Danfoss Akva Lux II Reno Eco Fact sheet

Fact Sheet

Akva Lux II Reno Eco flat station

For replacement of gas boilers in apartment buildings and multi-family houses. Direct heating and instantaneous domestic hot water.

Application

The Akva Lux II Reno Eco is a flat station for direct heating and a pressure and temperature

controlled instantaneous domestic hot water

heater for two-pipe systems, designed for decentralized heat distribution and is especially

suitable for apartment buildings, where existing gas boilers should be replaced. The existing

connections for DHW and DCW as well as supply and return of secondary heating circuits can

be used without major changes, but it is recommended that the connections for the primary

hot water flow and return are to lead through

the chimney. Optionally the cold water supply

can also be established in top of the unit.

District heating (DH)

The station is supplied with heating water from

a heating center or a buffer storage, and it is pre

fabricated with interconnecting components

such as differential pressure controller, strainer,

thermostatic bypass FJVR, sensor pockets and

fitting piece for insertion of a heat meter.

Heating (HE)

The differential pressure controller reduces the

high, fluctuating pressure in the district heating

network to a constant operating pressure that

maintains a constant pressure in the heating

circuit(s). The room temperature is adjusted solely using the radiator thermostats. To controll

the room temperature the station can be supplied with zone valve/thermal actuator TWA-A,

which enables connection to an electronic programmable room thermostat.

-

Domestic hot water (DHW)

The domestic hot water is prepared in the heat

exchanger based on the flow principle and

the temperature is regulated by the PTC2+P

self-acting controller with integrated differential

pressure controller. The pressure-controlled part

allows primary and secondary side flow through

the heat exchanger, only when hot water is

tapped and blocks the flow immediately after

completion of the tapping process.

The thermostatic part controls the domestic hot

water temperature. Thanks to the quick-acting

hydraulic control of the heat exchanger, it is large

ly protected from the formation of lime scale and

growth of bacteria. The integrated differential

pressure controller compensates for variations in

supply temperature and varying differential pres

sure and thereby ensures a constant domestic

hot water temperature at all times. A thermostat

ic bypass enables tapping of hot water without

any delay, – ensuring the best possible efficiency

and economy. For registration of the cold water

consumption the station is equipped with a fit

ting piece for mounting of a cold water meter in

the DCW inlet.

Bypass

The station is equipped with bypass function as

a standard.

Construction

All pipes are made of stainless steel. The connections are made by nuts and gaskets. The station

can be supplied with a white-lacquered steel

sheet cover for wall mounting.

FEATURES AND BENEFITS

FEATURES AND BENEFITS

• Flat station for exhange of existing gas

boilers

• Direct heating, DHW heating based on

flow principle

• With integrated fresh water system for

decentralized DHW heating

-

• Capacity: 15 DCW / 55 kW DHW

• Compact, space-saving design

-

• Also suitable for low-temperature

systems with 55 ° C supply flow

-

• Innovative, energy-saving controller

PTC2+P in combination with high performance heat exchanger for on-demand

-

water heating without no-load losses

• Pipes and plate heat exchanger

made of stainless steel

• Minimized risk of lime scale and bacteria

formation

• With pipe insulation

www.danfoss.com

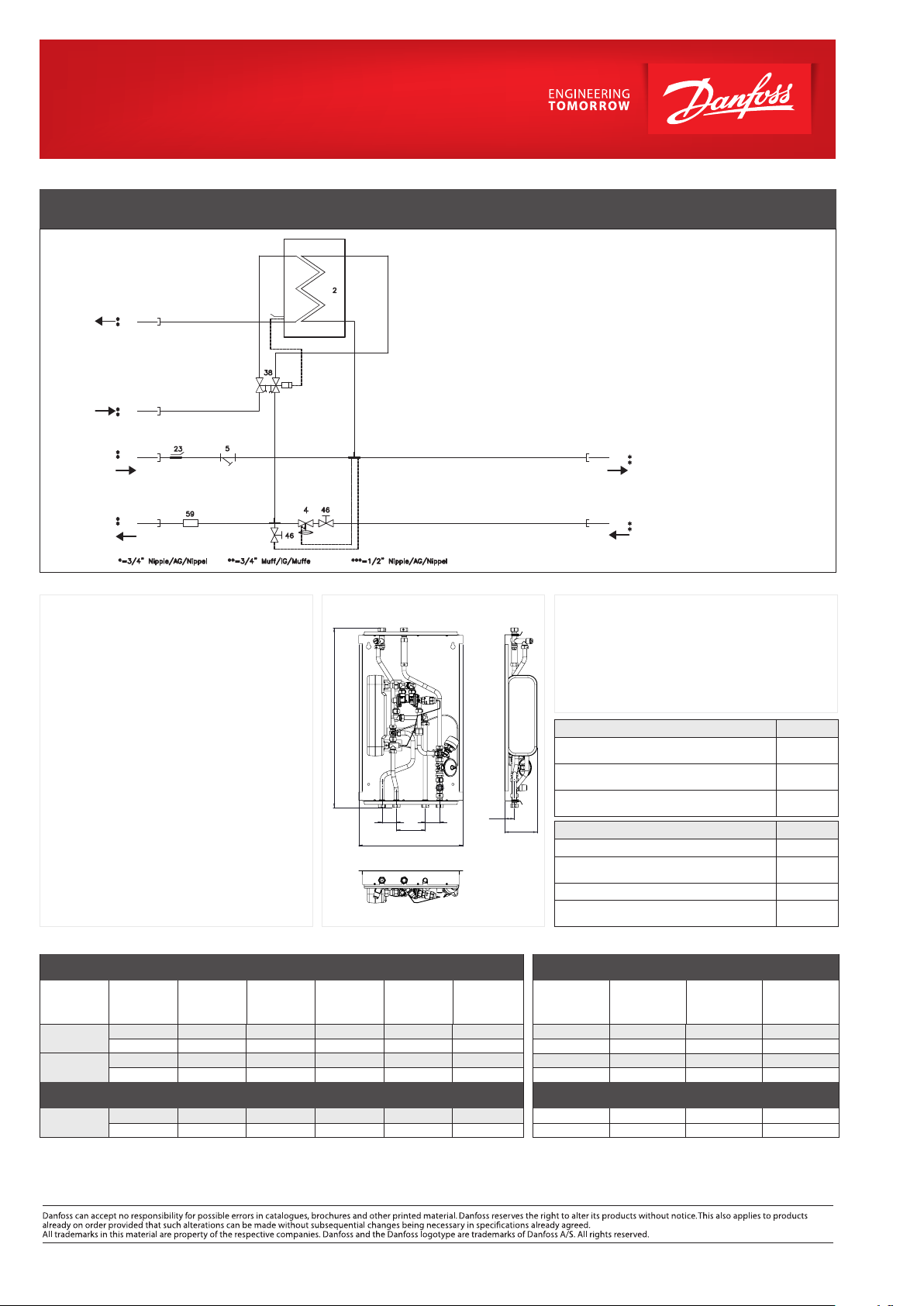

SHALTPLAN - BEISPIEL

E

D

C

B

A

87

CIRCUIT DIAGRAM - EXAMPLE

DHW

DCW

2 Plate heat exchanger DHW

4 Differential pressure controller

5 Strainer

23 Sensor pocket M10 (internal thread)

38 PTC2+P controller

46 RA-C DN 15 zone valve

59 Fitting piece for heat meter (¾” x 110 mm)

Supply

Primary

Return

Primary

Design specifications:

Nominal pressure (prim/sec.): PN 10/10

Max. supply temperature: 95 °C

Min. ΔP: See capacity examples

DCW static pressure: p

Brazing material (HEX): Copper

= 2 bar

min

Weight : 22 kg

incl. cover

Cover: White-lacquered steel

Dimensions (mm):

Without cover: H 809,5 × W 470 × T 146,9

Mit Verkleidung: H 1120 x W 480 x T 149

Connections sizes:

DH: G ¾“ (ET)

DCW, DHW, HE: G ¾“ (ET)

Dimensional sketch:

5 6 7

809,5

1 2 3 4

65

65

130

470

HE

Supply

HE

Return

Connections:

1. Heating (HE) supply (bottom)

2. Domestic hot water (DHW) (bottom)

3. Domestic cold water (DCW (bottom)

4

. Heating (HE) return (bottom)

5. District heating (DH) supply (top)

6. District heating (DH) return (top)

7. Option: Domestic cold water supply (top)

Type Code No.

Akva Lux II Reno Eco Type 1, w/ pipe insulation,

zone valve, Cover

Akva Lux II Reno Eco Type 2, w/ pipe insulation,

zone valve, Cover

Akva Lux II Reno Eco Type 3, w/ pipe insulation,

44

146,9

zone valve, Cover

Accessories Code No.

145B4054

145B4055

145B4056

Cover W 480 x D 150 x H 1120 mm 145H4282

Ball valve set for ECO 2 pcs. DVGW,

4 pcs. heating (76mmx3/4”ET/IT)

145H4015

Actuator TWA-A NC 230 V for zone valve 088H3112

Top connection DCW with fitting piece for

DCW meter 3/4” x 110 mm

144B2420

DHW: Capacity examples, 10 °C/50 °C

Typ e

XB 06H-1 26

XB 06H-1 40

DHW

Capacity

KW

35,0

45,0

45,0

55,0

Primary

Supply

[°C]

65 22

65 22

65 22

65 21

Secondary

Supply

[°C]

Pressure loss

*primary

[kPa]

Flow rate

primary

[l/h]

21 690 11, 5

36 900 12, 0

28 870 14,5

43 1080 18,0

Flow rate

secondary

[l/min]

DHW: Capacity examples, 10 °C/50 °C

XB06H+ 60

* w/o heat meter

32,3

41,0

Danfoss Redan A/S · District Heating · Omega 7, Søften · DK-8382 Hinnerup · Denmark

55 20

55 21

24 800 13,3

40 1030 17,2

Heating: Capacity examples

Heiting

Capacity

kW

10 20 430 41

10 30 287 28

10 40 215 30

15 20 645 71

Heating: Capacity examples

15 30 430 42

15 40 323 34

* w/o heat meter

Tel.: +45 87 43 89 43 · Fax: +45 87 43 89 44 · redan@danfoss.com · www.redan.danfoss.dk

© Danfoss | Produced by Danfoss Redan | 2017.02

Heating circuit

Δt

[° C]

Flow rate

primary

[l/h]

Pressure loss

*primary

[kPa]

VL.LZ.K1.02

Loading...

Loading...