Data Sheet

Electric expansion valve

Type AKV 10P and AKV 10PS

For liquid injection into evaporators

AKV 10P and AKV10PS are electric operated

expansion valves designed for refrigeration

plants.

The AKV 10P and AKV 10PS valves are normally

controlled by a controller from Danfoss range

of ADAP- KOOL® controllers, that ensures a

precise liquid injection into evaporators.

The AKV 10P and AKV 10PS valves are supplied

as a part program, as follows:

• Separate valve

• Separate coil with terminal box, DIN plug or

cable

• Spare parts in the form upper part, orice and

lter

The orice and piston assemblies are

replaceable. The AKV 10P and AKV 10PS valves

cover a wide capacity range.

AI274942819146en-000601

Electric expansion valve, type AKV 10P and AKV 10PS

Features

Precise control of liquid injection

• Optimum utilization of the evaporator

• Increased energy eciency and COP

• Improved overall system performance

• Enables energy saving minimum stable superheat and adaptive defrost algorithms due to turbulent ow

• Provides excellent distribution and oil return

• Repetitive operation of the valve at all conditions

Superior valve technology

• Soft pulse operation makes possible to have a low noise valve that guarantees precise ow control and increased

energy eciency of the system

Fully Serviceable valve

• Fast troubleshooting during system diagnostics

• Replaceable lter and orice assembly

• Special Service coil available for installation and servicing

Fast opening/closing within sec.

• Quick reaction to the operating condition.

• Minimizes the risk of liquid refrigerant owing into the compressor at shut down and low pressure cut out at start

up

• Normally closed Solenoid tight shut-o valve

• Prevents migration of the refrigerant during stand-still

• Reduced complexity by reducing number of components in the system

Supports variety of refrigerants with wider regulation range

• Wide application scope

Compact, lightweight design

• Flexible and easy integration in any system

Wider selection range

• Wider range of AC and DC voltage coils

• Coils with various cable lengths

Valve construction

• Internal and external corrosion resistant

Protecting the environment and climate

• Manufactured according to ISO/TS16949

• Second – to – none quality and reliability

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 2

AK-CC 550 case controller

AK-CC 750 case controller

EKC 315A superheat controller

DML/DMSC Eliminator® hermetic l‐

ter drier

Solenoid coil with terminal box

Solenoid coil with DIN spade and pro‐

tection cap

Solenoid coil with cable

Solenoid coil with DIN spade

Junction box NEMA 2

Conduit boss NEMA 4

Electric expansion valve, type AKV 10P and AKV 10PS

Portfolio overview

Related products

Table 1: Related products

Standard coil for AKV 10P/ AKV 10PS

Table 2: Standard coil for AKV 10P/ AKV 10PS

UL coil for AKV 10P / AKV 10PS

Table 3: UL coil for AKV 10P / AKV 10PS

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 3

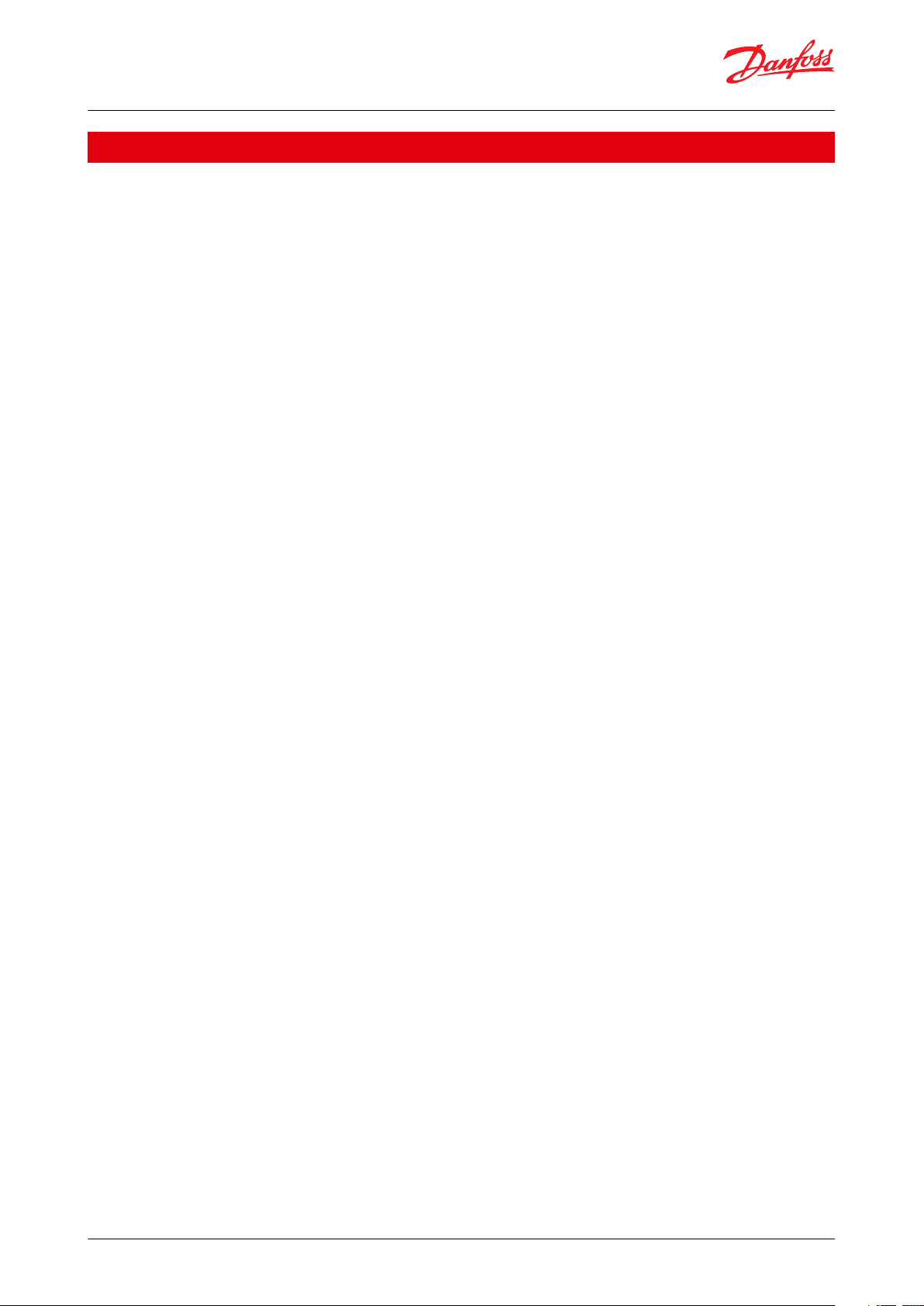

Danfoss

R64-3049.10

1

2

3

4

5

12345

Reveiver

Filter

AKV 10P / AKV 10PS

Evaporator

Max. 1 m/s

Electric expansion valve, type AKV 10P and AKV 10PS

Applications

Typical Application

Figure 1: Application

WARNING:

Filter < 40 micron micro is required for AKV 10 PS recommended lter drier, type DML / DMSC

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 4

Features

Direct operated valve

Servo operated valve

Valve type

AKV 10P0 to AKV 10P8

AKV 10PS4 to AKV 10PS8

Working principle

PWM (Pulse-width modulation)

PWM (Pulse-width modulation)

Recommended period of cycle time

6 Seconds

6 Seconds

Regulation range (Capacity range)

10 – 100%

10 – 100%

Connection type

Solder

Solder

Evaporating temperature (on outlet side of valve)

-60 – 60 °C / -76 – 140 °F

-60 – 60 °C / -76 – 140 °F

Ambient temperature (coil dependent)

-50 – 80 °C / -58 – 176 °F

-50 – 80 °C / -58 – 176 °F

Max. OPD

35 bar / 508 psig (AKV 10P0 to AKV 10P6)

35 bar / 508 psig

Max. OPD

18 bar / 261 psi (AKV 10P7 to AKV 10P8)

N/A

Min. OPD

0 bar / 0 psi

0.1 bar / 1.45 psi

Filter, replaceable

Internal 100 μm

Internal 53 μm

Max. working pressure

90 barg / 1305 psig

90 barg / 1305 psig

MAP (Max. Abnormal Pressure) 1305 psig

1305 psig

1305 psig

COT (Continuous Operation Temperature)

140 °F

140 °F

Recommended Danfoss

lter

N/A

ELIMINATOR® Hermetic

lter drier, type DML / DMSC

features

values

Design

In accordance with IEC 60335

Power supply

Alternating current (AC) and direct current (DC)

Permissible voltage variation

Alternating current (AC):

50 Hz and 60 Hz: -10% – 15%

50/60 Hz: ± 10%

Direct current (DC): +/- 10%

Electric expansion valve, type AKV 10P and AKV 10PS

Product specication

Technical data

Refrigerant

R1233zd, R1234yf, R1234ze, R1270, R134a, R22, R23, R290, R32, R404A, R407A, R407C, R407F, R407H, R410A, R422B,

R422D, R438A, R444B, R448A, R449A, R449B, R450A, R452A, R452B, R454A, R454B, R454C, R455A, R463A, R469A,

R507, R513A, R513B, R515A, R515B, R516A, R600, R600a, R744.

WARNING:

Safety notes for ammable refrigerants (R454C, R454A, R1234ze, R1270, R290, R32, R444B, R452B, R454B,

R600, R600a, R455A, R516A, R1234yf):

• This product is validated in accordance to ATEX, EN 378, ISO 5149, ASHRAE 15, IEC 60335-2-x or equivalent

standards.

• Ignition risk is evaluated in accordance to ISO 5149 and IEC 60335.

• See safety note below.

WARNING:

Safety notes:

• The product can be applied on systems with R454C, R454A, R1234ze, R1270, R290, R32, R444B, R452B, R454B,

R600, R600a, R455A, R516A, R1234yf as the working uid.

• For countries where safety standards are not an indispensable part of the safety system Danfoss recommend the

installer to get a third party approval of the system containing ammable refrigerant.

• Note, please follow specic selection criteria stated in the datasheet for these particular refrigerants.

• The valve must only be used in closed circuit refrigeration system, where no oxygen is present acc. EN 378, ISO

5149 ASHRAE 15 or IEC 60335-2-x or equivalent standards.

WARNING:

It is recommended to selected Servo operated AKV 10PS valves for those application where higher MOPD (with low

coil power) and high dampening is required.

Technical data - Standard coils for AKV 10P / AKV 10PS

Table 4: Technical data

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 5

features

values

Insulation of coil wire

Class H according to IEC 85

Connection

Terminal box, DIN spade or cable

Enclosure, IEC 60529

IP20, IP65 or IP67

Ambient temperature

-40 °C – 80 °C / -40 °F – 176 °F (coil dependent)

features

values

Design

In accordance with UL 429

Power supply

Alternating current (AC)

Permissible voltage variation

Alternating current (AC):

50 Hz and 60 Hz: -10% – 15%

50/60 Hz: ± 10%

Insulation of coil wire

Class H according to IEC 85

Connection

Junction box or Conduit boss

Enclosure, IEC 60529

Junction box NEMA 2 ~ IP 12–32

Conduit boss NEMA 4 ~ IP 54

Ambient temperature

-40 °C – 50 °C / -40 °F – 122 °F

Electric expansion valve, type AKV 10P and AKV 10PS

WARNING:

Safety notes for ammable refrigerants (R454C, R454A, R1234ze, R1270, R290, R32, R444B, R452B, R454B, R600,

R600a, R455A, R516A, R1234yf):

1.

The products (only refer to IP65/67 coils) are validated in accordance to ISO 5149, IEC 60335 (ref. IEC/EN

60079-15). Ignition risk is evaluated in accordance to ISO 5149 and IEC 60335 (ref. IEC/EN 60079-15). See safety

note below.

2.

Please make sure that there is no spark, arc during the application, especially the connection of coils.

3.

Follow the instruction to mount the coil correctly and apply the O-ring for sealing, to prevent the moisture

penetrate inside the coils.

4.

Always install a fuse ahead of the coil to avoid short circuit (fuse size should be around 2 times of rated current,

and time lag: medium);

5.

The coil used in an area of not more than pollution degree 2.

WARNING:

Safety notes:

1.

The product (only refer to IP65/67 coils) can be applied on systems with R454C, R454A, R1234ze, R1270, R290,

R32, R444B, R452B, R454B, R600, R600a, R455A, R516A, R1234yf as the working uid.

2.

For countries where safety standards are not an indispensable part of the safety system Danfoss recommend the

installer to get a third party approval of the system containing ammable refrigerant.

3.

Note, please follow specic selection criteria stated in the datasheet for these particular refrigerants.

4.

Note that the product (only refer to IP65/67 coils) has NOT been veried ATEX or IECEx or IEC 60079 series zone 2

compliant. This product is only validated for systems in compliance with ISO5149, IEC 60335 (ref. IEC/EN

60079-15). It is the responsibility of the user to verify such compliance. Improper use can cause explosion, re,

leakage potentially causing death, personal injury, or damage to property.

Technical data - UL coil for AKV 10P/AKV 10PS

Table 5: Technical data

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 6

ABCDE

F

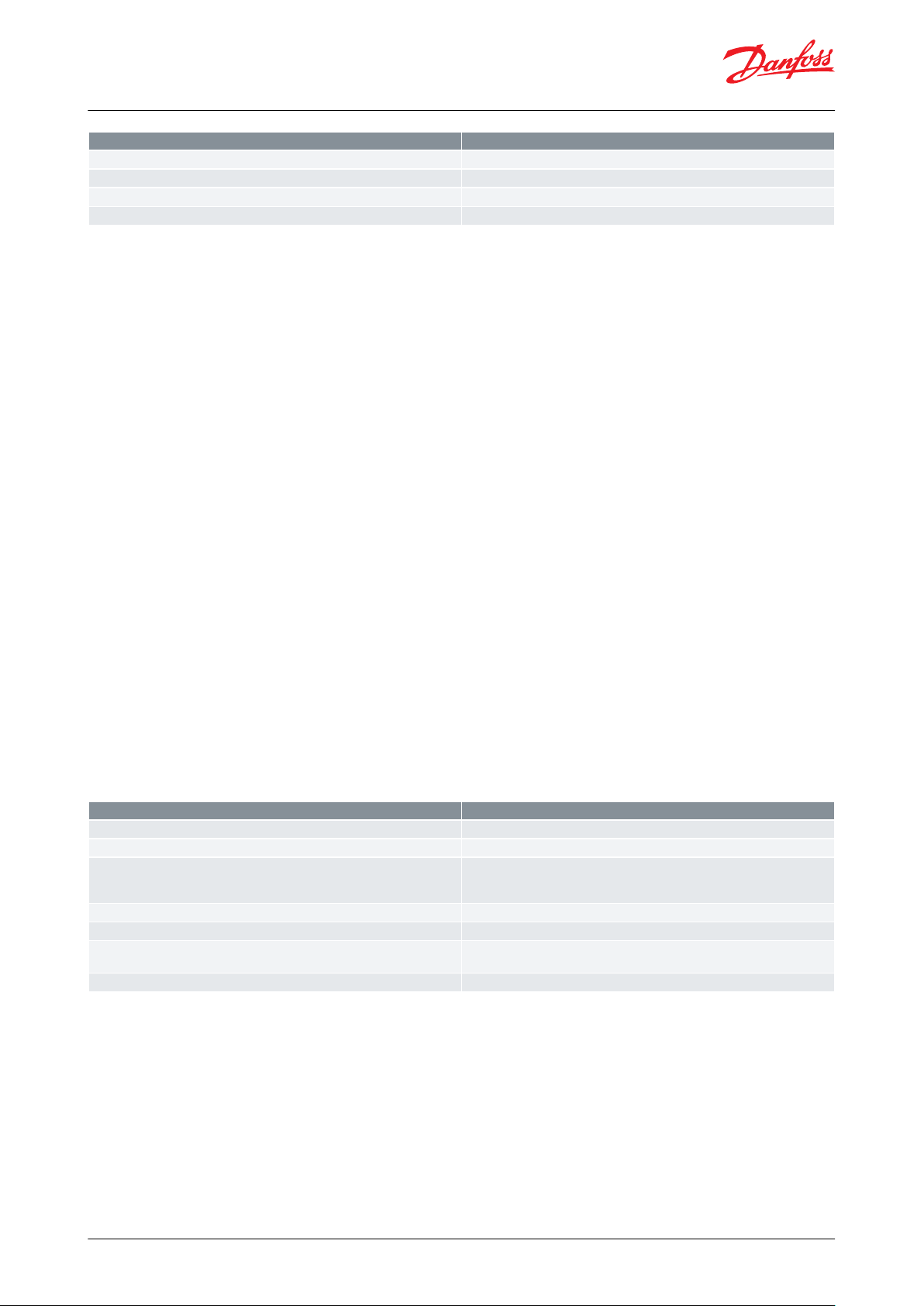

Direct operated valve AKV 10P0 - AKV 10P8

Servo operated valve AKV 10PS4 - AKV 10PS8

A

B

C

D

E

F

A

B

C

D

E

F

Company logo

Type designation (0 = orice size)

Code

Max. working pressure

Media temperature

Manufacturer address

Valve

type /

orice

no.

R744

(2)

R407A / R507

(1)

R404A

(1)

k

V

value

C

V

value

(3)

Connection size

Solder ODF/ODF

Code no.

Single

pack

Code no.

Industri‐

al pack

16 pcs.

pr. Pack

Refrig.

Freezing

Refrig.

Freezing

[kW]

[kW]

[TR]

[TR]

[kW]

[TR]

[kW]

[TR]

[m

3

/h]

[gpm]

[in]

[mm]

AKV 10P0

0.40

0.63

0.11

0.18

0.31

0.09

0.22

0.06

0.003

0.0035

3/8 × 1/2

–

068F5210

068F5230

AKV 10P0

0.40

0.63

0.11

0.18

0.31

0.09

0.22

0.06

0.003

0.0035

–

10 × 12

068F5200

068F5220

AKV 10P1

1.17

1.84

0.33

0.52

0.9

0.26

0.64

0.18

0.009

0.0104

3/8 × 1/2

–

068F5211

068F5231

AKV 10P1

1.17

1.84

0.33

0.52

0.9

0.26

0.64

0.18

0.009

0.0104

–

10 × 12

068F5201

068F5221

AKV 10P2

2.06

3.25

0.58

0.92

1.58

0.45

1.12

0.32

0.016

0.021

3/8 × 1/2

–

068F5212

068F5232

AKV 10P2

2.06

3.25

0.58

0.92

1.58

0.45

1.12

0.32

0.016

0.021–10 × 12

068F5202

068F5222

AKV 10P3

3.14

4.97

0.89

1.41

2.41

0.69

1.72

0.49

0.024

0.028

3/8 × 1/2

–

068F5213

068F5233

AKV 10P3

3.14

4.97

0.89

1.41

2.41

0.69

1.72

0.49

0.024

0.028–10 × 12

068F5203

068F5223

AKV 10P4

6.10

9.64

1.74

2.74

4.68

1.33

3.33

0.95

0.046

0.053

3/8 × 1/2

–

068F5214

068F5234

AKV 10P4

6.10

9.64

1.74

2.74

4.68

1.33

3.33

0.95

0.046

0.053–10 × 12

068F5204

068F5224

AKV 10P5

8.49

13.41

2.41

3.81

6.52

1.86

4.64

1.32

0.064

0.074

3/8 × 1/2

–

068F5215

068F5235

AKV 10P5

8.49

13.41

2.41

3.81

6.52

1.86

4.64

1.32

0.064

0.074–10 × 12

068F5205

068F5225

AKV 10P6

15.14

23.90

4.30

6.80

11.60

3.30

8.27

2.35

0.114

0.132

3/8 × 1/2

–

068F5216

068F5236

AKV 10P6

15.14

23.90

4.30

6.80

11.60

3.30

8.27

2.35

0.114

0.132–10 × 12

068F5206

068F5226

AKV 10P7

24.58

38.80

6.99

11.03

18.81

5.35

13.40

3.82

0.185

0.214

1/2 × 5/8

–

068F5217

–

AKV 10P7

24.58

38.80

6.99

11.03

18.81

5.35

13.40

3.82

0.185

0.214–12 x 16

068F5207

–

AKV 10P8

33.26

52.43

9.46

14.91

25.40

7.23

18.10

5.16

0.250

0.289

1/2 × 5/8

–

068F5218

–

AKV 10P8

33.26

52.43

9.46

14.91

25.40

7.23

18.10

5.16

0.250

0.289–12 x 16

068F5208

–

Electric expansion valve, type AKV 10P and AKV 10PS

Valve identication (Examples of labels)

Table 6: Valve identication

Capacity

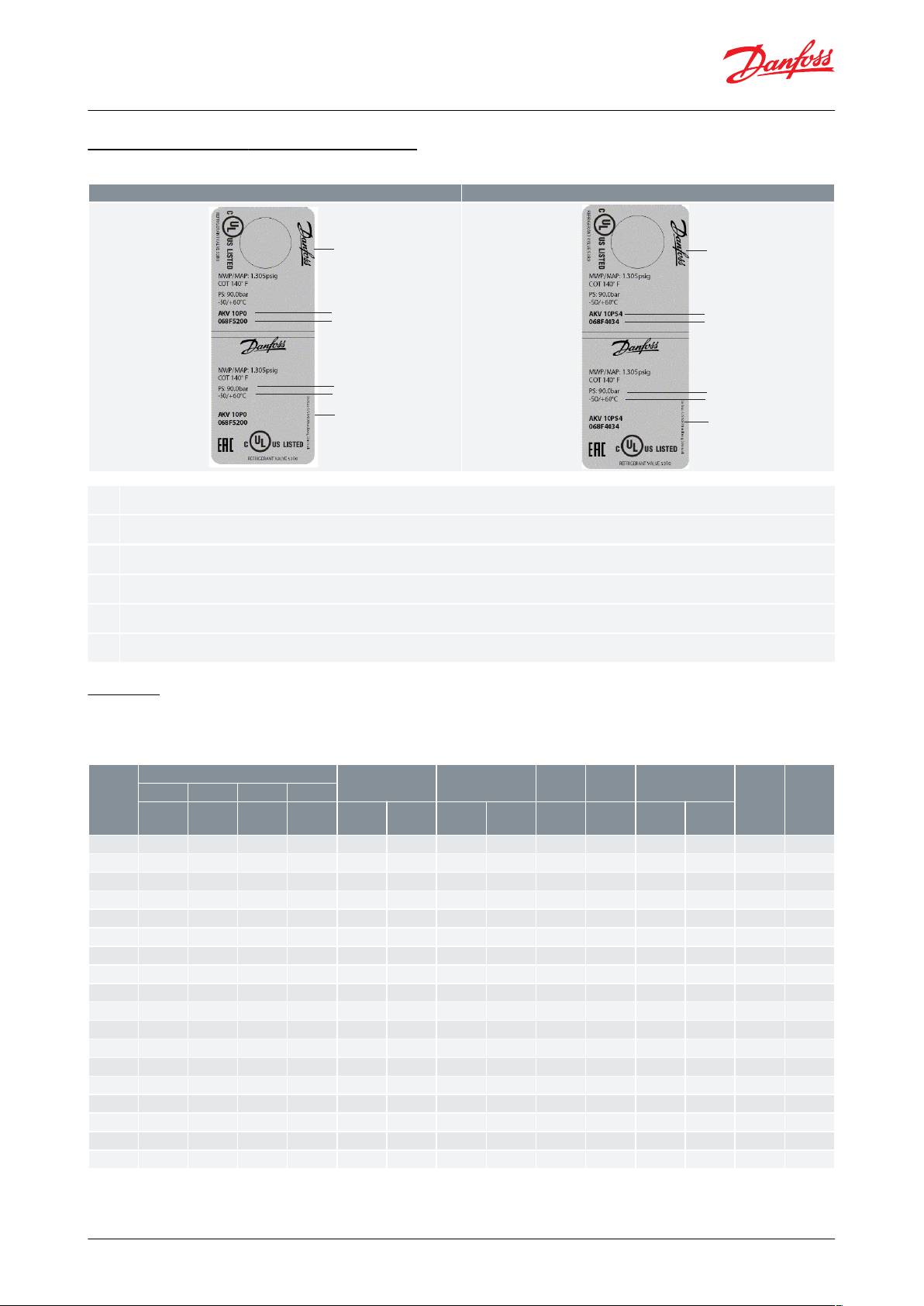

Direct operated valve AKV 10P - Rated capacity

Table 7: Direct operated valve AKV 10P

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 7

Valve type /

orice no.

R744

(2)

R407A

(1)

R404A/ R507

(1)

kV val‐ueCV val‐

ue

(3)

Connection size Sol‐

der ODF/ODF

Code no.

Single pack

Code no. In‐

dustrial

pack 16 pcs.

pr. Pack

Refrig.

Freez‐

ing

Refrig.

Freez‐

ing

[kW]

[kW]

[TR]

[TR]

[kW]

[TR]

[kW]

[TR]

[m3/h]

[gpm]

[in]

[mm]

AKV 10PS4

6.10

9.64

1.74

2.74

4.68

1.33

3.33

0.95

0.046

0.053

3/8 × 1/2

–

068F4044

068F5184

AKV 10PS4

6.10

9.64

1.74

2.74

4.68

1.34

3.33

0.88

0.046

0.053–10 × 12

068F4034

068F5174

AKV 10PS5

8.49

13.41

2.41

3.81

6.52

1.86

4.64

1.32

0.064

0.074

3/8 × 1/2

–

068F4045

068F5185

AKV 10PS5

8.49

13.41

2.41

3.81

6.52

1.86

4.64

1.32

0.064

0.074–10 × 12

068F4035

068F5175

AKV 10PS6

15.14

23.90

4.30

6.80

11.60

3.30

8.27

2.35

0.114

0.132

3/8 × 1/2

–

068F4046

068F5186

AKV 10PS6

15.14

23.90

4.30

6.80

11.60

3.30

8.27

2.35

0.114

0.132–10 × 12

068F4036

068F5176

AKV 10PS7

24.58

38.80

6.99

11.03

18.81

5.35

13.40

3.82

0.185

0.214

1/2 × 5/8

–

068F4047

–

AKV 10PS7

24.58

38.80

6.99

11.03

18.81

5.35

13.40

3.82

0.185

0.214–12 × 16

068F4037

–

AKV 10PS8

33.26

52.43

9.46

14.91

25.40

7.23

18.10

5.16

0.250

0.289

1/2 × 5/8

–

068F4048

–

AKV 10PS8

33.26

52.43

9.46

14.91

25.40

7.23

18.10

5.16

0.250

0.289–12 × 16

068F4039

–

A

B

Electric expansion valve, type AKV 10P and AKV 10PS

(1)

(1)

Rated capacities are based on:

Rated capacities are based on:

Condensing temperature tc = 38 °C / 100 °F

Condensing temperature tc = 38 °C / 100 °F

Liquid temperature tl = 37 °C / 98 °F

Liquid temperature tl = 37 °C / 98 °F

Evaporating temperature te = 4 °C / 39 °F

Evaporating temperature te = 4 °C / 39 °F

(2)

(2)

Rated capacities are based on:

Rated capacities are based on:

Condensing temperature tc = 0 °C / 32 °F

Condensing temperature tc = 0 °C / 32 °F

Evaporating temperature Refrig. te = -10 °C / 14 °F

Evaporating temperature Refrig. te = -10 °C / 14 °F

Evaporating temperature Freezing. te = -30 °C / -22 °F

Evaporating temperature Freezing. te = -30 °C / -22 °F

Subcooling = 1°C / 1.8 °F

Subcooling = 1°C / 1.8 °F

(3)

(3)

Cv value is calculated from Kv value in above table

Cv value is calculated from Kv value in above table

Servo operated valve AKV 10PS - Rated capacity

Table 8: Servo operated valve AKV 10PS

(1)

(1)

Rated capacities are based on:

Rated capacities are based on:

Condensing temperature tc = 38 °C / 100 °F

Condensing temperature tc = 38 °C / 100 °F

Liquid temperature tl = 37 °C / 98 °F

Liquid temperature tl = 37 °C / 98 °F

Evaporating temperature te = 4 °C / 39 °F

Evaporating temperature te = 4 °C / 39 °F

(2)

(2)

Rated capacities are based on:

Rated capacities are based on:

Condensing temperature tc = 0 °C / 32 °F

Condensing temperature tc = 0 °C / 32 °F

Evaporating temperature Refrig. te = -10 °C / 14 °F

Evaporating temperature Refrig. te = -10 °C / 14 °F

Evaporating temperature Freezing. te = -30 °C / -22 °F

Evaporating temperature Freezing. te = -30 °C / -22 °F

Subcooling = 1°C / 1.8 °F

Subcooling = 1°C / 1.8 °F

(3)

(3)

Cv value is calculated from Kv value in above table

Cv value is calculated from Kv value in above table

Flow direction

AKV 10P/10PS is designed for single ow direction and following pictures from A to B refers the normal ow.

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 8

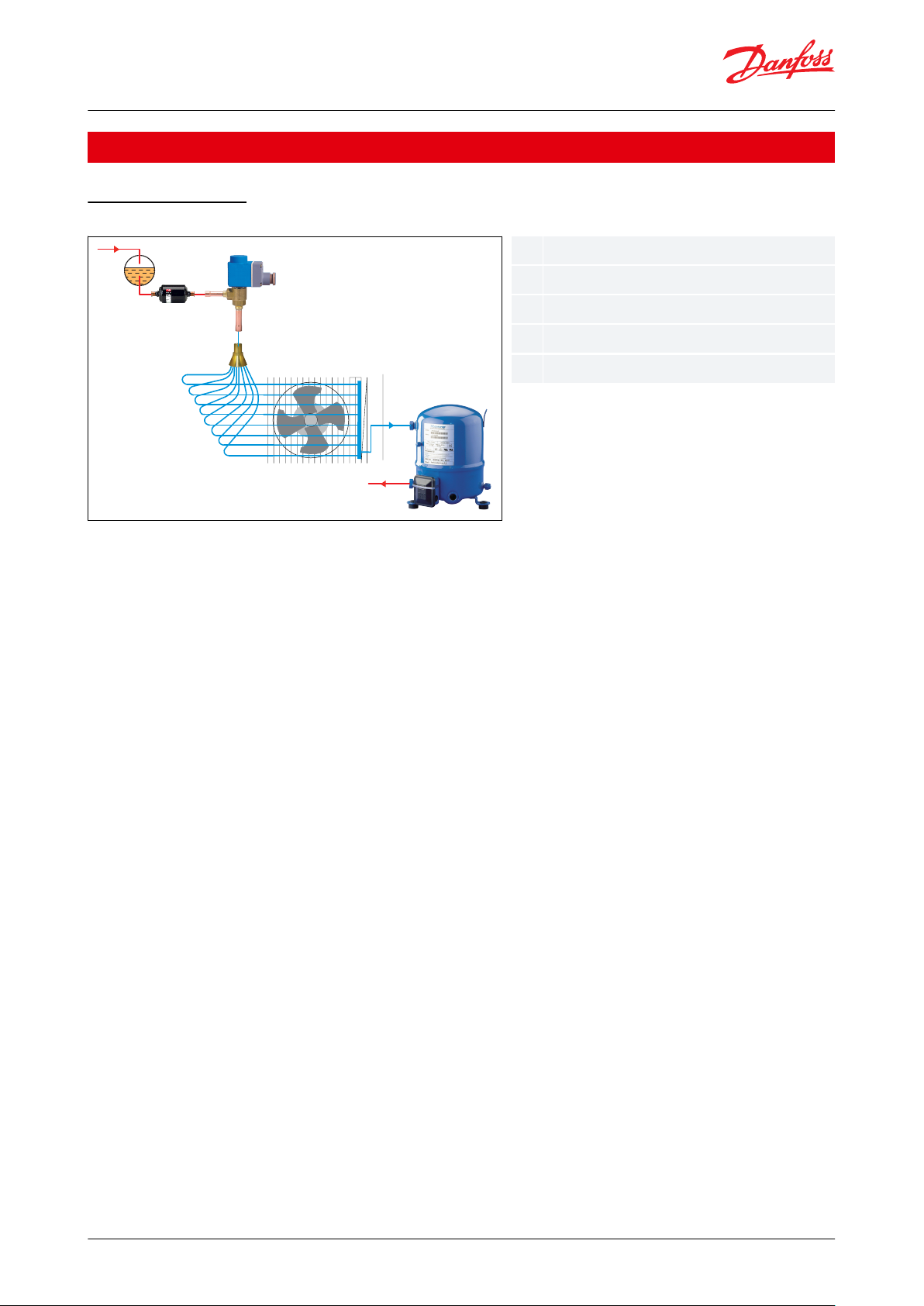

123456789

F6032

Type BE230CS

018F6193

-40T50 ˚C

220-230V 60Hz 14W 24VA

220-230V 50Hz 17W 31VA

MADE IN DENMAR

K

Danfoss A/S, 6430 No

rdborg, Denmark

Spare part no.

Ta

mbient

1

5

6

7

8

9

2

4

3

Type designation

Code no.

Voltage, frequency,Power consumption

Approvals

Company logo

Country of Origin

Ambient temperature

Production date

Manufacturer address

12345

6

MADE IN DENMARK

Type BJ024CS

018F4100Spare part no.

24V

24V

To be u se d wi t h l is t ed va l ve bo dy

E V R- E V R H -E V R C -E V R P -E V 2 x x s e r i es

AKV-AKVA

Se e ar ma tur e tu be or lab el

60Hz

50Hz

14W

14W

1

4

5

6

2

3

Type designation

Code no.

Voltage, frequency, Power consumption

Company logo

Country of Origin

Approvals

Electric expansion valve, type AKV 10P and AKV 10PS

Coil Identication

Figure 2: Standard Coil

Figure 3: UL Coil

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 9

123

45678

AKV 10P0 – AKV 10P8

AKV 10PS4 – AKV 10PS8

4

3

1

5

7

2

4

3

1

5

8

2

6

Inlet (connection)

Outlet (connection)

Copper gasket

Amature

Protection lter 100 micron (AKV 10P) and 53 mi-

cron (AKV 10PS)

Piston

Orice ( AKV 10P)

Orice (AKV 10PS)

Electric expansion valve, type AKV 10P and AKV 10PS

Design

Table 9: Design

Material

1.

Copper

2.

Copper

3.

Cu/Tn

4.

Stainless steel

5.

Nylon/stainless steel

6.

Brass

7.

Stainless steel

8.

Stainless steel

The valve capacity is regulated by means of pulse-width modulation. Within a period of six seconds a voltage signal

from the controller will be transmitted to and removed from the valve coil. This makes the valve open and close for

the ow of refrigerant.

The relation between this opening and closing time indicates the actual capacity. If there is an intense need for

refrigeration, the valve will remain open for almost all six seconds of the period. If the required amount of

refrigeration is modest, the valve will only stay open during a fraction of the period.

The amount of refrigeration needed is determined by the controller. When no refrigeration is required, the valve will

remain closed and thus function as a solenoid valve.

AKV 10P0 - AKV 10P8 is a direct operated valve which can operate at 0 bar/0 psi dierential pressure.

AKV 10PS4 - AKV 10PS8 is a servo piston operated valve which needs a minimum dierential pressure of 0.1 bar /

1.45 psi to open the valve and keep it open.

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 10

Danfoss

68Z8088.20

3

/

8

in.

10 mm

1

/2 in.

12 mm

2

5

/8 in.

67 mm

3

12

/

17

in.

94 mm

2

20

/

21

in.

75 mm

1

7

/

8

in.

48 mm

5

/

16

in.

8 mm

3

/8 in.

10 mm

Danfoss

68F627.20

2

20

/

21

in.

75 mm

2

5

/8 in.

67 mm

5

/

16

in.

8 mm

3

/8 in.

10 mm

3

12

/

17

in.

94 mm

2

1

/

4

in.

57 mm

Danfoss

68F631.30

3

/

8

in.

10 mm

1/2 in.

12 mm

2 61/

64

in.

75 mm

3

10

/

16

in.

92 mm

2

7

/

8

in.

73 mm

1

7

/

8

in.

48 mm

3

/

8

in.

10 mm

15

/32 in.

12 mm

Danfoss

68F630.30

2

7

/

8

in.

73 mm

2

61

/64 in.

75 mm

3

/8 in.

10 mm

15

/32 in.

12 mm

3

10

/

16

in.

92 mm

2 1/4 in.

57 mm

Electric expansion valve, type AKV 10P and AKV 10PS

Dimensions and weight

Dimensions and weight AKV 10P valve

Table 10: AKV 10P0 - AKV 10P6 (Weight excluding coil: 0.30 kg / 0.66 lbs)

Table 11: AKV 10P7 - AKV 10P8 (Weight excluding coil: 0.343 Kg / 0.76 lbs)

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 11

Danfoss

68Z829.20

3

/

8

in.

10 mm

1/2 in.

12 mm

2

5

/8 in.

67 mm

3

18

/

20

in.

99 mm

2

20

/

21

in.

75 mm

1

7

/

8

in.

48 mm

5

/

16

in.

8 mm

3

/8 in.

10 mm

Danfoss

68F628.20

2

20

/

21

in.

75 mm

2

5

/8 in.

67 mm

5

/

16

in.

8 mm

3

/8 in.

10 mm

3

18

/

20

in.

99 mm

2

1

/

4

in.

57 mm

Danfoss

68F631.30

3

/

8

in.

10 mm

1/2 in.

12 mm

2 61/

64

in.

75 mm

3

14

/

17

in.

97 mm

2

7

/

8

in.

73 mm

1

7

/

8

in.

48 mm

3

/

8

in.

10 mm

15

/32 in.

12 mm

Danfoss

68F630.30

2

7

/

8

in.

73 mm

2

61

/64 in.

75 mm

3

/8 in.

10 mm

15

/32 in.

12 mm

3

14

/

17

in.

97 mm

2 1/4 in.

57 mm

Electric expansion valve, type AKV 10P and AKV 10PS

Dimensions and weight AKV 10PS valve

Table 12: AKV 10PS4 – AKV 10PS6 (Weight excluding coil: 0.335 Kg / 0.74 lbs)

Table 13: AKV 10PS 7 - AKV 10PS8 (Weight excluding coil: 0.343 Kg / 0.76 lbs)

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 12

Terminal box 10 W

Weight 0.29 Kg / 0.6 lbs

Cable 10 W

Weight 0.29 Kg / 0.6 lbs

94 mm

Danfoss

18F68.10

45 mm

57 mm

47 mm

71 mm

Danfoss

18F69.10

57 mm

45 mm

46 mm

DIN socket 10 W

Weight 0.24 Kg / 0.5 lbs

Terminal box 12 - 20 W

Weight 0.55 Kg / 1.2 lbs

86 mm

Danfoss

18F70.10

51 mm

45 mm

57 mm

47 mm

28 mm

110 mm

Danfoss

16F71.10

45 mm

57 mm

68 mm

Junction box

Weight 0.860 lbs / 0.39 kg

Conduit boss

Weight 0.717 lbs / 0.33 kg

52mm (2 in.)

50mm (2 in.)

100mm (4 in.)

48mm (2 in.)

74mm (3 in.)

41mm (15/8in.)

Electric expansion valve, type AKV 10P and AKV 10PS

Dimension and weight standard coils

Table 14: Dimension and weight standard coils

Dimensions and weight UL coils

Table 15: Dimensions and weight UL coils

Appendix: Dimensioning of the liquid line

Correctly dimensioned liquid line

To obtain a correct supply of liquid to the AKV 10P/PS valve, the liquid line to the individual AKV 10P/PS valve must

be correctly

dimensioned.

The liquid ow rate should not exceed 1 m/s (3 ft/s).

Dimensioning of the liquid line must be based on the capacity of the valve at the pressure drop with which it is

operating and not on the evaporator’s capacity.

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 13

Type

Pipe dimension

Refrigeration

Freezing

AKV 10P0

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P1

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P2

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P3

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P4

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P5

3⁄8 in / 10 mm

1⁄2 in / 12 mm

AKV 10P6

1⁄2 in / 12 mm

5⁄8 in / 15 mm

AKV 10P7

5⁄8 in / 15 mm

3⁄4 in / 18 mm

AKV 10P8

5⁄8 in / 15 mm

3⁄4 in / 18 mm

Type

Pipe dimension

Refrigeration

Freezing

AKV 10P0

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P1

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P2

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P3

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P4

3⁄8 in / 10 mm

3⁄8 in / 10 mm

AKV 10P5

1⁄2 in / 12 mm

1⁄2 in / 12 mm

AKV 10P6

1⁄2 in / 15 mm

1⁄2 in / 15 mm

AKV 10P7

5⁄8 in / 16 mm

5⁄8 in / 16 mm

Symptom

Possible Cause

Remedy

Valve does not open

Lack of proper electrical connection/Power

Check the connection between valve and a controller

Incorrect voltage/frequency

Check coil

specication against measured operating

voltage

Dierential pressure too high/low

Check

dierential pressure of valve against technical

speciifcation

Replace with suitable valve and or coil

Impurities in the valve

Check dirt inside valve and clean out impurities

Burnt out coil

Never take the coil

o the valve if voltage is applied.

The coil can burn out

Check the wiring diagram and wiring itself

Check relay contacts, lead connections and fuses

Valve stuck open after being assembled

Check Instruction if all correct parts are used, and correctly assembled

Valve does not open after

orice has been exchanged

to a larger capacity due to high dierential pressure

Replace with suitable valve and or coil

Internal leakage/ valve does not close or closes partially

Continuous voltage on coil

Do not remove powered coil

o the valve

Impurities in the valve

Check dirt inside valve and clean out impurities

Pulsation in discharge line

Dierential pressure too

high in open position

Check pressure and

ow conditions

Check the supply voltage in the coil

Replace with suitable valve

Electric expansion valve, type AKV 10P and AKV 10PS

Table 16: CO

2

Table 17: R407A

NOTE:

The conditions are the same as for the rated capacities.

Evaporating temperature is -10 °C for refrigeration and -30 °C for freezing.

The super heat is 8 K for both refrigeration and freezing.

Pipes are according ANSI or DIN-EN.

If conditions deviate from above, the pipe dimensions should be checked.

Troubleshooting

Table 18: Troubleshooting

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 14

Symptom

Possible Cause

Remedy

Insucient capacity

Valve capacity too small

Check refrigeration system capacity and compare

with valve capacity

Replace with larger valve if necessary

- larger capacity orice in AKV 10P

- larger capacity piston in AKV 10PS

Suction pressure too low Evaporator superheat too

high

Check superheat performance, the settings SH min

and SH max. in the super heat controller

Check valve capacity

Check coil excitation time

Also check section "High Superheat"

Valve blocked with foreign material

Valve strainer blocked, replace strainer with a new

one

Evaporator fully or partly iced up

Valve blocked with foreign material

Replace valve strainer/lter

Also check ''Insucient capacity''

De-ice evaporator

High superheat

Lack of sub-cooling

Check refrigerant

Also refer to section Insucient capacity

Controller is not setup/tuned properly

Check the controller superheat settings and sensors

connected to it Tune PID parameters in the controller

Flash gas

Lack of sub-cooling ahead of valve

Check refrigerant for ash gas ahead of valve/external

subcooler If the valve is placed much higher than

condenser outlet

Check pressure dierence

Oversized valve selected

Limit max opening degree of the valve setting in controller

Check refrigeration system capacity and compare

with valve capacity

Use proper valve size suitable for the system

Pulsations in liquid line

High ow velocity, max. 1 m/s

Check ow velocity, using coolselector2

Change to AKV 10PS for maximum dampening eect

Use larger diameter pipes to reduce ow velocity

Overheating coil

Armature is not moving when coil is energized

Check section valve does not open

Too high voltage supply, dirt in valve, too high MOPD)

Electric expansion valve, type AKV 10P and AKV 10PS

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 15

Multi-

pack code

no.

Identical Industrial

pack code no.

Identical

spare part

coil with

DIN spade

Supply voltage/

power/frequen‐

cy

Connection type/ en‐

closure rating

MOPD of individual coil (bar)

AKV 10P

AKV 10PS

Orice size

Orice

size

Code no.

Pcs. per

pack

0 to 34567 to 8

PS4 to

PS8

DC coils - with/without terminal box

018F6780---100 V DC 18 W

With terminal box, IP

67

332235351829018F6860---110V DC 16 W

With terminal box, IP

67

353235351835018F6851---220V DC 20 W

With terminal box, IP

67

353435351835018F6781

018F8781

25

018F6991

230 V DC 18 W

With terminal box, IP

67

2616353518

22

AC coils - with cable

018F4961

018F8291

6

Not rele-

vant

230 V AC 16 W,

50 Hz

With 8 m cable, IP 67

352525251435018F6264--

Not rele-

vant

220 V AC 14 W,

60 Hz

With 1 m cable, IP 67

25

N/A18N/A

N/A25018F6282

018F8232

24

Not rele-

vant

220-230 V AC 16

W, 50 Hz

With 1 m cable, IP 67

352525251435-

018F8290

12

Not rele-

vant

220-230 V AC 17

W, 50 Hz

With 3 m cable, IP 67

3525252514

35

AC coils - with/without terminal box

018F6807--

-

24 V AC 11 W, 50

Hz

With terminal box, IP

67

22141913922018F6904--

-

24 V AC 24 W, 50

Hz

With terminal box, IP

67

353535301835018F6815--

-

24 V AC 15 W, 60

Hz

With terminal box, IP

67

261622151024018F6906

018F890624-

24 V AC 22 W, 60

Hz

With terminal box, IP

67

352634221535018F6813--

-

110 V AC 16 W,

60 Hz

With terminal box, IP

67

351830181435018F6701

018F8701

50

018F6176

230 V AC 12 W,

50 Hz

With terminal box, IP

67

25

N/A18N/A

N/A25018F6801

018F880124-

220 V AC 15 W,

50 Hz

With terminal box, IP

67

352525

N/A

N/A25018F6732

018F8732

50

018F6193

230 V AC 17 W,

50 Hz

With terminal box, IP

67

352525251435018F6905--

-

230 V AC 19 W,

50 Hz

With terminal box, IP

67

353535301835018F6713--

-

240 V AC 15 W,

60 Hz

With terminal box, IP

67

25182518N/A30018F6814--

-

230 V AC 16 W,

60 Hz

With terminal box, IP

67

3525351814

35

Electric expansion valve, type AKV 10P and AKV 10PS

Ordering

Standard global coils

Table 19: Standard global coils

WARNING:

1.

N/A: Coil is not suitble due to too low MOPD.

2.

Multi-pack and spare part coil code nos. can be ordered as single parts.

3.

MOPD table is based on:

◦ Nominal voltage

◦ Max media temperature 60 °C (140 °F)

◦ Max ambient temperature 50 °C (122 °F)

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 16

Multi-pack

code no.

Supply voltage/ power/

frequency

Wire length

MOPD of individual coil (bar)

AKV 10P

AKV 10PS

Orice size

Orice size

(in)

(cm)

0 to 34567 to 8

PS4 to PS8

018F4100

24 V AC 14 W, 60 Hz

71825182514N/A2524 V AC 14 W, 50 Hz

7183525352518

35

018F4110

110 V AC 16 W, 60 Hz

71825182518N/A30110 V AC 16 W, 50 Hz

718353035251835120 V AC 15 W, 60 Hz

7183518351814

35

018F4120

208 V AC 14 W, 60 Hz

71818141814N/A25240 V AC 14 W, 60 Hz

718352535181435230 V AC 17 W, 50 Hz

718353035301835018F4130

120 V AC 16 W, 60 Hz

718353035251435018F4132

208 V AC 16 W, 60 Hz

718353035251435018F4134

240 V AC 16 W, 60 Hz

7183530352514

35

Multi-pack

code no.

Supply voltage/ power/

frequency

Wire length

MOPD of individual coil (bar)

AKV 10P

AKV 10PS

Orice size

Orice size

(in)

(cm)

0 to 34567 to 8

PS4 to PS7

018F4102

24 V AC 14 W, 60 Hz

184625182514N/A2524 V AC 14 W, 50 Hz

18463525352518

35

018F4103

24 V AC 14 W, 60 Hz

71

18025182514

N/A2524 V AC 14 W, 50 Hz

71

180352535251835

018F4104

24 V AC 14 W, 60 Hz

98

25025182514

N/A2524 V AC 14 W, 50 Hz

98

250352535251835

018F4112

110 V AC 16 W, 60 Hz

184625182518N/A30110 V AC 16 W, 50 Hz

1846353035251835120 V AC 15 W, 60 Hz

18463518351814

35

018F4113

110 V AC 16 W, 60 Hz

369125182518N/A30110 V AC 16 W, 50 Hz

3691353035251835120 V AC 15 W, 60 Hz

36913518351814

35

018F4114

110 V AC 16 W, 60 Hz

71

18025182518

N/A30110 V AC 16 W, 50 Hz

71

180353035251835

120 V AC 15 W, 60 Hz

71

180351835181435

018F4115

110 V AC 16 W, 60 Hz

98

25025182518

N/A30110 V AC 16 W, 50 Hz

98

250353035251835

120 V AC 15 W, 60 Hz

98

250351835181435

018F4122

208 V AC 14 W, 60 Hz

184618141814N/A25240 V AC 14 W, 60 Hz

1846352535181435230 V AC 17 W, 50 Hz

18463530353018

35

018F4123

208 V AC 14 W, 60 Hz

98

25018141814

N/A25240 V AC 14 W, 60 Hz

98

250352535181435

230 V AC 17 W, 50 Hz

98

250353035301835

018F4131

120 V AC 16 W, 60 Hz

98

250353035251435

018F4133

208 V AC 16 W, 60 Hz

98

250353035251435

018F4135

240 V AC 16 W, 60 Hz

98

250353035251435

Electric expansion valve, type AKV 10P and AKV 10PS

BJ and BX Coils (UL coils)

Table 20: AC coils - Junction box NEMA 2 (type BJ)

Table 21: AC coils - Conduit boss NEMA 4 (type BX)

WARNING:

1.

2.

3.

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 17

N/A: Coil is not suitble due to too low MOPD.

Multi-pack coil code nos. can be ordered as single parts.

MOPD table is based on:

◦ Nominal voltage

◦ Max media temperature 60 °C (140 °F)

◦ Max ambient temperature 50 °C (122 °F)

Dan

f

oss

68F636.1

0 1 2

3

4 5 6

7 8

Danfoss

68F636.1

Danfoss

68F642.20

4

5 6

7

8

4

5 6

7

8

AKV 10P0 – AKV 10P3

Orice kit 1

AKV 10P4 – AKV 10P8

Orice kit 2

AKV 10P0– AKV 10P8

Armature kit 3*

AKV 10P0 - AKV 10P8

Filter kit 4

Code no. 068F5151

Code no. 068F5152

Code no. 068F5153

Code no. 068F5154

Dan

f

oss

68F636.1

0 1 2

3

4 5 6

7 8

Danfoss

68F636.1

1 X

10 X

10 X

Danfoss

68Z8101

AKV 10PS4 - AKV 10PS8

Orice kit 5

AKV 10PS4 - AKV 10PS8

Filter Kit 6

AKV 10PS4 - AKV 10PS8

Armature kit 7*

Code no. 068F5155

Code no. 068F5156

Code no. 068F5161

Electric expansion valve, type AKV 10P and AKV 10PS

Spareparts

For Direct operated AKV 10P

*Retrot kit for converting

AKV 10-1 - AKV 10-7 and

AKVH 10-0 - AKVH 10-6 to

AKV 10P0 - AKV 10P8

For servo operated AKV 10PS

Retrot kit for converting

AKV 10-1 -AKV 10-7 and

AKVH 10-0 - AKVH 10-6 to

AKV 10PS4 - AKV 10PS8

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 18

Type

Voltage

Frequency

Quantity

Code no. Multi pack

[V]

[Hz]

[Pcs]

DIN plug

Max. 250

50 / 60

100

042N0156

Product

Description

Code no.

Solenoid valve Tester

Permanent magnet for AKV 10P and AKV 10PS (for in-

stallation and testing purpose)

018F0091

Electric expansion valve, type AKV 10P and AKV 10PS

Accessories

Figure 4: Plug for DIN

spade connection

Single pack = 1 product in a box with installation guide

Multi pack = box with x pieces single pack (can be split)

Industrial pack = x pieces in one box (cannot be split)

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 19

File name

Document type

Document topic

Approval_authority

033F1035.AJ

Manufacturers Declaration

PED

Danfoss

Electric expansion valve, type AKV 10P and AKV 10PS

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Valid approvals

(Refrigerant valve) 53RO

Low Voltage Directive (LVD) 2014/35/EU

Table 22: Approvals for AKV 10P and 10PS

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 20

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.10 AI274942819146en-000601 | 21

Loading...

Loading...