Page 1

ENGINEERING TOMORROW

User Guide

BACnet MS/TP Communication with MBS UBR-01 Router

VLT® HVAC Drive FC 102 • VACON® 100 HVAC

vlt-drives.danfoss.com

Page 2

Page 3

Contents User Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Product Overview

1.4 Symbols, Abbreviations, and Conventions

2 Network

2.1 Network Set-up

2.2 Cabling of the Networks

2.2.1 BACnet MS/TP Cabling (NW #2) 4

2.2.2 Ethernet Cabling (NW #1) 4

3 Addressing and Setting up the Devices on the Networks

3.1 Setting up the IP Address and Subnet Mask of the PC

3.2 Setting up the UBR-01

3.3 Conguring the Frequency Converters

4 Testing the BACnet Settings in a Delta BMS System

2

2

2

2

2

3

3

4

5

5

5

7

8

MG92N102 Danfoss A/S © 05/2017 All rights reserved. 1

Page 4

Introduction BACnet MS/TP Communication with MBS UBR-01 Router

11

1 Introduction

1.1 Purpose of the Manual

This user guide provides information on the conguration

and use of the universal BACnet Router UBR-01 from MBS

with Danfoss VLT® HVAC Drive FC 102 and VACON® 100

HVAC, using the embedded BACnet MS/TP communication.

The user guide details:

The electrical connection of the RS485.

•

The IP settings of the PC.

•

The settings of the UBR-01 router.

•

The relevant communication parameters of the

•

frequency converter.

For further settings of the UBR-01, refer to www.mbs-

ugw.de/ubr-01bacnet-router/.

VLT® is a registered Danfoss trademark.

VACON® is a registered trademark.

BACnet® is a registered trademark of ASHRAE.

Additional Resources

1.2

Resources available for the frequency converters and

optional equipment:

The VLT® HVAC Drive FC 102 Operating Guide

•

provides the necessary information for getting

the frequency converter up and running.

The VLT® HVAC Drive FC 102 Design Guide provides

•

detailed information about capabilities and

functionality to design motor control systems.

The VLT® HVAC Drive FC 102 Programming Guide

•

provides greater detail on working with

parameters and many application examples.

The VACON® 100 BACnet Installation Manual

•

describes how to commission and parameterize

the BACnet protocol.

The VACON

•

provides greater detail on the parameters and

application examples.

Supplementary publications and manuals are available

from Danfoss. See drives.danfoss.com/knowledge-center/

technical-documentation/ for listings.

®

100 HVAC Application Manual

Product Overview

1.3

Use the BACnet MS/TP UBR-01 router to enable communication in a BACnet network. The router is the device

sending messages through the network. The messages can

be from master to slave or slave to master, and the router

can trigger alarms and/or warnings if the communication is

lost.

1.4 Symbols, Abbreviations, and

Conventions

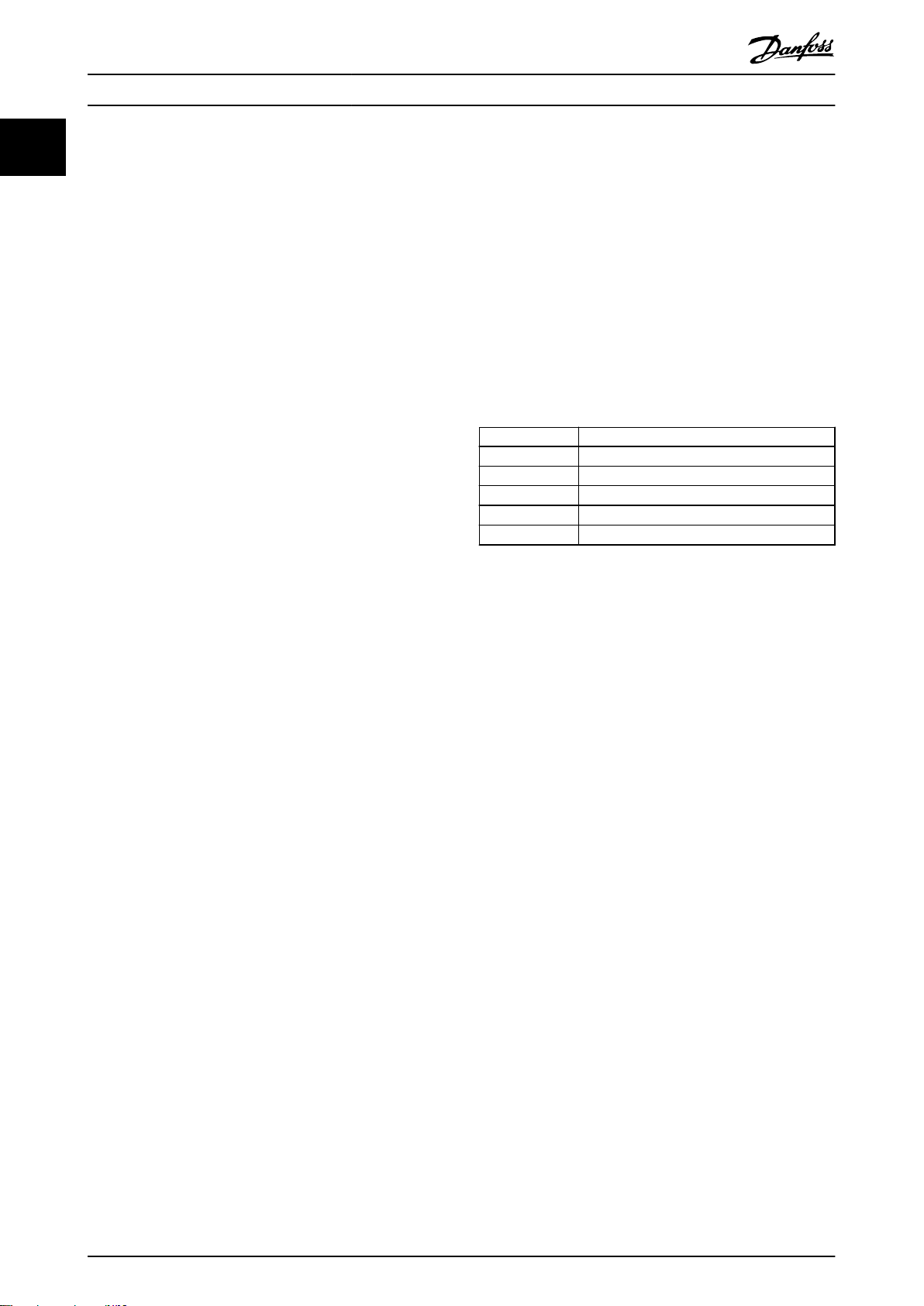

Abbreviation Denition

BMS Building management system

EMC Electromagnetic compatibility

IP Internet protocol

PC Personal computer

TCP Transmission control protocol

Table 1.1 Symbols and Abbreviations

Conventions

Numbered lists indicate procedures.

•

Bullet lists indicate other information and

•

description of illustrations.

Italicized text indicates the following:

•

- Cross-reference.

- Link.

- Parameter name.

- Parameter option.

- Parameter group name.

All dimensions are in metric values (imperial

•

values in brackets).

An asterisk (*) indicates the default setting of a

•

parameter.

2 Danfoss A/S © 05/2017 All rights reserved. MG92N102

Page 5

A

B

C

E

F

D

NW #1

NW #2

130BF303.10

Network User Guide

2 Network

2.1 Network Set-up

The system consists of 2 networks:

Ethernet network (shown as Network number 1-NW#1)

•

BACnet MS/TP network (shown as Network number 2-NW#2)

•

For the correct function of this network system, it is mandatory to follow the instructions on installation of the communication cables given in this user guide.

2 2

A PC with web browser

B Ethernet switch

C BMS controller

D UBR-01 BACnet Ethernet to MS/TP router

E

F

NW #1 Ethernet network, network number 1

NW #2 BACnet MS/TP network, network number 2

Illustration 2.1 Router Running BACnet Ethernet

VLT® HVAC Drive FC 102

VACON® 100 HVAC

MG92N102 Danfoss A/S © 05/2017 All rights reserved. 3

Page 6

UBR-01

D

FC 102

E

B+ A- Shld

61 68 69

130BF304.11

30 A-

B+

Vacon 100

F

130BD866.12

≥200 mm (7.9 in) or

≥500 mm (20 in)

2

1

Network BACnet MS/TP Communication with MBS UBR-01 Router

2.2 Cabling of the Networks

2.2.1 BACnet MS/TP Cabling (NW #2)

22

To ensure correct functionality of the BACnet MS/TP

network, be sure to do the cabling correctly. Pay special

attention to mounting of the cable shield and to

termination of the network.

2.2.2 Ethernet Cabling (NW #1)

NOTICE

EMC INTERFERENCE

Use shielded cables for motor and control wiring, and

separate cables for eldbus communication, motor

wiring, and brake resistor. Failure to isolate eldbus

communication, motor, and brake resistor cables can

result in unintended behavior or reduced performance.

NOTICE

Never connect the shield to terminal 61 on the

frequency converter.

Minimum 200 mm (7.9 in) clearance between power,

motor, and control cables is required. For power sizes

above 315 kW (450 hp), increase the minimum distance

to 500 mm (20 in).

NOTICE

When the eldbus cable crosses a motor cable or a brake

resistor cable, ensure that the cables cross at an angle of

90°.

Illustration 2.2 Grounding Shielded Cables

Shielding of frequency converters connected to the same

ground potential

1. Use an adequate equalizing cable to eliminate

the risk of equalizing current running into the

shield of the BACnet cables.

2. Mount the shield at the terminal marked Shld on

the router.

3. On the frequency converters, connect the shield

to the ground shield brackets.

Shielding of frequency converters without the same

ground potential

If the frequency converters do not have the same ground

potential, only connect the shield to ground in 1 location.

Expect a lower EMC performance.

1 Ethernet cable

2

90° crossing

Illustration 2.3 Cable Routing

For the Ethernet, use standard shielded Cat5e patch cables.

Maximum cable length is 100 m (328 ft).

An Ethernet switch distributes the packets to the participants on the Ethernet network. For industrial installation,

only use industrial graded products as other products may

cause faults and sporadic loss of communication.

4 Danfoss A/S © 05/2017 All rights reserved. MG92N102

Page 7

130BF307.10

Addressing and Setting up t... User Guide

3 Addressing and Setting up the Devices on the Networks

For proper function of the network, congure each device correctly.

Device Product Device

instance

A PC 10000 N/A N/A N/A 192.168.0.xxx 255.255.255.000

B N/A N/A N/A N/A N/A N/A N/A

C N/A 1 N/A 1 N/A N/A N/A

D UBR-01 router, RS485 100 0 1 & 2 38400 192.168.0.1 255.255.255.0

E

VLT® HVAC Drive FC 102, 1

frequency converter

F

VACON® 100 HVAC, 2nd frequency

converter

Table 3.1 BACnet and Ethernet Settings

st

1001 1 N/A 38400 N/A N/A

1002 2 N/A 38400 N/A N/A

3.1 Setting up the IP Address and Subnet

Mask of the PC

On the PC, set up the IP address in the Internet Protocol

Version 4 (TCP/IP) Properties conguration menu.

1. Open the Control panel window.

2. Select View network status and tasks.

3. Select Local Area Connection.

4. Select Properties.

5. Select Internet Protocol Version 4 (TCP/IPv 4).

6. Select Properties.

7. Select Use the following IP address.

8. Set the IP address to 192.168.0.xx, where xx must

be a number not currently used on the network.

9. Set the subnet mask to 255.255.255.000.

10. Exit the windows to activate the new IP

addresses.

MAC address Network number Baud rate IP address Subnet mask

3.2 Setting up the UBR-01

To route to and from the MS/TP network, congure the

UBR-01 router via the router web page.

As factory setting, the UBR-01 has the IP address

192.168.0.1.

1. Enter the IP address 192.168.0.1 in the web

browser address bar.

2. Press Enter.

2a The main page of the router web page

opens.

3 3

Illustration 3.1 Entering the IP Address in the Web Browser

MG92N102 Danfoss A/S © 05/2017 All rights reserved. 5

Page 8

130BF308.10

130BF309.10

130BF310.10

130BF311.10

Addressing and Setting up t... BACnet MS/TP Communication with MBS UBR-01 Router

3. Consult the manual for the UBR-01 for login and

password. Danfoss recommends to change the

default login and password, since keeping the

default is a security vulnerability.

9. Click Save.

10. Open the MS/TP menu.

11. Enter the settings shown in Illustration 3.4.

4. Open the Device menu.

33

5. Enter the settings shown in Illustration 3.2.

Illustration 3.4 Settings in the MS/TP Menu

Illustration 3.2 Settings in the Device Menu

6. Click Save.

7. Open the Ethernet menu.

8. Enter the settings shown in Illustration 3.3.

12. Click Save.

13. Open the Activate menu.

14. Click Activate and restart to activate the settings,

see Illustration 3.5.

14a The router restarts and the new settings

become active, see Illustration 3.6.

Illustration 3.5 Settings in the MS/TP Menu

Illustration 3.3 Settings in the Ethernet Menu

6 Danfoss A/S © 05/2017 All rights reserved. MG92N102

Page 9

130BF312.10

Addressing and Setting up t... User Guide

Illustration 3.6 Router Restarting

3.3 Conguring the Frequency Converters

3 3

To enable the frequency converters to communicate over the embedded BACnet MS/TP network, set the parameters listed

in Table 3.2 and Table 3.3.

For correct programming of the frequency converter, see the VLT® HVAC Drive FC 102 Programming Guide for details on

setting up motor size, motor voltage, ramp times, and more.

Parameter Setting

First frequency converter (E)

Parameter 8-01 Control Site [2] Control word only

Parameter 8-02 Control Source [1] FC Port

Parameter 8-03 Control Timeout Time

Parameter 8-04 Control Timeout Function

Parameter 8-10 Control Prole [0] FC Prole

Parameter 8-30 Protocol [5] BACnet

Parameter 8-31 Address 1

Parameter 8-32 Baud Rate [4] 38400 Baud

Parameter 8-70 BACnet Device Instance 1001

Table 3.2 Required Communication Parameters and their Correct Settings, VLT® HVAC Drive FC 102

Parameter Setting

Parameter 3.2.1 Control Place FieldbusCTRL

Parameter 3.2.2 Local/Remote Control Remote

Parameter 5.8.3.1.5 Communication Timeout

Parameter 3.9.1.6 (ID 733) Fieldbus Fault Stop

Parameter 5.8.1.1 Protocol BACnet MSTP

Parameter 5.8.3.1.2 MAC Address 2

Parameter 5.8.3.1.1 Baud Rate 38400

Parameter 5.8.3.1.3 Instance Number 1002

10.0 s

[2] Stop

10.0 s

1)

1)

Second frequency converter (F)

1)

Table 3.3 Required Communication Parameters and their Correct Settings, VACON® 100 HVAC

1) To achieve a stable system, it is recommended that 3 write commands are sent within the timeout set in parameter 8-03 Control Timeout Time.

MG92N102 Danfoss A/S © 05/2017 All rights reserved. 7

Page 10

130BF514.11

130BF533.10

Testing the BACnet Settings... BACnet MS/TP Communication with MBS UBR-01 Router

4 Testing the BACnet Settings in a Delta BMS System

For testing the settings in the UBR-01 router and in the

frequency converters, a BMS tool is used for:

Scanning the network.

•

Find the BACnet devices.

•

Showing the device objects.

44

•

Illustration 4.1 BMS Tool Scanning the Network

By selecting the frequency converter with device instance

1001, the BMS starts the discovery of the frequency

converter objects and shows their present value. This

proves the correct function of the UBR-01 and the

frequency converters connected via BACnet.

Illustration 4.3 List of VACON® 100 Objects and their Values

Illustration 4.2 List of VLT® HVAC Drive FC 102 Objects and

their Values

8 Danfoss A/S © 05/2017 All rights reserved. MG92N102

Page 11

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed. All trademarks in this material are property

of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

130R0724 MG92N102 05/2017

*MG92N102*

Loading...

Loading...