Page 1

Installation Instruction

Cable to cable Splice

Heat shrink technology connection system

Page 2

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Table of contents

1 Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

2 Certications / Approvals� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

3 Technical data � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

4 Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

5 Kit contents � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

6 Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Required tools / equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cautions and warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Preparation of trace heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Trace heater to trace heater connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

Cold lead cable to trace heater connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation of the end seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 25

9 Safety � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 26

10 Sécurité et advertissements � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 27

1 Overview

This manual introduces the installation and operation of Danfoss heat shrink splice technology. The

connection is established using splice lugs and sealed with heat shrink tubes. Catalog No.: 088L0006.

The trace heating system uses a self-regulating trace heater. It features a temperature-dependent

resistive heating element that regulates and limits the heat according to the ambient temperature. If

the ambient temperature rises, the power output of the trace heater is reduced. This self-regulating

property prevents overheating which would cause damage to the trace heater. Even crossing or overlapping with other trace heaters (or other portions of the same trace heater) are possible.

The heating system is set up as a xed equipment heating system for pipes in ordinary areas. Thanks to

the parallel design the trace heater can be cut and installed to any required length (mind the maximum

heating circuit length according to system’s design guide).

It is suitable for the following self-regulating trace heaters:

• Danfoss PX Pipe Trace Heating System

• Danfoss RX-C Roof and Gutter De-Icing System

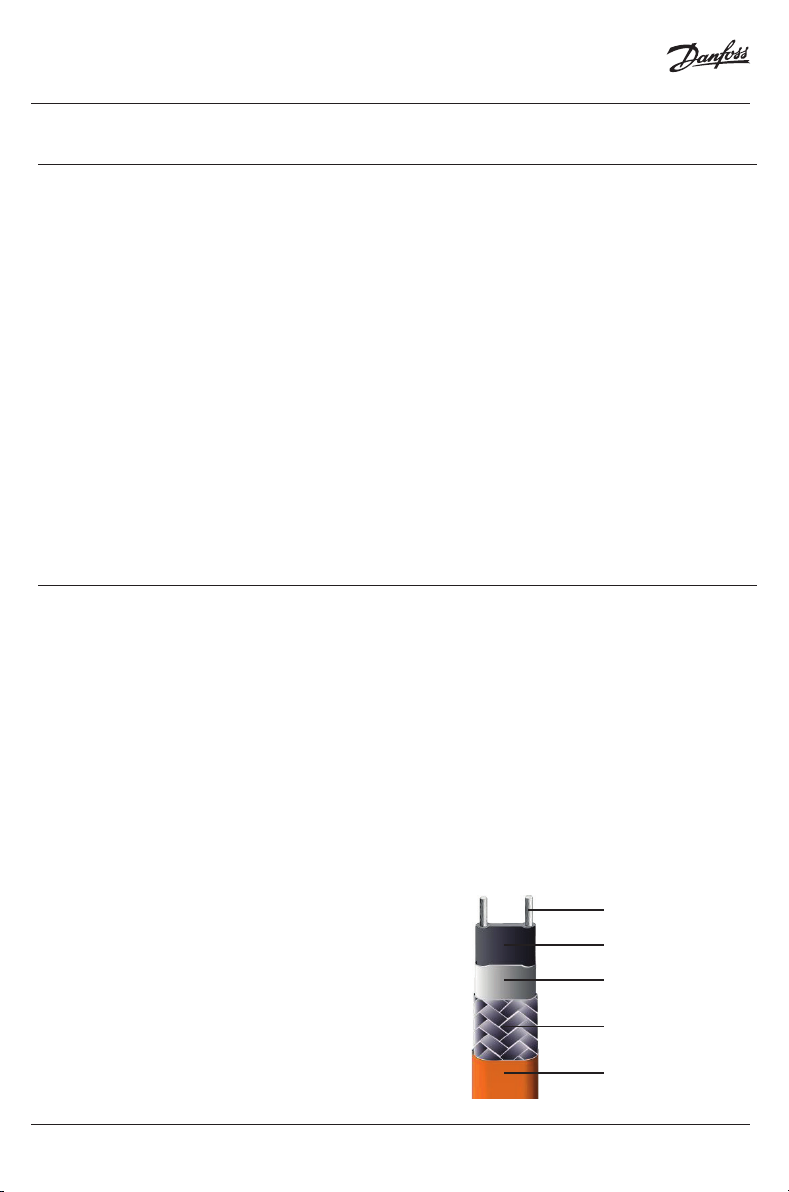

bus wire

heating matrix

insulation jacket

The following terms describe the parts of the trace heater

within these instructions:

grounding braid

outer jacket

2 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 3

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

2 Certications / Approvals

Heat shrink technology connection system for Danfoss PX/RX trace heaters.

3 Technical data

Ambient temperature range -67 to +185 °F / -55 to +85° C

Operation temperature range -67 to +185 °F / -55 to +85° C

Min. installation temperature -4 °F / -20 °C

Max. circuit load 24 A

Ingress protection NEMA Type 4X

Protection classication N/A - for use in ordinary locations only!

AN396730292442en-US0103

© Danfoss | 2022.02 | 3

Page 4

Installation Instruction

4 Safety

Cable to cable Splice - Heat shrink technology connection system

Safety

For safe installation and operation of the cold applied

connection system the technical requirements and

instructions given in this manual must be followed.

WARNING

Risk of re or electrical shock. Follow these guidelines to

avoid personal injury or material damage.

• All electrical systems and installations must comply

with Danfoss requirements and be installed in

accordance with the relevant electrical codes and any

other applicable national and local codes.

• The US and Canadian electrical codes require ground

fault protection to be provided for all trace heating

circuits.

• Install the connection system and trace heaters

carefully.

• Use the trace heater and connection system in

accordance with the intended purpose and strictly

comply with the operational data specied in section

Technical Data.

• The bending radius of the trace heater must be at least

1” (25 mm).Do not bend on the narrow axis.

• Any defective component of the kit must be replaced

before installation.

• To avoid short circuits, do not connect the trace heater

bus wires together.

• Keep all components and the trace heaters dry before

and during installation.

• Beware of hot surfaces when using the heat gun.

• Keep these instructions for future reference.If

applicable, leave them with the end user.

• De-energize before installation or servicing.

• Use only original accessories.

NOTICE

The following instructions are provided in English only.

Refer to www.danfoss.com for the French version.

Sécurité

An de garantir la sécurité lors de l’installation et de

l’utilisation du système de connexion à liaison froide, il est

impératif de respecter les exigences ainsi que les consignes

techniques mentionnées dans le présent manuel.

AVERTISSEMENT

Risque d’incendie ou d’électrocution. Suivez ces consignes

pour éviter toute blessure ou dommage matériel.

• Tous les systèmes et installations électriques doivent

satisfaire aux exigences imposées par la société

Danfoss et doivent être installés conformément aux

normes électriques en vigueur ainsi qu’aux autres

prescriptions nationales et locales applicables.

• Les normes électriques américaines et canadiennes

imposent une protection contre les défauts à la terre

pour tous les circuits de traçage électrique.

• Notez que le guide de conception fourni avec chaque

cable chauant contient des informations importantes

additionalles qu’il convient de respecter en plus du

present manuel.

• La pose du système de connexion et des câbles

chauants doit être réalisée avec le plus grand soin.

• Utilisez le câble chauant et le système de

connexion adaptés à l’usage prévu et répondant aux

caractéristiques de fonctionnement spéciées à la

section Caractéristiques techniques.

• Le rayon de courbure du câble chauant ne doit pas

être inférieur à 1” (25 mm).Ne pas courber le câble

chauant sur la tranche.

• Tout élément défectueux dans le kit doit être remplacé

avant l’installation.

• Pour éviter un court-circuit, ne jamais raccorder

ensemble les deux conducteurs du câble chauant.

• Conservez tous les éléments et les câbles chauants

au sec avant et pendant l’installation.

• Soyez prudent lors de l’utilisation du pistolet à air

chaud, certaines surfaces peuvent devenir brûlantes.

• Conservez ces instructions pour un usage ultérieur.Le

cas échéant, remettez-les à l’utilisateur nal.

• Mettre hors tension avant toute installation ou

opération de maintenance.

• Utilisez exclusivement des pièces et accessoires

d’origine.

AVIS

Les instructions qui suivent sont fournies en anglais

uniquement. Veuillez vous référer au site www.danfoss.com

pour la version française.

4 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 5

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

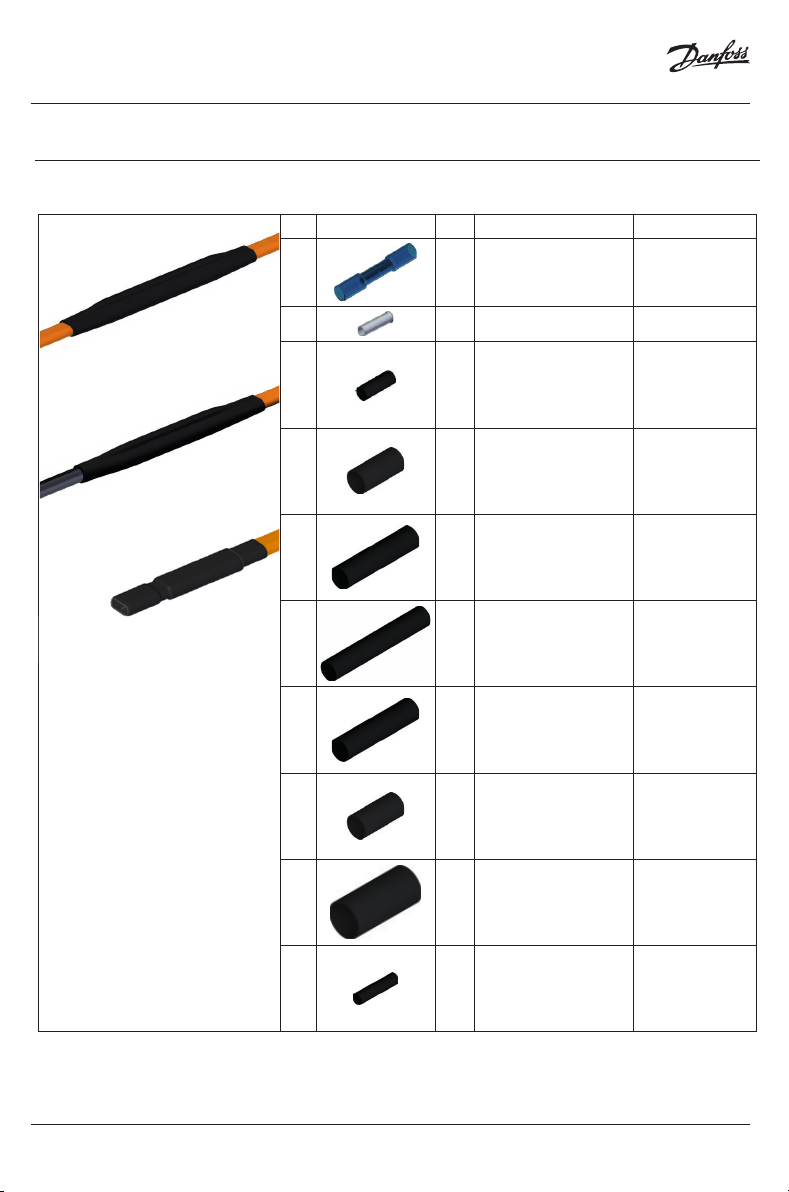

5 Kit contents

The following table lists the kit contents for the Danfoss heat shrink technology connection system:

No. Component Qty. Designation Dimensions

Bus wire splice lug

Heat shrink technology

connection system for

Danfoss PX / RX trace heaters

1 3 x

2 4 x Ferrule -

3 4 x

4 2 x

5 1 x

6 1 x

7 1 x

8 1 x

9 1 x

10 2 x

with heat shrink

tube

Heat shrink tube for

bus wires

Outer heat shrink

tube for bus wires

Connection covering

heat shrink tube

Final covering heat

shrink tube

Outer protection

heat shrink tube

Heat shrink tube for

end-termination

Outer heat shrink

tube for end-termi-

nation

Protection heat

shrink tube for

end-termination

-

Length:

1 3/8" / 35 mm

Diameter:

3/16” / 4,8 mm

Length:

3/4” / 19 mm

Diameter:

3/8” / 9,5 mm

Length:

4 1/2” / 115 mm

Diameter:

1/2” / 12 mm

Length:

7” / 175 mm

Diameter:

3/4” / 19 mm

Length:

8" / 200 mm

Diameter

3/4" / 19 mm

Length:

3/4” / 19 mm

Diameter:

1/2” / 12 mm

Length:

3 1/8" / 80 mm

Diameter:

3/4” / 19 mm

Length:

2 3/8” / 60 mm

Diameter:

3/4” / 19 mm

AN396730292442en-US0103

© Danfoss | 2022.02 | 5

Page 6

Installation Instruction

6 Installation

Cable to cable Splice - Heat shrink technology connection system

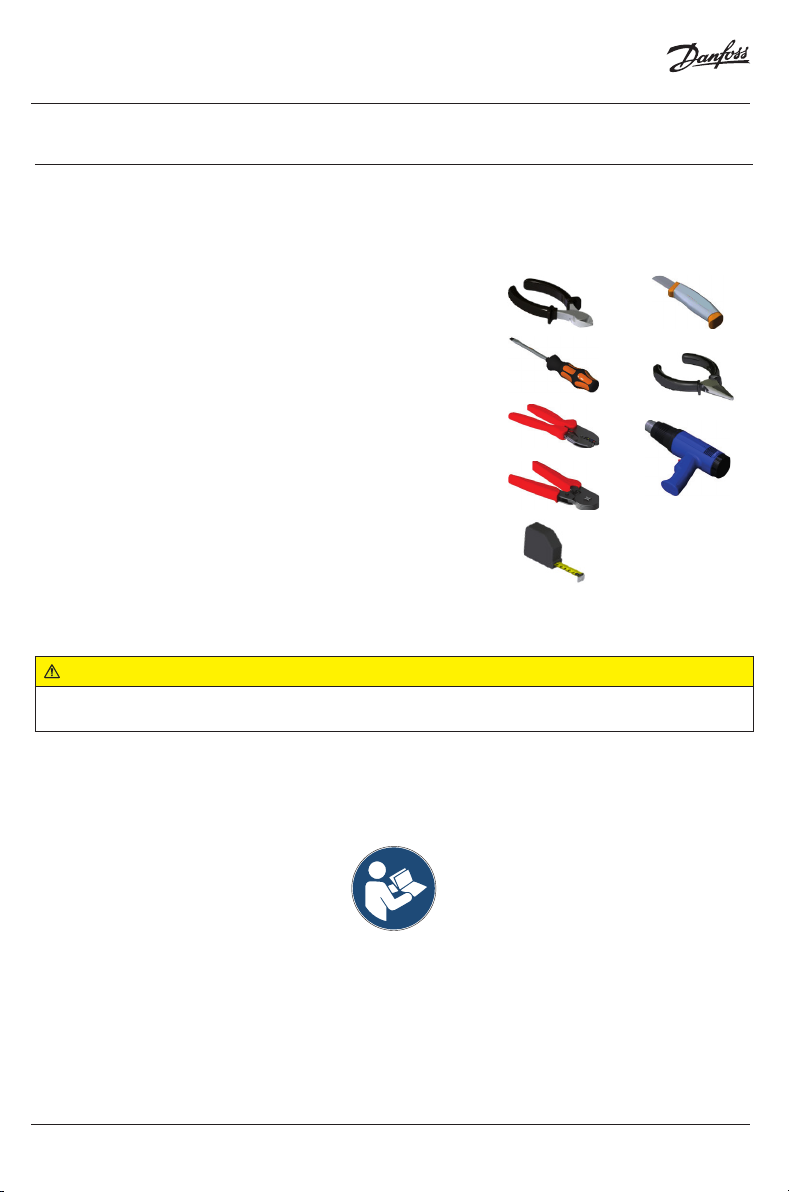

Required tools / equipment

The following tools and equipment are required for installation of the connection system:

• Wire cutters

• Flat screwdriver

• Crimping pliers 97 52 37 KNIPEX or equivalent

• Square-crimp crimping pliers

• Tape measure

• Utility knife

• Needle-nose pliers (2x)

• Heat gun

2 x

Cautions and warnings

WARNING:

Risk of re or electrical shock. De-energize all power circuits before installation or servicing. Always

use ground fault equip-ment protection with the heat tracing system.

• Double-check that all power circuits are de-energized before you begin your work.

1

2

• Make sure that you do not exceed the maximum heating circuit length for the trace heater type you

use. Refer to the design guide of the heating system.

6 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 7

Installation Instruction

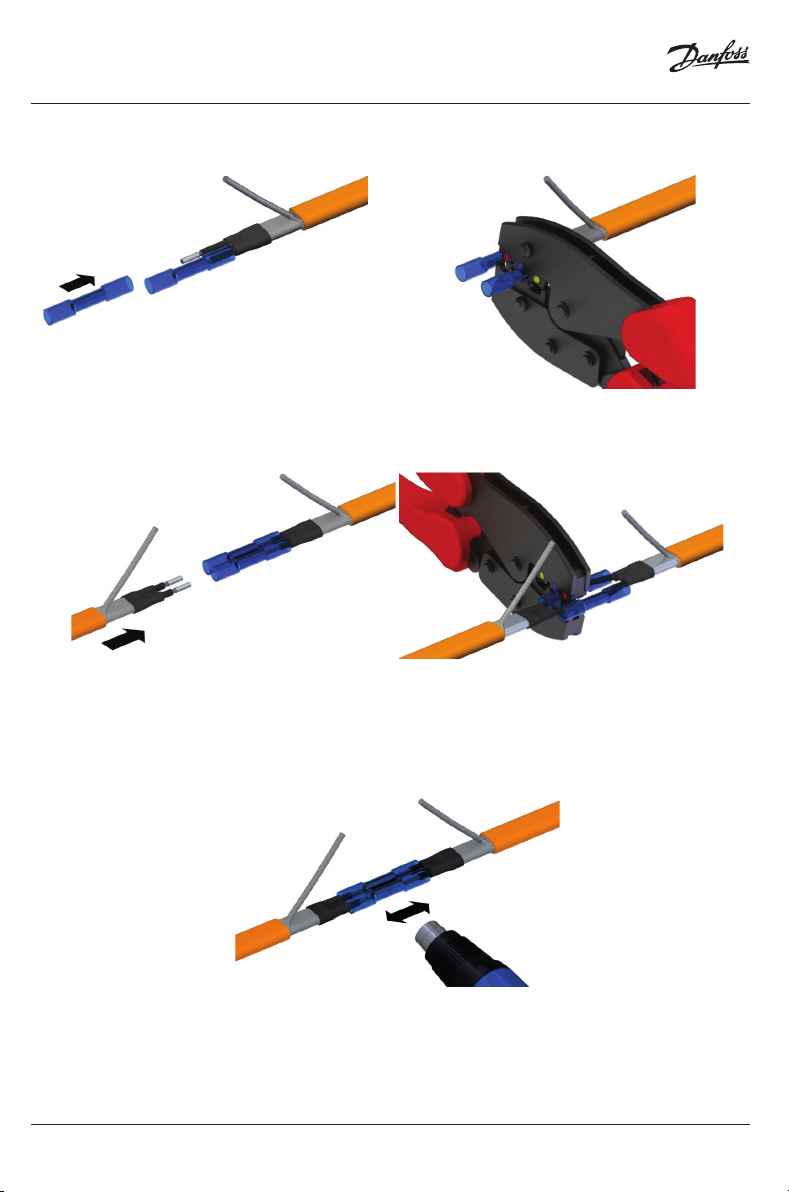

Preparation of trace heaters

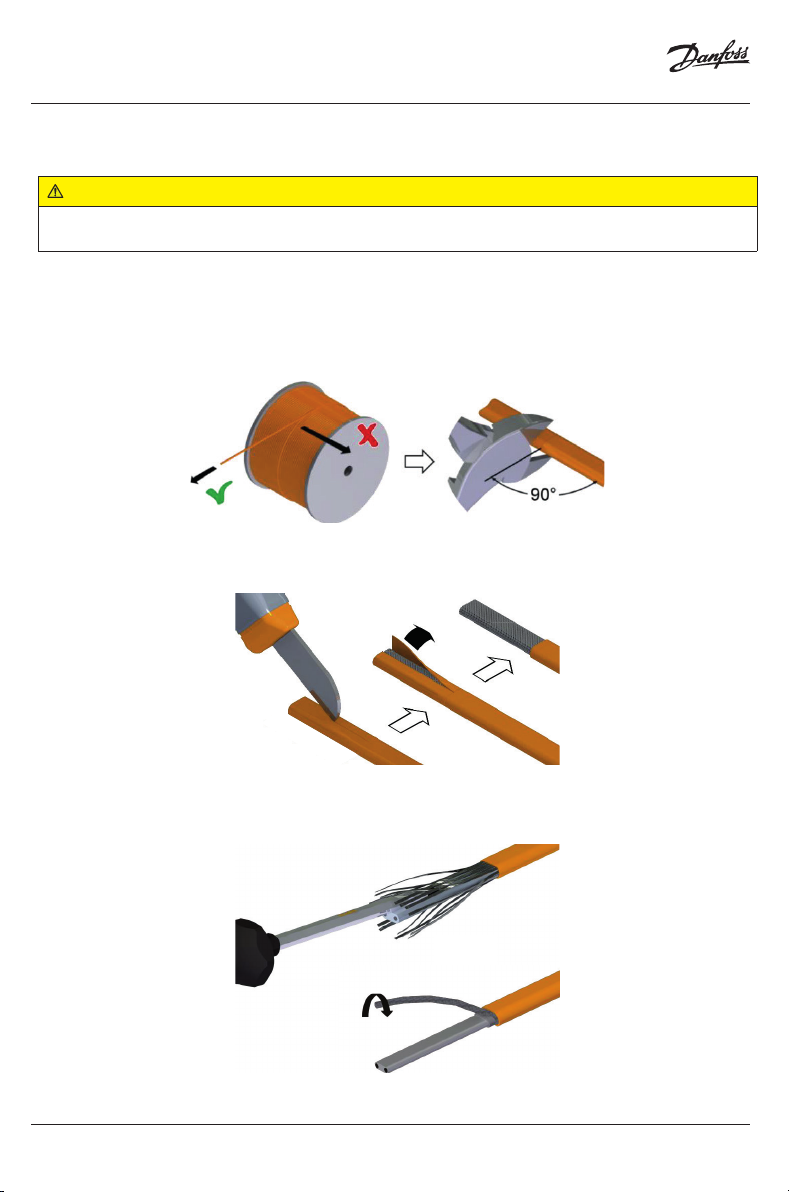

WARNING:

Risk of short cuts and/or material damage. Keep the trace heater ends dry before and during installation. Observe the design guide of the trace heating system.

Cable to cable Splice - Heat shrink technology connection system

Unroll the required trace heater in a straight line and cut to the cor-rect length. Cut o the trace

heater ensuring a straight cut.

Do not bend or pinch the trace heater, or pull it over sharp edges.

Remove 2 3/8" (60 mm) of the outer jacket on the end of the trace heater.

Carefully separate the strands of the grounding braid of the insulation jacket.

Twist the grounding braid in order to form a pigtail.

3

4

5

AN396730292442en-US0103

© Danfoss | 2022.02 | 7

Page 8

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

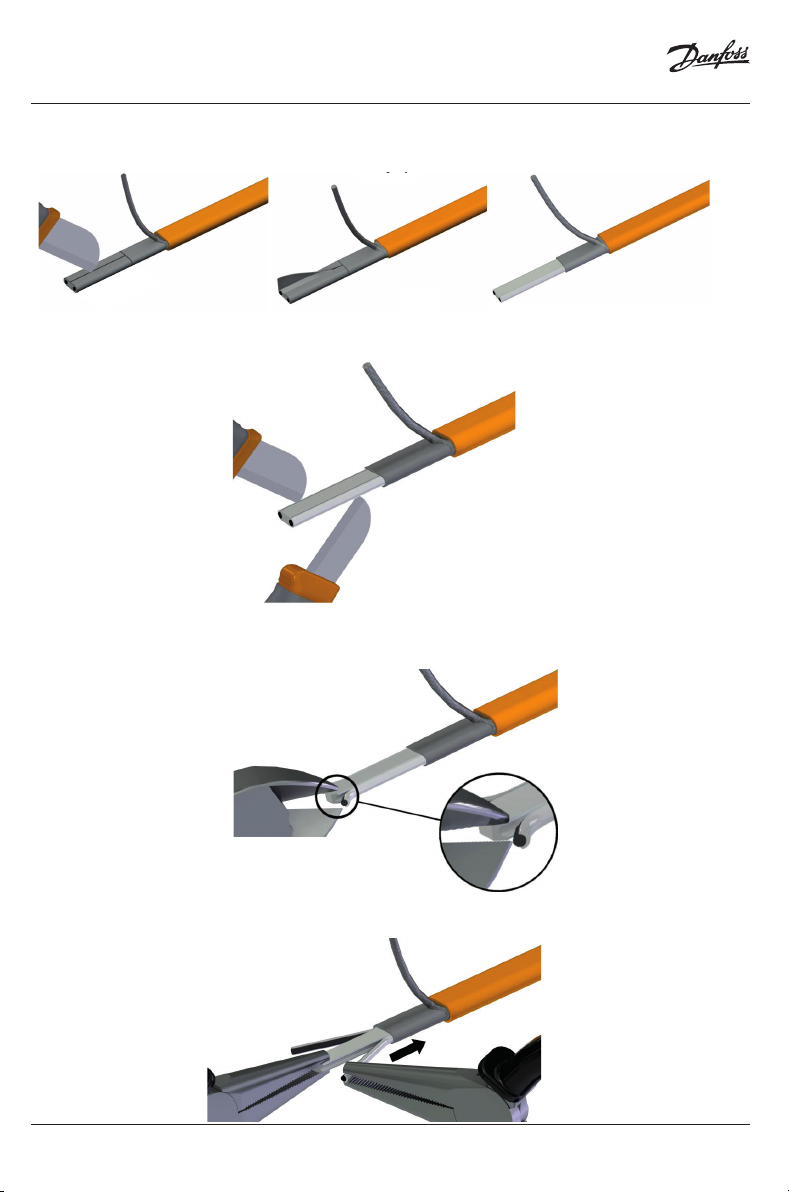

Remove 1 1/2" (40 mm) of the insulating jacket.

Make a small cut over and under each bus wire. Take care not to damage the bus wires.

Carefully make an incision into the edges of the heating matrix. Take care not to damage the bus

wires.

6

7

8

Pull o the bus wires while holding the heating matrix.

8 | © Danfoss | 2022.02

9

AN396730292442en-US0103

Page 9

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

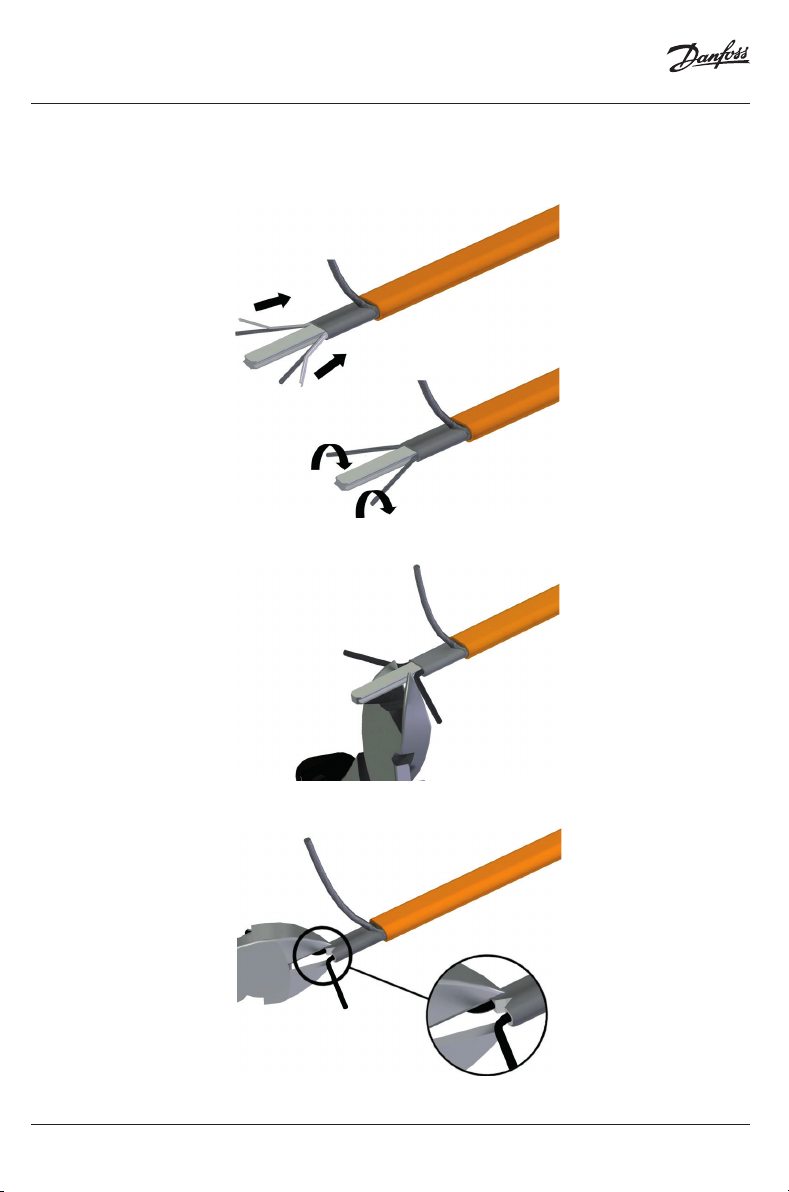

Remove any heating matrix that sticks to the bus wires.

Twist the bus wires.

Remove the remaining heating matrix. Take care not to damage the bus wires.

10

11

Cut in a triangle (¼” (5 mm)) between the bus wires.

AN396730292442en-US0103

12

© Danfoss | 2022.02 | 9

Page 10

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

CAUTION

Risk of burns. Beware of hot surfaces when using the heat gun.

ATTENTION

Risque de brûlures. Faites attention aux surfaces chaudes en utilisant le décapeur thermique.

Slide the bus wire heat shrink tubes (no. 4) all the way onto the bus wires.

Shrink the tubes at a temperature of 275 °F / 135 °C.

NOTICE

For acheiving a tube's temperature of 135 °C, the heat gun may be set to 250 °C setpoint (depends on

Manufacturer / Model) and may be held at a distance of approximately 10 mm to the heat shrink tubes.

Take care for moving circumferently to acheive perfect shrink process on the entire tubes.

All tubes are equipped with glue, which ist melt by the heat shrinking. Observe the glue is squeezing

out on both ends of the tubes and on full circumference.

:

:

13

14

Slide the outer heat shrink tube (no. 5) over the end of the trace heater.

Leave a gap of 1/4" (5 mm) to the outer jacket.

Shrink the tube at a temperature of 275 °F / 135 °C.

While still hot, compress the tube between the bus wires using pliers and hold for 5 seconds.

Repeat steps 3-14 for both trace heaters�

10 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 11

Installation Instruction

Trace heater to trace heater connection

Slide the outer protection heat shrink tube (no. 8) the nal covering heat shrink tube (no. 7) and

the connection covering heat shrink tube (no. 6) onto the rst trace heater.

Cable to cable Splice - Heat shrink technology connection system

15

Slide a ferrule (no. 3) onto both of the bus wires.

Crimp on the ferrules using square-crimp crimping pliers.

16

17

Repeat steps 16-17 for both trace heaters�

AN396730292442en-US0103

© Danfoss | 2022.02 | 11

Page 12

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Slide the bus wire splice lugs (no. 1) all the way onto the bus wires and crimp them on.

Now, slide the bus wires of the second trace heater all the way into the bus wire splice lugs

and crimp them on.

Shrink the red heat shrink tubes of the bus wire splice lugs at a temperature of 275 °F / 135 °C

until the adhesive oozes out.

If one of the outer heat shrink tubes (no. 5) opens up while shrinking, compress it again using pliers

and hold for 5 seconds.

18

19

20

12 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 13

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Slide the connection covering heat shrink tube (no. 6) onto the crimp connection. Make sure

to leave 3/8” / 10 mm of space between the heat shrink tube and the outer jacket.

Shrink the tube at a temperature of 275 °F / 135 °C.

Shorten the twisted shielding braid on both sides to 2 1/2" (65 mm).

21

22

AN396730292442en-US0103

© Danfoss | 2022.02 | 13

Page 14

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Slide the splice lug (no. 1) all the way onto the twisted grounding braid of one of the trace

heaters.

Now, slide the twisted grounding braid of the other trace heater into the other end of the splice lug.

Crimp on the splice lug on both sides using the at crimping pliers.

Shrink the tube at a temperature of 275 °F / 135 °C.

Slide the nal covering heat shrink tube (no. 7) onto the connection.

Shrink the tube at a temperature of 275 °F / 135 °C.

Repeat the steps with the Outer protection heat shrink tube (no. 8)

23

24

14 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 15

Installation Instruction

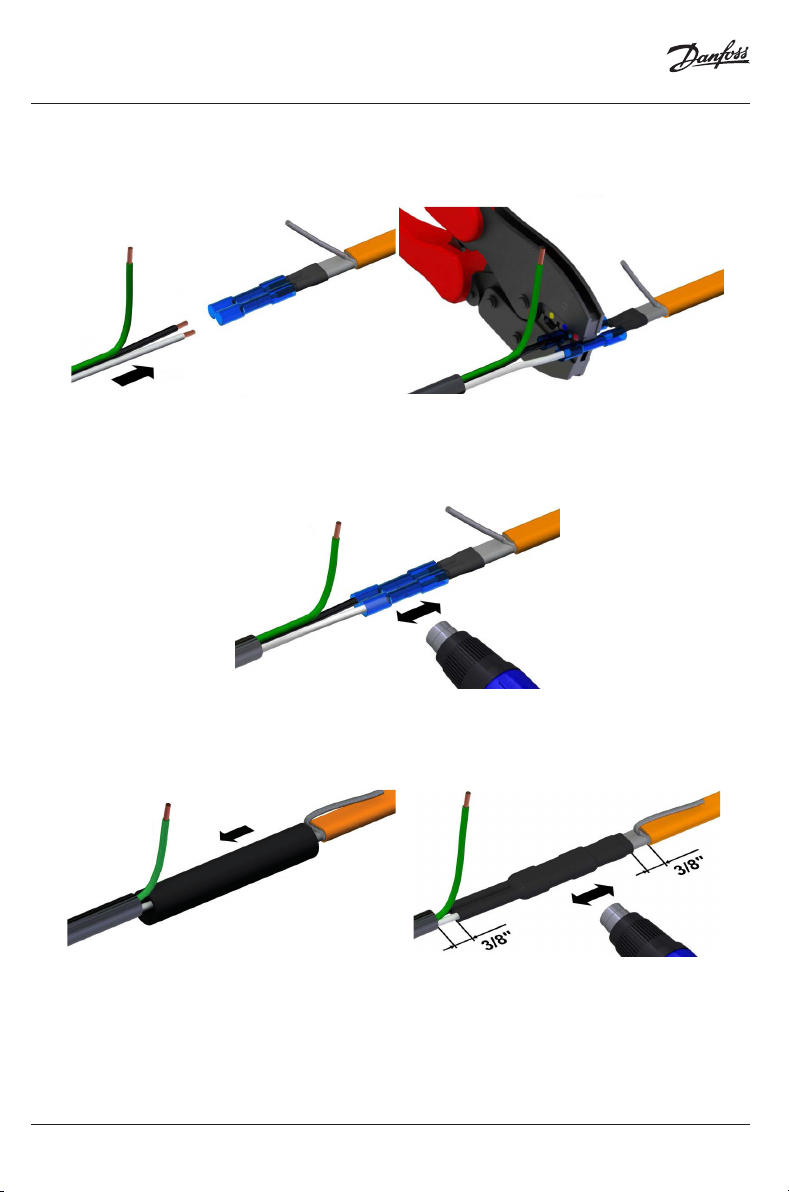

Preparation of the cold lead cable

Remove 3" (75 mm) of the outer jacket on the end of the cold lead cable.

Cable to cable Splice - Heat shrink technology connection system

3"

25

Remove 5/8" (15 mm) of the insulation of the bus wires and the grounding conductor.

5/8"

26

© Danfoss | 2022.02 | 15AN396730292442en-US0103

Page 16

Installation Instruction

Cold lead cable to trace heater connection

Slide the outer protection heat shrink tube (no.8) the nal covering heat shrink tube (no. 7)

and the connection covering heat shrink tube (no. 6) onto the trace heater.

Cable to cable Splice - Heat shrink technology connection system

27

Slide a ferrule (no. 3) onto both of the bus wires.

28

16 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 17

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Crimp on the ferrules using square-crimp crimping pliers.

Slide the bus wire splice lugs (no. 1) all the way onto the bus wires and crimp them on.

29

30

© Danfoss | 2022.02 | 17AN396730292442en-US0103

Page 18

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Now, slide the bus wires of the cold lead cable all the way into the bus wire splice lugs and

crimp them on.

Shrink the blue heat shrink tubes of the bus wire splice lugs at a temperature of 275 °F / 135 °C

until the adhesive oozes out.

If the outer heat shrink tube (no. 5) opens up while shrinking, compress it again using pliers and hold

for 5 seconds.

Slide the connection covering heat shrink tube (no. 6) onto the crimp connection. Make sure to

leave ⁄” / 10 mm of space between the heat shrink tube’s ends and the outer jacket.

Shrink the tube at a temperature of 275 °F / 135 °C.

31

32

33

18 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 19

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Shorten the twisted shielding braid to 2 1/2" (65 mm).

2 1/2"

Slide the splice lug (no. 1) all the way onto the twisted grounding braid of one of the trace

heaters.

Now, slide the twisted grounding braid of the other trace heater into the other end of the splice lug.

Crimp on the splice lug on both sides using the at crimping pliers.

Shrink the tube at a temperature of 275 °F / 135 °C.

34

35

© Danfoss | 2022.02 | 19AN396730292442en-US0103

Page 20

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Slide the nal covering heat shrink tube (no. 7) onto the connection.

Shrink the tube at a temperature of 275 °F / 135 °C.

Repeat the steps with the Outer protection heat shrink tube (no. 8).

36

20 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 21

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Installation of the end seal

Cut the trace heater o straight.

Remove 1 1/4" (30 mm) of the outer jacket on the trace heater.

37

Remove the exposed grounding braid. Make sure that the insulation jacket is not damaged.

Cut in a triangle (3/8" (5 mm)) between the bus wires.

Put the inner heat shrink tube for the end-termination (length: 3/4" (19 mm);

diameter: 1/2" (12 mm) over the end of the trace heater.

Leave an overlap of 3/8" (10 mm).

Beginning at the end of the cable, shrink the tube at a temperature of 275 °F / 135 °C.

38

39

© Danfoss | 2022.02 | 21AN396730292442en-US0103

Page 22

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

While still hot, compress the end of the tube using pliers and hold for 5 seconds.

NOTICE

For acheiving a tube's temperature of 135 °C, the heat gun may be set to 250 °C setpoint (depends

on Manufacturer / Model) and may be held at a distance of approximately 10 mm to the heat shrink

tubes. Take care for moving circumferently to acheive perfect shrink process on the entire tubes.

All tubes are equipped with glue, which ist melt by the heat shrinking. Observe the glue is squee-

zing out on both ends of the tubes and on full circumference.

Now, put the outer heat shrink tube (length: 3 1/8" (80 mm); diameter: 3/4" (19 mm)) over the end

of the trace heater.

Make sure that it overlaps the bared part of the trace heater for 3/4" (19 mm).

Beginning at the end of the cable, shrink the tube at a temperature of 275 °F / 135 °C.

Fold over the overlapping end of heat shrink tube 3/8" (10 mm).

Slightly press the end using pliers.

40

41

22 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 23

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

Now, put the rst protection heat shrink tube (length: 2 1/3" (60 mm); diameter: 3/4" (19 mm)

over the end of the trace heater.

Leave a gap to the outer heat shrink tube of 3/4" (19 mm).

Beginning at the end of the trace heater, shrink the tube at a temperature of 275 °F / 135 °C.

Fold over the overlapping end of the heat shrink tube 3/8" (10 mm).

Slightly press the end using pliers.

Now, put the second protection heat shrink tube

(length: 2 1/3" (60 mm); diameter: 3/4" (19mm)) over the end of the trace heater.

Leave a gap to the very rst heat shrink tube of 3/8" (10 mm).

Beginning at the end of the trace heater, shrink the tube at a temperature of 275 °F / 135 °C.

42

© Danfoss | 2022.02 | 23AN396730292442en-US0103

Page 24

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

8 Troubleshooting

Problem Possible cause Remedy

Trace heater remains cold No power supply

Trace heater or cold lead cable not

properly connected

Control unit adjusted incorrectly

Automatic circuit breaker

disengages

Automatic circuit breaker

defective

Automatic circuit breaker has

wrong tripping characteristics,

e. g. “B” instead of “C”

Nominal circuit breaker size is

insucient

Maximum heating circuit length

has been exceeded

End seal has not been installed|

Short circuit

Humidity inside the connection

system or end seal

Ground fault protection

Trace heater damaged

is disengaged

Moisture in the junction box

Ground fault protection defective

Check the supply line

Connect the trace heater and

cold lead cable according to the

installation instructions

Adjust the control unit according

to the installation instructions

Replace the automatic circuit

breaker

Install an automatic circuit

breaker with Type-C tripping

characteristics

Install an automatic circuit breaker

with higher capacity (Observe

the maximum amperage of all

components of the trace heating

circuit!)

Split the heating circuit into

separate circuits

Install the end seal according to

the installation instructions

Identify the cause and remedy the

fault (e. g. ensure that tape tails are

not twisted)

Replace the connection system /

end seal

Replace the trace heater at the

point where it is damaged

Dry the junction box.

Be sure that the conduit drain is

installed and breathing properly

Replace the ground fault

protection device(s)

24 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 25

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

9 Safety

For safe installation and operation of the cold applied connection system the technical requirements and instructions given

in this manual must be followed.

WARNING

Risk of re or electrical shock.Follow these guidelines to avoid personal injury or material damage.

• All electrical systems and installations must comply with Danfoss requirements and be installed in accordance with

the relevant electrical codes and any other applicable national and local codes.

• The US and Canadian electrical codes require ground fault protection to be provided for all trace heating circuits.

• Install the connection system and trace heaters carefully.

• Note that the design guide that comes with each trace heater contains further important information and must be

followed in addition to this manual.

• Use the trace heater and connection system in accordance with the intended purpose and strictly comply with the

operational data specied in section Technical Data.

• The bending radius of the trace heater must be at least 1” (25 mm).Do not bend on the narrow axis.

• Any defective component of the kit must be replaced before installation.

• To avoid short circuits, do not connect the trace heater bus wires together.

• Keep all components and the trace heaters dry before and during installation.

• Beware of hot surfaces when using the heat gun.

• Keep these instructions for future reference.If applicable, leave them with the end user.

• De-energize before installation or servicing.

• Use only original accessories.

Preparation of the trace heater

WARNING

Risk of re or electrical shock.De-energize all power circuits before installation or servicing. Always use ground fault

equipment within the heat tracing system.

• Double-check that all power circuits are de-energized before you begin your work.

• Make sure that you do not exceed the maximum heating circuit length for the trace heater type you

use.Refer to the system manual of the heating system.

WARNING

Risk of electrical shock and material damage.The gland body and grommet for PX/RX trace heaters are slightly dierent.

Make sure to use the cable gland kit that ts the trace heater you use.

WARNING

Risk of burns.Beware of hot surfaces when using the heat gun.

AN396730292442en-US0103

© Danfoss | 2022.02 | 25

Page 26

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

10 Sécurité et advertissements

An de garantir la sécurité lors de l’installation et de l’utilisation du système de connexion par tech nique de

thermorétraction Danfoss, il est impératif de respecter les exigences techniques ainsi que les consignes mentionnées dans

le présent manuel.

AVERTISSEMENT

Risque d’incendie ou d’électrocution. Suivez ces consignes pour éviter toute blessure ou dommage matériel.

• Tous les systèmes et installations électriques doivent satisfaire aux exigences imposées par la socié té Danfoss et

doivent être installés conformément aux normes électriques en vigueur ainsi qu’aux autres prescriptions nationales et

locales applicables.

• Les normes électriques américaines et canadiennes imposent une protection contre les défauts à la terre pour tous les

circuits de traçage électrique.

• La pose du système de connexion et des câbles chauants doit être réalisée avec le plus grand soin.

• Utilisez le câble chauant et le système de connexion adaptés à l’usage prévu et répondant aux caractéristiques de

fonctionnement spéciées à la section Caractéristiques techniques.

• Le rayon de courbure du câble chauant ne doit pas être inférieur à 1” (25 mm). Ne pas courber le câble chauant sur

la tranche.

• Tout élément défectueux dans le kit doit être remplacé avant l’installation.

• Pour éviter un court-circuit, ne jamais raccorder ensemble les deux conducteurs du câble chauant.

• Conservez tous les éléments et les câbles chauants au sec avant et pendant l’installation.

• Le câble de liaison froide doit être conforme aux exigences locales et être constitué de ls AWG 16 au minimum.

• Soyez prudent lors de l’utilisation du pistolet à air chaud, certaines surfaces peuvent devenir brû lantes.

• Chaque circuit chauant doit être clairement identié par un moyen permanent mentionnant le nom du fabricant, le

type de circuit, sa puissance et sa tension.

• N’employez jamais de ruban adhésif en vinyle, même en complément de ce kit.

• Conservez ces instructions pour un usage ultérieur. Le cas échéant, remettez-les à l’utilisateur nal.

• Mettre hors tension avant toute installation ou opération de maintenance.

• Utilisez exclusivement des pièces et accessoires d’origine Danfoss.

Avertissements et mises en garde

AVERTISSEMENT

Risque d’incendie ou de choc électrique. Éteignez tous les circuits d’alimentation avant l’installation ou l’entretien. Toujours

utiliser un équipement de défaut à la terre dans le système de traçage thermique.

• Vériez bien que tous les circuits électriques sont hors tension avant de débuter votre travail.

• Veillez à ne pas dépasser la longueur de circuit de traçage maximale autorisée pour le type de câble

chauant utilisé. Consultez à ce sujet le guide de conception du système de traçage.

AVERTISSEMENT

Risque d’électrocution et/ou de dommages matériels.Le corps du presse-étoupe et le passe-l destinés aux câbles

chauants PX/RX sont légèrement diérents.Prenez donc garde á bien utiliser le corps du presse-étoupe et le passe-l

adaptés au cäble chauant utilisé.

AVERTISSEMENT

Risque de brülure.Soyez prudent lors de l’utilisation du pistolet á ait chaud, certaines surfaces peuvent devenir brülantes.

26 | © Danfoss | 2022.02

AN396730292442en-US0103

Page 27

Installation Instruction

Cable to cable Splice - Heat shrink technology connection system

© Danfoss | 2022.02 | 27AN396730292442en-US0103

Page 28

Danfoss

11655 Crossroads Circle

Baltimore, MD 21220 USA

Phone: 1-888-DANFOSS (326-3677)

Fax: 416-352-59 81

lx.danfoss.com

28 | © Danfoss | 2022.02

088L8015 & AN396730292442en-US0103

Loading...

Loading...