Data Sheet

Liquid level sensor

Type AKS 4100 and AKS 4100U

Designed specically to measure liquid levels in

a wide range of refrigeration applications

The AKS 4100/4100U liquid level sensor is

designed specically to measure liquid levels in

a wide range of refrigeration applications.

The AKS 4100/4100U liquid level sensor is

based on a proven techhology called Time

Domain Reectometry (TDR) or Guided Micro

Wave.

AKS 4100/4100U liquid level sensor can be

used to measure the liquid level of many

dierent refrigerants in vessels, accumulators,

receivers, standpipes, etc.The electrical output

is a 2-wired, loop powered 4 – 20 mA output

signal, which is proportional to the refrigerant

liquid level.

AKS 4100/4100U in a cable version is suitable

for HCFC, Non ammable HFC and R717

(Ammonia), and diering lengths from 800

mm / 31.5 in. and up to 5000 mm / 197 in.

The coaxial version of AKS 4100/4100U is

designed for use with R744 (CO2), HCFC, Non

ammable HFC and R717 (Ammonia).

The AKS 4100/4100U coaxial version should

always be used for marine applications for all

refrigerant types. The AKS 4100/4100U cable

version should NOT be used for CO2 or marine

applications.

Dust, foam, vapour, agitated surfaces, boiling

surfaces, changes in density or in the dielectric

constant , εr, for the liquid have no inuence on

the AKS 4100/4100U performance.

Oil accumulated in the bottom of a standpipe

will not disturb the liquid level signal and it is

not necessary to remove AKS 4100/4100U for

cleaning after oil has been drained out of the

standpipe.

AI243386442914en-001101

Liquid level sensor, type AKS 4100 and AKS 4100U

Features

• Approved and qualied by Danfoss for refrigeration applications

• One product covering several probe lengths (cable version)

• A single product for all commonly used refrigerants (cable version)

• Cable version requires less top-end clearance for installation and service

• Proven operation with all refrigerants in combination with oil

• No need to clean cable version when fully covered by oil

• The cable version is very compact and easy to handle, ship, install and use with dierent lengths and refrigerants

• Changes of the liquid dielectric constant (εr) do not aect operation

• 5000 mm / 197 in. probe length with cable version

• 2-wire loop powered; no separate transformer needed

• Multi language HMI. Level and setting readout in mm,cm,m (ft, in.)

◦ Language HMI versions:

▪ English (default), German, French, Spanish

▪ English (default),Japanese, Chinese Russian

NOTE:

AKS 4100/4100U can be connected directly to Danfoss EKE 347 liquid level controller and thus be powered from EKE

347.If used together with Danfoss EKC 347 liquid level controller, a 14 – 30 V DC supply is required.

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 2

Liquid level sensor, type AKS 4100 and AKS 4100U

Media

Refrigerants

The listed refrigerants are qualied and approved by Danfoss:

(1)

R717 / NH3: -40 / +50 °C / (-40 / +122 °F)

R744 / CO2: -50 / +15 °C / (-58 / +59 °F)

HCFC: R22 -50 / +48 °C / (-58 / +118 °F)

HFC: R404A -50 / +15 °C / (-58 / +59 °F)

R410A -50 / +15 °C / (-58 / +59 °F)

R134A -40 / +50 °C / (-40 / +122 °F)

The listed refrigerants may be used in the complete temperature range of AKS 4100/4100U, however, the accuracy

may be aected if the above listed temperature range is exceeded.

Other refrigerants within the groups of HCFC and HFC can be detected and measured if the following conditions are

fullled:

Reference conditions

Dielectric constant

Cable version can be used in R717 / NH3, HCFC and HFC (εr, liquid > 5.6 ).

The coaxial version is mandatory for use in:

• R744 / CO2 (εr, liquid > 1.3)

• Marine applications

The coaxial version can also be used in the refrigerants:

• R717 / NH3, HCFC and HFC

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

1

AKS 4100 Coaxial 280mm and AKS 4100U Coaxial 11 in are only released for R717/NH

3

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 3

123

4

Signal converter, which can be supplied with or without HMI

Mechanical process connection with 5 m / 197 in., Ø2 mm / 0.08 in. stainless

cable

Counterweight

Accessory bag comprising:

• 3 mm set screws

• Red cover to protect mechanical process connection (2) prior to mounting

signal converter

• Setting label

Description

Features

Refrigerant temperature

-60 °C / +100 °C (-76 °F / +212 °F)

Ambient temperature

-40 °C / +80 °C (-40 °F / +176 °F)

For HMI : -20 °C / +60 °C (-4 °F / +140 °F)

Process pressure

-1 – 100 bar / -14.5 – 1450 psig

Terminals (spring loaded)

0.5 – 1.5 mm2 (~20-15 AWG)

Ambient temperature supply voltage limitations:

-40 °C / +80 °C (-40 °F / +176 °F)

-20 °C / +80 °C (-4 °F / +176 °F) : 14 – 30 V DC

Liquid level sensor, type AKS 4100 and AKS 4100U

Product specication

Pressure and temperature data

Table 1: Pressure and temperature data

Product concept

AKS 4100/4100U is available in two dierent versions:

• Cable version

• Coaxial version

Cable version

Figure 1: CABLE version

With the cable version it is possible to adapt the AKS 4100/4100U to any possible length in the range of 800 mm /

31.5 in. to 5000 mm / 196.9 in.

Cable version can be used in R717 / NH3, HCFC and HFC (εr, liquid > 5.6).

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 4

123

4

Signal Converter (with or without HMI)

Mechanical process connection with 5 m / 197 in., Ø2 mm / 0.08 stainless wire

Tube(s) depending on required length

Accessory bag comprising:

• End Connector (incl. 3 mm / 0.12 in. set screws.)

• 3 mm / 0.12 in. set crews (1 set screw pr. tube)

• Red cover to protect mechanical process connection (2), before Signal

Converter is mounted

• Setting label

D22 marking

1

2

Signal Converter (with or without HMI)

Mechanical process connection 280 mm / 11 in., 8 mm / 0.3 in. inner rod

Liquid level sensor, type AKS 4100 and AKS 4100U

Figure 2: AKS 4100/4100U cable version must ALWAYS be installed in a standpipe

Coaxial version

Coaxial D14 version

Figure 3: Coaxial D14 version

Coaxial D22 version

Figure 4: Coaxial D22 version

The coaxial version is mandatory for use in:

• R744 / CO2 (εr, liquid > 1.3)

• Marine applications

The coaxial version can also be used in the refrigerants:

• R717 / NH3, HCFC and HFC

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 5

a

b

Danfoss type

Tube diameter

Type selection in HMI

Thread

AKS 4100, 280 mm

22 mm

0.87 in.

D22

G1 in. pipe thread

AKS 4100, 500 mm

14 mm

0. 55 in.

D14

G1 in. pipe thread

AKS 4100, 800 mm

14 mm

0.55 in.

D14

G1 in. pipe thread

AKS 4100, 1000 mm

14 mm

0.55 in.

D14

G1 in. pipe thread

AKS 4100, 1200 mm

14 mm

0.55 in.

D14

G1 in. pipe thread

AKS 4100, 1500 mm

14 mm

0.55 in.

D14

G1 in. pipe thread

AKS 4100, 1700 mm

14 mm

0.55 in.

D14

G1 in. pipe thread

AKS 4100, 2200 mm

14 mm

0.55 in.

D14

G1 in. pipe thread

AKS 4100U, 11.0 in.

22 mm

0.87 in.

D22

¾ in. NPT

AKS 4100U, 19.2 in.

14 mm

0.55 in.

D14

3

⁄4 in. NPT

AKS 4100U, 30 in.

14 mm

0.55 in.

D14

3

⁄4 in. NPT

AKS 4100U, 45 in.

14 mm

0.55 in.

D14

3

⁄4 in. NPT

AKS 4100U, 55 in.

14 mm

0.55 in.

D14

3

⁄4 in. NPT

AKS 4100U, 65 in.

14 mm

0.55 in.

D14

3

⁄4 in. NPT

AKS 4100U, 85 in.

14 mm

0.55 in.

D14

3

⁄4 in. NPT

*

AKS 4100

B C D

Liquid level sensor, type AKS 4100 and AKS 4100U

Figure 5: AKS 4100/4100U, Coaxial can be installed in a standpipe (a) or directly in a vessel (b)

Table 2: The coaxial version is available in the following probe lengths:

Optional HMI

The optional HMI Service/Display unit is used for commissioning and quick on-site setup and is easily mounted on

the AKS 4100/4100U.

The service unit supports mulitple languages in both SI and US units.

Supported standard languages: English (default), German, French, Spanish, Japanese, Chinese and Russian.

Figure 6: HMI display unit

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 6

123

4567A

B

C & D

4 – 20 mA output displayed as bar graph and in percentage [%]

Measurement name (in this example, DISTANCE)

Device tag name

Measurement reading and unit

Device status (markers)

Marker 1, 2 and 3 (Error)

Hardware problem; the Signal Converter hardware is defective. Contact Danfoss

Marker 4 and 5 (Notication)

Depending on the level, the marker is ON or OFF. Used for Danfoss service information only

Keypad buttons

Flashing star indicating unit in operation

Enter menu system Enter QUICK SETUP

Unit change at distance/level readout: m, cm, mm, in, ft

Change between:

Distance

(1)

Level

(2)

Output (%)

(3)

Output (mA)

(4)

Description

Probe types

Values

Options

Cable

Mechanical process connection with 5 m / 197 in., Ø2 mm / 0.08 in. stainless cable:

Mechanical thread on the mechanical process connection

AKS 4100: G1 in. pipe thread. Aluminium gasket included

AKS 4100U: ¾ in. NPT

Coaxial D14

Mechanical process connection with 5 m / 197 in., Ø2 mm / 0.08 in. stainless cable

and 14 mm / 0.55 in. outer stainless tube:

Mechanical thread on the mechanical process connection

AKS 4100: G1 in. pipe thread. Aluminium gasket included

AKS 4100U: ¾ in. NPT

Stainless steel tubes supporting the available probe length

Coaxial D22

Mechanical process connection with in 22 mm / 0.87 in. outer stainless tube.

8 mm / 0.3 in. inner rod.

Mechanical thread on the mechanical process connection

AKS 4100: G1 in. pipe thread. Aluminium gasket included

AKS 4100U: ¾ in. NPT

LCD display

Insertions (probe) length

Coaxial D14

AKS 4100: 500, 800, 1000, 1200, 1500, 1700 and 2200 mm

AKS 4100U: 19.2, 30, 45, 55, 65, 85 in.

Coaxial D22

AKS 4100: 280 mm

AKS 4100U: 11.0 in.

Single cable Ø2 mm / 0.08 in.: 800 – 5000 mm / 31.5-197 in.

Dead zone

This depends on the type of probe. (see pages 7 and 8)

Liquid level sensor, type AKS 4100 and AKS 4100U

(1)

(1)

If the display is set to “DISTANCE” the displayed value will be the distance from the Reference point to the top surface of the liquid refrigerant

If the display is set to “DISTANCE” the displayed value will be the distance from the Reference point to the top surface of the liquid refrigerant

(see Page 11 and Page 12)

(see Page 11 and Page 12)

(2)

(2)

If the display is set to “LEVEL” then the value displayed will be: PROBE LENGTH (entered in QUICK SETUP) – DISTANCE (see Page 11 and Page 12)

If the display is set to “LEVEL” then the value displayed will be: PROBE LENGTH (entered in QUICK SETUP) – DISTANCE (see Page 11 and Page 12)

(3)

(3)

Will represent the level of refrigerant,in percent, scaled (entered in QUICK SETUP) according to: SCALE 4 mA (0%), SCALE 20 mA (100%) (see

Will represent the level of refrigerant,in percent, scaled (entered in QUICK SETUP) according to: SCALE 4 mA (0%), SCALE 20 mA (100%) (see

Page 11 and Page 12).

Page 11 and Page 12).

(4)

(4)

Will represent the level of refrigerant, in 4 – 20 milliampere, scaled (entered in QUICK SETUP) according to: SCALE 4 mA (4 mA), SCALE 20 mA

Will represent the level of refrigerant, in 4 – 20 milliampere, scaled (entered in QUICK SETUP) according to: SCALE 4 mA (4 mA), SCALE 20 mA

(20 mA) (see Page 11 and Page 12).

(20 mA) (see Page 11 and Page 12).

Design

Table 3: Design

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 7

Description

Values

Display

Integrated LCD display

128 × 64 pixels in 8-step greyscale with 4-button keypad

Interface languages

English (default), German, French, Spanish, Japanese, Chinese, Russian

Description

Values

Ambient temperature

-40 °C / +80 °C (-40 °F / +175 °F)

For HMI: -20 °C / +60 °C (-4 °F / +140 °F)

Storage temperature

-40 °C / +85 °C (-40 °F / +185 °F)

Process connection temperature

Standard: -60 °C / +100 °C (-76 °F / +212 °F)

Operating pressure

Standard: -1 bar to 100 bar / -14.5 psig to 1450 psig

Description

Values

Liquid dielectric constant (εr)

Cable version to be used in R717 / NH3, HCFC and HFC

εr, liquid > 5.6

Coaxial version is mandatory in R744 / CO2

εr, liquid > 1.3

Vibration resistance

EN 60721-3-4 (1 – 9 Hz: 3 mm / 10 – 200 Hz:1g; 10g shock half-wave sinusoidal: 11 ms)

Protection category

IP 66/67 equivalent to NEMA type 4X (housing) and type 6P (probe)

Description

Values

Dimensions and weights

See Dimensions and weights

Description

Values

Housing

Aluminium

Coaxial D14 and D22 version

Standard: Stainless steel (1.4404 / 316L)

Single cable

Standard: Stainless steel (1.4401 / 316)

Process tting

Standard: Stainless steel (1.4404 / 316L)

Gaskets

EPDM (-50 / +150 °C (-58 / +300 °F)

Cable gland

Plastic (black)

Description

Values

Single cable Ø2 mm / 0.08¨

AKS 4100: G1 inch pipe thread. Aluminium gasket included

AKS 4100U: ¾ in. NPT

Coaxial D14 and D22 version

AKS 4100: G1 inch pipe thread. Aluminium gasket included

AKS 4100U: ¾ in. NP

Description

Values

Power supply

Terminals output:

14 – 30 V DC. Min./Max. Value for an output of 22 mA at the terminal.

Ambient temperature limitations: -40 °C / +80 °C (-40 °F / +176 °F) : 16 – 30 V DC

-20 °C / +80 °C (-4 °F / +176 °F) : 14 – 30 V DC

Current output load

RL [Ω] ≤ ((Uext -14 V)/20 mA).

– Default (Error output set to 3.6 mA)

RL [Ω] ≤ ((Uext -14 V)/22 mA).

– (Error output set to 22 mA)

Cable gland

AKS 4100: PG 13, M20×1.5 ; (cable diameter: 6 – 8 mm / 0.24 – 0.31 in.)

AKS 4100U: ½ in. NPT

Cable entry capacity (terminal)

0.5 – 1.5 mm2 (~20-15 AWG)

Description

Values

Output signal

4 – 20 mA or 3.8 – 20.5 mA acc. to NAMUR NE 43

Resolution

±3 μA

Temperature drift

Typically 75 ppm/K

Error signal

High: 22 mA; Low: 3.6 mA acc. to NAMUR NE 43; Hold (frozen value - not available with NAMURNE 43 compliant output

Liquid level sensor, type AKS 4100 and AKS 4100U

Table 4: Display and User interface

Table 5: Operating conditions

Table 6: Other conditions:

Table 7: Installation conditions

Table 8: Material

Table 9: Process connections - Thread

Table 10: Electrical connections

Table 11: Input and output

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 8

Power supply U [VDC]

Current output load R

L

[ ]

Features

Description

Measuring principle

2-wire loop-powered level transmitter; Time Domain Reectometry (TDR )

Application range

Level measurement of liquid refrigerants.

Approved refrigerants:

Halogen Free / Environmently friendly: R717 / NH3, R744 / CO

2

HCFC and non ammable HFC.

Primary measured value

Time between the emitted and received signal

Secondary measured value

Distance or level

Liquid level sensor, type AKS 4100 and AKS 4100U

Minimum power supply voltage

Figure 7: Use this graph to nd the minimum power supply voltage for a given current output load:

NOTE:

Minimum power supply voltage for an output of 22mA at the terminal.

Measuring system

Table 12: Measuring system

Measuring principle (Cable and Coaxial)

The AKS 4100/4100U electronic converter emits low-intensity, high frequency electromagnetic pulses with a width

of approximately 1 nanosecond, which travel at the speed of light along the probe (wire or coaxial cable) down to

the liquid surface.

The pulses are reected by the liquid surface, guided back along the probe, and received and analysed by the AKS

4100/4100U electronic converter and then converted into a liquid level reading. This method is called time domain

reectometry (TDR) or guided microwave.

The dielectric constant, εr, of the liquid is a key parameter and has a direct impact on the degree of reection of the

high frequency electromagnetic pulses. Liquids with high εr values, such as ammonia, produce strong reections,

while liquids with low εr values, such as CO2, produce weak reections.

As long as the εr value of the liquid refrigerant is higher than 1.2, AKS 4100/4100U can detect the liquid level and

level measurement accuracy is not aected.

NOTE:

If the temperature condition in the standpipe /vessel is known, a constant (dielectric constant of the refrigerant gas)

can be entered (parameter 2.5.3 GAS EPS.R), in order to obtain improved Top and Bottom Dead Zone values.

Refer to Page 11 page 10 and Page 12 for Measuring range of AKS 4100/4100U - CABLE version and COAXIAL

version.

For details of gas constant values for dierent temperatures and refrigerants plus the procedure for entering these

via the HMI, refer to Page 23 and Page 24.

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 9

123456789

The electromagnetic (EM) pulse is transmitted by the signal converter

The pulse goes down the probe at the speed of light in air, V1

The pulse is reected

The pulse goes up the probe at speed, V1

The converter receives the pulse and records the signal

The EM pulse moves at speed, V1

Transmitted EM pulse

Half of this time is equivalent to the distance from the reference point of the device (the ange facing) to the

surface of the product

Received EM pulse

Liquid level sensor, type AKS 4100 and AKS 4100U

Figure 8: Measuring principle (Cable and Coaxial)

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 10

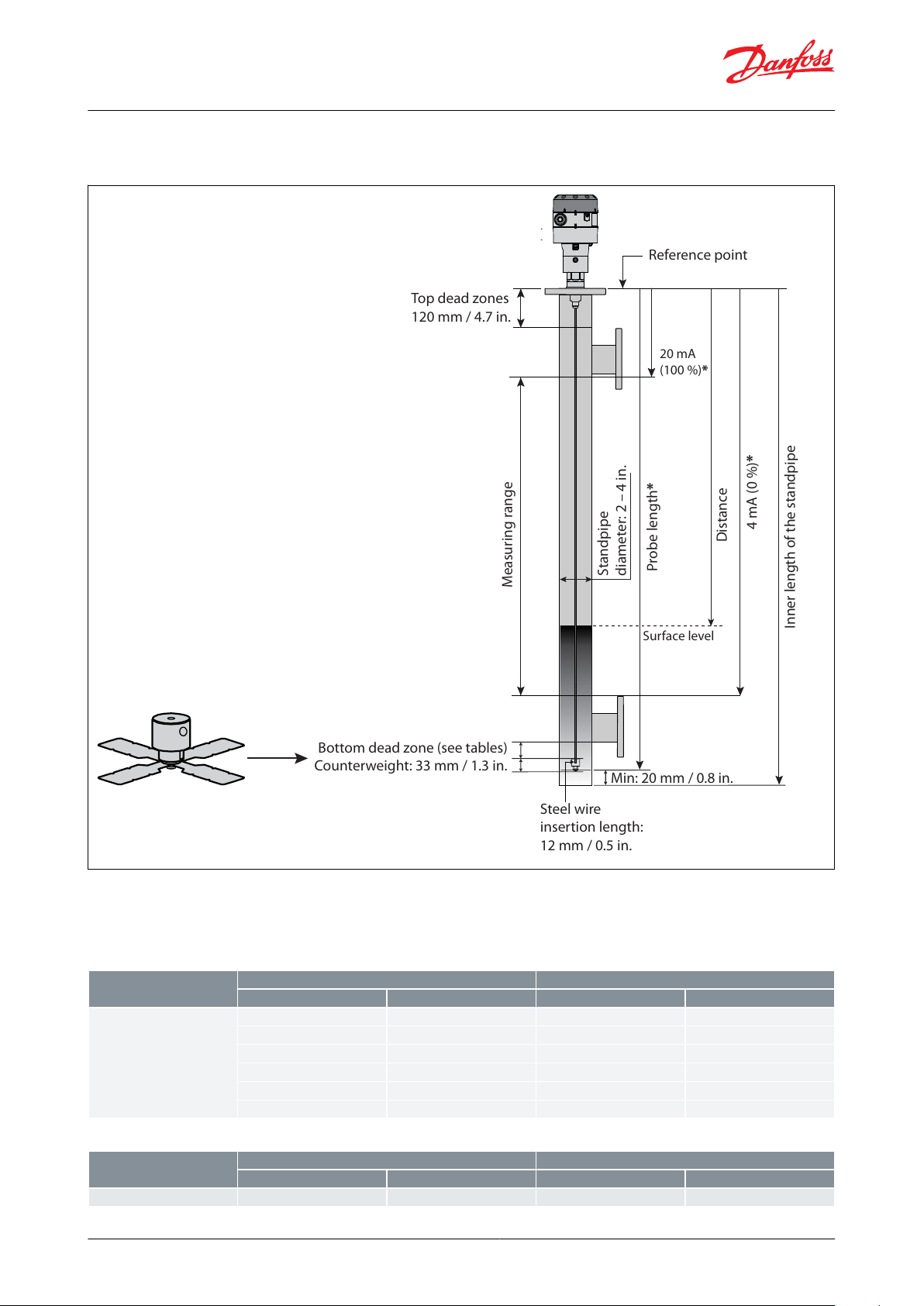

Top dead zones

120 mm / 4.7 in.

Measuring range

Bottom dead zone (see tables)

Counterweight: 33 mm / 1.3 in.

Min: 20 mm / 0.8 in.

Steel wire

insertion length:

12 mm / 0.5 in.

Probe length*

4 mA (0 %)*

Inner length of the standpipe

20 mA

(100 %)*

Reference point

Distance

Surface level

Standpipe

diameter: 2 – 4 in.

Refrigerant

Probe length range

Bottom dead zone

[mm]

[in.]

[mm]

[in.]

Ammonia, HFC, HCFC

800

31.5

115

4.2

801 – 999

31.5 – 39

120

4.7

1000 – 1999

39 – 79

150

5.9

2000 – 2999

79 – 118

180

7.1

3000 – 3999

118 – 157

210

8.3

4000 – 5000

157 – 197

240

9.4

Refrigerant

Probe length range

Bottom dead zone

[mm]

[in.]

[mm]

[in.]

Ammonia, HFC, HCFC

800 – 5000

31.5 – 197903.5

Liquid level sensor, type AKS 4100 and AKS 4100U

Measuring range of AKS 4100/4100U - CABLE version

Figure 9: Measuring range of AKS 4100/4100U - CABLE version

NOTE:

* Values to be entered into HMI Quick Setup menu and recorded on the setting label. Stick the setting label onto the

Signal Converter either inside or outside.

Table 13: Bottom deadzone values based on the factory setting of dielectric constant

Table 14: Improved Bottom dead zone values after the adjustment of dielectric constant

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 11

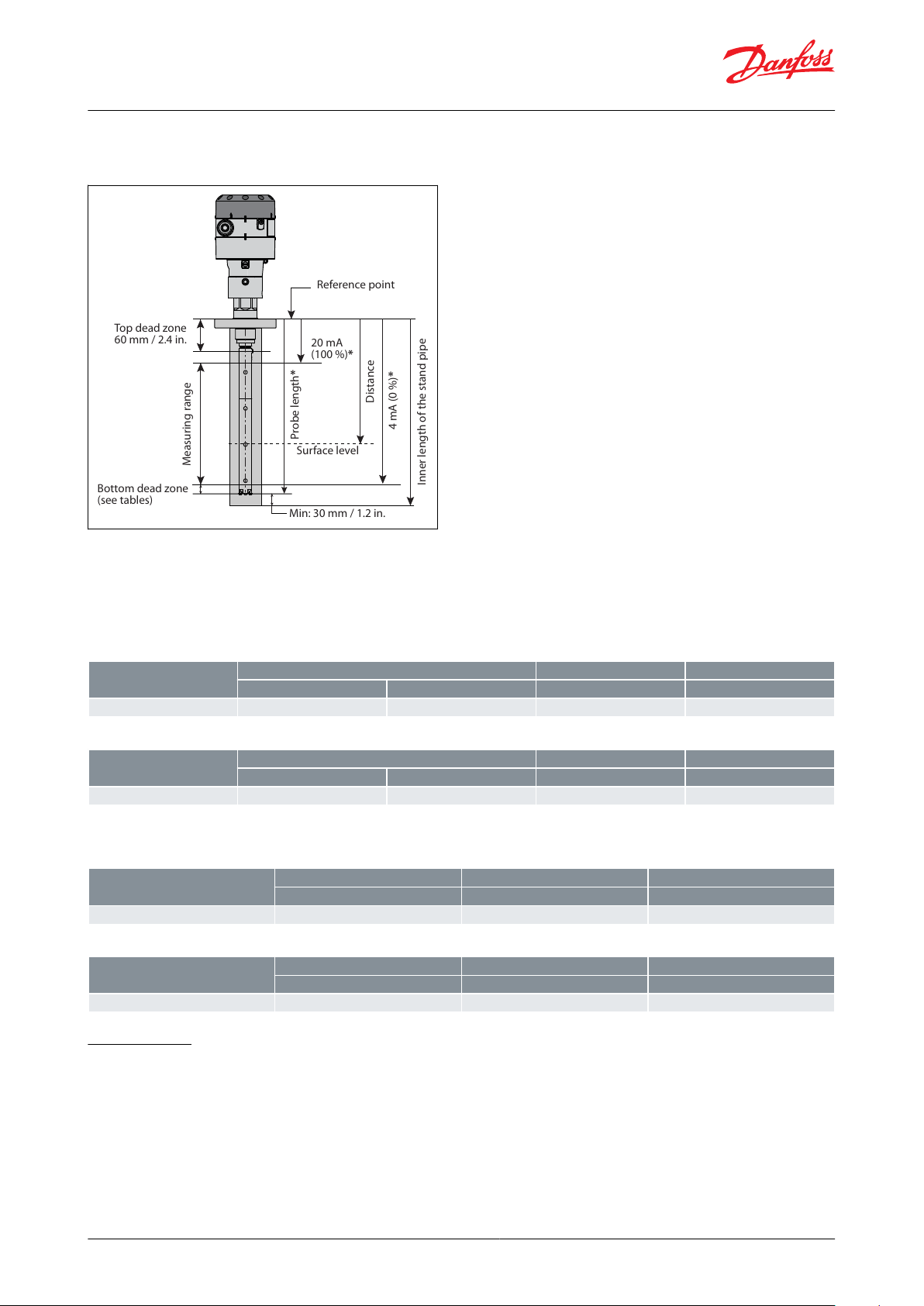

Top

dead

zone

120 mm /

4.7 in.

Measuring range

Bottom

dead

zone

(see tables)

Min: 30 mm / 1.2 in.

Probe length*

4 mA (0 %)*

Inner length of the stand pipe

20 mA

(100 %)*

Reference point

Distance

Surface level

Refrigerant

Probe length

Bottom Dead Zone

Bottom Dead Zone

[mm]

[in.]

[mm]

[in.]

CO

2

500

19.7

170

6.7

800

31.5

1000

39.4

1200

47.2

1500

59.1

1700

66.9

2200

86.6

Liquid level sensor, type AKS 4100 and AKS 4100U

Measuring range of AKS 4100/4100U - COAXIAL D14 version

Figure 10: Measuring range of AKS 4100/4100U - COAXIAL D14 version

NOTE:

* Values to be entered into HMI Quick Setup menu and recorded on the setting label. Stick the setting label onto the

Signal Converter either inside or outside.

AKS 4100

Table 15: Dielectric Constant εr always set during Quick Setup

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 12

Refrigerant

Probe length

Bottom Dead Zone

Bottom Dead Zone

[mm]

[in.]

[mm]

[in.]

Ammonia

500

19.7953.7

800

31.5

104

4.1

1000

39.4

110

4.3

1200

47.2

116

4.6

1500

59.1

125

4.9

1700

66.9

131

5.2

2200

86.6

146

5.8

Refrigerant

Probe length

Bottom Dead Zone

Bottom Dead Zone

[mm]

[in.]

[mm]

[in.]

Ammonia

500

19.7

80

3.2

800

31.5

1000

39.4

1200

47.2

1500

59.1

1700

66.9

2200

86.6

Refrigerant

Probe length

Bottom Dead Zone

Bottom Dead Zone

[mm]

[in.]

[mm]

[in.]

HCFC,HFC

500

19.7

115

4.5

800

31.5

124

4.9

1000

39.4

130

5.1

1200

47.2

136

5.4

1500

59.1

145

5.7

1700

66.9

151

5.9

2200

86.6

166

6.5

Refrigerant

Probe length

Bottom Dead Zone

Bottom Dead Zone

[mm]

[in.]

[mm]

[in.]

HCFC,HFC

500

19.7

100

3.9

800

31.5

1000

39.4

1200

47.2

1500

59.1

1700

66.9

2200

86.6

Refrigerant

Probe Length

Bottom Dead Zone

Bottom Dead Zone

[in.]

[in.]

[mm]

CO

2

19.2

6.7

170

3045556585

Liquid level sensor, type AKS 4100 and AKS 4100U

Table 16: Factory setting

Table 17: Improved Bottom dead zone values after the adjustment of dielectric constant

Table 18: Factory setting

Table 19: Improved Bottom dead zone values after the adjustment of dielectric constant

NOTE:

It is mandatory to input dielectric constant for CO2 applications.

AKS 4100U

Table 20: Dielectric Constant εr always set during Quick Setup

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 13

Refrigerant

Probe Length

Bottom Dead Zone

Bottom Dead Zone

[in.]

[in.]

[mm]

Ammonia

19.2

3.739530

4.05

103454.5

114554.8

122655.1

130855.7

145

Refrigerant

Probe Length

Bottom Dead Zone

Bottom Dead Zone

[in.]

[in.]

[mm]

Ammonia

19.2

3.1

80

3045556585

Refrigerant

Probe Length

Bottom Dead Zone

Bottom Dead Zone

[in.]

[in.]

[mm]

HCFC,HFC

19.2

4.52

115304.84

123455.29

134555.59

142655.89

150856.49

165

Refrigerant

Probe Length

Bottom Dead Zone

Bottom Dead Zone

[in.]

[in.]

[mm]

HCFC,HFC

19.2

3.94

100

3045556585

Liquid level sensor, type AKS 4100 and AKS 4100U

Table 21: Factory setting

Table 22: Improved Bottom dead zone values after the adjustment of dielectric constant

Table 23: Factory setting

Table 24: Improved Bottom dead zone values after the adjustment of dielectric constant

NOTE:

It is mandatory to input dielectric constant for CO2 applications.

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 14

Measuring range

4 mA (0 %)*

Top dead zone

60 mm / 2.4 in.

Bottom dead zone

(see tables)

20 mA

(100 %)*

Probe length*

Reference point

Distance

Surface level

Inner length of the stand pipe

Min: 30 mm / 1.2 in.

Refrigerant

Probe length

Bottom Dead Zone

Bottom Dead Zone

[mm]

[in.]

[mm]

[in.]

Ammonia

2801148

1.9

Refrigerant

Probe length

Bottom Dead Zone

Bottom Dead Zone

[mm]

[in.]

[mm]

[in.]

Ammonia

2801140

1.6

Refrigerant

Probe Length

Bottom Dead Zone

Bottom Dead Zone

[in.]

[in.]

[mm]

Ammonia

11

1.9

48

Refrigerant

Probe Length

Bottom Dead Zone

Bottom Dead Zone

[in.]

[in.]

[mm]

Ammonia

11

1.6

40

Liquid level sensor, type AKS 4100 and AKS 4100U

Measuring range of AKS 4100/4100U - COAXIAL D22 version

Figure 11: Measuring range of AKS 4100/4100U - COAXIAL D22 version

NOTE:

* Values to be entered into HMI Quick Setup menu and recorded on the setting label. Stick the setting label onto the

Signal Converter either inside or outside.

AKS 4100

Table 25: Factory setting

Table 26: Improved Bottom dead zone values after the adjustment of dielectric constant

AKS 4100U

Table 27: Factory setting

Table 28: Improved Bottom dead zone values after the adjustment of dielectric constant

Connections

Mechanical connection

Cable version / Coaxial version:

• AKS 4100

◦ G1 in. pipe thread

◦ Aluminium gasket included

• AKS 4100U

3

◦

⁄4 in. NPT

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 15

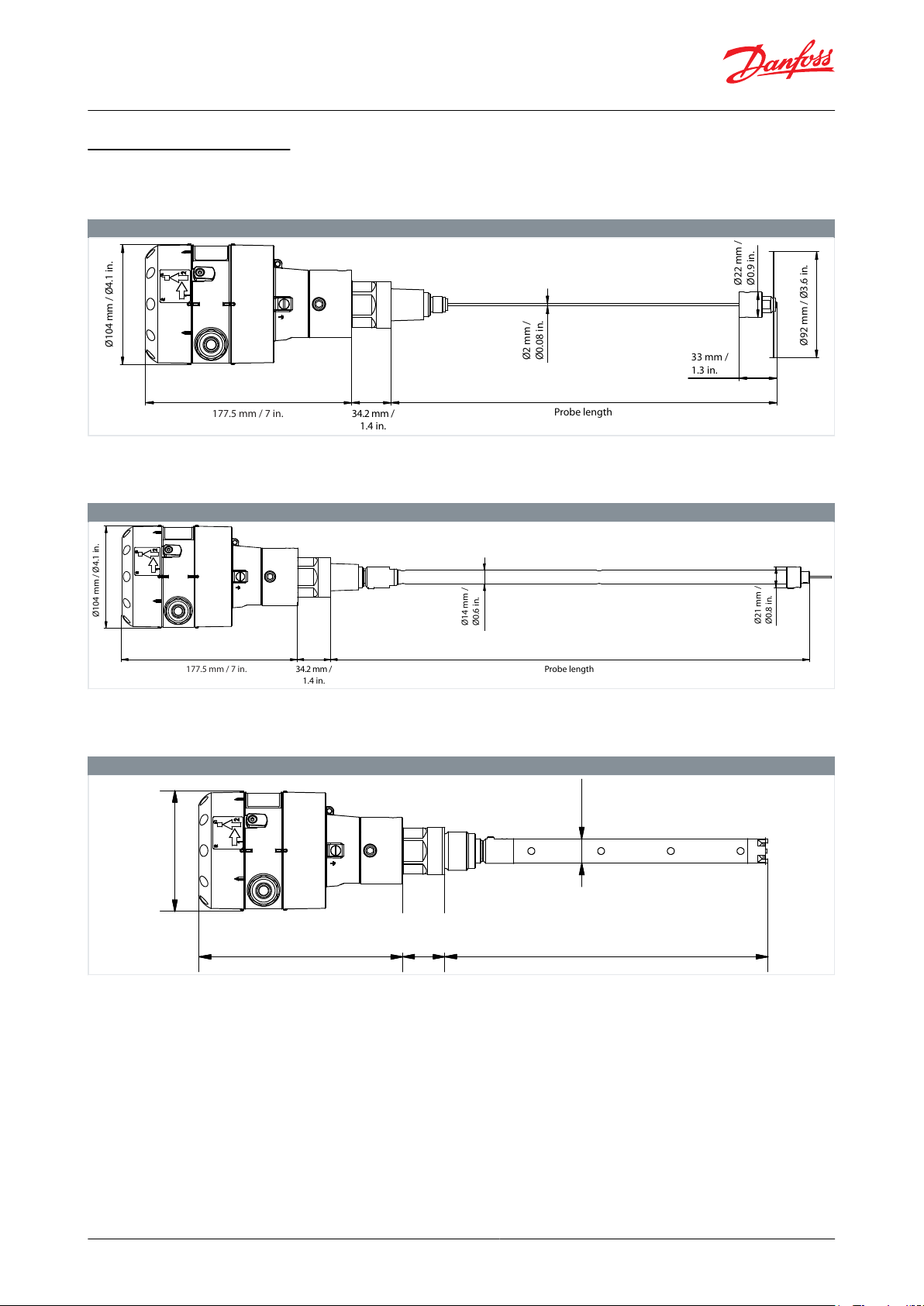

Weight: approx. 2.3 kg / 5.1 lbs

Probe length

Ø104 mm / Ø4.1 in.

177.5 mm / 7 in. 34.2 mm /

1.4 in.

Ø2 mm /

Ø0.08 in.

Ø22 mm /

Ø0.9 in.

Ø92 mm / Ø3.6 in.

33 mm /

1.3 in.

Weight: approx. 3.8 kg / 8.4 lbs

Ø104 mm / Ø4.1 in.

177.5 mm / 7 in. 34.2 mm /

1.4 in.

Probe length

Ø14 mm /

Ø0.6 in.

Ø21 mm /

Ø0.8 in.

Weight: 2.4 kg / 5.3 lbs

Ø 104 mm / Ø 4.1 in.

177.5 mm / 7 in.

34.2 mm /

1.4 in.

Probe length

21.1 mm /

0.8 in.

Liquid level sensor, type AKS 4100 and AKS 4100U

Dimensions and weights

CABLE version

Table 29: CABLE version

COAXIAL D14 version

Table 30: Coaxial D14 version

COAXIAL D22 version

Table 31: Coaxial D22 version

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 16

Description

Refrigerant

Code number with HMI

English (default)

German

French

Spanish

Code number with HMI

English (default)

Japanese

Chinese

Russian

Code number Without

HMI*

AKS 4100 with 5 m / 197 in., Ø2 mm / Ø0.08

in. stainless cable and counterweight

Ammonia, R134A, R404A, R410A, R22

084H4501

084H4550

084H4500

AKS 4100U with 5 m / 197 in., Ø2 mm / Ø0.08

in. stainless cable and counterweight

Ammonia, R134A, R404A, R410A, R22

084H4521

084H4571

084H4520

Description

Probe length

Refrigerant

Code number with

HMI

English (default)

German

French

Spanish

Code number with

HMI

English (default)

Japanese

Chinese

Russian

Code number With‐

out HMI*

mm

in.

AKS 4100 - Coaxial D14

500

Ammonia, CO

2

, R134A, R404A, R410A, R22

084H4510

084H4560

084H4503

AKS 4100 - Coaxial D14

800

Ammonia, CO

2

, R134A, R404A, R410A, R22

084H4511

084H4561

084H4504

AKS 4100 - Coaxial D14

1000

Ammonia, CO

2

, R134A, R404A, R410A, R22

084H4512

084H4562

084H4505

AKS 4100 - Coaxial D14

1200

Ammonia, CO

2

, R134A, R404A, R410A, R22

084H4513

084H4563

084H4506

AKS 4100 - Coaxial D14

1500

Ammonia, CO

2

, R134A, R404A, R410A, R22

084H4514

084H4564

084H4507

AKS 4100 - Coaxial D14

1700

Ammonia, CO

2

, R134A, R404A, R410A, R22

084H4515

084H4565

084H4508

AKS 4100 - Coaxial D14

2200

Ammonia, CO

2

, R134A, R404A, R410A, R22

084H4516

084H4566

084H4509

Liquid level sensor, type AKS 4100 and AKS 4100U

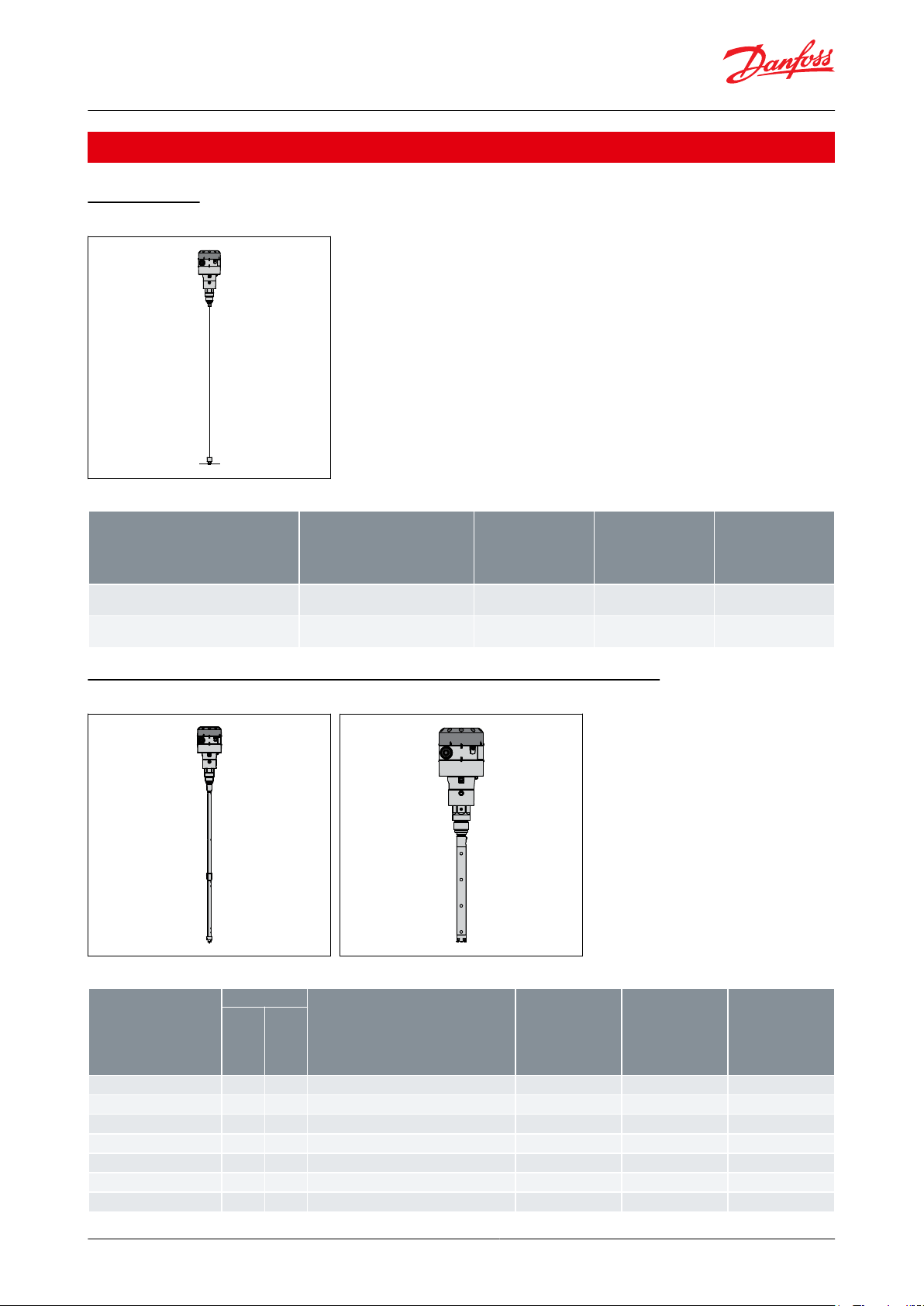

Ordering

Cable version

Figure 12: Cable version

Table 32: Cable version

Coaxial version (available in predened lengths, with or without HMI)

Figure 13: Coaxial version D14 Figure 14: Coaxial version D22

Table 33: Coaxial version - D14

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 17

Description

Probe length

Refrigerant

Code number with

HMI

English (default)

German

French

Spanish

Code number with

HMI

English (default)

Japanese

Chinese

Russian

Code number With‐

out HMI*

mm

in.

AKS 4100U - Coaxial D14

19.2

Ammonia, CO2, R134A, R404A, R410A, R22

084H4530

084H4580

084H4524

AKS 4100U - Coaxial D14

30

Ammonia, CO2, R134A, R404A, R410A, R22

084H4531

084H4581

084H4525

AKS 4100U - Coaxial D14

45

Ammonia, CO2, R134A, R404A, R410A, R22

084H4532

084H4582

084H4526

AKS 4100U - Coaxial D14

55

Ammonia, CO2, R134A, R404A, R410A, R22

084H4533

084H4583

084H4527

AKS 4100U - Coaxial D14

65

Ammonia, CO2, R134A, R404A, R410A, R22

084H4534

084H4584

084H4528

AKS 4100U - Coaxial D14

85

Ammonia, CO2, R134A, R404A, R410A, R22

084H4535

084H4585

084H4529

Description

Probe length

Refrigerant

Code number with

HMI

English (default)

German

French

Spanish

Code number with

HMI

English (default)

Japanese

Chinese

Russian

Code number With‐

out HMI*

mm

in.

AKS 4100 - Coaxial D22

280

Ammonia

084H4517

084H4567

084H4518

AKS 4100U - Coaxial D22

11

Ammonia

084H4536

084H4586

084H4537

AKS 4100 - Coaxial D22

280

CO2, R134A, R404A, R410A, R22

084H4572

084H4573

084H4574

AKS 4100U - Coaxial D22

11

CO2, R134A, R404A, R410A, R22

084H4575

084H4576

084H4577

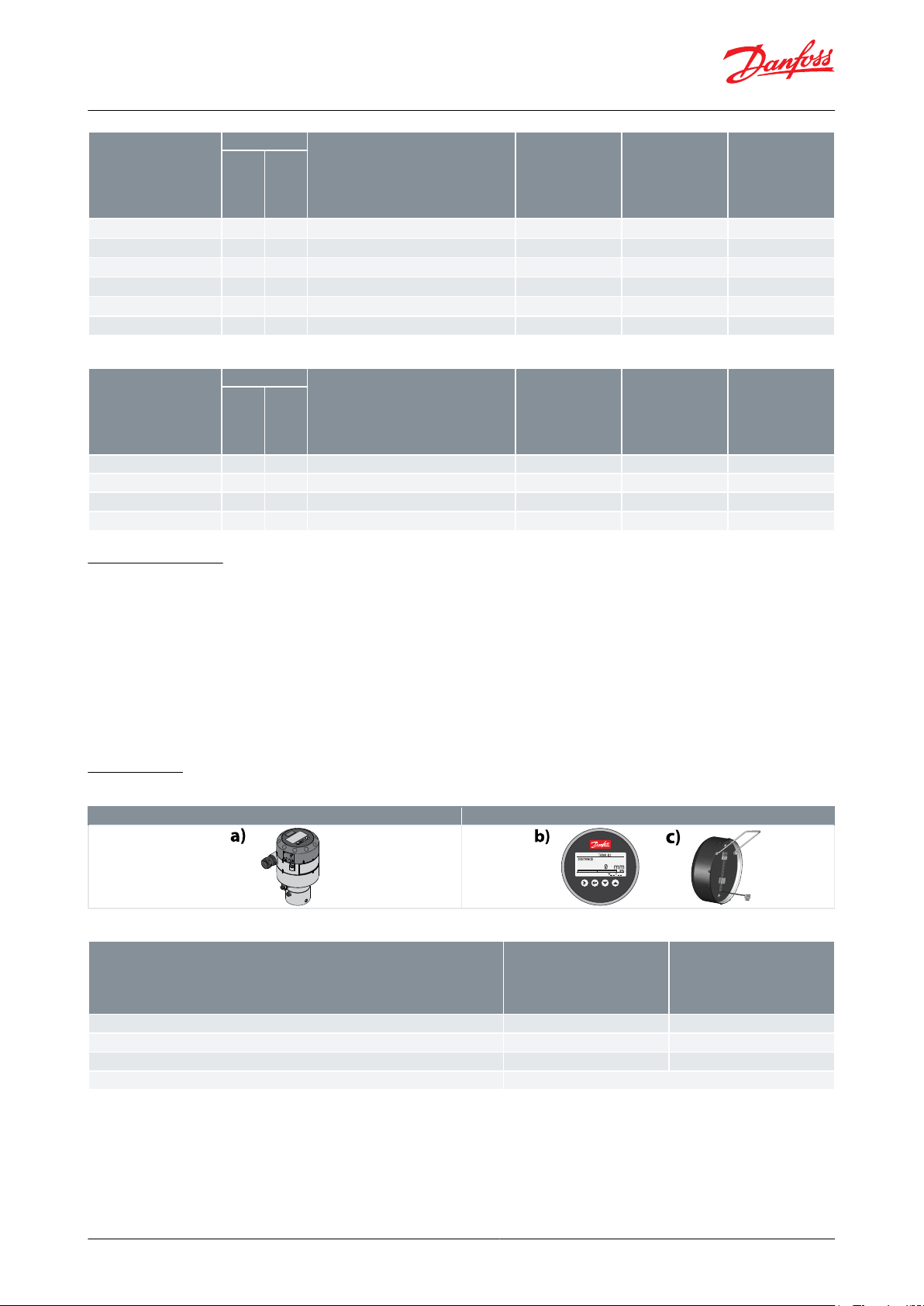

AKS 4100/4100U excluding cable gland

HMI Service/Display unit

Description

Code number with HMI

English (default)

German

French

Spanish

Code number with HMI

English (default)

Japanese

Chinese

Russian

AKS 4100/4100U HMI Service/Display unit with rear cover and mounting bracket -

c)

084H4540

084H4590

AKS 4100/4100U HMI Display -

b)

084H4548

084H4598

AKS 4100/4100U Signal Converter + Metaglass with HMI, excluding cable gland -

a)

084H4555

084H4556

AKS 4100/4100U converter connecting cable (5 pcs.)

084H4557

Liquid level sensor, type AKS 4100 and AKS 4100U

Table 34: Coaxial version - D22

HMI display unit

When ordering without HMI please observe:

NOTE: Each AKS 4100/AKS 4100 must always be programmed via the HMI display unit.

The HMI display unit can be ordered separately:

• 084H4540 / 084H4590 AKS 4100/4100U HMI display unit with rear cover and mounting bracket. The mounting

bracket is very useful when the AKS 4100/4100U have to be programmed. The same AKS 4100/4100U HMI display

unit can be used to programme more AKS 4100/4100U and both Cable and Coaxial versions.

• 084H4548 / 084H4598 AKS 4100/4100U HMI display unit (usually spare part).

Accessories

Table 35: Accessories

Table 36: Accessories

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 18

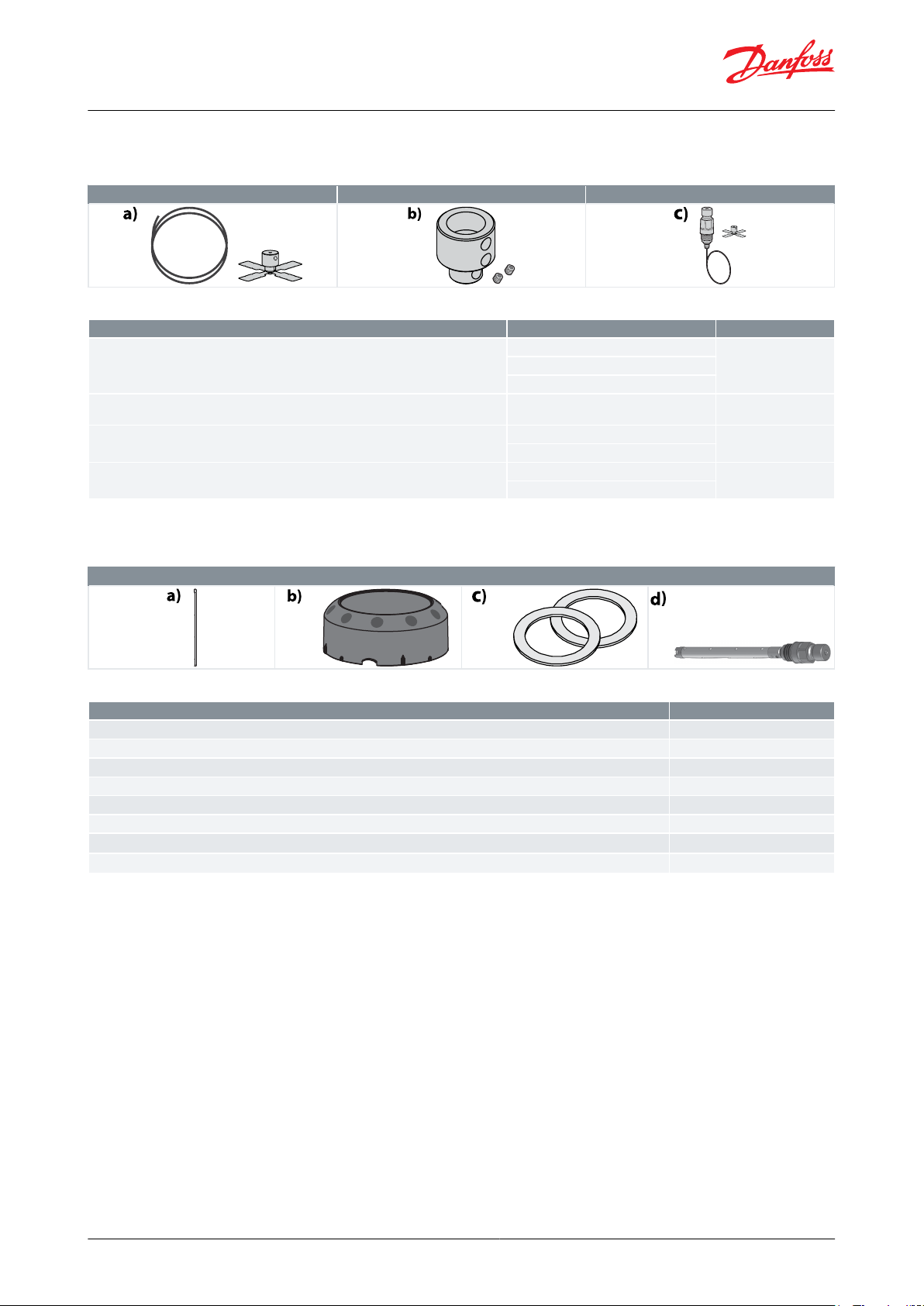

Cable and counterweight - CABLE version

End connector incl screws - COAXIAL D14 version

Process connection, counterweight and cable

Description

Content

Code number

Cable and counterweight for AKS 4100/4100U - CABLE version - a)

Cable - 5 m / 197 in., Ø2 mm / Ø0.08 in.

084H4542

Crimp

Counterweight

End connector incl screws for AKS 4100/4100U - COAXIAL D14 version - b)

End connector (incl. 3 mm / 0.12 in. set

screws)

084H4549

Process connection, counterweight and 5 m / 197 in., Ø2 mm / Ø0.08 in. cable for AKS 4100

- CABLE and COAXIAL D14 version - c)

1 in. process connection

084H4545

Counterweight

Process connection, counterweight and 5 m / 197 in., Ø2 mm / Ø0.08 in. cable for AKS

4100U - CABLE and COAXIAL D14 version - c)

3

⁄4 in. NPT process connection

084H4546

Counterweight

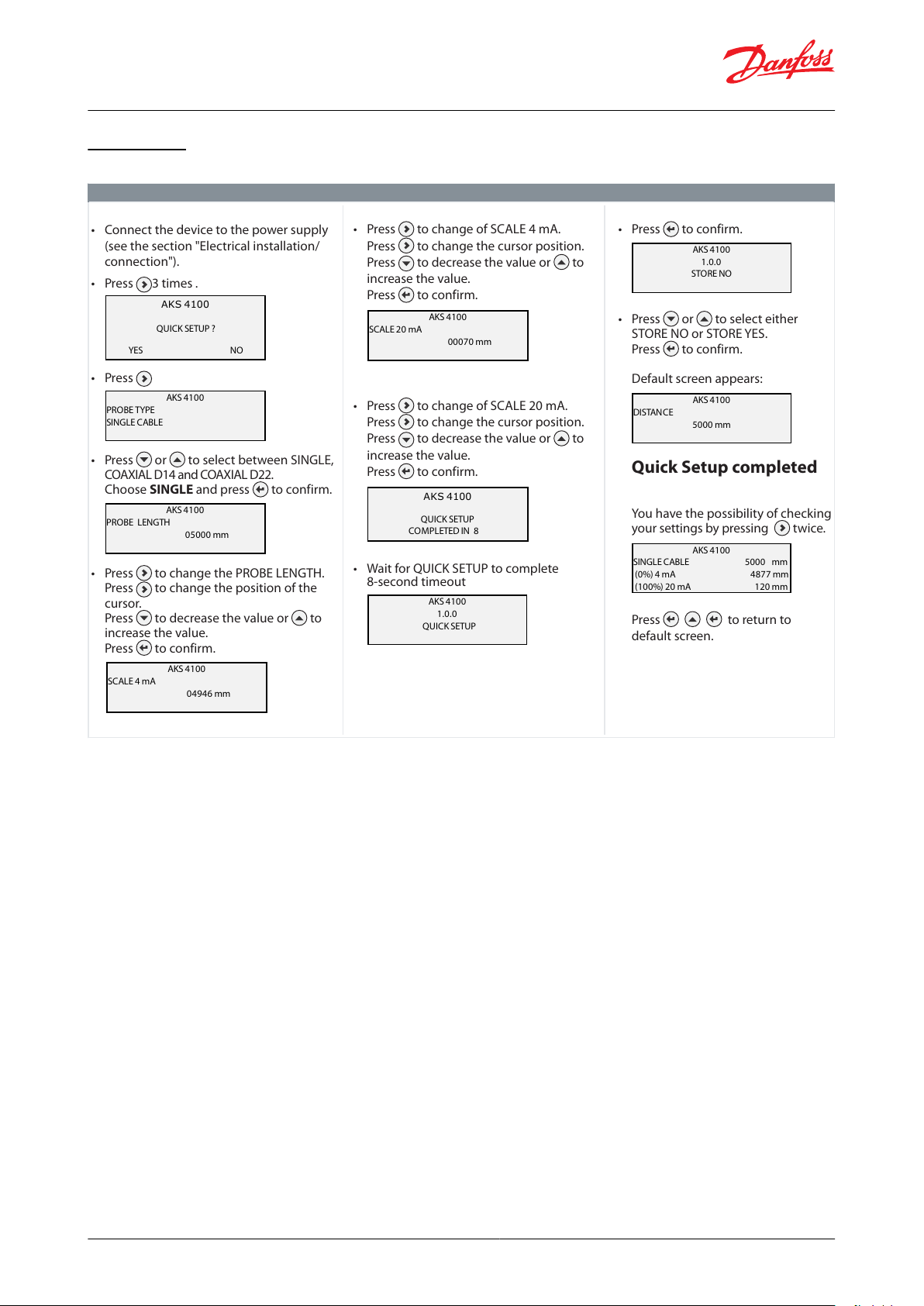

Other spare parts

Description

Code number

AKS 4100/4100U Coaxial tube. Tube length: 680 mm / 26.8 in. - a)

084H4543

AKS 4100/4100U blank top cover for signal converter - b)

084H4544

AKS 4100/4100U Aluminium gaskets (10 pcs.) for 1 in. process connection - c)

084H4547

AKS 4100 1 in. welding connection

027F1010

Process connection AKS 4100 - Coaxial D22 - G1 in. - 280 mm. For Ammonia only - d)

084H4551

Process connection AKS 4100U - Coaxial D22 -

3

⁄4 in. NPT – 11 in. For Ammonia only - d)

084H4552

Process connection AKS 4100 - Coaxial D22 - G1 in. - 280 mm. For CO2, R134A, R404A, R410A, R22 only - d)

084H4558

Process connection AKS 4100 - Coaxial D22 -

3

⁄4 in. NPT – 11 in. For CO

2

, R134A, R404A, R410A, R22 only - d)

084H4559

Liquid level sensor, type AKS 4100 and AKS 4100U

Service kits

Table 37: Service kits

Table 38: Service kits

Other spare parts

Table 39: Other spare parts

Table 40: Other spare parts

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 19

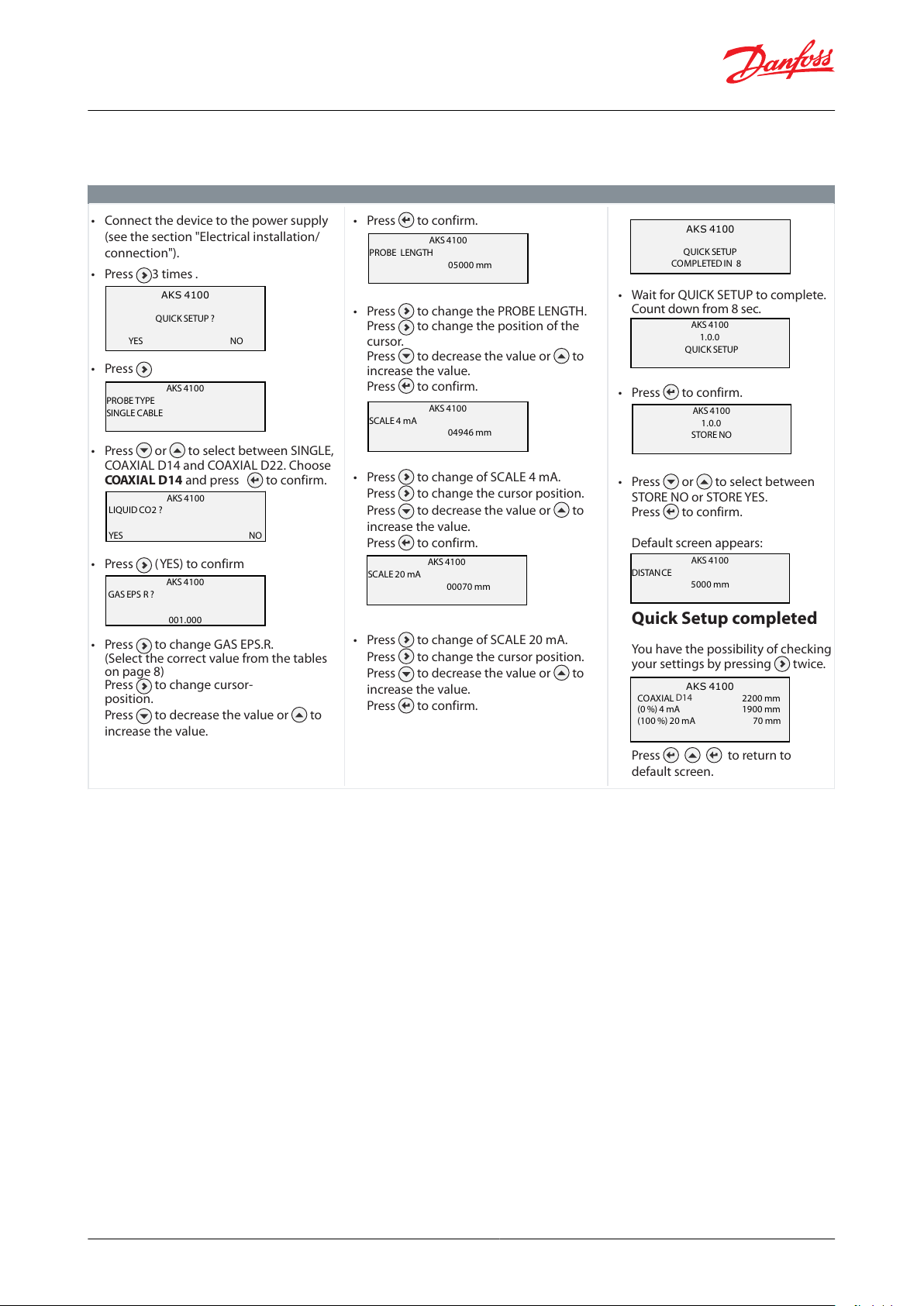

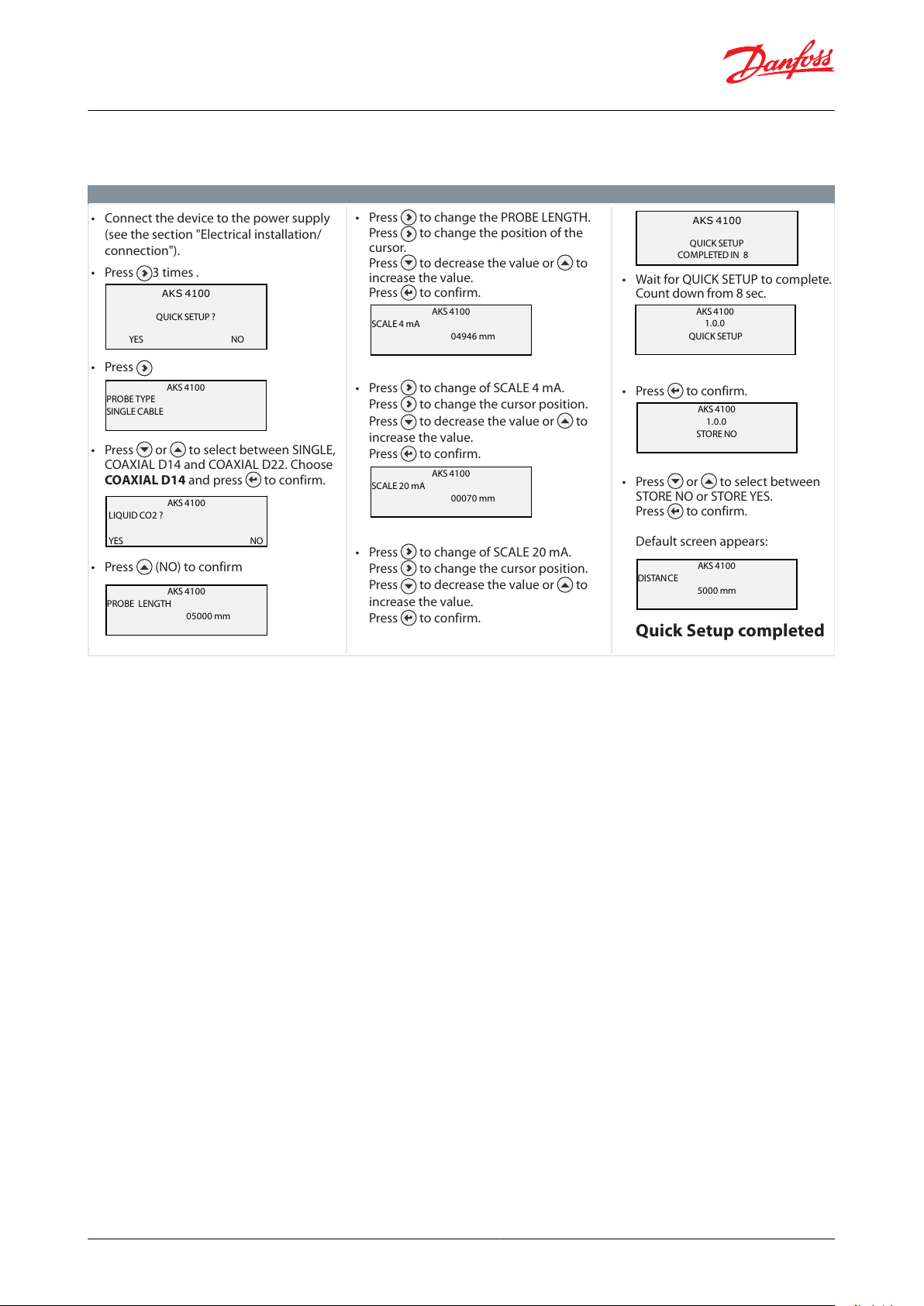

Quick Setup (all values below are only examples)

• Connect the device to the power supply

(see the section "Electrical installation/

connection").

• Press 3 times .

• Press

• Press or to select between SINGLE,

COAXIAL D14 and COAXIAL D22.

Choose SINGLE and press to confirm.

• Press to change the PROBE LENGTH.

Press to change the position of the

cursor.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

QUICK SETUP?

YES NO

AKS 4100

PROBE TYPE

SINGLE CABLE

AKS 4100

PROBE LENGTH

05000 mm

AKS 4100

SCALE 4mA

04946 mm

AKS 4100

SCALE 20 mA

00070 mm

• Press to change of SCALE 4 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

• Press to change of SCALE 20 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

• Wait for QUICK SETUP to complete

8-second timeout

AKS 4100

QUICK SETUP

COMPLETED IN 8

AKS 4100

1.0.0

QUICK START

AKS 4100

1.0.0

STORE NO

AKS 4100

DISTANCE

5000 mm

• Press to confirm.

• Press or to select either

STORE NO or STOREYES.

Press to confirm.

Default screen appears:

Quick Setup completed

You have the possibility of checking

your settings by pressing twice.

Press to return to

default screen.

QUICK SETUP?

QUICK SETUP

AKS 4100

SINGLE CABLE 5000 mm

(0%) 4 mA 4877 mm

(100%) 20 mA 120 mm

Liquid level sensor, type AKS 4100 and AKS 4100U

Quick setup

Table 41: Quick Setup

NOTE:

The signal converter can be programmed with or without mechanical process connector assembled.

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 20

Quick Setup (all values below are only examples)

• Connect the device to the power supply

(see the section "Electrical installation/

connection").

• Press 3 times .

• Press

• Press or to select between SINGLE,

COAXIAL D14 and COAXIAL D22. Choose

COAXIAL D14 and press to confirm.

• Press (YES) to confirm

• Press to change GAS EPS.R.

(Select the correct value from the tables

on page 8)

Press to change cursor-

position.

Press to decrease the value or to

increase the value.

AKS 4100

QUICK SETUP?

YES NO

AKS 4100

PROBE TYPE

SINGLE CABLE

• Press to confirm.

• Press to change the PROBE LENGTH.

Press to change the position of the

cursor.

Press to decrease the value or to

increase the value.

Press to confirm.

• Press to change of SCALE 4 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

• Press to change of SCALE 20 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

• Wait for QUICK SETUP to complete.

Count down from 8 sec.

• Press to confirm.

• Press or to select between

STORE NO or STOREYES.

Press to confirm.

Default screen appears:

Quick Setup completed

You have the possibility of checking

your settings by pressing twice.

Press to return to

default screen.

AKS 4100

GAS EPS R ?

001.000

AKS 4100

PROBE LENGTH

05000 mm

AKS 4100

SCALE 4mA

04946 mm

AKS 4100

SCALE 20 mA

00070 mm

AKS 4100

QUICK SETUP

COMPLETED IN 8

AKS 4100

1.0.0

QUICK START

AKS 4100

1.0.0

STORE NO

AKS 4100

DISTANCE

5000 mm

AKS 4100

LIQUID CO2 ?

YES NO

QUICK SETUP

AKS 4100

COAXIAL 220 0mm

(0 %) 4 mA 1900 mm

(100 %) 20 mA 70 mm

D14

Liquid level sensor, type AKS 4100 and AKS 4100U

When CO2 is used:

Table 42: Quick Setup (all values below are only examples)

NOTE:

The signal converter can be programmed with or without mechanical process connector assembled.

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 21

For all other refrigerants

• Connect the device to the power supply

(see the section "Electrical installation/

connection").

• Press 3 times .

• Press

• Press or to select between SINGLE,

COAXIAL D14 and COAXIAL D22. Choose

COAXIAL D14 and press to confirm.

• Press (NO) to confirm

AKS 4100

QUICK SETUP?

YES NO

AKS 4100

PROBE TYPE

SINGLE CABLE

• Press to change the PROBE LENGTH.

Press to change the position of the

cursor.

Press to decrease the value or to

increase the value.

Press to confirm.

• Press to change of SCALE 4 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

• Press to change of SCALE 20 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

• Wait for QUICK SETUP to complete.

Count down from 8 sec.

• Press to confirm.

• Press or to select between

STORE NO or STOREYES.

Press to confirm.

Default screen appears:

Quick Setup completed

AKS 4100

LIQUID CO2 ?

YES NO

AKS 4100

SCALE 4mA

04946 mm

AKS 4100

SCALE 20 mA

00070 mm

AKS 4100

QUICK SETUP

COMPLETED IN 8

AKS 4100

1.0.0

STORE NO

AKS 4100

DISTANCE

5000 mm

AKS 4100

1.0.0

QUICK START

AKS 4100

PROBE LENGTH

05000 mm

QUICK SETUP

Liquid level sensor, type AKS 4100 and AKS 4100U

For all other refrigerants

Table 43: For all other refrigerants

NOTE:

Please note that Coaxial D22 version can only be used in R717/NH3)

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 22

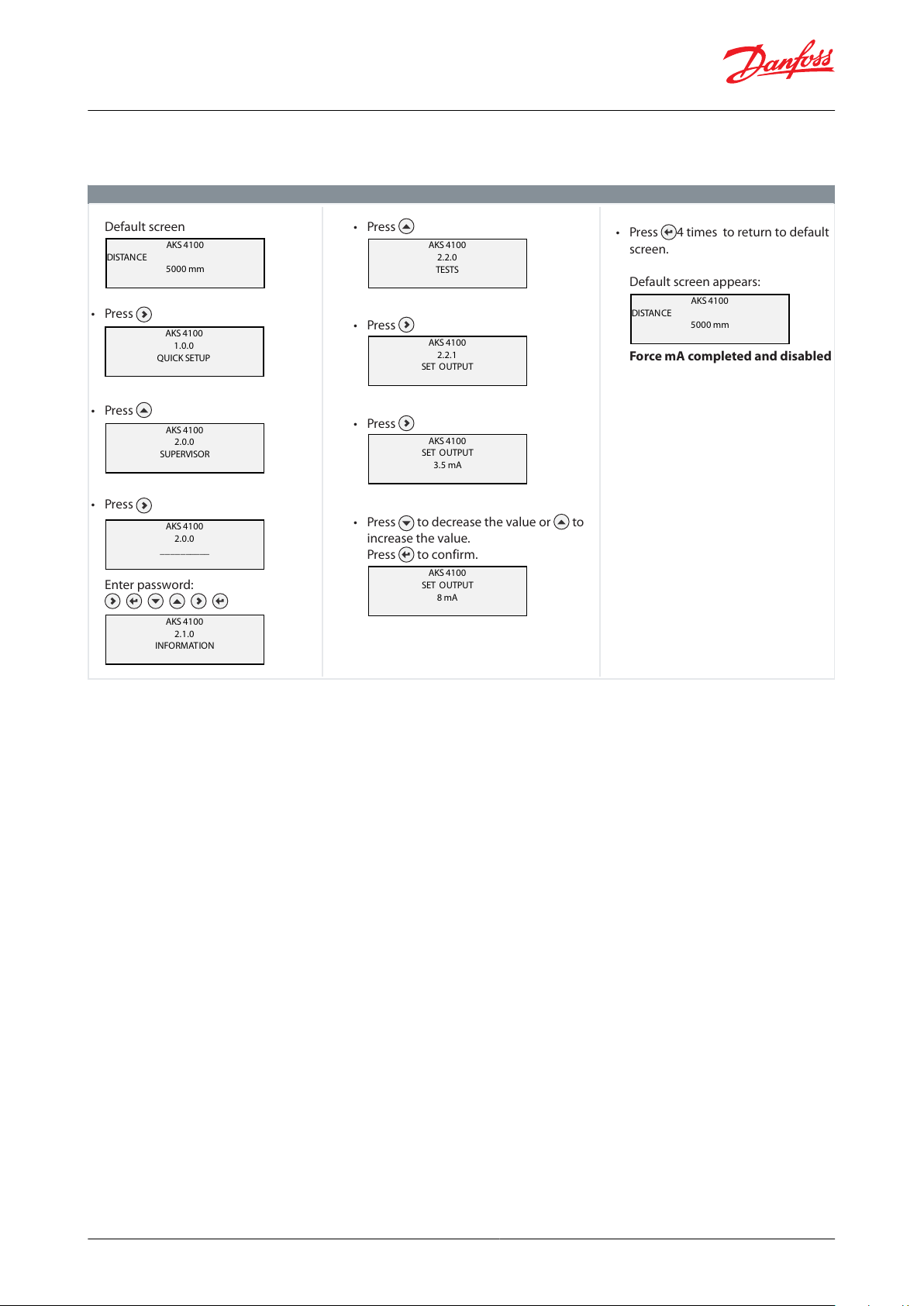

Forcing mA output (all values below are only examples)

Default screen

• Press

• Press

• Press

Enter password:

AKS 4100

DISTANCE

5000 mm

AKS 4100

2.0.0

SUPERVISOR

AKS 4100

2.0.0

____ ______

AKS 4100

2.1.0

INFORMATION

AKS 4100

2.2.0

TESTS

AKS 4100

2.2.1

SET O UTPUT

AKS 4100

SET O UTPUT

3.5 mA

AKS 4100

SET O UTPUT

8 mA

AKS 4100

DISTANCE

5000 mm

• Press

• Press

• Press

• Press to decrease the value or to

increase the value.

Press to confirm.

• Press 4 times to return to default

screen.

Default screen appears:

Force mA completed and disabled

AKS 4100

1.0.0

QUICK START

QUICK SETUP

Liquid level sensor, type AKS 4100 and AKS 4100U

CABLE and COAXIAL version

Table 44: CABLE and COAXIAL version

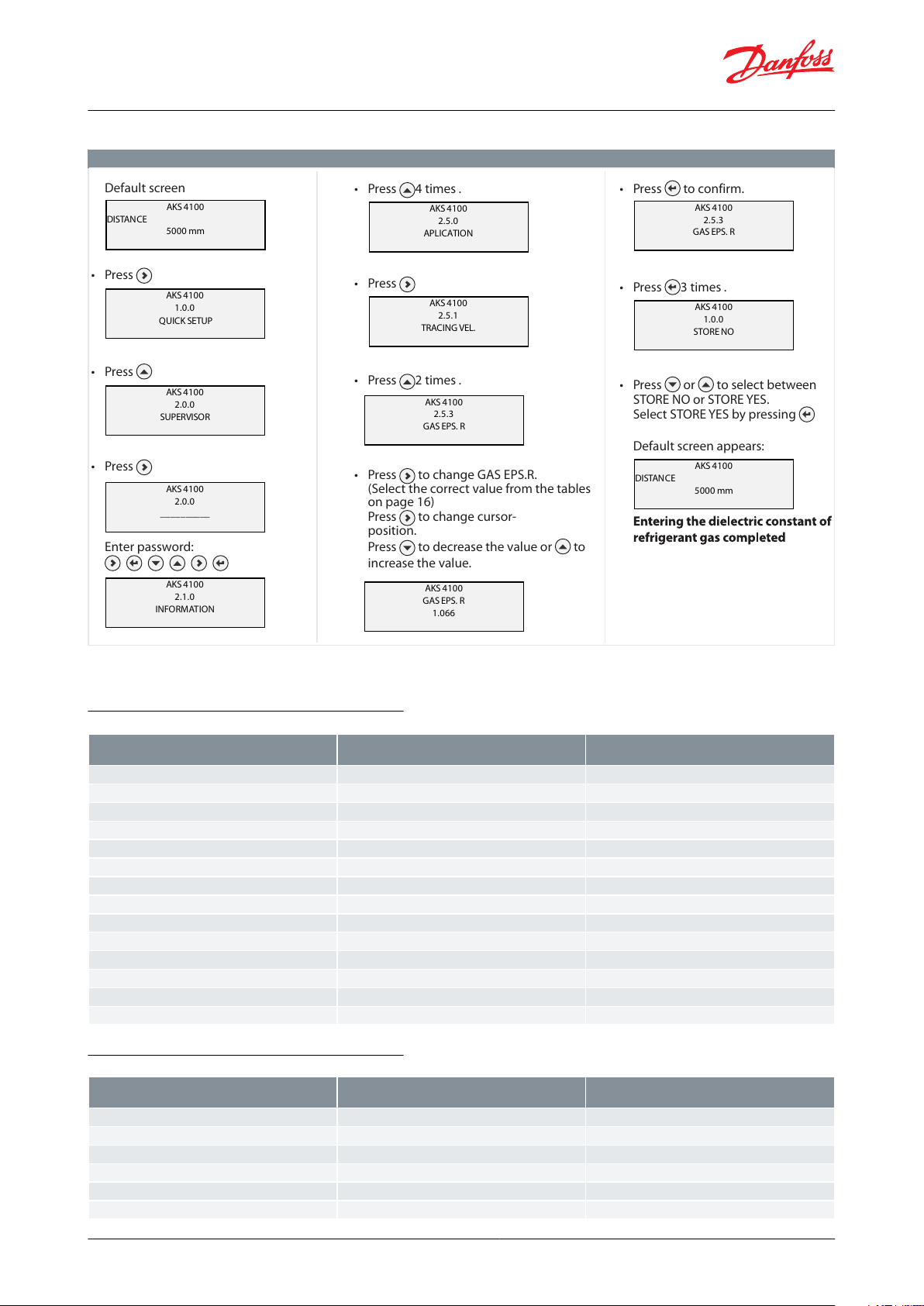

Entering refrigerant dielectric gas constant

Optional Procedure

Optional Procedure If the temperature condition in the stand pipe is known, a constant (dielectric constant of the

refrigerant gas) can be entered (parameter 2.5.3 GAS EPS.R), in order to obtain lower Top and Bottom Dead Zone

values (see Measuring range of AKS 4100/4100U - CABLE version and Measuring range of AKS 4100/4100U -

COAXIAL D14 version ).

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 23

Entering refrigerant dielectric gas constant (all values below are only examples)

Default screen

• Press

• Press

• Press

Enter password:

AKS 4100

DISTANCE

5000 mm

AKS 4100

1.0.0

QUICK START

AKS 4100

2.0.0

SUPERVISOR

AKS 4100

2.0.0

____ ______

AKS 4100

2.1.0

INFORMATION

AKS 4100

2.5.0

APLICATION

AKS 4100

2.5.1

TRACING VEL.

• Press 4 times .

• Press

• Press 2 times .

• Press to change GAS EPS.R.

(Select the correct value from the tables

on page 16)

Press to change cursor-

position.

Press to decrease the value or to

increase the value.

AKS 4100

2.5.3

GAS EPS. R

AKS 4100

GAS EPS. R

1.066

AKS 4100

2.5.3

GAS EPS. R

AKS 4100

1.0.0

STORE NO

AKS 4100

DISTANCE

5000 mm

• Press to confirm.

• Press 3 times .

• Press or to select between

ST

Select STORE YES by pressing

ORE NO or STORE YES.

Default screen appears:

QUICK SETUP

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

-60 – -42

-76 – -43

1

-41 – -18

42 – 0

1.01

-17 – -5

1 – 23

1.02

-4 – 4

24 – 39

1.03

5 – 12

40 – 54

1.04

13 – 18

55 – 64

1.05

19 – 24

65 – 75

1.06

25 – 28

76 – 82

1.07

29 – 33

83 – 91

1.08

34 – 37

92 – 99

1.09

38 – 40

100 – 104

1.1

41 – 44

105 – 111

1.11

45 – 47

112 – 117

1.12

48 – 50

118 – 122

1.13

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

-60 – -50

-76 – -58

1

-49 – -25

57 – -13

1.01

-24 – -10

-12 – 14

1.02

-9 – 0

15 – 32

1.03

1 – 8

33 – 46

1.04

9 – 15

47 – 59

1.05

Liquid level sensor, type AKS 4100 and AKS 4100U

Table 45: Entering refrigerant dielectric gas constant

Saturated vapour dielectric constant (default value: 1.066)

Temperature range: -60 / +50 °C (-76 / +122 °F)

Table 46: R717 (NH3)

Temperature range: -60 / +48 °C (-76 / +118 °F)

Table 47: R22

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 24

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

16 – 21

60 – 70

1.06

22 – 26

71 – 79

1.07

27 – 31

80 – 88

1.08

32 – 35

89 – 95

1.09

36 – 39

96 – 102

1.1

40 – 42

103 – 108

1.11

43 – 45

109 – 113

1.12

46 – 48

114 – 118

1.13

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

-65 – -47

-85 – -52

1.01

-46 – -35

-51 – -31

1.02

-34 – -26

-30 – -14

1.03

-25 – -19

-13 – -2

1.04

-18 – -13

-1 – 9

1.05

-12 – -8

10 – 18

1.06

-7 – -4

19 – 25

1.07

-3 – 0

26 – 32

1.08

1 – 4

33 – 40

1.09

5 – 7

41 – 45

1.1

8 – 10

46 – 50

1.11

11 – 12

51 – 54

1.12

13 – 15

55 – 59

1.13

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

-60 – -48

-76 – -54

1.01

-47 – -36

-53 – -32

1.02

-35 – -28

-31 – -18

1.03

-27 – -21

-17 – -6

1.04

-20 – -15

-17 – -5

1.05

-14 – -10

-4 – 14

1.06

-9 – -6

13 – 22

1.07

-5 – -2

23 – 29

1.08

-1 – 2

30 – 36

1.09

3 – 5

37 – 41

1.1

6 – 8

42 – 47

1.11

9 – 11

48 – 52

1.12

12 – 13

53 – 56

1.13

14 – 15

57 – 59

1.14

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

-56.0 – -42.0

-69 – -43

1.01

-41.0 – -28.0

-42 – -18

1.02

-27.0 – -17.0

-17 – 2

1.03

-16.0 – -9.0

3 – 16

1.04

-8.0 – -3.0

17 – 27

1.05

-2.0 – 2

28 – 36

1.06

3 – 7

37 – 45

1.07

Liquid level sensor, type AKS 4100 and AKS 4100U

Temperature range: -65 / +15 °C (-85 / +59 °F)

Table 48: R410A

Temperature range: -60 / +15 °C (-76 / +59 °F)

Table 49: R507

Temperature range: -56 / +15 °C (-69 / +59 °F)

Table 50: R744 (CO2)

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 25

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

8 – 11

46 – 52

1.08

12 – 14

53 – 58

1.091559

1.1

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

-60 – -42

-76 – -43

1

-41 – -18

-42 – -0

1.01

-17 – -4

1 – 25

1.02

-3 – 5

26 – 41

1.03

6 – 13

42 – 56

1.04

14 – 20

57 – 68

1.05

21 – 25

69 – 77

1.06

26 – 30

78 – 86

1.07

31 – 34

87 – 94

1.08

35 – 38

95 – 100

1.09

39 – 42

101 – 108

1.1

43 – 45

109 – 113

1.11

46 – 48

114 – 119

1.12

49 – 50

120 – 122

1.13

Temperature [°C]

Temperature [°F]

Dielectric constant of refrigerant gas Parameter

2.5.3 GAS EPS.R

-60 – -47

-76 – -52

1.01

-46 – -35

-51 – -31

1.02

-34 – -26

-30 – -14

1.03

-25 – -19

-13 – -2

1.04

-18 – -14

-1 – 7

1.05

-13 – -9

8 – 16

1.06

-8 – -4

17 – 25

1.07

-3 – 0

26 – 32

1.08

1 – 3

33 – 38

1.09

4 – 6

39 – 43

1.1

7 – 9

44 – 49

1.11

10 – 12

50 – 54

1.12

13 – 15

55 – 59

1.13

Liquid level sensor, type AKS 4100 and AKS 4100U

Temperature range: -60 / +50 °C (-76 / + 122 °F)

Table 51: R134a

Temperature range: -60 / +15 °C (-76 / +59 °F)

Table 52: R404A

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 26

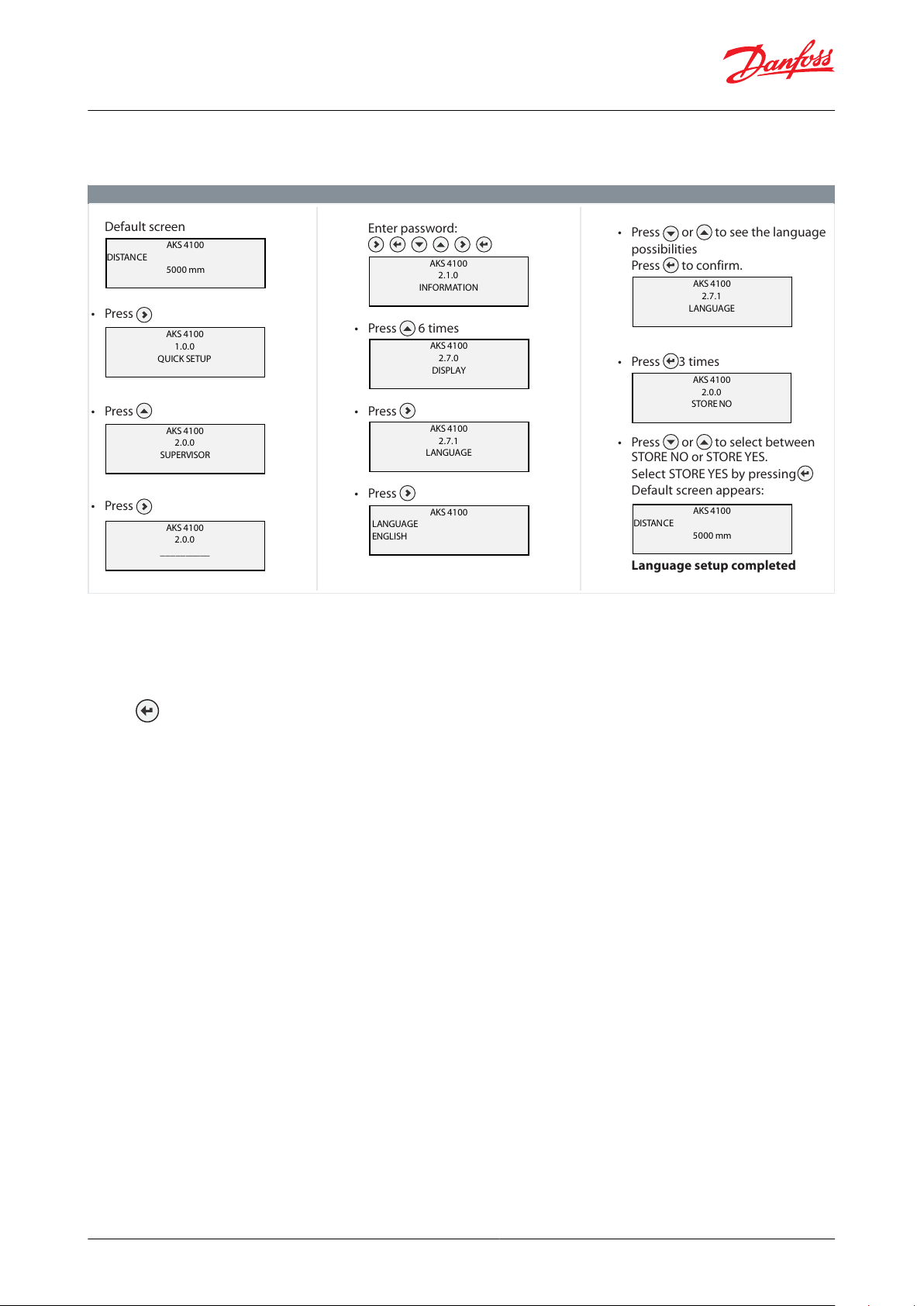

How to change the language setting (Default: English)

Default screen

• Press

• Press

• Press

AKS 4100

DISTANCE

5000 mm

AKS 4100

1.0.0

QUICK START

AKS 4100

2.0.0

SUPERVISOR

AKS 4100

2.0.0

____ ______

AKS 4100

2.1.0

INFORMATION

AKS 4100

DISTANCE

5000 mm

Enter password:

• Press 6 times

• Press

• Press

• Press or to see the language

possibilities

Press to confirm.

• Press 3 times

• Press or to select between

STORE NO or STOREYES.

Select STORE YES by pressing

Default screen appears:

Language setup completed

QUICK SETUP

AKS 4100

2.7.0

DISPLAY

AKS 4100

2.7.1

LANGUAGE

AKS 4100

LANGUAGE

ENGLISH

AKS 4100

2.7.1

LANGUAGE

AKS 4100

2.0.0

STORE NO

Liquid level sensor, type AKS 4100 and AKS 4100U

How to change the language setting (Default: English)

Table 53: How to change the language setting

Reset to factory setting

• Go to SUPERVISOR menu (see CABLE and COAXIAL version)

• Go to parameter 2.9.4 Reset Factory

• Select RESET FACTORY YES

• Press 3 times to return to default screen

• Factory reset completed

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 27

File name

Document type

Document topic

Approval authority

GOST FR.C.29.004.A 51938

Measuring - Performance Certicate

UA.1O146.D.00075-19

UA Declaration

EMCD/LVD

LLC CDC EURO-TYSK

033F0689.AA

EU Declaration

EMC

Danfoss

MD 033F0686.AH

Manufacturers Declaration

PED

Danfoss

033F0695.AA

Manufacturers Declaration

China RoHS

Danfoss

0F18749.513467890YTN

Pressure - Safety Certicate

CRN

TSSA

0F19272.2

Pressure - Safety Certicate

CRN

TSSA

This device fulls the statutory requirements of the EMC directives. The manufacturer certies successful testing of the product by applying the CE mark.

Valid for AKS 4100 - Not valid for AKS 4100U:

Pattern Approval Certicate of Measuring Instruments for the Russian Federation

Valid for AKS 4100 - Not valid for AKS 4100U:

In compliance with EMC regulations in the Russian Federation

EMC

EMC Directives 2004 / 108 / EC and 93 / 68 / EEC in conjunction with

EN 61326-1 (2006) and EN 61326-2-3 (2006). The device conforms to these standards if:

- the device has a coaxial probe or

- the device has a single probe that is installed in a metallic tank

LVD

Low-Voltage Directives 2006 / 95 / EC and 93 / 68 / EEC in conjunction with EN 61010-1 (2001)

NAMUR

NAMUR NE 21 Electromagnetic Compatibility (EMC) of Industrial Process and Laboratory Control Equipment

NAMUR NE 43 Standardization of the Signal Level for the Failure Information of Digital Transmitters

Liquid level sensor, type AKS 4100 and AKS 4100U

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 54: Valid approvals

Table 55: Approvals and certication

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 28

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.07 AI243386442914en-001101 | 29

Loading...

Loading...