Data sheet

AM-PBU 25 Electronic Power

Backup for 24VAC Actuators

AM-PBU 25 is a standby mains power backup

unit for AME 85 or AME 55 actuators. It is used

as an “Electronic Spring Return” unit. During a

power failure an actuator can be powered to its

open or closed position. Normal control of the

actuator automatically resumes when power

returns. The charger section of the AM-PBU 25

keeps the battery in peak condition at all times.

The battery can be monitored remotely from a

building management system (BMS) or volt

meter.

The AM-PBU 25 can serve one AME 85 actuator

or two AME 55 actuators.

Ordering &

Technical Data:

Operation: During normal operation 24 VAC power passes through normally open relay contacts

AM-PBU 25 Code No.: 082H7090

Power requirement 24 Vac / 40 VA

Power output 24 Vac / 25 VA, 2 spdt contacts

Output cycle time 6.5 minutes

Battery 12 V, 1.2 Ah

Ambient temperature

Ambient humidity max. 65 % RH

Enclosure rating NEMA 1 (IP 00)

Standards Emission EN 50081-1

Weight 0.67lb (0.3 kg)

Dimensions 7.5x5.0x1.9in (190 x 127 x 50mm) - panel mounted

in the AM-PBU 25 to the power input terminals on the actuators. In the event of a

power failure the AM-PBU 25 starts to provide 24Vac power to the actuator from the

frequency converter.

14…122°F (-10...50 °C)

Immunity - EN 50082-1

Heat - IEC 68-2-2

This drives the valve either open or closed depending on the wiring of the actuator. The

power backup cycle lasts for 6.5 minutes. Normal operation is resumed when power is

restored.

The condition of the battery can be monitored with terminals TG and BT connected to a

volt meter or Building Management System (BMS).

VD.HU.D1.22©Danfoss 2/2012

1

Data sheet

AM-PBU 25 Electronic Power

Backup for 24VAC Actuators

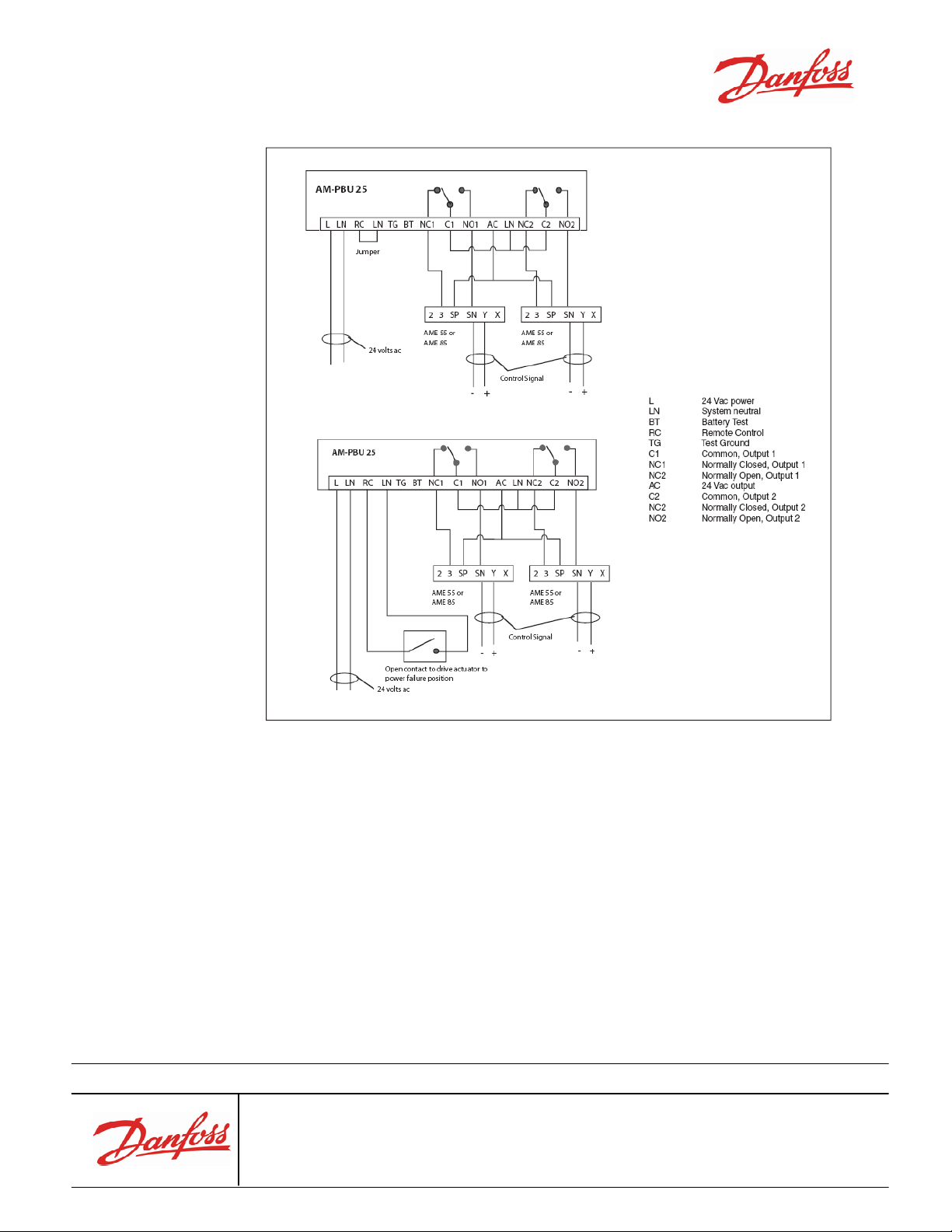

Electrical Wiring:

The jumper between LN & RC can be replaced by a connection to a building

management system (BMS), a controller, or a manual switch. When the contact opens,

the building mains power is disconnected and the AM-PBU 25 goes through a cycle,

running on battery power. This feature can be used for remote control of the valve or for

testing the battery. Connecting terminals TG and BT to a BMS or volt meter and taking a

reading during an exercise cycle, gives a good indication of battery condition.

Connecting NC1 or NC2 to terminal 3 on the actuator drives the valve stem down on

power failure; connecting NC1 or NC2 to terminal 2 drives the valve stem up on power

failure.

Danfoss can accept no responsibi lity for possible errors in printed materials and reserves the right to alter its products without notice. All trademarks in this material are property of the

respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All right reserved.

Head Office: USA Office:

Danfoss Inc. Danfoss Inc.

Mississauga, ON CANADA Baltimore, MD USA

Tel: 866-375-4822 Fax: 905.285.2055 Tel: 866-375-4822 Fax: 443.512.0270

www.na.heating.danfoss.com

VD.HU.D1.22©Danfoss 2/2012

Loading...

Loading...