Data Sheet

Axial Piston Motors

L and K Frame

For more than 40 years, Danfoss has been developing

state-of-the-art components and systems for mobile

machinery used in off -highway operations around

the world. We have become a preferred supplier by

offering the best of what really matters: The hardware

inside your vehicle application.

The L/K motor is designed for use primarily in mobile

equipment using existing and proven technology.

These motors have been optimized with regard to

options, life, package size and installed cost.

The L/K motor family consists of five base

displacements which all fit in one package size. Two

different configurations are available, an SAE-B twobolt, or a cartridge style motor.

These motors are a two-position, variable

displacement, with smooth, shift-on-the-go

capability. The working displacement range of 3.4:1

with a minimum angle option to Zero degree

provides exceptional versatility in the application of

L/K motors. The motor is spring biased to maximum

displacement and can be hydraulically shifted to

minimum angle

Features

Wide range of options

•

Integral loop flush valve with relief plus

orifice

•

Minimum angle option to Zero degrees

•

Speed sensor with zero rpm and

direction sensing capability

•

Single and Two line control available for

SAE mount motors. Single line control

available for cartridge motors

•

Twin radial (side) or axial (end) porting

is available

•

Multiple minimum displacement

options available

•

Reduced maximum displacement

options

•

Tapered input shaft with shaft seal dust

protector for fan drive applications

©

Danfoss | September 2017 L1003165 | AI00000330en-Us0202 | 1

Installation and Packaging benefits

•

SAE-B two-bolt, and cartridge mounting

•

Three clean sides with superior

clearance and access to mounting bolts

•

Short and compact: fits into wheel end

and compact installations with

improved porting

•

The cartridge motor fits through a 178

mm [7 Inch] mounting hole of a

gearbox pilot for subassembly

installation of motor to gearbox

•

High Efficiency - nine piston rotating

groups with an 18 degree maximum

angle

•

Low control pressure requirement (14

bar for servo) - no undue parasitic

power loss. Smooth two-speed shift

from minimum to maximum angle

Designed for Durability and Flexibility

•

Versatility - working displacement range

of 3.4:1 with a minimum angle option to

Zero degrees. SAE-B two-bolt, and

cartridge mounting available

•

Five displacements allow the optimum

selection of hydraulic motor for the

lowest possible installed cost

•

Reliability - uses existing technology

•

Suitable for closed and open circuit

applications

•

Designed for maximum system

pressures up to 420 bar [6100 psi]

Comprehensive technical literature is

online at powersolutions.danfoss.com

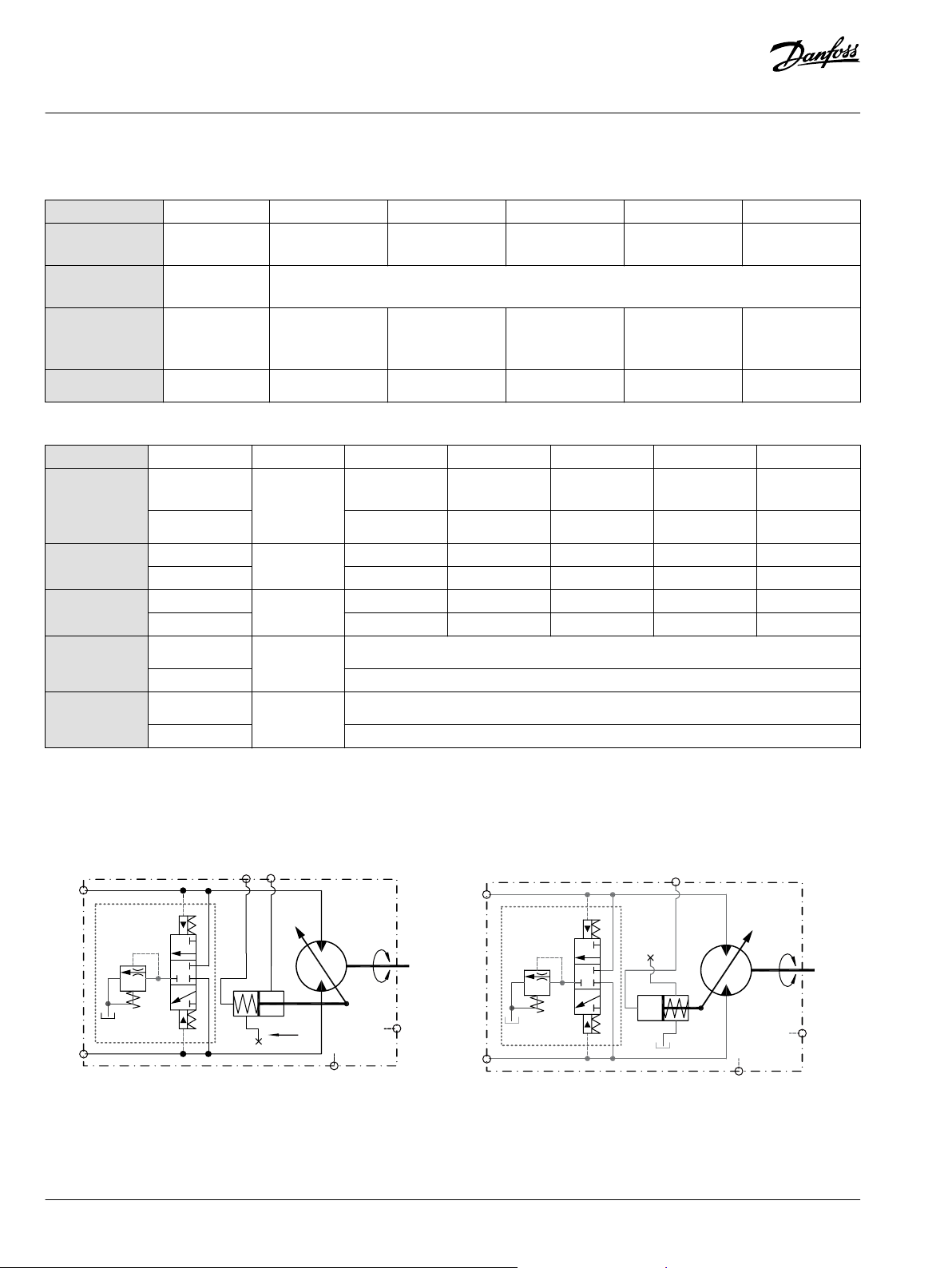

Cartridge motor schematic, single line control

SAE Motor schematic, two line control

A

B

Optional

X1

X2

L1

L2

Min.

Disp.

A

B

Optional

X1

L1

L2

L/K Cartridge Motor

L/K SAE Motor

Data Sheet

L and K Frame Motors

Technical specifications

Physical properties

Parameter Unit L25 L30 L35 K38 K45

Displacement

maximum

Weight (cartridge

and SAE-B)

Mass moment of

inertia of rotating

components

Theoretical torque

Operating parameters

Parameter Unit L25 L30 L35 K38 K45

System

pressure

Speed limit

(at max. disp)

Speed limit

(at min. disp)

Case pressure

Shift pressure

(single line

control)

1

2

1

Refer to bulletin 520L0627 for pressure definitions

Limit when motor angle is 12 degrees or less

Schematics

cm3 [in3] 25 [1.50] 30 [1.83] 35 [2.14] 38 [2.32] 45 [2.75]

kg [ lb] 15.4 [34]

kg•m2

[slug•ft2]

N•m/bar

[lbf•in/1000psi]

Maximum

operating

Maximum

Rated min-1 (rpm) 3400 3500 3600 3600 3500

Maximum 3950 4150 4300 4000 3900

Rated min-1 (rpm) 4400 4450 4500 4650 4500

2

Maximum 5000 5150 5300 5200 5050

Maximum

operating

Maximum 6 [87]

Maximum

operating

Maximum 69 [1000]

0.001666

[0.001229]

0.40

[244]

bar [psi]

bar [ psi] 2 [29]

bar [ psi] 14 [203]

400

[5800]

420

[6090]

0.001582

[0.001167]

0.48

[293]

350

[5075]

375

[5440]

0.001530

[0.001128]

0.56

[347]

300

[4350]

325

[4715]

0.002326

[0.001716]

0.60

[366]

350

[5075]

415

[6019]

0.002286

[0.001687]

0.72

[439]

300

[4350]

350

[5075]

2 | © Danfoss | September 2017 L1003165 | AI00000330en-Us0202

Loading...

Loading...