Page 1

Danfoss

17 - 904.30

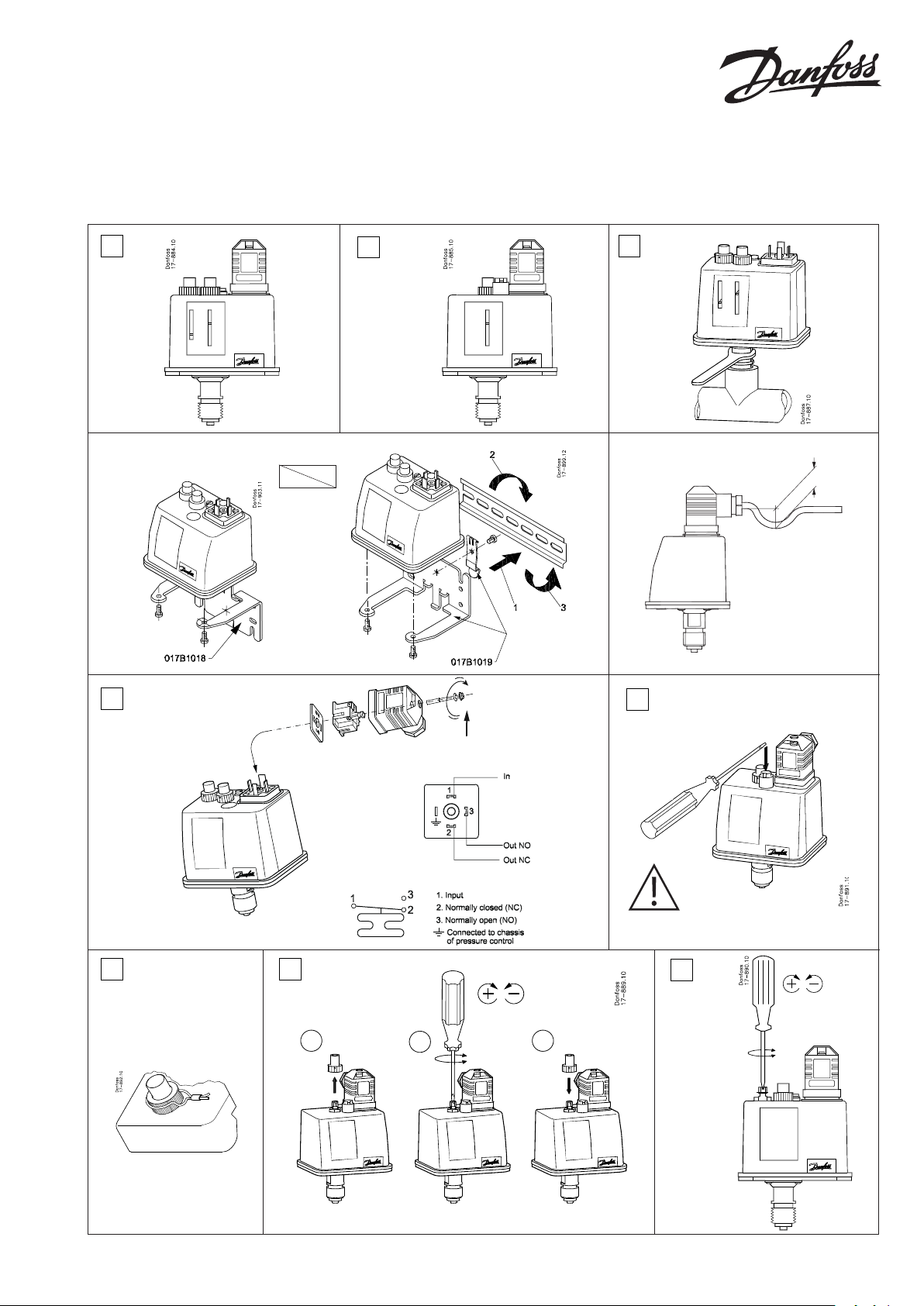

Installation guide

Pressure switch

Type BCP

1

017R9328

Mounting accessories

BCP01

2

3

017R9328

min. 20 mm

4

permissible torque

50/60 Ncm

6

7

1

2

Danfoss

17 - 888.20

3

5

8

© Danfoss | DCS (az) | 2017.11 IC.PI.P10.K8.53 / 520B8307 1

Page 2

ENGLISH

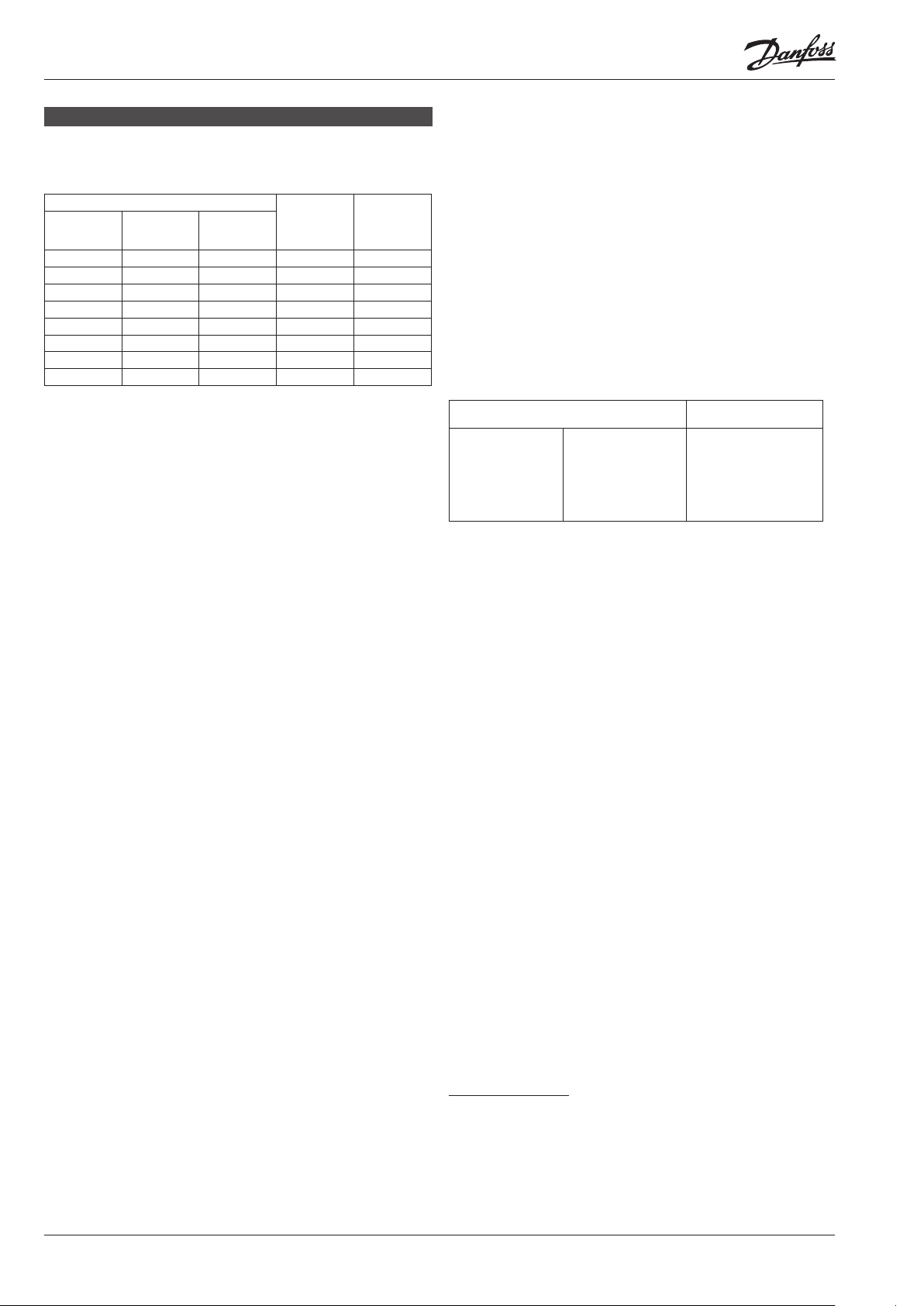

Technical data

BCP pressure controller with auto reset (fig.1)

BCP pressure limiter with manual reset (fig.2)

Typ e Range

Controller Min. limiter Max. limiter

BCP01 – – 0.03 – 0.3 0.4

BCP1 – – 0.1 – 1.1 6

BCP2 BCP2L BCP2H 0 – 2.5 10

BCP3 BCP3L BCP3H 0 – 6.0 16

BCP4 BCP4L BCP4H 1 – 10 25

BCP5 BCP5L BCP5H 2 – 16 32

BCP6

BCP7

**

**

BCP6L BCP6H

– BCP7H

**

**

[bar]

5 – 25 40

10 – 40 63

Max. working

pressure

MWP

[bar]

Max. test pressure: 1.1 × MWP

Min. test pressure: 1 bar

Media: steam, water, air

Max. allowable vacuum: 0.5 bar (BCP1 type only)

Max. media temperature: max. 120 °C

Ambient temperature: -20 − 70 °C

***

Enclosure: IP65

Pressure connection: G ½A

Action type according to EN 60730:

Type BCP 2B

Type BCPL/ BCPH 2BD

*)

If the system pressure e xceeds MWP then accurac y of the switch

setti ng can be lost.

**)

Pressure switches with double bellows

***)

For BCP01 type: -10 – 70 °C

Installation

In order to prevent malfunction of the pressure switch, the

installation must be carried out acc. to the below description.

The cover of BCP should never be dismounted. This is not

necessary neither for installation nor for use of the switch.

The plug should be mounted after installation of the pressure

switch.

Mount the pressure switch directly on the pipe. Always use a

wrench. (fig.3).

Damp strong pressure pulsations. A damping loop will often be

sufficient. Insert a water filled loop as a temperature barrier - for

example a 10 mm copper tube - if there is a risk of the pressure

connection to the switch becoming heated to more than 120 °C.

2. Where pipe supplies the limiter in addition to other limiters:

ø20 mm - for all lengths of pipes.

Functional testing of the limiter

Since the pressure limiter has no internal possibility for functional

testing, there has to be a provision made for functional testing of

*

the device at the boiler site.

The result of the test must be clearly visible to the boiler operator.

The test function should not decrease the boiler safety or lead the

pressure limiter to become inoperable e.g. by possible permanent

override.

Wiring

Electrical connection:

Plug DIN 43650, Pg 11 (fig. 4)

Contact load

Type A contacts

gold plated silver

When used as gold

contacts:

Min. 1 mA, 5 V

Max. 100 mA , 30 V

1)

If used with current higher than 100 mA and voltage higher than 30 V the gold

layer will be burned away and the unit can not be used as gold again.

2)

AC-1 Ohmic load, cosφ 1.

3)

AC-15 induc tive load like coil

and contactors with cosφ 0.3.

4)

DC 13 Direct current load.

When used as silver

1)

contact s

Max:

AC-1: 6 A, 250 V

AC-15: 1 A, 250 V

DC 13 10 W, 250 V

2)

3)

Using the appliance in other than described AC-1, AC-3, AC-15 or

DC-13 modes, may not be as a limiter.

Short circuit protection

The BCP contact system and any co-operated external contactors

or relays should, against the effects of short circuits, be overcurrent protected with 0.6 safety factor.

It means that the nominal current of the device, as stated by the

manufacturer, is to be multiplied by a safety factor of 0.6.

Example:

Rated load for AC-15 is 2A.

Safety factor is 0,6 in consequence: fuse = 2A x 0,6 = 1,2A or less.

Expected electrical life time:

Min. 250.000 cycles under full contact load.

4)

Type B contacts

silver-cadium oxide

Min. 500 mA , 250 V

Max:

AC-1: 10 A, 250 V

AC-15: 2 A, 250 V

DC 13 50 W, 250 V

2)

3)

4)

Steam boilers:

Connecting pipes for the limiter should be connected to the

steam space of the boiler and if necessary, the limiter shall be

protected against the steam temperature by a water seal.

If isolating valve is fitted on the connection pipe, the valve must

be fitted with a position locking device.

Adjustment

IMPORTANT:

- Do not adjust pointers beyond the highest or lowest indicator

marks on the scale plate, as this may cause inaccurate switch

operation.

- Do not apply torque greater than 50 Ncm as it can damage the

pointers.

Fully flooded hot water generators:

The limiter should be connected to the supply pipe before the

first shut-off valve. The limiter body should be installed vertically

so that dirt does not enter the limiter. If there is the possibility of

sludge build-up in the connection pipe it should be possible to

purge the pipe. Such purging must not remove the water seal or

introduce dirt into the water seal.

In addidition, the connection pipe and its boiler connection must

be designed for cleaning and inspection and have a clear bore of

at least:

1. Where pipe supplies only the limiter:

ø8 mm - if pipe is less than 1m long

ø15 mm - if pipe is more than 1 m long

- The scale plate is only for reference and for more precise

setting a pressure gauge should be used.

- Low Switching Point must be above absolute vacuum!

If the differential is set too high on the controller then it will not

switch.

Pressure controller

Scale plate directly indicates High Switching Point (HSP) and

Differential.

1. Set High Switching Point (HSP) by adjusting range screw (fig. 7)

2. Then set Differential by adjusting differential screw (fig. 8)

3. Low Switching Point (LSP) is equal to High Switching Point (HSP)

less Differential:

LOW = HIGH − DIFFERENTIAL

2 IC.PI.P10.K8.53 / 520B8307 © Danfoss | DCS (az) | 2017.11

Page 3

Low pressure limiter

Scale plate directly indicates Low Switching Point. There is no

pointer for Differential.

Differential value is fixed and printed on the scale plate.

1. Set Low Switching Point by adjusting range screw (fig. 7)

2. High Switching Point is equal to Low Switching Point plus

Differential:

HIGH = LOW + DIFFERENTIAL

High pressure limiter

Scale plate directly indicates High Switching Point. There is no

pointer for Differential.

Differential value is fixed and printed on the scale plate.

1. Set High Switching Point by adjusting range screw (fig. 7)

2. Low Switching Point is equal to High Switching Point less

Differential:

LOW = HIGH - DIFFERENTIAL

Protection for settings

The protective cap on adjustment screws may be used to lock

and seal the settings (fig. 6)

Manual reset

For resetting use the screwdriver (Fig. 5)

Manual reset is possible to operate only after return of pressure

to cut-in level.

Before releasing the reset, the cause of the shutdown must be

found and eliminated.

BCP pressure controller with auto reset as a limiting

device

Since the pressure controller BCP has no lockout with manual

resetting, this function must be realized externally as a part of a

safety logic e.g. by external contactors and/or relays which then

are to be used according to the requirements of prEN50156-1

standard for safety relevant hardware.

External closure must not be interlocked, while loss of auxiliary

energy must lead to a closure.

Resetting must not be automated; it has to be performed

manually.

Resetting on fault must lead to a repeated closure. When BCP

limits, for rising or falling application, the external safety logic

must change to the fail safe position.

Endurance of any external contactors and relays must be

according to EN12952-11, which means 250000 switching cycles

under conditions similar to operating conditions and be capable

of a mechanical life time of 2 000 000 switching cycles.

Conditions similar to operating conditions include chemical and

climatic influences as well as electrical and mechanical stresses.

In addition, contactors must fulfil EN60947 and relays must fulfil

EN60255.

BCP with double bellows

BCP6, BCP6H, BCP7, and BCP7H have a double bellows; an outer

bellows and a regulating (inner) bellows.

When system pressure exceeds the set value, the BCP will

automatically stop the plant. The double bellows system prevents

loss of media in the event of bellows rupture. A rupture in the

inner bellows will cause the switch cut-out pressure to fall about 3

times less the set value, thus the system will stop. A rupture in the

outer bellows will cause the switch cut-out pressure to fall to about

3 bar under the set value, thus providing a fail-safe function.

Safety requirements

Installation

• Internal rules and legislation current in the country concerned

with respect to health and safety at work must be observed

• For safety reasons, the installation of pressure switches must

be carried out only by qualified staff, trained in all technical

aspects of their operation,

• Before installation the pipes must be depressurised and purged

(empty of its fluid) in order to avoid any danger to the operator,

• It is essential to isolate the power supply before wiring

connections are made to avoid possible electrical shock or

damage to equipment. Never touch live parts with your fingers

or with any tool,

• DIN plug supplied by Danfoss and cable approved for the

application must be used. The cable must be connected with

adequate stress relief in order to prevent that pulling forces can

be carried through the cable to the plug.

Commissioning

Before putting pressure switch into operation, check that:

• The working conditions are compatible with the details given

in the product label and this instruction notice,

• All electrical connections have been properly made,

• Installation is tight after assembly.

Operation

• This notice must be available on site where pressure switches

are installed,

• Internal rules and legislation current in the country concerned

with respect to health and safety at work must be observed

• Personnel carrying out any intervention on the pressure switch

must be qualified for the task,

• The pressure switch should be checked regularly to see if it

operates properly,

• The BCP cover must not be removed under any circumstances

• Any overload of the pressure switch must be prevented.

Overloaded or damaged switch must be exchanged.

• It is essential to disconnect the plug before dismounting the

switch from the system,

• All operations must be performed using suitable tools

• It is the responsibility of the user to check that there is no

leakage after a faulty operation or on a periodic basis under

normal conditions,

• Only pressure switches designed, constructed and released

by Danfoss must be used for the applicaiton concerned.

Danfoss can accept no responsibility in case of alterations

made on the pressure switches or the use of them against the

instructions of Danfoss,

• Danfoss is not responsible for any damage which may be

caused by the use of parts, accessories or switches which are

not original Danfoss parts.

© Danfoss | DCS (az) | 2017.11 IC.PI.P10.K8.53 / 520B8307 3

Page 4

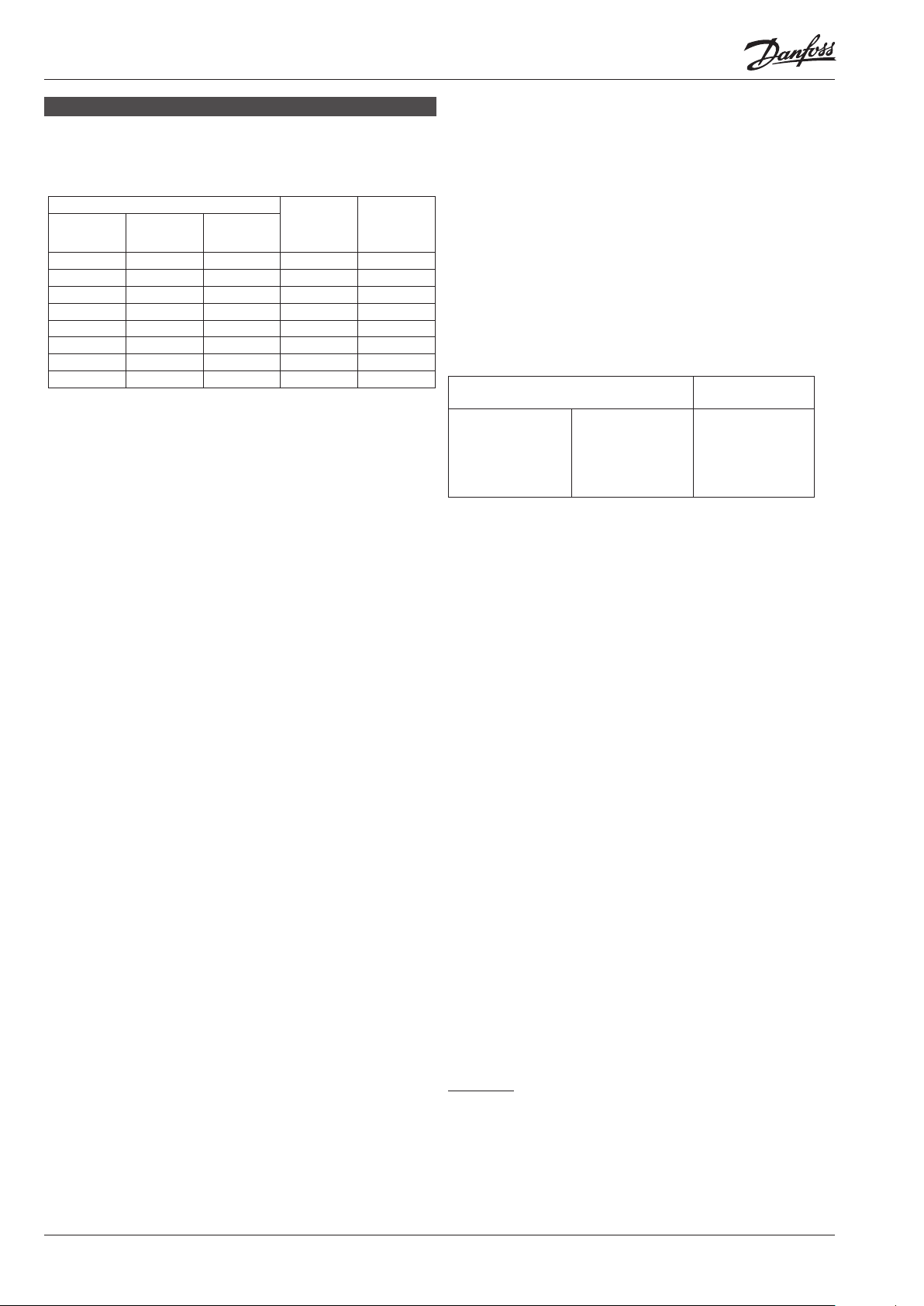

DANSK

2. Hvor røret forsyner pressostaten såvel som andre pressostater

ø20 mm - for alle rørlængder

Tekniske data

BCP Pressostat med automatisk reset (fig.1)

BCP Trykbegrænser med manuel reset (fig.2)

Typ e Område

Pressostat

BCP01 – – 0.03 til 0.3 0.4

BCP1 – – 0.1 t il 1.1 6

BCP2 BCP2L BCP2H 0 til 2.5 10

BCP3 BCP3L BCP3H 0 til 6.0 16

BCP4 BCP4L BCP4H 1 til 10 25

BCP5 BCP5L BCP5H 2 til 16 32

**

BCP6

**

BCP7

Min.

Begrænser

BCP6L BCP6H

– BCP7H

Maks.

Begrænser

**

**

10 til 40 63

[bar]

5 til 25 40

Maks.

arbejdstryk

MWP

[bar]

*

Maks. prøvetryk: 1.1 × MWP

Min. prøvetryk: 1 bar

Medie: damp, vand, luft

Maks. tilladte vakuum: 0,5 bar (BCP1 type kun)

Maks. medietemperatur: maks. 120 °C

Omgivelsestemperatur: -20 til 70 °C

***

Kapsling: IP 65

Tryktilslutning: G ½A

Handlingstype i.h.t. EN 60730:

Type BCP 2B

Type BCPL/ BCPH 2BD

*)

Hvis systemtrykket overstiger MWP, kan kontrolindstillingens

nøjagtighed gå tabt.

**)

Pressostat med dobbeltbælg

***)

Til BCP01 type: -10 – 70 °C

Montering

Installationen skal udføres i overensstemmelse med

nedenstående beskrivelse for at forhindre funktionsfejl på

pressostaten.

BCPs beskyttelseshætte må aldrig afmonteres. Dette er ikke

nødvendigt. Hverken ved installation eller ved anvendelse af

pressostaten.

Stikket skal monteres efter installation af pressostaten.

Monter pressostaten direkte på røret. Anvend altid en skruenøgle.

(fig.3).

Dæmp stærke trykpulsationer. En dæmpesløjfe vil ofte

være til-trækkelig. Indsæt en vandfyldt rør søjle som en

temperaturbarriere - f.eks. et 10 mm kobberrør - hvis der er risiko

for, at tryktilslutningen til pressostaten kan blive varmere end

120 °C.

Dampkedler:

Tilslutningsrørene til begrænseren bør tilsluttes damprummet

i kedlen og, hvis det er nødvendigt, skal pressostaten beskyttes

mod damptemperaturen med en vandlås. Hvis der monteres en

ventil på forbindelsesrøret, skal den monteres med en positionslåseanordning.

Oversvømmet varmtvandsgenerator:

Begrænseren skal tilsluttes forsyningsrøret før den første afspærringsventil. Pressostaten skal monteres lodret, så der ikke kommer

snavs ind i denne. Hvis der kan opstå slamophobning i tilslutningsrøret, skal det være muligt at rense røret. Ved rensning skal det

sikres at vandlåsen bevares og at der ikke kommer snavs i denne.

Desuden skal tilslutningsrøret og den tilhørende kedeltilslutning

være udviklet til rensning og eftersyn og have en klar lysning på

mindst:

1. Hvor røret kun forsyner pressostaten:

ø8 mm - hvis røret er kortere end 1 m

ø15 mm - hvis røret er længere end 1 m

Funktionstest af pressostaten

Da trykbegrænseren ikke har nogen indbygget mulighed for

funktionstest, skal der laves en mulighed for funktionstest af

enheden ved kedlen.

Testresultatet skal være tydeligt synligt for kedelbrugeren,

testfunktionen bør ikke reducere kedelsikkerheden eller

forårsage, at trykbegrænseren bliver ikke-funktionel f.eks., ved

mulig permanent tilsidesættelse.

Kabelføring

Elektrisk tilslutning:

Stik DIN 43650, Pg 11 (fig. 4)

Kontaktbelastning

4)

Type B kontak ter

Sølv (AgCdO)

Min. 500 mA , 250 V

Maks:

AC-1: 10 A, 250 V

AC-15: 2 A, 250 V

DC 13 50 W, 250 V

2)

3)

4)

Type A kontak ter

Au belagte A g

Anvendt som guldkontakter

Min. 1 mA, 5 V

Maks. 100 m A, 30 V

1)

Ved anvendelse under strøm højere end 100 mA og en spænding over 30 V,

forsvinder guldet og enheden kan ikke længere anvendes.

2)

AC-1 ohmsk belastning, cosφ 1.

3)

AC-15 induk tiv last som spoler og kontakter med cosφ 0. 3.

4)

DC 13 Jævnstrømslast.

Anvendt som sølvkon-

1)

takter

Maks:

AC-1: 6 A, 250 V

AC-15: 1 A, 250 V

DC 13 10 W, 250 V

2)

3)

Hvis apparatet anvendes på en anden måde end de beskrevne

AC-1, AC-3, AC-15 eller DC-13 tilstande, må det ikke være i

egenskab af en begrænser.

Kortslutningsbeskyttelse

BCP kontaktsystemet og alle samarbejdende eksterne kontaktorer

eller relæer skal være overstrømsbeskyttet mod kortslutninger

med en sikkerhedsfaktor på 0.6.

Det betyder, at apparatets normale strømstyrke, som angivet af

producenten, skal ganges med en sikkerhedsfaktor på 0.6.

Eksempel:

Den nominelle belastning for AC15 er 2A.

Sikkerhedsfaktor er 0.6, hvilket betyder: sikring = 2A x 0.6 = 1.2A

eller mindre.

Forvendet elektrisk levetid

MIN. 250.000 koblinger ved fuld kontaktbelastning.

Justering

VIGTIGT:

- Juster ikke visere ud over de højeste eller laveste indikatormar keringer på skalapladen, da dette kan resultere i upræcise

styrefunktioner.

- Anvend ikke et moment højere end 50 Ncm, da dette kan skade

viserne.

- Skalapladen er kun til reference. Der bør anvendes et mano meter for at opnå præcis indstilling.

- Lavt omskiftepunkt skal være over absolut vakuum!

Hvis forskellen er indstillet for højt på pressostaten, vil den ikke

omkoble.

Pressostat

Skalapladen angiver direkte det høje omskiftepunkt (HSP=High

Switching Point) og differens:

1. Indstil det høje omkoblingspunkt (HSP=High Switching Point)

ved at justere indstillingsskrue (fig. 7).

2. Indstil derefter differensen ved at justere på differensskruen. (fig. 8).

3. Det lave omskiftningspunkt (LSP=Low Switching Point) er lig

med det høje omskiftningspunkt minus den indstillede differens.

LAV = HØJ − DIFFERENS

4 IC.PI.P10.K8.53 / 520B8307 © Danfoss | DCS (az) | 2017.11

Page 5

Lavtryksbegrænser

Skalapladen angiver direkte det lave omskiftepunkt. Der er

ingen viser for differens. Differensværdien er fast og trykt på

skalapladen.

1. Indstil det lave omskiftepunkt ved at justere indstillingsskrue

(fig. 7)

2. Det høje omskiftepunkt er lig med det lave omskiftepunkt plus

den faste differens:

HØJ = LAV + DIFFERENS

Højtryksbegrænser

Skalapladen angiver direkte det høje omskiftepunkt. Der er

ingen viser for differens. Differensværdien er fast og trykt på

skalapladen.

1. Indstil det høje omskiftepunkt ved at justere indstillingsskruen

(fig. 7)

2. Det lave omskiftepunkt er lig med det høje omskiftepunkt

minus den faste differens:

LAV = HØJ - DIFFERENS

Beskyttelse af indstillinger

Beskyttelseskappen på justeringsskurer kan anvendes til at låse

og forsegle indstillingerne (fig. 6)

Manuel reset

Nulstil ved hjælp af skruetrækkeren (Fig. 5)

Det er kun muligt at aktivere manuel reset efter tilbageføring af

tryk til omskiftningstrykket. Årsagen til udkoblingen skal findes

og ernes, før pressostaten resetes.

BCP pressostat med automatisk reset som

trykbegrænser

Eftersom pressostaten BCP ikke har spærring med manuel reset,

skal denne funktion gennemføres eksternt som en del af en

sikkerhedslogik, f.eks. af eksterne kontaktor og/ eller relæer, som

derefter skal anvendes i henhold til kravene for prEN50156-1

standarden for sikkerhedsrelevant udstyr.

Den eksterne sikkerhedslogik må ikke udføres med interlock,

mens tab af stryespænding resulterer i omskiftning.

Reset må ikke være automatiseret, den skal udføres manuelt.

Reset af en fejl skal føre til gentagen kontaktomskiftning. Når

BCP trykbegrænser, i forbindelse med stigende eller faldende

applikationer, skal den eksterne sikkerhedslogik skiftes til en failsafe position.

Holdbarheden for eksterne kontaktorer og relæer skal være i.h.t.

EN12952-11, hvilket betyder 250000 koblinger under forhold, der

svarer til driftsforholdene og skal kunne opnå en mekanisk livstid

på 2 000 000 koblinger.

Forhold, der svarer til driftsforhold, omfatter kemiske og klimabetingede påvirkninger såvel som elektriske og mekaniske påvirkninger. Desuden skal kontaktorer efterkomme EN60947, og relæer

skal efterkomme EN60255.

BCP med dobbelbælg

BCP6, BCP6H, BCP7, og BCP7H er forsynet med dobbelt bælg, en

ydre bælg og en regulerende (indre) bælg.

Når trykket i anlægget overstiger indstillingsværdien, vil BCP’en

automatisk standse anlægget. Dobbeltbælgsystemet forhindrer

tab af medie i tilfælde af bælgbrud. Ved brud på den indre bælg

falder apparatets brydetryk til ca. 3 gange under den indstillede

værdi. Herved stoppes anlægget. Ved brud på den ydre bælg

falder apparatets brydetryk til ca. 3 bar under den indstillede

værdi. Herved opnås fail-safe funktion.

Sikkerhedskrav

Montering

• Interne regler og lovgivning angående sundhed og sikkerhed

på arbejdet, der er gældende i det pågældende land, skal over holdes,

• Installationen af pressostater må af sikkerhedgrunde kun

udføres af kvalificeret personale, som er uddannet i alle

tekniske aspekter af driften,

• Før montering skal trykket tages af rørene, og de skal tømmes

for væske for at undgå fare for brugeren,

• Det er vigtigt at afbryde strømforsyningen, før ledningsføring

foretages, for at undgå muligt elektrisk chok eller skade på

udstyret. Strømførende dele må aldrig røres med fingrene eller

med værktøj,

• Der skal bruges DIN-stik leveret af Danfoss og kabler godkendt

til denne anvendelse. Kablet skal monteres med passende

aflastning for at undgå, at trækpåvirkninger kan føres

gennem kablet ud i stikket.

Ibrugtagning

Før pressostater tages i drift, skal det kontrolleres at:

• Driftsbetingelserne stemmer overens med de detaljer, som er

angivet på produktets mærkeplade og i denne instruktion,

• Alle elektriske tilslutninger er korrekt udført,

• Installationen er godt efterspændt, efter montage.

Drift

• Denne meddelelse skal være tilgængelig på stedet, hvor

pressostaten er monteret,

• Interne regler og lovgivning angående sundhed og sikkerhed

på arbejdet, der er gældende i det pågældende land, skal

overholdes,

• Det personale, som udfører indgreb på pressostaten, skal være

kvalificeret til opgaven,

• Pressostaten skal kontrolleres regelmæssigt for at kontrollere,

om den fungerer korrekt,

• BCP-dækslet må under ingen omstændigheder ernes,

• Al overbelastning af pressostaten skal undgås. En overbelastet

pressostat skal udskiftes,

• Det er vigtigt at frakoble stikket, før pressostaten afmonteres

fra anlægget,

• Al betjening skal udføres med passende værktøj,

• Det er brugerens ansvar, periodisk at kontrollere om der er

lækage på pressostaten. Denne kontrol skal især udføres ved

funktionsfejl,

• Pressostater udviklet af Danfoss må kun anvendes til de

applikationer de er udviklet til,

Danfoss kan ikke påtage sig ansvaret, hvis der er foretaget

ændringer på pressostaterne, eller hvis de er blevet brugt imod

Danfoss’ instruktioner,

• Danfoss er ikke ansvarlig for skader, der er forårsaget af

anvendelsen af dele, tilbehør eller pressostater, som ikke er

originale Danfoss dele.

© Danfoss | DCS (az) | 2017.11 IC.PI.P10.K8.53 / 520B8307 5

Page 6

DEUTSCH

Technische Daten

Druckregler BCP mit automatischer Rückstellung (Abb.1)

Druckregler BCP mit manueller Rückstellung (Abb. 2)

Typ Bereich

**

**

Min. Begren-

zer

BCP6L BCP6H

- BCP7H

Regler

BCP01 – – 0.03 bis 0.3 0.4

BCP1 – – 0.1 bi s 1.1 6

BCP2 BCP2L BCP2H 0 bis 2.5 10

BCP3 BCP3L BCP3H 0 bis 6.0 16

BCP4 BCP4L BCP4H 1 bis 10 25

BCP5 BCP5L BCP5H 2 bis 16 32

BCP6

BCP7

Max.

Begrenzer

[bar]

**

5 bis 25 40

**

10 bis 40 63

Max.

Betriebs-

überdruck

MWP

[bar]

*

Max. Prüfdruck: 1.1 × MWP

Min. Prüfdruck: 1 bar

Medien: Dampf, Wasser, Luft

Max. zulässiger Vakuum: 0,5 Bar (BCP1 Typ)

Max. Medientemperatur: max. 120 °C

Umgebungstemperatur: -20 bis 70 °C

***

Schutzart: IP65

Druckanschluss: G ½A

Betätigungsart gemäß EN 60730:

Typ BCP 2B

Typ BCPL/ BCPH 2BD

*)

Wenn der Syst emdruck MWP übe rsteigt, kann die Gen auigkeit

der Regeleinstellung verloren gehen.

**)

Druckregler mit doppeltem Wellrohrsystem.

***)

Für BCP01: -10 − 70 °C

Einbau

Um eine Fehlfunktion der Druckregelung zu verhindern, muss der

Einbau gemäß der nachstehenden Beschreibung erfolgen.

Der Deckel des BCP sollte nicht demontiert werden. Dies ist weder

für den Einbau noch die Verwendung des Reglers notwendig.

Der Stecker des BCP sollte nach Einbau des Reglers befestigt

werden.

Den Druckregler direkt am Rohr befestigen. Zur Befestigung

immer einen Schlüssel verwenden. (Abb. 3).

Starke Druckpulsationen sind zu dämpfen. Eine Dämpfungsschleife ist häufig ausreichend. Eine wassergefüllte Schleife als

Temperatursperre ist einzufügen - z.B. ein 10-mm-Kupferrohr falls die Gefahr besteht, dass der Druckanschluss zum Regler auf

mehr als 120 °C erhitzt wird.

Dampfkessel:

Verbindungsrohre für den Druckbegrenzer sollten an den Dampfraum des Kessels angeschlossen werden und der Druckbegrenzer

muss ggf. gegen die Dampftemperatur durch eine mit Wasser

gefüllte Rohrschleife geschützt werden. Wenn ein Absperrventil

am Anschlussrohr vorgesehen ist, muss das Ventil mit einem

Anschlag versehen werden.

Vollständig mit Wasser gefüllte Heißwassererzeuger:

Der Druckbegrenzer sollte vor dem ersten Absperrventil an eine

Zuleitung angeschlossen werden. Das Druckbegrenzergehäuse

muss vertikal eingebaut werden, sodass kein Schmutz in den

Druckbegrenzer gelangt. Falls die Möglichkeit der Ansammlung

von Schlamm im Anschlussrohr besteht, sollte es möglich sein,

das Rohr zu entleeren. Dadurch darf aber nicht die Rohrschleife

entleert oder Schmutz in sie eingetragen werden.

Zusätzlich muss das Anschlussrohr und seine Kesselverbindung

zur Reinigung und Kontrolle ausgelegt sein, und eine freie

Bohrung der folgenden Mindestgröße haben:

1. Wenn das Rohr nur den Druckbegrenzer versorgt:

ø8 mm - wenn das Rohr unter 1 m lang ist

ø15 mm - wenn das Rohr über 1 m lang ist

2. Wenn das Rohr den Druckbegrenzer und andere

Druckbegrenzer versorgt;

ø20 mm - für alle Rohrlängen

Funktionsprüfung des Druckbegrenzers

Da der Druckbegrenzer keine interne Option zur Funktionsprüfung hat, müssen Vorkehrungen für die Funktionsprüfung des

Geräts am Kesselstandort getroffen werden.

Das Ergebnis der Prüfung muss für den Kesselbediener klar

ersichtlich sein. Die Prüffunktion sollte die Kesselsicherheit nicht

vermindern oder zur Funktionsunfähigkeit des Druckbegrenzers

führen, z.B. durch mögliche permanente Umgehung.

Verdrahtung

Elektrischer Anschluss:

Stecker DIN 43650, Pg 11 (Abb. 4)

Kontaktlast:

Typ A Kontakte

Silber / Go ld (goldbeschichtetes Silber)

Bei Anwendung als

Goldkontakt:

Min. 1 mA, 5 V

Max. 100 mA , 30 V

1)

Beim andauerndem Einsatz mit einer Stromstärke größer als 100 mA und einer

Spannung über 30V verschwindet das Gold und das Gerät kann nicht mehr

verwendet werden.

2)

AC-1 Ohmsche Last, cosφ 1.

3)

AC-15 induc tive Last wie z.B. bei Spulen und Schützen cosφ 0.3.

4)

DC 13 Direkter Laststrom.

Bei Anwendung als

Silberkontakt

Max:

AC-1: 6 A, 250 V

AC-15: 1 A, 250 V

DC 13 10 W, 250 V

1)

2)

3)

4)

Typ B Kontakte

Silber (AgCdO)

Min. 500 mA , 250 V

Max:

AC-1: 10 A, 250 V

AC-15: 2 A, 250 V

DC 13 50 W, 250 V

2)

3)

4)

Das Gerät darf in einer anderen Betriebsart als den

beschriebenen AC-1, AC-3, AC-15 oder DC-13 nicht als Begrenzer

verwendet werden.

Kurzschluss-Schutz

Das BCP-Kontaktsystem und alle gleichzeitig betätigten externen

Schütze oder Relais müssen gegen die Auswirkungen eines

Kurzschlusses mit einem Sicherheitsfaktor von 0,6 gegen

Überspannung geschützt werden.

Dies bedeutet, dass der Nennstrom des Geräts laut

Herstellerangaben mit einem Sicherheitsfaktor von 0,6

multipliziert werden soll.

Beispiel:

Nennlast für AC15 ist 2A.

Sicherheitsfaktor ist 0.6, daher: Sicherung = 2A x 0,6 = 1,2A oder

weniger.

Erwartete elektrische Lebensdauer:

Min. 250.000 Schaltspiele bei voller Kontaktlast

Einstellung

WICHTIG:

- Zeiger nicht über die obere oder untere Anzeigermarke an der

Skalenplatte einstellen, da dies falschen Reglerbetrieb zur

Folge haben kann,

- Kein größeres Moment als 50 Nm aufwenden, da dies die

Zeiger beschädigen kann,

- Die Skalenplatte dient nur als Richtschnur und zur präziseren

Einstellung sollte ein Manometer verwendet werden,

- Der untere Schaltpunkt muss über dem absoluten Vakuum

liegen!

Ist die Differenz am Regler zu hoch eingestellt, schaltet er nicht.

Druckregler

Die Skalenplatte zeigt den oberen Schaltpunkt (HSP= High

Switching Point) und Differenz an.

1. Oberen Schaltpunkt (HSP=High Switching Point)über die

Bereichschraube einstellen (Abb. 7)

2. Danach die Differenz durch die Differenzschraube einstellen

(Abb. 8)

3. Der untere Schaltpunkt (LSP=Low Switching Point) ist gleich

dem oberen Schaltpunkt (HSP=High Switching Point) minus

Differenz:

UNTERER = OBERER − DIFFERENZ

6 IC.PI.P10.K8.53 / 520B8307 © Danfoss | DCS (az) | 2017.11

Page 7

Niederdruckbegrenzer

Die Skalenplatte zeigt den unteren Schaltpunkt direkt an. Es gibt

keinen Zeiger für Differenz.

Der Differenzwert ist festgelegt und auf der Skalenplatte

aufgedruckt.

1. Unteren Schaltpunkt über die Bereichschraube einstellen

(Abb. 7),

2. Der obere Schaltpunkt ist gleich dem unteren Schaltpunkt plus

Differenz:

OBERER = UNTERER + DIFFERENZ

Hochdruckbegrenzer

Die Skalenplatte zeigt den oberen Schaltpunkt direkt an. Es gibt

keinen Zeiger für Differenz.

Der Differenzwert ist festgelegt und auf der Skalenplatte

aufgedruckt.

1. Oberen Schaltpunkt über die Bereichschraube einstellen

(Abb. 7)

2. Der untere Schaltpunkt ist gleich dem oberen Schaltpunkt

minus Differenz:

UNTERER = OBERER - DIFFERENZ

Sicherung der Einstellung

Die Schutzkappe an den Einstellschrauben kann zum Blockieren

und Feststellen der Einstellung verwendet werden (Abb. 6).

Manuelle Rückstellung

Zur Rückstellung den Schraubenzieher verwenden (Abb. 5)

Die manuelle Rückstellung ist nur nach Rückkehr des Drucks auf

den Einschaltwert möglich.

Vor Freigabe der Rückstellung muss der Grund für die

Abschaltung gefunden und beseitigt werden.

Druckregler BCP mit automatischer

Rückstellung als Begrenzungseinrichtung

Da der Druckregler BCP keine Sperrung mit manueller

Rückstellung hat, muss diese Funktion extern als Teil einer

Sicherheits-schaltlogik umgesetzt werden, z.B. über externe

Schütze und/ oder Relais, die dann entsprechend den

Anforderungen der Norm prEN50156-1 für sicherheitsrelevante

Geräte verwendet werden.

Die externe Schließung darf nicht verriegelt sein, während Verlust

der Hilfsenergie zum Schließen führen muss.

Die Rückstellung darf nicht automatisch sein, sie muss manuell

durchgeführt werden.

Die Rückstellung bei einer Störung darf nicht zu wiederholter

Schließung führen.

Wenn der BCP begrenzend eingreift, muss die externe Sicherheitslogik für steigende oder fallende Anwendungen in die FailsafeStellung wechseln.

Die Lebensdauer aller externen Schütze und Relais muss

EN12952-11 entsprechen, was 250.000 Schaltzyklen unter

Bedingungen, die den Betriebsbedingungen ähnlich sind,

bedeutet, und sie müssen eine mechanische Lebensdauer von

2.000.000 Schaltzyklen besitzen.

Den Betriebsbedingungen ähnliche Bedingungen sind chemische

und klimatische Einflüsse sowie elektrische und mechanische

Belastungen. Zusätzlich müssen Schütze EN60947 und Relais

EN60255 erfüllen.

BCP mit doppeltem Wellrohr

BCP6, BCP6H, BCP7, und BCP7H sind mit einem doppelten Wellrohrsystem ausgerüstet; einem äußeren Wellrohr und einem

inneren, regulierenden Wellrohr.

Wenn der Anlagendruck den eingestellten Wert überschreitet,

schaltet das Gerät automatisch die Anlage aus. Das doppelte

Wellrohrsystem verhindert Medienverlust bei einem Bruch

des Wellrohrs. Bei Bruch des inneren Wellrohrs schaltet der

Druckregler ca. 3 x unter dem eingestellten Druck die Anlage ab.

Bei Bruch des äußeren Wellrohrs schaltet der Druckregler ca. 3 bar

unter dem eingestellten Druck die Anlage ab und bietet damit

eine Failsafe-Funktion.

Sicherheitsanforderungen

Einbau

• Einschlägig geltende Vorschriften und Gesetze zum

Arbeitsschutz müssen beachtet werden,

• Aus Sicherheitsgründen darf der Einbau von Druckreglern nur

von qualifiziertem Personal ausgeführt werden, das in allen

technischen Aspekten seines Betriebs ausgebildet ist,

• Vor dem Einbau müssen die Rohrleitungen drucklos gemacht

und (von Flüssigkeiten) entleert werden, um Gefährdung des

Bedieners zu vermeiden,

• Die Stromversorgung muss vor dem Herstellen von

elektrischen Anschlüssen unbedingt getrennt werden, um

Stromschlaggefahr und Schäden an Betriebsmitteln und

Geräten zu verhindern. Spannungsführende Teile dürfen

niemals mit den Fingern oder einem Werkzeug berührt

werden,

• Der von Danfoss gelieferte DIN-Stecker und ein für die

Anwendung zugelassenes Kabel müssen verwendet werden.

Das Kabel muss mit ausreichender Zugentlastung

angeschlossen werden, um zu verhindern, dass Zugkräfte

durch das Kabel zum Stecker übertragen werden.

Inbetriebnahme

Bevor der Druckregler in Betrieb genommen wird, folgende

Kontrollen durchführen:

• Die Arbeitsbedingungen entsprechen den Daten auf dem

Produktschild und dieser Anleitung,

• Alle elektrischen Anschlüsse sind vorschriftsmäßig ausgeführt

worden,

• Die Anlage ist nach der Montage dicht.

Betrieb

• Dieser Hinweis muss am Einbauort von Druckreglern verfügbar

sein,

• Einschlägig geltende Vorschriften und Gesetze zum Arbeits schutz müssen beachtet werden,

• Personal, das Eingriffe am Druckregler vornimmt, muss für die

Aufgabe qualifiziert sein,

• Der Druckregler muss regelmäßig überprüft werden, um seine

ordnungsgemäße Funktion sicherzustellen,

• Der BCP-Deckel darf unter keinen Umständen entfernt werden,

• Jegliche Überlastung des Druckreglers muss verhindert

werden. Ein überlasteter oder beschädigter Regler muss

ausgetauscht werden,

• Der Stecker muss vor dem Ausbau des Reglers aus der Anlage

unbedingt abgeklemmt werden,

• Alle Arbeiten müssen unter Verwendung geeigneter

Werkzeuge durchgeführt werden,

• Es ist Aufgabe des Anwenders sicherzustellen, dass nach

fehlerhaftem Betrieb oder unter normalen Bedingungen auf

regelmäßiger Basis keine Undichtigkeiten vorliegen,

• Nur von Danfoss konstruierte, gefertigte und freigegebene

Druckregler dürfen für die betreffende Anwendung eingesetzt

werden,

• Danfoss übernimmt keine Verantwortung für Schäden, die

durch die Verwendung von Teilen, Zubehör oder Reglern, die

keine Originalteile von Danfoss sind, verursacht werden.

© Danfoss | DCS (az) | 2017.11 IC.PI.P10.K8.53 / 520B8307 7

Page 8

FRANCAIS

Caractéristiques techniques

Régulateur de pression BCP à réarmement automatique (fig.1)

Limiteur de pression BCP à réarmement manuel (fig.2)

Typ e Plage

Régulateur Limiteur min. Limiteur max.

BCP01 – – 0.03 à 0.3 0.4

BCP1 – – 0 .1 à 1.1 6

BCP2 BCP2L BCP2H 0 à 2.5 10

BCP3 BCP3L BCP3H 0 à 6.0 16

BCP4 BCP4L BCP4H 1 à 10 25

BCP5 BCP5L BCP5H 2 à 16 32

BCP6

BCP7

**

**

BCP6L BCP6H

– BCP7H

**

**

[bar]

5 à 25 40

10 à 40 63

Pression d’essai max.: 1.1 × MWP

Pression d’essai min.: 1 bar

Fluide: vapeur, eau, air

Tirer au vide max. autorisé : 0,5 Bar (type BCP1 uniquement)

Température de fluide max.: max. 120 °C

Température ambiante: -20 à 70 °C

***

Etanchéité: IP65

Raccord de pression: G ½A

Type d’action conformement à la norme EN 60730:

Type BCP 2B

Type BCPL/ BCPH 2BD

*)

Si la pression du système d épasse la press ion de travail max ., la

précision du réglage du régulateur peut être réduite.

**)

Régulateurs de pression à double soufflet.

***)

Pour BCP01: -10 à 70 °C

Installation

Afin d’éviter tout dysfonctionnement du régulateur de pression,

l’installation doit être effectuée conformément à la description

ci-dessous.

Ne jamais démonter le cache du BCP. Ce n’est nécessaire ni pour

l’installation ni pour l’utilisation du régulateur.

La prise doit être montée après installation du régulateur de

pression.

Monter le régulateur de pression directement sur le tuyau. Utiliser

toujours une clé (fig.3).

Atténuer les fortes vibrations liées à la pression. Une boucle

d’amortissement est souvent suffisante. Insérer une boucle

remplie d’eau servant de protection thermique (un tube en cuivre

de 10 mm par exemple) s’il existe un risque de voir le raccord de

pression vers le régulateur atteindre une température supérieur à

120 °C .

Générateurs de vapeur:

Les tuyaux de raccordement du limiteur doivent être connectés

à la chambre de vapeur du générateur et le limiteur doit si

nécessaire être protégé de la température de la vapeur par un

joint hydraulique. Si une vanne d’isolement est installée sur les

tuyaux de raccordement, elle doit être équipée d’un dispositif de

blocage de position.

Générateur d’eau chaude entièrement immergé:

Le limiteur doit être raccordé au tuyau d’alimentation avant la

première vanne d’arrêt. Le corps du limiteur doit être installé

à la verticale pour que les saletés n’y pénètrent pas. En cas de

formation de boue dans le tuyau de raccordement, il doit être

possible de purger le tuyau. Cette purge ne doit pas entraîner le

démontage du joint hydraulique ou l’introduction de saletés dans

le joint.

De plus, le tuyau de raccordement et son raccord au générateur

doivent être accessibles au nettoyage et à l’inspection et présenter un alésage net d’au moins:

1. Pour un tuyau alimentant uniquement le limiteur:

ø8 mm - si le tuyau mesure moins d’1m de long

ø15 mm - si le tuyau mesure plus d’1m de long

Pression de

travail max.

MWP

[bar]

2. Pour un tuyau alimentant ce limiteur en plus d’autres limiteurs;

ø20 mm - quelle que soit la longueur du tuyau.

Test fonctionnel du limiteur

Comme il est impossible d’effectuer un test fonctionnel du

limiteur de pression seul, des dipositions doivent être prises pour

tester le limiteur à l’emplacement du générateur.

*

Le résultat du test doit être clairement visible pour l’opérateur du

générateur. Le test ne doit pas réduire la sécurité du générateur

ou rendre le limiteur de pression inefficace par exemple par un

surpassement permanent éventuel.

Câblage

Branchement électrique:

Prise DIN 43650, Pg 11 (fig. 4)

Charge de contact:

Contact s type A

Argent/ Plaqué or

Utilisé com me contacts

dorés:

Min. 1 mA, 5 V

Max. 100 mA , 30 V

1)

Si l’utilisation est faite à + de 100 mA et un courant + de 30 V le contact or sera

détruit et l’unité ne pourra plus être utilisée.

2)

AC-1 charge ohmique, cosφ 1.

3) AC-15 charge inductive identique aux bobines et contacterus cosφ 0.3.

4)

DC 13 charge directe.

Utilisé com me contacts en

1)

argent

Max:

AC-1: 6 A, 250 V

AC-15: 1 A, 250 V

DC 13 10 W, 250 V

2)

3)

4)

Contact s type B

Argent (AgCdO)

Min. 500 mA , 250 V

Max:

AC-1: 10 A, 250 V

AC-15: 2 A, 250 V

DC 13 50 W, 250 V

2)

3)

4)

L’utilisation du dispostif sous un mode autre que le mode AC-1,

AC-3, AC-15 ou DC-13 ne permet pas au limiteur de remplir son

rôle.

Protection contre les courts circuits

En raison des effets des courts-circuits, le système de contact BCP

et les relais ou les contacteurs externes contrôles simultanément

doivent être protégés contre les surintensités avec un coefficient

de sécurité de 0,6.

Cela signifie que le courant nominal du dispositif, comme indiqué

par le fabriquant, sera multiplié par un coefficient de sécurité de

0,6.

Exemple:

La charge nominale de l’AC15 est de 2A.

Le coefficient de sécurité est 0,6; par conséquent: fusible = 2A x

0,6 = 1,2A ou moins.

Durée de vie électrique attendue

Min. 250.000 cycles en charge de contact élevée.

Réglage

IMPORTANT:

- Ne pas ajuster les aiguilles au-delà des repères supérieurs ou in férieurs de la plaque graduée car cela peut provoquer un dys fonctionnement du régulateur.

- Ne pas appliquer de couple supérieur à 50 Ncm au risque

d’endommager les aiguilles.

- La plaque graduée sert uniquement de référence; il convient

d’utiliser un manomètre pour obtenir un réglage plus précis.

- Le point de commutation inférieur doit être au-dessus du vide

absolu!

Si le différentiel est réglé trop haut sur le régulateur, celui-ci ne se

déclenche pas.

Régulateur de pression

La plaque graduée indique directement le point de commutation

supérieur (HSP=High Switching Point)et le différentiel.

1. Régler le point de commutation supérieur (HSP=High Switching

Point) en ajustant la vis de réglage de la plage (fig. 7)

2. Régler ensuite le différentiel en ajustant la vis de réglage de la

plage (fig. 8)

3. Le point de commutation inférieur (LSP=Low Switching Point)

est égal au point de commu tation supérieur (HSP=High

Switching Point) moins le différentiel:

BAS = HAUTE − DIFFÈRENTIEL

8 IC.PI.P10.K8.53 / 520B8307 © Danfoss | DCS (az) | 2017.11

Page 9

Limiteur basse pression

La plaque graduée indique directement le point de commutation

inférieur. Il n’y a pas d’aiguille pour le différentiel.

La valeur différentielle est fixe et imprimée sur la plaque graduée.

1. Régler le point de commutation inférieur en ajustant la vis de

réglage de la plage (fig. 7)

2. Le point de commutation supérieur est égal au point de com mutation inférieur plus le différentiel:

HAUTE = BAS + DIFFÈRENTIEL

Limiteur haute pression

La plaque graduée indique directement le point de commutation

supérieur. Il n’y a pas d’aiguille pour le différentiel.

La valeur différentielle est fixe et imprimée sur la plaque graduée.

1. Régler le point de commutation supérieur en ajustant la vis de

réglage de la plage (fig. 7).

2. Le point de commutation inférieur est égal au point de

commutation supérieur moins le différentiel:

BAS = HAUTE - DIFFÈRENTIEL

Protection des réglages

Le capuchon de protection des vis de réglage permet de verrouiller

les réglages et d’assurer leur étanchéité (fig. 6).

Réarmement manuel

Pour le réarmement, utiliser un tournevis (Fig. 5).

Le réarmement manuel peut être réalisé uniquement après

le retour de la pression au niveau de l’enclenchement. Avant

d’effectuer le réarmement, détecter puis éliminer la cause de

l’arrêt.

Régulateur de pression BCP à réarmement

automatique servant de dispositif de limitation

Comme le régulateur de pression BCP n’est pas équipé d’un

verrouillage avec réarmement manuel , cette fonction doit

être assurée de manière externe dans le cadre d’une logique de

sécurité par exemple par des contacteurs externes et/ou des relais

qui sont alors utilisés conformément aux exigences de la norme

prEN50156-1 relative aux matériels de sécurité.

Consignes de sécurité

Installation

• Il convient de respecter les règlements et la législation internes

en vigueur dans le pays en matière de santé et de sécurité au

travail.

• Pour des raisons de sécurité, l’installation de régulateurs de

pression doit être effectuée uniquement par du personnel

qualifié, formé à tous les aspects techniques de leur

fonctionnement.

• Avant installation, les tuyaux doivent être dépressurisés et

purgés (vidés de tout fluide) afin d’écarter tout danger pour

l’opérateur.

• Il est essentiel d’isoler l’alimentation secteur avant de procéder

aux raccordements des câbles pour éviter un éventuel choc

électrique ou des dégâts su l’équipment. Ne jamais toucher les

parties sous tension avec les mains ou avec un quelconque

outil.

• Utiliser la prise DIN fournie par Danfoss et le câble prévu pour

l’application. Le câble doit être raccordé avec la tension

appropriée afin d’éviter que des forces de traction ne soient

transportées par le câble jusqu’à la prise.

Mise en service

Avant de mettre le régulateur de pression en service, vérifier que:

• les conditions de fonctionnement sont compatibles avec les

informations disponibles sur l’étiquette du produit et dans la

notice d’utilisation.

• toutes les connexions électriques ont été effectuées

correctement.

• l’installation est étanche après assemblage.

Fonctionnement

La fermeture externe ne doit pas être verrouillée et la perte

d’énergie auxiliaire doit entraîner une fermeture. Le réarmement

ne doit pas être automatique; il doit être effectué manuellement.

Le réarmement après une panne doit entraîner une fermeture

répétée. Lorsque le BCP joue un rôle de limiteur, pour des

applications montantes ou descendantes, la logique de sécurité

externe doit être remplacée par la position de sécurité intégrée.

La longévité des contacteurs externes et des relais doit être conforme à la norme EN12952-11, à savoir 250 000 cycles de

commutation dans des conditions similaires aux conditions

de fonctionnement et présenter une durée de vie mécanique

de 2 000 000 cycles de commutation. Les conditions similaires

aux conditions de fonctionnement englobent les influences

chimiques et climatiques ainsi que les contraintes électriques

et mécaniques. Les contacteurs doivent par ailleurs respecter la

norme EN60947 et les relais doivent être conformes à la norme

EN60255.

BCP avec double soufflet

BCP6, BCP6H, BCP7 et BCP7H sont pourvus d’un système de

double soufflet: un soufflet extérieur et un soufflet (intérieur)de

régulation.

Quand la pression du système dépasse la valeur de réglage, le

BCP arrête automatiquement l’installation. Le système à double

soufflet èvite la perte de fluide en cas de rupture d’un soufflet.

En cas de rupture du soufflet intérieur, la pression d’ouverture

du régulateur chute à environ 3 fois en dessous de la valeur de

réglage, et en conséquence le système s’arrête.

En cas de rupture du soufflet extérieur, la pression d’ouverture du

régulateur chute à environ 3 bar sous la valeur de réglage. Ceci

assure la sécurité intrinsèque.

• Cette notice doit être disponible sur le site d’installation des

régulateurs de pression.

• Il convient de respecter les règlements et la législation internes

en vigueur dans le pays en matière de santé et de sécurité au

travail.

• Le personnel qui intervient sur le régulateur de pression doit

être qualifié pour la tâche concernée.

• Examiner régulièrement le régulateur de pression pour vérifier

s’il fonctionne correctement.

• Le cache du BCP ne doit en aucun cas être enlevé.

• Èviter toute surcharge du régulateur de pression pour vérifier

s’il fonctionne correctement.

Remplacer tout régulateur en surcharge ou endommagé.

• La prise doit absolutement être débranchée avant de démonter

le régulateur du système.

• Toutes les interventions doivent être effectuées avec les outils

adaptés.

• Il incombe à l’utilisateur de vérifier l’absence de fuite après un

fonctionnement incorrect ou après une période de

fonctionnement déterminée dans des conditions normales.

• Seuls les régulateurs de pression conçus, fabriqués et

commercialisés par Danfoss doivent être utilisés pour

l’application concernée. Danfoss ne saurait en aucun cas

être tenu pour responsable des modifications apportées aux

régulateurs de pression ou d’une utilisation non conforme aux

instructions de Danfoss.

• Danfoss n’est pas responsable des dommages provoqués par

l’utilisation de pièces, accessoires ou régulateurs qui ne sont

pas des composants Danfoss d’origine.

© Danfoss | DCS (az) | 2017.11 IC.PI.P10.K8.53 / 520B8307 9

Page 10

ESPAÑOL

Datos técnicos

Controlador de presión BCP con reset automático (fig. 1).

Limitador de presión BCP con reset manual (fig. 2).

Tipo Rango

Controlador

BCP01 – – 0.03 a 0.3 0.4

BCP1 – – 0,1 a 1,1 6

BCP2 BCP2L BCP2H 0 a 2,5 10

BCP3 BCP3L BCP3H 0 a 6,0 16

BCP4 BCP4L BCP4H 1 a 10 25

BCP5 BCP5L BCP5H 2 a 16 32

BCP6

BCP7

Limitador

mín.

**

**

BCP6L BCP6H

– BCP7H

Limitador

máx.

[bar]

**

**

5 a 25 40

10 a 40 63

Presión máx. de prueba: 1.1 × MWP

Presión mín. de prueba: 1 bar

Medios: vapor, agua, aire

Temperatura máx. de los medios: máx. 120 °C

Temperatura ambiente: -20 a 70 °C

***

Protección: IP65

Conexión de presión: G ½A

Tipo de acción, de acuerdo con EN 60730

Tipo BCP 2B

Tipo BCPL/ BCPH 2BD

*)

Si la presión del sistema supera la MWP, se puede perder la precisión de los

ajustes del controlador.

**)

Controladores de presión con doble fuelle.

***)

Para BCP01: -10 − 70 °C.

Instalación

Para evitar que el controlador de presión funcione

incorrectamente, la instalación se debe realizar según las

indicaciones que encontrará más abajo.

Nunca desmonte la cubierta del BCP. No es necesario para la

instalación ni para la utilización del controlador.

Monte el conector después de instalar el controlador de presión.

Instale el controlador de presión directamente en el tubo. Utilice

siempre una llave (fig. 3).

Amortigüe las pulsaciones de presión fuertes. En la mayoría de las

ocasiones, bastará con un circuito de amortiguación. Si existe el

riesgo de que la conexión de presión del controlador alcance una

temperatura superior a 120 ºC, utilice un circuito relleno de agua

como barrera térmica, por ejemplo, un tubo de cobre de 10 mm.

Calderas de vapor:

Conecte los tubos de conexión del limitador al espacio para el

vapor de la caldera y, si fuera necesario, proteja el limitador de

la temperatura del vapor con un anillo de impermeabilidad. Si

la válvula de aislamiento encaja en el tubo de conexión, debería

estar equipada con un dispositivo de bloqueo de la posición.

Generadores de agua caliente

El limitador debe conectarse a la tubería de suministro antes que

la primera válvula de cierre. El cuerpo del limitador debe estar

instalado verticalmente para que no entre suciedad. Si existe la

posibilidad de que se formen residuos en el tubo de conexión, se

podría purgar el tubo. Durante el purgado, no retire el anillo de

impermeabilidad ni permita que se introduzca suciedad.

Además, el tubo de conexión y su conexión con la caldera deben

estar diseñados para limpiarse e inspeccionarse y tener un

diámetro de al menos:

1. Si el tubo solo suministra al limitador:

ø8 mm, si el tubo mide menos de 1 m de largo.

ø15 mm, si el tubo mide más de 1 m de largo.

2. Si el tubo suministra a más de un limitador:

ø20 mm, para todos los tipos de tubo.

Pres. de fun cionamiento

*

máx.

MWP

[bar]

Prueba de funcionamiento del limitador

Dado que no existe la posibilidad interna de realizar una prueba

de funcionamiento al limitador de presión, debe preverse esta

circunstancia donde se encuentre la caldera para poder realizar

pruebas de funcionamiento. La prueba de funcionamiento no

tendría que disminuir la seguridad de la caldera ni la operatividad

del limitador de presión producida, por ejemplo, por una posible

inhibición permanente.

Cableado

Conexión eléctrica:

Conector DIN 43650, pág. 11 (fig. 4)

Carga de contacto:

Contacto tipo A

De plata / oro (Au Ag recubierto)

Cuando se utiliza como

contactos de oro:

Min. 1 mA, 5 V

Max. 100 mA , 30 V

1)

Si se utiliza con corriente superior a 100 mA y el voltaje superior a 30V de la capa

deoro se evapora y la unidad no puede ser utilizado de nuevo como el oro

2)

AC-1 carga óhmica cos φ1.

3)

AC-15 carga inductiva como la bobina y contac tos con cosφ 0.3.

4)

DC 13 De carga de corriente direc ta.

Cuando se utiliza como

contactos de plata

Max:

AC-1: 6 A, 250 V

AC-15: 1 A, 250 V

DC 13 10 W, 250 V

2)

3)

Si se utiliza la aplicación en un modo distinto al descrito en los

modos AC-1, AC-3, AC-15 o DC-13, puede que no funcione como

con un limitador.

Protección contra cortocircuito

El sistema de contactos del BCP y cualquier contactor externo

o relé que haya intervenido deben estar protegidos contra los

posibles efectos de un cortocircuito o sobretensión mediante un

factor de seguridad de 0,6.

Ejemplo:

La carga nominal para AC15 es de 2 A.

Si el factor de seguridad es 0,6, entonces:

el fusible = 2 A x 0,6 =1,2 A o inferior.

Vida útil eléctrica prevista

Min 250.000 ciclos a plena carga con el contacto.

Ajuste

IMPORTANTE:

- No ajuste los punteros más allá del indicador más alto o más

bajo de la placa de la escala, porque podría provocar un fun

cionamiento incorrecto del control.

- No aplique ningún par mayor de 50 Ncm, ya que podría dañar

los punteros.

- La placa de la escala es solo una referencia; si desea obtener un

ajuste más preciso, utilice un manómetro.

- El punto de conmutación bajo debe estar por encima del vacío

absoluto.

Si el diferencial está ajustado demasiado alto en el controlador, no

se activará.

Controlador de presión

La placa de la escala indica directamente el punto de

conmutación superior y el diferencial.

1. Defi na el punto de conmutación superior ajustando el tornillo

de intervalo (fig. 7).

2. Defi na el diferencial ajustando el tornillo de diferencial (fig. 8).

3. El punto de conmutación inferior es igual al punto de

conmutación superior menos el diferencial:

PUNTO INFERIOR = PUNTO SUPERIOR – DIFERENCIAL

1)

4)

Contacto tipo B

Plata (AgCdO)

Min. 500 mA , 250 V

Max:

AC-1: 10 A, 250 V

AC-15: 2 A, 250 V

DC 13 50 W, 250 V

2)

3)

4)

10 IC.PI.P10.K8.53 / 520B8307 © Danfoss | DCS (az) | 2017.11

Page 11

Limitador de presión decresiente

La placa de la escala indica directamente el punto de

conmutación inferior. No hay ningún puntero para el diferencial.

El valor fi jo del diferencial está indicado en la placa de la escala.

1. Defi na el punto de conmutación inferior ajustando el tornillo

de intervalo (fig. 7).

2. El punto de conmutación superior es igual al punto de conmu tación inferior más el diferencial:

PUNTO SUPERIOR = PUNTO INFERIOR + DIFERENCIAL

Limitador de presión creciente

La placa de la escala indica directamente el punto de

conmutación superior. No hay ningún puntero para el diferencial.

El valor fi jo del diferencial está indicado en la placa de la escala.

1. Defi na el punto de conmutación superior ajustando el tornillo

de intervalo (fig. 7).

2. El punto de conmutación inferior es igual al punto de conmu tación superior menos el diferencial:

PUNTO INFERIOR = PUNTO SUPERIOR – DIFERENCIAL

Protección de los ajustes

La tapa protectora de los tornillos de ajuste se puede utilizar para

bloquear y sellar los ajustes (fig. 6).

Reset manual

Para reiniciar, utilice el destornillador (fig. 5).

El reset manual solo se podrá realizar después de que la presión

vuelva al nivel de activación. Antes de activar el reset, encuentre y

elimine la causa de la parada.

Requisitos de seguridad

Instalación

La ruptura del fuelle exterior provocará una disminución de la

presión de desconexión de 3 bar por debajo del valor

predeteminado, proporcionando una función a prueba de fallos.

• Es necesario tener en cuenta las normas internas y la legislación

vigente en el país respecto a la salud y la seguridad en el

trabajo.

• Por razones de seguridad, la instalación de controladores de

presión debe realizarla solo personal cualifi cado y con cono cimiento de todos los aspectos técnicos de su funcionamiento.

• Antes de la instalación, los tubos deben despresurizarse y pur garse (vaciar los líquidos) para evitar que el operario sufra algún

daño.

• Para evitar una posible descarga eléctrica o daños en el equipo,

es absolutamente necesario cortar la alimentación de red antes

de realizar cualquier conexión del cableado. Nunca toque las

partes conductoras con los dedos ni con ninguna herramienta.

• Es obligatorio utilizar los conectores DIN proporcionados por

Danfoss y un cable adecuado para la aplicación. Para evitar que

las fuerzas de tracción se puedan desplazar del cable al conec tor, el cable debe conectarse con una atenuación de la tensión

apropiada.

Controlador de presión del BCP con reset

automático como dispositivo limitador

Como el controlador de presión BCP no tiene ningún dispositivo

de cierre con reset manual, esta función debe realizarse de forma

externa y en un marco de seguridad, teniendo en cuenta, por

ejemplo, los contactores externos o los relés que más tarde se

utilizarán según los requisitos de la normativa prEN50156-1 sobre

el hardware de seguridad.

El cierre externo no debe interbloquearse, ya que la pérdida de

energía auxiliar podría provocar que se cerrara.

El reinicio no debe ser automático, sino manual. Si se realiza un

reinicio en caso de fallo, el cierre debe repetirse. En el caso de

limitadores BCP para aplicaciones de aumento o disminución, la

seguridad externa debe cambiarse a la posición a prueba

de fallos.

La resistencia de cualquier contactor externo y los relés debe ser

conforme a la normativa EN 12952-11, lo cual implica que 250 000

ciclos de conmutación estén en condiciones similares a las

condiciones de funcionamiento y puedan alcanzar una vida útil

mecánica de 2 000 000 ciclos de conmutación.

Las condiciones similares a las condiciones de funcionamiento

incluyen las infl uencias climáticas y químicas, así como las

tensiones eléctricas y mecánicas. Asimismo, los contactores

deben seguir la normativa EN 60947 y los relés, por su parte, la EN

60255.

BCP con doble fuelle

BCP6, BCP6H, BCP7 y BCP7H tienen doble fuelle: un fuelle

exterior y otro regulador (interior).Cuando la presión del

sistema sobrepasa el valor establecido, el BCP parará la planta

automáticamente. Si se produjera la ruptura del fuelle, el sistema

de doble fuelle evitaría que se perdieran los medios. La ruptura

del fuelle interior provocará una disminución de la presión de

desconexión del controlador 3 veces menor que el valor ajustado,

y así el sistema se parará.

Puesta en marcha

Antes de poner en funcionamiento el controlador de presión,

compruebe que:

• las condiciones de trabajo son compatibles con la información

incluida en la etiqueta del producto y sus instrucciones;

• todas las conexiones eléctricas se han realizado correctamente;

• tras el montaje, la instalación no sufre ninguna fuga.

Funcionamiento

• Esta información debe estar disponible en el lugar donde se

instalan los controladores de presión.

• Es necesario tener en cuenta las normas internas y la legislación

vigente en el país respecto a la salud y la seguridad en el

trabajo.

• Todo el personal que manipule el controlador de presión debe

estar cualifi cado para ello.

• Se debe comprobar regularmente si el controlador de presión

funciona adecuadamente.

• La tapa del BCP no debe retirarse en ningún caso.

• Es necesario evitar la sobrecarga del controlador de presión.

Cambie el controlador cuando esté sobrecargado o dañado.’

• Es necesario desconectar el conector antes de desmontar el

controlador del sistema.

• Todos los operarios deben utilizar las herramientas apropiadas.

• Comprobar que no exista ninguna fuga después de un funcio namiento incorrecto o de forma habitual en condiciones nor males es responsabilidad del usuario.

• Solo se deben utilizar controladores diseñados, fabricados y

distribuidos por Danfoss para esta aplicación. Si se realizan

alteraciones en los controladores de presión o una utilización

contraria a las instrucciones, Danfoss no aceptará ninguna

responsabilidad.

• Danfoss no se responsabiliza de ningún daño originado por la

utilización de piezas, accesorios o controladores que no sean

piezas originales Danfoss.

© Danfoss | DCS (az) | 2017.11 IC.PI.P10.K8.53 / 520B8307 11

Page 12

ITALIANO

Dati tecnici

Pressostati BCP con reinserzione automatica (fig.1)

Pressostati BCP con reinserzione manuale (fig.2)

Tipo Campo

Automatico Riarmo min. Riarmo max.

BCP01 – – 0.03 a 0.3 0.4

BCP1 – – 0.1 a 1.1 6

BCP2 BCP2L BCP2H 0 a 2.5 10

BCP3 BCP3L BCP3H 0 a 6.0 16

BCP4 BCP4L BCP4H 1 a 10 25

BCP5 BCP5L BCP5H 2 a 16 32

BCP6

BCP7

**

**

BCP6L BCP6H

– BCP7H

**

**

Pressione di prova max.: 1.1 × MWP

Pressione di prova min.: 1 bar

Mezzi: vapore, acqua, aira

Temperatura max. dei mezzi: max. 120 °C

Temperatura ambiente: -20 a 70 °C

Protezione: IP65

Attacco di pressione: G ½A

Tipo di azione in conformità con EN 60730:

[bar]

5 a 25 40

10 a 40 63

***

Pressione di

esercizio max.*

MWP

[bar]

Collaudo funzionale del pressostato di blocco

Dal momento che il pressostato di blocco non dispone di metodi

interni per collaudarne la funzionalità, prevedere un collaudo

funzionale del dispositivo presso la caldaia.

Il risultato del collaudo dovrà essere chiaramente visibile

all’operatore della caldaia. Il collaudo non deve compromettere

la sicurezza della caldaia o mettere fuori uso il pressostato, ad

esempio a causa di una deformazione permanente.

Cabliaggio

Conexión eléctrica:

Enchufe DIN 43650, pag. 11 (fig. 4)

Carico di contatto

Contatti tipo A

Argento/ oro (Ag rivestito Au)

Utilizzati come contatti

d’or o:

Min. 1 mA, 5 V

Max. 100 mA , 30 V

1)

Se usato per corrente superiore a 100 mA e la tensione superiore a 30V l ’oro

viene rimosso e l’unità non può essere utilizzato come l’oro di nuovo.

2)

AC-1 Carico ohmico, cosφ 1.

3)

AC-15 carico induttivo come bobine e contattori con cosφ 0. 3.

4)

DC 13 Carichi in corrente continua.

utilizzati come contatti in

1)

argento

Max:

AC-1: 6 A, 250 V

AC-15: 1 A, 250 V

DC 13 10 W, 250 V

2)

3)

4)

Contatti tipo B

Argento (AgCdO)

Min. 500 mA , 250 V

Max:

AC-1: 10 A, 250 V

AC-15: 2 A, 250 V

DC 13 50 W, 250 V

2)

3)

4)

Tipo BCP 2B

Tipo BCPL/ BCPH 2BD

*)

Se la pres sione nel siste ma supera la MWP, c’è il rischio che la

precisione venga ridotta.

**)

Pressostati con doppio sof fietto

***)

Per BCP01: -10 a 70 °C

Installazione

Per evitare guasti al pressostato, l’installazione dovrà essre

effettuata secondo la descrizione seguente.

Non smontare mai il coperchio del BCP. Non è necessario né per

l’installazione né per utilizzare il pressostato.

Il connettore elettrico deve essere montato dopo aver installato il

pressostato.

Montare il pressostato direttamente sul tubo usando sempre una

chiave (fig.3).

Servirsi solo dei fori di montaggio previsti; non aggiungere altri

fori al pressostato. Smorzare le forti pulsazioni della pressione.

A tale scopo è di norma sufficiente un anello di smorzamento.

Inserire un anello riempito d’acqua come barriera di temperatura,

ad esempio un tubo di rame da 10 mm, se vi è rischio che il

raccordo di pressione del pressostato si surriscaldi oltre 120 °C.

Caldaie a vapore:

I tubi di raccordo del pressostato di blocco devono essere

collegati allo spazio per il vapore della caldaia e, se necessario, si

dovrà provvedere alla protezione dalla temperatura del vapore

mediante una tenuta idraulica. Se la valvola di isolamento è

montata sul tubo di raccordo, dovrà essere montata con un

dispositivo di blocco posizione.

Generatori d’acqua calda completamente sommersi:

Il pressostato di blocco deve essere collegato al tubo di

alimentazione prima della prima valvola di intercettazione.

Installare il pressostato di blocco in verticale per impedire

l’ingresso di impurità. Se vi è il rischio di notevole formazione di

fango nel tubo di raccordo, assicurarsi che sia possibile spurgare

il tubo. Tale spurgo non deve rimuovere la tenuta idraulica né

introdurre sporcizia nella stessa. Inoltre il tubo di raccordo e il

relativo raccordo per caldaia devono essere progettati tenendo

a mente le operazioni di pulizia e di controllo e devono avere un

alesaggio ben definito di almeno:

1. Se il tubo alimenta solo il pressostato:

ø8 mm - se il tubo ha una lunghezza inferiore a 1 m

ø15 mm - se il tubo ha una lunghezza superiore a 1 m

2. Se il tubo alimenta questo ed altri pressostati;

Protezione corto circuito

L’uso dell’apparecchiatura in modalità diverse da quelle descritte

AC-1, AC-3, AC-15 o DC-13 potrebbe inficiare la funzione di

pressostato di blocco il sistema di contatti del BCP ed eventuali

contattori esterni o relè aggiuntivi, per evitare gli effetti dei

cortocircuiti, deve essere protetto da sovracorrenti con un

coefficiente di sicurezza di 0,6. Vale a dire che la corrente

nominale del dispositivo, come dichiarato dal fabbricante, deve

essere moltiplicata per detto coefficiente di sicurezza 0,6.

Esempio:

Il carico nominale per AC15 è 2A.

Il coefficiente di sicurezza è 0,6, dunque:

fusibile = 2A x 0,6 = 1,2A o meno.

Durata elettrica prevista

250.000 cicli con contatto a pieno carico.

Regolazione

IMPORTANTE:

- Non regolare gli indicatori oltre i simboli più alti o più bassi sulla

targhetta, in quanto la regolazione potrebbe risultare

imprecisa,

- Non applicare una coppia superiore a 50 Ncm per evitare danni

agli indicatori,

- La targhetta funge solo da riferimento. Per un’impostazione

più precisa servirsi di un manometro,

- Il Punto di Commutazione Inferiore deve essere superiore al

vuoto assoluto!

Se il differenziale impostato sul pressostato è troppo elevato, non

avverà alcuna commutazione.

Pressostato

Nella targhetta sono indicati direttamente sia il punto di

commutazione superiore (HSP=High Switching Point) ed anche il

differenziale.

1. Impostare il Punto di Commutazione Superiore (HSP=High

Switching Point) agendo sulla vite di regolazione (fig. 7)

2. Quindi impostare il Differenziale agendo sulla vite di

regolazione

dello stesso (fig. 8)

3. Il Punto di commutazione inferiore (LSP=Low Switching Point)

corrisponde al Punto di commutazione superiore (HSP=High

Switching Point) impostato meno il Differenziale:

INFERIORE = SUPERIORE − DIFFERENZI

ø20 mm - per tubi di qualsiasi lunghezza.

12 IC.PI.P10.K8.53 / 520B8307 © Danfoss | DCS (az) | 2017.11

Page 13

Pressostato di blocco alla minima pressione

La targhetta indica direttamente il Punto di Commutazione

Inferiore. Non è previsto alcun indicatore per il differenziale.

Il valore del differenziale è fisso ed è stampato sulla targhetta.

1. Impostare il Punto di Commutazione Inferiore agendo sulla vite

di regolazione (fig. 7)

2. Il riarmo manuale è possibile solo quando la pressione ha

superato il punto di commutazione inferiore più il differenziale

SUPERIORE = INFERIORE + DIFFERENZIALE

Pressostato di blocco alla massima pressione

La targhetta indica direttamente il Punto di Commutazione

Superiore. Non è previsto alcun indicatore per il Differenziale.

Il valore del differenziale è fisso ed è stampato sulla targhetta.

1. Impostare il Punto di Commutazione Superiore agendo sulla

vite di regolazione (fig. 7)

2. Il riarmo manuale è possibile solo quando la pressione è scesa

al di sooto del punto di commutazione superiore meno il

differenziale

INFERIORE = SUPERIORE - DIFFERENZIALE

Protezione delle impostazioni

Il cappuccio di protezione sulle viti di regolazione può essere

utilizzato per bloccare e sigillare le impostazioni (fig. 6)

Reinserzione manuale

Per il riarmo servirsi del cacciavite (Fig. 5)

Prima di riarmare manualmente accertarsi che la causa della

commutazione sia stata individuata e risolta.

Pressostato BCP con reinserzione automatica

come dispositivo di blocco

Poiché i pressostati automatici BCP non dispongono di blocco

con reinserzione manuale, questa funzione deve essere realizzata

esternamente come parte di un dispositivo logico di sicurezza,

ad es. mediante contattori e/o relè esterni da utilizzare secondo i

requisti degli standard prEN50156-1 per l’hardware di sicurezza.

Il dispositivo eletttrico esterno non deve essere interbloccato,

dovranno essere utilizzati i contatti normalmente chiusi di

quest’ultimo. La reinserzione deve essere realizzata con pulsante

di riarmo manuale.

La reinserzione dopo un guasto deve condurre a una successiva

chiusura dei contatti. L’intervento del BCP in salita o in discesa

come organo di sicurezza deve condurre il dispositivo logico di

sicurezza esterno nella posizione di autoprotezione.

La durata dei contattori e dei relè esterni deve essere conforme

a EN12952-11, che corrisponde a 250000 cicli di commutazionein

condizioni analoghe a quelle operative, inoltre devono avere

una durata meccanica di 2 000 000 cicli di commutazione. Le

condizioni analoghe a quelle operative includono le influenze

chimiche e climatiche e le sollecitazioni elettriche e meccaniche

Inoltre i contattori devono soddisfare la EN60947 e i relè la

EN60255.

BCP con doppio soffietto

BCP6, BCP6H, BCP7 e BCP7H dispongono di doppio soffietto, un

soffietto esterno e un soffieto di regolazione (interno).

Quando la pressione del sisterna supera il valore impostato,

il BCP arresta automaticamente l’impianto. Il sistema con

doppio soffietto evita perdite di fluidi in caso di rottura di un

valvola a soffietto. La rottura del soffietto interno determina

una aumento della pressione di intervento del pressostato di

circa 3 volte rispetto al valore impostato, causando l’ arresto

del sistema. La rottura del soffietto esterno determina una

aumento della pressione di intervento del pressostato di circa 3

bar rispetto al valore impostato, a garanzia di un funzionamento

intrinsecamente sicuro.

Requisiti di sicurezza

Installazione

• Rispettare le regole e la legislazione in vigore nel paese

di utilizzo relative alla prevenzione e alla sicurezza sul lavoro,

• Per ragioni di sicurezza, l’installazione dei pressostati deve

essere eseguita solo da personale qualificato e addestrato per

il tipo di mansione,

• Prima dell’installazione, i tubi devono essere depressurizzati e

spurgati (svuotati del liquido) per evitare pericolo per

l’operatore,

• È fondamentale isolare l’alimentazione prima di effettuare le

connesioni del cablaggio per evitare scosse elettriche o danni

alle apparecchiature. Non toccare le parti sotto tensione con le

dita o qualsiasi strumento,

• Utilizzare solo la spina DIN fornita da Danfoss e i cavi approvati

per l’applicazione. I Cavi devono essere ancorati in modo

adeguato per evitare che accidentali trazioni possano trasferirsi

al connettore.

Messa in servizio

Prima di mettere in funzione il pressostato, verificare che:

• Le condizioni di esercizio siano compatibili con i dettagli forniti

sull’etichetta del prodotto e nelle presenti istruzioni ,

• Siano stati eseguiti correttamente tutti i collegamenti elettrici,

• Dopo l’installazione non ci siano perdite di fluido.

Funzionamento

• La presente informativa deve essere disponibile in loco durante

l’installazione dei pressostati,

• Rispettare le regole interne e la legislazione in vigore nel paese

in questione relative alla salute e alla sicurezza sul lavoro,

• Il personale che svolge interventi sul pressostato deve essere

gualificato per la,

• Il funzionamento del pressostato deve essere controllato

regolarmente,

• Il coperchio del BCP non deve essere rimosso in nessun caso

• Evitare sovraccarichi del pressostato,

Se il pressostato ha subito un sovraccarico o un guasto,

sostituirlo,

• Scollegare sempre il connettore elettrico prima di smontare il

pressostato,

• Tutte le operazioni devono essere eseguite con l’ausilio di

strumenti adatti,

• Sarà responsabilità dell’utente verificare l’assenza di perdite

dopo un guasto o periodicamente in condizioni normali di

esercizio,

• Solo i pressostati progettati, costruiti e distribuiti da Danfoss

devono essere impiegati in caso di sostituzione degli stessi,

• Danfoss non è responsabile di danni derivanti dall’uso di parti,

accessori o pressostati non originali Danfoss.

© Danfoss | DCS (az) | 2017.11 IC.PI.P10.K8.53 / 520B8307 13

Loading...

Loading...