Technical Information

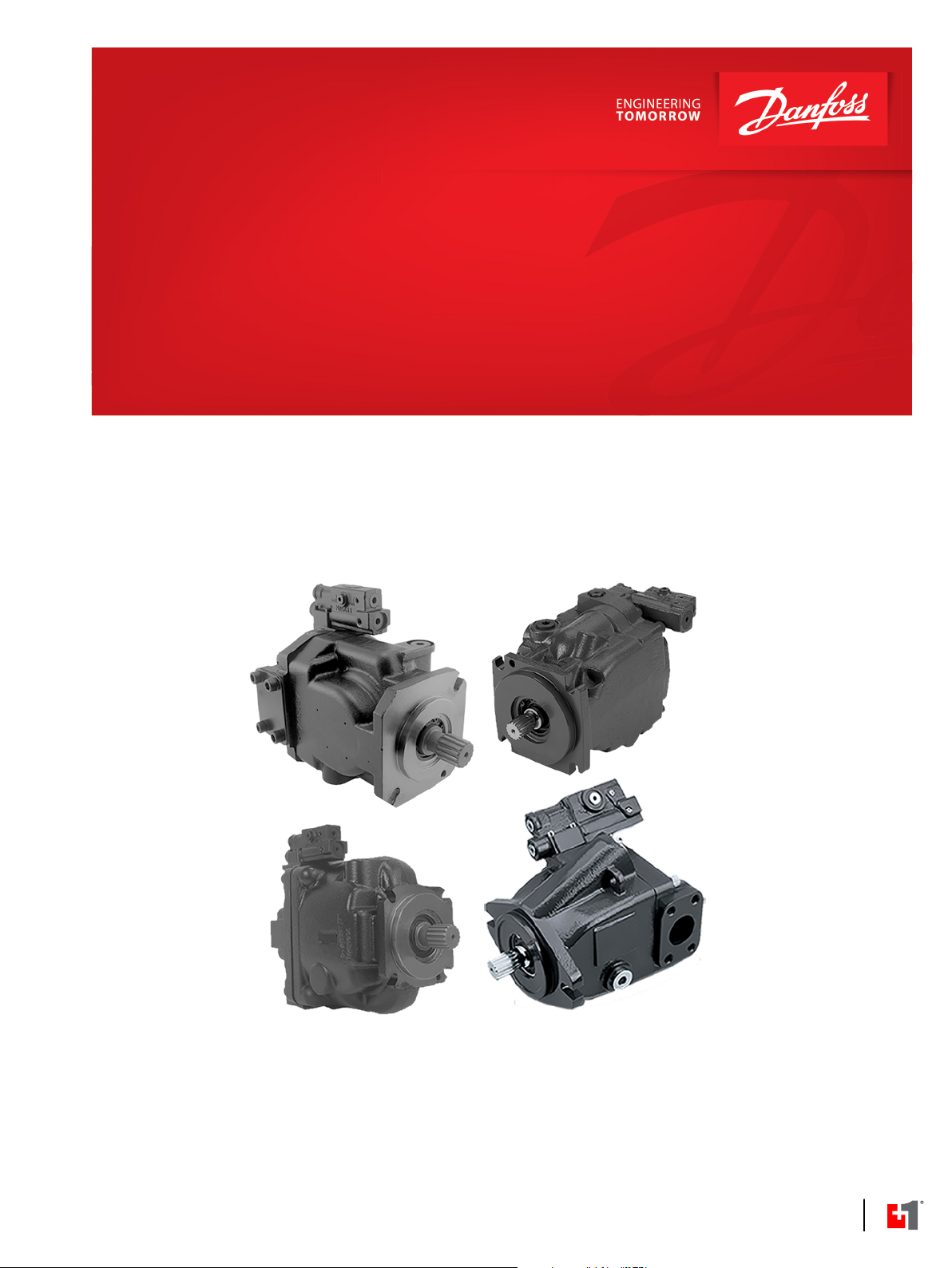

Series 45

Axial Piston Open Circuit Pumps

www.danfoss.com

Technical Information

Series 45 Pumps

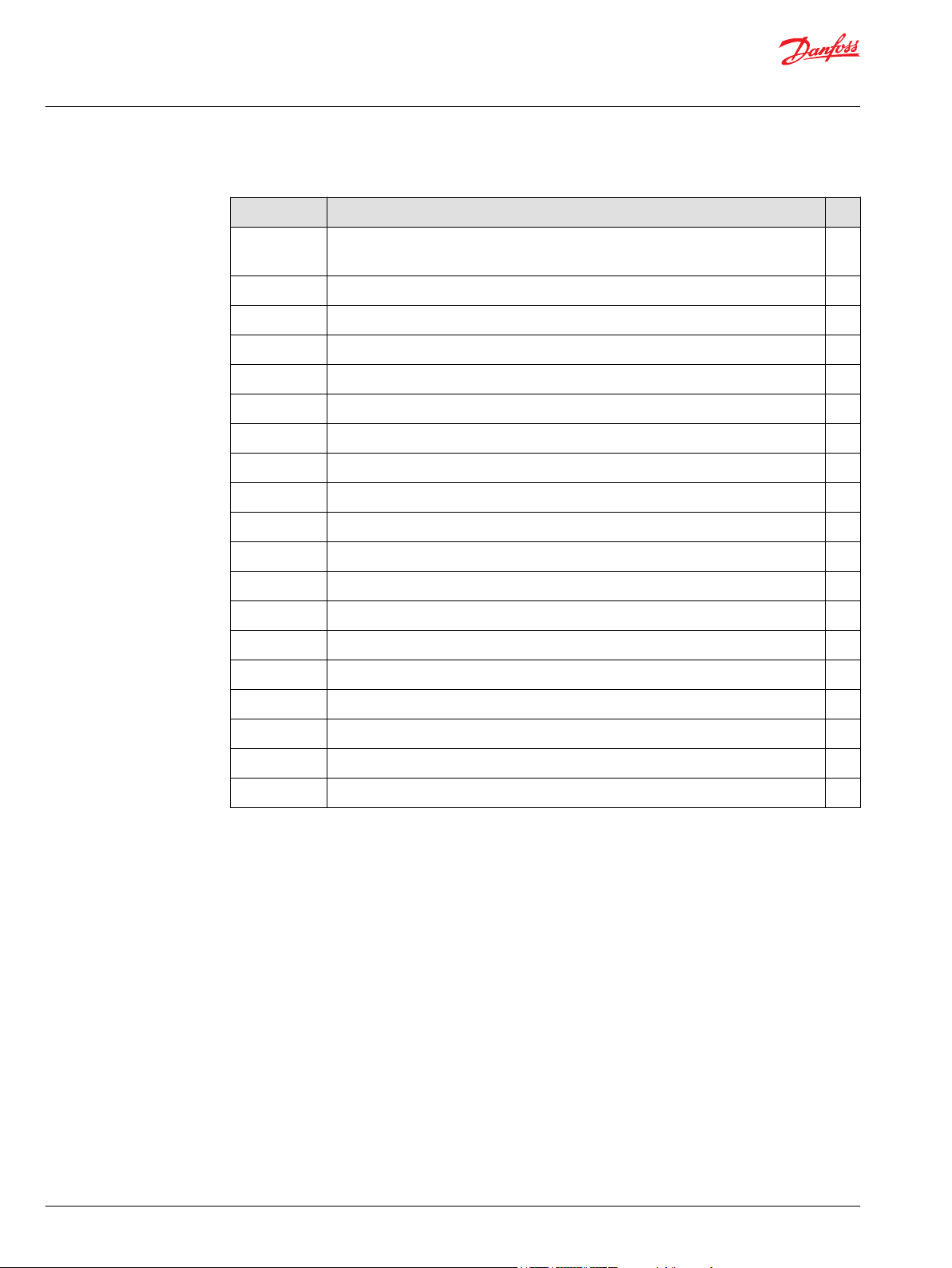

Revision history Table of revisions

Date Changed Rev

January 2022 Clarified importance of relief valve for system protection; added mounting flange technical

data to frame F

April 2021 Added K2 040C displacement performance graphs 1104

June 2020 Changed document number from 'BC00000019' and '520L0519' to 'BC152886483703' 1103

October 2019 Added K2 040C displacement technical data 1001

July 2019 Removed excess content 0903

June 2019 Removed M1 ports from K2 schematics and other minor changes 0902

March 2018 Minor updates 0901

September 2017 Corrected performance curves for K2 Pumps 0812

August 2017 Corrected typo 0811

April 2017 Update the TOC 0810

March 2017 add K2 Frame 0809

July 2016 Fan Drive Control configuration-corrected G and H model code tables 0808

July 2016 Fan Drive Control configuration-included G and H model code tables 0807

June 2016 Various edits - Fan Drive Control 0806

April 2016 Various edits - Fan Drive Control 0805

March 2016 Add Fan Drive Control 0804

1201

March 2015 Add E Frame ETL control and Angle Sensor HC

October 2014 Add ETL control and Angle Sensor HB

July 2014 Danfoss layout HA

2 | © Danfoss | January 2022 BC152886483703en-001201

Technical Information

Series 45 Pumps

Contents

General Information

Overview..............................................................................................................................................................................................8

Design...................................................................................................................................................................................................8

Benefits.................................................................................................................................................................................................8

Typical applications.........................................................................................................................................................................9

The Series 45 product family........................................................................................................................................................9

Load sensing open circuit system............................................................................................................................................11

Servo Control Orifice.....................................................................................................................................................................12

Servo Control Orifice Principle.............................................................................................................................................12

Servo Control Orifice Performance.................................................................................................................................... 13

Pacing Factor..............................................................................................................................................................................14

Hydraulic Controls......................................................................................................................................................................... 14

Pressure compensated controls..........................................................................................................................................14

Operation............................................................................................................................................................................... 14

Pressure compensated system characteristics.........................................................................................................15

Typical applications for pressure compensated systems.....................................................................................15

Remote pressure compensated controls.........................................................................................................................15

Remote pressure compensated system characteristics........................................................................................16

Typical applications for remote pressure compensated systems..................................................................... 17

Load sensing controls.............................................................................................................................................................17

LS control with bleed orifice............................................................................................................................................17

Integral PC function............................................................................................................................................................18

Load sensing system characteristics............................................................................................................................ 18

Electric Controls..............................................................................................................................................................................18

Electric Proportional Controls (EPC)...................................................................................................................................18

PLUS+1® Compliance......................................................................................................................................................... 18

Electric Proportional Control Principle........................................................................................................................18

Electric Proportional Control Response/Recovery..................................................................................................19

Electric Proportional Control Characteristic – Normally Closed.........................................................................20

Electric Proportional Control Characteristic – Normally Open...........................................................................21

Electric On-Off Controls..........................................................................................................................................................23

PLUS+1 Compliance...........................................................................................................................................................23

Electric On-Off Control Principle....................................................................................................................................23

Electric On-Off Control Response/Recovery..............................................................................................................24

Electric On-Off Control Performance vs. Ambient Temperature Characteristic...........................................24

Electric On-Off Control Characteristic – Normally Closed.................................................................................... 25

Electric On/Off Control Characteristic – Normally Open.......................................................................................26

Electric dump valve PC/LS controls....................................................................................................................................27

Electronic Torque Limiting Controls (ETL).......................................................................................................................27

PLUS+1 Compliance...........................................................................................................................................................27

Electric Torque Limiting Control Principle................................................................................................................. 28

Electronic Torque Limiting Control Characteristic..................................................................................................29

Fan Drive Control (FDC)..........................................................................................................................................................29

PLUS+1 Compliance...........................................................................................................................................................29

Fan Drive Control Principle .............................................................................................................................................31

Fan Drive Control System Characteristics.................................................................................................................. 31

Unintended Applications for Fan Drive Control Systems.....................................................................................32

Fan Drive Control characteristic - Normally Closed ...............................................................................................32

Solenoid data – Normally closed...................................................................................................................................33

Fan Drive Control configuration....................................................................................................................................35

NC Fan Drive Control 3D Views......................................................................................................................................35

Angle Sensor....................................................................................................................................................................................35

PLUS+1 Compliance................................................................................................................................................................ 35

Angle Sensor Principle............................................................................................................................................................36

Angle Sensor Characteristics................................................................................................................................................36

J & F-Frame (45-90cc) Angle Sensor Identification Convention:........................................................................37

E-Frame (100-147cc) Angle Sensor Identification Convention:..........................................................................37

Angle sensor electrical specifications............................................................................................................................... 40

Angle Sensor Calibration....................................................................................................................................................... 40

©

Danfoss | January 2022 BC152886483703en-001201 | 3

Technical Information

Series 45 Pumps

Contents

Frame K2

Angle Sensor Functionality...................................................................................................................................................40

Charge Pump Circuits...................................................................................................................................................................40

Example Circuit #1....................................................................................................................................................................40

Example Circuit #2....................................................................................................................................................................41

Operating parameters..................................................................................................................................................................42

Fluids.............................................................................................................................................................................................42

Viscosity........................................................................................................................................................................................42

Temperature...............................................................................................................................................................................42

Inlet pressure..............................................................................................................................................................................43

Case pressure............................................................................................................................................................................. 43

Pressure ratings.........................................................................................................................................................................44

Speed ratings............................................................................................................................................................................. 44

Duty cycle and pump life.......................................................................................................................................................44

Speed, flow, and inlet pressure............................................................................................................................................45

Design parameters........................................................................................................................................................................ 46

Installation...................................................................................................................................................................................46

Filtration.......................................................................................................................................................................................46

Reservoir...................................................................................................................................................................................... 46

Fluid velocity.............................................................................................................................................................................. 46

Shaft loads...................................................................................................................................................................................47

Bearing life.................................................................................................................................................................................. 47

Mounting flange loads............................................................................................................................................................48

Estimating overhung load moments.................................................................................................................................48

Auxiliary mounting pads........................................................................................................................................................49

Input shaft torque ratings......................................................................................................................................................49

Understanding and minimizing system noise............................................................................................................... 50

Understanding and minimizing system instability...................................................................................................... 50

LS System Over-Signaling......................................................................................................................................................50

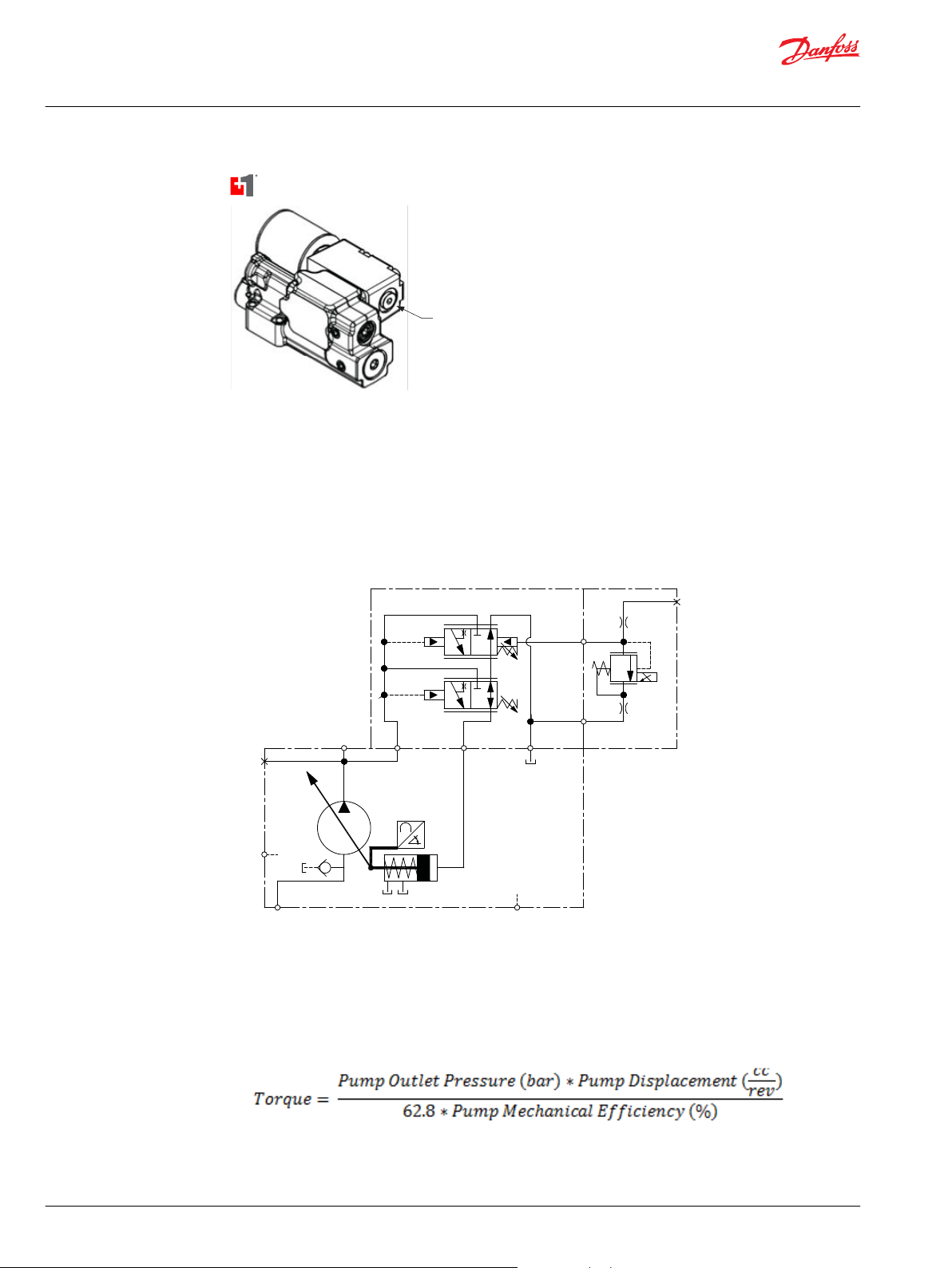

Sizing equations.............................................................................................................................................................................51

Design................................................................................................................................................................................................ 52

Technical Specifications.............................................................................................................................................................. 53

Order Code.......................................................................................................................................................................................53

Performance K2-25C..................................................................................................................................................................... 59

Performance K2-30C..................................................................................................................................................................... 60

Performance K2-38C..................................................................................................................................................................... 61

Performance K2-40C..................................................................................................................................................................... 62

Performance K2-45C..................................................................................................................................................................... 63

Hydraulic Controls......................................................................................................................................................................... 64

Pressure Compensated Controls.........................................................................................................................................64

Remote Pressure Compensated Controls........................................................................................................................65

Load Sensing Pressure Compensated Controls.............................................................................................................66

Load Sensing Control with Bleed Orifice /Pressure Compensated........................................................................ 67

Electric Controls..............................................................................................................................................................................68

Connectors..................................................................................................................................................................................68

Continuous Duty Operating Range................................................................................................................................... 68

Solenoid Data - Normally Closed........................................................................................................................................ 68

Solenoid Data - Normally Open...........................................................................................................................................68

Normally Closed Electric On/Off with Pressure Compensation Controls.............................................................69

Normally Open Electric On/Off with Pressure Compensation Controls............................................................... 69

Normally Closed Electric Proportional with Pressure Compensation Controls................................................. 71

Normally Open Electric Proportional with Pressure Compensation Controls....................................................72

Normally Closed Fan Drive Control....................................................................................................................................73

Input Shafts...................................................................................................................................................................................... 74

Installation Drawings....................................................................................................................................................................76

Axial Ported Endcap.................................................................................................................................................................76

Axial Ported Endcap O-ring Boss Ports Installation Dimensions.............................................................................77

Radial Ported Endcap Split Flange Ports..........................................................................................................................78

Radial Ported Endcap O-ring Boss Ports...........................................................................................................................79

4 | © Danfoss | January 2022 BC152886483703en-001201

Technical Information

Series 45 Pumps

Contents

Frames L and K

Frame J

Radial Ported Endcap Installation Dimensions..............................................................................................................80

Front Mounting Flange - SAE-B two bolt.........................................................................................................................80

Auxiliary Mounting Pads........................................................................................................................................................81

SAE-A auxiliary mounting pad........................................................................................................................................81

SAE-B auxiliary mounting pad........................................................................................................................................81

SAE-A Fixed flange..............................................................................................................................................................82

Auxiliary Mounting Pad - Running Cover...................................................................................................................82

Electric solenoid, left side.................................................................................................................................................83

Fan drive control..................................................................................................................................................................83

Displacement Limiter................................................................................................................................................................... 83

Design................................................................................................................................................................................................ 85

Technical Specifications.............................................................................................................................................................. 86

Order code........................................................................................................................................................................................86

Performance L25C......................................................................................................................................................................... 92

Performance L30D.........................................................................................................................................................................93

Performance K38C.........................................................................................................................................................................94

Performance K45D.........................................................................................................................................................................95

Hydraulic Controls......................................................................................................................................................................... 96

Pressure Compensated Controls.........................................................................................................................................96

Remote Pressure Compensated Controls........................................................................................................................96

Load Sensing/Pressure Compensated Controls............................................................................................................97

Load Sensing Control with Bleed Orifice /Pressure Compensated........................................................................ 98

Electric Controls..............................................................................................................................................................................99

Connector....................................................................................................................................................................................99

Continuous Duty Operating Range.................................................................................................................................100

Solenoid Data - Normally Closed......................................................................................................................................100

Solenoid Data - Normally Open........................................................................................................................................ 100

Normally Closed Electric On/Off with Pressure Compensation Controls.......................................................... 100

Normally Open Electric On/Off with Pressure Compensation Controls.............................................................101

Normally Closed Electric Proportional Controls with PC and LS Compensation............................................102

Normally Open Electric Proportional Controls with PC and LS Compensation...............................................104

Input shafts.................................................................................................................................................................................... 106

Installation drawings..................................................................................................................................................................107

Axial Ported Endcap..............................................................................................................................................................107

Axial Ported Endcap Installation Dimensions..............................................................................................................108

Radial Ported Endcap Split Flange Ports........................................................................................................................108

Radial Ported Endcap O-ring Boss Ports........................................................................................................................ 109

Radial Ported Endcap Rear View.......................................................................................................................................109

Radial Ported Endcap Installation Dimensions........................................................................................................... 110

Front Mounting Flange - SAE-B two bolt.......................................................................................................................110

Auxiliary Mounting Pads......................................................................................................................................................111

SAE-A auxiliary mounting pad..................................................................................................................................... 111

SAE-B auxiliary mounting pad......................................................................................................................................111

Auxiliary Mounting Pad - Running Cover.................................................................................................................112

Electric Solenoid, Left Side..................................................................................................................................................112

Electric Solenoid, Right Side...............................................................................................................................................112

Displacement limiter..................................................................................................................................................................113

Design..............................................................................................................................................................................................114

Technical Specifications............................................................................................................................................................115

Order code..................................................................................................................................................................................... 115

Performance J45B........................................................................................................................................................................126

Performance J51B........................................................................................................................................................................127

Performance J60B........................................................................................................................................................................128

Performance J65C....................................................................................................................................................................... 129

Performance J75C....................................................................................................................................................................... 130

Hydraulic Controls.......................................................................................................................................................................131

©

Danfoss | January 2022 BC152886483703en-001201 | 5

Technical Information

Series 45 Pumps

Contents

Frame F

Pressure Compensated Controls......................................................................................................................................131

Remote Pressure Compensated Controls..................................................................................................................... 132

Load sensing/Pressure compensated Controls...........................................................................................................133

Load sensing Control with Bleed Orifice/ Pressure Compensated...................................................................... 134

Electric Controls........................................................................................................................................................................... 135

Connectors............................................................................................................................................................................... 135

Continuous Duty Operating Range.................................................................................................................................135

Solenoid Data - Normally Closed......................................................................................................................................135

Solenoid Data - Normally Open........................................................................................................................................ 135

Fan Drive Control Solenoid Data - Normally Closed..................................................................................................136

Normally Closed Electric On/Off with Pressure Compensation Controls.......................................................... 136

Normally Open Electric On/Off with Pressure Compensation Controls.............................................................137

Normally Closed Electric Proportional with Pressure Compensation Controls...............................................138

Normally Open Electric Proportional with Pressure Compensation Controls................................................. 139

Normally Closed Electric Torque Limiting Control with Pressure Compensation Controls........................141

Normally Closed Fan Drive Control ................................................................................................................................ 142

Input shafts.................................................................................................................................................................................... 143

Installation drawings..................................................................................................................................................................146

Axial Ported Endcap..............................................................................................................................................................146

Axial Ported Endcap Installation Dimensions..............................................................................................................147

Right Fan Drive Control........................................................................................................................................................148

Radial Ported Endcap Split Flange Ports........................................................................................................................148

Radial Ported Endcap Rear View.......................................................................................................................................149

Radial Ported Endcap Installation Dimensions........................................................................................................... 150

Right Angle Sensor Position Installation Dimensions...............................................................................................151

Front Mounting Flange........................................................................................................................................................152

Auxiliary mounting pads..................................................................................................................................................... 153

SAE-A auxiliary mounting pad (integrated)............................................................................................................ 153

SAE-A auxiliary mounting pad (non-integral)........................................................................................................ 154

SAE-B auxiliary mounting pad......................................................................................................................................155

SAE-C auxiliary mounting pad..................................................................................................................................... 155

Running cover....................................................................................................................................................................156

Radial Endcap Clockwise.....................................................................................................................................................156

Radial Endcap Counterclockwise..................................................................................................................................... 157

Axial Endcap Clockwise........................................................................................................................................................157

Axial Endcap Counterclockwise........................................................................................................................................157

Displacement limiter..................................................................................................................................................................158

Design..............................................................................................................................................................................................159

Technical Specifications............................................................................................................................................................160

Order code..................................................................................................................................................................................... 160

Performance F74B.......................................................................................................................................................................166

Performance F90C.......................................................................................................................................................................167

Hydraulic Controls.......................................................................................................................................................................168

Pressure Compensated Controls......................................................................................................................................168

Remote Pressure Compensated Controls..................................................................................................................... 168

Load Sensing/Pressure Compensated Controls..........................................................................................................169

Load Sensing Control with Bleed Orifice/Pressure Compensated.......................................................................170

Electric Controls........................................................................................................................................................................... 171

Connectors............................................................................................................................................................................... 171

Continuous Duty Operating Range.................................................................................................................................172

Solenoid Data - Normally Closed......................................................................................................................................172

Solenoid Data - Normally Open........................................................................................................................................ 172

Fan Drive Control Solenoid Data - Normally Closed..................................................................................................172

Normally Closed Electric On/Off with Pressure Compensation Controls.......................................................... 172

Normally Open Electric On/Off with Pressure Compensation Controls.............................................................173

Normally Closed Electric Proportional with Pressure Compensation Controls...............................................174

Normally Open Electric Proportional with Pressure Compensation Controls................................................. 175

Normally Closed Electric Torque Limiting Control with Pressure Compensation Controls........................177

6 | © Danfoss | January 2022 BC152886483703en-001201

Technical Information

Series 45 Pumps

Contents

Frame E

Normally Closed Fan Drive Control................................................................................................................................. 178

Input shafts.................................................................................................................................................................................... 179

Installation drawings..................................................................................................................................................................180

Axial Ported Endcap..............................................................................................................................................................180

Axial Ported Endcap Installation Dimensions..............................................................................................................180

Right Fan Drive Control........................................................................................................................................................181

Radial Ported Endcap Split Flange Ports........................................................................................................................181

Radial Ported Endcap Rear View.......................................................................................................................................182

Radial Ported Endcap Installation Dimensions........................................................................................................... 183

Right Angle Sensor Position Installation Dimensions...............................................................................................184

Front Mounting Flange........................................................................................................................................................185

Radial Endcap Clockwise.....................................................................................................................................................187

Radial Endcap Counterclockwise..................................................................................................................................... 188

Axial Endcap Clockwise........................................................................................................................................................188

Axial Endcap Counterclockwise........................................................................................................................................188

Displacement limiter..................................................................................................................................................................188

Design..............................................................................................................................................................................................190

Technical Specifications............................................................................................................................................................191

Order code..................................................................................................................................................................................... 191

Performance E100B.....................................................................................................................................................................198

Performance E130B.....................................................................................................................................................................199

Performance E147C.................................................................................................................................................................... 200

Hydraulic Controls.......................................................................................................................................................................201

Pressure Compensated Controls......................................................................................................................................201

Remote Pressure Compensated Controls..................................................................................................................... 201

Load Sensing/Pressure Compensated............................................................................................................................202

Load Sensing Control with Bleed Orifice/Pressure Compensated.......................................................................203

Electric Controls........................................................................................................................................................................... 204

Connectors............................................................................................................................................................................... 204

Continuous Duty Operating Range.................................................................................................................................205

Solenoid Data - Normally Closed......................................................................................................................................205

Solenoid Data - Normally Open........................................................................................................................................ 205

Normally Closed Electric On/Off with Pressure Compensation Controls.......................................................... 205

Normally Open Electric On/Off with Pressure Compensation Controls.............................................................206

Normally Closed Electric Proportional with Pressure Compensation Controls...............................................207

Normally Open Electric Proportional with Pressure Compensation Controls................................................. 209

Normally Closed Electric Torque Limiting Control with Pressure Compensation Controls........................210

Input shafts.................................................................................................................................................................................... 212

Installation drawings..................................................................................................................................................................213

Axial Ported Endcap..............................................................................................................................................................213

Axial Ported Endcap Installation Dimensions..............................................................................................................214

Radial Ported Endcap Installation Dimensions........................................................................................................... 215

Right Angle Sensor Position Installation Dimensions...............................................................................................216

Radial Ported Endcap Rear View.......................................................................................................................................217

Radial Ported Endcap Split Flange Ports........................................................................................................................217

Front Mounting Flange........................................................................................................................................................218

Endcap Dimensions...............................................................................................................................................................219

Auxiliary mounting pads..................................................................................................................................................... 220

Displacement Limiters...............................................................................................................................................................222

©

Danfoss | January 2022 BC152886483703en-001201 | 7

Technical Information

Series 45 Pumps

General Information

Overview

Design

Series 45 is a complete family of high performance variable displacement, axial piston pumps. Each frame

is designed to exceed the demanding work function requirements of the mobile equipment marketplace.

Each frame within the Series 45 family is uniquely designed to optimize performance, size, and cost.

High Performance

•

Displacements from 25 cm³ - 147 cm³ [1.53 - 8.97 in3/rev]

•

Speeds up to 3600 rpm

•

Pressures up to 310 bar [4495 psi]

•

Variety of control system options including load sensing and pressure compensated

Latest Technology

•

Customer-driven using quality function deployment (QFD) and design for manufacturability (DFM)

techniques

•

Optimized design maximizes efficiency and quiet operation

•

Computer-modeled castings to optimize inlet conditions for maximum pump speed

•

Compact package size minimizing installation space requirements

•

Heavy-duty tapered roller bearings for long life

•

Single piece rigid housing to reduce noise and leak paths

•

Integrated controls for high speed response and system stability

Benefits

Reliability

•

Designed to rigorous standards

•

Proven in both laboratory and field

•

Manufactured to rigid quality standards

•

Long service life

•

Significantly fewer parts

•

No gasket joints

•

Robust input shaft bearings to handle large external shaft loads

•

Integrated gauge ports for monitoring operating conditions

Reduced Installation Costs

•

Through-drive capability for multi-circuit systems

•

Range of mounting flanges, shafts and porting options for ease of installation

•

Compact size minimizes installation space requirements

•

Help meet engine emission standards

•

Reduce engine size by managing power usage more effectively

Reduce Operating Costs

•

Optimize machine power usage to maximize fuel economy

•

Simple design reduces service requirements

•

Heavy duty taper roller shaft bearings provide long service life

8 | © Danfoss | January 2022 BC152886483703en-001201

Technical Information

Series 45 Pumps

General Information

Typical applications

Increased Customer Satisfaction

•

Reduced noise for operator comfort

•

High performance increases productivity

Reduced Heat Load on Cooling System

•

High efficiency reduces hydraulic heat generation

•

Allows for smaller cooling packages

Cranes

•

Telescopic handlers

•

Forklift trucks

•

Wheel loaders

•

Sweepers

•

Backhoe loaders

•

Forestry and agricultural machinery

•

Fan drives

•

Paving Machines

•

Mining Equipment

•

Mowers

•

Dozers

•

Drilling Machines

•

Mini-Excavators

•

Other Applications

•

The Series 45 product family

Basic units

The series 45 family of open circuit, variable piston pumps, offers a range of displacements from 25 to 147

cm³/rev [1.53 to 8.97 in3/rev]. With maximum speeds up to 3600 rpm and continuous operating

pressures up to 310 bar [4495 psi], product selection is easily tailored to the flow and pressure

requirements of individual applications.

K2 Frame J Frame F Frame E Frame

©

Danfoss | January 2022 BC152886483703en-001201 | 9

Technical Information

Series 45 Pumps

General Information

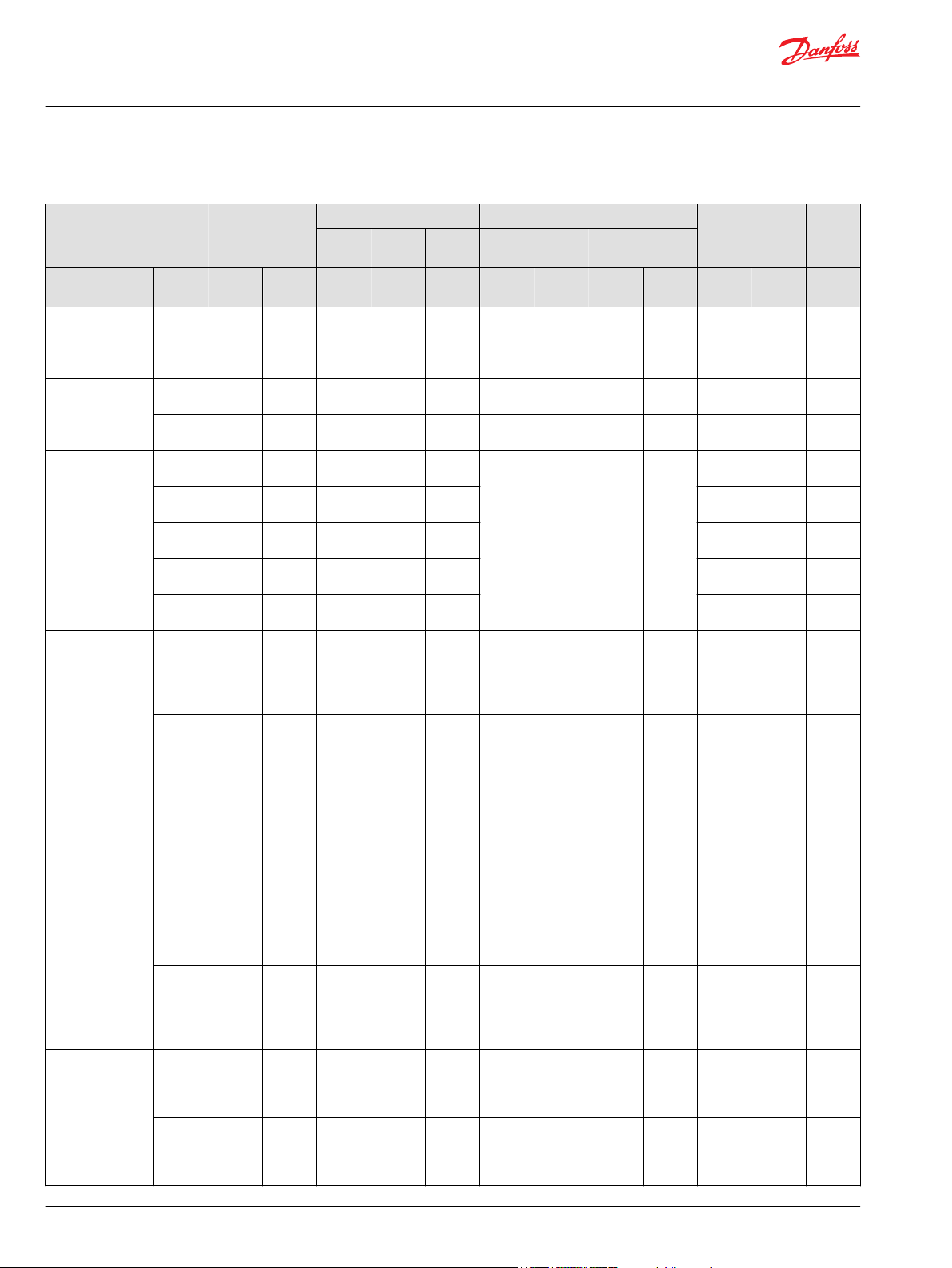

General performance specifications

Pump Displacement Speed Pressure Theoretical flow

Contin

Max. Min. Cont. Max.

(at rated speed)

uous

Frame Model cm

3

3

in

min

(rpm)

-1

min

(rpm)

-1

min

(rpm)

-1

bar psi bar psi US

gal/min

l/min Flange

Frame L L25C 25 1.53 3200 3600 500 260 3770 350 5075 21.0 80.0 SAE B -

L30D 30 1.83 3200 3600 500 210 3045 300 4350 25.4 96.0 SAE B -

Frame K K38C 38 2.32 2650 2800 500 260 3770 350 5075 26.6 100.7 SAE B -

K45D 45 2.75 2650 2800 500 210 3045 300 4350 31.5 119.3 SAE B -

Frame K2 K2-25C 25 1.53 3450 3750 500 260 3771 350 5076 22.8 86.3 SAE B -

K2-30C 30 1.83 3200 3450 500 25.4 96.0 SAE B -

K2-38C 38 2.32 2900 3050 500 29.1 110.2 SAE B -

K2-40C 40 2.44 3100 3200 500 34.5 124 SAE B -

K2-45C 45 2.75 2900 3050 500 34.5 130.5 SAE B -

Frame J J45B 45 2.75 2800 3360 500 310 4495 400 5800 33.3 126.0 SAE B 2-

J51B 51 3.11 2700 3240 500 310 4495 400 5800 36.4 137.7 SAE B 2-

J60B 60 3.66 2600 3120 500 310 4495 400 5800 41.2 156.0 SAE B 2-

J65C 65 3.97 2500 3000 500 260 3770 350 5075 42.9 162.6 SAE B 2-

J75C 75 4.58 2400 2880 500 260 3770 350 5075 47.5 180.0 SAE B 2-

Frame F F74B 74 4.52 2400 2800 500 310 4495 400 5800 46.9 177.6 SAE B 2-

F90C 90 5.49 2200 2600 500 260 3770 350 5075 52.3 198 SAE B 2-

Mounti

ng

2 bolt

2 bolt

2 bolt

2 bolt

2 bolt

2 bolt

2 bolt

2 bolt

2 bolt

bolt

SAE C 2

and 4bolt

bolt

SAE C 2

and 4bolt

bolt

SAE C 2

and 4bolt

bolt

SAE C 2

and 4bolt

bolt

SAE C 2

and 4bolt

bolt

SAE C 4bolt

bolt

SAE C 4bol

10 | © Danfoss | January 2022 BC152886483703en-001201

Technical Information

Series 45 Pumps

General Information

General performance specifications (continued)

Pump Displacement Speed Pressure Theoretical flow

Contin

uous

Frame Model cm

Frame E E100B 100 6.10 2450 2880 500 310 4495 400 5800 64.7 245.0 SAE C 4-

E130B 130 7.93 2200 2600 500 310 4495 400 5800 75.5 286.0 SAE C 4-

E147C 147 8.97 2100 2475 500 260 3770 350 5075 81.5 308.7 SAE C 4-

3

3

in

min

(rpm)

Max. Min. Cont. Max.

-1

min

(rpm)

-1

min

(rpm)

-1

bar psi bar psi US

(at rated speed)

l/min Flange

gal/min

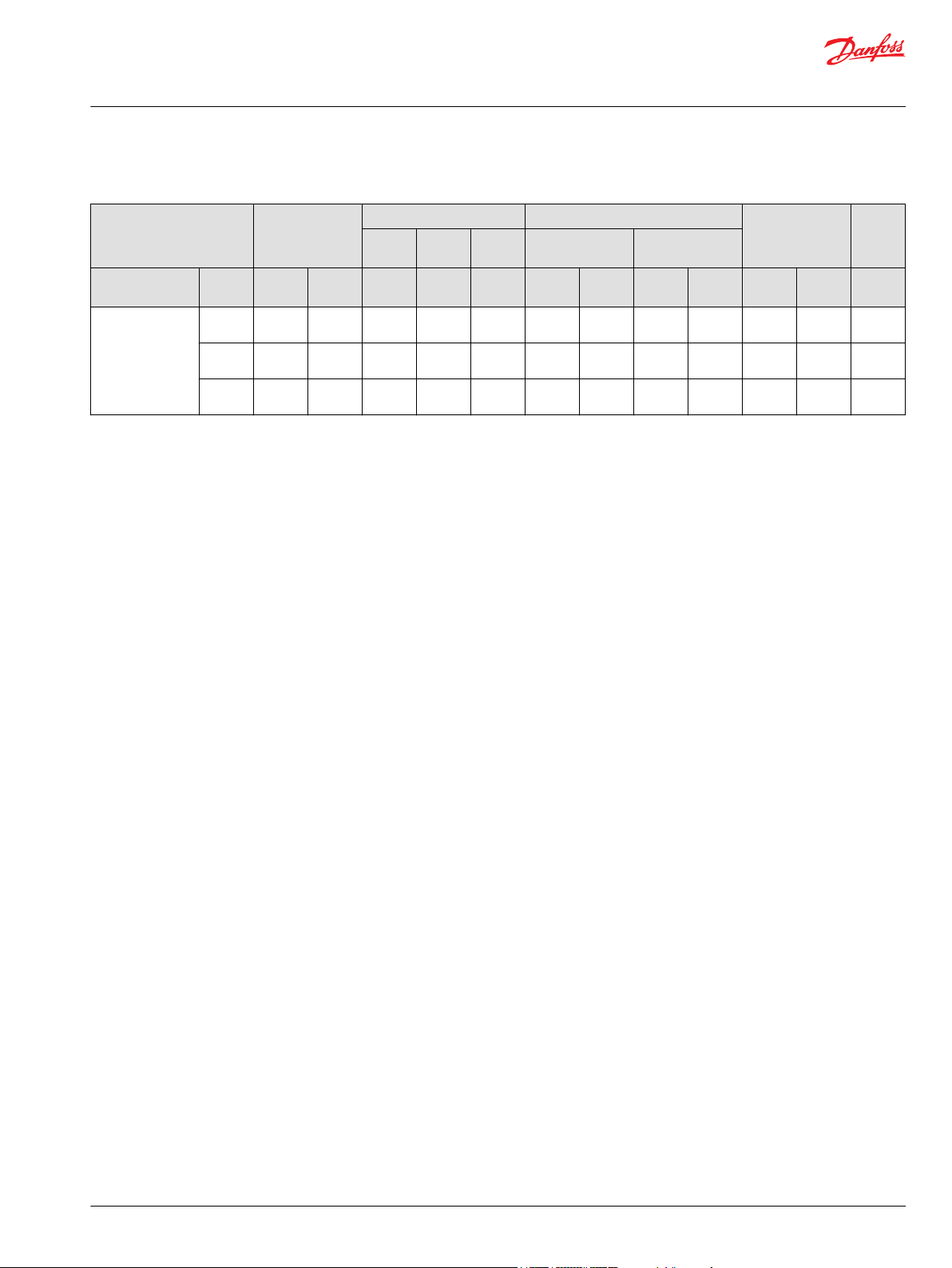

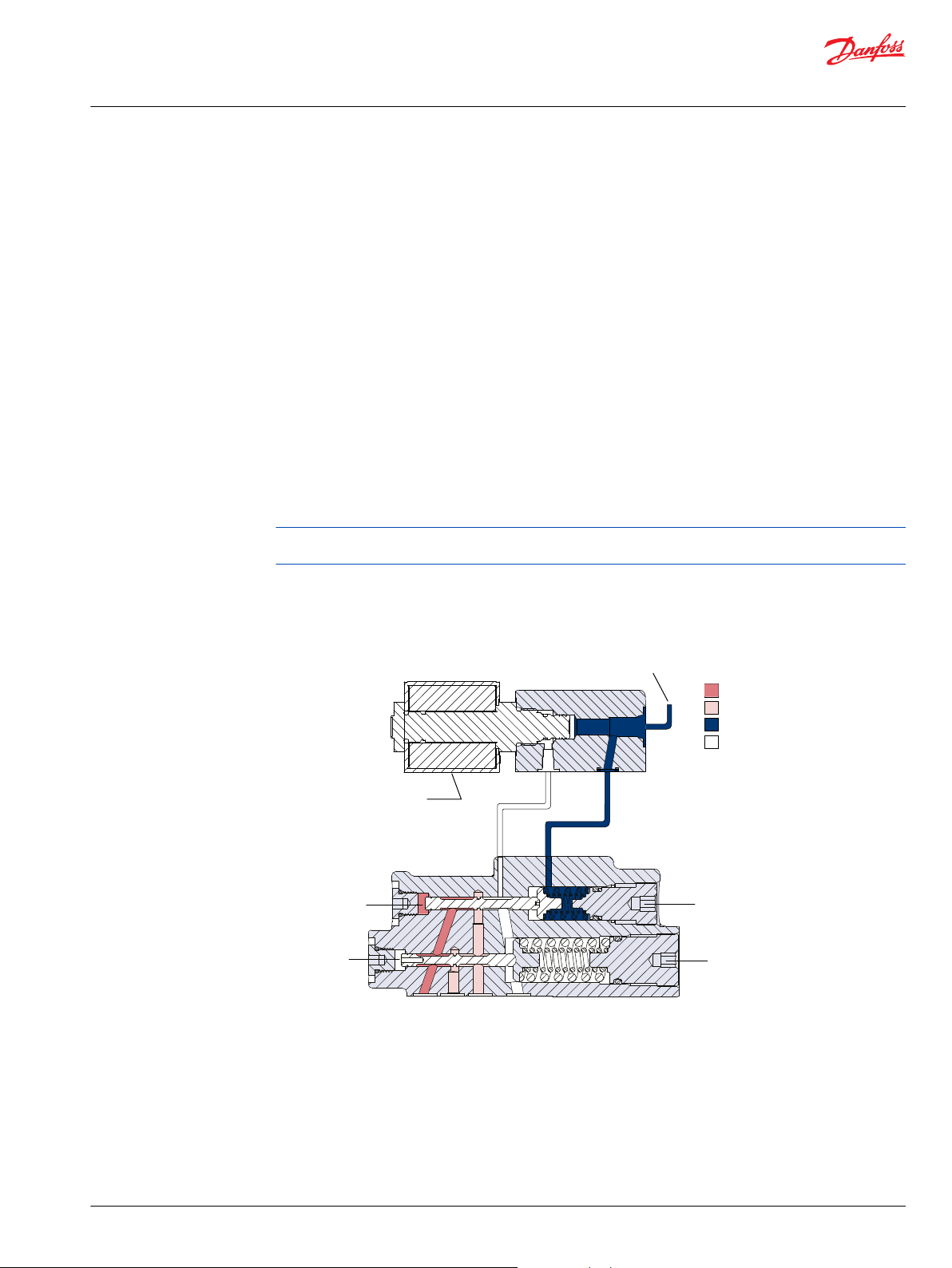

Load sensing open circuit system

The pump receives fluid directly from the reservoir through the inlet line. A screen in the inlet line

protects the pump from large contaminants. The pump outlet feeds directional control valves such as

PVG-32’s, hydraulic integrated circuits (HIC), and other types of control valves. The PVG valve directs

pump flow to cylinders, motors and other work functions. A heat exchanger cools the fluid returning

from the valve. A filter cleans the fluid before it returns to the reservoir.

Flow in the circuit determines the speed of the actuators. The position of the PVG valve determines the

flow demand. A hydraulic pressure signal (LS signal) communicates demand to the pump control. The

pump control monitors the pressure differential between pump outlet and the LS signal, and regulates

servo pressure to control the swashplate angle. Swashplate angle determines pump flow.

Actuator load determines system pressure. The pump control monitors system pressure and will decrease

the swashplate angle to reduce flow if system pressure reaches the PC setting. A secondary system relief

valve in the PVG valve acts as a back-up to control system pressure.

Mounti

ng

bolt

bolt

bolt

©

Danfoss | January 2022 BC152886483703en-001201 | 11

P109124

K2 Frame Series 45

open circuit axial

piston pump with

load sensing control

Reservoir

Filter

Heat exchanger

System pressur e

Servo pressur e

Actuator pressur e

Load sense pressur e

Actuator retur n

Suction / case drain /

system retur n

Double-ac ting cylinder

Bi-directional

gear moto r

PVG 32

mulit-sec tion

load

sensing

contro l

valve

Technical Information

Series 45 Pumps

General Information

Pictorial circuit diagram

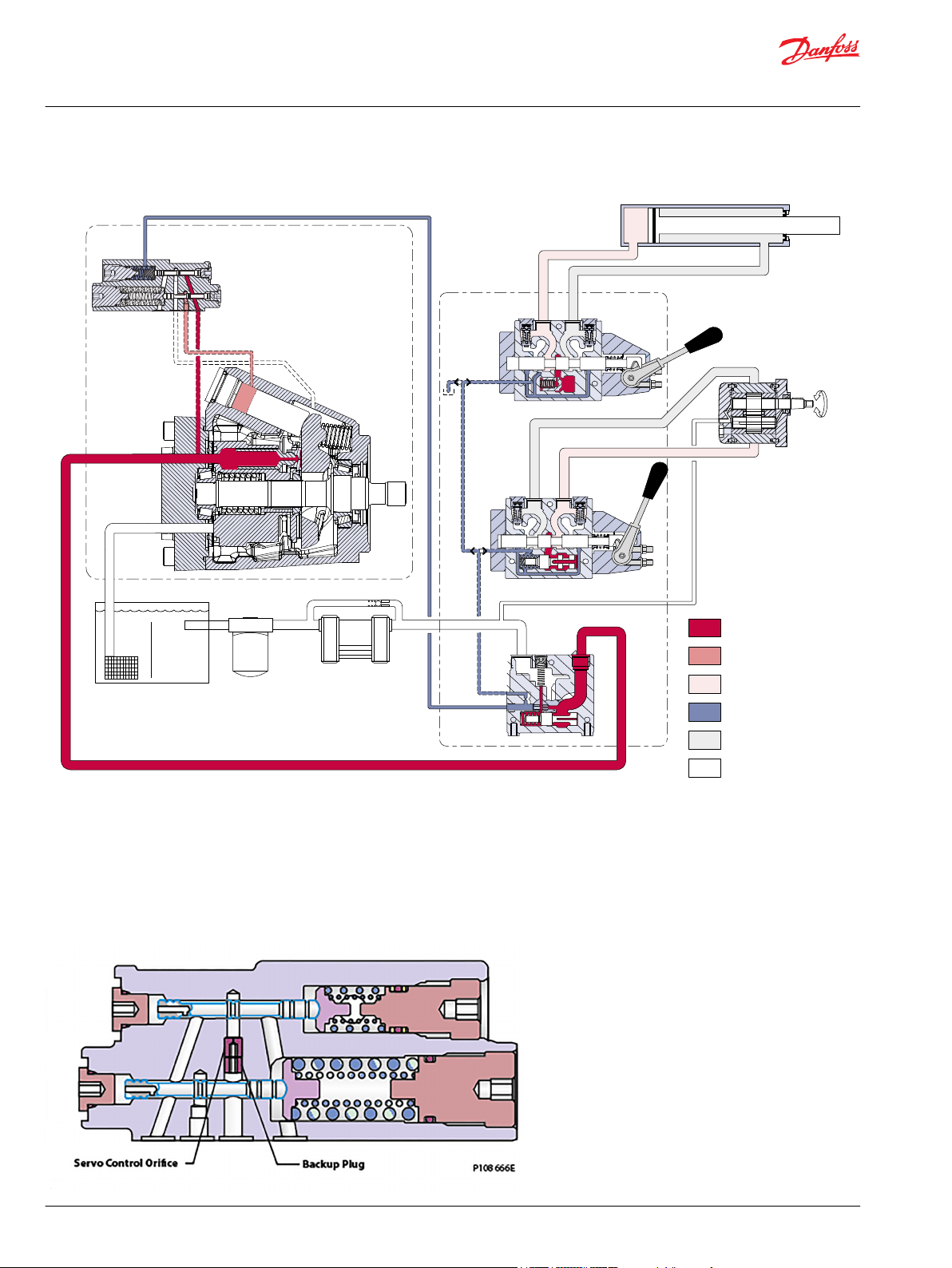

Servo Control Orifice

Servo Control Orifice Principle

Series 45 controls offer an optional servo control orifice (not available with Pressure Compensation only

Controls) available to aid in tuning system performance. The optional servo control orifice restricts flow

to and from the servo system in the pump, effectively pacing the motion of the servo system.

12 | © Danfoss | January 2022 BC152886483703en-001201

P108 664E

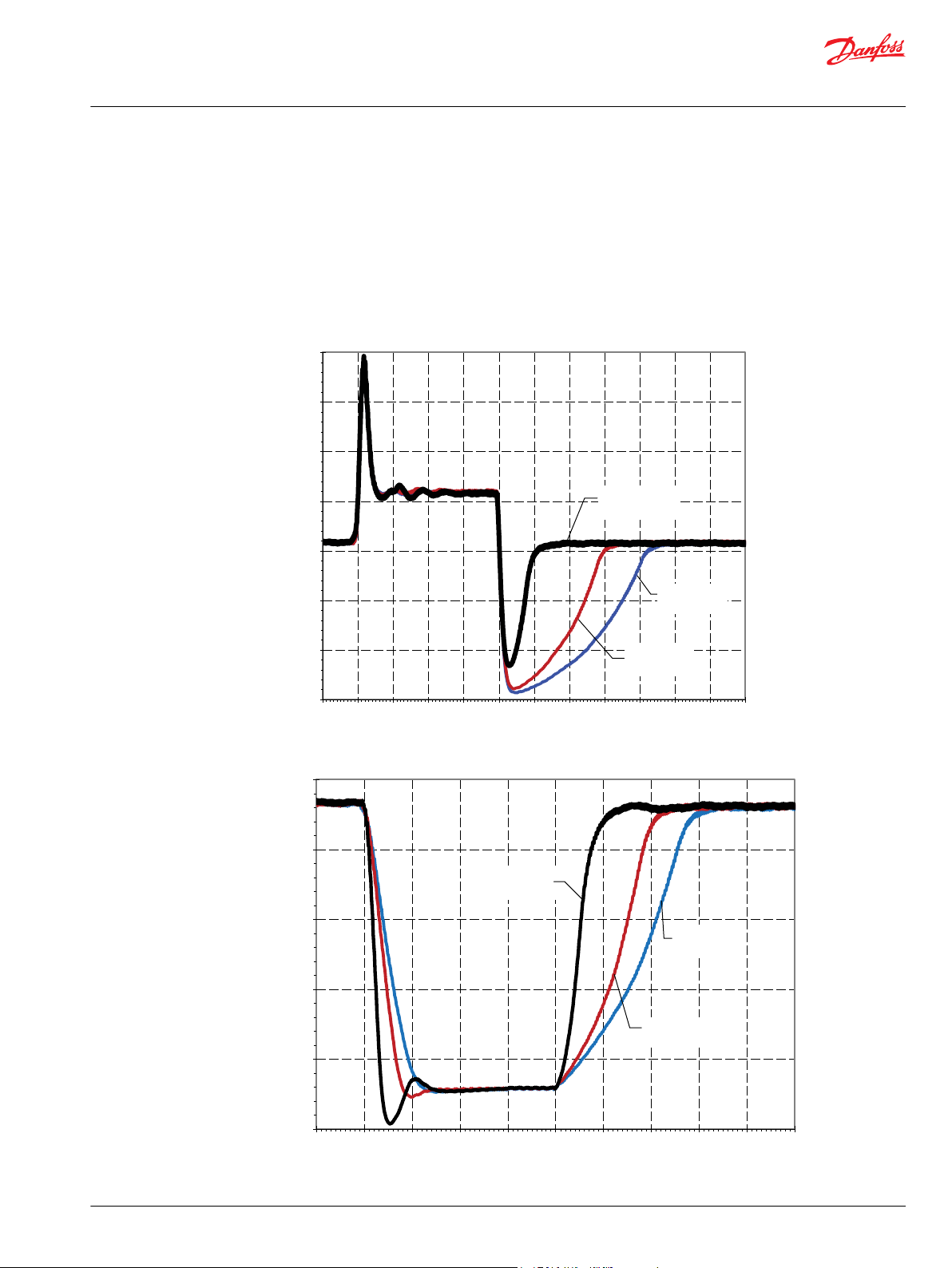

0

50

100

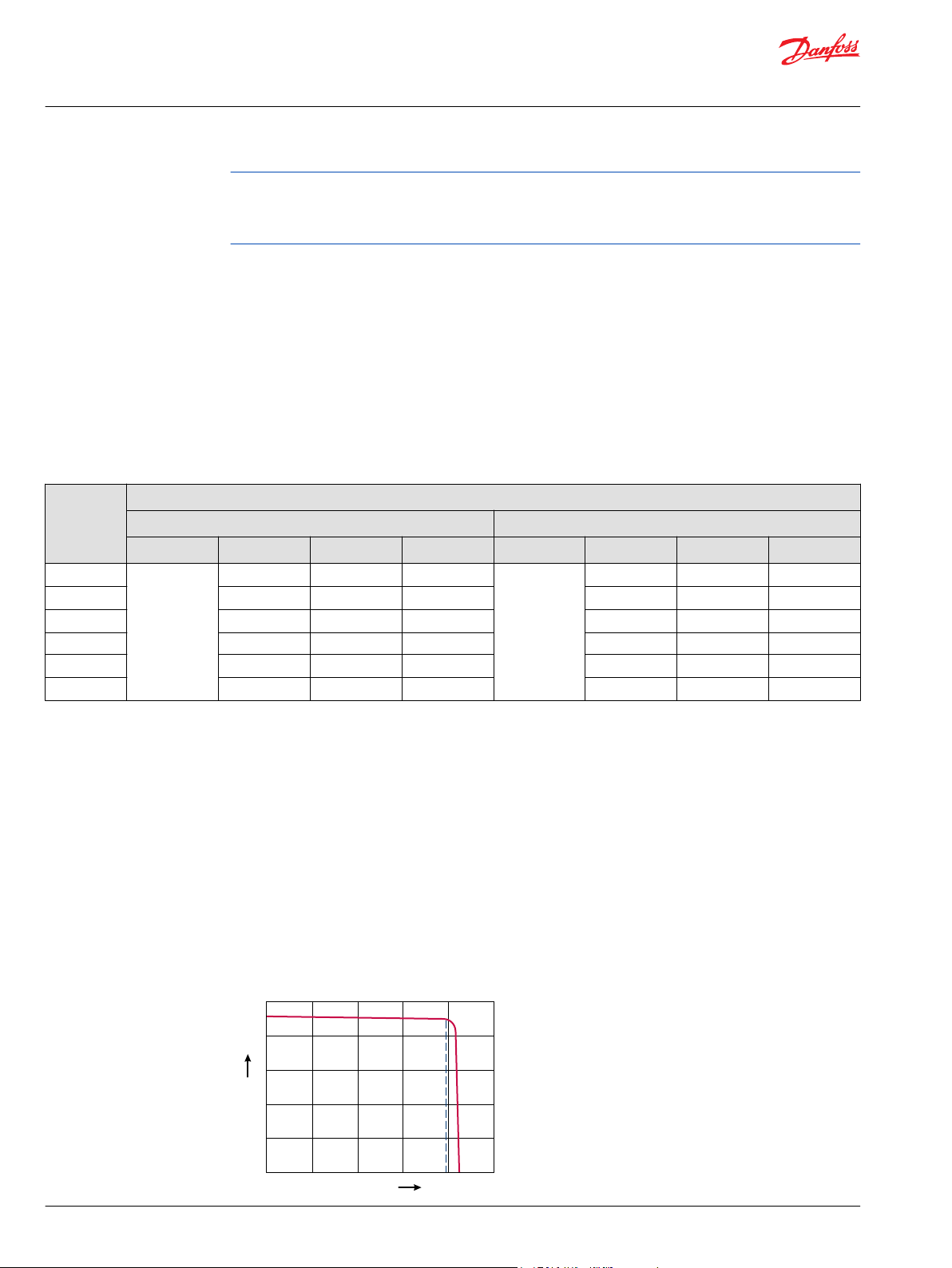

150

200

250

300

350

System Pressure (bar)

Time

Relative Servo Control Orifice Performance

Generic PC Response and Recovery

Input Speed=1800rpm, Temperature=49°C, PC Setting=210Bar, LS Setting=20Bar

1.0mm Servo

Control Orifice

0.8mm Servo

Control Orifice

Without Servo

Control Orifice

0

50

100

150

200

250

System Pressure (bar)

Time

Relative Servo Control Orifice Performance

Generic LS Response and Recovery

Input Speed = 1800rpm, Temperature=49 C, PC Setting=310Bar, LS Setting=30Bar

0.8mm Servo

Control Orifice

1.0mm Servo

Control Orifice

Without Servo

Control Orifice

P108 665E

Technical Information

Series 45 Pumps

General Information

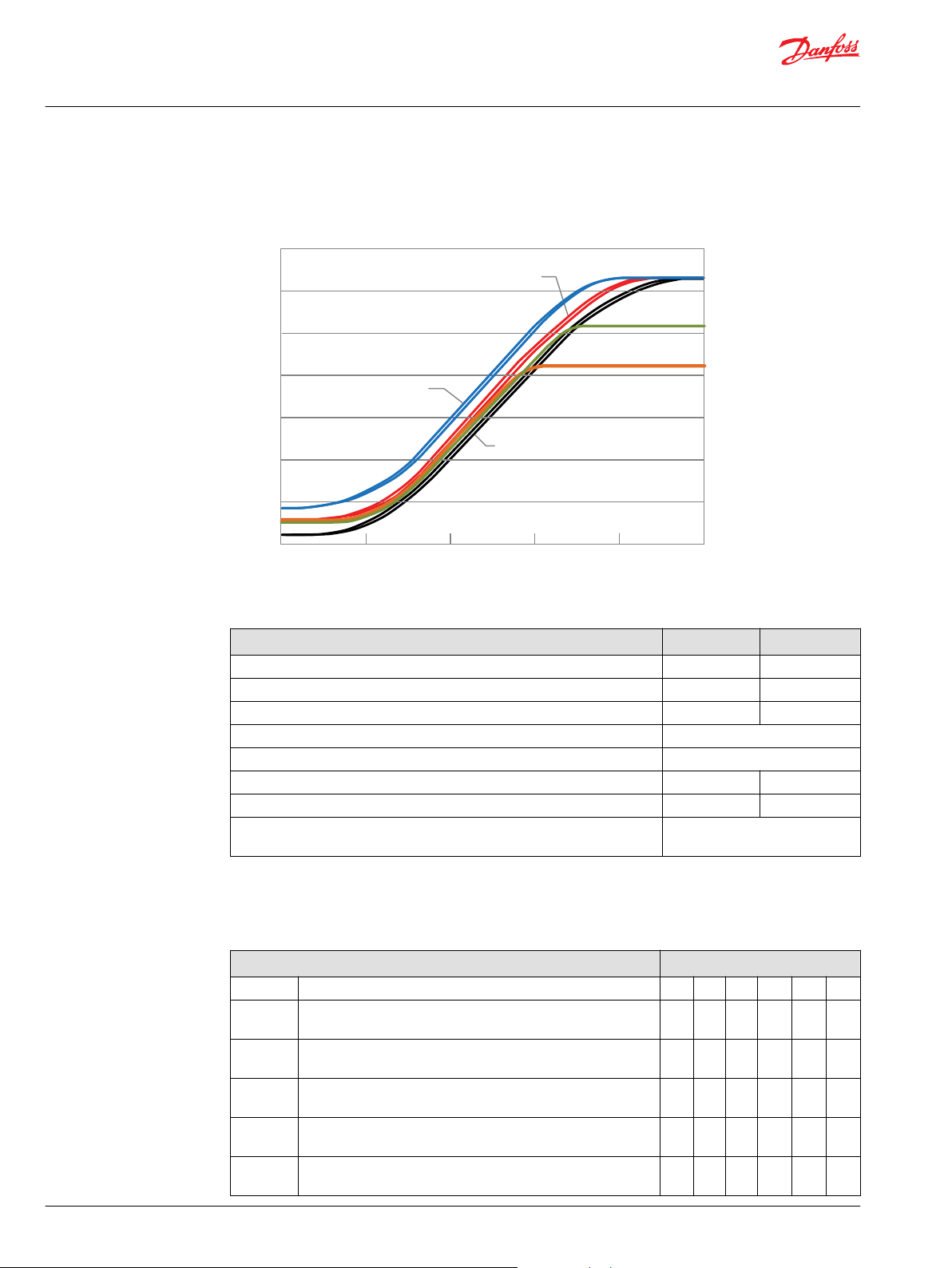

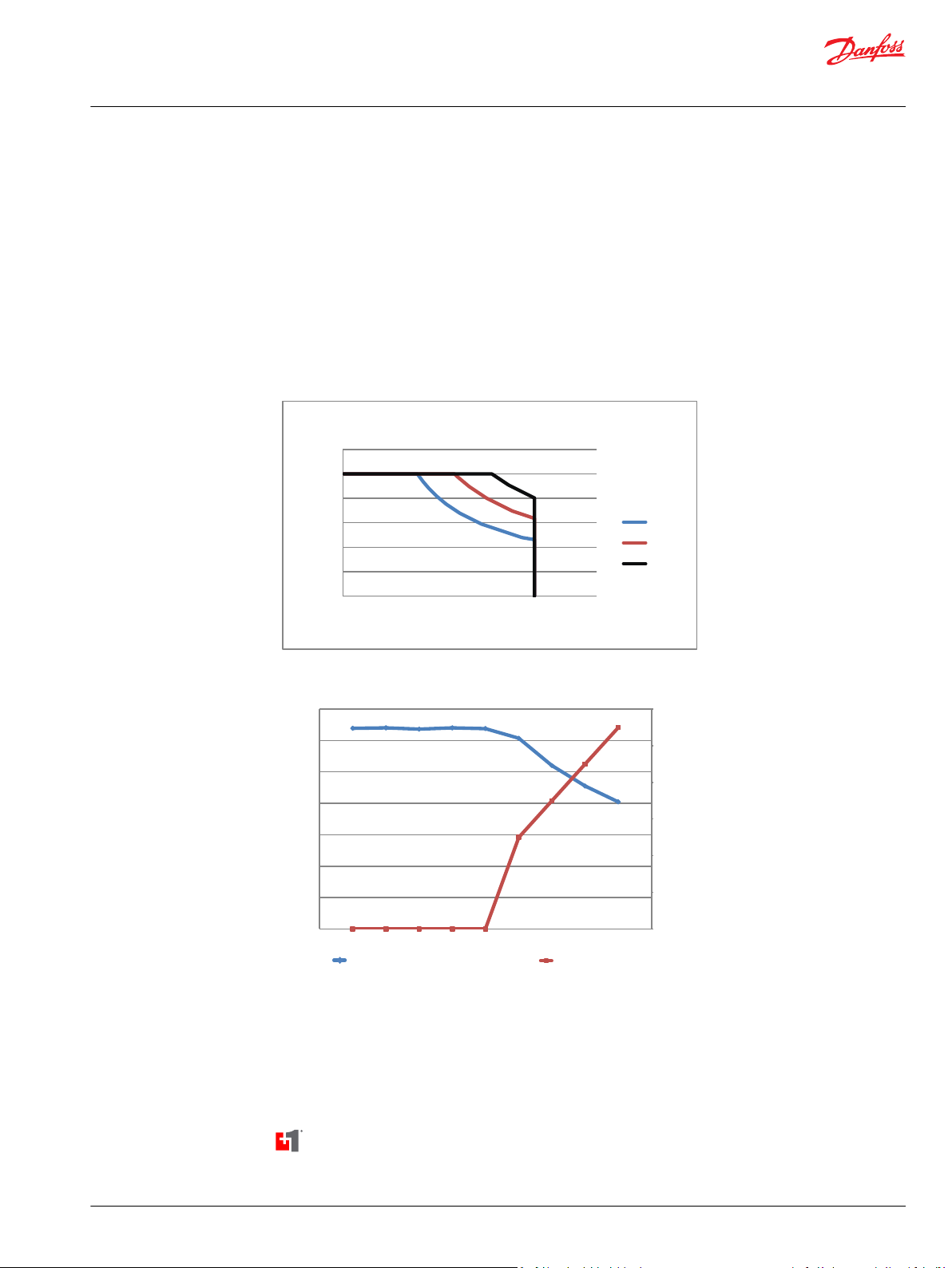

Servo Control Orifice Performance

The use of the Servo Control Orifice will provide additional pacing to the pump, while the response of the

pump to pressure spikes remains unaffected. The Pressure Compensation Function response and

recovery, as well as the Load Sense Function response and recovery are shown below, and outline the

relative impact in response and recovery of the Servo Control Orifices. Note that these graphs are meant

as a generic comparison only, and that unique effects on response and recovery behavior for each

specific frame are shown later in this section.

©

Danfoss | January 2022 BC152886483703en-001201 | 13

0

0

Q max

Pressure

Fl

ow

P101 166E

PC setting

Technical Information

Series 45 Pumps

General Information

We recommend that systems experiencing instability use a Servo Control Orifice. Start with the largest

size orifice available, and work down to the smaller size until the system is satisfactorily tuned. All FanDrive systems should start with a 0.8mm Servo Control Orifice if possible. Systems including motors are

more likely to require the Servo Control Orifice option.

Pacing Factor

Use of a Servo Control Orifice adds a pacing factor to each Series 45 Frame, impacting the behavior of the

pumps reactivity. This pacing factor can be multiplied by the specific Frame/Displacement/Control

selection’s response and recovery times, to determine the final paced response and recovery times.

Unique response and recovery times can be found in each frame-specific chapter, in the desired control

section. The paced response and recovery relationship is shown below.

Response (Damped)= Response (Specific Disp.Control) *Pacing Factor

Recovery (Damped)= Recovery (Specific Disp.Control) *Pacing Factor

Pacing Factors are unique to each orifice size, and can impact each frame differently. Below are the

Pacing Factors for each Servo Control Orifice Size by frame.

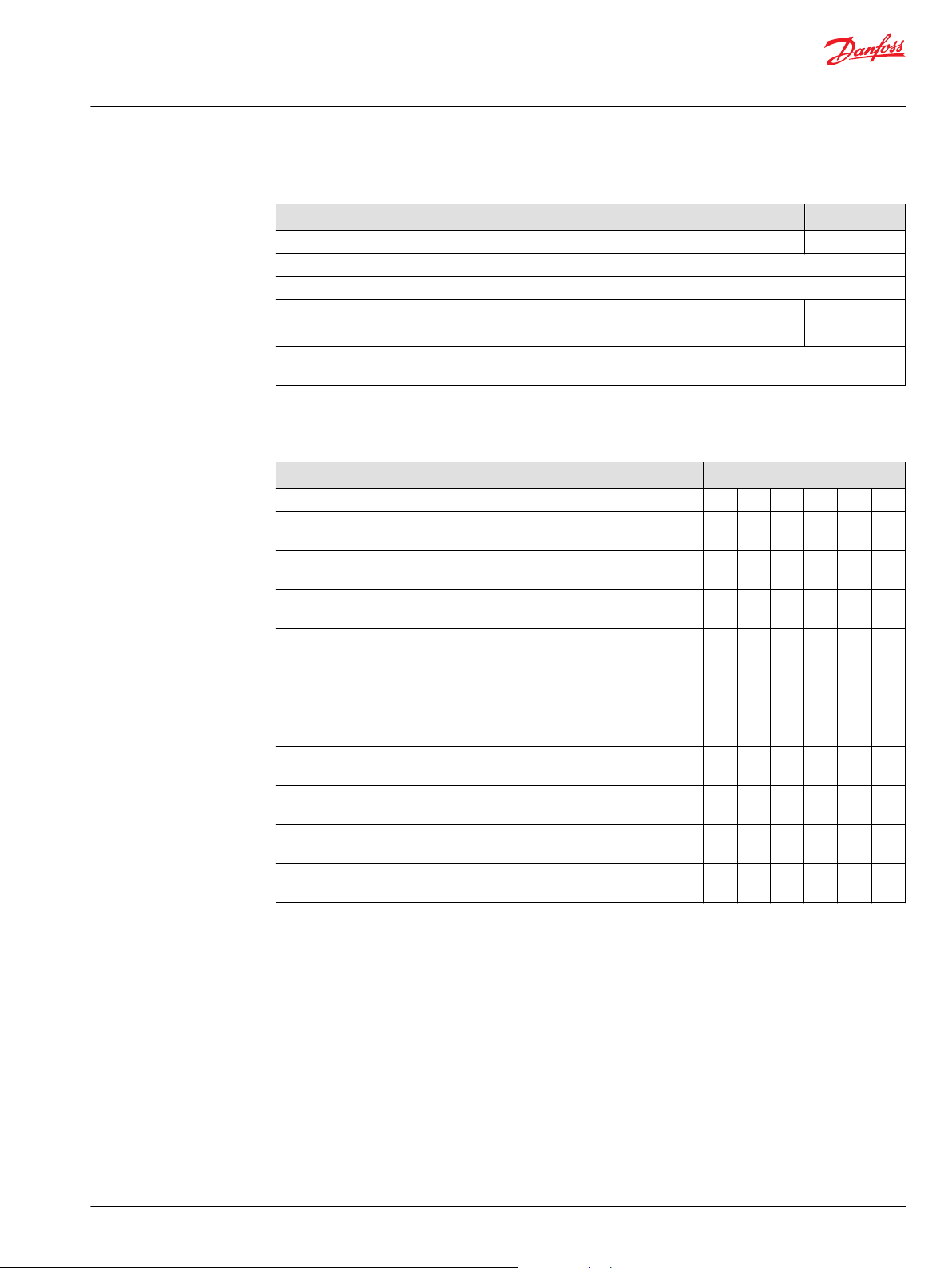

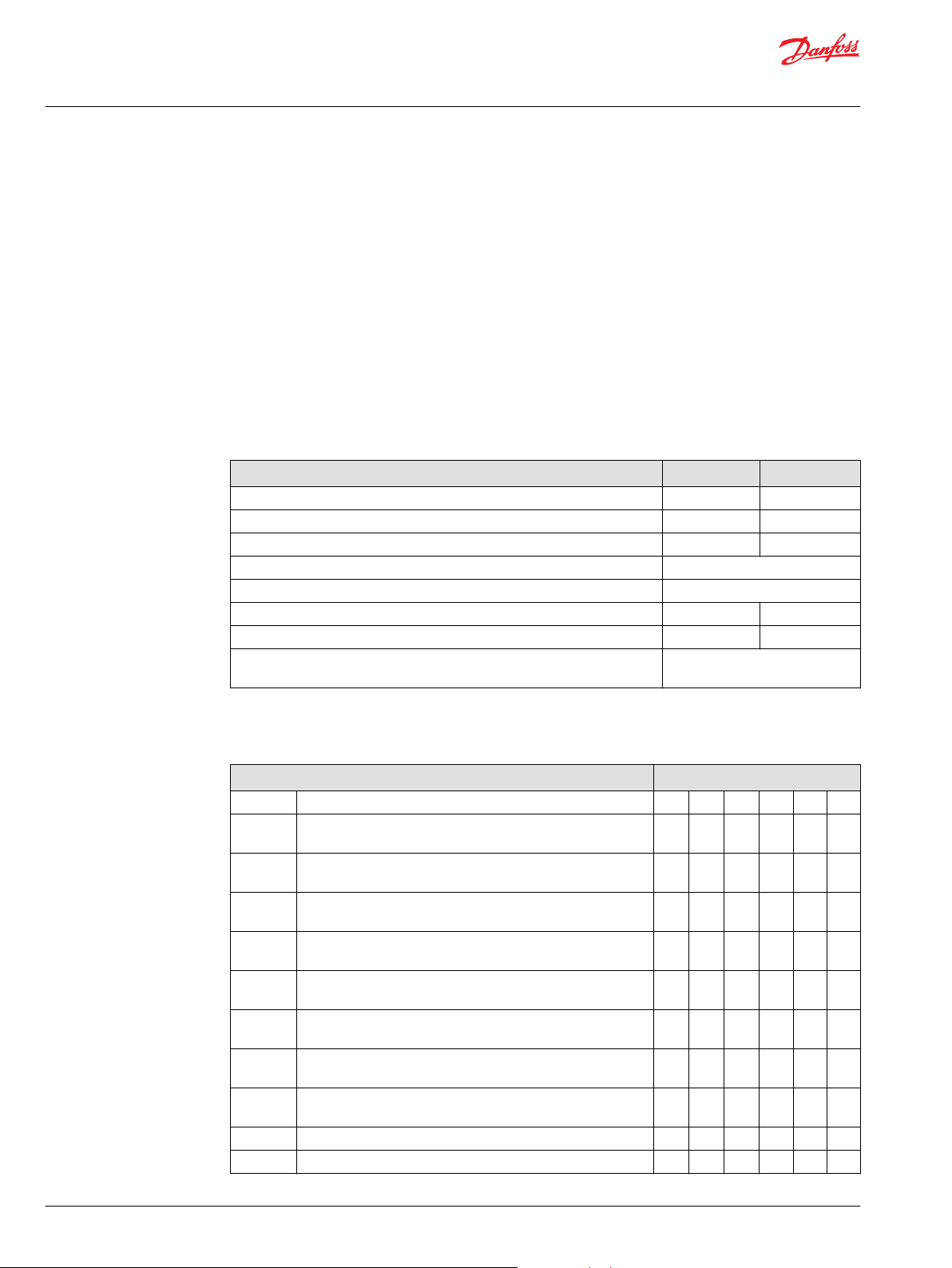

Frame Pacing Factors - Servo Control Orifice

1.0 mm Servo Control Orifice 0.8 mm Servo Control Orifice

PC Response PC Recovery LS Response LS Recovery PC Response PC Recovery LS Response LS Recovery

*

E-Frame

F-Frame

J-Frame

K2-Frame 2.3 2.0 2.0 3.2 2.6 2.6

K-Frame

L-Frame

*

PC Response from 160 bar to 210 bar, PC Recovery from 210 bar to 160 bar at 1800 rpm: LS Response from 230 bar to 30 bar, LS Recovery from 30 bar

to 230 bar at 1800 rpm.

**

** PC Response from 160 bar to 210 bar, PC Recovery from 210 bar to 160 bar at 1800 rpm: LS Response from 160 bar to 20 bar, LS Recovery from 20

bar to 160 bar at 1800 rpm.

Hydraulic Controls

*

*

**

**

1

(No Effect)

2.3 2.0 2.0 1

2.3 2.0 2.0 3.2 2.6 2.6

2.3 2.0 2.0 3.2 2.6 2.6

2.3 2.3 2.3 3.7 3.1 3.1

2.3 2.3 2.3 3.7 3.1 3.1

(No Effect)

3.2 2.6 2.6

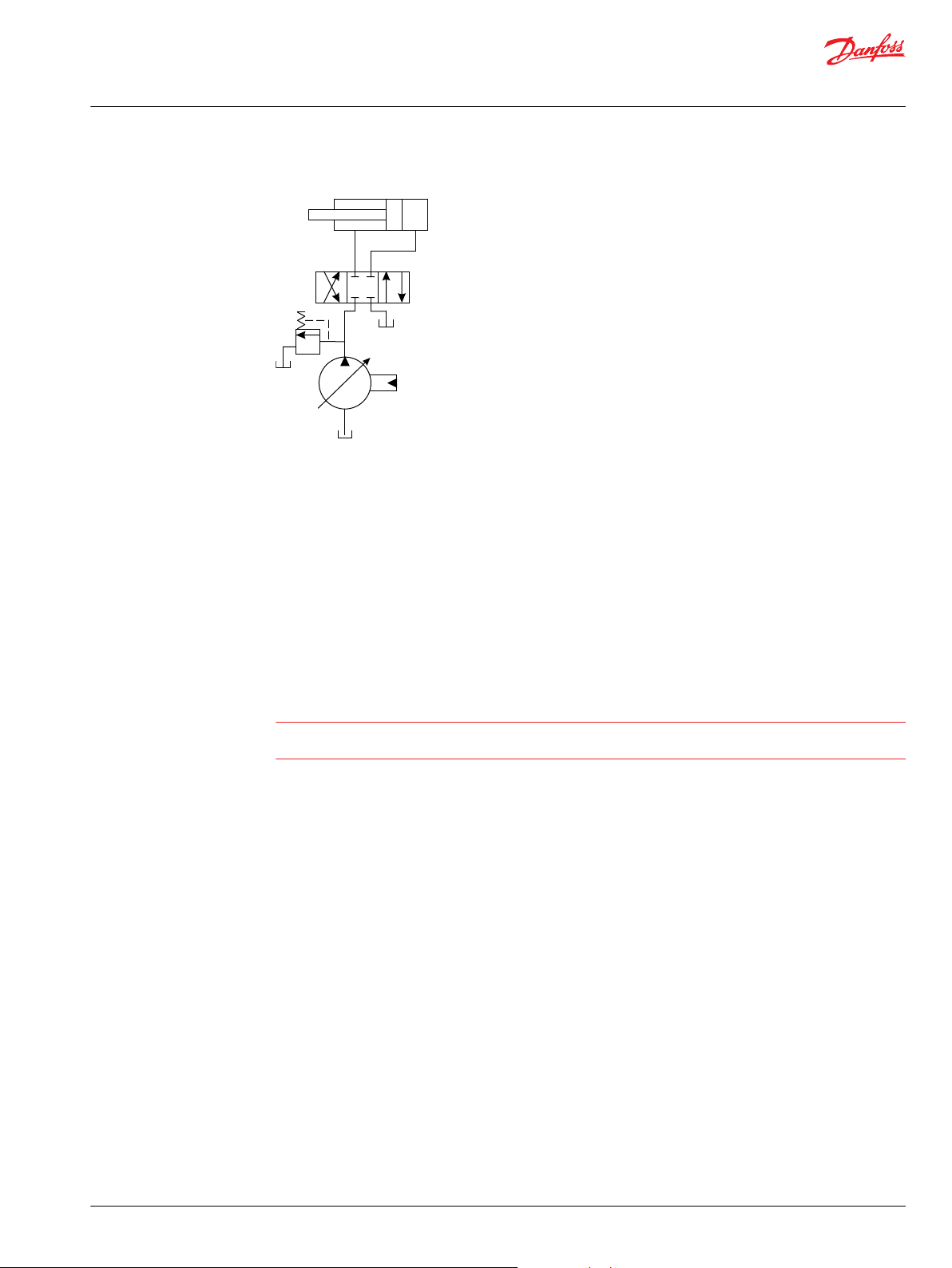

Pressure compensated controls

Operation

The PC control maintains constant system pressure in the hydraulic circuit by varying the output flow of

the pump. Used with a closed center control valve, the pump remains in high pressure standby mode at

the PC setting with zero flow until the function is actuated. This condition is often called a dead head

condition.

Typical operating curve

14 | © Danfoss | January 2022 BC152886483703en-001201

P101 965

W

Technical Information

Series 45 Pumps

General Information

Simple closed-center circuit

Once the closed center valve is opened, the PC control senses the immediate drop in system pressure

and increases pump flow by increasing the swashplate angle. The pump continues to increase flow until

system pressure reaches the PC setting. If system pressure exceeds the PC setting, the PC control reduces

the swashplate angle to maintain system pressure by reducing flow. The PC control continues to monitor

system pressure and changes swashplate angle to match the output flow with the work function

pressure requirements.

If the demand for flow exceeds the capacity of the pump, the PC control directs the pump to maximum

displacement. In this condition, actual system pressure depends on the actuator load.

Each section includes control schematic diagrams, setting ranges, and response / recovery times for each

control available. Response is the time (in milliseconds) for the pump to reach zero displacement when

commanded by the control. Recovery is the time (in milliseconds) for the pump to reach full displacement

when commanded by the control. Actual times can vary depending on application conditions.

Warning

A relief valve is required to be installed in the pump outlet for additional system protection. Failure to

install a relief valve may lead to system damage and/or injury.

Pressure compensated system characteristics

Constant pressure and variable flow

•

High pressure standby mode when flow is not needed

•

System flow adjusts to meet system requirements

•

Single pump can provide flow to multiple work functions

•

Quick response to system flow and pressure requirements

•

Typical applications for pressure compensated systems

Constant force cylinders (bailers, compactors, refuse trucks)

•

On/off fan drives

•

Drill rigs

•

Sweepers

•

Trenchers

•

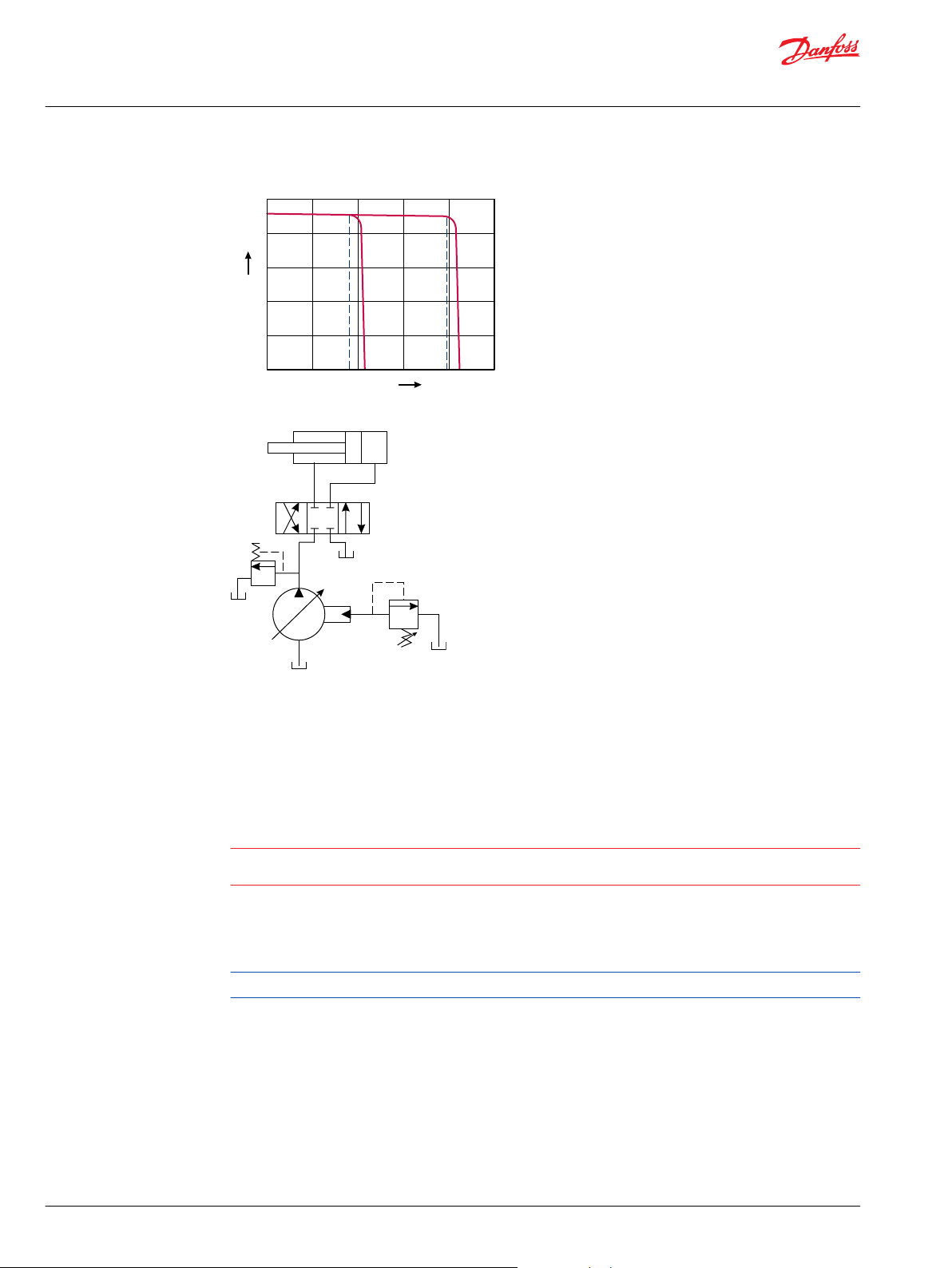

Remote pressure compensated controls

The remote PC control is a two-stage control that allows multiple PC settings. Remote PC controls are

commonly used in applications requiring low and high pressure PC operation.

©

Danfoss | January 2022 BC152886483703en-001201 | 15

0

0

Q max

Pressure

Fl

ow

P101 969E

PC setting

Remote PC setting

P101 966

W

Technical Information

Series 45 Pumps

General Information

Typical operating curve

Closed center circuit with remote PC

The remote PC control uses a pilot line connected to an external hydraulic valve. The external valve

changes pressure in the pilot line, causing the PC control to operate at a lower pressure. When the pilot

line is vented to reservoir, the pump maintains pressure at the load sense setting. When pilot flow is

blocked, the pump maintains pressure at the PC setting. An on-off solenoid valve can be used in the pilot

line to create a low-pressure standby mode. A proportional solenoid valve, coupled with a

microprocessor control, can produce an infinite range of operating pressures between the low pressure

standby setting and the PC setting.

Warning

A relief valve is required to be installed in the pump outlet for additional system protection. Failure to

install a relief valve may lead to system damage and/or injury.

Each section includes control schematic diagrams, setting ranges, and response / recovery times for each

control available. Response is the time (in milliseconds) for the pump to reach zero displacement when

commanded by the control. Recovery is the time (in milliseconds) for the pump to reach full displacement

when commanded by the control. Actual times can vary depending on application conditions.

Size the external valve and plumbing for a pilot flow of 3.8 l/min [1 US gal/min].

Remote pressure compensated system characteristics

Constant pressure and variable flow

•

High or low pressure standby mode when flow is not needed

•

System flow adjusts to meet system requirements

•

Single pump can provide flow to multiple work functions

•

Quick response to system flow and pressure requirements

•

16 | © Danfoss | January 2022 BC152886483703en-001201

0

0

P101 968E

PC setting

Flow

Pressure

Q max

P101 967

Technical Information

Series 45 Pumps

General Information

Typical applications for remote pressure compensated systems

Modulating fan drives

•

Anti-stall control with engine speed feedback

•

Front wheel assist

•

Road rollers

•

Combine harvesters

•

Wood chippers

•

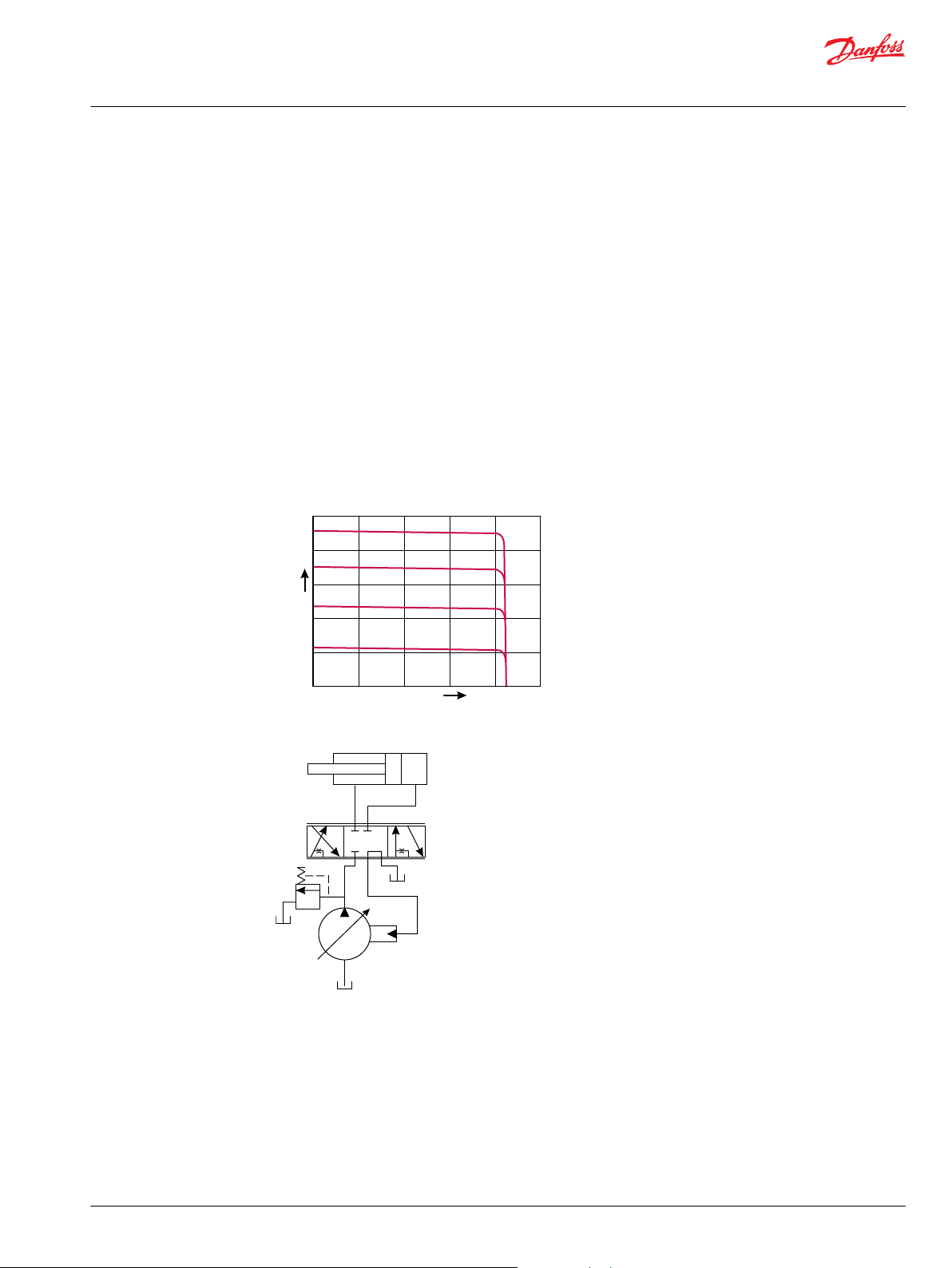

Load sensing controls

Operation

The LS control matches system requirements for both pressure and flow in the circuit regardless of the

working pressure. Used with a closed center control valve, the pump remains in low-pressure standby

mode with zero flow until the valve is opened. The LS setting determines standby pressure.

Typical operating curve

Load sensing circuit

Most load sensing systems use parallel, closed center, control valves with special porting that allows the

highest work function pressure (LS signal) to feed back to the LS control. Margin pressure is the difference

between system pressure and the LS signal pressure. The LS control monitors margin pressure to read

system demand. A drop in margin pressure means the system needs more flow. A rise in margin pressure

tells the LS control to decrease flow.

LS control with bleed orifice

The load sense signal line requires a bleed orifice to prevent high-pressure lockup of the pump control.

Most load-sensing control valves include this orifice. An optional internal bleed orifice is available, for use

with control valves that do not internally bleed the LS signal to tank.

©

Danfoss | January 2022 BC152886483703en-001201 | 17

W

Technical Information

Series 45 Pumps

General Information

Electric Controls

Integral PC function

The LS control also performs as a PC control, decreasing pump flow when system pressure reaches the PC

setting. The pressure compensating function has priority over the load sensing function.

Warning

A relief valve is required to be installed in the pump outlet for additional system protection. Failure to

install a relief valve may lead to system damage and/or injury.

Load sensing system characteristics

Variable pressure and flow

•

Low pressure standby mode when flow is not needed

•

System flow adjusted to meet system requirements

•

Lower torque requirements during engine start-up

•

Single pump can supply flow and regulate pressure for multiple circuits

•

Quick response to system flow and pressure requirements

•

Electric Proportional Controls (EPC)

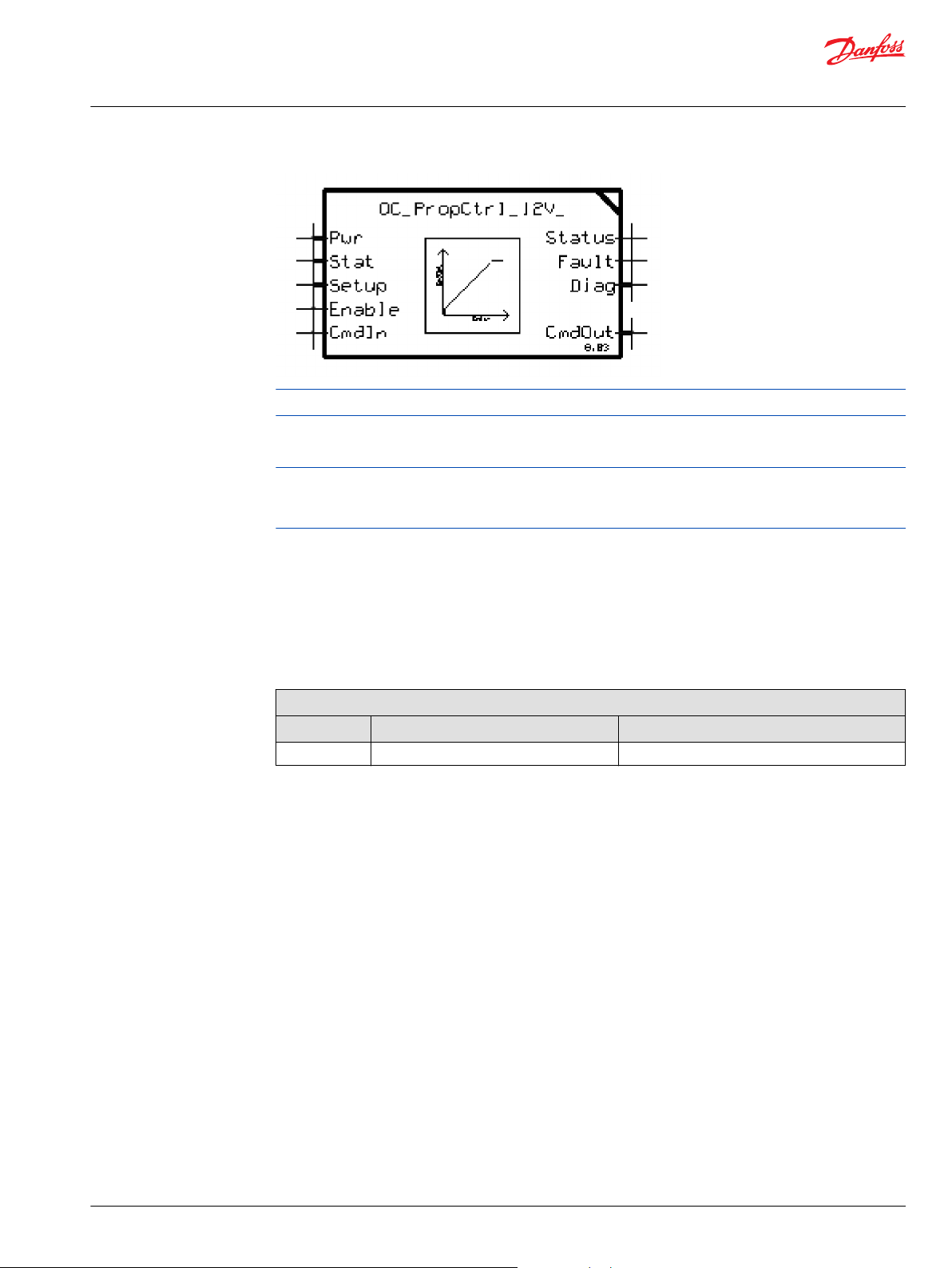

PLUS+1® Compliance

All Series 45 Electric controls have met and passed the Danfoss PLUS+1® compliance standard testing,

and as such, this Series 45 control is PLUS+1® compliant. PLUS+1® compliance blocks are available on the

Danfoss website, within the PLUS+1® Guide section.

Electric Proportional Control Principle

The Electric Proportional Control consists of a proportional solenoid integrated into a Remote Pressure

Compensated control. This control allows the pump to be operated at any pressure limit between the

Load Sense and Pressure Compensation settings by varying the current sent to the solenoid.

18 | © Danfoss | January 2022 BC152886483703en-001201

Technical Information

Series 45 Pumps

General Information

Reference individual frame sections for the margin (LS) setting vs low pressure standby relationship.

Electric proportional controls have a unique relationship between margin (LS) setting and low pressure

standby. This relationship is available in the electric proportional controls section for each frame.

For fan-drive systems, and systems with motors, use a minimum 15bar LS setting to enhance system

stability. As the LS setting is reduced, the risk for system instability may be increased. A 20bar LS setting is

recommended as a starting point for all new applications.

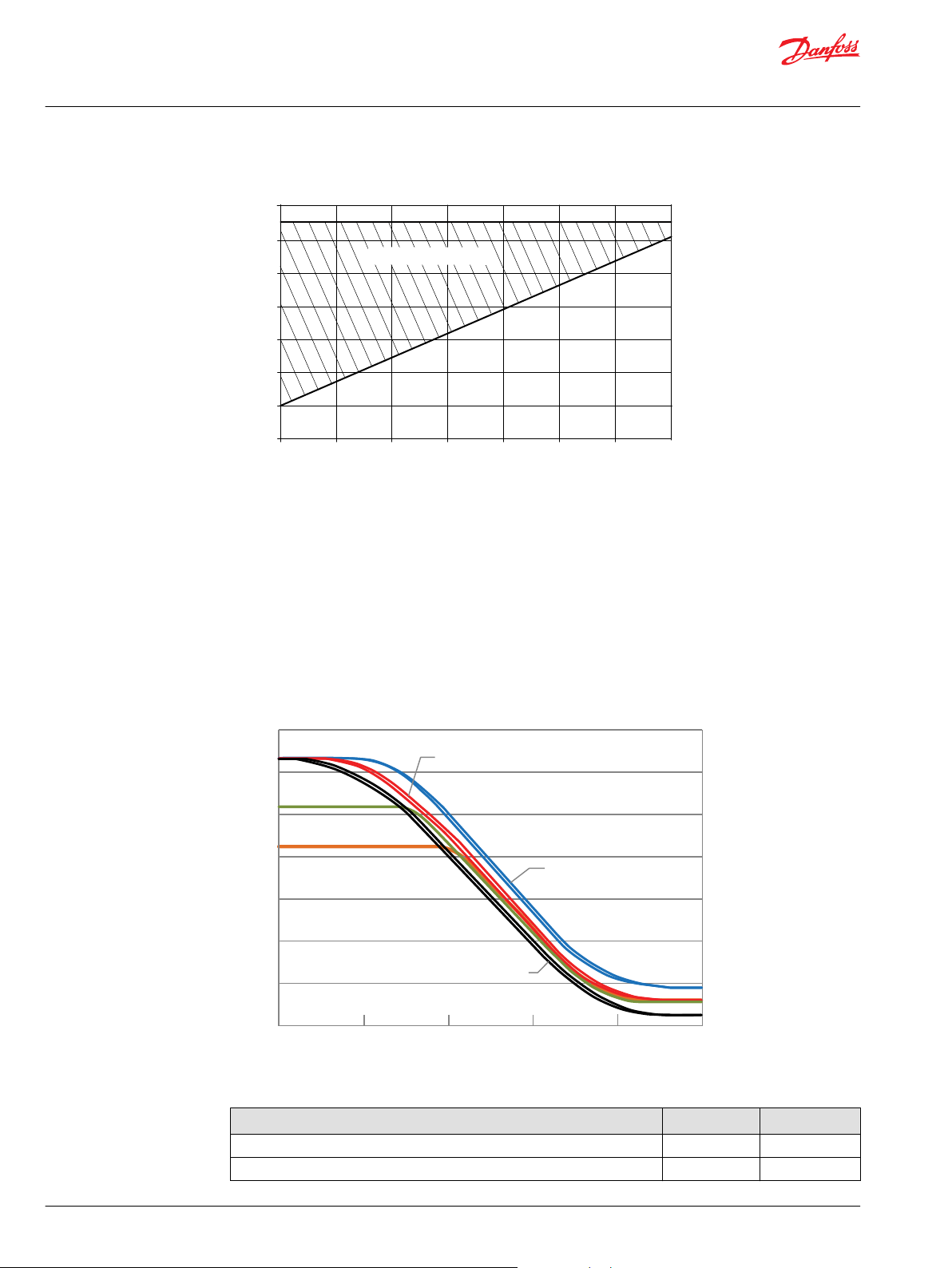

Electric Proportional Control Response/Recovery

S45 Electric Proportional Controls require the use of a servo control orifice, and are available with two

possible servo control orifice options. The servo control orifice is used to enhance system stability, as well

as dampen the pump reactiveness. A smaller orifice diameter will add dampening to the pump

reactiveness, while a larger orifice will allow quicker pump reaction. Fan-Drive applications, as well as

systems with the pump supplying motors, are recommended to use the 0.8mm diameter orifice to

enhance system stability.

Module “G” Options for Electric Proportional Controls

Frame “E” - 0.8mm Orifice “F” - 1.0mm Orifice

All Frames

• •

Specific Electric Proportional Control Response/Recovery times are shown for the available servo control

orifice options in the control section within each specific frame section. These times represent the

response from 100bar to 200bar, and recovery from 200bar to 100bar. As the upper pressure approaches

the PC setting, the PC function will begin to assist in clipping pressure overshoots during the pump’s

response, and will decrease the response times of the pump to equal those of the PC response.

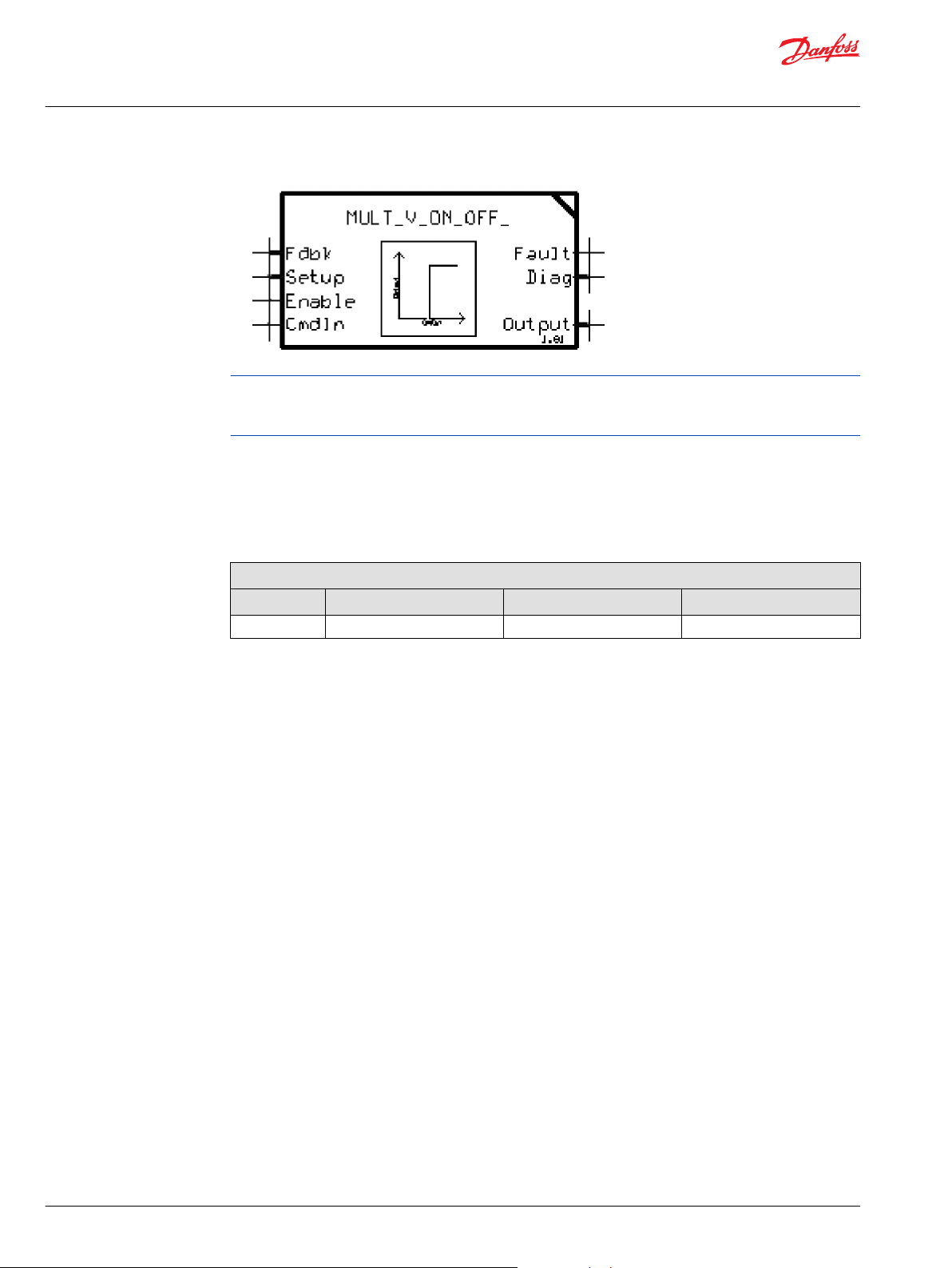

Electric Proportional Control Pressure vs. Flow Characteristic

The Electric Proportional Controls continuous duty operating temperature range is shown below; this

guideline should be followed as well as the maximum current limitations. Note that rated voltage refers

to either a 12V or 24V coil. Under high temperature conditions, current required to operate the solenoid

increases.

©

Danfoss | January 2022 BC152886483703en-001201 | 19

50

60

70

80

90

100

-40

100

Percent of Rated Voltage (%)

Ambient Temperature (°C)

P108 415E

-30

-20

-10

0

60

80

10

20

30

40

50

70

90

110

120

Operating Range

0

50

100

150

200

250

300

350

System Pressure (Bar)

0

0.2

0.4

0.6

0.8

1

Current proportion I/I max

310 Bar PC, 10 Bar LS

310 Bar PC, 20 Bar LS

310 Bar PC, 30 Bar LS

260 Bar PC, 20 Bar LS

210 Bar PC, 20 Bar LS

P108 657E

Technical Information

Series 45 Pumps

General Information

Continuous Duty Operating Temperature

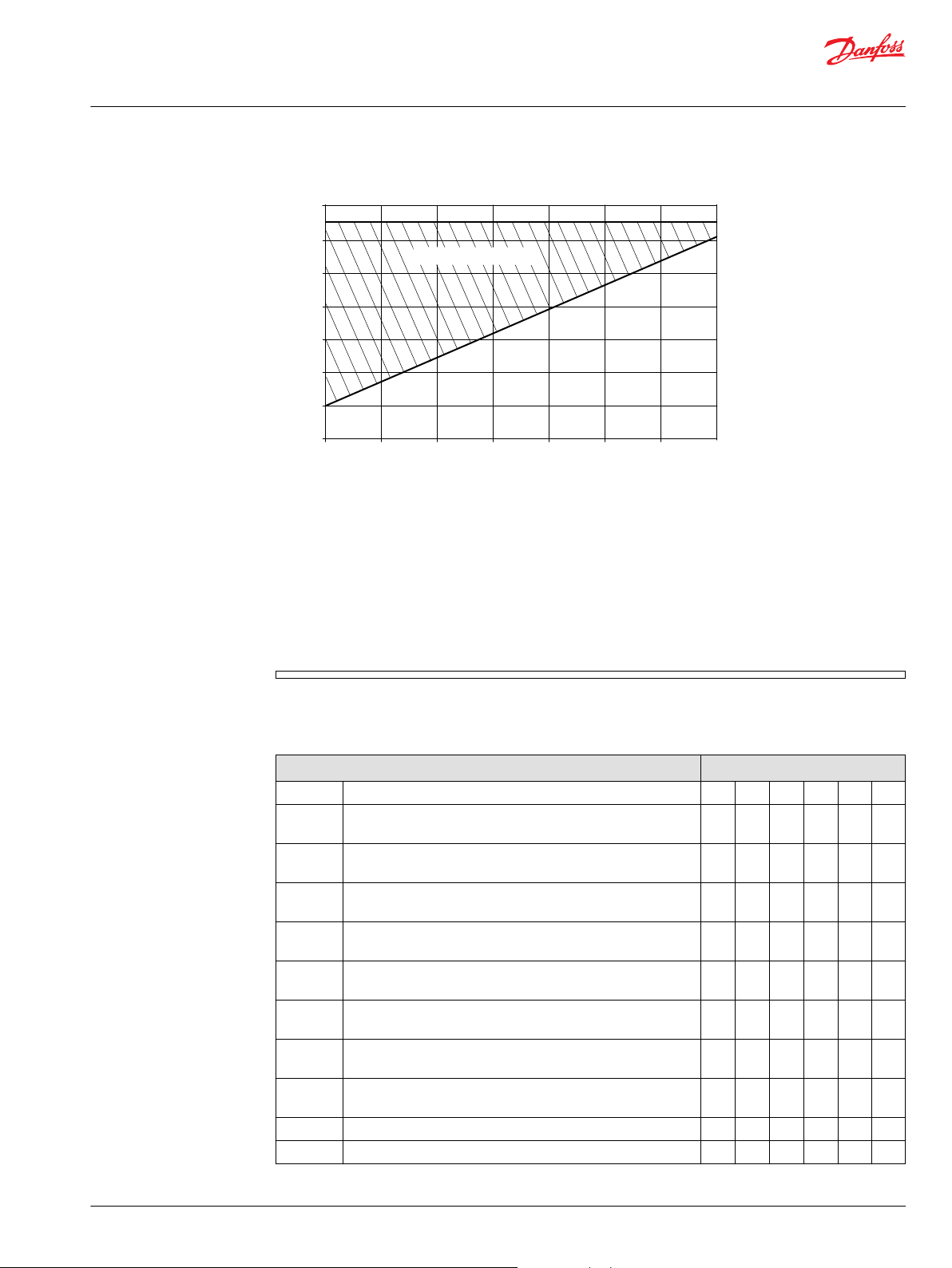

Electric Proportional Control Characteristic – Normally Closed

When an electric current is sent to the Normally Closed configuration control, the pump pressure

decreases proportional to an increase in current. When the load in the system changes, the pump will

adjust its displacement to maintain the pressure demanded by the controlling current. This control is

especially useful for fan-drives, due to the direct relationship between fan-speed and pump pressure.

Due to the nature of Electric Proportional Controls, the relationship between current and pump pressure

is unique for each individual PC/LS pressure setting combination. The relationship between different PC

settings and different LS settings on the Pressure vs. Current Characteristic curve are shown below. The

hydraulic schematic for the Normally Closed Electric Proportional control is shown below as well.

Operating Pressure vs. Input Current (N.C. EPC)

20 | © Danfoss | January 2022 BC152886483703en-001201

Solenoid Data – Normally Closed

Voltage 12V 24V

Maximum Current 1800 mA 920 mA

Inrush Current 1700 mA 800 mA

Technical Information

Series 45 Pumps

General Information

Solenoid Data – Normally Closed (continued)

Voltage 12V 24V

Coil Resistance @ 20°C [70°F] 7.1 Ω 28.5 Ω

PWM Range 200-300 Hz

PWM Frequency (preferred) 250 Hz

IP Rating (IEC 60529 | DIN 40050-9) IP67 IP67

IP Rating (IEC 60529 | DIN 40050-9) with mating connector IP69K IP69K

Operating Temperature Consistent with Pump Limits:

-40°C (-40°F) to 104°C (220°F)

The available Normally Closed Electric Proportional Controls for the Series 45 are shown below. The

allowable Pressure Compensator (PC) and Load Sense (LS) pressure settings are provided for each frame

in their respective sections.

Electric Proportional Controls Options – Normally Closed Frame

Code Description L K

AH Electric Proportional Pressure Control w/Pressure Comp. (NC,

12VDC) Left

AL Electric Proportional Pressure Control w/Pressure Comp. (NC,

24VDC) Left

AV Electric Proportional Pressure Control w/Pressure Comp. (NC,

12VDC) Right

AK Electric Proportional Pressure Control w/Pressure Comp. (NC,

24VDC) Right

BH Electric Proportional Pressure Control w/Pressure Comp. (NC,

12VDC) [>280 bar] Left

BL Electric Proportional Pressure Control w/Pressure Comp. (NC,

24VDC) [>280 bar] Left

BM Electric Proportional Pressure Control w/Pressure Comp. (NC,

12VDC) [>280 bar] Right

BK Electric Proportional Pressure Control w/Pressure Comp. (NC,

24VDC) [>280 bar] Right

EM Electric Proportional Pressure Control w/Pressure Comp. (NC,

12VDC)

EN Electric Proportional Pressure Control w/Pressure Comp. (NC,

24VDC)

• •

• •

K2

J F E

• • • •

• • • •

• • •

• • •

• • •

• • •

• • •

• • •

Notes:

1. Left = E-Frame: CW Only, F-Frame: CW Only, J-frame: CW Axial, CCW Radial

2. Right = E-Frame: CCW Only, F-Frame: CCW Only, J-frame: CCW Axial, CW Radial

3. K/L Frame Controls are not rotation dependent

4. K2 Frame electric controls are limited only for Left orientation and up to 260 Bar

Electric Proportional Control Characteristic – Normally Open

When an electric current is sent to the normally open configuration control, the pump pressure increases

proportional to an increase in current. When the load in the system changes, the pump will adjust its

displacement to maintain the pressure demanded by the controlling current. This control is especially

useful for fan-drives, due to the direct relationship between fan-speed and pump pressure.

Due to the nature of Electric Proportional Controls, the relationship between current and pump pressure