Page 1

Compression

Control

Hybrid Valve

Tech Note

Page 2

Compression Control Hybrid Valve

Tech Note

Revisions

HISTORY OF REVISIONS

Table of Revisions

Date Page Changed Rev.

May 2007 - First edition AA

© 2007 Sauer-Danfoss. All rights reserved.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer-Danfoss reserves the right to alter its products without prior notice. This also applies to products

already ordered provided that such alterations aren’t in conflict with agreed specifications. All trademarks in

this material are properties of their respective owners. Sauer-Danfoss and the Sauer-Danfoss logotype are

trademarks of the Sauer-Danfoss Group.

2

11022635 • Revision AA • May 2007

Page 3

Compression Control Hybrid Valve

Tech Note

Contents

GENERAL DESCRIPTION

SYSTEM DESIGN

PARAMETERS

TECHNICAL

SPECIFICATIONS

MODEL CODE

INSTALLATION

DRAWINGS

Overview ...........................................................................................................................................................4

Typical applications .......................................................................................................................................4

Standard features ...........................................................................................................................................4

Fluids ...................................................................................................................................................................5

Filtration.............................................................................................................................................................5

Base stock and additives ........................................................................................................................ 5

Viscosity........................................................................................................................................................ 5

For more information ..............................................................................................................................5

Return line filtration .................................................................................................................................5

Cleanliness...................................................................................................................................................5

Specifications ...................................................................................................................................................6

Typical performance .....................................................................................................................................6

HIC inlet or outlet ........................................................................................................................................... 7

Truck Schematic ..............................................................................................................................................7

Max load telescopic section .......................................................................................................................8

Dimensions Inlet Hybrid Valve - 11027345 ...........................................................................................9

Dimensions Outlet Hybrid Valve - 11027346 .....................................................................................10

SCHEMATICS

Compression Control Hybrid Valve Schematics ................................................................................11

11022635 • Revision AA • May 2007

3

Page 4

Compression Control Hybrid Valve

Tech Note

General Description

OVERVIEW The Sauer-Danfoss directional control valves are designed to give customer flexibility

over a broad range of flow and pressure capabilities. Actuator options include a range

of levers, cable actuators, hydraulic and pneumatic pilot controls, two-axis joysticks,

and electrohydraulic solenoids. Flow rates range from 0 to 100 l/min [26 US gal/min].

Configurations include compact mono-block and flexible modular styles..

The Compression Control Hybrid Valve is designed to improve the operation of rear

loader garbage trucks. It increases the packing ratio, adds more payload capacity and

moves the load to provide better weight distribution.

COMPRESSION CONTROL

HYBRID VALVE

TYPICAL APPLICATIONS

STANDARD FEATURES • PO check valve that provides flow and pressure to open the telescopic cylinder when

• Rear loader garbage trucks

the tailgate is closed

• Pressure compensator valve to avoid the garbage spring effect during the packing

stroke of the telescopic cylinder

• Flexible HIC designs to adapt to vehicle architecture

• Higher capacity with constant refuse density

For more information regarding spool types, actuation options, cabling and electrical

options, spool centering and detent options and auxiliary valves, refer to Sauer-Danfoss

publication Directional Control Valves Technical Information, 520L0564.

4

11022635 • Revision AA • May 2007

Page 5

Compression Control Hybrid Valve

Tech Note

System Design Parameters

FLUIDS Hydraulic fluid performs three basic functions in a hydraulic system: It transfers energy,

lubricates moving components, and transports heat and contaminants out of the system.

Base stock and additives

Sauer-Danfoss valves are designed to operate with mineral-based fluids containing

oxidation, rust, and foam inhibitors, compatible with fluoroelastomer seals. Consult your

fluid supplier for information on seal compatibility.

Viscosity

Viscosity is the most important property of a hydraulic fluid. It is a measurement of how

the fluid resists flow. Low viscosity fluids increase internal leakage; high viscosity fluids

increase pressure drop through the valve. Use a fluid that meets the viscosity limits

published in this catalog. For specific requirements, see technical data in each section.

Temperature

Temperature affects a fluid’s viscosity. Higher temperature fluid has lower viscosity.

Operating at excessive temperatures may have other detrimental effects on your

hydraulic fluid. Design your hydraulic system to operate within the specified temperature

range. Specific requirements are published in each section.

For more information

For more information on hydraulic fluid selection refer to Sauer-Danfoss publication

Hydraulic Fluids and Lubricants Technical Information, 520L0463.

FILTRATION Effective filtration is critical to a hydraulic system’s performance and working life. Employ

system filtration capable of meeting the published requirements in each valve section.

Be aware that other components in the system may have more stringent requirements.

Design your filtration system to satisfy the requirements of the most sensitive

component.

Return line filtration

Return line filtration is generally adequate for Sauer-Danfoss valves. We recommend a

10 micron nominal (20 micron absolute) or finer filter. Insure the filter in your system is

properly sized and maintained. To facilitate proper filter maintenance, use a pressure

gauge or other indicator to signal when it is necessary to change the filter. Never

allow filter to reach its bypass condition. Follow the filter manufacturer’s maintenance

recommendations.

Cleanliness

Hydraulic system contamination must not exceed the limits published for each valve.

Limits are specified per ISO 4406 (1999). When measuring system contamination,

calibrate test equipment in accordance with the ACFTD method.

For more information

For more information on system filtration, refer to Sauer-Danfoss publication Design

Guidelines for hydraulic fluid cleanliness, 520L0467.

11022635 • Revision AA • May 2007

5

Page 6

Compression Control Hybrid Valve

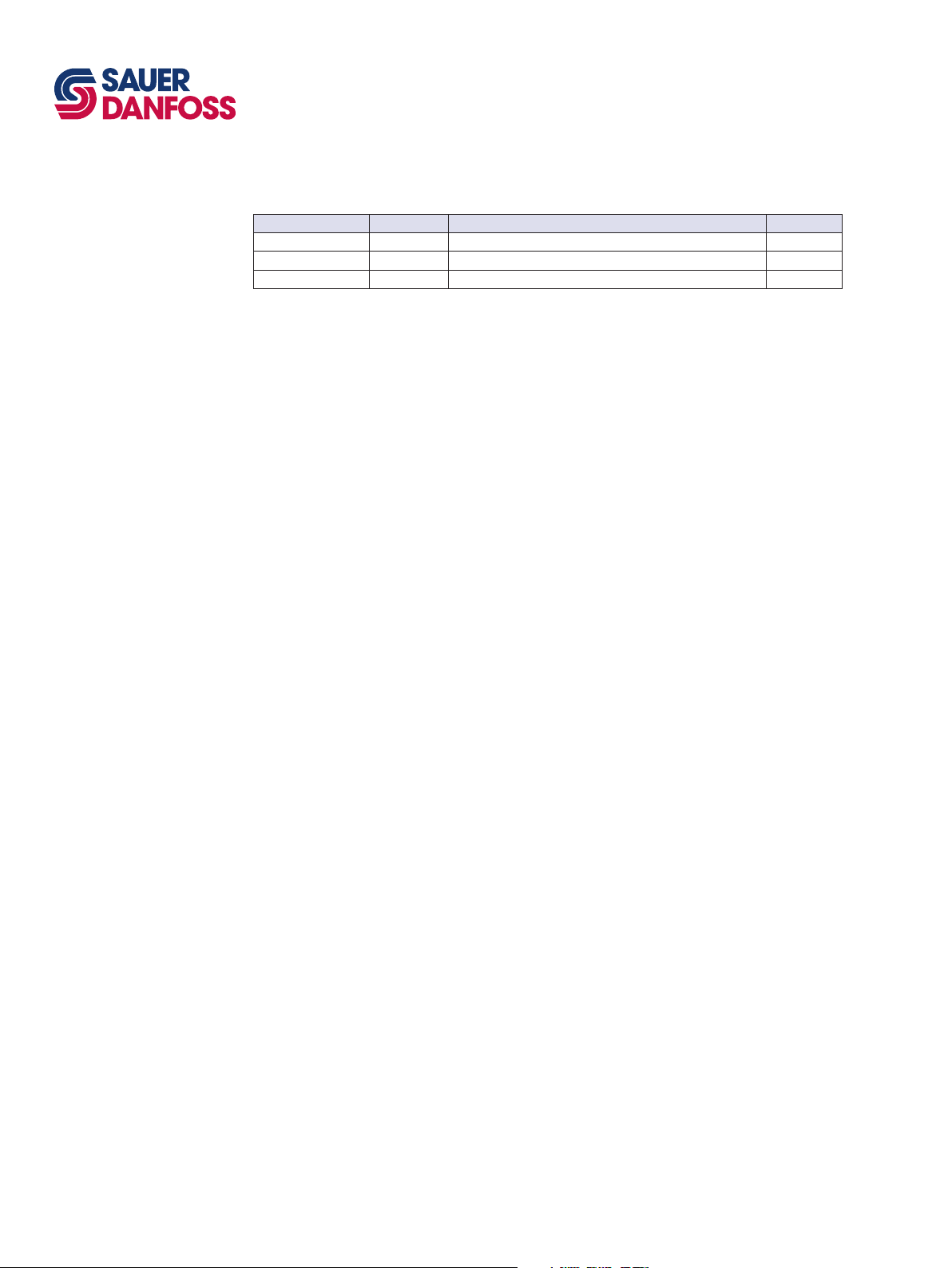

Pressure Drop (Inlet Port - Work Ports)

10 20 30 40 50 60 70 80 90 100

[2.64] [5.28] [7.93] [10.57] [13.21] [15.85] [18.49] [21.14] [23.78] [26.42]

Flow (liter/minute)

Flow [gallon/minute]

Pressure (bar) [PSI]

(P-B1)

(P-A1)

(P-A2)

P-A1 Telescopic Cylinder

P-B1 Telescopic Cylinder

P-A2 Rear Cover Cylinder

P106 551E

0

1

2

3

4

5

6

7

8

9

10

11

12

0 [0]

1 [14.5]

2 [29]

3 [43.5]

4 [58]

5 [72.5]

6 [87]

7 [101.5]

8 [116]

9 [130.5]

10 [145]

11 [159.5]

12 [174]

13 [188.5]

Pressure Drop (Inlet Port - Work Ports)

P-A2

P-B2

P-A1

P-B2 Telescopic Cylinder

P-A2 Telescopic Cylinder

P-A1 Rear Cover Cylinder

P106 552E

Pressure (bar) [PSI]

0 [0]

1 [14.5]

2 [29]

3 [43.5]

4 [58]

5 [72.5]

6 [87]

7 [101.5]

8 [116]

9 [130.5]

10 [145]

11 [159.5]

12 [174]

10

20

30

40 50

60

70

80

90

100

[2.64]

[5.28]

[7.93]

[10.57] [13.21]

[15.85]

[18.49]

[21.14]

[23.78]

[26.42]

Flow (liter/minute)

Flow [gallon/minute]

Tech Note

Technical Specifications

SPECIFICATIONS

TYPICAL PERFORMANCE

Based on oil temperature

of 45°–50°C [113°–122° F].

Viscosity 32 mm²/sec

(cSt) [151 SUS]. CDS

spool leakage (standard)

at 70 bar [1015 psi],

50°C [122°F], ISO VG46:

10 cm³/min [0.61 in³/min]

Maximum flow (CDS 100) 100 l/min [26.4 US gal/min]

Work pressure 210 bar [3050 psi]

Maximum pressure 250 bar [3625 psi]

Maximum pressure (outlet section) 40 bar [580 psi]

Temperature range -40º to 80º C [-40 to 176º F]

Recommended fluid type Mineral based hydraulic oil

Recommended viscosity 26-55 mm²/sec (cSt) [123-255 SUS]

Minimum fluid cleanliness (per ISO 4406) 19/16

Pressure drop (P-A1, P-B1, P-A2) HIC inlet

6

11022635 • Revision AA • May 2007

Pressure drop (P-B2, P-A2, P-A1) HIC outlet

Page 7

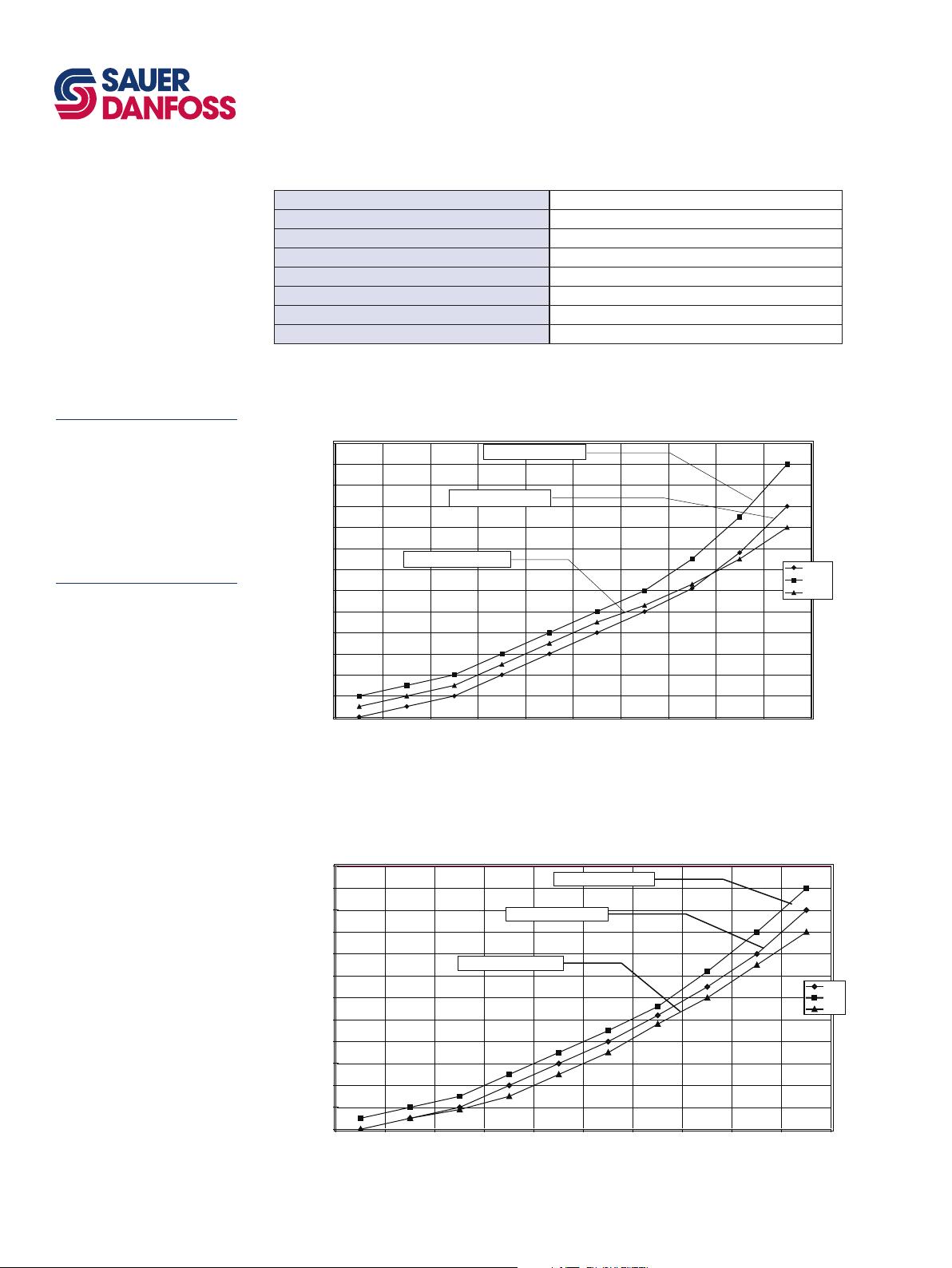

Compression Control Hybrid Valve

VDP06/NC

2

3

1

ATM

M

M

Gear

pump

P106 558E

Max load valve

M

Inlet

Oil tank

Blade

cylinder

Tailgate

Tailgate cylinder

Garbage container

Slide cylinder

Ejector panel

Telescopic ejector cylinder

Power

beyond

Tank

AA

B

A

B

Rear valve

Inlet

A

A

B

B

Tank

Tech Note

Model Code

HIC INLET OR OUTLET

Ports

BSP (M10 mounting threads)

Metric (ISO 6149 and M10 mounting threads)

SAE ORB (3/8 English threads)

Main relief setting*

Unloader

12 VDC

24 VDC

PC/LS Unloader

12 VDC

24 VDC

External pilot (matches port type selected)

Sequence valve pressure

ML 100

PC/LS Fixed Pump ML only

X X X

X X X

X X X

140/48 140/48

X

X

X

X

X X X

# # #

* Default setting if not specified

TRUCK SCHEMATIC

11022635 • Revision AA • May 2007

7

Page 8

Compression Control Hybrid Valve

Tech Note

Model Code

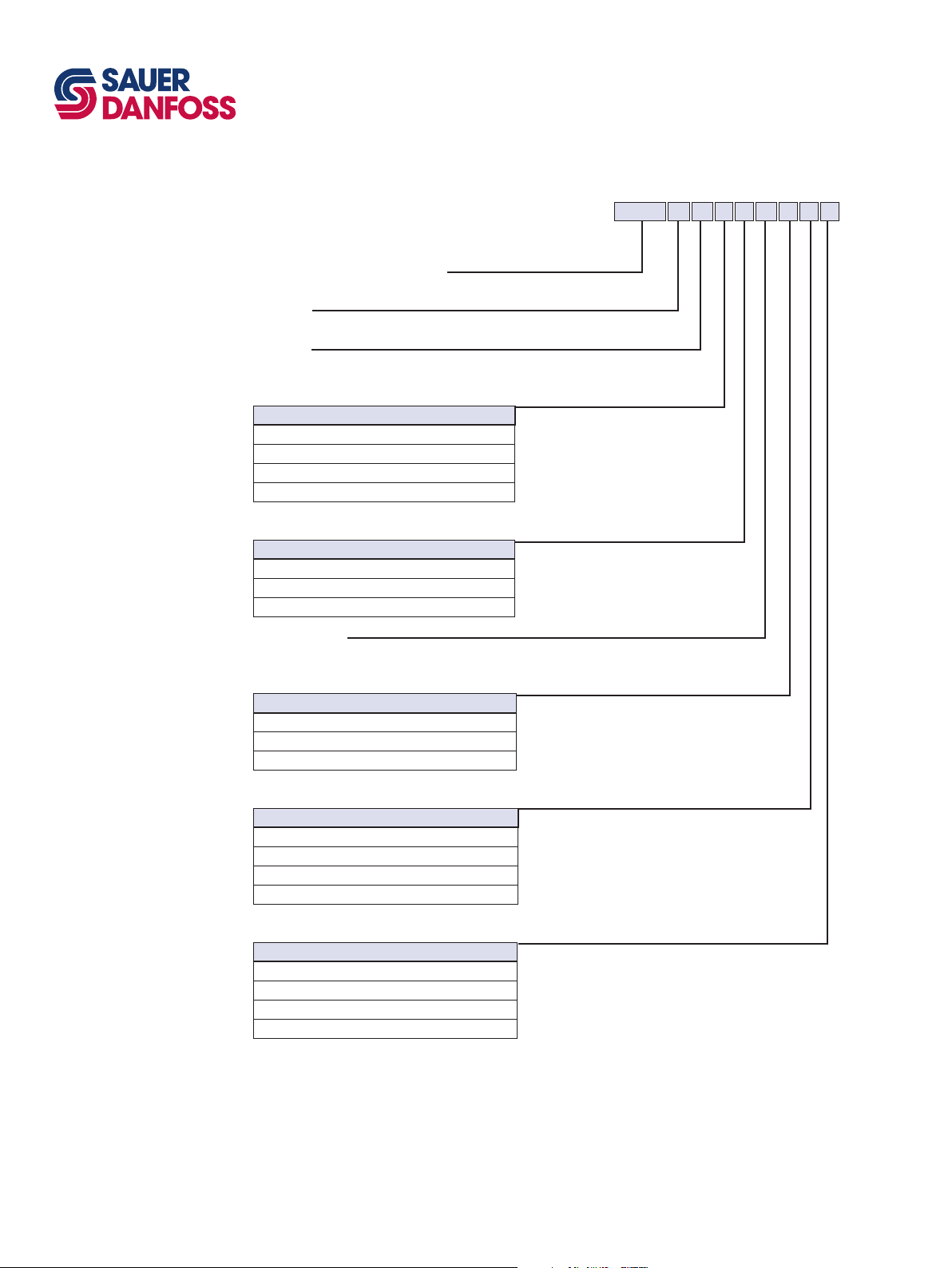

MAX LOAD TELESCOPIC

SECTION

Max Load Telescopic Section

Parallel

4W/3P

Actuation

Description

EH On/Off

Manual

Pneumatic

Etc.

Actuation side

Description

Handle, A side

Handle, B side

Etc.

Spring center

Inlet covers order code (example)

M100 1

A * * A * * *

Port threads, Type and Size

Description

SAE

Metric (ISO 6149)

BSP

A side auxiliary valves

Description

Anti-cavitation

Relief plus anti-cavitation

Plug

Special safety check valve

B side auxiliary valves

Description

Anti-cavitation

Relief plus anti-cavitation

Plug

Special safety check valve

For information regarding Work Section model codes, refer to pages 39-40 in SauerDanfoss publication Directional Control Valves Technical Information, 520L0564.

8

11022635 • Revision AA • May 2007

Page 9

142.50

[5.610]

SAE #12

1 1/16 12-UN

Side inlet

123.00

[4.843]

SAE #12

1 1/16 12-UN

Top inlet port

(optional gage port)

SAE #4

7/16 20-UNF

Gage port

Sequence valve

SAE #10

7/8 14-UNF

Work port

SAE #12

1 1/16 12-UN

Power beyond

30.50

[1.201]

144.00

[5.669]

M10x1.5(2x)

127.00

[5.000]

Dimensions mm [in]

P106 550E

Compression Control Hybrid Valve

Tech Note

Installation Drawings

DIMENSIONS INLET

HYBRID VALVE - 11027345

11022635 • Revision AA • May 2007

9

Page 10

DIMENSIONS OUTLET

142.50

[5.610]

123.00

[4.843]

SAE #12

1 1/16 12-UN

Tank

SAE #4

7/16 20-UNF

Gage port

Sequence valve

SAE #10

7/8 14-UNF

Work ports

30.50

[1.201]

144.00

[5.669]

127.00

[5.000]

Dimensions mm [in]

P106 553E

SAE #12

1 1/16 12-UN

Top Inlet Port

SAE #12

1 1/16 12-UN

Power Beyond

M10 x 1.5 (2)

SAE #12

1 1/16 12-UN

Side inlet

HYBRID VALVE - 11027346

Compression Control Hybrid Valve

Tech Note

Installation Drawings

10

11022635 • Revision AA • May 2007

Page 11

COMPRESSION CONTROL

PB

P

Gage port

External port

M

A

B

B

External pilot

T

ATMS

Inlet

Telescopic cylinder

Rear cover cylinder

Outlet

P106 549E

P106 554E

PB

P

M

A

B

B

T

ATMS

Inlet

Telescopic cylinder

Rear cover cylinder

Outlet

A

M

HYBRID VALVE SCHEMATICS

HIC Inlet Valve - 11027345

Compression Control Hybrid Valve

Tech Note

Schematics

HIC Outlet Valve - 11027346

11022635 • Revision AA • May 2007

11

Page 12

OUR PRODUCTS

Sauer-Danfoss Mobile Power and Control Systems

– Market Leaders Worldwide

Hydrostatic transmissions

Hydraulic power steering

Electric power steering

Electrohydraulic power steering

Closed and open circuit axial piston

pumps and motors

Gear pumps and motors

Bent axis motors

Orbital motors

Transit mixer drives

Planetary compact gears

Proportional valves

Directional spool valves

Cartridge valves

Hydraulic integrated circuits

Hydrostatic transaxles

Integrated systems

Sauer-Danfoss is a comprehensive supplier providing complete

systems to the global mobile market.

Sauer-Danfoss serves markets such as agriculture, construction, road

building, material handling, municipal, forestry, turf care, and many

others.

We offer our customers optimum solutions for their needs and

develop new products and systems in close cooperation and

partnership with them.

Sauer-Danfoss specializes in integrating a full range of system

components to provide vehicle designers with the most advanced

total system design.

Sauer-Danfoss provides comprehensive worldwide service for its

products through an extensive network of Global Service Partners

strategically located in all parts of the world.

Local address:

Fan drive systems

Electrohydraulics

Microcontrollers and software

Electric motors and inverters

Joysticks and control handles

Displays

Sensors

11022635 • Revision AA • May 2007

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000

Fax: +1 515 239-6618

Sauer-Danfoss GmbH & Co. OHG

Postfach 2460, D-24531 Neumünster

Krokamp 35, D-24539 Neumünster, Germany

Phone: +49 4321 871-0

Fax: +49 4321 871 122

www.sauer-danfoss.com

Sauer-Danfoss ApS

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444

Fax: +45 7488 4400

Sauer-Danfoss-Daikin LTD

Sannomiya Grand Bldg. 8F

2-2-21 Isogami-dori, Chuo-ku

Kobe, Hyogo 651-0086, Japan

Phone: +81 78 231 5001

Fax: +81 78 231 5004

Loading...

Loading...