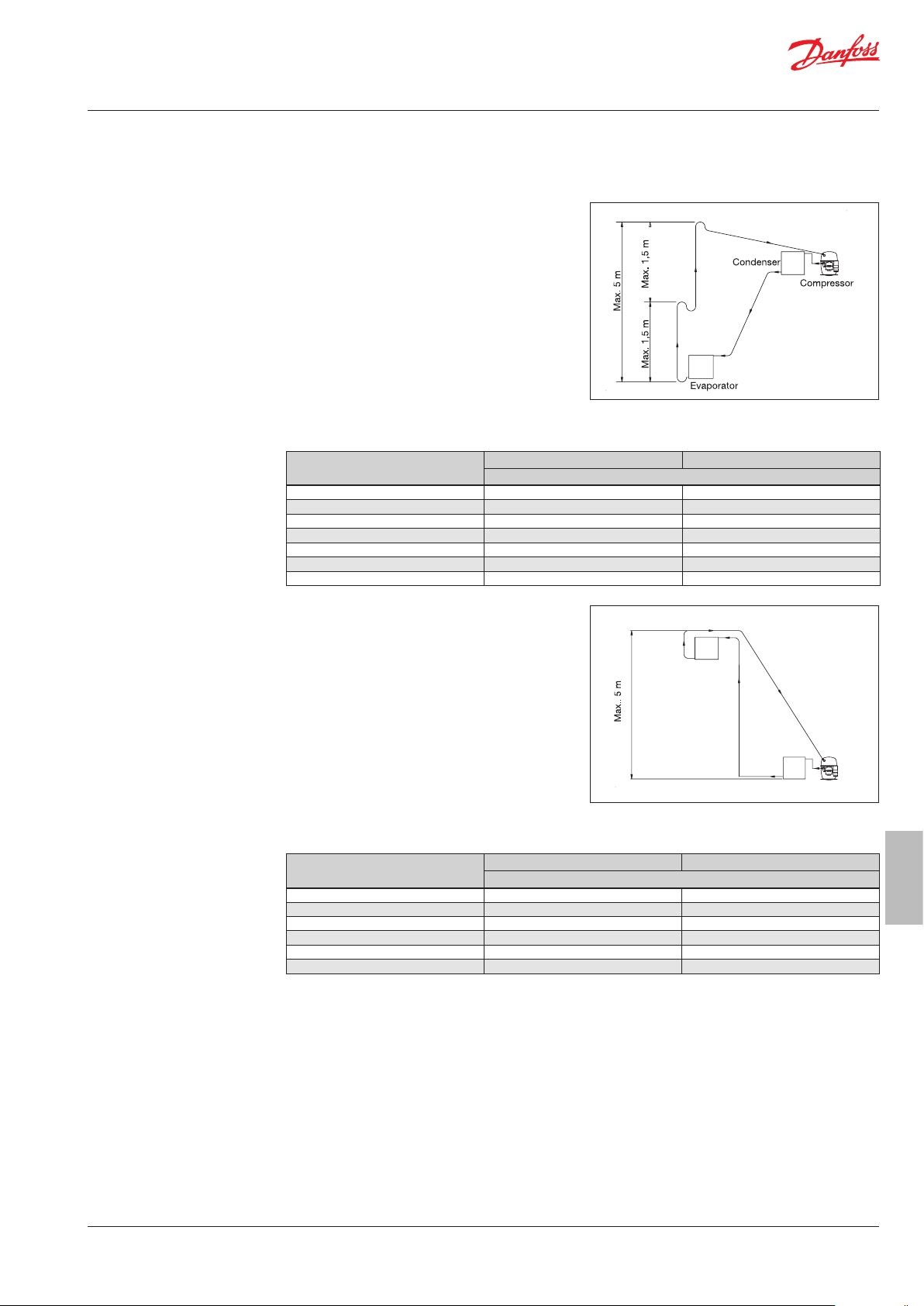

1. Condensing unit and evaporator are

located on the same level.

The suction line should be arranged slightly

downward from the compressor. The max.

permissible distance between the condensing

unit and the cooling position (evaporator) is

30 m.

TL 8 6

FR 10 6

NL 10 6

SC 10 8

GS 12/16 10

SC-TWIN 16 10

Evaporator

Suction Line Liquid Line

Diameter copper pipe [mm]

Condenser

Compressor

6 DKRCC.PF.000.G3.02 / 520H6471

Page 7

Fitters’ Notes Condensing units

Tubing layout of the

condensing units with

1-cylinder compressors

(types TL, FR, NL,SC, GS and

SC-TWIN) (continued)

To ensure the oil return, the following crosssections are recommended for the intake and

liquid lines:

2. The condensing unit is arranged above the

evaporator.

The ideal height dierence between the

condensing unit and the evaporator position

is a max. of 5 m. The tube length between

the condensing unit and the evaporator

should not exceed 30 m. The suction lines

must be laid out with double arcs in the form

of oil traps above and below. This is done

using a U-shaped arc at the lower end and a

P-shaped arc at the upper end of the vertical

riser. The max. distance between the arcs is

1 to 1.5 m. To ensure the oil return, the

following pipe diameters are recommended

for the suction and liquid lines:

Suction Line Liquid Line

Diameter copper pipe [mm]

TL 8 6

FR 10 6

NL 10 6

SC 12/15 10 8

All other SCs 12 8

GS 16 10

SC TWIN 16 10

3. The condensing unit is arranged under the

evaporator.

The ideal height dierence between the

condensing unit and the evaporator is a max.

of 5 m. The tube length between the

Evaporator

condensing unit and the evaporator should

not exceed 30 m. The suction lines must be

laid out with double arcs in the form of oil

traps above and below. This is done using a

U-shaped arc at the lower end and a P-shaped

arc at the upper end of the vertical riser. The

max. distance between the arcs is 1 to 1.5 m.

To ensure the oil return, the following pipe

diameters are recommended for the suction

and liquid lines:

Suction Line Liquid Line

Diameter copper pipe [mm]

TL 8 6

FR 10 6

NL 10 6

SC 12 8

GS 16 10

SC TWIN 16 10

Condenser

Compressor

Condensing

units

7DKRCC.PF.000.G3.02 / 520H6471

Page 8

Fitters’ Notes Condensing units

Tubing layout of the

condensing

units with hermetic

Maneurop®

reciprocating piston

compressors,

1-2-4 cylinder

The tubes should be laid out to be exible

(dispersible in three planes or with “AnaConda”).

When laying the tubing, you should try to make

the shortest and most compact tubing network

possible.

Low-lying areas (oil traps), where oil might

accumulate should be avoided. Horizontal lines

should be laid inclined slightly downward toward

the compressor. To guarantee the oil return, the

suction speed at the risers must be at least

8-12 m/s.

For horizontal lines, the suction speed must

not fall below 4 m/s. The vertical suction lines

must be laid out with double arcs in the form of

oil traps above and below. This is done using a

U-shaped arc at the lower end and a P-shaped

arc at the upper end of the vertical tubing. The

maximum height of the riser is 4 m, unless a

second U-shaped arc is attached.

max. 4 m

max. 4 m

0.5 fall,

4 m/s or more

U shaped arc as short as possible

8 to 12 m/s

0.5 fall,

4 m/s or more

To condenser

U shaped arc

Evaporator

Leak check

If the evaporator is mounted above the

condensing unit, you must ensure that no liquid

refrigerant enters the compressor during the

work-stoppage phase. To avoid condensation

droplets from forming and to prevent an

unwanted rise of the intake gas over-heating,

the suction line must generally be insulated.

Adjusting the intake gas over-heating is done

individually for each use. You can nd more

detailed information in the following sections

under “max. permitted temperatures.“

Danfoss condensing units are checked in the

factory for leaks using helium. They are also

lled with a protective gas and must therefore

be evacuated from the system. In addition, the

added refrigerant circuit must be leak-checked

using nitrogen. The suction and liquid valves of

the condensing unit remain closed during this.

The use of coloured leak-checking agents will

void the warranty.

U shaped arc as short as possible

8 to 12 m/s at

lowest capacity

From evaporator

U shaped arc as short as possible

To compressor

8 to 12 m/s at

highest capacity

8 DKRCC.PF.000.G3.02 / 520H6471

Page 9

Fitters’ Notes Condensing units

Soldering The most common solders are alloys of

copper, zinc and tin. For “silver, copper“ (silver

content ~ 40 %) the melting point is between

approx. 655°C and 755°C. The coated silver

solder contains the ux needed for soldering.

This should be removed after soldering.

Silver solder can be used to solder together

various materials, e.g. steel/copper. Ag 15%

solder is su cient to solder copper to copper.

Protective gas

At the high soldering temperatures under the

in uence of ambient air, oxidation products form

(scaling).

The system must therefore have protective gas

owing through it when soldering. Supply a weak

stream of a dry, inactive gas through the tubes.

Only begin soldering when there is no

atmospheric air left in the a ected component.

Initiate the work procedure with a strong stream

of protective gas, which you can reduce to a

minimum when you start soldering.

This weak ow of protective gas must be

maintained during the entire soldering process.

The soldering must be done using nitrogen and

gas with a gentle ame. Only add the solder

when the melting point temperature has been

reached.

Fork burner:

Condensing

units

9DKRCC.PF.000.G3.02 / 520H6471

Page 10

Fitters’ Notes Condensing units

Evacuating and lling

The vacuum pump should be able to suction o

the system pressure to approx. 0.67 mbar, in two

stages if possible.

Humidity, ambient air and protective gas should

be removed. If possible, provide for a two-ended

evacuation, from the suction and the liquid side

of the condensing unit.

Use the connections at the suction and discharge

valves of the condensing units.

For lling the system, a lling level indicator,

lling cylinder and/or a scale is used for smaller

condensing units. The refrigerant can be fed into

the liquid line in the form of a liquid if a lling

valve is installed.

Otherwise, the refrigerant must be fed into the

system in gaseous form via the suction stop

valve while the compressor is running (break the

vacuum beforehand).

Please observe that the refrigerants R404A, R507

and R407C are mixtures.

The refrigerant manufacturers recommend lling

R507 as a liquid or gas, whereas R404A and

especially R407C should be lled in liquid form.

Therefore we must recommend that R404A, R507

and R407C are lled as described using a lling

valve.

If the amount of refrigerant to be lled is

unknown, continue lling until no bubbles

are visible in the inspection glass. During this,

you need to keep a constant watch on the

condensing and suction gas temperature in order

to guarantee normal operating temperatures.

Please observe the following procedures for

evacuating and lling the Danfoss condensing

units with the 1-cylinder compressors, types

TL, FR, NL, SC and SC TWIN.

For evacuating, both external hoses are connected

to a service battery aid and the condensing unit is

evacuated with stop-valves 1 and 2 open (spindle

in the center position).

After evacuation, both valves (4 and 5) are

connected to the service battery. Only then is the

vacuum pump switched o.

The refrigerant bottle is connected at the centre

connection of the service battery aid 3, and the

lling piece is briey vented.

The corresponding valve of service battery aid 4

is opened and the system is lled via the manometer connection of the suction stop valve with

the maximum allowable refrigerant operating

lling for a compressor that is in operation.

10 DKRCC.PF.000.G3.02 / 520H6471

Page 11

Fitters’ Notes Condensing units

Evacuating and lling

(continued)

Please observe the following recommendation

for evacuating and lling the Danfoss

condensing units with condensing units with

hermetic Maneurop® reciprocating piston

compressors MTZ and NTZ.

We recommend that you carry out the evacuation

as described in the following:

1. The service valves of the condensing unit

must be closed.

2. After the leak check, if possible, a two-ended

evacuation should be carried out using a

vacuum pump to 0.67 mbar (abs.)

It is recommended that you use coupling

lines with a large through-put and that you

connect them to the service valves.

3. Once a vacuum of 0.67 is reached, the system

is separated from the vacuum pump. During

the next 30 minutes, the system must not rise.

If the pressure rises quickly, the system has a

leak.

A new leak check and evacuation (after 1)

must be carried out. If the pressure rises

slowly, this is an indication that humidity

is present. If this is the case, perform a new

evacuation (after 3).

Exceeding the max.

allowable operational

lling capacity and

setting up outdoors

4. Open the service valves of the condensing

unit and break the vacuum with nitrogen.

Repeat procedures 2 and 3.

General information:

The compressor should only be switched on if the

vacuum has been broken.

For compressor operation with a vacuum in the

compressor housing, there is a risk of voltage

spark-over in the motor winding.

If the refrigerant is lled beyond the max.

allowable operational lling capacity or when

setting up outdoors, protective precautions

must be taken.

You can nd the max. allowable operational

lling capacities in the technical information

and/or installation instructions for the Danfoss

compressors. If there are any questions, your

local Danfoss sales company will be glad to

assist you.

One quick and easy solution for preventing

refrigerant displacements during the

shut-down phases is the use of a crankcase

heater.

Condensing

units

11DKRCC.PF.000.G3.02 / 520H6471

Page 12

Fitters’ Notes Condensing units

Exceeding the max.

allowable operational

lling capacity and

setting up outdoors

(continued)

For Danfoss condensing units that are

equipped with 1-cylinder compressors, types

TL, FR, NL, GS, SC and SC TWIN, following size

of crankcase heaters can be used:

Crankcase heater for TL/FR/NL 35 W, order

no. 118U0050

Crankcase heater for GS, SC and SC-TWIN 55

W, order no. 118U0051

Housing heaters must be mounted directly

above the welded seam. For TWIN compressors,

both compressors must have a housing heater.

The electrical connection can be carried out as

follows:

For activated main switches, the change-over

contact of the regulating thermostat (e.g. KP 61)

takes over the switching function, i.e. compressor

o – heater on, and vice versa. The housing

heater should also be switched on approx. 2–3

hours before startup after a long down-time of

the cooling system.

For setting up the condensing units outdoors, it is

generally recommended to use housing heaters.

Please observe the following wiring recommendations.

The Danfoss condensing units with hermetic 1,

2 or 4-cylinder Maneurop® reciprocating piston

compressors MTZ and NTZ come standard

equipped with a self-regulating PTC 35 W

crankcase heater.

The self-regulating PTC heater protects against

refrigerant displacement during the shutdown

phase. However, reliable protection is only

aorded when the oil temperature is 10 K above

the saturation temperature of the refrigerant.

It is advisable to check by means of tests that a

sucient oil temperature is reached for both low

and high ambient temperatures.

For condensing units that are set up outdoors

and exposed to low ambient temperatures or

for cooling applications with larger amounts of

refrigerant, an additional belt crankcase heater is

often required for the compressor.

The heater should be mounted as close to the

oil sump as possible in order to ensure ecient

transfer of heat to the oil. Belt crankcase heaters

are not self-regulating.

The regulating is supposed to be achieved

by the heater being switched on when the

compressor is stopped and switched o when

the compressor is running.

These measures prevent the refrigerant from

condensing in the compressor. You must observe

that the crankcase heater is switched on at

least 12 hours prior to the compressor startup whenever the condensing units are being

restarted after a long down-time.

12 DKRCC.PF.000.G3.02 / 520H6471

Page 13

Fitters’ Notes Condensing units

“Pump-down“ If it is not possible to keep the oil temperature

at 10 K over the saturation temperature of the

refrigerant using the crankcase heater during

compressor down-time or when liquid refrigerant

ows back, a pump-down process on the low

pressure end must be used to prevent the further

possibility of refrigerant displacement during

shutdown phases.

The solenoid valve in the liquid line is controlled

by a thermostat. If the solenoid valve closes, the

compressor provides suction on the low pressure

end until the low pressure switch switches o the

compressor at the set switching point.

With “pump-down“, the activation point of the

low pressure switch must be set lower than

the saturation pressure of the refrigerant at the

lowest ambient temperature of the condensing

unit and the evaporator.

A liquid separator provides protection against

refrigerant displacement at the start-up, during

operation or after the hot gas defrosting process.

The liquid separator protects against refrigerant

displacement during the shut-down period while

the internal free volume of the suction end of the

system is increased.

The liquid separator should be laid out according

to the manufacturer’s recommendations.

As a rule, Danfoss recommends that the holding

capacity of the liquid separator not be less than

50% of the entire system’s lling capacity.

A liquid separator should not be used in systems

with zeotropic refrigerants such as R407C, for

example.

Condensing

units

13DKRCC.PF.000.G3.02 / 520H6471

Page 14

Fitters’ Notes Condensing units

Max. allowable

temperatures

For the Danfoss condensing units with

1-cylinder compressors (types TL, FR, NL, GS,

SC and SC TWIN), the evaporator superheat

(measured at the sensor of the expansion valve

meaning the temperature at pressure gauge)

should be between 5 and 12 K.

The max. return gas temperature is measured

at the compressor intake: 45°C. Impermissibly

high intake gas over-heating leads inevitably

to a quick rise in the discharge temperature.

This must not exceed 135°C for the SC compressor

and 130°C for the TL, NL and FR compressors.

The pressure tube temperature is measured

50 mm away from the pressure connector of the

compressor.

For condensing units with hermetic

Maneurop® reciprocating piston compressors

MTZ and NTZ, the evaporator superheat (E-valve

sensor) should be between 5 and 12 K.

The max. return gas temperature, measured at

the compressor suction connector is 30°C.

Impermissibly high intake gas superheat

inevitably leads to a rapid rise in the pressure gas

temperature, the maximum value of which must

not be exceeded (130°C).

For special applications (multi-evaporator systems),

the use of an oil separator is recommended in the

pressure line.

14 DKRCC.PF.000.G3.02 / 520H6471

Page 15

Fitters’ Notes Condensing units

Introduction These notes pertain to Danfoss packaged

condensing units used for refrigeration systems.

They provide necessary information regarding

safety and proper usage of this product.

The condensing unit includes following:

Microchannel condenser

(Optyma Plus™ New Generation &

Optyma™ Slim Pack)

Fin and tube condenser (Optyma Plus™)

Reciprocating or scroll compressor

Receiver with stop valve

Ball valves

Sight glass

High & low pressure switches

Filter drier

Electronic controller

(only Optyma Plus™ New Generation)

Main circuit breaker

(Main switch with overload protection)

Fan and compressor capacitors

Compressor contactor

Robust weather proof housing

Handling and storage Store and transport the unit in an upright

position.

15DKRCC.PF.000.G3.02 / 520H6471

Condensing

units

Page 16

Fitters’ Notes Condensing units

Installation precautions

Ensure adequate space around the unit for

air circulation and to open doors.

Avoid installing the unit in aggressive and

dusty environments.

Ensure a foundation with horizontal surface

(less than 3° slope), strong and stable

enough to carry the entire unit weight and

to eliminate vibrations and interference.

Ensure that the power supply corresponds

to the unit characteristics (see nameplate).

When installing units for HFC refrigerants,

use equipment specically reserved for

HFC refrigerants which was never used for

CFC or HCFC refrigerants.

Use clean and dehydrated refrigeration-

grade copper tubes and silver alloy brazing

material.

Use clean and dehydrated system compo-

nents.

The suction piping connected to the

compressor must be exible in 3 dimensions

to dampen vibrations. Furthermore piping

has to be done in such a way that oil return

for the compressor is ensured and the risk of

liquid slug over in compressor is eliminated.

Minimum mounting distances

Q W

R

Q: AIR in R: AIR inout

Unit

Housing 1

(Code n 114X31 -- or 114X41 - -)

Housing 2

(Code n 114X32 -- or 114X42 --)

Housing 3

(Code n 114X33 -- or 114X43 --)

Housing 4

(Code n 114X31 -- or 114X41 --)

Remove cap and access cap

X

W

(mm)X(mm)Y(mm)Z(mm)

250 550 456 456

250 650 530 530

250 760 581 581

250 900 700 700

OPEN position

16 DKRCC.PF.000.G3.02 / 520H6471

Page 17

Fitters’ Notes Condensing units

Installation The installation in which the condensing

unit is installed must comply to EEC Pressure

directive (PED) nr. 97/23/EC.

The condensing unit itself is not a ”unit” in

the scope this directive.

It is recommended to install the unit on

rubber grommets or vibration dampers

(not supplied).

It is possible to stack units on top of each

other (only Optyma Plus™ New Generation).

Unit maximum stacking

Housing 1

(Code no. 114X31-- or 114X41--) 3

Housing 2

(Code no. 114X32-- or 114X42--) 2

Housing 3

(Code no. 114X33-- or 114X43--) 2

Housing 4

(Code no. 114X34-- or 114X44--) no stacking

When stacking, the topmost unit must be

secured to the wall.

Slowly release the nitrogen holding charge

through the schrader port.

Connect the unit to the system as soon

as possible to avoid oil contamination from

ambient moisture.

Avoid material entering into the system

while cutting tubes. Never drill holes where

burrs cannot be removed.

Braze with great care using state-of-the-art

technique and vent piping with nitrogen gas

ow.

Connect the required safety and control

devices. When the schrader port is used for

this, remove the internal valve.

It is recommended to insulate the suction

pipe up to the compressor inlet with 19 mm

thick insulation.

17DKRCC.PF.000.G3.02 / 520H6471

Condensing

units

Page 18

Fitters’ Notes Condensing units

Leak detection

Vacuum dehydration Never use the compressor to evacuate the

Electrical connections Switch o and isolate the main power supply.

Never pressurize the circuit with oxygen or

dry air. This could cause re or explosion.

Do not use dye for leak detection

Perform a leak detection test on the

complete system

The maximum test pressure is 32 bar.

When a leak is discovered, repair the leak

and repeat the leak detection.

system Connect a vacuum pump to both the

LP & HP sides.

Pull down the system under a vacuum of

500 m Hg (0.67 mbar) absolute.

Do not use a megaohmmeter nor apply

power to the compressor while it is

under vacuum as this may cause internal

damage.

Ensure that power supply can not be switched

on during installation.

All electrical components must be selected as

per local standards and unit requirements.

Refer to wiring diagram for electrical connec-

tions details.

Ensure that the power supply corresponds to

the unit characteristics and that the power

supply is stable (nominal voltage ±10% and

nominal frequency ±2,5 Hz)

Dimension the power supply cables according

to unit data for voltage and current.

Protect the power supply and ensure correct

earthing.

Make the power supply according to local

standards and legal requirements

Optyma Plus™ New Generation is equipped

with an electronic controller. The controller is

regulating fan speed and crankcase heater.

The unit is equipped with a main switch with

overload protection. The overload protection is

factory preset but it is recommended to check

the value before taking the unit in operation.

The value for the overload protection can be

found in the wiring diagram in the front door

of the unit.

The unit is equipped with high and low pres-

sure switches, which directly cut the power

supply to the compressor in case of activation.

Parameters for high and low pressure cut outs

are preset in the controller, adapted to the

compressor installed in the unit (Optyma Plus™

New Generation)

For units with a 3-phase scroll compressor

(OPMPUxxxxxxxxE), correct phase sequence

for compressor rotation direction shall be

observed.

Determine the phase sequence by using a

phase meter in order to establish the phase

orders of line phases L1, L2 and L3.

Connect line phases L1, L2 and L3 to main

switch terminals T1, T2 and T3 respectively.

18 DKRCC.PF.000.G3.02 / 520H6471

Page 19

Fitters’ Notes Condensing units

Filling the system

Setting the electronic

controller

(only Optyma Plus™ New

Generation)

Never start the compressor under vacuum.

Keep the compressor switched o .

Use only the refrigerant for which the unit

is designed for.

Fill the refrigerant in liquid phase into the

condenser or liquid receiver. Ensure a slow

charging of the system to 4 – 5 bar for

R404A and approx. 2 bar for R134a.

The remaining charge is done until the

installation has reached a level of stable

nominal condition during operation.

Never leave the lling cylinder connected

to the circuit.

The unit is equipped with an electronic

controller which is factory programmed with

parameters for use with the actual unit.

By default, the electronic controller display

shows the temperature value for the suction

pressure in °C. To show the temperature

value for the condensing pressure, push the

lower button.

The electronic controller is factory preset for

operation with refrigerant R404A. If another

refrigerant is used, the refrigerant setting

must be changed. Parameter r12 must be set

to 0 before (software main switch = o ).

Push the upper button for a couple of seconds.

The column with parameter codes appears.

Push the upper or lower button to nd

parameter code o30.

Push the middle button until the value for this

parameter is shown.

Push the upper or lower button to select the

new value: 2 = R22, 3 = R134a, 13 = User

de ned, 17 = R507, 19 = R404A, 20 = R407C.

Push the middle button to con rm the selected

value.

19DKRCC.PF.000.G3.02 / 520H6471

Condensing

units

Page 20

Fitters’ Notes Condensing units

Verication before

commissioning

Start-up Never start the unit when no refrigerant is

Use safety devices such as safety pressure

switch and mechanical relief valve in

compliance with both generally and locally

applicable regulations and safety standards.

Ensure that they are operational and properly

set. Check that the settings of high-pressure

switches and relief valves don’t exceed the

maximum service pressure of any system

component.

Verify that all electrical connections are

properly fastened and in compliance with

local regulations.

When a crankcase heater is required, the

unit must be energized at least 12 hours

before initial start-up and start-up

after prolonged shutdown for belt type

crankcase heaters.

The unit is equipped with a main switch

with overload protection. Overload

protection is preset from factory, but it

is recommended to check the value

before taking the unit in operation.

The overload protection value can be

found in the wiring diagram in the unit

front door.

charged.

All service valves must be in the open

position.

Check compliance between unit and power

supply.

Check that the crankcase heater is working.

Check that the fan can rotate freely.

Check that the protection sheet has been

removed from the backside of condenser.

Balance the HP/LP pressure.

Energize the unit. It must start promptly.

If the compressor does not start, check

wiring conformity and voltage on

terminals.

Optimum

Location

Area

p

c

Eventual reverse rotation of a 3-phase

compressor can be detected by following

phenomena; the compressor doesn’t

build up pressure, it has abnormally high

sound level and abnormally low power

consumption. In such case, shut down the

Only for scroll compressors:

20 DKRCC.PF.000.G3.02 / 520H6471

unit immediately and connect the phases

to their proper terminals.

If the rotation direction is correct the low

pressure indication on the controller

(or low pressure gauge) shall show a

declining pressure and the high pressure

indication (or high pressure gauge) shall

show an increasing pressure.

po < p

p

o

c

Page 21

Fitters’ Notes Condensing units

Check with running unit

Check the fan rotation direction. Air must ow

from the condenser towards the fan.

Check current draw and voltage.

Check suction superheat to reduce risk of

slugging.

When a sight glass is provided observe the oil

level at start and during operation to conrm

that the oil level remains visible.

Respect the operating limits.

Check all tubes for abnormal vibration. Move-

ments in excess of 1.5 mm require corrective

measures such as tube brackets.

When needed, additional refrigerant in liquid

phase may be added in the low-pressure side

as far as possible from the compressor. The

compressor must be operating during this

process.

Do not overcharge the system.

Never release refrigerant to atmosphere.

Before leaving the installation site, carry out

a general installation inspection regarding

cleanliness, noise and leak detection.

Record type and amount of refrigerant charge

as well as operating conditions as a reference

for future inspections.

Maintenance part 1 Always switch o the unit at main switch before

opening the fan door (s).

Internal pressure and surface temperature

are dangerous and may cause permanent injury.

Maintenance operators and installers require

appropriate skills and tools. Tubing temperature

may exceed 100°C and can cause severe burns.

Ensure that periodic service inspections to

ensure system reliability and as required by local

regulations are performed.

To prevent system related problems, following

periodic maintenance is recommended:

Verify that safety devices are operational and

properly set.

Ensure that the system is leak tight.

Check the compressor current draw.

Conrm that the system is operating in a way

consistent with previous maintenance records

and ambient conditions.

Check that all electrical connections are still

adequately fastened.

Condensing

units

21DKRCC.PF.000.G3.02 / 520H6471

Page 22

Fitters’ Notes Condensing units

Maintenance part 2 Keep the unit clean and verify the absence of

rust and oxidation on the unit components,

tubes and electrical connections.

The condenser must be checked at least once

a year for clogging and be cleaned if deemed

necessary. Access to the internal side of the

condenser takes place through the fan door

or fan panel. Microchannel coils tend to

accumulate dirt on the surface rather than

inside, which makes them easier to clean than

n-&-tube coils.

Switch o the unit at main switch before

opening the fan door or removing fan panel.

Remove surface dirt, leaves, bres, etc. with

a vacuum cleaner, equipped with a brush

or other soft attachment. Alternatively, blow

compressed air through the coil from the

inside out (only at Microchannel condensers –

at n and tube condensers blow according to

the original air ow direction), and brush

with a soft bristle.

Do not use a wire brush. Do not impact or

scrape the coil with the vacuum tube or air

nozzle.

Before closing the fan door, turn the fan

blade in the right position to avoid that the

door hits the fan.

If the refrigerant system has been opened,

the system has to be ushed with dry air or

nitrogen to remove moisture and a new

lter drier has to be installed. If evacuation

of refrigerant has to be done, it shall be

done in such a way that no refrigerant can

escape to the environment.

22 DKRCC.PF.000.G3.02 / 520H6471

Loading...

Loading...