Page 1

Data Sheet

Electric expansion valves

Type AKVA 10, AKVA 15 and AKVA 20

Designed for ammonia refrigerating plant

AKVA are electric expansion valves designed for

ammonia refrigerating plant.

The AKVA valves are normally controlled by a

controller from Danfoss’ range of ADAP-KOOL

controllers.

The AKVA valves are supplied as a component

programme, as follows:

• Separate valve

• Separate coil with terminal box or cable

• Spare parts in the form upper part, orice and

lter

The individual capacities are indicated with a

number forming part of the type designation.

The number represents the size of the orice of

the valve in question.

A valve with orice 3 will for example be

designated AKVA 10-3.

The orice assembly is replaceable.

Features

• The valve requires no adjustment

• Wide regulation range

• Replaceable orice assembly

• Wide range of coils for d.c. and a.c.

• Quick reaction in whole range of stated

capacity.

• In some applications AKVA can be used both

as expansion valve and solenoid valve.

• Classication: DNV, CRN, BV, EAC etc. To get

an updated list of certication on the

products please contact your local Danfoss

Sales Company.

®

AI183786440857en-000801

Page 2

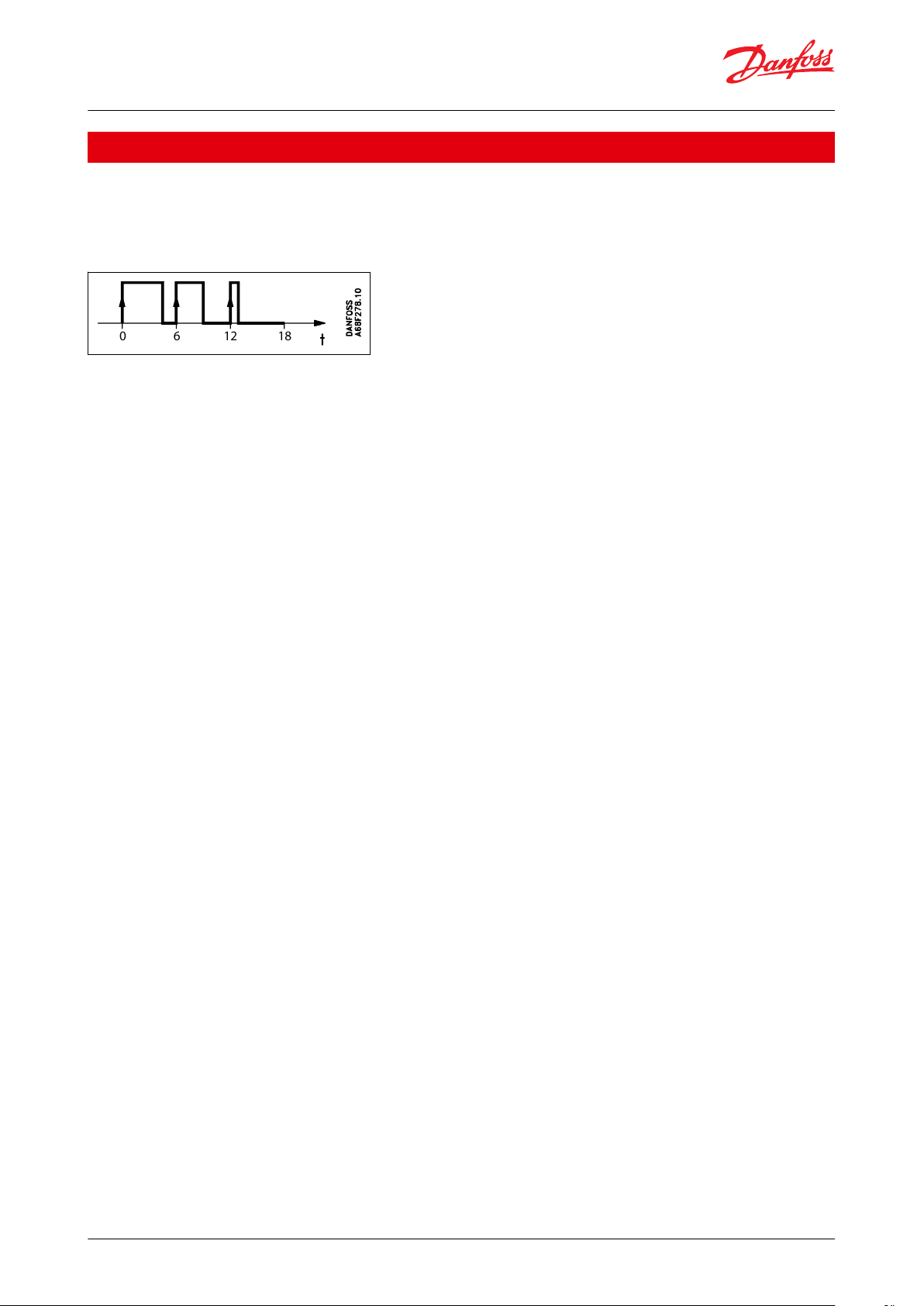

0

6

12

18

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Functions

The valve capacity is regulated by means of pulse-width modulation. Within a period of six seconds a voltage signal

from the controller will be transmitted to and removed from the valve coil. This makes the valve open and close for

the ow of refrigerant.

Figure 1: Function

The relation between this opening and closing time indicates the actual capacity. If there is an intense need for

refrigeration, the valve will remain open for almost all six seconds of the period. If the required amount of

refrigeration is modest, the valve will only stay open during a fraction of the period. The amount of refrigeration

needed is determined by the controller. When no refrigeration is required, the valve will remain closed.In some

applications, AKVA can advantage-ously be used both as expansion valve and solenoid valve. See Applications

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 2

Page 3

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Applications

Recommendations

It is important to realize when AKVA is operating, that the valve always is fully open or fully closed. That means that

this way of operation should always be considered during the refrigeration design. (Piping, liquid velocity, sub

cooling etc.)

Danfoss have the following recommendations/guidelines to be taken into considerations:

• In 1:1 applications (1 evaporator, 1 condenser and 1 compressor) chillers with a small amount of refrigerant or

installed in front of a Plate Heat Exchangers, it must be observed that every time the AKVA is fully open or closed it

will have a signicant impact on the hole system. (e.g. pressure variations on suction side).

Please observe that the performance of such a system is not only related to one component. (e.g. AKVA) Other

factors which is very important to include in the overall refrigeration system design:

◦ Liquid distribution at and design of evaporator

◦ total evaporator coil is of adequate length thus superheat can be controlled within the entered period time

(normal 6 sec. or 3 sec.)

◦ mounting principle of temperature sensor, to ensure a steady and fast signal can be detected by the electronic

system.

• If pressure dependent valves like, ICS with pilots like CVP e.t.c., is installed between evaporator and compressor, it

can eect the lifetime of ICS, because the piston of the ICS will operate together with operation of AKVA. Type of

refrigerant and evaporator has a big inuende of the size of pulsations after the evaporator and in front of the ICS.

• AKVA is a direct pressure independent valve. That means that if non-Danfoss electronic controllers is used,

intelligent and fast optimal control is needed, because the quick pressure changes only can be detected and

compensated via the electronic control system.

• Liquid lines must be designed according to AKVA capacity and not evaporator capacity.

• To avoid ash-gas ensure sucient sub-cooling or design liquid lines thus to big pressure drop is avoided, when

AKVA is open. If not sucient subcooling is not obtained (normally 4K) it will have an impact on the lifetime of the

vale).

• Where the demand for safety level is extremely high, (e.g. Liquid Level Control in a pump seperator) an extra valve

can be installed in front of AKVA to avoid leakage. This valve must be Danfoss type EVRAT.

• Always install a 100 µm lter in front of AKVA 15 and AKVA 20 valves.

• If AKVA has to be used in chillers. Please contact Danfoss.

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 3

Page 4

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Media

Refrigerants

For R717 (Ammonia) and R744 (CO2)

.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 4

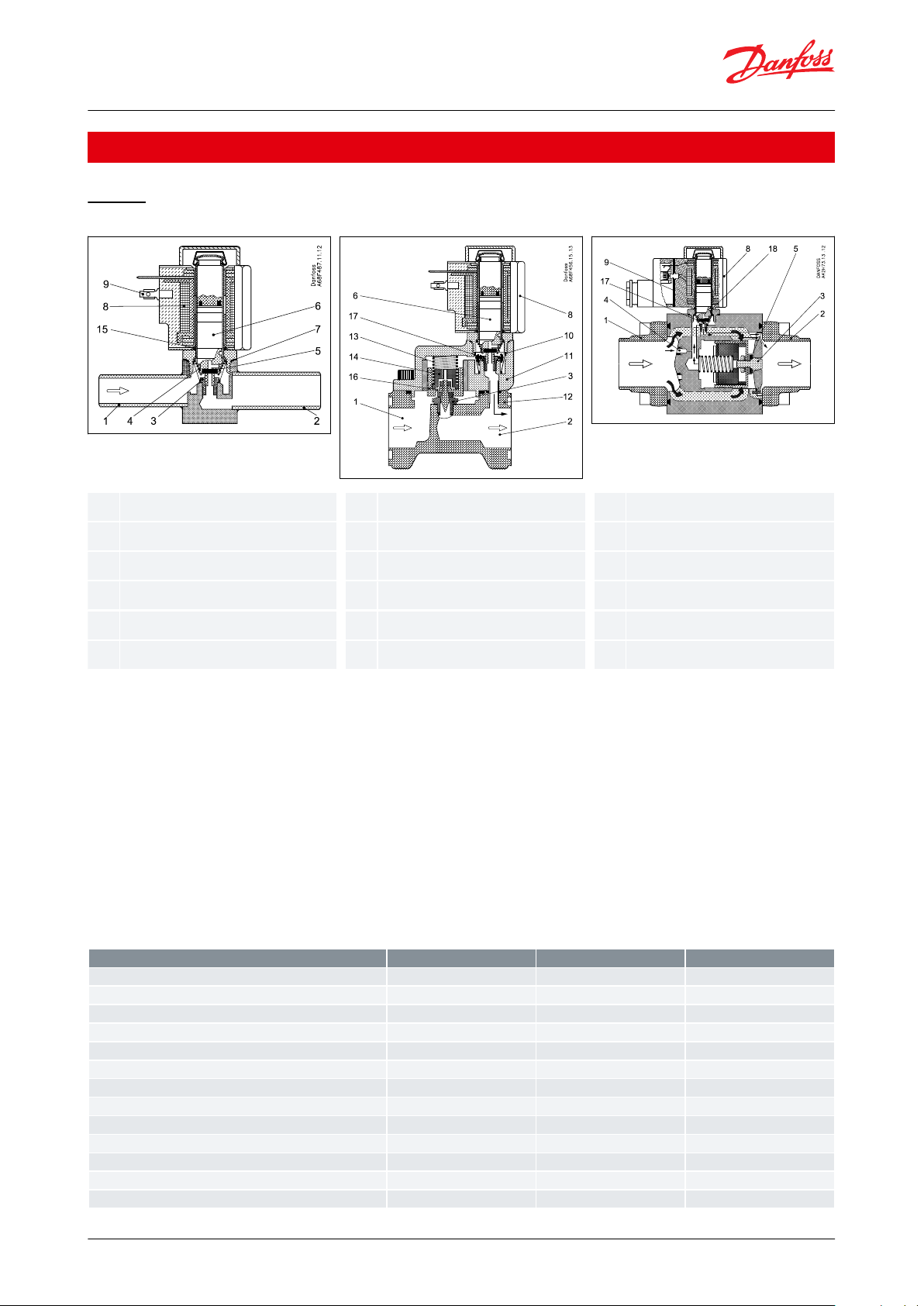

Page 5

1.2.3.4.5.6.7.8.9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Inlet

Outlet

Orice

Filter

Valve seat

Armature

Aluminium gasket

Coil

DIN plug

Filter

Cover

Valve body

Spring

Orice assembly

O-ring

Piston assembly

Pilot orice

Pilot valve

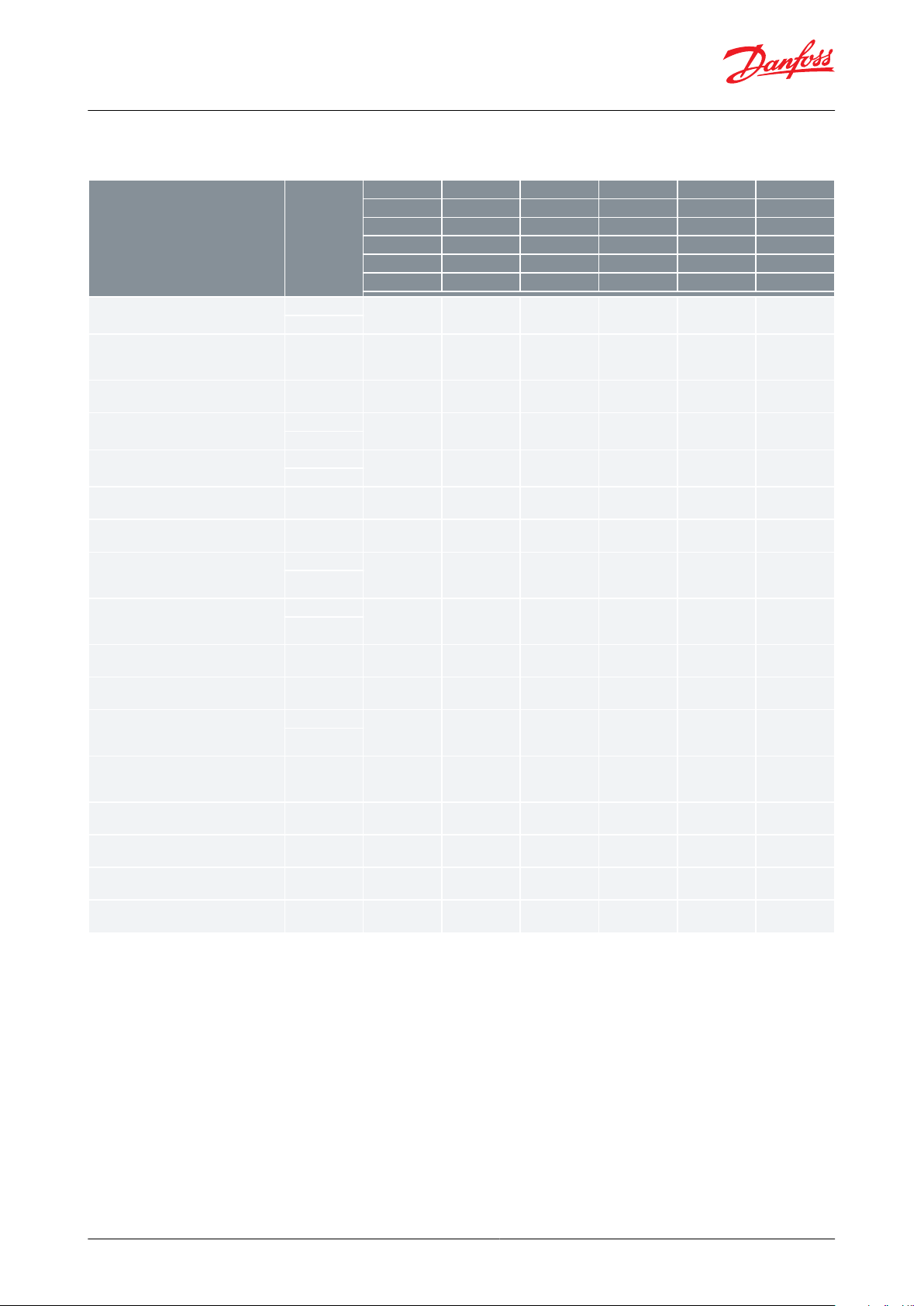

Valve type

AKVA 10

AKVA 15

AKVA 20

Tolerance of coil voltage

+10 / -15%

+10 / -15%

+10 / -15%

Enclosure to IEC 529

Max. IP 67

Max. IP 67

Max. IP 67

Working principle (Pulse-width modulation)

PWM

PWM

PWM

Recommend period of time

6 seconds

6 seconds

6 seconds

Capacity (R717)

4 to 100 kW

125 to 500 kW

500 to 3150 kW

Regulation range

10 - 100%

10 - 100%

10 - 100%

Connection

Weld

Weld

Weld

Media temperature

- 50 to 60 °C

- 40 to 60 °C

- 40 to 60 °C

Ambient temperature

- 50 to 50 °C

- 40 to 50 °C

- 40 to 50 °C

Leak of valve seat

< 0.02% of kv-value

< 0.02% of kv-value

< 0.02% of kv-value

MOPD

18 bar

22 bar

18 bar

Filter

Internal 100 µm replaceable

external 100 µm

external 100 µm

Max. working pressure

PS = 42 bar

PS = 42 bar

PS = 42 bar

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Product specication

Design

Figure 2: AKVA 10 Figure 3: AKVA 15 Figure 4: AKVA 20

The AKVA 10 valves covers a capacity range from 4 kW to 100 kW (R 717) and are divided into 8 capacity ranges. The

AKVA 10 valve bodies are made in stainless steel and have weld connections..

The AKVA 15 valves covers a capacity range from 125 kW to 500 kW (R 717) and are divided into 4 capacity ranges.

The AKVA 15 valves have ange connections.

The AKVA 20 valves cover a capacity range from 500 kW to 3150 kW (R 717) and are divided into 5 capacity ranges.

The AKVA 20 valve has weld connections.

The AKVA valves can be used for:

• Flooded evaporation (high/low pressure)

• Pump separators

• Direct expansion. See Applications.

If AKVA has to be used in chillers please contact Danfoss.

Table 1: Technical data

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 5

Page 6

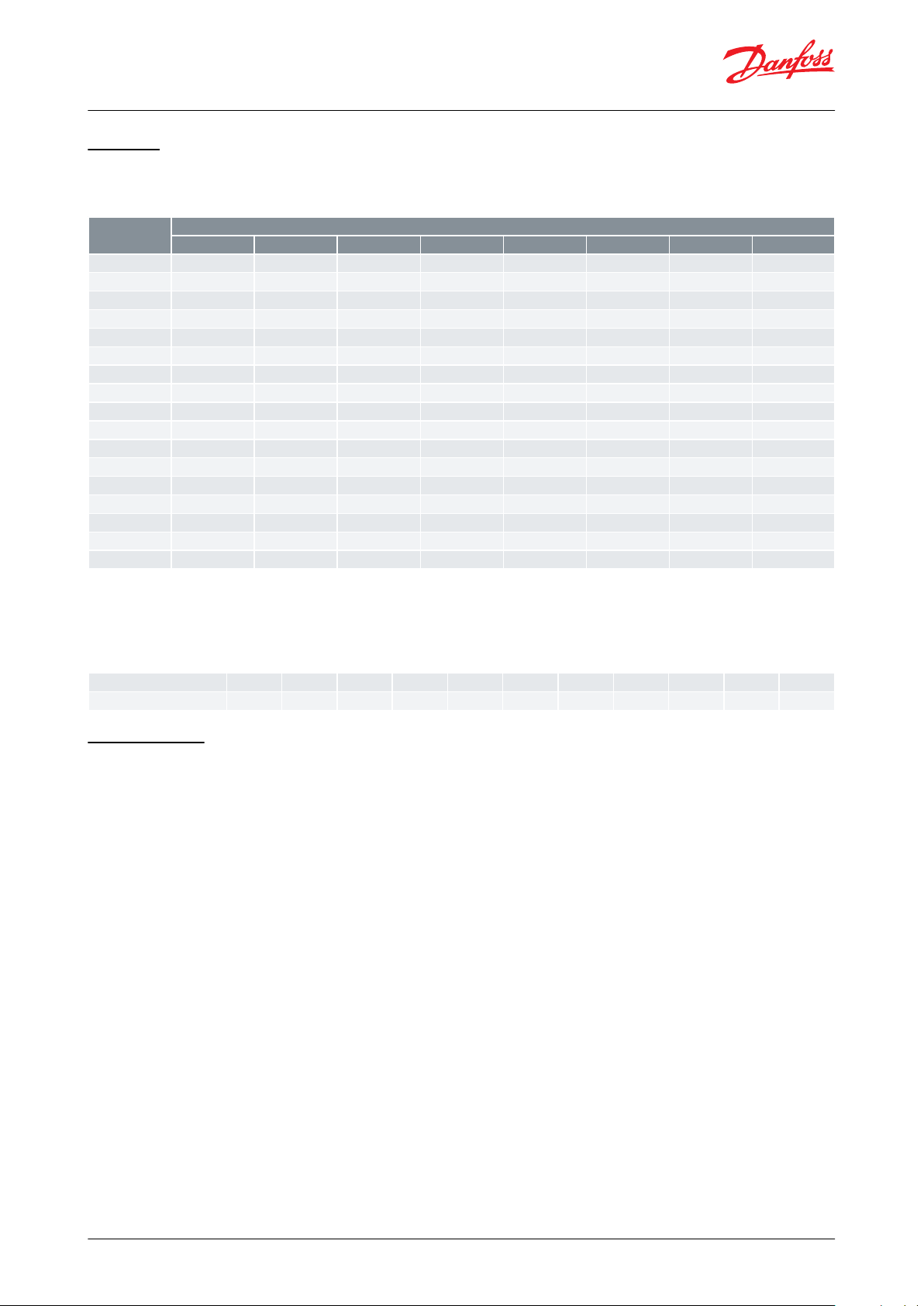

Valve type

Capacity in kW at pressure drop across valve ∆p bar

2468101214

16

AKVA 10 - 1

2.2

3.1

3.7

4.1

4.4

4.755.2

AKVA 10 - 2

3.5

4.9

5.8

6.577.5

7.9

8.3

AKVA 10 - 3

5.6

7.7

9.1

10.2

11.1

11.9

12.5

13.1

AKVA 10 - 4

9.1

12.4

14.7

16.5

17.9

19.2

20.2

21.1

AKVA 10 - 5

14.2

19.4

22.9

25.72829.9

31.6

33

AKVA 10 - 6

23

31.2

36.4

41.44548.1

50.7

53.1

AKVA 10 - 7

36.6

49.3

58.16570.6

75.3

79.4

83

AKVA 10 - 8

59.1

78.9

93.5

104

112

120

126

131

AKVA 15 - 1

95.7

113

127

138

148

156

163

AKVA 15 - 2

153

181

203

221

236

250

261

AKVA 15 - 3

231

274

308

335

358

377

395

AKVA 15 - 4

383

455

510

555

593

625

655

AKVA 20 - 1

383

455

510

555

593

625

655

AKVA 20 - 2

612

726

814

886

947

999

1045

AKVA 20 - 3

959

1137

1275

1388

1482

1564

1635

AKVA 20 - 4

1552

1836

2057

2239

2391

2523

2639

AKVA 20 - 5

2479

2921

3267

3550

3789

3994

4174

Correction factor

2K4K10K

15K

20K

25K

30K

35K

40K

45K

50K

R717

1.01

1.00

0.98

0.96

0.94

0.92

0.91

0.89

0.87

0.86

0.85

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Capacity

Range: - 40 °C to 10 °C

Table 2: R717

Correction for subcooling

The liquid injected capacity must be corrected, if the subcooling deviates from 4 K. Use the actual correction factor

indicated in the table. Multiply the liquid injected capacity by the correction factor to obtain the corrected capacity.

Table 3: Correction factors for subcooling ∆t

sub

Dimensioning

To obtain an expansion valve that will function correctly under dierent load conditions it is necessary to consider

the following points when the valve has to be dimensioned.

These points must be dealt with in the following sequence:

1.

Evaporator capacity

2.

Pressure drop across the valve

3.

Correction for subcooling

4.

Correction for evaporating temperature

5.

Determination of valve size

6.

Correctly dimensioned liquid line

Example for a direct expansion system

Evaporator capacity

The evaporator capacity is found in the specications from the evaporator supplier.

Pressure drop across the valve

The pressure drop across the valve directly determines the capacity and must therefore be considered. The pressure

drop across the valve is normally calculated as the condensing pressure minus the evaporating pressure and other

pressure drops in the liquid line, distributor, evaporator, etc. It is indicated in the following formula: ∆pvalve = pc –

(pe + ∆p1 + ∆p3 + ∆p4)

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 6

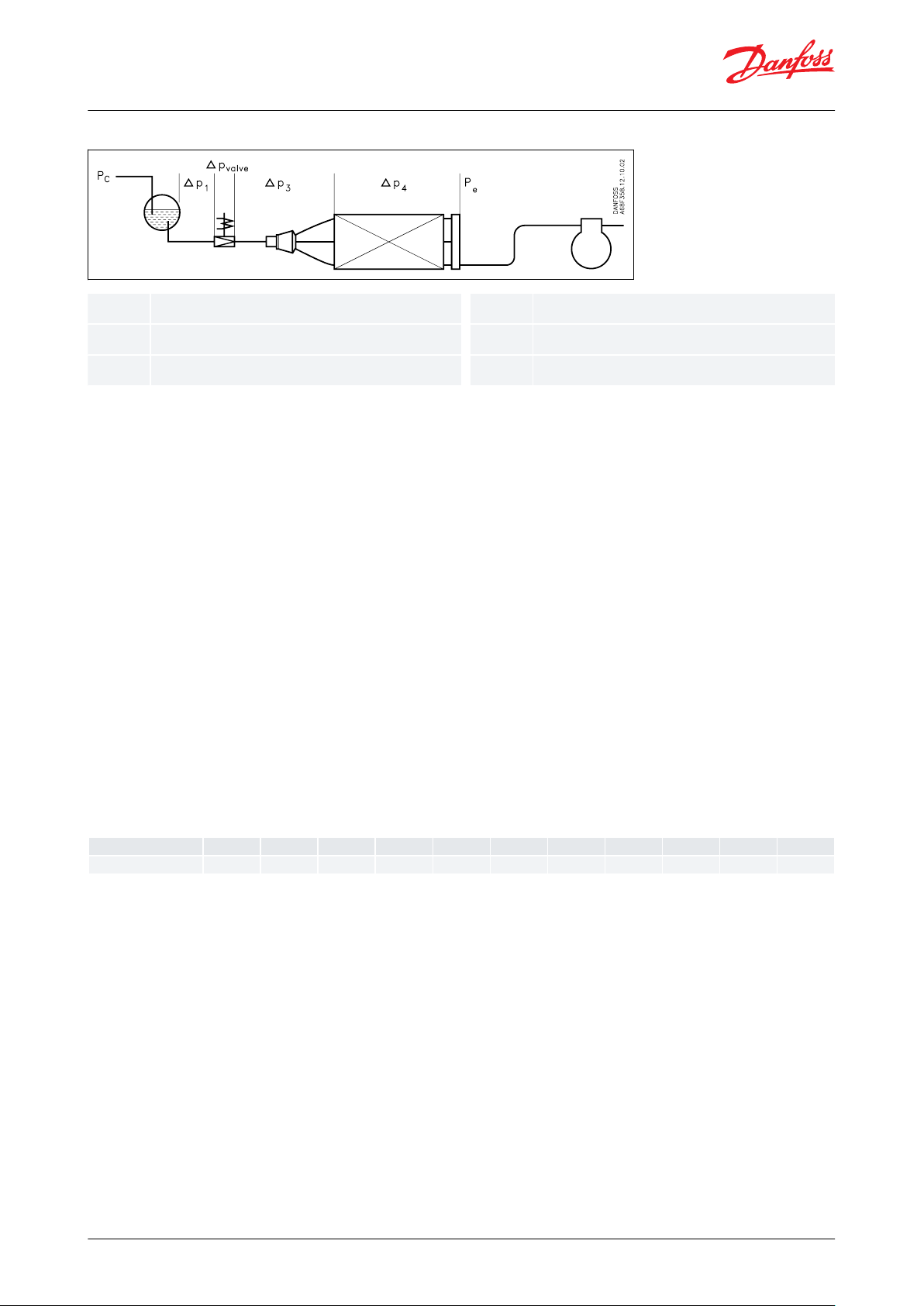

Page 7

∆p

valvepcpe∆p1∆p3∆p4

pressure drop across the valve

condensing pressure

evaporating pressure

pressure drop across the liquid line

pressure drop across the distributor system

pressure drop across the evaporator

Correction factor

2K4K10K

15K

20K

25K

30K

35K

40K

45K

50K

R717

1.01

1.00

0.98

0.96

0.94

0.92

0.91

0.89

0.87

0.86

0.85

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Figure 5: Example of a direct expansion system

NOTE:

The pressure drop across the liquid line and the distributor system must be calculated on the basis of the valve’s

max. capacity, as the valve operates with pulse-width modulation.

Example of calculation of pressure drop across a valve:

• Refrigerant: R 717

• Condensing temperature: 35 °C (pc = 13.5 bar)

• Evaporating temperature: -20 °C (pe = 1.9 bar)

• ∆p1 = 0.2 bar

• ∆p3 = 0.8 bar

• ∆p4 = 0.1 bar

This will give you the following equation:

∆p

= pc – (pe + ∆p1 + ∆p3 + ∆p4)

valve

= 13.5 – (1.9 + 0.2 + 0.8 + 0.1)

= 10.5 bar

The found value for “pressure drop across the valve” is used later in the section “Determination of valve size”.

Correction for subcooling

The evaporator capacity used must be corrected, if the subcooling deviates from 4 K. Use the actual correction

factor indicated in the table. Multiply the evaporator capacity by the correction factor to obtain the corrected

capacity.

Table 4: Correction factors for subcooling ∆t

sub

Corrected capacity = evaporator capacity x correction factor.

The corrected capacity is used in the section “Determination of valve size”.

NOTE:

Too little subcooling may cause ash gas.

Example of correction:

Refrigerant: R 717

Evaporator capacity Qe: 300 kW

Subcooling: 10 K

Correction factor according to the table = 0.98

Corrected evaporator capacity = 300 x 0.98 = 294 kW

Correction for evaporating temperature (te)

To obtain a correctly dimensioned valve it is important that the application is considered. Depending on the

application, the valve should have an overcapacity enabling it to cope with the extra amount of refrigeration

needed during certain periods, e.g. during the defrost recovery process. The valve’s opening degree should

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 7

Page 8

Evaporating temperature te °C

50-10

-15

-20

-30

-40

AKVA 10, AKVA 15, AKVA 20

1.0

1.0

1.0

1.0

1.2

1.3

1.4

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

therefore be between 50 and 75% when regulating. In this way it is ensured that the valve has a suciently wide

regulation range, so that it can manage changed loads at or near the normal working point. Correction factors

based on the evaporating temperature are indicated below:

Table 5: Correction factors for evaporating temperature (te)

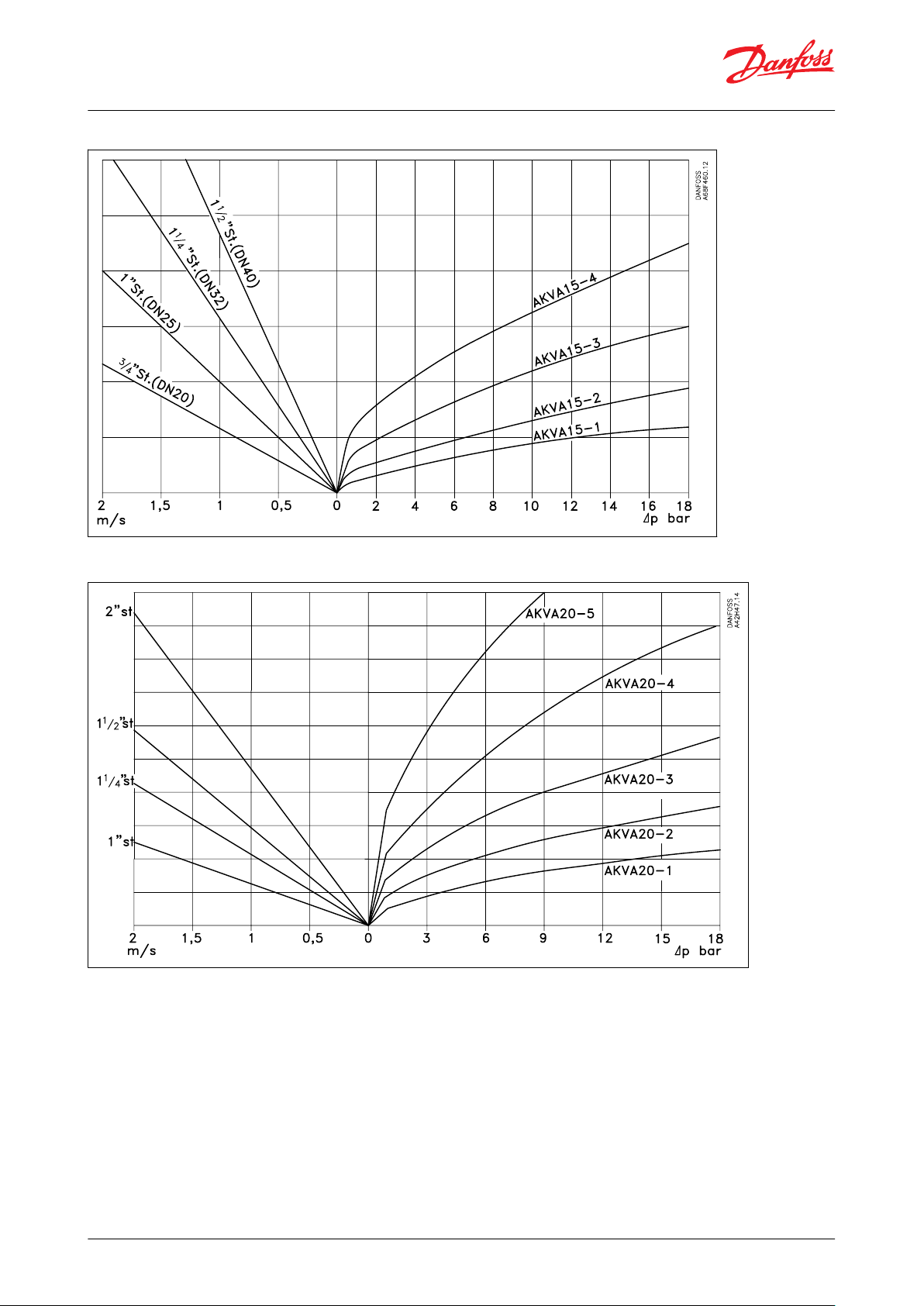

Correctly dimensioned liquid line

To obtain a correct supply of liquid to the AKVA valve, the liquid line to the individual AKVA valve must be correctly

dimensioned. The liquid ow rate must not exceed 1 m/sec at a fully open valve.

This must be observed on account of the pressure drop in the liquid line (lack of subcooling) and pulsations in the

liquid line. Dimensioning of the liquid line must be based on the capacity of the valve at the pressure drop with

which it is operating (cf. capacity table), and not on the evaporator's capacity, see gures below

Figure 6: AKVA-10

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 8

Page 9

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Figure 7: AKVA-15

Figure 8: AKVA-20

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 9

Page 10

Inlet

Outlet

Valve type

ABC

Connection

Weight without

coil

Inlet

Outletmmmmmmin.

in.

kg

AKVA 10

1 – 66060

113

3⁄81

⁄2

0.35

AKVA 10

7 – 86060

113

1⁄23

⁄4

0.35

AKVA 15

AKVA 20

L = 148 mm

Weight without coil = 2.0 kg

Weight without coil = 4.1 kg

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Dimension and weight

Figure 9: Dimension

Table 6: AKVA 10

Table 7: Dimensions

Determination of valve size

When the valve size meeting the required capacity is selected it is important to note that the capacity indications

are the valve’s rated capacity, i.e. when the valve is 100% open. In this section we tell you how the valve’s size is

determined.

There are three factors that have an inuence on the choice of the valve:

• the pressure drop across the valve

• the corrected capacity (correction for subcooling)

• the corrected capacity for evaporating temperature

The three factors have been described earlier in this section on dimensioning.

When these three factors have been established, the selection of the valve can be made:

• First you multiply the “corrected capacity” by a value stated in the table.

• Use the new value in the capacity table in combination with the pressure drop value.

• Now select the valve size.

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 10

Page 11

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Example of selection of valve

Use as starting point the two earlier mentioned examples, where the following two values have been obtained:

∆pvalve = 10.5 bar

Q

e corrected

= 294 kW

From "Table 5: Correction factors for evaporating temperature (te)", factor 1.2 is given for the evaporating

temperature -20 °C.

The dimensioned capacity will then be: 1.2 x 294 kW = 353 kW.

Now select a valve size from table 8 "Rated Capacity".

With the given values ∆p

= 10.5 bar and a capacity of 353 kW, AKVA 15 - 4 is selected.

valve

This valve will have a capacity of approx. 555 kW.

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 11

Page 12

Valve type

Rated capacity

(1)

kv-value

Connections Inlet

x outlet

Code no.

Connections Inlet

x outlet

Code no.

kW

tons

m3/h

in.

in.

AKVA 10-141.1

0.01

3

⁄8 × 1⁄2

068F3261

1

⁄2 × 3⁄4

068F3281

AKVA 10-2

6.3

1.8

0.015

3

⁄8 × 1⁄2

068F3262

1

⁄2 × 3⁄4

068F3282

AKVA 10-3102.8

0.022

3

⁄8 × 1⁄2

068F3263

1

⁄2 × 3⁄4

068F3283

AKVA 10-4164.5

0.038

3

⁄8 × 1⁄2

068F3264

1

⁄2 × 3⁄4

068F3284

AKVA 10-5257.1

0.055

3

⁄8 × 1⁄2

068F3265

1

⁄2 × 3⁄4

068F3285

AKVA 10-64011.4

0.103

3

⁄8 × 1⁄2

068F3266

1

⁄2 × 3⁄4

068F3286

AKVA 10-76317.9

0.162

1

⁄2 × 3⁄4

068F3267

AKVA 10-8

100

28.4

0.251

1

⁄2 × 3⁄4

068F3268

AKVA 15-1

125350.25

Flange

068F5020

(2)

AKVA 15-2

200600.4

Flange

068F5023

(2)

AKVA 15-3

300900.63

Flange

068F5026

(2)

AKVA 15-4

500

1401Flange

068F5029

(2)

AKVA 20-1

500

140

1

1

1

⁄4 × 1 1⁄4

042H2101

AKVA 20-2

800

240

1.6

1

1

⁄4 × 1 1⁄4

042H2102

AKVA 20-3

1250

350

2.5

1

1

⁄4 × 1 1⁄4

042H2103

AKVA 20-4

2000

600

4

1

1

⁄2 × 1 1⁄2

042H2104

AKVA 20-5

3150

900

6.3

2 × 2

042H2105

Valve type

Connection (in.)

Code no.

AKVA 15-1 to 4

3

⁄4

027N1220

1

027N1225

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Ordering

Rated capacity and ordering

Figure 10: Ordering

Table 8: Rated capacity

(1)

(1)

Rated capacities are based on

Rated capacities are based on

Condensing temperature tc = 32 °C

Condensing temperature tc = 32 °C

Liquid temperature tl = 28 °C

Liquid temperature tl = 28 °C

Evaporating temperature te = 5 °C

Evaporating temperature te = 5 °C

(2)

(2)

Incl. bolts and gaskets but without anges

Incl. bolts and gaskets but without anges

Figure 11: Flange

Table 9: Flange set for AKVA 15

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 12

Page 13

Strainer type

Code no.

House

Strainer insert 100 mm

FIA 20 D STR

148B5343

148H3122

FIA 25 D STR

148B5443

148H3123

FIA 32 D STR

148B5544

FIA 40 D STR

148B5625

FIA 50 D STR

148B5713

148H3157

AKVA 20

FIA

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

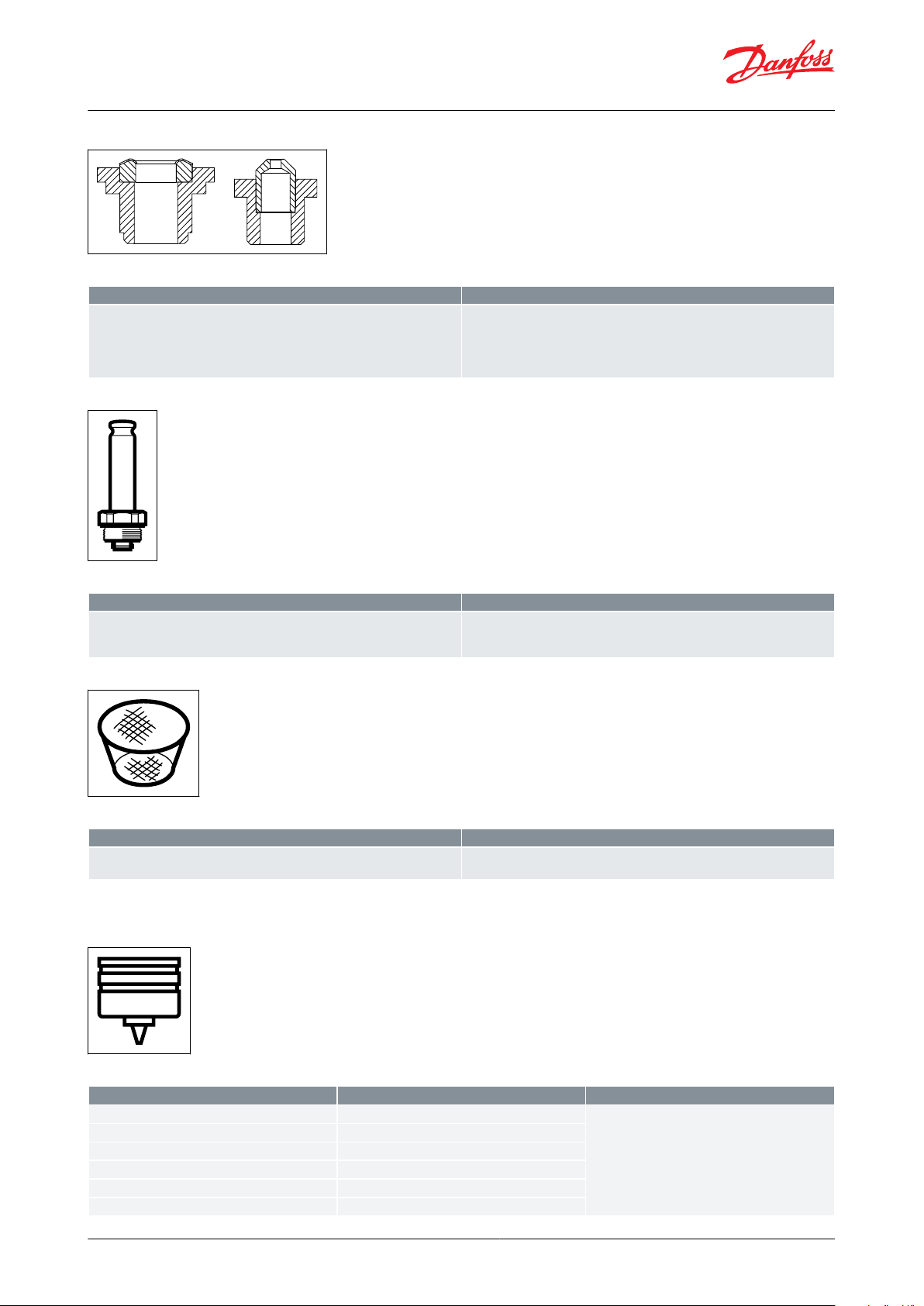

Accessories

Strainer

On plants with ammonia and similar industrial plant a strainer must be mounted in front of AKVA 15 and AKVA 20.

AKVA 10 has built-in strainer and external strainer is not necessary.

Figure 12: Strainer

Table 10: Recommended strainer for AKVA 15 / 20

For further information: see Danfoss catalogue AI222586432958

Figure 13: Example of combinations

Spare parts

AKVA 10

Figure 14: Orice

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 13

Page 14

Type

Code no.

Contents

AKVA 10-1

068F0526

1 pcs. orice

1 pcs. Al. gasket

1 pcs. cap for coil

AKVA 10-2

068F0527

AKVA 10-3

068F0528

AKVA 10-4

068F0529

AKVA 10-5

068F0530

AKVA 10-6

068F0531

AKVA 10-7

068F0532

AKVA 10-8

068F0533

Code no.

Contents

068F0540

10 pcs. lters

10 pcs. Al. gaskets

Code no.

Contents

068F5045

1 pcs. armature

1 pcs. armature tube

1 pcs. Al. gasket

Type

Code no.

Contents

AKVA 15-1

068F5265

1 pcs. piston assembly

1 pcs. gasket

1 pcs. O-ring

2 pcs. labels

AKVA 15-2

068F5266

AKVA 15-3

068F5267

AKVA 15-4

068F5268

Type

Code no.

Contents

Gasket set

068F5264

Complete gasket set

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Table 11: Orice

Figure 15: Filter

Table 12: Filter

Figure 16: Upper part

Table 13: Upper part

AKVA 15

Figure 17: Piston

Table 14: Piston

Table 15: Piston

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 14

Page 15

Code no.

Contents

068F5261

Main orice

Pilot orice

Al gaskets

O-rings

Gasket

Code no.

Contents

068F5045

1 pcs. armature

1 pcs. armature tube

1 pcs. Al. gasket

Code no.

Contents

068F0540

10 pcs. lters

10 pcs. Al. gaskets

Type

Code no.

Contents

AKVA 20-0.6

042H2039

1 pcs. piston assembly

3 pcs. O-rings

AKVA 20-1

042H2040

AKVA 20-2

042H2041

AKVA 20-3

042H2042

AKVA 20-4

042H2043

AKVA 20-5

042H2044

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Figure 18: Orice set

Table 16: Orice set

Figure 19: Upper part

Table 17: Upper part

Figure 20: Filter

Table 18: Filter

AKVA 20

Figure 21: Piston

Table 19: Piston

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 15

Page 16

Type

Code no.

Contents

AKVA 20-0.6

068F5270

Main orice, dia. 8 mm

Pilot orice, dia. 1.8 mm

2 pcs. Al. gaskets

O-ring

AKVA 20-1

068F5270

AKVA 20-2

068F5270

AKVA 20-3

068F5270

AKVA 20-4

068F5271

Main orice, dia. 14 mm

Pilot orice, dia. 2.4 mm

2 pcs. Al. gaskets

O-ring

AKVA 20-5

068F5271

Type

Code no.

Contents

Gasket set

042H0160

Complete gasket set for new and old valves

Code no.

Contents

068F5045

1 pcs. armature

1 pcs. armature tube

1 pcs. Al. gasket

D.C. coils

Code no.

AKVA

AKVA

AKVA

AKVA

AKVA

AKVA

10-1

10-6

10-7

15-1

20-1

20-4

10-2

10-8

15-2

20-2

20-5

10-3

15-3

20-3

10-4

15-4

10-5

220 V DC 20 W, standard

with terminal box

018F6851++++++

100 V DC 18 W, special

with terminal box

with DIN plugs

018F6780++++++

230 V DC 18 W, special

with terminal box

with DIN plugs

018F6781

(1)

+++++

+

018F6991

(1)

230 V DC 18 W, special

with 2.5 m cable

with 4.0 m cable

with 8.0 m cable

018F6288

(1)

+++++

+

018F6278

(1)

018F6279

(1)

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Figure 22: Orice set

Table 20: Orice set

Table 21: Gasket set

Figure 23: Upper part

Table 22: Upper part

Coils for AKVA valves

Table 23: Coils for AKVA valves

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 16

Page 17

A.C. coils

Code no.

AKVA

AKVA

AKVA

AKVA

AKVA

AKVA

10-1

10-6

10-7

15-1

20-1

20-4

10-2

10-8

15-2

20-2

20-5

10-3

15-3

20-3

10-4

15-4

10-5

240 V AC 10 W, 50 Hz with terminal

box with DIN plugs

018F6702

++–+–

–

018F6177

240 V AC 10 W, 60 Hz

with terminal box

with DIN plugs

018F6713++–+––

240 V a.c. 12 W, 50 Hz

with terminal box

018F6802+++++–

220 V AC 10 W, 50 Hz with

terminal box with DIN plugs

018F6701

++–+–

–

018F6176

220 V a.c. 10 W, 60 Hz

with terminal box with DIN plugs

018F6714

++–+–

–

018F6189

220 V AC 12 W, 50 Hz

with terminal box

018F6801++–++–

220 V a.c. 12 W, 60 Hz

with terminal box

018F6814++–++–

115 V AC 10 W, 50 Hz

with terminal box

with DIN plugs

018F6711

++–+–

–

018F6186

115 V AC 10 W, 60 Hz

with terminal box

with DIN plugs

018F6710

++–+–

–

018F6185

110 V a.c. 12 W, 50 Hz

with terminal box

018F6811++–++–

110 V a.c. 12 W, 60 Hz

with terminal box

018F6813++–++–

24 V AC 10 W, 50 Hz

with terminal box

with DIN plugs

018F6707

+––+–

–

018F6182

24 V AC 10 W, 60 Hz

with terminal box

with DIN plugs

018F6715+––+––

24 V AC 12 W, 50 Hz

with terminal box

018F6807+––+++

24 V AC 12 W, 60 Hz

with terminal box

018F6815+––+++

24 V AC 20 W, 50 Hz

with terminal box

018F6901++++++

24 V AC 20 W, 60 Hz

with terminal box

018F6902++++++

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

(1)

(1)

Recommended for commercial refrigeration plant

Recommended for commercial refrigeration plant

Table 24: Coils for AKVA valves

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 17

Page 18

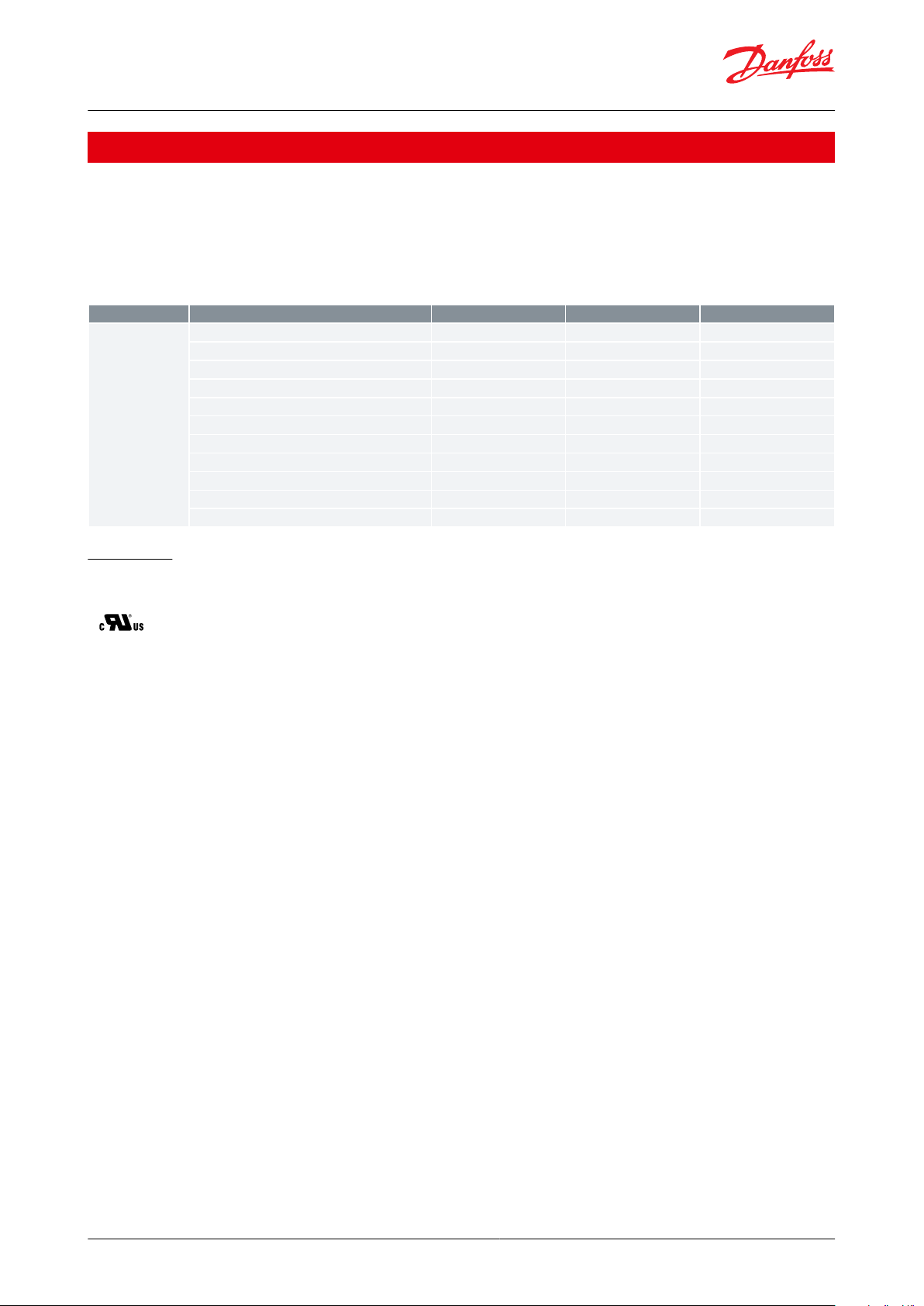

Type

File name

Document type

Document topic

Approval authority

AKVA

MH7648

Electrical - Safety Certicate

UL

MD 033F0686.AH

Manufacturers Declaration

PED

Kolding - Denmark

MD 033F0691.AE

Manufacturers Declaration

RoHS

Kolding - Denmark

RU Д-DK.БЛ08.B.00189_18

EAC Declaration

EMC

Kolding - Denmark

RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

Kolding - Denmark

RU Д-DK.РА01.B.72054_20

EAC Declaration

PED

Kolding - Denmark

033F0474.AC

Manufacturers Declaration

ATEX

Kolding - Denmark

RMRS 19.10034.262

Marine - Safety Certicate

Kolding - Denmark

TSSA CRN 0C22766.5267890YTN

Pressure - Safety Certicate

CRN

Kolding - Denmark

TUV 0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

Kolding - Denmark

UL MH7648

Electrical - Safety Certicate

Kolding - Denmark

Electric expansion valves, Type AKVA 10, AKVA 15 & AKVA 20

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 25: Valid approvals

Approvals

• DEMKO, Denmark SETI, Finland SEV, Switzerland

• AKVA 20 are CE marked according to pressure Equipment Directive 97/23

• UL listed to UB.S.og Canadian standards (separatecode.nos.)

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 18

Page 19

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.05 AI183786440857en-000801 | 19

Loading...

Loading...