Data sheet

ChangeOver and NovoCon ChangeOver - Motorized 6-port Ball Valves

Description

ChangeOver

6

NovoCon ChangeOver

6

The ChangeOver6 and NovoCon ChangeOver6

are 6-port motorized ball valves that performs a

diverting function between two water circuits in

4-pipe changeover system.

This diverting function allows the cooling and

heating capacity of a fan coil unit to be increased

for the same compact size compared to a double

coil model where the heating and cooling water

circuits each have their own coil.

The ChangeOver6 and NovoCon ChangeOver6

are 6-port motorized ball valves and not suitable

for flow control. Flow is modulated by the

AB-QM pressure independent balancing control

valve to avoid overflow and reduced efficiency of

boiler or chiller.

Typical applications are:

• Radiant ceiling panel, supplied by 4 pipes

(Heating supply and return and cooling

supply and return)

• Fan coil unit, with single coil supplied by 4

pipes (Heating supply and return and cooling

supply and return)

Features (ChangeOver6):

• No cross-flow between supply circuits

• Single on/off control signal to changeover

supply circuits

• Visual indication of actual valve position;

• Silent and reliable operation

• Maintenance free

• Teflon seal and polished chrome valve ball to

prevent valve sticking

• Manual override

NovoCon ChangeOver6:

The Actuator NovoCon ChangeOver6 is a unique

6-port motorised ball valve solution, which is

controlled directly from NovoCon® S and performs

a diverting function between two water circuits in

4-pipe ChangeOver6 system.

The NovoCon® S bus actuator controls the flow and

the 6-port diverting valve with actuator, switches

between heating and cooling, characterized by that:

• There is only one single plug-in cable, with bus

connection and power supply to the NovoCon®

S actuator. One plug-in cable between the

6-port Actuator NovoCon® S ChangeOver6 and

the NovoCon® S actuator , which includes a

0-10V control signal, feedback signal and power

connection.

• The NovoCon® S PIBCV actuator detects by means

of comparing 0-10V control & feedback signal if

6-port actuator is in manual operation or if the

valve is blocked (feedback signal does not follow

control signal).

• 6-port actuator is in maintenance mode able to

fully close the valve to prevent any leakage.

Features (NovoCon ChangeOver6):

• No cross-flow between supply circuits

• Simple connection and control

• Visual indication of actual valve position

• Silent and reliable operation

• Alarm

• Plug-in cable

• Quick-fit to actuator

• Maintenance free

• Teflon seal and polished chrome valve ball to

prevent valve sticking

• Manual override

Ordering

© Danfoss | 2020.11

Typ e

Actuator ChangeOver

Actuator NovoCon ChangeOver

Actuator NovoCon ChangeOver6 Energy

Actuator NovoCon ChangeOver6 Flexible

Note: Act uators with 5 m and 10 m cable length are p roduced on request. Please n ote this increases lead time.

Typ e DN

ChangeOver6

valve

6

6

1 / Surface temperature sensors 1.5 Plug-in 003Z8521

k

VS

Connection

(m3/h)

15 2.4 Rp ½ 003Z315 0

20 4.0 Rp ¾ 003Z 3151

Cable length

(m)

1.5 Open end 003Z315 5

5.0 Open end 003Z315 6

10 Open end 00 3Z3157

1 Plug-in 003Z8520

1.5 Open end 003Z8522

Code No.

Typ e DN Fire load class1)Code No.

ChangeOver6

insulation

1)

According to DIN 4102

Connection

15 B2 003Z3159

AI162886480177en-000605 | 1

Code No.

Data sheet ChangeOver6 and NovoCon ChangeOver6

Ordering (continued) Accessory

Picture Typ e To pip e To valve Code No.

Union connection (1 pcs.)

(C W617N )

Union connection 1 PCS

(C W617N )

Long union connection (1 pcs.)

(C W617N )

Long union connection (1 pcs.)

(C W617N )

Rp ½ DN 15 003Z0232

Rp ¾ DN 20 003Z0233

Rp ½ DN 15 003 Z3161

Rp ¾ DN 20 0 03Z3162

Technical data

Actuator ChangeOver

6

NovoCon ChangeOver

6

Power supply V 24 AC ± 20% 24 AC/DC ±25%

Operating power consumption VA 5 (only when running)

Running: 3.5VA@24V AC / 2.0W@24V DC

Standby: 0. 5W@24V AC / 0.3W@24V DC

Frequency Hz 50/60 50/60

Running speed

sec/90°

80 120

Control input 2-point Controlled by from NovoCon® S CO6, Energy, I/O

Unable to move, Cooling, Moving from Cooling

Feed back signal /

towards Heating, Shutt-off, Moving from Heating

towards Cooling, Heating

Operating torque Nm 10 10

Rotation angle 90 ° 90°

Ambient temperature

Storage and transport temperature −10 … 80 -20 … 70

°C

0 … 55 5 … 50

Ambient humidity 95% r.h., non-condensing 95% r.h., non-condensing (according to EN 60730-1)

Protection Class II according to EN 60730-1 III safety extra-low voltage

Grade of enclosure IP42 according to EN 60529 IP53 according to EN 60529

Weight g 405 600

m 1.5 1. 0

Connection cable

mm

2

3×0.5 (halogen free)

003Z8520: 5x0.32 (halogen free)

003Z8521: 5x0.32 (halogen free. Sensors PVC)

003Z8522: 4x0.5 (halogen free)

Applied standards:

- mar k in g in acco rd an ce with

standards

EN 60730

Low Voltage Directive

EMC-Directive

RoHS II: 2011/65/EU

Valve

DN 15 20

0.7 (at 200l/h = 100% flow of AB-QM DN15 LF)

Diff. pressure

1)

7.3 (at 650l/h = 100% flow of AB-QM DN15)

kPa

25.0 (at 1200l/h = 100% flow of AB-QM

7.6 (at 1100l/h = 100% flow of AB-QM DN20)

22.6 (at 1900l/h = 100% flow of AB-QM DN20HF)

DN15HF)

k

VS

kVS of one por t 3.4 5.65

m3/h

2.4 4.0

Nominal pressure PN 16

Medium temperature °C 0 … 90

Water and water mixture for closed heating and cooling systems according to plant t ype I for

Medium

When used in plant Type II for DIN EN 14868 appropriate protective measures are taken. The

DIN EN 14868.

requirements of VDI 2035, part 1 + 2 are observed.

Max. operating torque

2)

Shut off

Nm 3.0

kPa 800

Valve neck Quick fix connection

Connection Internal thread : Rp ¹/ (ISO7/1) Internal thread : Rp ¾ (7/1)

Certifications and standards PED directive 2014/68/EU Art. 4§

Weight g 114 0 1750

Materials

Body and connection CW 602 N (DZR)

Ball CW 614 N Chrome plated

Stem CW 614 N Nickel plated

Seals P.T.F.E. (TEFLON)

O-ring 70 EPDM 281

1)

differe ntial pressure for both por ts

2)

manual override (for service purposes only)

2 | © Danfoss | 2020.11

AI162886480177en-000605

Data sheet ChangeOver6 and NovoCon ChangeOver6

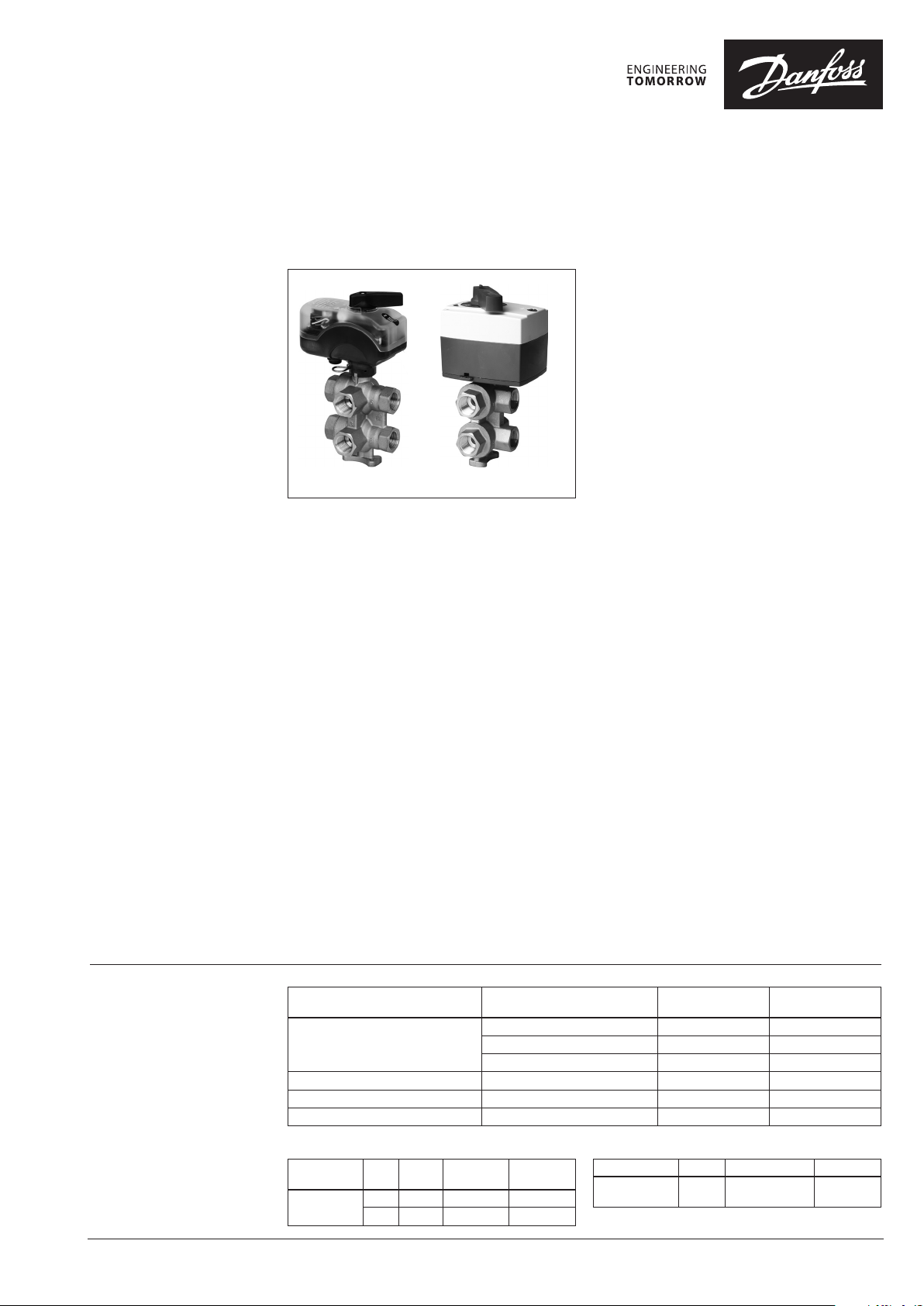

Installation positions

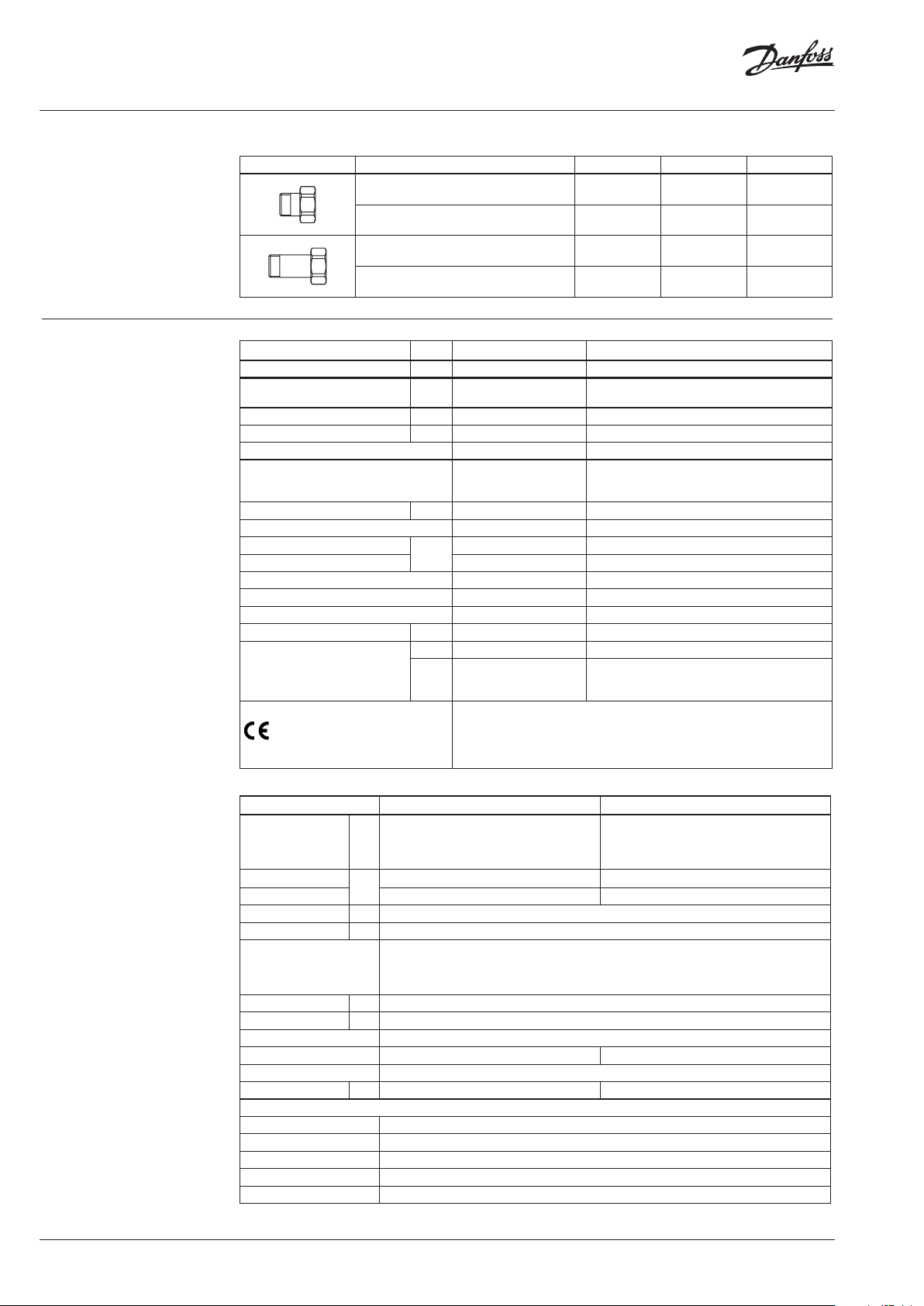

Application principles

ChangeOver

6

(ChangeOver6)

2 connections to the

controller.

ChangeOver

6

NovoCon ChangeOver

6

AME 110NL

AO

DO

ChangeOver6 signal

Radiant

Panel

ROOM CONTROLER

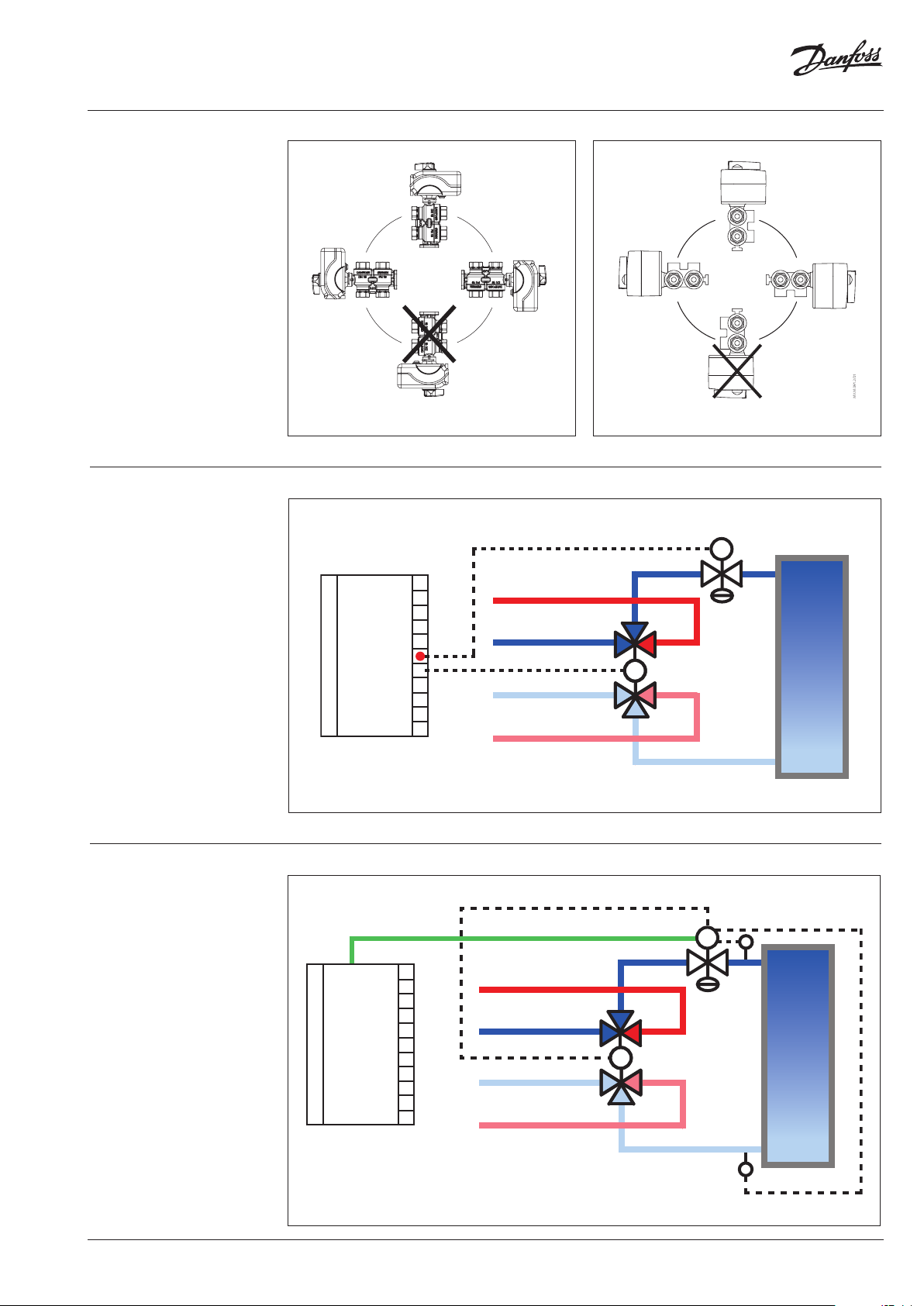

Application principles

ChangeOver

6

(NovoCon ChangeOver6)

Separate maximum flow

presetting for cooling

and heating is possible in

NovoCon® S. Feedback signal

and alarms are also available.

Only one connection to the

controller.

AI162886480177en-000605

T1 supply

Radiant

Panel

BUS

NovoCon®

ChangeOver6 signal

ChangeOver6 signal

DO

ROOM CONTROLER

T2 return

© Danfoss | 2020.11 | 3

Data sheet ChangeOver6 and NovoCon ChangeOver6

Application principles

(ChangeOver6)

Anti-sticking requirements:

To reduce the risk of the ball

valve sticking due to water

quality, the valve must be

partially rotated at least every

7 days. An operation at least

once per week to reduce the

risk of higher toque loading

on the actuator. Reversing the

control signal for a maximum

of 40 seconds will rotate the

valve through 45 degrees to

the zero flow position without

changing between heating

and cooling.

The ChangeOver6 is a 6-port valve with rotary actuator that switches the flow between heating

and cooling. An AB-QM pressure independent balancing and control valve with actuator is used to

balance the system and modulate the flow. For modulating control, the AME 110NL actuator should

be used. For fieldbus control (BACnet or Modbus) NovoCon® S should be used.

Cooling:

Heating:

3

Application principles

(NovoCon ChangeOver6)

Anti-sticking requirements:

To reduce the risk of the ball

valve sticking due to water

quality, the valve must be

partially rotated at least

every 7 days. By default this is

handled by NovoCon® S.

The ChangeOver6 is a 6-port valve with rotary actuator that switches the flow between heating and

cooling. An AB-QM pressure independent balancing and control valve with actuator is used to balance

the system and modulate the flow. When using the NovoCon® S for flow control, both NovoCon® S and

the Actuator NovoCon® ChangeOver6 are controlled by one single data point.

Cooling:

Heating:

4 | © Danfoss | 2020.11

AI162886480177en-000605

Data sheet ChangeOver6 and NovoCon ChangeOver6

Marking

The 6 ports of the ChangeOver6 valve allow the

following flow directions.

Control signal - 0 VAC (black wire):

Port 1 to por t 2 and port 3 to port 4

Control signal - 24 VAC (black wire):

Port 5 to por t 2 and port 3 to port 6

Heating or cooling distribution pipes

Ports 1, 4, 5 and 6

Terminal unit pipes

Ports 2 and 3

No mixing

Source 1 open Shut off Source 2 open

Shut off and manual override for service purposes only

CO6 in contrary to other ball valves includes shut off function. This function can be used only during

maintenance and replaces the need of four ball valves.

AI162886480177en-000605

© Danfoss | 2020.11 | 5

Data sheet ChangeOver6 and NovoCon ChangeOver6

Design flow setting for

heating and cooling

(in case of using onl y one AB-QM as

shown on pic ture above)

(ChangeOver6)

The design flow needed for heating is generally less than for cooling. Actuator AME 110NL supports this

difference by proportionately limiting the control voltage with a linear characteristic. The NovoCon® S

enables different design flows to be set via fieldbus communication. See the example below.

Example:

AB-QM 4.0 DN15 factory setting 100% = 650 l/h

Cooling: - ChangeOver6 set to cooling - control signal 0 V,

- PIBCV max. flow demand to terminal unit ~585 l/h = 90% presetting of AB-QM DN15

- Control signal to AME = 0 - 10 V

Heating: - ChangeOver6 set to heating - control signal 24 V,

- PIBCV max. flow demand to terminal unit ~286 l/h (=44% of AB-QM DN15 flow), presetting of

AB-QM DN15 equal to cooling,needed desgn flow achieaved by voltage limitation on AME.

- Control signal to AME = 0 - 5 V

6

ChangeOver

control signal

control signal

AB-QM PIBCV

Control signal

(NovoCon ChangeOver6)

Cooling connected to port 1 and 4 Heating connected to port 5 and 6

Control signal for the Actuator NovoCon ChangeOver

Stop moving Cooling Shut- off Heating

CO6 mode 1. 0 V 2.5 V 5.5 V 8.5 V

Feedback signal from the Actuator NovoCon ChangeOver

Unable to move Cooling

1.0 V 2.5 V 4.0 5.5 V 7.0 V 8.5 V

Pump head calculation To calculate required pump head:

- determine the critical circuit;

- calculate pump head without ChangeOver6

solution (ChangeOver6 + AB-QM);

- starting pressure for ChangeOver6 DN15

solution is ~23.3kPa (ChangeOver6 7.3kPa +

AB-QM DN15 16kPa);

- add the starting pressure to the pump head.

Close

Source 1 Source 2

6

6

Moving direction:

Cooling to Heating

Shut-of f

Angle

Moving direction:

Heating to Cooling

Heating

6 | © Danfoss | 2020.11

AI162886480177en-000605

Data sheet ChangeOver6 and NovoCon ChangeOver6

LED signalling

(NovoCon ChangeOver6)

Wiring

LED orange (Rotate Left)

LED red / green

LED orange (Rotate Right)

LED signal

Left/CCW yellow shining Rotating CCW

Right/CW yellow shining Rotating CW

Green blinking Normal operation / invalid signal received

Green shining Normal operation

Red blinking Valve stuck

Red shining Break of line/no signal

Description of signal

There are combinations of more than one LED possible. In such cases the actual condition is sum of all

indications (for example: red blinking, left yellow shining, green shining = rotating CCW, valve stuck)

Actuator ChangeOver

Actuator NovoCon ChangeOver

6

6

• Plug in cable to NovoCon® S

Actuator NovoCon ChangeOver6 Energy

• Plug in cable including 2xPT1000 surface

temperature sensors to NovoCon® S

Actuator NovoCon® ChangeOver6 Flexible

Red Power 24V

Black GND

White CO6 Control signal

Grey CO6 Feedback signal

AI162886480177en-000605

© Danfoss | 2020.11 | 7

Data sheet ChangeOver6 and NovoCon ChangeOver6

Design (ChangeOver6)

1. Valve body

2. Connection

3. Ball with L-bore

4. Ball sealing with O-ring

5. Spindle with double O-ring

6. Connection spindle

with O-ring

7. Actuator

8. Actuator connection pin

9. Snap ring

9

7

2

6

5

1

Design (NovoCon ChangeOver6)

1. Valve body

2. Connection

3. Ball with L-bore

4. Ball sealing with O-ring

5. Spindle with double O-ring

6. Connection spindle

with O-ring

7. Ac tu ator

8. Actuator connection pin

9. Snap ring

Manual override

(for service purposes only)

Caution:

Do not manually operate the

drive if power is connected!

If manual override has

been used when power is

connected actuator will

always return to its end

position.

Rotate

manual

handle

90°

3

8

ChangeOver

Press and hold

4

9

0

°

6

NovoCon ChangeOver

45° ± 6°

6

8 | © Danfoss | 2020.11

Heating

Cooling

AI162886480177en-000605

Data sheet ChangeOver6 and NovoCon ChangeOver6

Dimensions

(ChangeOver6)

DN15/20

L

H1

H

H2

L1

d

M

L2

L L1 L2 L3 L4 L5 H H1 H2 d M

DN

15

20 92 35 74 46 ~214 60

115

80 32 66

55

mm

38 ~192

~94

L3

L4

L5

45

12 M5

Dimensions

(NovoCon ChangeOver6)

DN15/20

L

H1

H

H2

L1

L5

d

M

L2

L L1 L2 L3 L4 L5 H H1 H2 d M

DN

15

20 92 32 87 46

84

80 32 82

101

mm

38

~205

~22 5

~98

L4

L3

45

12 M5

60

AI162886480177en-000605

© Danfoss | 2020.11 | 9

Data sheet ChangeOver6 and NovoCon ChangeOver6

Tender text:

(ChangeOver6)

Tender text:

(NovoCon ChangeOver6)

The Danfoss

ChangeOver6 is a 6-port motorized ball valve that switches flow between a heating

and cooling water circuit in a 4-pipe system and eliminates cross-flow. A single digital signal switches

between heating and cooling, and flow control must be performed by a separate pressure independent

control valve that can modulate flow rates to suit the heating and cooling circuits.

ChangeOver6 valve:

- Differential pressure drop over the

ChangeOver6 valve:

- Differential pressure drop over the valve DN15 is <7.3 kPa for 650l/h, KVS is fixed at 2.4 m3/h

- Differential pressure drop over the valve DN20 is <7.6 kPa for 1100l/h, KVS is fixed at 4 m3/h

- No cross-flow between the heating and cooling circuits

- Manual shut off up to 8 bar

- Dezincification resistant brass (DZR)

- Medium temperature range 0°C to 90°C

ChangeOver6 actuator:

- Supply Voltage: 24V AC±20% 50-60Hz

- 2 point control input: 24V AC

- Manual override

- Halogen free cable: 1.5m (5m and 10m)

- Rotation angle: 90 degrees

- Rotating torque: 10 Nm

- IP Class: 42

A separate tender text is available for the Danfoss AB-QM pressure independent balancing & control

valve and the AME110NL 0-10V geared actuator and the NovoCon® S BACnet and ModBus geared actuator.

In a 4-pipe ChangeOver6 system switching flow between heating and cooling circuits is done with a

6-port motorized ball valve, connected directly to digital PIBCV actuator.

Flow control for heating and cooling circuit is performed by a separate pressure independent control

valve and modulating actuator.

1)

6-port ball valve:

- Differential pressure drop over the valve DN15 is <7.3 kPa for 650l/h, KVS is fixed at 2.4 m3/h

- Differential pressure drop over the valve DN20 is <7.6 kPa for 1100l/h, KVS is fixed at 4 m3/h

- No cross-flow between the heating and cooling circuits up to 8 Bar

- Dezincification resistant brass (DZR)

- Medium temperature range 0°C to 90°C

- Zero leakage shut-off functon for maintenance

6-port ball valve actuator:

- Supply Voltage: 24V AC/DC

- Manual and remote shut off function for maintenance

- Feedback signal for valve position

- LED status indication including alarms for valve blocked or missing signal

- Plug in cable, optional with 2x temperature sensors: 1m or open end 2m cable.

- Power consumption: <4 VA running and 0.5W standby

- Click on mounting

1)

A separate tender text is available for the Danfoss AB-QM pressure independent balancing & control

valve and NovoCon® S fieldbus actuator.

10 | © Danfoss | 2020.11

AI162886480177en-000605

Data sheet ChangeOver6 and NovoCon ChangeOver6

AI162886480177en-000605

© Danfoss | 2020.11 | 11

Data sheet ChangeOver6 and NovoCon ChangeOver6

12 | © Danfoss | DHS-SRMT/SI | 2020.11

AI162886480177en-000605

Loading...

Loading...