Page 1

Data sheet

Pressure switch

Type BCP

The BCP type is a series of dedicated pressure switches for

safety and pressure monitoring of steam and hot water boilers.

The BCP incorporates a single-pole changeover microswitch

where the contact position depends on the pressure in the

connection port and the range set value.

For installations, in which operation is particularly critical for

safety reason, the use of fail-safe control is recommended.

Features

Approvals

y Available as high and low pressure limiters as well as

pressure controllers

y Wide pressure range:

from low pressure BCP1 with narrow dierential to high

pressure BCP7

y The fail-safe dual bellows enable premature cut-out when

fault occurs

y DIN plug mounted on the top of control for easy electrical

wiring

y Single-pole changeover switch (SPDT), switch + alarm

CE-marked in accordance with EN 60947-4/-5

VdTŰV-Merkblatt „Druck 100”

TŰV. SDWFS/SDBFS . 15 - 335

y Direct mounting on pressure connection or wall mounting

by means of a bracket

y Versions with automatic and manual resets available

y Screw adjustments made on top of housing

y Manual reset for pressure limiters possible only by means

of tools

y Safety Integrity Level: SIL 2 according to IEC 61508:2010

CE marked in accordance with 2014/68/EU,

category IV, safety equipment, testing basis

pr EN12952-11 and EN12953-9.

IC.PD.P10.1M.02 | 520B7825 | 1© Danfoss | DCS (jmn) | 2017.02

Page 2

Data sheet | Pressure switch, type BCP

Materials in contact with

media

Technical data

Bellows: stainless steel X2CrNi19-11,

1.4306 acc. to EN 10088-2

Pressure connection: nickel plated free cutting steel or stainless

steel X5CrNi18-10,

1.4301 acc. to EN 10088-2

Media Steam, water, air

Ambient temperature -20 – 70 °C

Media temperature

Enclosure

Up to 120 °C

(Above 120 ˚C a water-filled loop must be installed).

IP65

Type BCP - 2B

Action t ype acc. to EN 60730

Types BCPL/BCPH - 2BDF

Electrical connection Plug DIN 43650, Pg 11

Switch type SPDT, snap action microswitch

Contact material Silver/gold (gold plated silver)

Minimum 1mA, 5V

2

Contact load

Maximum1)

) AC-1: 6A, 250V

3

) AC-15: 1A , 250 V

4)

DC 13 10W, 250 V

Ordering

Expected electrical lifetime Min. 250 000 cycles under full contact load.

1

) If used with current higher than 100mA and voltage higher than 30V

the gold layer will be burnt away and the unit can’t be used at a lower

current again.

2

) AC-1 Ohmic load, cosφ 1.

3

) AC-15 inductive load like coil and contactors

with, cosφ 0.3.

4) DC-13 Direct current load.

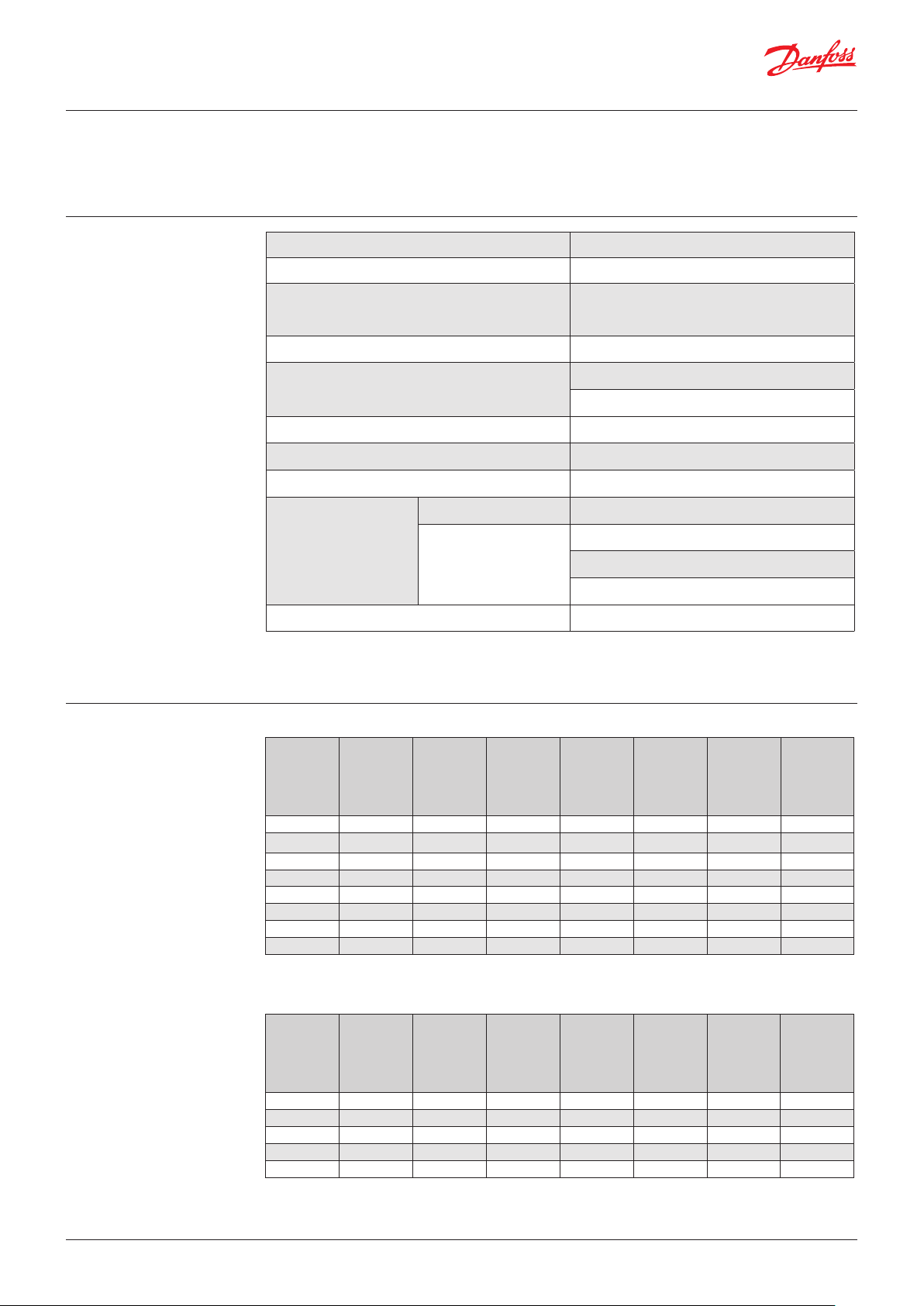

High pressure limiters

Type Range

[bar]

Fixed

Dierential

avg.

[bar]

Reset

Max. operating

pressure

[bar]

Max.

test

pressure

[bar]

Pressure

connection

Code no.

BCP1H 0.1 – 1.1 0.10 Man. 6 7 G 1⁄2 A 017B0030

BCP2H 0.0 – 2.5 0.20

Man.

10 11

G 1⁄2 A

017B0034

BCP3H 0.0 – 6.0 0.40 Man. 16 18 G 1⁄2 A 017B0038

BCP3H 0.0 – 6.0 0.40 Man. 16 18 G 1⁄2 A 017B01381)

BCP4H 1.0 – 10.0 0.45 Man. 25 28 G 1⁄2 A 017B0042

BCP5H 2.0 – 16.0 1.20 Man. 32 35 G 1⁄2 A 017B0046

BCP6H 5.0 – 25.0 1.50 Man. 40 45 G 1⁄2 A 017B0050

BCP7H 10.0 – 40.0 2.30 Man. 63 70 G 1⁄2 A 017B0054

Low pressure limiters

Type Range

[bar]

Fixed

Dierential

avg.

[bar]

Reset

Max. operating

pressure

[bar]

Max.

test

pressure

[bar]

Pressure

connection

Code no.

BCP2L 0.0 – 2.5 0.20 Man. 10 11 G 1⁄2 A 017B0058

BCP3L 0.0 – 6.0 0.40 Man. 16 18 G 1⁄2 A 017B0062

BCP4L 1.0 – 10.0 0.45 Man. 25 28 G 1⁄2 A 017B0066

BCP5L 2.0 – 16.0 1.20 Man. 32 35 G 1⁄2 A 017B0070

BCP6L 5.0 – 25.0 1.20 Man. 40 45 G 1⁄2 A 017B0074

© Danfoss | DCS (jmn) | 2017.022 | IC.PD.P10.1M.02 | 520B7825

Page 3

Data sheet | Pressure switch, type BCP

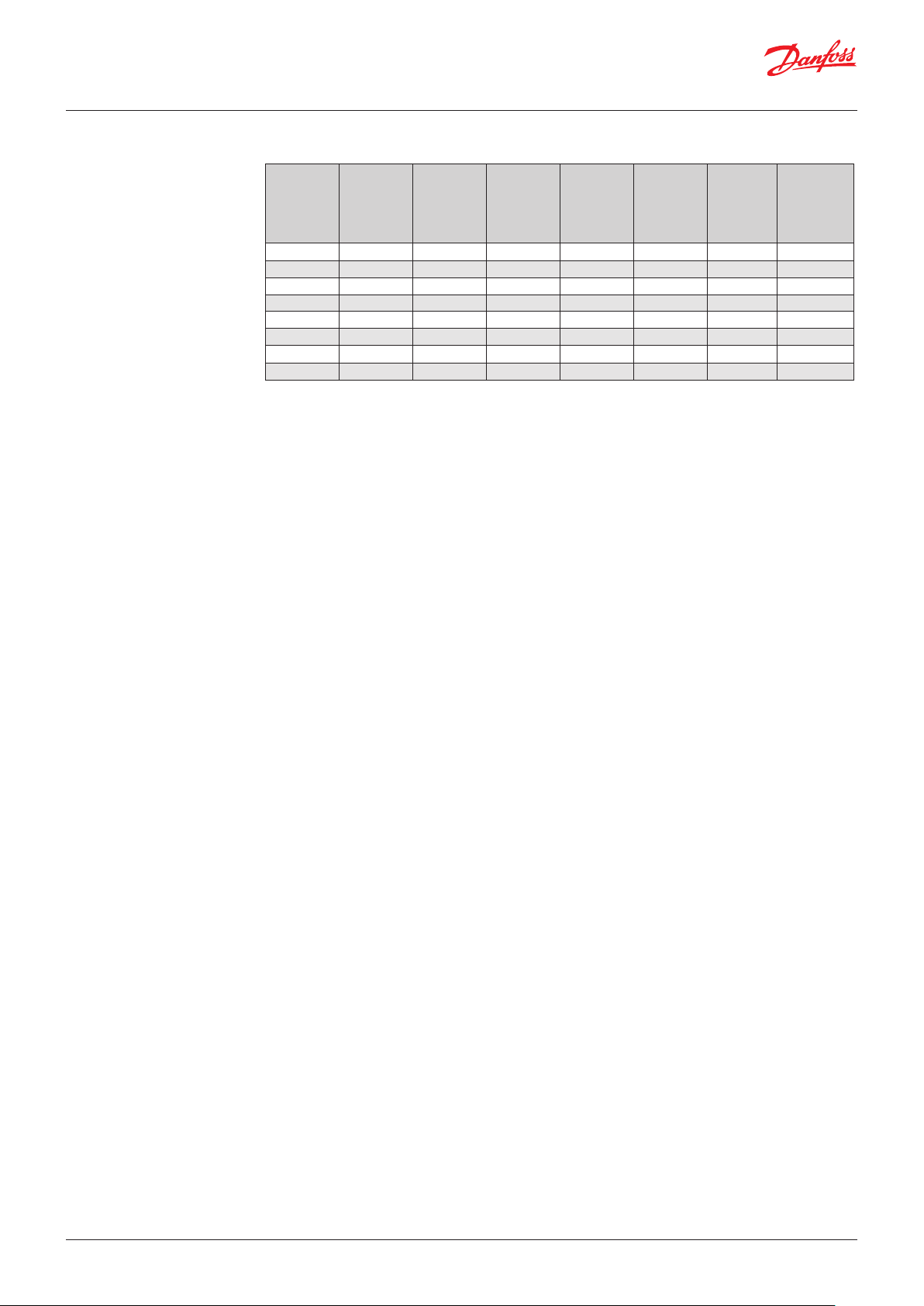

Ordering

Pressure controllers

Dierential

Type Range

[bar]

BCP1 0.1 – 1.1 0.15 – 0.6

BCP2 0.0 – 2.5 0.4 – 1.0 Auto 10 11 G 1⁄2 A 017B0006

BCP3 0.0 – 6.0 0.7 – 1.4 Auto 16 18 G 1⁄2 A 017B0010

BCP3 0.0 – 6.0 0.7 – 1.4 Auto 16 18 G 1⁄2 A 017B01101)

BCP4 1.0 – 10.0 1.0 – 2.5 Auto 25 28 G 1⁄2 A 017B0014

BCP5 2.0 – 16.0 2.0 – 3.2 Auto 32 35 G 1⁄2 A 017B0018

BCP6 5.0 – 25.0 2.5 – 4.0

BCP7 10.0 – 40.0 3.0 – 6.0 Auto 63 70 G 1⁄2 A 017B0026

1

) Stainless steel pressure connector

avg.

[bar]

Reset

Auto

Auto

Max. operating

pressure

[bar]

6 7

40 45

Max.

test

pressure

[bar]

Pressure

connection

G 1⁄2 A

G 1⁄2 A

Code no.

017B0002

017B0022

© Danfoss | DCS (jmn) | 2017.02 IC.PD.P10.1M.02 | 520B7825 | 3

Page 4

Danfoss

17-894.11

Data sheet | Pressure switch, type BCP

Design and function

1. Main spindle

2. Main spring

3. Dierential spindle

4. Dierential spring

5. Reset spring

6. Activating arm

7. Bellows

8. Pressure connection

9. Reset push button

10. Dierential knob

11. DIN plug

12. Microswitch

13. Michroswitch bracket

14. Range knob

Pressure switch, type BCP

Reset

Version with automatic reset cut-in again automatically when

the pressure falls to the set point minus dierential. Version

with manual reset has to be cut in manually by means of tool.

Fail-safe bellows concept

BCP 6, BCP 6H, BCP 7, and BCP 7H have a double bellows: an

operating bellows (inner) and safety bellows (outer).

17-893.11

3

2

1. Pressure connection

2. Regulating bellows

3. Safety bellows

1

Danfoss

Microswitch

BCP is a microswitch based control with DIN plug. Such design

enables easy electrical connection and makes control suitable

for operation with modern electronic systems, as PLC.

Silver/gold plated contacts

Silver/gold plated contacts are used for low currents and

middle range of current, especially in applications with PLC

or other corresponding electronic devices. Such contacts

have also signicantly lower emission of electromagnetic

noises produced on contact break. EMC (Electro Magnetic

Compatibility) is an important parameter where electronic

equipment is used. A gold plated contact has a silver layer

under the gold and can therefore also be used in the middle

range of load. The gold will disappear at loads above 0,1 A.

Note:

Ambient temperature inuence

All BCP pressure switches operate independently of changes in

ambient temperature around the switch.

Therefore the settings for cut-out pressure and dierential

stay constant unless the permissible ambient temperature is

exceeded.

When system pressure exceeds the set value, the BCP will

automatically stop the plant.

A rupture in the inner bellows cause the control cut-out

pressure to fall about 3 times less then the preset value, thus

the system stops prematurely.

A rupture in the outer bellows cause the control cut-out

pressure to fall about 3 bar under the preset value, thus

providing a fail-safe function.

In other BCP types with single bellows assembly, fail-safe

function is satised by proved 2 millions cycles mechanical life

time test.

© Danfoss | DCS (jmn) | 2017.024 | IC.PD.P10.1M.02 | 520B7825

Page 5

Data sheet | Pressure switch, type BCP

Setting

Terminology

Note:

Cut-in and cut-out pressures of the system should always be

checked with accurate pressure gauges.

Pressure settings for switches (with automatic reset)

Set the cut-out pressure on RANGE scale and dierential on

DIFF. scale. Restart pressure is equal to cut-out pressure minus

pre-set dierential value.

Pressure switches with manual reset

High pressure limiters

Set cut-out pressure on the RANGE scale. Pressure limiter can

only be manually reset by pressing reset button by means

of tools when the pressure is equal to or below the cut-out

pressure minus value of the dierential.

Pressure limiters

Limiters are devices that, on reaching a xed value interrupt

and lock out the energy supply.

Manual unlocking is required before restart.

A limiter shall be such that a single fault in any related part shall

not lead to a loss of the safety function.

Note:

If a BCP pressure controller with automatic reset is used as

limiter, lockout must be realized externally as a part of safety

logic, e.g.: by external contactors and/ or relays according to

requirements of standard prEN501156-1 for safety relevant

hardware. External closure must be interlocked, while loss of

auxiliary energy must lead to closure.

Resetting must not be automated; it has to be performed

manually.

Resetting on fault must lead to a repeated closure.

When BCP limits, is for rising or falling applications, the external

safety logic must change to fail-safe position.

Fail-safe control

A control is fail-safe if it has the capability to remain in a safe

condition or transition to a safe condition when a fault occurs.

Low pressure limiters

Set cut-out pressure on RANGE scale. Limiter can only be

reset manually by pressing (with tool) the reset button when

pressure rises to cut-out pressure plus dierential or above it.

Note:

Pressure limiters have no dierential scale. Fixed dierential

value is printed on the scale plate.

Maximum working pressure

The maximum permissible pressure for safe

functioning of the system or any of its components.

Snap function

A specic contact force is maintained in micro-switch until snap

is initiated, therefore, contact bounce cannot occur as a result,

for example, of slight vibrations before cut-out.

These design features ensure that the cut-out point of the BCP

control remains very accurate and completely independent of

the magnitude of the current load.

Set point

A predetermined value to which a control is adjusted and at

which it performs its intended function.

Dierential

The dierence between pressure cut-out and pressure cut-in.

Reset

1. Manual reset

A unit with manual reset can only be restored to operational

mode by activation of the external reset button.

Note:

If the system pressure exceeds PS/MWP then accuracy of the

control settings can be lost.

Maximum test pressure

The maximum pressure applied in strength or leakage tests on

heating systems or components thereof.

2. Automatic reset

A unit with automatic reset is restored to operational mode

automatically

© Danfoss | DCS (jmn) | 2017.02 IC.PD.P10.1M.02 | 520B7825 | 5

Page 6

Data sheet | Pressure switch, type BCP

Installation in steam

systems

Dimensions [mm] and

weights [kg]

To protect the pressure element against excessive temperature

of the media, above allowable 120 °C the insertion of waterlled loop is recommended.

BCP types except for BCP 1 and BCP 1H

Types BCP 1 and BCP1H

Net weight: 0.5 kg

© Danfoss | DCS (jmn) | 2017.026 | IC.PD.P10.1M.02 | 520B7825

Page 7

Accessories for BCP

17-900.11

4x

pressure switches

Mounting bracket, code number 017B1018, for direct mountng on

the wall

Mounting bracket for T 35 mm rail, code number 017B1019

For 35mm rail

Danfoss

17-901.11

ø5.5

Mounting of BCP on the 35 mm rail

Danfoss

For 35mm rail

© Danfoss | DCS (jmn) | 2017.02 IC.PD.P10.1M.02 | 520B7825 | 7

Loading...

Loading...