Page 1

MAKING MODERN LIVING POSSIBLE

Basic™ Heating Systems

DANFOSS HEATING SOLUTIONS Handbook

Page 2

Handbook Basic™ Heating Systems

2

VGCTB202 © Danfoss 10/2009

Page 3

Handbook Basic™ Heating Systems

Index

Page

Underfloor heating with heated screed as liquid or cement screed . . . . . . . . . . . . . . . . . . . . . 4

Basic heating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Advantages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Relevant standards for underfloor heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Minimum thermal resistance of insulation

under floor heating systems from EN 1264, Part 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

BasicRail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

BasicClip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

BasicGrip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Basic insulation overlap panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Floor constructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Thermal resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Basic perimeter insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tanking for liquid screed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

BasicRail - types of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

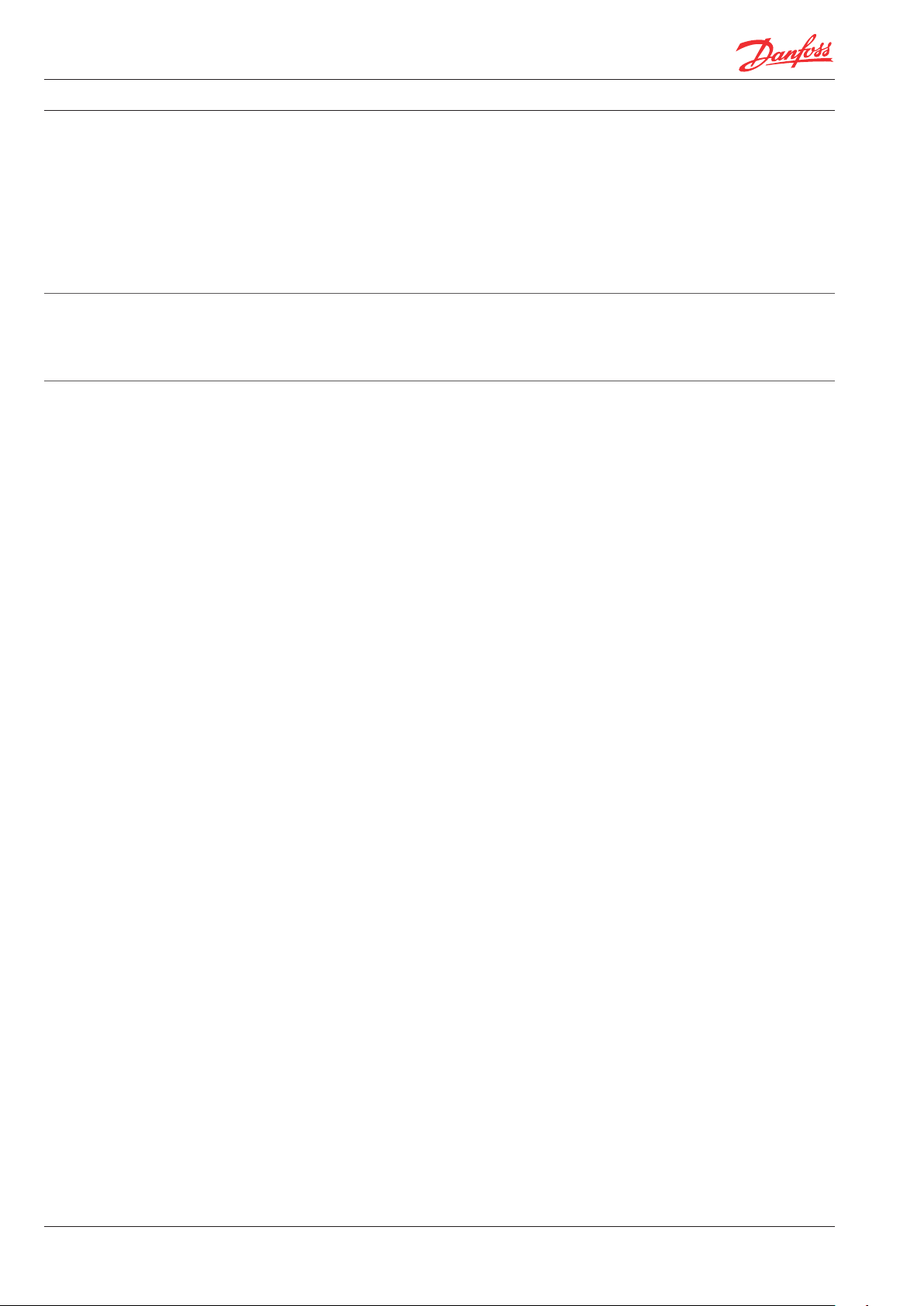

Application sheet - BasicRail, Room with floor meeting window. . . . . . . . . . . . . . . . . . . . . . . 9

BasicClip and BasicGrip - types of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Application sheet - BasicClip, Conservatory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Application sheet - BasicGrip, Conservatory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Advice on installing BasicGrip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Too ls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Heated screed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Danfoss screed additives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Screed joints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Movement gap strips for BasicRail and BasicClip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Important! Before and after installation of screed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16+Heating up screed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Active load and height of screed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Categories of loaded areas, in accordance with EN 1991 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Minimum nominal thickness in mm for active loads in heated screed with Basic heating systems. . 17

After installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Information for finished floors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Thermal resistance R

of different finishes fully bonded to the floor . . . . . . . . . . . . . . . . 18

finished flo or

Output tables, BasicRail heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Output tables, BasicClip and BasicGrip heating systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

VGCTB202 © Danfoss 10/2009

3

Page 4

Handbook Basic™ Heating Systems

Underfloor heating with

heated screed as liquid

or cement screed

Basic heating systems

Advantages

Underfloor heating, with its low supply temperature, has many advantages. It runs maintenancefree, is energy saving and ensures comfortable

room temperatures.

Rooms with underfloor heating allow greater

freedom for interior design. The Danfoss FH pipes

enclosed in cement or liquid screed give off

The Danfoss underfloor heating systems with

heated screed - Basic heating systems - are low

temperature underfloor heating systems suitable

for all new buildings. They can be installed in all

rooms and floors of blocks of flats or in business

premises.

The grey Danfoss composite pipes are installed,

according to worked out distances, using

BasicClip, BasicGrip or BasicRail on insulation

panels giving the pipe lay-out. The water flowing

though the composite or PE-RT pipes gently

warms the screed which works as heating

element. It is possible to lay all common floor

• Low energy saving temperature

• Cost eective, no additional costs

• 100% impervious to air, no heat exchanger

necessary

• Comfortable, clean and healthy air

• Greater freedom of interior design, more living

space for whole family

• Maintenance-free

comfortable warmth without any drafts, - creating

a dustfree, hygenic environment.

coverings on top of Danfoss underfloor heating,

except perhaps heavy exotic carpets or special

engineered wood flooring which would need

extra calculations when planning the system.

Since low water temperatures are required to

achieve the required room temperatures, Danfoss

underfloor heating systems are ideal for use with

boilers, solar energy and heat pumps. This means

that producers of energy saving heat will find an

ideal partner in underfloor heating.

Relevant standards for

underfloor heating

The following regulations and EN Standards

should be observed when planning and installing

floor heating:

EN 1991 Action on structures

EN 1264 Underfloor Heating, Systems and

Components

DIN 4109 Sound Insulation in the Building

Industry

ISO EN 140-8 Measurement of sound insulation

in buildings and building elements

EN 13813 Screed Material and Floor Screeds

Local building regulations.

Professional information on interface co-ordination

when planning heated underfloor construction

(ref: BVF).

For underfloor heating the EN 1264, part 4

standards are applicable.

Three Danfoss basic constructions are possible:

A, B and C.

They meet the minimum insulation requirements

in relation to use and position in the house.

4

VGCTB202 © Danfoss 10/2009

Page 5

Handbook Basic™ Heating Systems

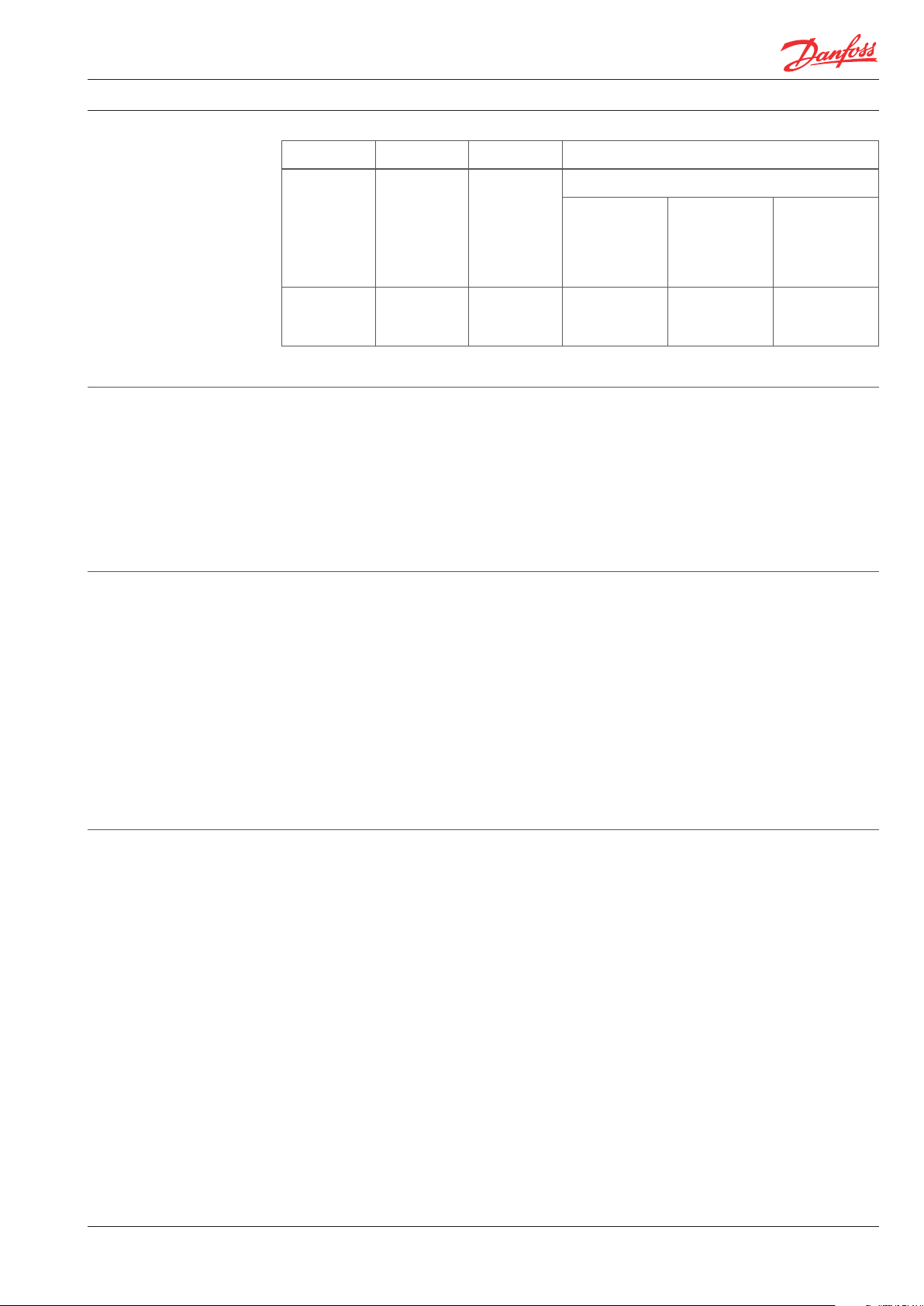

Minimum thermal

resistance of insulation

under floor heating

systems from EN 1264,

part4

BasicRail

Construction A B C

Heated room

below

Thermal

resistance

(m K/W)

* When groundwater table is < 5 m this value should be raised!

The composite pipes are clipped onto the BasicRail

self-adhesive clip rails at regular distances.

The maximum of 2 m between the clip rails should

only be applied when using cement screed.

When using liquid screed a maximum distance of

1m should be observed. Because of the fluid

consistency of liquid screed it could run under

the pipes and can push them upwards.

0.75 1.2 5 1.2 5 1.5 2

Unheated or

occasionally

heated room

below or

room on

ground floor*

Outside air temperature below construction

Design

outside

temperature

Td > 0° C

In accordance with EN 1264 Danfoss FH pipes

should be laid more than

• 50 mm away from vertical construction, such as

walls

• 200 mm from chimneys and open re places,

open and walled-up shafts, as well as lift shafts

Design

outside

temperature

0° C > Td ≥ -5° C

Design

outside

temperature

-5° C > Td ≥ -15° C

BasicClip

BasicGrip

The BasicClip System is a tacker system where the

pipes are tacked onto the insulation with u-shaped

tacker pins. The insulation overlap panels are

supplied as 2 x 1 m pre-folded panels. The foil

clad panels give a perfect grip for the barbs in

the EPS and under the foil.

The grid pattern on the panel foil is 50 mm which

allows the different laying distances to be kept :

100 and 150 mm for Edge Zones, and 200, 250

and 300 mm for Comfort Zones.

Any additional insulation should be laid under

the BasicClip overlap panels.

The BasicGrip panel system consists of deeply

drawn foil with studs that allow perfect laying of

pipes.

With their size of 1 x 1 m, the panels are easy to

lay and can be installed by just one person.

The panels can be cut with the usual cutter knife.

The studded panels facilitate correct pipe

distances. Laying the pipes diagonally is possible

without additional grips. It is safe to walk on the

strong foam studded panels.

When using the BasicGrip panel without thermal

insulation the deeply drawn foil is correspondingly

thicker.

The laying distance is calculated in multiples of

50 mm, so that possible pipe distances in the

Edge Zone are 100 and 150 mm and in the

Comfort Zone 200, 250 and 300 mm are achieved.

Any additional insulation should be laid under

the BasicGrip panels.

BasicClip insulation overlap panels are available

in 2 variations:

• with 35 mm thermal and impact sound

insulation EPS

• with 20 mm thermal and impact sound

insulation EPS

For optimum installation of the system an

expansion profile is available to overcome

expansion gaps and door thresholds.

The system is suitable for liquid (CAF) and

cement screeds (CT).

BasicGrip panels are available in 3 variations:

• with 35 mm thermal and impact sound

insulation EPS

• with 11 mm thermal insulation EPS

• without insulation

For optimum installation of the system, the

following additional products are on offer:

• An expansion prole to overcome expansion

gaps and door thresholds

• Door and manifold panels with varying

insulation thickness

• PE –String to seal perimeter insulation when

using liquid screed

The system is suitable for liquid (CAF) and

cement screeds (CT).

VGCTB202 © Danfoss 10/2009

5

Page 6

Handbook Basic™ Heating Systems

Basic insulation overlap

panels

Floor constructions

The individual components of the overlap

insulation panels are bonded and consist of the

Continuous sound impact insulation also has to

be installed.

following layers:

• Bonded multi-layer foil with 5 cm grids to

facilitate exact pipe laying

• A thermal and impact sound insulation layer

made of polystyrene

What type of insulation is used, depends on the

type of floor and the building. If the concrete is

even and free of other installations, a single layer

of insulation is sucient. In 90% of all new

buildings heating, sanitation and electrical

services are installed which require double layer

insulation.

For height adjustment, thermal insulation, e.g.

EPS 035 DEO 20 mm is laid between the pipe

channels and gaps around the pipes are filled

with Danfoss Dry Levelling Compound.

Finally, the Basic insulation overlap panels are

installed. The surface of these 2 m2 (1 + 1 m2

foldable) insulation panels are very strong, safe

to walk on, and form a very good surface for

BasicClip and BasicRail heating systems.

The strong foil is a technically perfect base for

cement and liquid screeds.

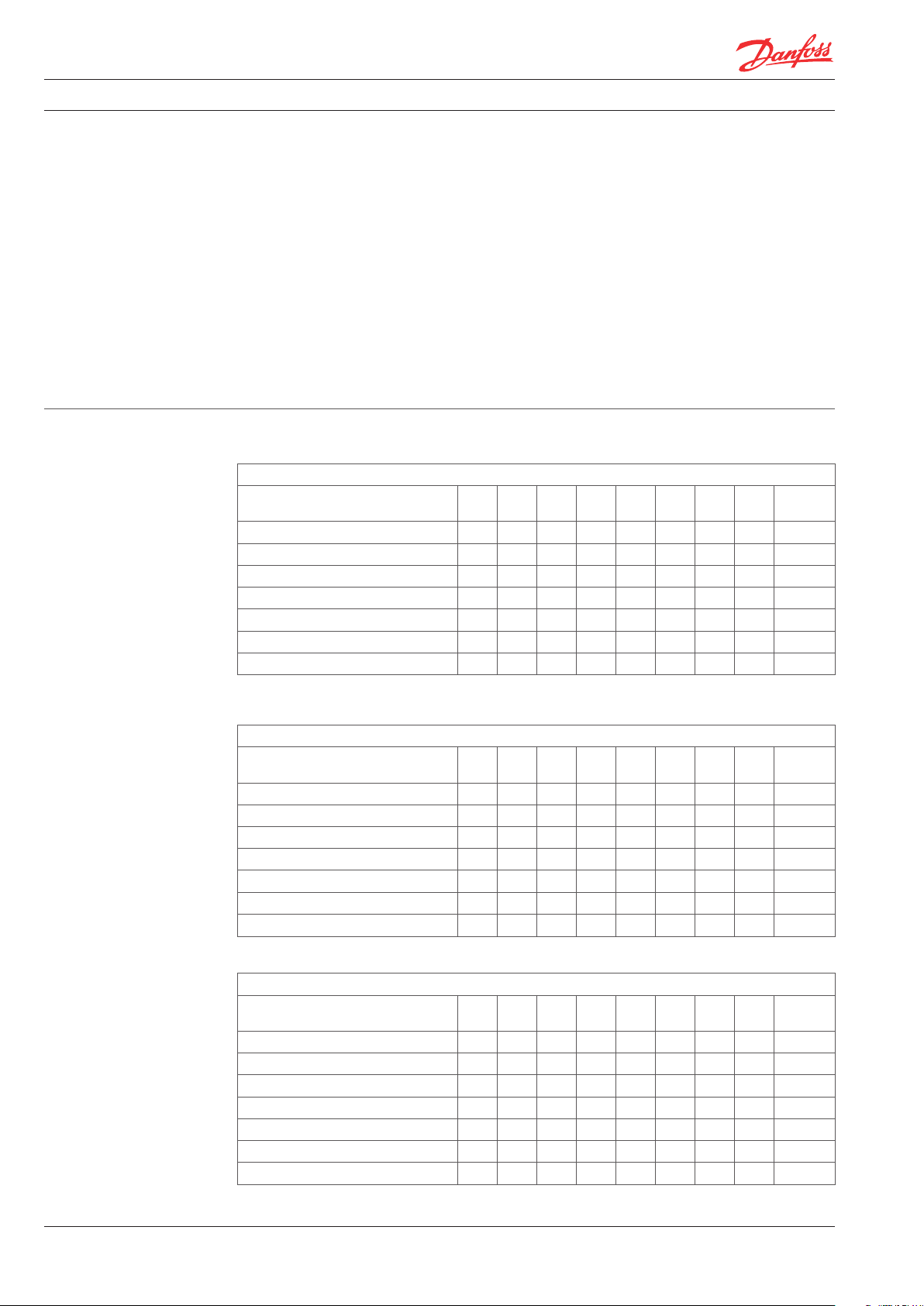

A: Floor construction above rooms of equal use/ temperature; Minimum thermal resistance

R

= 0.75 m2K/W

min

Construction with insulation panels 20/35 mm plus additional insulation:

Insulation panels 20/35 mm

R = 0.44 m2K/W; R = 0.77 m2K/W

20 20 20 20 35 35 35 35 mm

+ + + + + + + +

EPS DEO λ =0.040 W/mK 20 - mm

EPS DEO λ=0.035 W/mK 20 - mm

PUR λ=0.030 W/mK 20 - mm

PUR λ =0.025 W/mK 20 - mm

Total thermal resistance R 0.94 1.01 1. 11 1.27 0.77 0.77 0.77 0.77 m K/W

Total insulation thickness 40 40 40 40 35 35 35 35 mm

B: Floor construction above occasionally or permanently unheated rooms, cellars or ground-

floor (ground water table > 5 m); minimum thermal resistance R

= 1.25 m2 K/W

min

Construction with insulation panels 20/35 mm plus additional insulation :

Insulation 20/35 mm

R = 0.44 m2K/W; R = 0.77 m2K/W

20 20 20 20 35 35 35 35 mm

+ + + + + + + +

EPS DEO λ = 0.040 W/mK 40 20 mm

EPS DEO λ = 0.035 W/mK 30 20 mm

PUR λ = 0 .030 W/mK 30 20 mm

PUR λ = 0.025 W/mK 30 20 mm

Total thermal resistance R 1.4 4 1. 30 1.44 1.6 4 1.27 1.34 1.43 1.57 m K/W

Total insulation thickness 60 50 50 50 55 55 55 55 mm

C: Construction for floors against outside air; minimum thermal resistance R

= 2.0 m2 K/W

min

Construction with insulation panels 20/35 mm plus additional insulation:

Insulation 20/35 mm

R = 0.44 m2K/W; R = 0.77 m2K/W

20 20 20 20 35 35 35 35 mm

+ + + + + + + +

EPS DEO λ = 0.040 W/mK 70 50 mm

EPS DEO λ = 0.035 W/mK 60 50 mm

PUR λ = 0 .030 W/mK 50 40 mm

PUR λ = 0.025 W/mK 40 40 mm

Total thermal resistance R 2 .19 2 .16 2 .11 2.04 2.02 2.2 2.1 2.37 m K/W

Total insulation thickness 90 80 70 60 85 85 75 75 mm

λ = Thermal conductivity in W/mK.

6

VGCTB202 © Danfoss 10/2009

Page 7

Handbook Basic™ Heating Systems

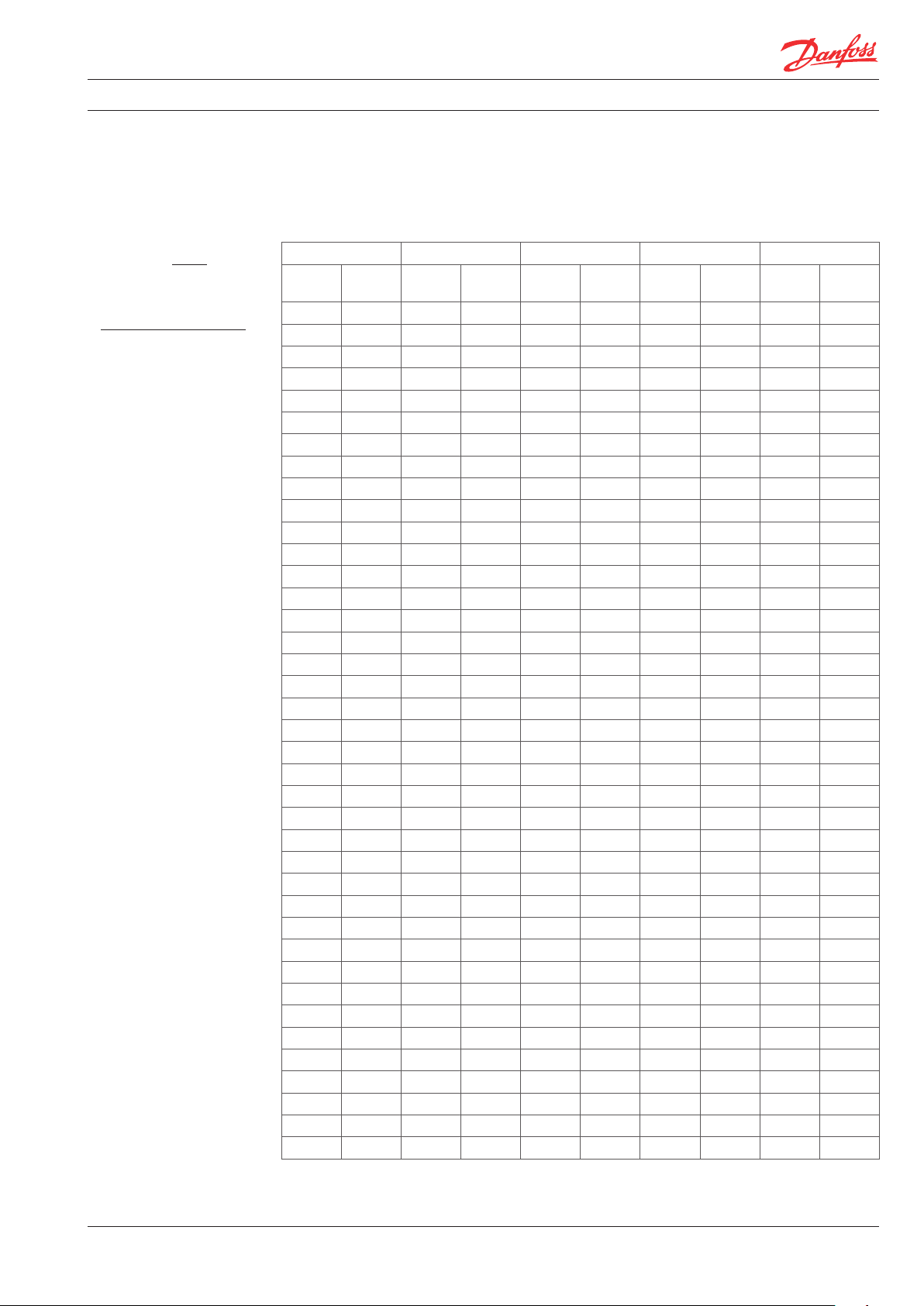

Thermal resistance

R

Insulation

Insulation thickness in (mm)

Thermal resistance in (W/mK)

[

d

=

λ

Other combinations are possible to achieve

certain built-up heights. The following table

indicates the thermal resistance of the different

insulations, dependent on their thickness.

EPS 045 DES EPS 040 DEO EPS 035 DEO PUR λ = 0.03

Thickness

[mm]

10 0.22 10 0.25 10 0.29 10 0.33 10 0.40

]

15 0.33 15 0.38 15 0.43 15 0.50 15 0.60

20 0.44 20 0.50 20 0. 57 20 0.67 20 0.80

25 0.56 25 0.63 25 0.71 25 0.83 25 1. 00

30 0. 67 30 0.75 30 0.86 30 1.00 30 1. 20

35 0.78 35 0.88 35 1.0 0 35 1.17 35 1. 40

40 0.89 40 1. 00 40 1 .14 40 1. 33 40 1. 60

45 1. 00 45 1.13 45 1. 29 45 1. 50 45 1. 80

50 1 .11 50 1. 25 50 1.43 50 1.67 50 2.00

55 1.2 2 55 1. 38 55 1. 57 55 1.8 3 55 2.20

60 1. 33 60 1. 50 60 1.7 1 60 2.00 60 2.40

65 1. 44 65 1. 63 65 1. 86 65 2 .17 65 2.60

70 1. 56 70 1.75 70 2.00 70 2.33 70 2.80

75 1.67 75 1. 88 75 2 .14 75 2.50 75 3.00

80 1.78 80 2.00 80 2.29 80 2.67 80 3.20

85 1. 89 85 2.13 85 2.43 85 2.83 85 3.40

90 2.00 90 2.25 90 2.57 90 3.00 90 3.60

95 2 .11 95 2.38 95 2.71 95 3 .17 95 3.80

100 2.22 100 2.50 100 2.86 100 3.33 10 0 4.00

105 2.33 105 2.63 105 3.00 105 3.50 10 5 4.20

110 2.44 11 0 2.75 11 0 3.14 110 3.67 11 0 4.40

115 2.56 115 2.88 115 3.29 115 3.83 115 4.60

120 2.67 120 3.00 120 3.43 120 4.00 120 4.80

125 2.78 125 3.13 125 3.57 125 4.17 125 5.00

130 2.89 130 3.25 130 3 .71 13 0 4. 33 130 5.20

135 3.00 135 3.38 135 3.86 135 4.50 135 5.40

140 3. 11 140 3.50 14 0 4.00 14 0 4.67 140 5.60

145 3.22 145 3.63 145 4 .14 145 4.83 145 5.80

150 3. 33 150 3.75 150 4.29 15 0 5.00 15 0 6.00

155 3.44 155 3.88 155 4.43 155 5 .17 155 6.20

160 3.56 16 0 4.00 16 0 4.57 16 0 5.33 160 6.40

165 3.67 165 4.13 165 4.71 165 5.50 165 6.60

170 3.78 170 4.25 170 4.86 17 0 5.67 17 0 6.80

175 3.89 17 5 4.38 17 5 5.00 175 5.83 175 7. 00

180 4.00 18 0 4.50 18 0 5.14 180 6.00 180 7. 2 0

185 4. 11 18 5 4.63 185 5.29 185 6 .17 18 5 7. 4 0

190 4.22 190 4.75 190 5.43 190 6. 33 190 7. 6 0

195 4.33 195 4.88 19 5 5.57 195 6.50 19 5 7. 80

200 4.44 200 5.00 200 5.71 200 6.67 200 8.00

R

insulation

[m K/W ]

Thickness

[mm]

R

[m K/W ]

insulation

Thickness

[mm]

The final layer should always be the Basic

insulation overlap panels 20/35 mm to guarantee

a stable base for further installation.

W/mK PUR λ = 0.025 W/mK

R

[m K/W ]

insulation

Thickness

[mm]

R

insulation

[m K/W ]

Thickness

[mm]

R

insulation

[m K/W ]

VGCTB202 © Danfoss 10/2009

7

Page 8

Handbook Basic™ Heating Systems

Basic perimeter

insulation

Tanking for

liquid screed

BasicRail

- types of installation

The Basic Perimeter insulation 150 mm consists of

8 mm PE-Foam. The double-sided adhesive tape

on the back allows it to be easily attached to the

wall. The adhesive tape on the room side of the

foil attaches the perimeter insulation to the

insulation panels.

In accordance with EN 1264 the perimeter

insulation can be compressed by 5 mm and thus,

When using liquid screed the insulation joints

should be taped over to accept screed with a

very thin consistency.

The heating circuits are laid in meander form,

which is an advantage when first installing the

pipes in the edge zones of the room (Edge Zone)

and then taking them to the centre of the room

(Comfort Zone): the warmer temperatures of the

heating circuit arrive at the outer zones (higher

floor temperature), and the cooled down water

heats the central zone (lower floor temperature).

together with the insulation panels, forms the

required tank for the screed as well as thermal

and sound bridges.

When using a double layer of insulation, the

additional insulation should be laid first. Should

their thickness exceed 5 cm, the perimeter

insulation is installed on top of the additional

insulation.

To achieve higher output around the edges or in

front of windows, you can lay the pipes in double

pattern.

Please see recommended layout patterns in

Danfoss application sheets.

8

VGCTB202 © Danfoss 10/2009

Page 9

Handbook Basic™ Heating Systems

Legend

FH Composite pipe

CC CZ 2 = 250 mm

Flow

BasicRail

Distances bet ween rails:

Liquid screed 1.00 m

Cement screed 1.50 - 2.0 0 m

FH Composite pipe

CC EZ 1 = 88 mm

Return

Perimeter insulation

Application Sheet

BasicRail

Room with floor meeting window

Danfoss HES VA.CT.H1.02 © Danfoss 11/2008 1

Heating circuit 1

Heating circuit 2

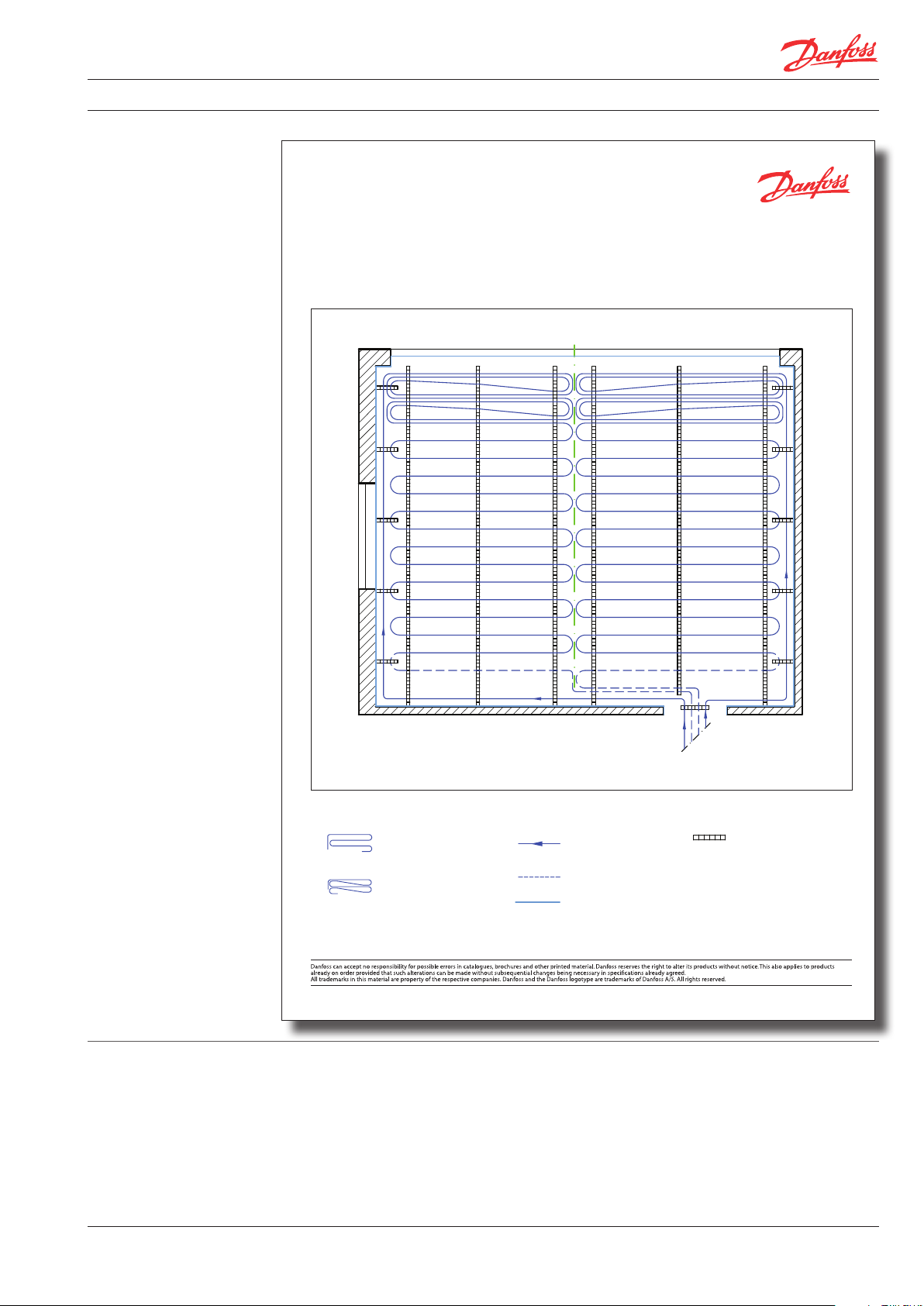

Application sheet

BasicClip and BasicGrip

- types of installation

The Danfoss wet systems BasicGrip and BasicClip

are laid in spiral form.

The Danfoss composite pipe is laid in spiral form

starting from the edge, leading to the centre of

the room. The pipe distance is twice that of the

calculated pipe spacing. The pipe is then led out

of the centre between the installed pipes.

The advantage is that pipes of higher temperature are next to those of lower temperature, thus

VGCTB202 © Danfoss 10/2009

producing an even surface temperature (higher

output).

Edge Zone: if a higher heat output is required,

the pipes in the Edge Zone (up to 1 m from wall)

can be laid closer, thus producing a higher

surface temperature.

9

Page 10

Handbook Basic™ Heating Systems

Legend

Pipe layout EZ 100

CC = 100 mm

Supply BasicClip clip,

2 clips per meter

Return

Pipe layout CZ 200

CC = 200 mm

Perimeter insulation

Application Sheet

BasicClip

Conservatory

Danfoss HES VA.EK.B1.02 © Dan foss 11/2008 1

Heating circuit 1

Heating circuit 2

Application sheet

10

VGCTB202 © Danfoss 10/2009

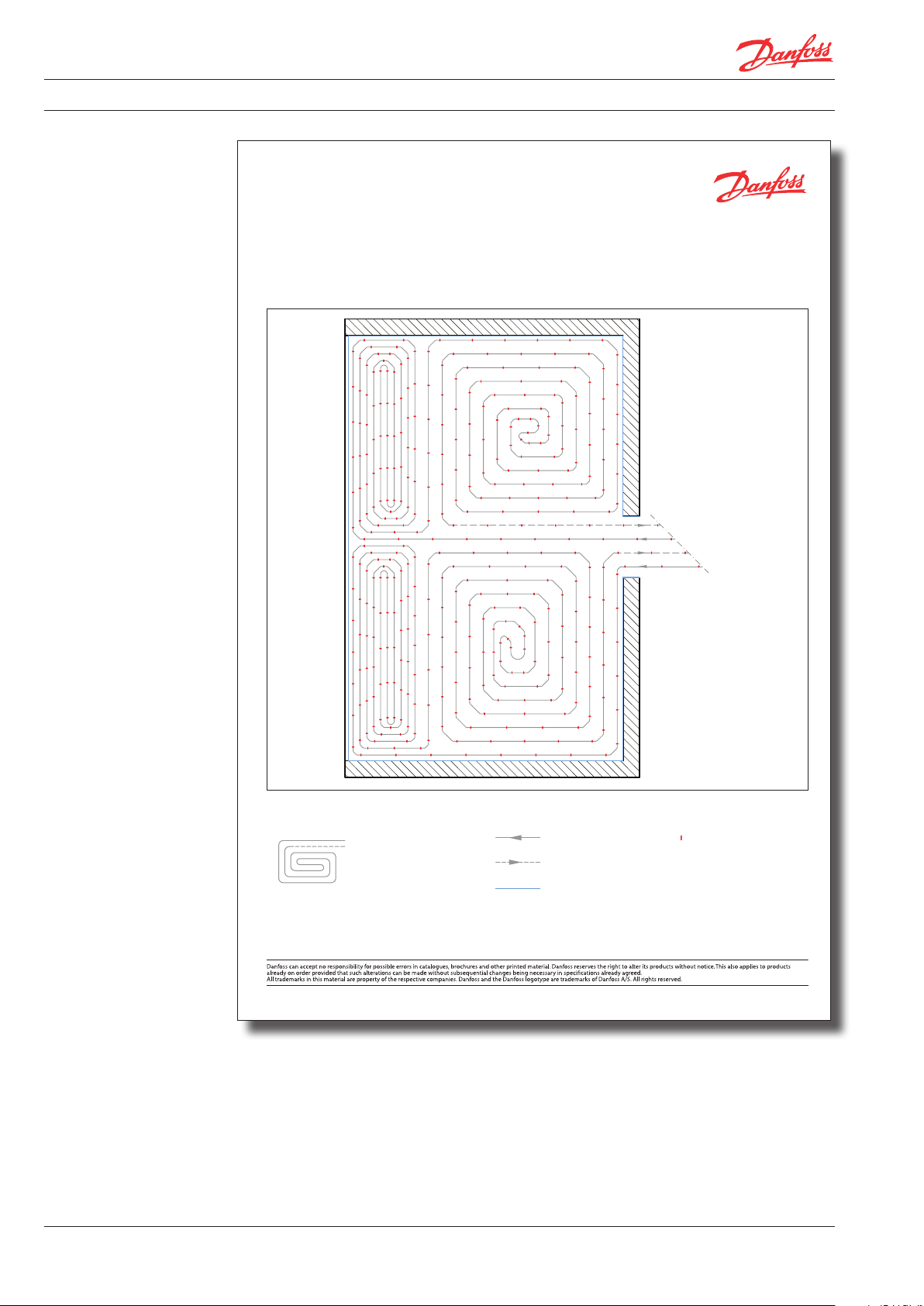

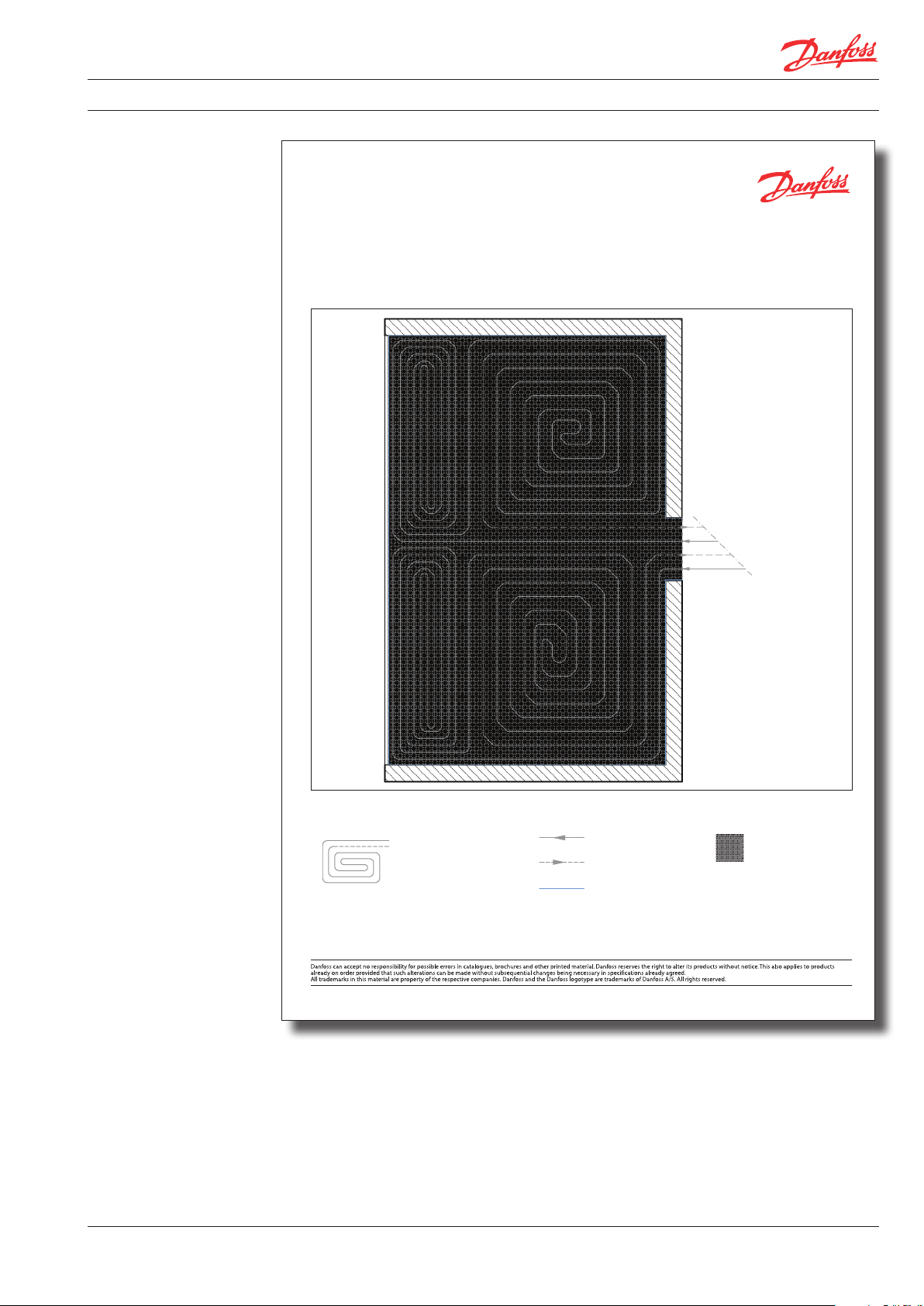

Page 11

Handbook Basic™ Heating Systems

Legend

Pipe layout EZ 100

CC = 100 mm

Supply BasicGrip panel

Size: 1 x 1 m

Return

Pipe layout CZ 200

CC = 200 mm

Perimeter insulation

Application Sheet

BasicGrip

Conservatory

Danfoss HES VA.EL. A1.02 © Danfoss 11/2008 1

Heating circuit 1

Heating circuit 2

Application sheet

VGCTB202 © Danfoss 10/2009

11

Page 12

Handbook Basic™ Heating Systems

A B C D E G H1

H2 I J K L

- Floor Construction

Advice on installing

BasicGrip

1: Begin installing in left hand corner. In order to

achieve a tight join at the wall, cut off both

overlaps on the first BasicGrip panel.

2: For panels B to G, cut off overlaps against the

wall.

Cut off overlaps

3: Shorten H1 according to room calculations and

also cut off overlap on wall side.

4: Start the next row with the remaining part (H2).

12

VGCTB202 © Danfoss 10/2009

Page 13

Handbook Basic™ Heating Systems

- Floor Construction

Tools

Pipe cutter

Danfoss pipe cutter incl. corrugated pipe

cutter for trimming the Danfoss composite

pipes 16 x 2.00 / 20 x 2.25 mm and the Danfoss

protective pipe.

Pipe cutter

Danfoss universal pipe cutter for trimming

composite pipes up to 32 x 3.00 mm and the

Danfoss clip rail.

Bevelling tool

Danfoss bevelling tool for calibrating and

bevelling the Danfoss composite pipes.

The handle is removable, so the tool can be

attached to rechargeable drills (< 500 r/min).

Dimensions of 16 - 20 mm allow inner and outer

bevels which facilitates installation

Pipe bending springs

Danfoss pipe bending springs are able to form

radiuses of up to 4 x D.

Press tool

Danfoss press tool is, together with the inserts,

suitable for pressing of Danfoss composite

pipes with dimensions of 16 and 20 mm.

Pipe dispensing wheel

Danfoss pipe dispensing wheel is indispensable

for one-man installations. It holds the coiled

pipe, is compact and easy to transport, and will

fit into narrow spaces.

Measurement base

Points marked out to measure the residual

moisture in the screed without damaging the

pipes.

VGCTB202 © Danfoss 10/2009

13

Page 14

Handbook Basic™ Heating Systems

Installation times

Heated screed

Installation Times for Basic Heating Systems *

Article / Unit

Installation of manifold without cabinet 55.00 Unit

Installation of manifold with cabinet 75.00 Unit

Installation of additional insulation without perimeter insulation, each layer 2.50 m

Installation of insulation overlap panels 20 mm / 35 mm incl. perimeter insulation 2.50 m

C-C = 88 mm type of installation 1 (pipe layout, connection to manifold) 11. 3 0 m

C-C = 120 mm type of installation 2 (pipe layout, connection to manifold) 8.40 m

C-C = 200 mm type of installation 1 (pipe layout, connection to manifold) 5.00 m

C-C = 250 mm type of installation 2 (pipe layout, connection to manifold) 4.00 m

C-C = 300 mm type of installation 3 (pipe layout, connection to manifold) 3.50 m

* 06/2004 Values based on practical experience.

Only heated screed should be used. The Danfoss

screed additive should be used when installing

cement screed. The screed additive Normal CT F4

has the effect of increasing thermal conductivity

as well as allowing the screed to retain more heat.

Both contribute to an even distribution of heat

within the room and guarantee better resistance

to pressure and more flexibility.

Liquid screed should be prepared as heated

screed. To achieve a very thin cement screed, the

Danfoss Screed Additive Special should be used.

It achieves an even better resistance to pressure

and more flexibility, as well as a higher thermal

conductivity.

Mastic asphalt is not suitable for Basic underfloor

heating systems. The outer sleeve of the

composite pipe is not resistant to the higher

temperatures of this form of screed.

The mean heating water temperature must not

exceed 55˚ C when using cement and Anhydrite

screeds.

Minutes

per unit

Unit

Danfoss screed additives

14

Normal:

The screed additive is added to the screed and

not the water.

• Required quantity per m2: 215 g

• Height of heated screed: 70 mm

• Screed quality: CT F4

• Volume of can: 10 kg

Mixing cement screed in connection with

underfloor heating.

Mortar-mix:

• 50 kg cement CEM I 32.5 R

• 250 kg gravel sand 0/8 mm (approx. 30-36

shovels full)

• 16-18 litres water

• 500 g (0.5 litre) Danfoss screed additive

Mixing instructions using a forced action mixer:

• 10 shovels full of gravel sand (approx. 30 litres)

• 50 kg cement CEM I 32.5 R

• 10 litres water

• 0.5 litres Danfoss screed additive

• 20-26 shovels full of gravel sand (approx. 110

litres)

• 6-8 litres water

• Mortar consistency of moist soil to malleable,

minimum mixing time 1 min.

VGCTB202 © Danfoss 10/2009

Special:

The screed additive Special is suitable when low

height screed is required. This synthetically

modified additive is added by the specialist

screeder.

• Required quantity per m2: 1820 g

• Height of heated screed: 65 mm

• Screed quality: CTF 5

• Volume of can: 10 kg

Page 15

Handbook Basic™ Heating Systems

10 m

2

10 m

2

40 m

2

10 m

2

15 m

2

30 m

2

Installation

Screed joints

Fresh screed mortar should be poured along the

length of the composite pipes and should be well

tamped. It must be protected from frost.

Screed should be installed at room temperatures

of above 5° C, and any draft should be avoided.

Fix certain points as measuring point to ascertain

residual moisture.

Floating screeds expand and contract depending

on temperature, particularly heated screeds. To

compensate for this, screed is divided into

geometric fields. The perimeter insulation allows

for some of the expansion, and movement gap

strips between the fields allow for movement

and avoid cracks (5 mm minimum expansion).

Movement gaps have to be allowed for on room

edges and between large and multi-angular

areas (e.g. L- or Z-shaped). The proportion of

width to length should not exceed 1:2.

Joints in the building should be mirrored in the

screed. The size of the areas should not exceed

40 m2 with a maximum length of 8 m.

Unusual area shapes exposed to higher temperatures tend to crack easily, so careful planning of

expansion joints is advisable.

The type of finished floor also determines the

layout of the screed areas. Screed temperature is

higher when carpet is laid but with tiles the

difference in temperature between upper and

lower surface of the screed is significantly higher,

which means these constructions tend to crack

more easily.

When composite pipes cross a screed joint, the

pipes should be protected with a movement gap

strip against expansion and shear stress.

This occurs when two adjacent screed slabs move

towards each other (expansion, buckling of the

embedded pipes), or move across each other

(shearing), or even do both.

There should be no heating pipes within a

distance of 10 cm (Ø20 cm) around that point.

The 40 cm long pipe sleeves absorb any movement of the screed and the composite pipe

remains permanently protected.

Movement gap strips for

BasicRail and BasicClip

Basic movement gap strip consists of a 2 m

long movement gap strips to install joints with

double-sided adhesive strip and a 100 mm high

The sleeves are pushed into the profile and

appropriate holes for the pipe channels are cut

into the movement joint.

perimeter insulation strip.

Pipe sleeves

• 40 cm long

• to protect crossing pipes

Installation

Before pouring the screed, the movement gap

strips are installed. The movement gap strips are

first attached to the given positions on the plan

(in agreement with the screeder and floor finisher).

They are attached to the insulation using the

double-sided tape. Afterwards a section of

perimeter insulation is inserted into the slot.

Pipes going through the movement joint should

be protected with an outer sleeve.

VGCTB202 © Danfoss 10/2009

15

Page 16

Handbook Basic™ Heating Systems

Important!

Before and after

installation of screed

• Heated screed is installed after pipe layout, insulations and joint gap strips are fixed.

• Before the screed is installed the building/room

must be completely plastered, windows and

doors must be firmly closed to avoid the screed

drying too fast and thus possibly causing cracks

or even other damage in the building.

• Before screeding, check again that screed areas

and heating circuits are co-ordinated and the

movement gap joints are not interrupted. If the

Danfoss composite pipes cross movement joints

they should be protected.

• When screeding, the pipes must be under

pressure so that possible problems are noticed

and can be rectified.

• Screed should be installed at temperatures

above 5° C (risk of frost).

Table to show when to lay the finished floor (according to moisture content)

Finished floor

Ceramic tiles or thickbed

natural-/ concrete stones thinbed

Textile finish vapour permeable

e.g. carpet vapour proof

Elastic finishes e.g. PVC, Linoleum, rubber 1.8 % 0.3 %

• Should a sudden unexpected frost occur after

screeding, care must be taken not to let the

temperature fall below 5° C. If it is possible to

turn on the Danfoss underfloor heating the flow

temperature must not exceed 25° C.

• Heating up should follow the Danfoss heating

up protocol. It is important to check the residual

moisture before laying the finished floor; this

would be done by the professional laying the

finished floor.

• The perimeter insulation remains in place and is

only cut to the appropriate height after the floor

is finished.

Approved moisture

content when cement

screed is used

3.0 % not applicable

2.0 % 0.3 %

3.0 % 1.0 %

1.8 % 0.3 %

Approved moisture

content when Anhydrite

screed is used

Heating up of screed

Active load and

height of screed

Engineered timber floor, laminates 1.8 % 0.3 %

The heating up of the screed should be carried

out according to the Heating Up Protocol.

After 7 days it is possible to walk on the cement

screed, but only after 21 days should the heating

up take place.

For Anhydride or Calcium Sulphate based screed

heating up can begin after 7 days, or according to

manufacturers’ recommendation. During heating

up, the automatic control should be off and the

supply temperature should be adjusted manually. All joints should be checked and any solid

matter should be removed from the joints. For

the first three days, the flow temperature should

be kept at 25° C, after that the maximum supply

temperature should be run for four days, and the

heating circuits should be turned off. While

cooling down the heated screed should be

protected from draft and rapid cooling. The

Depending on use, the floor construction will

have to meet different demands. These are

defined in EN 1991: Action on Structures.

floorer should now measure the residual

moisture and decide whether the final floor can

be laid.

It must be noted here, that during the first year,

because of residual moisture in new buildings,

the heating temperature should be higher than

normal. This additional moisture should dry out

during the first heating period. The heating up

process does not guarantee to achieve the

required moisture level of the screed. An

additional heating up operation may be necessary to establish whether the final floor can be

laid.

Commissioning of the underfloor heating after

the floor has been finished should be decided by

the final flooring firm.

16

VGCTB202 © Danfoss 10/2009

Page 17

Handbook Basic™ Heating Systems

Categories of

loaded areas,

in accordance

with EN 1991

The Danfoss construction sheets describe the

approved type of use. Depending on active and

constructions other than home and office

buildings.

point load, EN 1991 is also applicable for

qK

Category Use Examples

A1

Areas for

domestic and

A2 Stairs 2.0 - 4.0 2.0 - 4.0

residential

activities

A3 Balconies 2.5 - 4.0 2.0 - 3.0

B Office areas 2.0 - 3.0 1.5 - 4.5

C1

C2

Areas where

people may

congregate

(with the

C3

exception of

areas defined

under category

A, B, D)

C4

C5

D1

Shopping areas

D2 Areas in department stores 4.0 - 5.0 3.5 - 7. 0

Floors 1.5 - 2.0 2.0 - 3.0

Areas with tables , e.g. areas in schools, cafés, restaurants,

dining halls, reading rooms, receptions

Areas with fixed seats, e.g. areas in churches, theatres or

cinemas, conference rooms, lecture halls, assembly halls,

waiting rooms, railway waiting rooms

Areas without obstacles for moving people, e.g. areas in

museums, exhibition rooms etc. and access areas in public

administration buildings, hotels, hospitals, railway station

forecour ts

Areas with possible physical activities, e.g. dance halls,

gymnastic rooms, stages

Areas susceptible to large crowds, e.g. in buildings for

public events like concert halls, sports halls including

stands, terraces and access areas and railway platforms

Areas in general retail shops 4.0 - 5.0

(Active

load)

kN/m

2.0 - 3.0 3.0 - 4.0

3.0 - 4.0

3.0 - 5.0 4.0 - 7.0

4.5 - 5.0 3.5 - 7. 0

5.0 - 7.5 3.5 - 4.5

QK

(Point

load)

kN

2.5 - 7.0

(note 3)

3.5 - 7.0

(note 3)

Minimum nominal

thickness in mm for

active loads in heated

screed with Basic

heating systems

After installation

Note 1: Depending on their anticipated uses, areas likely to be categorised as C2, C3, C4 may be categorised as C5 by

decision of the client and/or National annex.

Note 2: The National annex may provide sub categories to A, B, C1 to C5, D1 and D2.

Note 3: Recommended values are highlighted. For categories C2 and D1 the recommended value is 4.0.

Different active loads are accomodated in the

thickness of the heated screed.

< 2 kN/m < 3 kN/m 5 kN/m

Point load below

2 kN/m

CT F4 with screed additive Normal 65 85 90 95

CAF F4 60 70 80 85

CT F5 with screed additive Special 60* 75 80 85

CAF F5 50* 65 70 75

Compactibility of insulation: max. 5 mm max. 3 mm.

Point load below

3 kN/m

Point load below

4 kN/m

*For insulation thickness < 40 mm the screed can be reduced by 5 mm .

When the installation is completed the individual

heating circuits are filled with water via the fill

and drain on the manifold.

The pressure test follows, which in winter can

also be done with pressurised air.

The project manager/architect is ready to sign

the hand-over protocol.

the manufacturer’s information needs to be

followed).

After starting the heat source, the individual heat

circuits are set via the valves.

Then the actuators are screwed onto the return

valves and connected via the Danfoss wiring

centre to the room thermostats.

Now the screed has to be installed quickly and

heated up according to protocol (for liquid screed

VGCTB202 © Danfoss 10/2009

17

Page 18

Handbook Basic™ Heating Systems

Information for

finished floors

The following floor finishes can be laid on

underfloor heating if they meet the thermal

resistance requirements of R

are approved by the manufacturer :

≤ 0.15 m2 K/W and

λ,B

• Ceramic tiles

• Natural worked stone

• Elastic nishes (PVC)

• Textile nishes (carpets)

• Engineered timber oor and laminates

It is important to adhere to the manufacturers'

advice.

The adhesives for stone tiles or ceramic finishes

used in the the thinbed method must be

appropriate for underfloor heating and for the

load bearing.

If the floor is laid using the thickbed method, the

heating up and response times are much greater

due to a higher build up.

Elastic and textile floor finishes should be fully

glued down. When laying textile floor finishes, it

is possible to use adhesives that allow a later

removal of the floor.

Natural products, such as engineered timber

floors or other timber products, adjust to their

environment which can cause contraction. This

does not mean a faulty floor. Depending on the

wood, expansion and contraction vary, but this

can be minimised by keeping an even temperature.

When installing engineered timber floors or

laminates, the thermal resistance data should be

provided as well as data for possible air gaps and

additional carpets.

It may be necessary to fill gaps between dry floor

elements before laying the finished floor.

Thermal resistance

R

finished floor

finishes fully bonded

of different

to the floor

Finished floor surface Thermal resistance: R

Natural stone 0.009

Ceramic tiles 0.01

PVC 0. 012

Linoleum 0. 015

Mosaic engineered timber - oak 0.044

Cork 0.062

Standard EN-1264 value 0.10 0

Carpet 0.10 8

Strip flooring - oak 0.122

Laminates 0.044

Multi-layer engineered timber (Parquett) 0.050 - 0.080

Maximum recommendation 0.15 0

[m K/W]

λ,B

18

VGCTB202 © Danfoss 10/2009

Page 19

Handbook Basic™ Heating Systems

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.00 (e.g. tiles).

λ,B

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Cement screed

Room

C-C 8.8

Mean heating

water temperature

θ

m

temperature

θ

i

Cement screed

θ

C-C 12

Surface

temperature

F

Cement screed

θ

VA 20

Surface

temperature

F

Cement screed

θ

VA 25

Surface

temperature

F

Cement screed

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 101. 0 24 .1 92 .1 23.4 73.6 21.8 63.9 21.0 55.7 20.3

30 18 80.4 25.4 73.3 24.8 58.5 23.5 50.8 22.9 44.3 22.3

30 20 66.6 26.2 60.7 25.7 48.5 24 .7 42.1 24 .1 36.7 23.6

30 22 52.6 27. 0 47. 9 26.6 38.3 25.8 33.2 25.3 29.0 24.9

30 24 38.3 2 7.8 34.9 2 7. 5 27. 9 26.8 24.2 26.5 2 1.1 26.2

35 15 13 5. 3 26.8 123 .4 25.9 98.5 23.9 85.6 22.8 74. 6 21.9

35 18 11 4. 8 28.2 10 4.6 2 7.4 83.5 25.6 72.6 24.7 63.3 23.9

35 20 101.0 29 .1 92 .1 28.4 73.6 26.8 63.9 26.0 55.7 25.3

35 22 8 7. 3 30.0 79.6 29.3 63.5 28.0 55.2 2 7. 2 48 .1 26.6

35 24 73.5 30.8 67. 0 30.3 53.5 29 .1 46.5 28.5 40.5 28.0

40 15 169. 4 29.5 15 4.5 28.4 12 3. 3 25.9 10 7.1 24.6 93.4 23.5

40 18 149.0 30.9 135 .8 29.9 108 .4 2 7.7 94.2 26.5 82 .1 25.5

40 20 135 .3 31. 8 12 3. 4 30.9 98.5 28.9 85.6 27. 8 74. 6 26.9

40 22 121 .6 32.7 110 . 9 31.9 88.5 30.1 76.9 2 9.1 67. 1 28.3

40 24 107. 9 33.6 98.4 32.9 78.6 31. 2 68.2 30.4 59.5 29.6

45 15 203.5 32.2 18 5.6 30.8 14 8. 2 27. 9 12 8. 7 26.3 112 . 2 25.0

45 18 18 3.1 33.6 166 .9 32.3 13 3.3 29.7 115 . 8 28.3 101.0 2 7.1

45 20 16 9.4 34.5 15 4. 5 33.4 123 . 3 30.9 1 07. 1 29.6 93.4 28.5

45 22 15 5.8 35.5 142 .0 34.4 113 . 4 3 2.1 98.5 30.9 85.9 29.8

45 24 142 .1 36.4 129 .6 35.4 103. 5 33. 3 89.9 32.2 78.4 31. 2

50 15 2 3 7.6 34.8 216. 6 33.2 173 .0 29.8 150 .2 28.0 131 .0 26.5

50 18 2 17. 2 36.2 19 8. 0 34.7 15 8.1 31.6 1 37. 3 30.0 119 . 8 28.6

50 20 203.5 3 7. 2 18 5.6 35.8 14 8. 2 32.9 12 8. 7 31.3 112 . 2 30.0

50 22 18 9.9 3 8.1 17 3.1 36.8 138 .2 34 .1 12 0.1 32.6 104 .7 31.4

50 24 176 .3 39 .1 160 .7 37. 8 12 8. 3 35.3 111. 5 33.9 97. 2 32.8

55 15 2 71.6 3 7. 3 2 47. 7 35.5 19 7.7 31.7 171. 8 29.7 149 .8 28.0

55 18 251. 2 38.8 22 9.1 37.1 182. 9 33.6 158 .9 31.7 138 .5 30 .1

55 20 23 7. 6 39. 8 216 .6 38.2 173 .0 34.8 15 0. 2 33.0 13 1.0 31. 5

55 22 224.0 40.7 204.2 39. 2 163 .0 36.0 141. 6 34.3 12 3. 5 32.9

55 24 210. 3 41.7 191. 8 40.3 153 .1 37. 3 13 3.0 35.7 11 6 .0 34.3

VA 30

Surface

temperature

F

Surface

temperature

Cement screed

θ

F

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

19

Page 20

Handbook Basic™ Heating Systems

- Installation

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.00 (e.g. tiles).

λ,B

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Liquid Screed

Room

C-C 8.8

Mean heating

temperature

Liquid screed

C-C 12

Surface

temperature

Liquid screed

VA 20

Surface

temperature

Liquid screed

VA 25

Surface

temperature

Liquid screed

water temperature

θ

θ

m

i

θ

F

θ

F

θ

F

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 117.1 25.4 10 6.4 24.5 84.3 22.7 73.0 21.8 63.2 20.9

30 18 93. 2 26.4 84.7 25.7 67. 0 24.3 5 8.1 23.5 50.3 22.8

30 20 7 7.1 27.1 70.1 26.5 55.5 25.3 48 .1 24.6 41. 6 2 4.1

30 22 60.9 2 7.7 55.4 2 7.3 43.8 26.3 38.0 25.7 32.9 25.3

30 24 44.4 28.3 40.3 27. 9 32.0 2 7. 2 27. 7 26.8 23.9 26.5

35 15 15 6. 8 28.5 142 .5 2 7.4 112. 8 25.0 9 7. 7 23.8 84.6 22.7

35 18 13 3.0 29.7 12 0. 8 28.7 95.7 26.6 82.9 25.6 71.7 24.7

35 20 11 7.1 30.4 106 .4 29.5 84.3 27. 7 73.0 26.8 63.2 25.9

35 22 101.2 31.1 91.9 30.3 72.8 28.7 63.0 2 7.9 54.6 27. 2

35 24 85.2 31.8 77. 4 31 .1 61. 3 29.8 5 3.1 2 9.1 45.9 28.4

40 15 196 .3 31. 6 178 .4 30.2 141. 3 2 7. 3 12 2. 3 25.8 105.9 24.5

40 18 172.6 32.8 15 6. 8 31 .5 12 4. 2 29.0 1 07. 6 27. 6 93.1 26.4

40 20 156 .8 33. 5 142 .5 32.4 112 . 8 30.0 9 7.7 28.8 84.6 27. 7

40 22 140 .9 34.3 12 8. 0 33.3 101. 4 31.1 8 7. 8 30.0 76. 0 29.0

40 24 12 5. 0 35.0 11 3. 6 3 4.1 90.0 32.2 77. 9 31.2 67. 4 30.3

45 15 235.9 34.6 214 .3 33.0 169.7 29.6 147. 0 27. 8 12 7. 2 26.2

45 18 212 .2 35.8 192 .8 34.3 152 .7 31.2 132 .2 29.6 114 . 4 28.2

45 20 19 6. 3 36.6 178 .4 35.2 141. 3 32 .3 12 2. 3 30.8 10 5.9 29.5

45 22 18 0.5 3 7. 4 16 4.0 3 6.1 129 .9 33.4 112 . 5 32.0 9 7.4 30.8

45 24 164. 7 38.2 149 .6 3 7. 0 118 . 5 34.5 102.6 33.2 88.8 3 2.1

50 15 275.3 3 7. 6 250.2 35.7 19 8.1 31.7 17 1.6 29.7 148 .5 2 7. 9

50 18 251. 6 38.8 228.7 3 7.1 181.1 33.4 156 .8 31. 5 135. 7 29.9

50 20 235.9 39.6 214 .3 38.0 169. 7 34.6 1 47. 0 32.8 12 7. 2 31. 2

50 22 220.1 40.4 19 9.9 38.9 15 8. 3 35.7 13 7.1 34.0 118 . 7 32.5

50 24 204.2 41.2 185 .6 39.8 14 7.0 36.8 12 7. 3 35. 2 11 0. 2 33.8

55 15 314 .8 40.5 286.0 38.4 226.5 33.9 19 6.1 31.6 169. 8 29.6

55 18 2 91.1 41. 8 264.5 39.8 209. 5 35.6 181. 4 33.5 15 7.0 31.6

55 20 275.3 42.6 250.2 40.7 19 8.1 36.7 17 1.6 34.7 148 .5 32.9

55 22 259.5 43.4 235. 8 41. 6 186 .8 3 7.9 161.7 35.9 140 .0 34.2

55 24 243.7 44.2 2 21.5 42. 5 17 5.4 39.0 151.9 3 7. 2 131. 5 35.5

VA 30

Surface

temperature

F

Surface

temperature

Liquid screed

θ

F

20

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

Page 21

Handbook Basic™ Heating Systems

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.05 (e.g. engineered timber floor /

λ,B

synthetic fibre).

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Liquid Screed

Room

C-C 8.8

Mean heating

temperature

Liquid screed

C-C 12

Surface

temperature

Liquid screed

VA 20

Surface

temperature

Liquid screed

VA 25

Surface

temperature

Liquid screed

water temperature

θ

θ

m

i

θ

F

θ

F

θ

F

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 81. 7 22.5 75.5 22.0 62.3 20.8 55.0 20.2 48.7 19.7

30 18 65.0 24 .1 60 .1 23.7 49.5 22.8 43.8 22.2 38.8 21.8

30 20 53.8 2 5.1 49.7 24.8 41. 0 24.0 36.2 23.6 32.1 23.2

30 22 42.5 2 6.1 39.3 25.8 32.4 25.2 28.6 24.9 25.4 24.6

30 24 31. 0 2 7.1 28.6 26.9 23.6 26.4 20.8 26.2 18. 5 25.9

35 15 10 9.4 24.8 101.1 24 .1 83.4 22.6 73.6 21.8 65.3 21.1

35 18 92.8 26.4 85.7 25.8 70.7 24.6 62.4 23.9 55.4 23.3

35 20 81. 7 27. 5 75.5 27. 0 62.3 25.8 55.0 25.2 48.7 24.7

35 22 70.6 28.6 65.2 28 .1 53.8 27.1 47. 5 26.6 42 .1 26 .1

35 24 59. 4 29.6 54.9 29.2 45.3 28.4 40.0 2 7.9 35.4 2 7. 5

40 15 1 37. 0 2 7. 0 12 6. 6 26 .1 104 .4 24.4 92.2 23.4 81.7 22.5

40 18 120. 5 28.7 111 . 3 2 7. 9 91.8 26.3 81.0 25.4 71. 8 24.7

40 20 109. 4 29. 8 101.1 2 9.1 83.4 2 7. 6 73.6 26.8 65.3 26 .1

40 22 98.4 30.9 90.8 30.2 74.9 28.9 66.2 28.2 58.7 27. 5

40 24 8 7. 3 32.0 80.6 31.4 66.5 30.2 58.7 29.5 52 .1 29.0

45 15 16 4.6 29.2 15 2.0 28.2 125 .4 26 .1 11 0. 7 24.9 98.2 23.8

45 18 14 8.1 30.9 13 6. 8 30.0 112 . 8 28.0 99.6 2 7.0 88.3 26.0

45 20 13 7.0 32.0 12 6. 6 31.1 10 4.4 29.4 92.2 28.4 81.7 2 7. 5

45 22 12 6. 0 33 .1 11 6. 4 32. 3 96.0 30.7 84.8 29.7 75 .1 28.9

45 24 115 . 0 34.2 10 6.2 33.5 8 7. 6 32 .0 77. 3 31.1 68.6 30.4

50 15 192 .2 31 .3 1 77. 5 30.2 146 .4 2 7. 7 129. 3 26.4 114 . 6 25.2

50 18 175 .6 33.0 162 .2 32.0 133 .8 29.7 11 8. 2 28.5 104 .7 27. 4

50 20 16 4.6 34.2 15 2. 0 33.2 12 5.4 3 1.1 11 0 .7 29.9 98.2 28.8

50 22 15 3.6 35.3 141.9 34.4 117. 0 32.4 103. 3 31.3 91.6 30.3

50 24 142.6 36.4 131. 7 35.6 108 .6 33.7 95.9 32.7 85.0 31. 8

55 15 219.7 33.4 202.9 3 2.1 16 7. 4 29.4 147. 8 27. 8 131. 0 26.5

55 18 203.2 35 .1 1 87. 7 33.9 15 4. 8 31.4 136 .7 30.0 121. 2 28.7

55 20 19 2. 2 36.3 17 7. 5 35.2 14 6.4 32.7 12 9. 3 31.4 11 4. 6 30.2

55 22 181.2 3 7.4 167. 3 36.4 138 .0 34 .1 12 1.9 32.8 108 .0 31.7

55 24 17 0.1 38.6 1 57.1 37. 6 12 9. 6 35.4 11 4. 5 34.2 101.5 3 3.1

VA 30

Surface

temperature

F

Surface

temperature

Liquid screed

θ

F

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

21

Page 22

Handbook Basic™ Heating Systems

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.05 (e.g. engineered timber floor /

λ,B

synthetic fibre).

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Cement screed

Room

C-C 8.8

Mean heating

water temperature

θ

m

temperature

θ

i

Cement screed

θ

C-C 12

Surface

temperature

F

Cement screed

θ

VA 20

Surface

temperature

F

Cement screed

θ

VA 25

Surface

temperature

F

Cement screed

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 73.3 21.8 67. 8 21. 3 56.2 20.3 49.9 19.8 44.4 19 .3

30 18 58.3 23.5 53.9 23 .1 44.7 22.3 39.7 21.9 35.4 21.5

30 20 48.3 24.6 44.6 24. 3 37. 0 23.6 32.9 23.3 29.3 22.9

30 22 38 .1 25.7 35.3 25.5 29.2 24.9 26.0 24.6 2 3.1 24.4

30 24 2 7. 8 26.8 25.7 26.6 21.3 26.2 18.9 26.0 16. 8 25.8

35 15 9 8.1 23.8 90.7 23.2 75. 2 21.9 66.8 21.2 59.5 20.6

35 18 83.2 25.6 77. 0 2 5.1 63.8 24.0 56.7 23.4 50.5 22.8

35 20 73.3 26.8 6 7.8 26.3 56.2 25.3 49.9 24.8 44.4 24.3

35 22 63.3 2 7.9 58.5 2 7. 5 48.5 26.7 43 .1 26.2 38.4 25.8

35 24 53. 3 29.1 49. 3 28.7 40.9 28.0 36.3 27. 6 32.3 2 7. 2

40 15 122 .8 25.8 113 . 6 2 5.1 94.2 23.5 83.7 22.7 74. 5 21.9

40 18 10 8.0 2 7. 6 99.9 2 7.0 82.8 25.6 73.6 24.8 65.5 24 .1

40 20 98 .1 28.8 90.7 28.2 75.2 26.9 66.8 26.2 59.5 25.6

40 22 88.2 30.0 81.5 29.5 67. 6 28.3 60 .1 2 7.7 53.5 2 7.1

40 24 78.2 31.2 72.4 30.7 60.0 29.7 53.3 29 .1 4 7.4 28.6

45 15 147. 6 2 7. 8 13 6. 5 26.9 113 .1 2 5.1 10 0.6 24.0 89. 5 2 3.1

45 18 132 .7 29.6 12 2. 8 28.8 101.8 2 7.1 90.5 26.2 80.5 25.4

45 20 12 2. 8 30.8 113 . 6 30 .1 94.2 28.5 83.7 27. 7 74. 5 26.9

45 22 112 .9 32 .0 104 .5 31. 4 86.6 29.9 7 7. 0 29 .1 68.5 28.4

45 24 103.0 33.2 95.3 32.6 79.0 31. 3 70.2 30.5 62.5 29.9

50 15 17 2. 3 29.8 15 9.3 28.7 132 .1 26.6 11 7.4 25.4 10 4.5 24.4

50 18 1 57. 4 31. 6 145 .6 30.7 120 .7 28.7 1 07. 3 27. 6 95.5 26.6

50 20 147. 6 32.8 136 .5 31.9 113 .1 3 0.1 10 0.6 29.0 89.5 28 .1

50 22 137. 7 34.0 12 7. 3 33.2 105 .6 31. 5 93.8 30.5 83.5 29.6

50 24 12 7. 8 35. 2 11 8. 2 34.5 98.0 32. 8 87.1 31.9 7 7. 5 31.1

55 15 19 6.9 31.7 182 .2 30.5 151.0 28 .1 134 .2 26.8 11 9. 4 25.6

55 18 18 2.1 33.5 168 .5 32.5 13 9.6 30.2 124 .1 29.0 11 0. 5 27. 8

55 20 17 2. 3 34.8 159 .3 33.7 13 2.1 31.6 117. 4 30.4 10 4.5 29.4

55 22 16 2.4 36.0 150 .2 35.0 124 .5 33.0 11 0 .7 31.9 98.5 30.9

55 24 152 .5 37. 2 141.1 36.3 116 . 9 34.4 103 .9 33.3 92.5 32.4

VA 30

Surface

temperature

F

Surface

temperature

Cement screed

θ

F

22

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

Page 23

Handbook Basic™ Heating Systems

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.10 (e.g. carpet).

λ,B

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Liquid screed

Room

C-C 8.8

Mean heating

temperature

Liquid screed

C-C 12

Surface

temperature

Liquid screed

VA 20

Surface

temperature

Liquid screed

VA 25

Surface

temperature

Liquid screed

water temperature

θ

θ

m

i

θ

F

θ

F

θ

F

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 62.7 20.9 58.7 20.5 49.8 19. 8 44.9 19. 3 40.6 19.0

30 18 49.9 22.8 46.7 22.5 39.6 21. 9 35.7 21.5 32.3 21.2

30 20 41. 3 24.0 38.7 23.8 32 .8 23.3 29.6 23.0 26.7 22.7

30 22 32.6 25.3 30.5 25 .1 25.9 24.6 23.4 24.4 21.1 24.2

30 24 23.8 26.4 22.3 26.3 18.9 26.0 17. 0 25.8 15. 4 25.6

35 15 84.0 22.7 78.6 22.2 66.6 21.2 60 .1 20.7 54.3 20.2

35 18 71. 2 24.6 66.7 24.2 56.5 23.4 51.0 22.9 4 6.1 22.4

35 20 62.7 25.9 58.7 25.5 49.8 24.8 44.9 24.3 40.6 24.0

35 22 54.2 27. 2 50.7 26.9 43.0 26.2 38.8 25.8 35.0 25.5

35 24 45.6 28.4 42.7 28.2 36.2 27. 6 32.6 27. 3 29.5 2 7. 0

40 15 10 5.1 24.4 98.4 23.9 83.5 22.6 75.2 21. 9 68.0 21. 3

40 18 92.4 26.4 86.5 25.9 73.4 24.8 66.2 24.2 59.8 23.6

40 20 84.0 27. 7 78.6 27. 2 66.6 26.2 60 .1 25.7 54.3 25.2

40 22 75.5 29.0 70.6 28.6 59.9 2 7. 6 54.0 2 7.1 48.8 26.7

40 24 67. 0 30.2 62.7 29.9 53.2 2 9.1 4 7.9 28.6 43.3 28.2

45 15 12 6. 3 26 .1 11 8. 2 25.5 100 .3 24.0 90.4 23.2 81.7 22.5

45 18 11 3. 6 2 8.1 10 6.3 2 7. 5 90.2 26.2 81.3 25.5 73.5 24.8

45 20 105 .1 29.4 98.4 28.9 83.5 27. 6 75.2 26.9 68.0 26.3

45 22 96.7 30.7 90.5 30.2 76.7 2 9.1 69.2 28.4 62.5 2 7.9

45 24 88.2 32.0 82.6 31. 6 70.0 30.5 63 .1 29.9 57.1 29.4

50 15 147. 4 2 7. 8 13 8. 0 2 7.1 117. 1 25.4 105 .5 24.4 95.4 23.6

50 18 134 .8 29.8 12 6.1 2 9.1 10 7.0 27. 6 96.4 26.7 8 7. 2 25.9

50 20 12 6. 3 31 .1 11 8. 2 30.5 100. 3 29.0 90.4 28.2 81.7 27. 5

50 22 117. 8 32.4 11 0. 3 31.8 93.6 30.5 84.3 29.7 76. 2 29.0

50 24 109.4 33.8 102 .4 33.2 86.8 31.9 78.3 31.2 70.8 30.6

55 15 16 8.6 29.5 15 7. 8 28.6 133. 8 26.7 12 0. 6 25.7 10 9.1 24.7

55 18 15 5.9 31. 5 145.9 30.7 12 3. 8 28.9 111. 6 27. 9 100.9 27. 1

55 20 14 7.4 32.8 138 .0 32 .1 117.1 30.4 10 5.5 29.4 95.4 28.6

55 22 139. 0 3 4.1 13 0.1 33.4 11 0 . 3 31 .8 99.5 31.0 89.9 30.2

55 24 130 .5 35. 5 122 . 2 34.8 103. 6 33. 3 93.4 32.5 84.4 31.7

VA 30

Surface

temperature

F

Surface

temperature

Liquid screed

θ

F

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

23

Page 24

Handbook Basic™ Heating Systems

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.10 (e.g. carpet).

λ,B

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Cement screed

Room

C-C 8.8

Mean heating

water temperature

θ

m

temperature

θ

i

Cement screed

θ

C-C 12

Surface

temperature

F

Cement screed

θ

VA 20

Surface

temperature

F

Cement screed

θ

VA 25

Surface

temperature

F

Cement screed

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 5 7. 7 20.5 53.9 20 .1 46 .1 19. 4 41. 8 19.1 3 7. 7 18 .7

30 18 45.9 22.4 42.9 22.2 36.7 21. 6 33.2 21.3 30.0 21. 0

30 20 38.0 23.7 35.5 23.5 30.3 23.0 2 7. 5 22.8 24.9 22.5

30 22 30.0 25.0 28 .1 24.8 24.0 24. 5 21. 7 24.2 19. 6 24.0

30 24 21. 9 26.3 20.5 26.1 17. 5 25.8 15. 8 25.7 14. 3 25.5

35 15 7 7. 2 22 .1 72.2 21.7 61 .7 20.8 55.9 20.3 50.5 19.8

35 18 65.5 24 .1 61. 3 23.8 52.3 23.0 47. 4 22.6 42 .9 22.2

35 20 5 7. 7 25.5 53.9 25 .1 46 .1 24.4 41. 8 2 4.1 37. 7 23.7

35 22 49.8 26.8 46.6 26.5 39.8 25.9 3 6.1 25.6 32.6 25.2

35 24 41.9 28 .1 39.2 27. 8 33.5 2 7. 3 30.4 2 7.0 2 7. 5 26.8

40 15 96.7 23.7 90.4 23.2 77. 2 22 .1 70.0 21. 5 63.3 20.9

40 18 85.0 25.8 79.5 25.3 67. 9 24.3 61. 6 23.8 55.6 23.3

40 20 7 7. 2 27. 1 72.2 26.7 61.7 25.8 55.9 25.3 50.5 24.8

40 22 69.4 28.5 64.9 28 .1 55.4 2 7. 3 50.3 26.8 45.4 26.4

40 24 61 .6 29.8 57. 6 29.4 49.2 28.7 44.6 28.3 40.3 27. 9

45 15 116 .1 25.3 108 .6 24.7 92.8 23.4 84 .1 22.7 76.0 22.0

45 18 104 .5 27. 4 9 7. 7 26.8 83.5 25.6 75.7 25.0 68.4 24.4

45 20 96.7 28.7 90.4 28.2 7 7.2 27.1 70.0 26.5 63.3 25.9

45 22 88.9 30 .1 83.2 29.6 71.0 28.6 64.4 28.0 58.2 27. 5

45 24 81.1 31. 4 75.9 31. 0 64.8 30.1 58.7 29.5 53 .1 29 .1

50 15 13 5.6 26.9 126 .8 26.2 108.3 24.7 98.2 23.8 88.7 23 .1

50 18 12 3.9 28.9 11 5. 9 28.3 99.0 26.9 89.7 26.2 81.1 25.4

50 20 116 .1 30.3 10 8.6 29.7 92.8 28.4 84 .1 27. 7 76.0 27. 0

50 22 108 .4 31.7 101. 4 31.1 86.6 29.9 78.5 29.2 70.9 28.6

50 24 10 0.6 33.0 9 4.1 32. 5 80.4 31. 4 72.8 30.7 65.8 30.2

55 15 155.0 28.4 145. 0 2 7.6 12 3. 8 25.9 11 2. 3 25.0 101. 5 24 .1

55 18 143 .3 30.5 13 4.1 29.7 11 4. 5 28.2 103.8 27. 3 93.8 26.5

55 20 135. 6 31 .9 126 .8 31. 2 10 8.3 29.7 98.2 28.8 88.7 28 .1

55 22 12 7.8 33.2 119 .6 32.6 102 .1 31. 2 92.6 30.4 83.7 29.7

55 24 120 .0 34.6 11 2. 3 34.0 95.9 32.7 86.9 31. 9 78.6 31.2

VA 30

Surface

temperature

F

Surface

temperature

Cement screed

θ

F

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

24

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

Page 25

Handbook Basic™ Heating Systems

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.15 (e.g. terry velvet / engineered

λ,B

timber, solid timber planks).

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Cement screed

Room

C-C 8.8

Mean heating

water temperature

θ

m

temperature

θ

i

Cement screed

θ

C-C 12

Surface

temperature

F

Cement screed

θ

VA 20

Surface

temperature

F

Cement screed

θ

VA 25

Surface

temperature

F

Cement screed

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 4 7. 6 19.6 4 4.9 19 .3 3 9.1 18 .8 35.8 18. 5 33.0 18. 3

30 18 3 7.8 21. 7 35.7 21.5 31.1 2 1.1 28.5 20.9 26.3 20.7

30 20 31. 3 23 .1 29.6 23.0 25.7 22.6 23.6 22.4 21.7 22.2

30 22 24.7 24.5 23.4 24.4 20.3 24 .1 18. 6 24.0 17. 2 23.8

30 24 18 .0 25.9 17. 0 25.8 14. 8 25.6 13. 6 25.5 12. 5 25.4

35 15 63.7 21. 0 60 .1 20.7 52.3 20.0 4 7.9 19 .6 44.2 19.3

35 18 54.0 23.1 51.0 22.9 44.4 22.3 40.7 22.0 3 7. 5 21. 7

35 20 4 7. 6 24.6 44.9 24.3 39.1 23.8 35.8 23.5 33.0 23.3

35 22 41.1 26.0 38.8 25.8 33.8 25.4 30.9 2 5.1 28.5 24.9

35 24 34.6 2 7.4 32.6 27. 3 28.4 26.9 26.0 26.6 24.0 26.5

40 15 79.7 22.3 75.2 21.9 65.5 2 1.1 60.0 20.7 55.3 20.3

40 18 70 .1 24.5 66.2 24.2 5 7.6 23.5 52.8 23.0 48.6 22.7

40 20 63.7 26.0 60 .1 25.7 52.3 25.0 47. 9 24.6 44.2 24.3

40 22 5 7. 2 27. 4 54.0 27.1 47. 0 26.5 43 .1 26.2 39.7 25.9

40 24 50.8 28.9 4 7.9 28.6 41. 7 28 .1 38.2 27. 8 35.2 2 7. 5

45 15 95.8 23.7 90.4 23.2 78.7 22.2 72.1 21.7 66.4 21. 2

45 18 86.2 25.9 81.3 25.5 70.8 24.6 64.9 24 .1 59.8 23.6

45 20 79.7 27. 3 75.2 26.9 65.5 26 .1 60.0 25.7 55. 3 25.3

45 22 73.3 28.8 69.2 28.4 60.3 27. 7 55.2 2 7. 2 50.9 26.9

45 24 66.9 30.2 63.1 29.9 55.0 29.2 50.4 28.8 46.4 28.5

50 15 111. 8 25.0 105. 5 24.4 91.9 23.3 84.2 22.7 7 7. 6 22 .1

50 18 102. 2 27. 2 96.4 26.7 84.0 25.7 7 7. 0 25.1 70.9 24.6

50 20 95.8 28.7 90.4 28.2 78.7 27. 2 72 .1 26.7 66.4 26.2

50 22 89.4 3 0.1 84.3 29.7 73.4 28.8 67. 3 28.3 62.0 27. 8

50 24 82.9 31. 6 78.3 31. 2 68.2 30.4 62.5 29.9 5 7. 5 29.4

55 15 127. 8 26.2 12 0. 6 25.7 10 5.1 24.4 96.3 23.7 88.7 23 .1

55 18 11 8 . 2 28.5 111. 6 27. 9 97. 2 26.8 89.0 2 6.1 82.0 25.5

55 20 111 .8 30.0 105.5 29.4 91.9 28.3 84.2 27. 7 7 7.6 27.1

55 22 10 5.4 31. 4 99.5 31. 0 86.6 29.9 79.4 29.3 73 .1 28.8

55 24 99.0 32.9 93.4 32.5 81.4 31. 5 74. 5 30.9 68.7 30.4

VA 30

Surface

temperature

F

Surface

temperature

Cement screed

θ

F

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

25

Page 26

Handbook Basic™ Heating Systems

Output table,

BasicRail heating

systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.15 (e.g. terry velvet / engineered

λ,B

timber, solid timber planks).

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Liquid screed

Room

C-C 8.8

Mean heating

temperature

Liquid screed

C-C 12

Surface

temperature

Liquid screed

VA 20

Surface

temperature

Liquid screed

VA 25

Surface

temperature

Liquid screed

water temperature

θ

θ

m

i

θ

F

θ

F

θ

F

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 51.1 19. 9 48.3 19. 6 41. 9 19 .1 38.2 18. 8 35.1 18. 5

30 18 40.7 22.0 38.4 21.8 33.3 21. 3 30.4 21.0 2 7.9 20.8

30 20 33.7 23.3 31.8 23.2 27. 6 22.8 25.2 22.6 2 3.1 22.4

30 22 26.6 24.7 2 5.1 24.6 21. 8 24.3 19 .9 24 .1 18. 2 23.9

30 24 19 .4 26.0 18. 3 25.9 15. 9 25.7 14. 5 25.6 13. 3 25.4

35 15 68.4 21.4 64.7 21.1 56 .1 20.3 51.1 19.9 47. 0 19. 5

35 18 5 8.1 23.5 54.8 23.2 4 7.6 22.6 43.4 22.2 39.8 21.9

35 20 51.1 24.9 48.3 24.6 41. 9 24 .1 38.2 23.8 35.1 23.5

35 22 44.2 26.3 41. 7 26 .1 36.2 25.6 33.0 25.3 30.3 25.0

35 24 37. 2 2 7. 7 35.1 2 7.5 30.5 2 7.1 2 7. 8 26.8 25.5 26.6

40 15 85.7 22.8 81.0 22.4 70.3 21. 5 64.0 21. 0 58.8 20.6

40 18 75.4 25.0 71. 2 24.6 61. 8 23.8 56.3 23.3 51.7 22.9

40 20 68.4 26.4 64.7 26.1 56 .1 25.3 51.1 24.9 4 7. 0 24. 5

40 22 61. 5 27. 8 5 8.1 2 7. 5 50.4 26.8 46.0 26.4 42.2 2 6.1

40 24 54.6 29.2 51.6 28.9 44.8 28.3 40.8 28.0 37. 5 2 7. 7

45 15 103 .0 24.2 9 7. 3 23.8 84.4 22.7 76 .9 22 .1 70.6 21.6

45 18 92.6 26.4 87. 5 26.0 75.9 25.0 69.2 24.4 63.5 24.0

45 20 85.7 2 7.8 81. 0 27. 4 70.3 26.5 64.0 26.0 58.8 25.6

45 22 78.8 29.2 74 .5 28.9 64.6 28.0 58.9 2 7.6 5 4.1 27. 1

45 24 71.9 30.7 6 7. 9 30.3 58.9 29.6 53.7 29 .1 49.3 28.7

50 15 12 0. 2 25.6 113 . 6 2 5.1 98.5 23.9 89.8 23.2 82.5 22.6

50 18 109. 9 27. 8 103 .8 27. 3 9 0.1 26.2 8 2.1 25.5 75.4 25.0

50 20 103 .0 29.2 9 7. 3 28.8 84.4 27. 7 76.9 2 7.1 70.6 26.6

50 22 96 .1 30.7 90.8 30.2 78.7 29.2 71. 8 28.7 65.9 28.2

50 24 89.2 32 .1 84.2 31.7 7 3.1 30.8 66.6 30.2 61. 2 29.8

55 15 137. 4 27. 0 129 .8 26.4 112 . 7 25.0 102. 7 24. 2 94.3 23.5

55 18 127. 1 29.2 120 .1 28.6 104 .2 27. 3 94.9 26.6 8 7. 2 25.9

55 20 120. 2 30.6 11 3. 6 3 0.1 98.5 28.9 89.8 28.2 82.5 2 7.6

55 22 113 . 3 32 .1 1 07. 0 31. 6 92.9 30.4 84.6 29.7 7 7.7 29.2

55 24 130 .5 35. 5 122 . 2 34.8 103. 6 33. 3 93.4 32.5 84.4 31.7

VA 30

Surface

temperature

F

Surface

temperature

Liquid screed

θ

F

26

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

Page 27

Handbook Basic™ Heating Systems

Output table,

BasicClip and BasicGrip

heating systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.00 (e.g. tiles).

λ,B

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Liquid screed

Room

C-C 10

Mean heating

temperature

Liquid screed

water temperature

θ

θ

m

i

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 11 2. 8 25.0 97. 9 23.8 84.3 22.7 73.0 21.8 63.2 20.9

30 18 89.7 26.2 7 7. 9 25.2 67. 0 24.3 5 8.1 23.5 50.3 22.8

30 20 74. 3 26.9 64.5 26.0 55.5 25.3 4 8.1 24.6 41.6 24 .1

30 22 58.7 27. 5 51.0 26.9 43.8 26.3 38.0 25.7 32.9 25.3

30 24 42. 8 28.2 37.1 27. 7 32.0 2 7. 2 27. 7 26.8 23.9 26.5

35 15 151.0 28 .1 131.1 26.5 112 . 8 25.0 9 7.7 23.8 84.6 22.7

35 18 12 8.1 29.3 111 . 2 2 7. 9 95.7 26.6 82.9 25.6 71.7 24.7

35 20 112 . 8 30.0 97. 9 28.8 84.3 27. 7 73.0 26.8 63.2 25.9

35 22 9 7. 4 30.8 84.6 29.7 72.8 28.7 63.0 27. 9 54.6 27. 2

35 24 82.0 31.5 71.2 30.6 61. 3 29.8 5 3.1 2 9.1 45.9 28.4

40 15 18 9.1 31.1 164 .2 29 .1 141. 3 2 7. 3 12 2. 3 25.8 105 .9 24.5

40 18 16 6.3 32. 3 144 .4 30.6 124 .2 29.0 1 07. 6 2 7. 6 93 .1 26.4

40 20 151.0 3 3.1 131. 1 31. 5 11 2. 8 30.0 9 7.7 28.8 84.6 27. 7

40 22 135 .7 33.9 117. 9 32.4 101. 4 31.1 8 7. 8 30.0 76. 0 29.0

40 24 12 0. 4 34.7 10 4.6 33.4 90.0 32.2 7 7. 9 31 .2 6 7. 4 30.3

45 15 2 2 7. 2 34.0 19 7. 2 31.7 169 .7 29.6 14 7.0 27. 8 12 7. 2 26.2

45 18 204.3 35.2 1 77. 4 33.2 152 .7 31. 2 132 .2 29.6 114 . 4 28.2

45 20 189.1 3 6.1 16 4.2 3 4.1 141 .3 32.3 12 2. 3 30.8 10 5.9 29.5

45 22 17 3. 9 36.9 151. 0 35 .1 12 9.9 33.4 11 2. 5 32.0 9 7. 4 30.8

45 24 158 .6 37. 7 1 37. 7 36.0 118 . 5 34.5 102.6 33.2 88.8 32 .1

50 15 265.2 36.8 230.3 34.2 19 8.1 31. 7 171 .6 29.7 14 8.5 27. 9

50 18 242.4 3 8.1 210. 5 35.7 181 .1 33.4 15 6. 8 31.5 135 .7 29.9

50 20 2 2 7. 2 39.0 19 7. 2 36.7 169. 7 34.6 1 47. 0 32.8 12 7.2 31.2

50 22 2 12.0 39.8 184 .0 3 7.7 15 8. 3 35.7 13 7.1 34.0 118 . 7 32.5

50 24 19 6. 7 40.6 170 . 8 38.6 14 7. 0 36.8 12 7. 3 35. 2 11 0. 2 33.8

55 15 303.2 39.7 263.3 36.7 226.5 33.9 19 6.1 31.6 169. 8 29.6

55 18 280.4 41. 0 243.5 38.2 209.5 35.6 181. 4 33.5 157. 0 31.6

55 20 265.2 41. 8 230.3 39. 2 19 8.1 36.7 17 1.6 34.7 148 .5 32.9

55 22 250.0 42.7 2 17.1 40.2 186 .8 3 7.9 161.7 35.9 14 0.0 34.2

55 24 234.8 43.5 203.8 41. 2 175 .4 39.0 151.9 37. 2 131.5 35.5

C-C 15

Surface

temperature

F

Liquid screed

θ

C-C 20

Surface

temperature

F

Liquid screed

θ

C-C 25

Surface

temperature

F

Liquid screed

θ

C-C 30

Surface

temperature

F

Surface

temperature

Liquid screed

θ

F

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

27

Page 28

Handbook Basic™ Heating Systems

Output table,

BasicClip and BasicGrip

heating systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.00 (e.g. tiles).

λ,B

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Cement screed

Room

C-C 10

Mean heating

water temperature

θ

m

temperature

θ

i

Cement screed

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 96.4 23.7 84.2 22.7 73.6 21.8 63.9 21.0 55.7 20.3

30 18 76.7 25.1 6 7.0 24.3 58.5 23.5 50.8 22.9 44.3 22.3

30 20 63.5 26.0 55.5 25.3 48.5 24.7 42.1 24 .1 36.7 23.6

30 22 50 .1 26.8 43.8 26.3 38.3 25.8 33.2 25.3 29.0 24.9

30 24 36.5 2 7.6 31. 9 2 7. 2 27. 9 26.8 24.2 26.5 21.1 26.2

35 15 12 9. 0 26.3 11 2. 7 25.0 98.5 23.9 85.6 22.8 74. 6 21.9

35 18 109 .4 27. 8 95.6 26.6 83.5 25.6 72.6 24.7 63.3 23.9

35 20 96.4 28.7 84.2 2 7.7 73.6 26.8 63.9 26.0 55.7 25.3

35 22 83.3 29.6 72.8 28.7 63.5 28.0 55.2 2 7. 2 48 .1 26.6

35 24 70 .1 30.5 61.2 29.8 53.5 29.1 46.5 28.5 40.5 28.0

40 15 161. 6 28.9 141. 2 2 7. 3 123 .3 25.9 1 07. 1 24.6 93.4 23.5

40 18 142.1 30.4 124 .1 29.0 108 .4 2 7.7 94.2 26.5 82 .1 25.5

40 20 12 9.0 31. 3 112 . 7 30.0 98.5 28.9 85.6 2 7.8 74 .6 26.9

40 22 11 6. 0 32.3 101.3 31.1 88.5 30 .1 76.9 29.1 6 7.1 28.3

40 24 102 .9 33.2 89.9 32. 2 78.6 31.2 68.2 30.4 59.5 29.6

45 15 19 4.1 31.4 169 .6 29.5 148 .2 27. 9 12 8. 7 26.3 112 . 2 25.0

45 18 174 .6 32.9 152.6 31.2 133 .3 29.7 11 5. 8 28.3 101. 0 2 7.1

45 20 161.6 33.9 1 41.2 32.3 12 3. 3 30.9 1 07. 1 29.6 93.4 28.5

45 22 14 8.6 34.9 129 .8 33.4 11 3. 4 32.1 98.5 30.9 85.9 29.8

45 24 135. 5 35.9 118 . 4 34.5 103 .5 33.3 89.9 32. 2 78.4 31.2

50 15 226.6 33.9 19 8.0 31.7 17 3. 0 29.8 15 0. 2 28.0 13 1.0 26.5

50 18 2 0 7.1 35.4 18 1.0 33.4 158 .1 31. 6 13 7. 3 30.0 119 . 8 28.6

50 20 19 4.1 36.4 169.6 34.5 14 8. 2 32.9 12 8. 7 31. 3 112 . 2 30.0

50 22 181.1 3 7. 4 15 8. 3 35.7 138 .2 34 .1 12 0.1 32.6 104 .7 31.4

50 24 168 .1 38.4 14 6.9 36.8 12 8. 3 35.3 111. 5 33.9 97. 2 32.8

55 15 259.1 36.4 226.4 33.9 1 97. 7 31. 7 171 .8 29.7 14 9.8 28.0

55 18 239.6 3 7.9 209.4 35.6 18 2.9 33.6 15 8. 9 31.7 138 .5 30 .1

55 20 226.6 38.9 198 .0 36.7 173 .0 34.8 15 0. 2 33.0 131 .0 31. 5

55 22 213. 6 39.9 18 6.7 37. 9 163 .0 36.0 141. 6 34.3 12 3. 5 32.9

55 24 200.6 40.9 175 .3 39.0 153. 1 3 7. 3 13 3. 0 35.7 11 6. 0 34.3

C-C 15

Surface

temperature

F

Cement screed

θ

C-C 20

Surface

temperature

F

Cement screed

θ

C-C 25

Surface

temperature

F

Cement screed

θ

C-C 30

Surface

temperature

F

Surface

temperature

Cement screed

θ

F

28

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

Page 29

Handbook Basic™ Heating Systems

Output table,

BasicClip and BasicGrip

heating systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.05 (e.g. engineered timber floor /

λ,B

synthetic fibre).

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Liquid screed

Room

C-C 10

Mean heating

temperature

Liquid screed

water temperature

θ

θ

m

i

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 79.5 22.3 70.8 21. 6 62.3 20.8 55.0 20.2 48.7 19.7

30 18 63.3 23.9 56.4 23.3 49.5 22.8 43.8 22.2 38.8 21.8

30 20 52.4 25.0 46.6 24. 5 41 .0 24.0 36.2 23.6 32.1 23.2

30 22 41. 4 26.0 36.9 25.6 32.4 25.2 28.6 24.9 25.4 24.6

30 24 3 0.1 27. 0 26.9 26.7 23.6 26.4 20.8 26.2 18. 5 25.9

35 15 10 6.4 24.5 94.8 23.6 83.4 22.6 73.6 21.8 65.3 21.1

35 18 90.3 26.2 80.4 25.4 70.7 24.6 62.4 23.9 55.4 23.3

35 20 79.5 27. 3 70.8 26.6 62.3 25.8 55.0 25.2 48.7 24.7

35 22 68.7 28.4 61.2 27. 8 53.8 27.1 47. 5 26.6 42 .1 26 .1

35 24 5 7.8 29.5 51.5 28.9 45.3 28.4 40.0 27. 9 35.4 2 7. 5

40 15 133 .3 26.7 118 . 8 25.5 104 .4 24.4 92.2 23.4 81.7 22.5

40 18 117. 2 28.4 10 4.4 2 7. 4 91.8 26.3 81.0 25.4 71. 8 24.7

40 20 106 .4 29. 5 94.8 28.6 83.4 27. 6 73.6 26.8 65.3 26.1

40 22 95.7 30.6 85.2 29.8 74. 9 28.9 66.2 28.2 58.7 27. 5

40 24 84.9 31. 8 75.6 31.0 66.5 30.2 58.7 29.5 5 2.1 29. 0

45 15 16 0.1 28.8 142.6 27. 4 12 5.4 26 .1 11 0 .7 24.9 98.2 23.8

45 18 144 .0 30.5 128 .3 29.3 112 . 8 28.0 99.6 2 7.0 88.3 26.0

45 20 13 3. 3 31.7 11 8 .8 30.5 104 .4 29.4 92.2 28.4 81.7 27. 5

45 22 122.6 32.8 109. 2 31.7 96.0 30.7 84.8 29.7 75 .1 28.9

45 24 111 . 8 34.0 9 9.6 33.0 8 7. 6 32.0 7 7. 3 31.1 68.6 30.4

50 15 186.9 30.9 166 .5 29.3 14 6.4 27. 7 12 9. 3 26.4 114 . 6 25.2

50 18 17 0.9 32.6 15 2. 2 31.2 133 .8 29.7 11 8 .2 28.5 10 4.7 2 7. 4

50 20 1 60.1 33.8 142.6 32.4 12 5. 4 31 .1 11 0. 7 29.9 98.2 28.8

50 22 14 9.4 35.0 13 3.1 33.7 117. 0 32.4 103 .3 31. 3 91.6 30.3

50 24 138 .7 3 6.1 12 3. 5 34.9 108.6 33.7 95.9 32.7 85.0 31.8

55 15 213.7 32.9 19 0.4 31. 2 16 7. 4 29.4 1 47. 8 2 7. 8 131. 0 26.5

55 18 197. 6 34.7 176 .1 33.0 15 4.8 31. 4 136 .7 30.0 121 .2 28.7

55 20 18 6.9 35.9 166 .5 34.3 14 6.4 32.7 12 9.3 31. 4 114 . 6 30.2

55 22 176. 2 3 7.1 157. 0 35.6 13 8. 0 34 .1 12 1.9 32.8 108 .0 31. 7

55 24 165. 5 34.2 1 47. 4 32.8 12 9. 6 35.4 11 4 . 5 34.2 101.5 3 3.1

C-C 15

Surface

temperature

F

Liquid screed

θ

C-C 20

Surface

temperature

F

Liquid screed

θ

C-C 25

Surface

temperature

F

Liquid screed

θ

C-C 30

Surface

temperature

F

Surface

temperature

Liquid screed

θ

F

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

29

Page 30

Handbook Basic™ Heating Systems

Output table,

BasicClip and BasicGrip

heating systems

Thermal resistance of the finished floor covering:

R

m2 K/W 0.05 (e.g. engineered timber floor /

λ,B

synthetic fibre).

Differential temperature (σ K) 5.

Heat output on the basis of EN 1264.

Cement screed

Room

C-C 10

Mean heating

water temperature

θ

m

temperature

θ

i

Cement screed

θ

°C °C W/m °C W/m °C W/m °C W/m °C W/m °C

30 15 70.4 21. 5 63.0 20.9 56.2 20.3 49.9 19.8 44.4 19 .3

30 18 56.0 23.3 50 .1 22.8 44.7 22.3 39.7 21.9 35.4 21.5

30 20 46.4 24.5 41. 5 24.0 37. 0 23.6 32 .9 23.3 29.3 22.9

30 22 36.7 25.6 32.8 25.3 29.2 24.9 26.0 24.6 23 .1 24.4

30 24 26.7 26.7 23.9 26.4 21. 3 26.2 18. 9 26.0 16.8 25.8

35 15 94.3 23.5 84.4 22.7 75.2 21.9 66.8 21.2 59.5 20.6

35 18 80.0 25.3 71.6 24.6 63.8 24.0 56.7 23.4 50.5 22.8

35 20 70.4 26.5 63.0 25.9 56.2 25.3 49.9 24.8 44.4 24.3

35 22 60.9 2 7. 7 54.4 2 7.2 48.5 26.7 43 .1 26.2 38.4 25.8

35 24 51. 2 28.9 45.8 28.4 40.9 28.0 36.3 27. 6 32.3 2 7. 2

40 15 11 8 .1 25.5 105.7 24. 5 94.2 23.5 83.7 22.7 74. 5 21.9

40 18 10 3.8 2 7. 3 92.9 26.4 82.8 25.6 73.6 24.8 65.5 24 .1

40 20 94.3 28.5 84.4 27. 7 75. 2 26.9 66.8 26.2 59.5 25.6

40 22 84.8 29.7 75.8 29.0 67. 6 28.3 60 .1 2 7.7 53.5 2 7.1

40 24 75. 2 30.9 67. 3 30.3 60.0 29.7 53.3 2 9.1 4 7. 4 28.6

45 15 141.9 2 7.4 126.9 26.2 113 .1 25 .1 10 0.6 24.0 89.5 2 3.1

45 18 1 27. 6 29.2 114 . 2 2 8.1 101. 8 2 7.1 90.5 26.2 80.5 25.4

45 20 118 .1 30.5 105.7 29.5 94.2 28.5 83.7 27. 7 74. 5 26.9

45 22 108. 6 31. 7 9 7. 2 30.8 86.6 29.9 77. 0 29 .1 68.5 28.4

45 24 9 9.1 32.9 88.6 32.1 79.0 31. 3 70.2 30.5 62.5 29.9

50 15 165 .6 29.2 14 8.2 27. 9 13 2.1 26.6 117. 4 25.4 104 .5 24.4

50 18 151.4 31.1 13 5.4 29.9 12 0. 7 28.7 10 7. 3 2 7.6 95.5 26.6

50 20 141.9 32.4 126.9 31 .2 113 .1 30.1 100 .6 29.0 89.5 2 8.1

50 22 13 2.4 33.6 11 8 .4 32.5 105 .6 31. 5 93.8 30.5 83.5 29.6

50 24 122 .9 34.8 109. 9 33.8 98.0 32. 8 87.1 31.9 7 7. 5 31.1

55 15 18 9.4 31.1 169. 4 29.5 151.0 2 8.1 13 4. 2 26.8 11 9. 4 25.6

55 18 175.1 33.0 156 .7 31 .5 13 9.6 30.2 124 .1 29.0 11 0 .5 27. 8

55 20 165.6 34.2 14 8.2 32.9 13 2.1 31. 6 11 7.4 30.4 104 .5 29.4

55 22 156 .1 35.5 13 9.7 34.2 12 4. 5 33.0 11 0 .7 31.9 98.5 30.9

55 24 146 .6 32.7 131. 2 31. 5 11 6. 9 34.4 103.9 33.3 92.5 32.4

C-C 15

Surface

temperature

F

Cement screed

θ

C-C 20

Surface

temperature

F

Cement screed

θ

C-C 25

Surface

temperature

F

Cement screed

θ

C-C 30

Surface

temperature

F

Surface

temperature

Cement screed

θ

F

30

Maximum floor surface temperature in accordance with EN 1264: Edge Zone 1.00 m

Comfort Zone

Bathrooms

VGCTB202 © Danfoss 10/2009

35 °C

29 °C

33 °C

Page 31

Handbook Basic™ Heating Systems

Output table,