Installation Guide

Danfoss

M84H0023_1

Danfoss

M84H0024_1

Danfoss

M84H0025_1

en

Liquid Level Sensor AKS 4100/4100U - Coaxial D14

zh

液位传感器 AKS 4100/4100U - 同轴套管式 D14

jp

タイプ AKS 4100/4100U - パイプ 式 D14

ru

Уровнимер AKS 4100/4100U - КОАКСИАЛ. D14

148R962 2

Available lengths:

可选长度:

使用できる長さ:

Доступные длины::

AKS 4100, 500 mm

AKS 4100, 800 mm

AKS 4100, 1000 mm

AKS 4100, 1200 mm

AKS 4100, 1500 mm

AKS 4100, 1700 mm

AKS 4100, 2200 mm

AKS 4100U, 19.2 in.

AKS 4100U, 30 in.

AKS 4100U, 45 in.

AKS 4100U, 55 in.

AKS 4100U, 65 in.

AKS 4100U, 85 in.

Info for UK customers only

Danfoss Ltd. Oxford Road, UB9

4LH Denham, UK

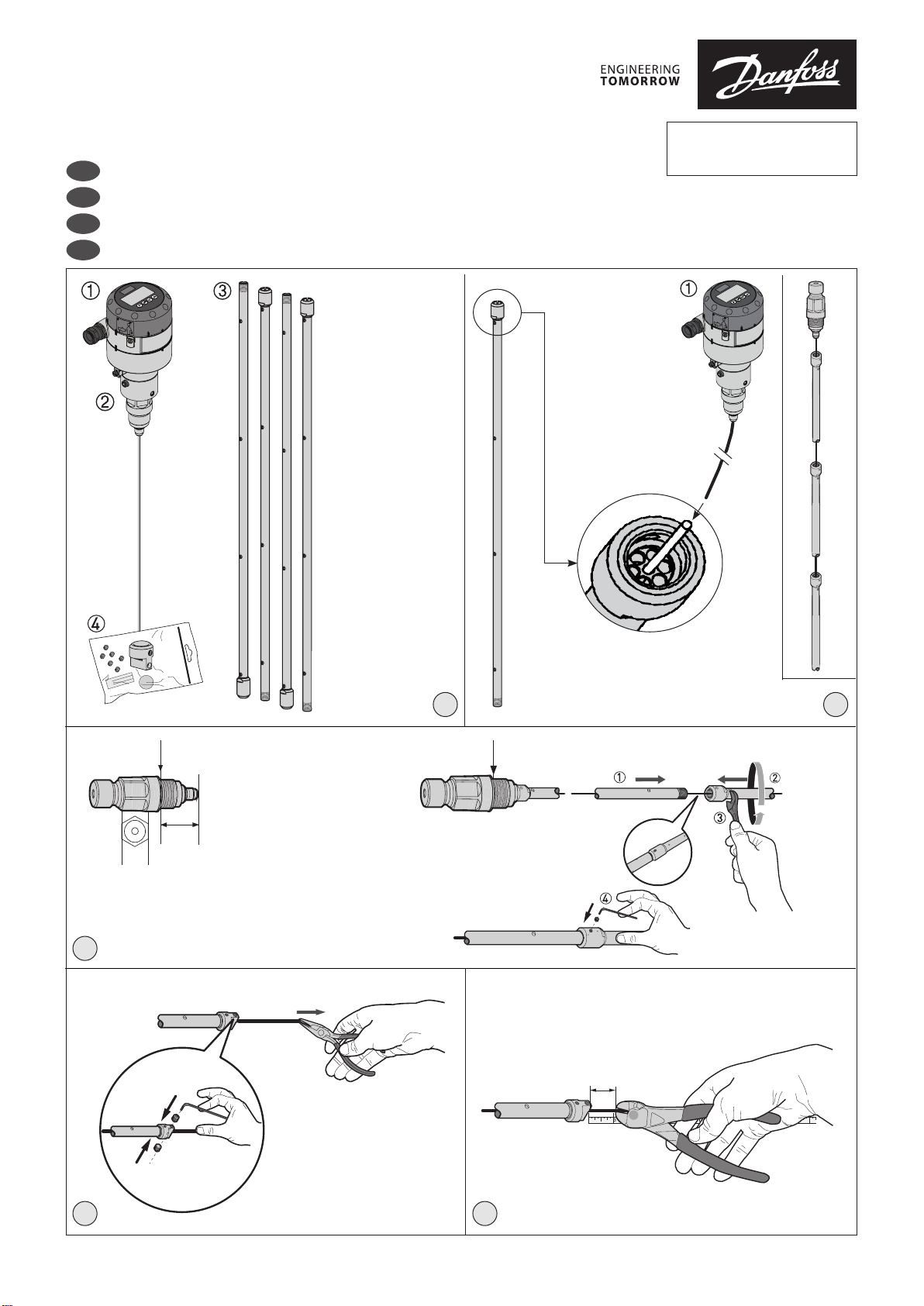

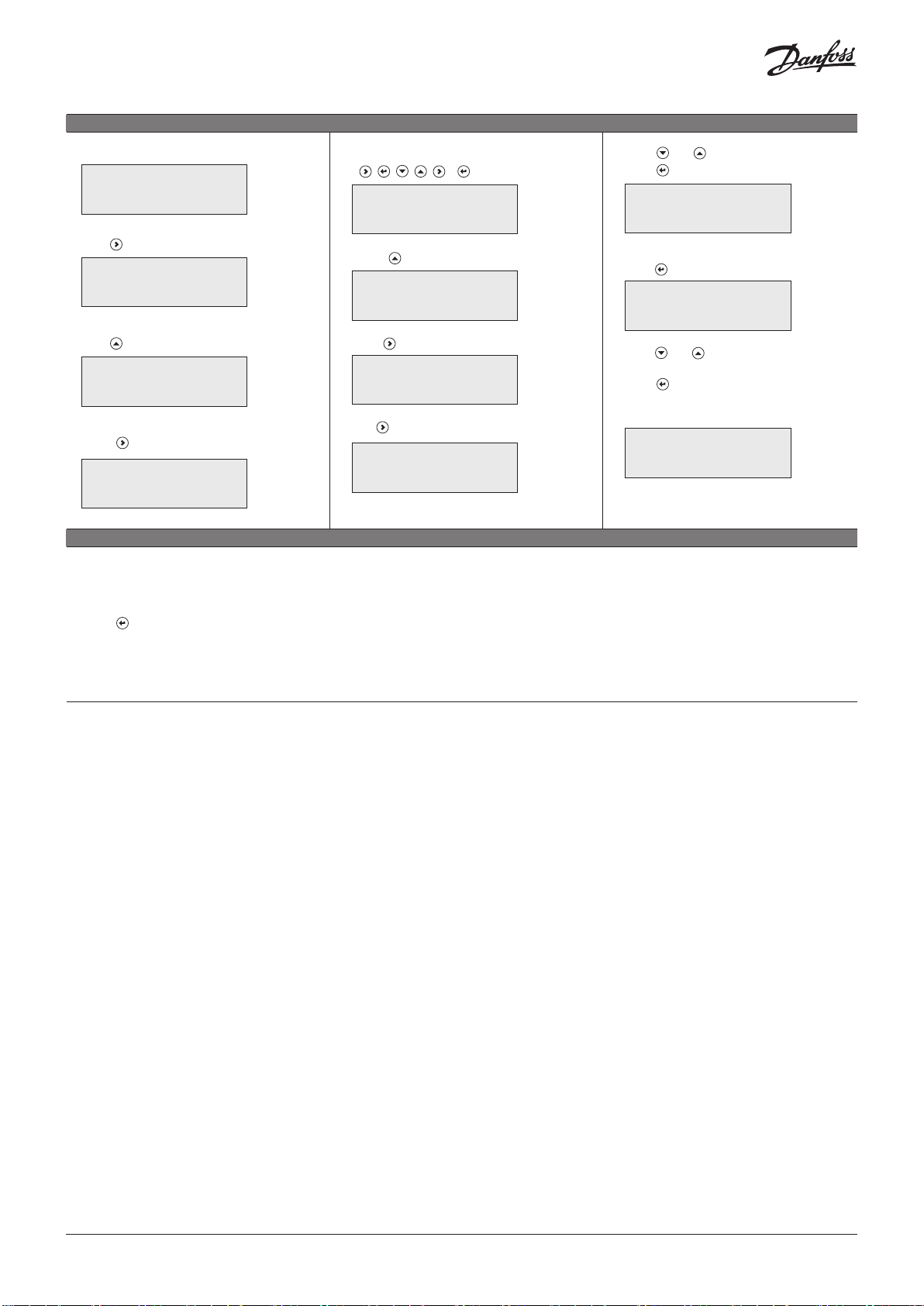

Push the wire through

the center hole.

将线缆

插入中间孔

ワイヤを

中央の穴に

押し込みます。

Пропустите трос через

центральное отверстие.

Danfoss

M84H0030_1

148R962 2

1 2

Reference point / 参照点 /

基準点 / Начальная точка

50 mm

36 mm

(1.4 in.)

(2 in.)

Reference point / 参照点 /

基準点 / Начальная точка

3

100 N

(23 lbs)

20 mm /

0.8 in.

4 5

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 1

B: 120 mm (4.7 in.)

H: (see tables)

Min: 30 mm (1.2 in.)

I: Ø2 mm (0.08 in.)

4 mA (0 %)*

Danfoss

M84H0072_1

20 mA

(100 %)*

A

G

C

D*

E

F

en zh

A Reference

point

B Top dead

zone

参照点

顶端死区

jp

基準点

上 部デ ッド

ゾーン

ru

2 | AN23828644201102-000501

C Measuring

D Probe

E Distance 距离

F Inner length

G Surface

H Buttom

* Values to be entered into HMI Quick Setup menu and recorded on the setting label.

Stick the setting label onto the Signal Converter either inside or outside.

将数值输入到 HMI 快速设置菜单,并在设置标签上标明。

将设置标签粘贴到信号转换器上,内侧或外侧均可。

HMI 高速設置メニューに入力して設定ラベルに記録する値。

内側か外側の設定ラベルを信号コンバータに貼り付けます。

Значения установленные при быстрой настройке уровнемера, необходимо

6

записать на бирку. Бирку можно разместить как и на преобразователе сигнала,

так и в нутри его.

Please note: It is mandatory to input dielectric constant for CO2 applications.

请注意:对于 CO2 应用,必须输入介电常数。

注意してください:CO2 を使用する場合には誘電率の入力が必須です

Внимание: при использовании с CO2 обезательно необходимо установить значение εr.

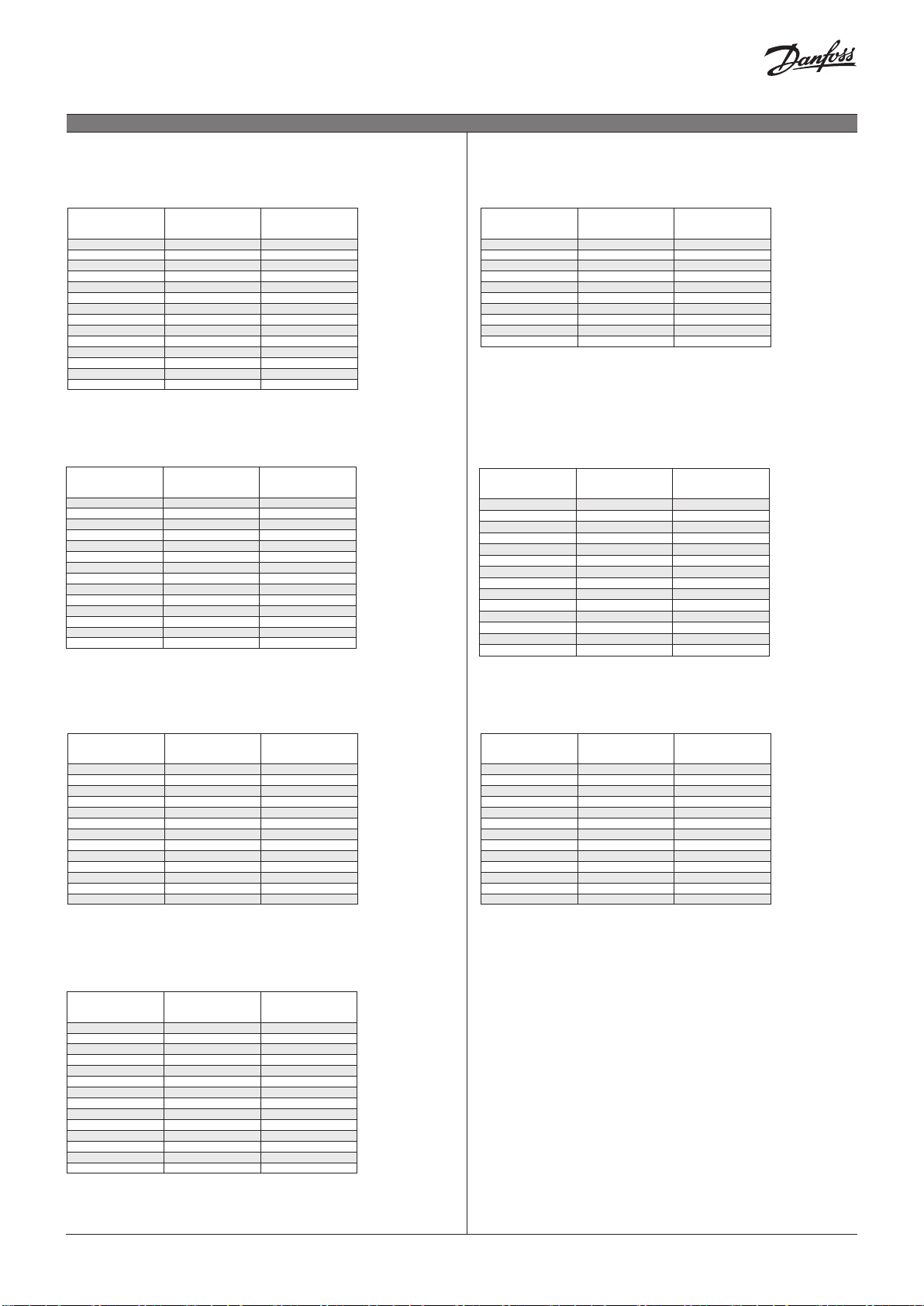

Dielectric Constant εr always set during Quick Setup

快速设置时总是要设置介电常数 εr

誘電率 εr は必ず高速設置中に設定してください。

Величина диэлектрической проницаемости (εr) всегда вводится через меню

«Быстрая настройка»

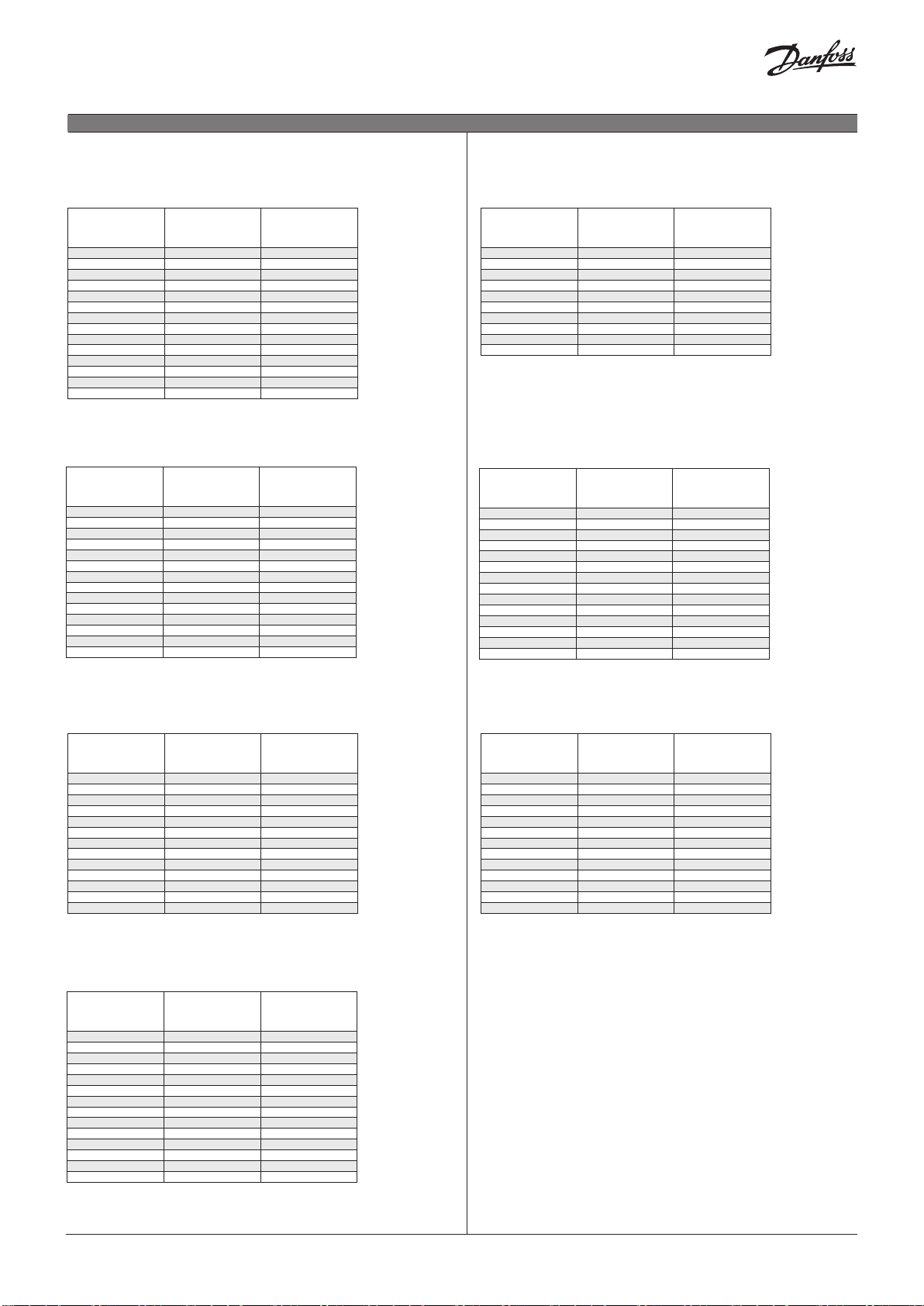

Refrigerant

制冷剂

冷媒

Хладагент

CO

2

Factory setting / 出厂设定 / 工場出荷時 の設定 / Заводская настройка

Refrigerant

制冷剂

冷媒

Хладагент

Ammonia

氨

アンモニア

Аммиак

Improved Bottom dead zone values after the adjustment of dielec tric constant

调整介电常数后,底端死区值有所改善

誘電率調整後の改良された下部デッドゾーンの値

Оптимизированные величины верхней и нижней мёртвых зон после введения

значения диэлектрической проницаемости

Refrigerant

制冷剂

冷媒

Хладагент

Ammonia

氨

アンモニア

Аммиак

Probe length

探头长度

プ ローブ 長

Длина измерительной

части

[mm] [in.] [mm] [in.]

500 19.7

800 31.5

1000 39.4

120 0 47. 2

150 0 59.1

170 0 6 6.9

2200 86.6

Probe length

探头长度

プ ローブ 長

Длина измерительной

части

[mm] [in.] [mm] [in.]

500 19.7 95 3.7

800 31.5 104 4.1

1000 39.4 110 4.3

120 0 47. 2 116 4.6

150 0 59.1 12 5 4.9

170 0 6 6.9 131 5. 2

2200 86.6 14 6 5.8

Probe length

探头长度

プ ローブ 長

Длина измерительной

части

[mm] [in.] [mm] [in.]

500 19.7

800 31.5

1000 39.4

120 0 47. 2

150 0 59.1

170 0 6 6.9

2200 86.6

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Нижняя м ертвая зона

170 6.7

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Нижняя м ертвая зона

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Нижняя м ертвая зона

80 3.2

Нижняя м ертвая зона

Нижняя м ертвая зона

Нижняя м ертвая зона

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Factory setting / 出厂设定 / 工場出荷時 の設定 / Заводская настройка

Refrigerant

制冷剂

冷媒

Хладагент

HCFC,HFC

Improved Bottom dead zone values after the adjustment of dielec tric constant

调整介电常数后,底端死区值有所改善

誘電率調整後の改良された下部デッドゾーンの値

Оптимизированные величины верхней и нижней мёртвых зон после введения

значения диэлектрической проницаемости

Refrigerant

制冷剂

冷媒

Хладагент

HCFC,HFC

Probe length

プ ローブ 長

Длина измерительной

[mm] [in.] [mm] [in.]

500 19.7 115 4.5

800 31.5 124 4.9

1000 39.4 130 5.1

120 0 47. 2 136 5.4

150 0 59.1 145 5.7

170 0 6 6.9 151 5.9

2200 86.6 16 6 6.5

Probe length

プ ローブ 長

Длина измерительной

[mm] [in.] [mm] [in.]

500 19.7

800 31.5

1000 39.4

120 0 47. 2

150 0 59.1

170 0 6 6.9

2200 86.6

range

length

of standpipe

level

dead zone

(see tables)

I Steel wire

insertion

length

探头长度

части

探头长度

части

测量范围

探头长度

計測範囲

プ ローブ 長

距離

立管内部

长度

直立管の内

部長さ

液位 液面レ ベル

底端死区

(参见表格)

下 部デッド

ゾーン (表を

参照

钢线插入长度鋼線挿入長

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Нижняя м ертвая зона

Bottom D ead Zone

底端死区

下 部デ ッド ゾーン

Нижняя м ертвая зона

100 3 .9

Bottom D ead Zone

下 部デ ッド ゾーン

Нижняя м ертвая зона

Bottom D ead Zone

下 部デ ッド ゾーン

Нижняя м ертвая зона

© Danfoss | DCS (ms) | 2020.12

底端死区

底端死区

Danf

M84H0010_1

④①

AKS 41/41U

AKS 4100/4100U

Unscrew

拧开

ねじを外す

Отвинтите

Screw

拧

ねじ

Закрутите

Screw

拧

ねじ

Закрутите

Connector for HMI

HMI 连接头

HMI 用コ ネクタ

Подсоединение HMI

8

oss

Cover stop. 2.5 mm / 0.2 in. Allen Key.

盖挡. 2.5 mm / 0.2 in. 内六角

カバー止め 2.5 mm / 0.2 インチ六角レンチ

Фиксатор крышки ключ на 2.5 мм/

0.2 дюйма.

Loosen cover stop

松开盖挡

カバー止めを緩めます

Фиксатор крышки

7

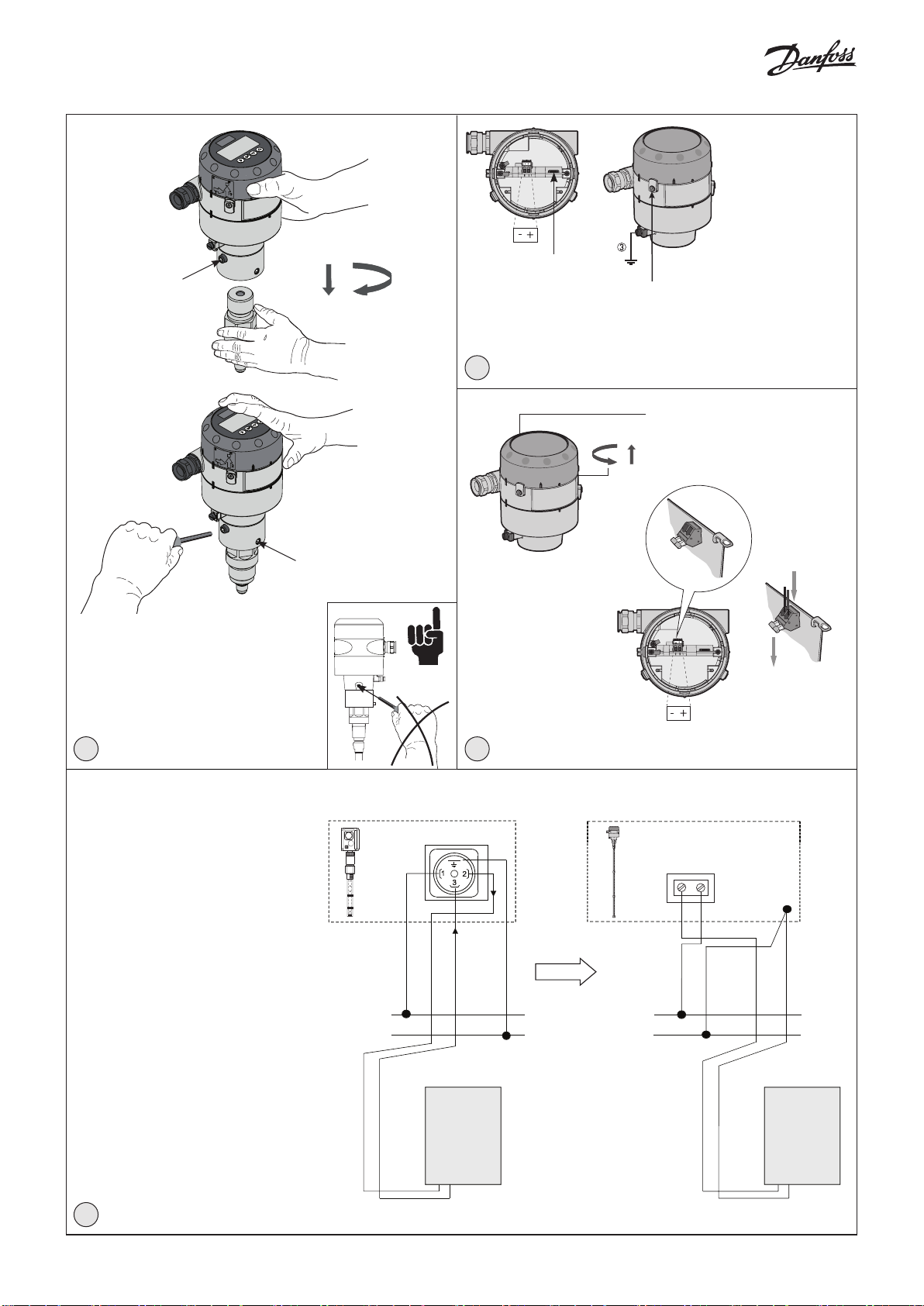

AKS 41/41U with a.c supply to

AKS 4100/4100U with d.c supply.

AKS 41/41U(交流电源)至

AKS 4100/4100U(直流电源)

AC 電源付き AKS 41/41U から DC 電源付き

AKS 4100/4100U へ

Замена AKS 41 на AKS 4100

AKS 41/41U перененный ток на

AKS 4100/4100U постоянный ток

①②③

24 V a.c (L)

24 V a.c (N)

9

(+)

(–)

Danfoss EKC 347

or PLC

4-20 mA

24 V d.c (+)

24 V d.c (–)

Danfoss

M84H0027_1

–

+

④

②

③

Danfoss EKC 347

or PLC

10

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 3

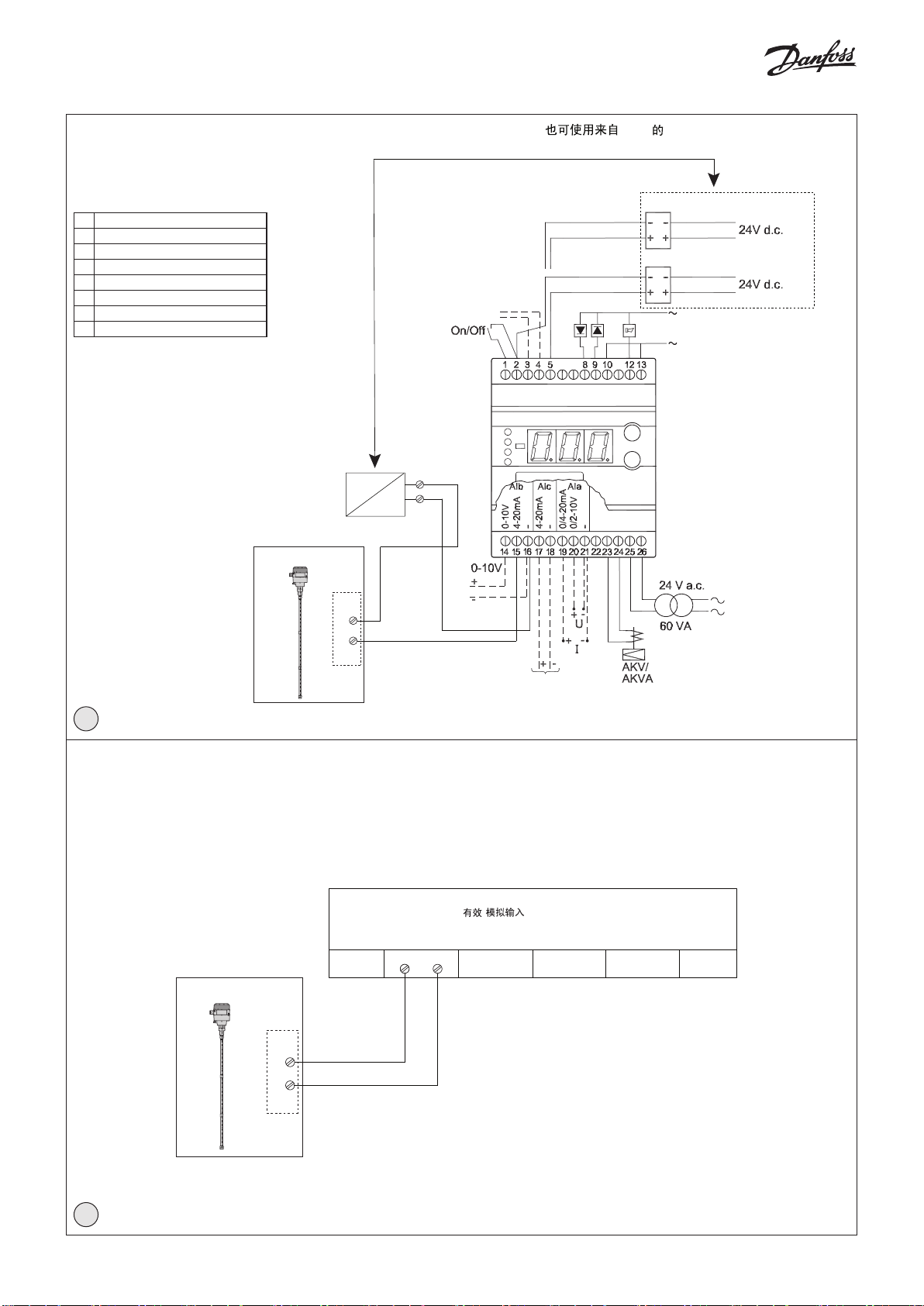

AKS 4100/4100U connected to EKC 347

Danfoss

M84H0074_1

AKS 4100/4100U 连接到 EKC 347

EKC 347 に接続した AKS 4100/4100U

AKS 4100 подсоединение к EKC 347

2. yellow / 黄 / 黄色 / желтый

1. grey / 灰色 / グレー / серый

green / 绿色 / 緑 /зеленый

brown / 棕色 / 茶 / коричневый

orang e / 橙 / オレン ジ / оранжевый

yellow / 黄 / 黄色 / желтый

brown / 棕色 / 茶 / коричневый

white / 白 / 白 / белый

24 V DC from ICAD can also be used /

ICAD からの 24 V d.c も 使 用 で き ます / Может использовать питание 24 в пост. тока от ICAD

ICAD

ICAD 1st generation (pre2010)

ICAD 2

/

24 V d.c

nd

generation (2010+)

(+)

Danfoss

M84H0073_2

11

AKS 4100/4100U connected to PLC

AKS 4100/4100U 连接到 PLC

AKS 4100/4100U PLC に接続

AKS 4100 подсоединение к PLC

AKS 4100/4100U

+

–

14-30 V d.c.

(–)

ICM/ICAD valve Feedback position

ICM / ICAD 阀反馈 位置

ICM/ICAD バルブ フィードバック位置

ICM/ICAD определение позиции клапана

PLC

Active an alog input 4 – 20 mA / 14 – 30 V DC

アクティブ アナログ入力 4~20 mA 14~30 V DC

Актив ный аналоговый вы ход 4 – 20 мА 14-30 В пост. тока

+

–

4-20 mA

14-30 V d.c.

E.g./ 例如/ 例 напр имер

EKC 347 5 VA

AKVA coil 20W 55 VA

AKS 4100/4100U

12

4 | AN23828644201102-000501

+

–

© Danfoss | DCS (ms) | 2020.12

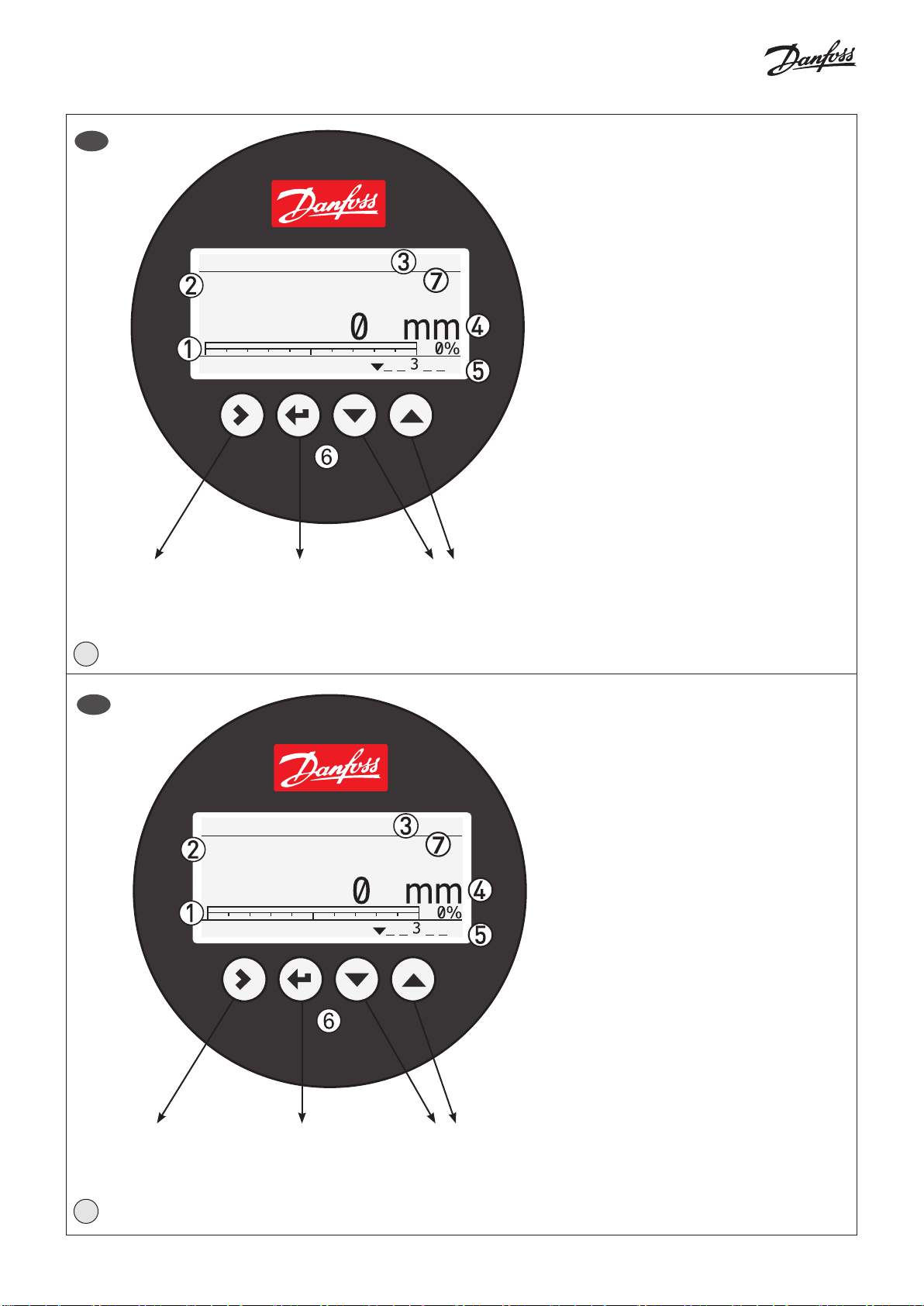

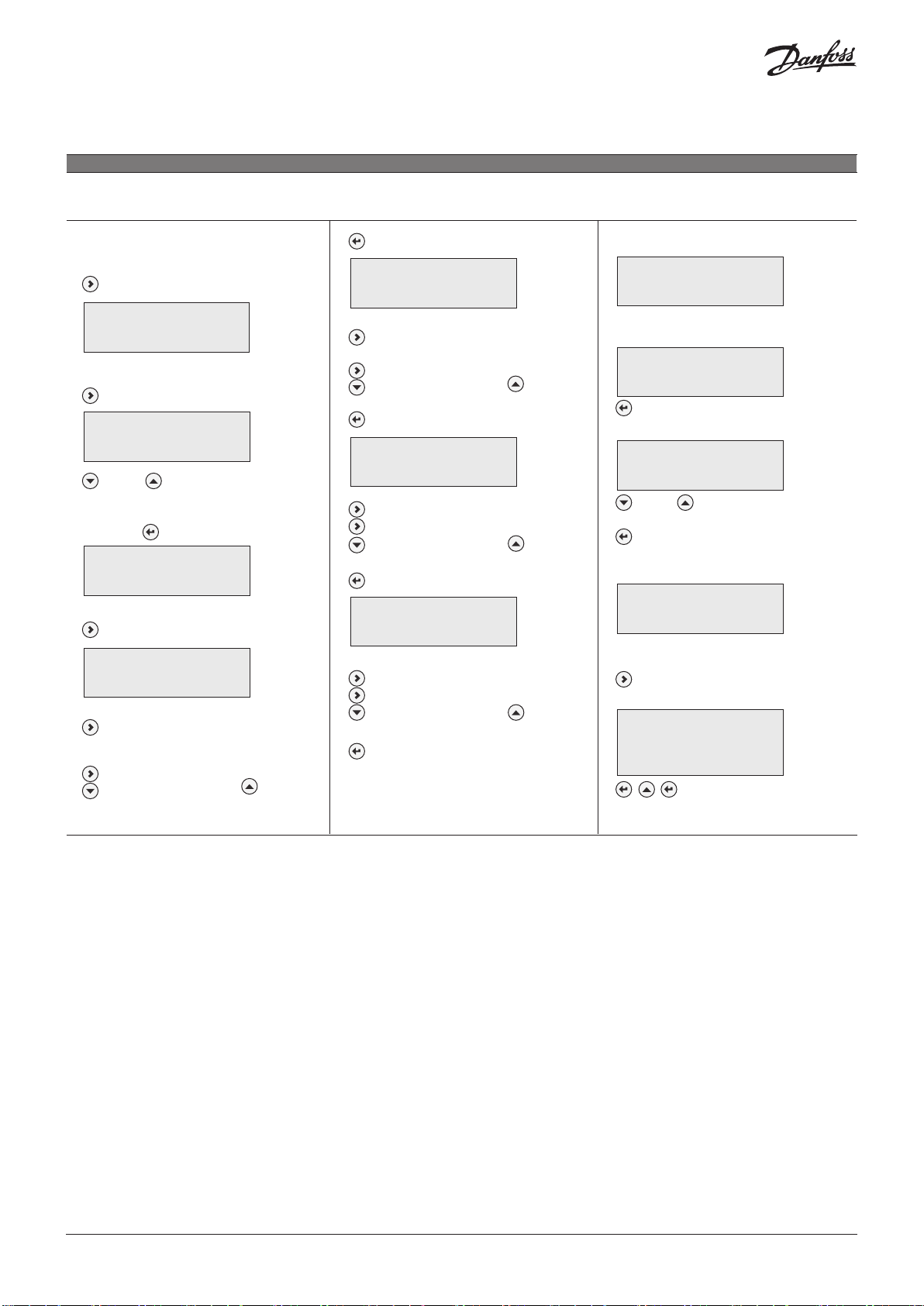

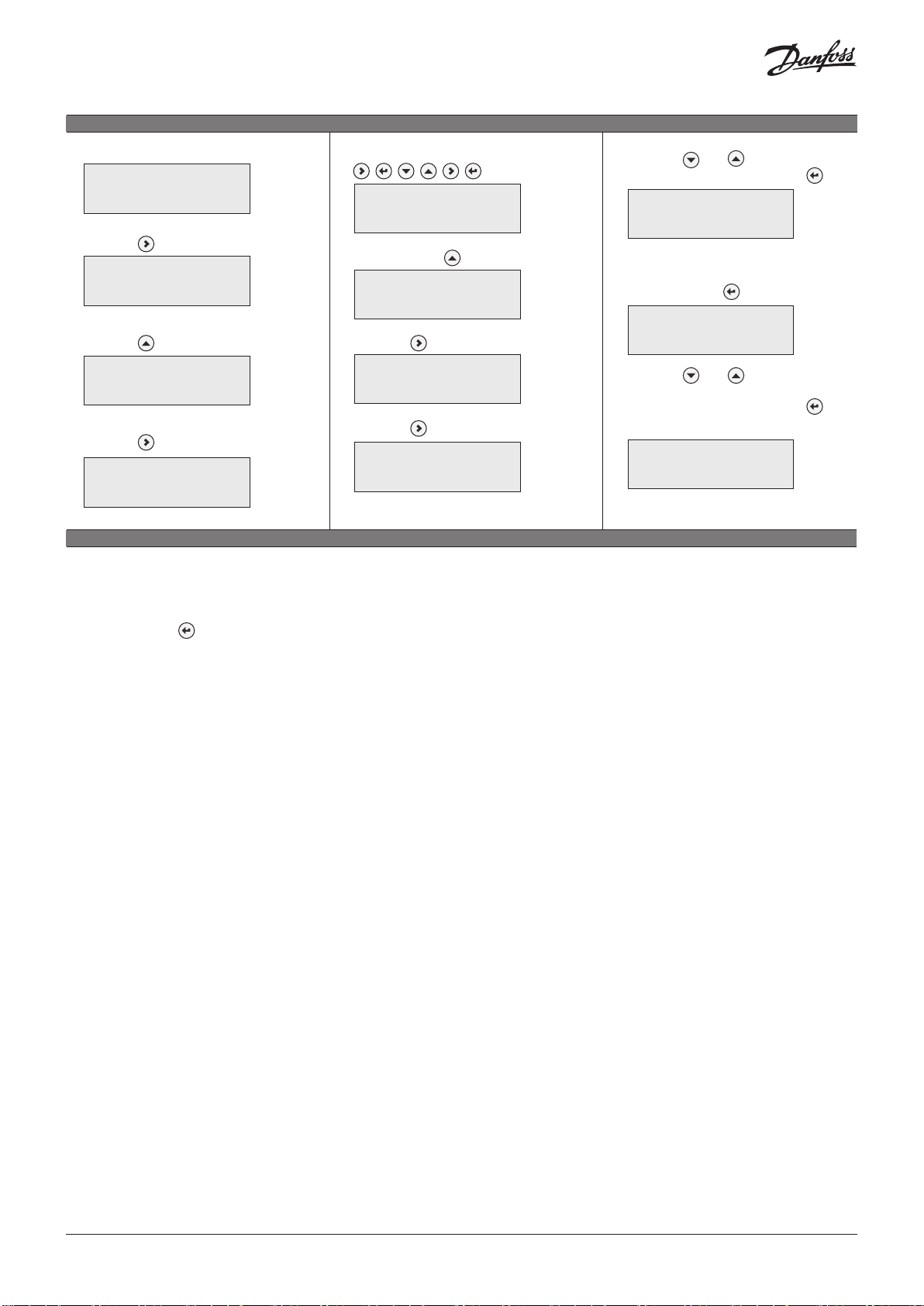

en

Enter menu system

Enter QUICK SETUP

13

DISTANCE

Unit change at

distance/level

readout:

m, cm, mm, in, ft

AKS 4100

*

Change between:

Distance*

Level**

Output (%)***

Output (mA)****

4 – 20 mA output displayed as bar graph

and in percentage [%]

Measurement name (in this example, DISTANCE)

Device tag name

Measurement reading and unit

Device status (markers)

Marker 1, 2 and 3 (Error)

Hardware problem; the Signal Converter hardware is

defective. Contact Danfoss.

Marker 4 and 5 (Notification)

Depending on the level, the marker is ON or OFF.

Used for Danfoss service information only.

Keypad buttons

Flashing star indicating unit in operation.

* DISTANCE is a display option.

If the display is set to “DISTANCE” the displayed value will

be the distance from the Reference point to the top

surface of the liquid refrigerant (see fig. 5).

** LEVEL is display option.

If the display is set to “LEVEL” then the value displayed

will be:

PROBE LENGTH (entered in QUICK SETUP)

– DISTANCE (see fig. 5).

*** OUTPUT (%) is display option.

Will represent the level of refrigerant,in percent, scaled

(entered in QUICK SETUP) according to: SCALE 4 mA

(0%), SCALE 20 mA (100%) (see fig. 5).

**** OUTPUT I (mA) is display option.

Will represent the level of refrigerant,in 4-20

milliampere, scaled (entered in QUICK SETUP)

according to: SCALE 4 mA (4 mA), SCALE 20 mA

(20 mA) (see fig. 5).

zh

距离

进入Menue system (菜单系统)

进入 QUICK SETUP (快速设置)

13

© Danfoss | DCS (ms) | 2020.12

AKS 4100

单位随距离/液位

读数而变化:

m、cm、mm、in、ft

*

切换选项:

Distance(距离) *

Level(液位)液位**

Output(输出)(%)***

Output(输出)(mA)****

① 4 – 20 mA 输出(以柱状图和百分比[%]显示)

② 测量值名称(本例中为距离)

③ 设备名称

④ 测量读数和单位

⑤ 设备状态(标记)

标记1、2和3(错误)

硬件问题;信号转换器硬件有缺陷。请联系丹佛斯。

标记4和5(通知)

根据不同的液位,标记为开或关。只用于丹佛斯服

务信息。

⑥ 按键

⑦ 闪烁的星星,表示设备正在工作。

* “Distance(距离)”是一个显示选项。

若将显示设为“Distance”,则显示的值是参照点至

制冷剂液面顶部的距离(参考图 6)。

** “Level(液位)”是一个显示选项。

若将显示设为“Level”,则显示的值为:

探头长度(在快速设置中输入) – 距离(参考图 6

)。

*** “Output(输出)(%)”是一个显示选项。

将以百分比形式显示制冷剂的液位,根据下列条件确

定标度(在快速设置中输入):

SCALE 4 mA(0%),SCALE 20 mA(100%)(参考图6)。

**** “Output(输出)(mA)”是一个显示

选项。

将以 4-20 毫安显示制冷剂的液位,根据下列条件确

定标度(在快速设置中输入):

SCALE 4 mA(4 mA),SCALE 20 mA

(20 mA)(参考图 6)。

AN23828644201102-000501 | 5

jp

メニュー システム に移 動

クイックセットアップ

に移動

13

距離

距離/レベル読み値

の単位を変更:

m、cm、mm、

イ ン チ 、フ ィ ー ト

AKS 4100

*

以下のいずれかに変更:

距離*

レベル*

出力 (%)***

出力 (mA)****

4 – 20 mA 出力をバーグラフとパーセンテージ

[%] で表示

計測名 (この例では「距離」)

装置タグ名

計測読み値と単位

装置ステータス (数値)

数値 1、2、3 (エラー)

ハ ードウェアの問題; 信号変換器 ハードウェアが故障。

Danfoss にご連絡ください。

数値 4 および 5 (通知)

レベルに応じて数値がオンまたはオフになります。

Danfoss のサービス情報としてのみ使用します。

キーパッド ボタン

点滅する星印は装置が動作中であることを示します。

* 「距離」は表示オプションです。

表示が「距離」に設定されている場合、表示

点から液体冷媒の上面までの距離になります (図 6 を参

照)。

** 「LEVEL ”レベル”」は表示オプションです。

表示が「LEVEL ”レベル”」に設定されている場合には、

表示される値は以下のようになります:プローブ長さ (高

速 設置で入力) – 距離 (図 5 を参照)。

***「OUTPUT (%) “出力(%)”」は表示オプションです。 冷媒

のレベルを (クイックセットアップで入力した) 以

下のスケールを基準としたパーセント単位で表示します:

4mA位置 (0%)、 20mA位置 (100%) (図 5 を参照)。

**** 「OUTPUT I (mA) “出力 (mA)”」は表示オプションです。 冷

媒のレベルを (クイックセットアップで入力した)

以下のスケールを基準として 4~20m A の範囲で表

示します:4mA位置 (4 mA)、 20mA位置 (20 mA) (図 5

を参照)。

される値は基準

ru

Вход в меню системы.

Запуск режима «Быстрая настройка».

13

Дистанция

Изменение единиц

измерения для

отображения расстояния/ уровня:

м, см, мм, дюймы,

футы.

AKS 4100

*

Переключение между:

Расстояние*

Уровень**

Выходной сигнал (%)***

Выходной сигнал (мА)****

Выходной сигнал 4 – 20 мА отображается на дисплее

в виде графической шкалы и виде процентов (%).

Наименование измеряемого параметра

(в данном примере это расстояние).

Модель уровнимера.

Единицы измерения.

Состояние прибора (в виде цифр):

Цифры 1, 2 и 3 (Ошибка)

Проблема с оборудованием; Отсутствие сигнала;

Низкое напряжение. Обратитесь в Danfoss.

Цыфры 4 и 5 (Уведомления)

В зависимости от значения уровня.

Кнопки панели управления

Мигающая звёздочка, показывает, что

прибор работает.

* РАССТОЯНИЕ.

В случае отображения на дисплее параметра

“РАССТОЯНИЕ”, измеряемой величиной будет являться

расстояние между нулевой точкой и поверхностью

жидкого холодильного агента (см. Рис. 5).

** УРОВЕНЬ.

В случае отображения на дисплее параметра

“УРОВЕНЬ”, измеряемой величиной будет являться

разница значений “ДЛИНА ТРОСА” (вводится при

“БЫСТРОЙ НАСТРОЙКЕ”) – РАССТОЯНИЕ (см. Рис. 5).

*** Выходной сигнал (%).

Указываетпроцент заполнения сосуда холодильным

агентом в зависимости от значения:

Точки 4 мА (0%) и Точки 20 мА (100%)

(см. Рис. 5) (указываются при “БЫСТРОЙ

НАСТРОЙКЕ”).

**** Выходной сигнал (мА).

Указывает уровень холодильного агента в сосуде, в

соответствии с диапозоном

4 – 20 мА, в зависимости от значения:

Точки 4 мА (0%) и Точки 20 мА (100%)

(см. Рис. 5) (указываются при “БЫСТРОЙ

НАСТРОЙКЕ”).

6 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

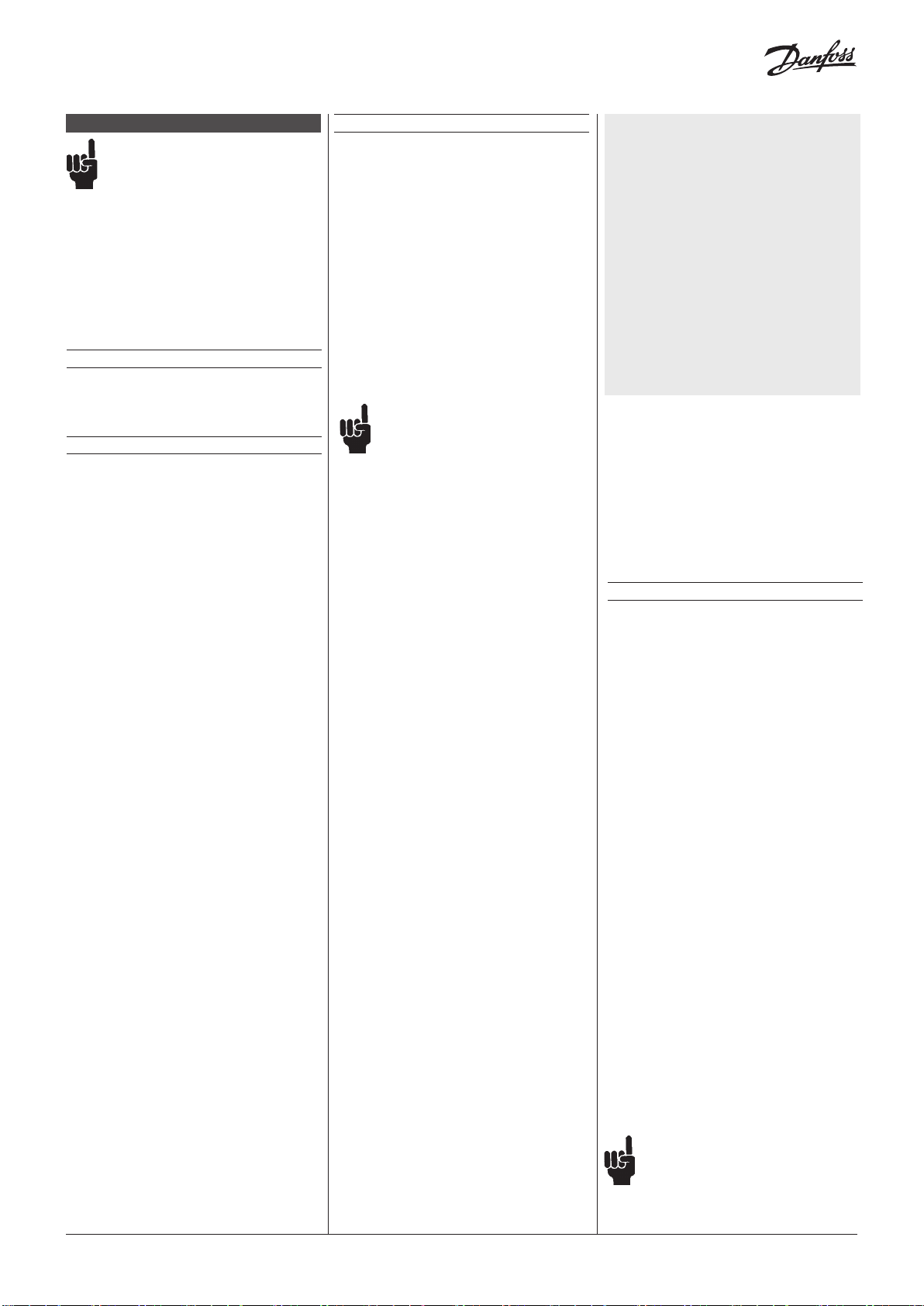

ENGLISH

Please observe that AKS 4100/4100U is

intended to always be* installed in a

standpipe (column/bypass/stilling well).

A standpipe is commonly used when:

• Servicing the AKS 4100/4100U

• There is highly conductive foam in the tank.

• The liquid is very turbulent or agitated.

AKS 4100/4100U Coaxial with or without

HMI does not need any change of setting to

operate, unless used in CO2.

Presetting:

4 mA : Probe length - 100 mm (4 in.)

20 mA: 120 mm (5 in.)

Refrigerants

AKS 4100/4100U is designed specifically to

measure liquid level in the most commonly

used refrigerants, including R744 (CO2),

R717(ammonia), HCFC, HFC and non corrosive

gases/liquids.

Basic data

AKS 4100/4100U is a passive 2-wire 4 – 20 mA

sensor that is loop powered.

Supply Voltage

14 – 30 V DC min/max. value for a max. output of

22 mA at the terminal

Load

RL [Ω] ≤ ((Uext -14 V)/20 mA).

– Default (Error output set to 3.6 mA)

RL [Ω] ≤ ((Uext -14 V)/22 mA).

– (Error output set to 22 mA)

Cable gland

AKS 4100 PG 13, M20×1.5 ;

(cable diameter:

6-8 mm (0.24-0.31in.)

AKS 4100U ½ in. NPT

Terminals (spring loaded)

0.5-1.5 mm2 (~20-15 AWG)

Enclosure

IP 67 (~NEMA type 4X)

Refrigerant temperature

-60 – 100 °C / -76 – 212 °F

Refrigerants

The listed refrigerants are qualified and approved

by Danfoss:

R717 / NH3: -40 – 50 °C / -40 – 122 °F

R744 / CO2: -50 – 15 °C / -58 – 59 °F

HCFC:

R22: -50 – 48 °C / -58 – 118 °F

HFC:

R404A: -50 – 15 °C / -58 – 59 °F

R410A: -50 – 15 °C / -58 – 59 °F

R134A -40 – 50 °C / -40 – 122 °F

Ambient temperature

-40 – 80 °C / -40 – 175 °F

For HMI : -20 – 60 °C / -4 – 140 °F

Process pressure

-1 – 100 barg / -14.5 – 1450 psig

Mechanical process connection with 5 m / 197 in.

Ø2 mm / 0.08 in. stainless cable:

AKS 4100 G1 inch pipe thread.

Aluminium gasket included

AKS 4100U ¾ in. NPT

(Further details in the Technical Brochure)

Mechanical Installation

Preparations prior to Mechanical Installation

Disassemble the Signal Converter from the

Mechanical process connection (use 5´mm hex

key, see fig. 7). Fit the red protection cover on

top of the Mechanical process connection to

protect it againt any moisture or dirt paticles.

Content supplied (fig 1)

Signal Converter (with or without HMI)

Mechanical process connection with

5 m / 197 in. Ø2 mm / 0.08 in. stainless wire

Tube(s)

Bag with:

End Connector (incl. 3 mm set screws.)

3 mm set crews (1 set screw pr. tube)

Red cover to protect Mechanical process

connection , before Signal converter is

mounted

Setting label.

Assembly of the segmented coaxial probe

Please observe that the stainless

steel wire is not permanently creased

or kinked.

1. Take the end of the stainless wire and feed it

through the center hole of the plastic spacer

located at the top of each tube (see fig. 2).

Feed the entire length of the stainless wire

through the tube and out at the bottom. If

more than one tube; repeat the steps.

2. Assemble the segments of tube and

(see fig. 3). Use a 17 mm open-end

wrench to tighten the assembled parts.

3. If more than one tube; repeat the steps

(see fig. 3).

4. Prior to assemble, disassemble signal

converter and mechanical process connection,

and fit red protection cap at mechanical

process connection. Thread the fully

assembled tube onto the mechanical process

connection .

5. Lock each tube by tightening the set screw

with a 3 mm hex key (see fig. 3).

6. Pull the stainless wire through the end

connector (see fig.4).

7. Attach the end connector to the bottom

of the fully assembled tube.

Tighten the set screw with a 3 mm hex key

(see fig. 4).

8. Pull the end of the stainless steel wire

extending from the end connector with

pliers (see fig. 4) to ensure that the tension in

the signal cable is correct. Tighten the 2 set

screws with a 3 mm hex key to lock the

stainless wire.

9. Cut the stainless wire about 20 mm / 0.8 in.

below the end connector (see fig. 5).

10. Measure the probe length (without the signal

converter) before fitting the assembled probe

in the standpipe (see fig. 6).

Use a torque wrench to tighten the

mechanical process connection

(fig. 1, item 2) to 120 Nm (89 lb/ft).

If factory setting needs adjustment

Probe length, scale 4 mA and 20 mA for HMI

Quick Setup.

Probe length:

See probe length on Danfoss product label or

measure probe length (see fig. 6).

Scale 4 mA: (for max. measuring range)

= Probe Length

– Bottom dead zone (see fig. 6)

Scale 20 mA:(for max. measuring range:)

= Top dead zone (see fig. 6)

Example (AKS 4100)

Given conditions:

Probe length: 1200 mm

Refrigerant: CO2, –35°C

The gas constant Er is always adjusted from

the Quick Setup

Probe length:

= 1200 mm

SCALE 4 mA setting for max. measuring range:

= Probe length (1200 mm)

– Bottom dead zone (see fig. 6)

(170 mm) = 1030 mm (40.9 in.)

SCALE 20 mA Setting for Max. Measuring

range:

= Top dead zone (see fig. 6)

= 120 mm / 4.7 in.

From page 11:

Dielectric constant of refrigerant gas

parameter 2.5.3 GAS EPS.R

= 1.02

How to mount the AKS 4100/4100U Converter

(see fig 7)

1. Unscrew the set and ventilation screws with a

5 mm Hexagon key in the Signal converter.

2. Push the Signal Converter downwards to stop

on the Mechanical process connection

3. Turn the Signal Converter to the wanted

position.

4. Screw the set screw with a 5 mm Hexagon key.

5. Screw the ventilation screw with a 5 mm

Hexagon key.

Electrical installation/connection

Output terminals (fig. 8 and 9):

1. Current output –

2. Current output +

3. Grounding terminal

Electrical installation procedure

1. Use a 2.5 mm Allen wrench to loosen the

cover stop.

2. Remove the terminal compartment cover

from the housing.

3. Do not disconnect the wire from the

terminal compartment cover.

Put the terminal compartment cover

adjacent to the housing.

4. Connect the wires to the device.

Tighten the cable entry glands.

5. Attach the terminal compartment cover

to the housing.

6. Use a 2.5 mm Allen wrench to tighten the

cover stop.

Note:

The signal converter can be programmed

with or without mechanical process connector

assembled.

Start up:

• Connect the converter to the power supply.

• Energize the converter.

Devices with the HMI display option only:

After 10 seconds the screen will display "Starting

up". After 20 seconds the screen will display the

software version numbers. After 30 seconds the

default screen (fig. 13) will appear.

Precausions when changing from

AKS 41/41U to the AKS 4100/4100U:

Please note:

The AKS 41/41U can be used with AC and DC

supply, but the AKS 4100/4100U can only be

used with a DC supply. Follow the instructions

in fig. 10.

Connecting to controller or PLC

Follow the instructions in fig. 11 or 12.

Note:

The current output will be set to 3.6 mA

whenever the AKS 4100/4100 detects an

error like Marker 1, 2 or 3 (see page 5).

Quick Setup →

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 7

Note:

The signal converter can be programmed with or without mechanical process connector assembled.

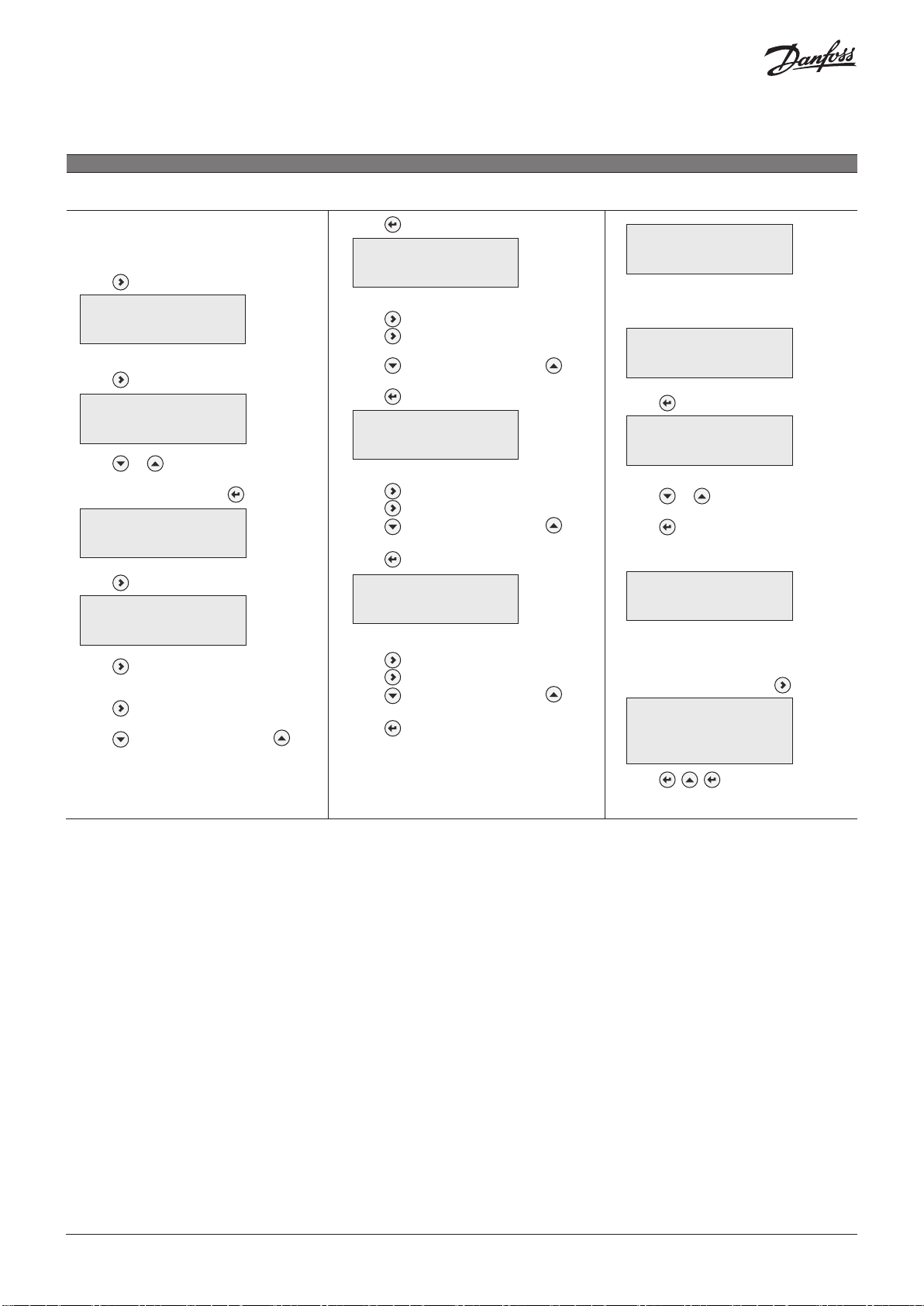

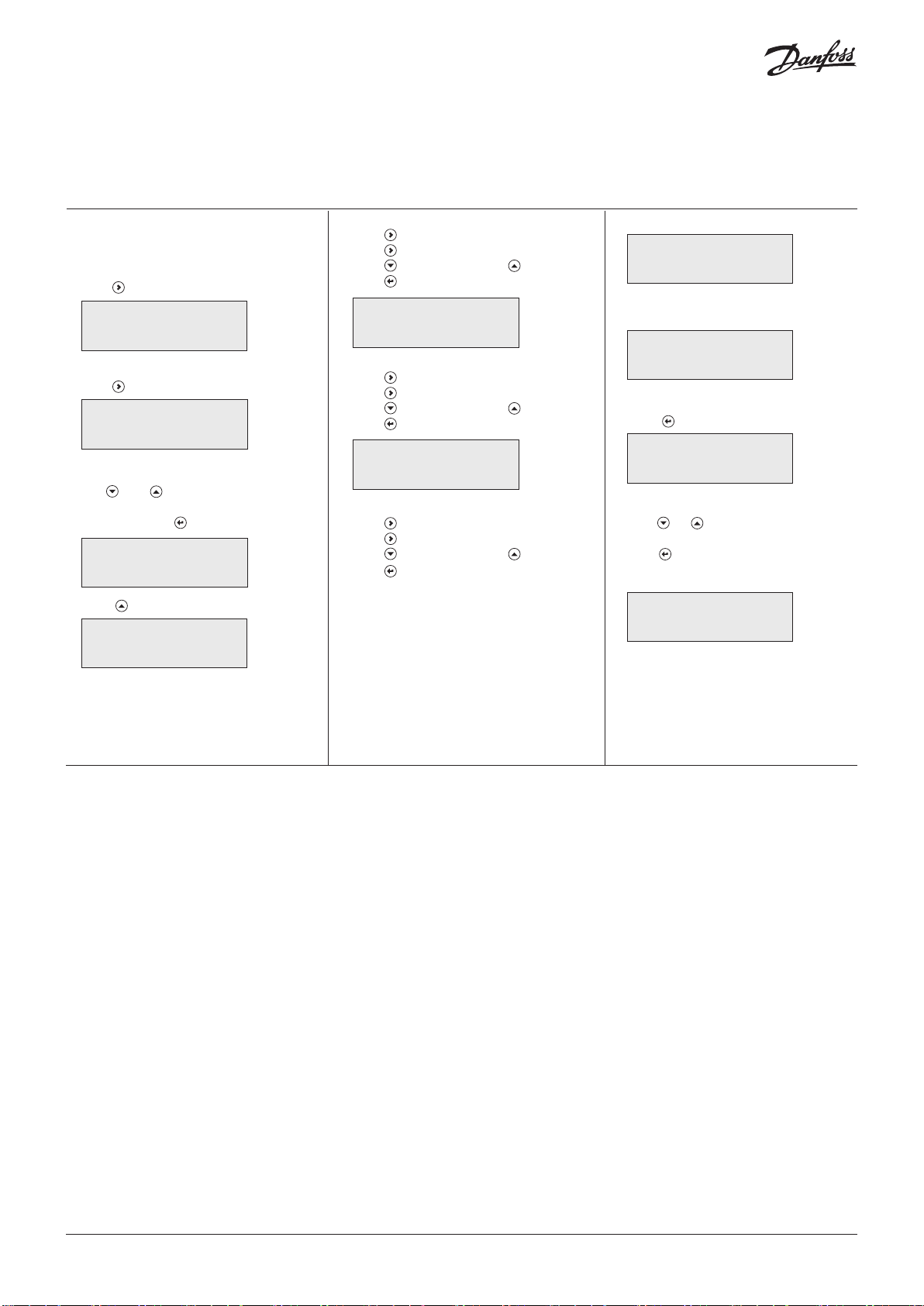

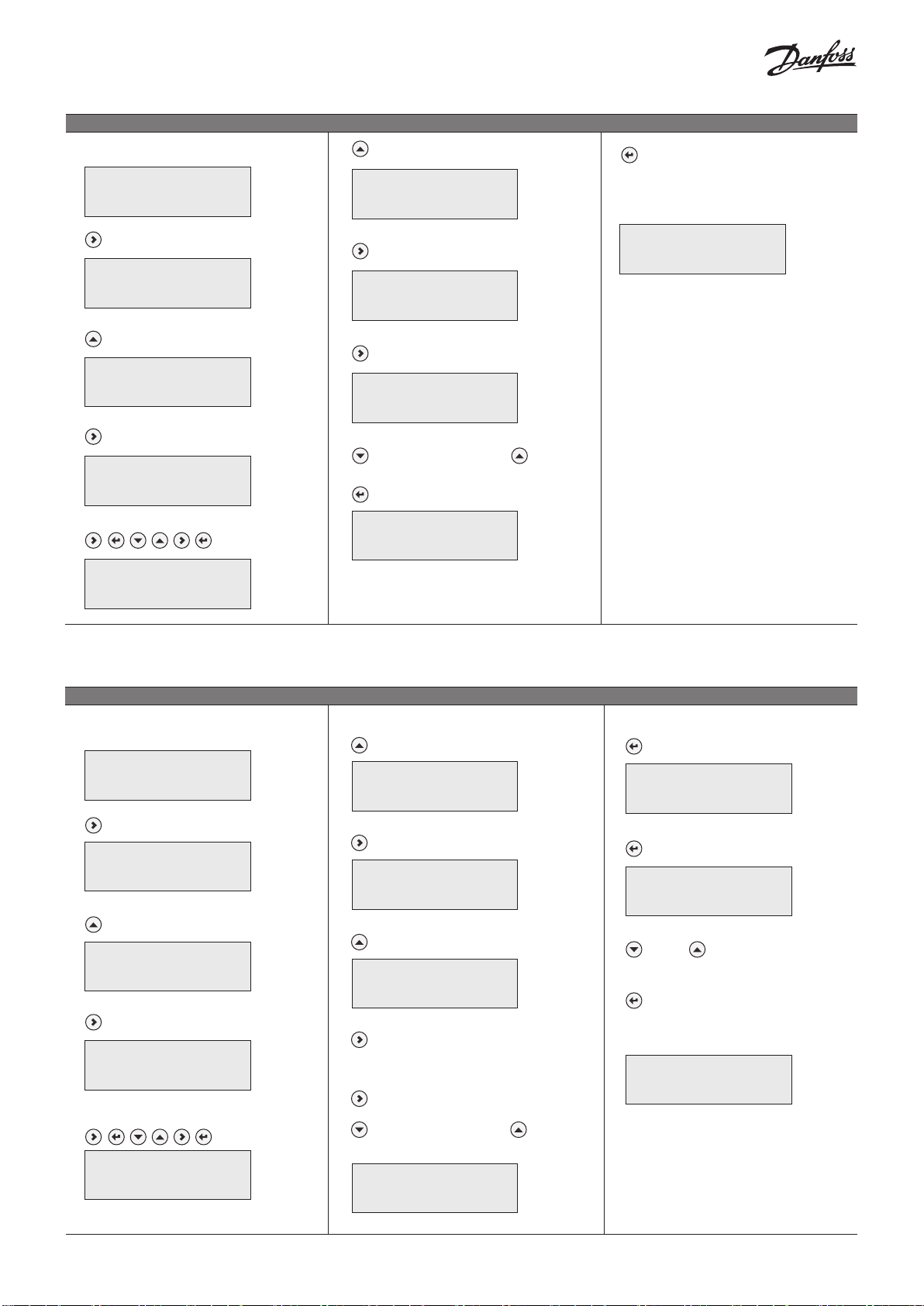

Quick Setup (all values below are only examples)

When CO2 is used:

• Connect the device to the power supply

(see the section "Electrical installation/

connection").

• Press 3 times.

AKS 4100

QUICK SETUP?

YES NO

• Press

AKS 4100

PROBETYPE

SINGLECABLE

• Press or to select between SINGLE,

COAXIAL D14 and COAXIAL D22. Choose

COAXIAL D14 and press to confirm.

AKS 4100

LIQUID CO2?

YES NO

• Press (YES) to confirm

AKS 4100

GAS EPS R?

001.000

• Press to change GAS EPS.R.

(Select the correct value from the tables

on page 8)

Press to change cursor position.

Press to decrease the value or to

increase the value.

• Press to confirm.

AKS 4100

PROBE LENGTH

05000 mm

• Press to change the PROBE LENGTH.

Press to change the position of the

cursor.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

SCALE 4mA

04946 mm

• Press to change of SCALE 4 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

SCALE 20mA

00070 mm

• Press to change of SCALE 20 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

QUICK SETUP

COMPLETED IN 8

• Wait for QUICK SETUP to complete.

Count down from 8 sec.

AKS 4100

1.0.0

QUICK SETUP

• Press to confirm.

AKS 4100

1.0.0

STORE NO

• Press or to select between

STORE NO or STORE YES.

Press to confirm.

Default screen appears:

DISTANCE

5000 mm

AKS 4100

Quick Setup completed

You have the possibility of checking

your settings by pressing twice.

COAXIAL D14 2200 mm

(0%) 4 mA 1900 mm

(100%) 20 mA 70 mm

Press

AKS 4100

to return to

default screen.

8 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

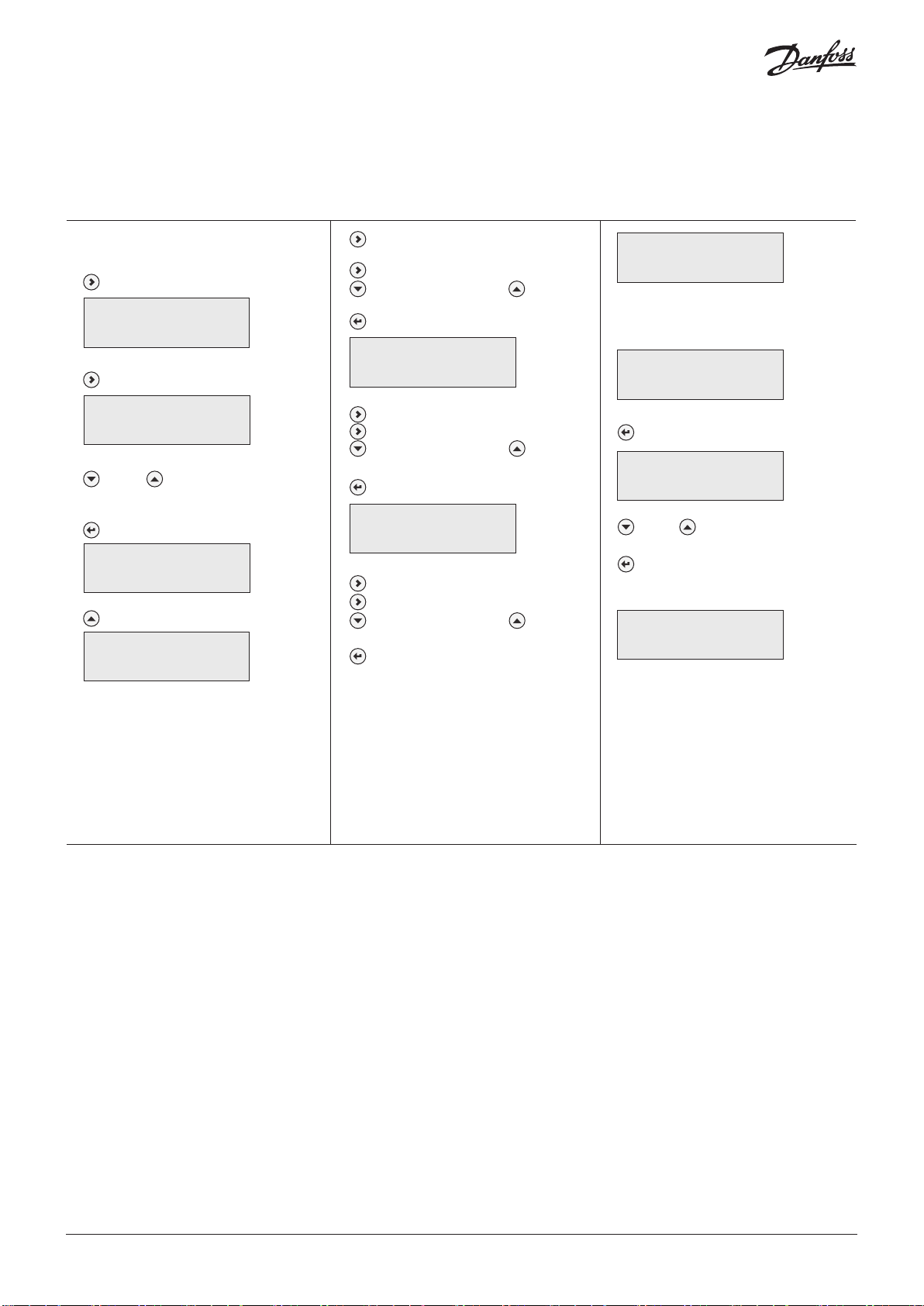

For all other refrigerants:

• Connect the device to the power supply

(see the section "Electrical installation/

connection").

• Press 3 times.

AKS 4100

QUICK SETUP?

YES NO

• Press

AKS 4100

PROBETYPE

SINGLECABLE

• Press or to select between SINGLE,

COAXIAL D14 and COAXIAL D22. Choose

COAXIAL D14 and press to confirm.

AKS 4100

LIQUID CO2?

YES NO

• Press (NO) to confirm

AKS 4100

PROBE LENGTH

05000 mm

• Press to change the PROBE LENGTH.

Press to change the position of the

cursor.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

SCALE 4mA

04946 mm

• Press to change of SCALE 4 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

SCALE 20mA

00070 mm

• Press to change of SCALE 20 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

QUICK SETUP

COMPLETED IN 8

• Wait for QUICK SETUP to complete.

Count down from 8 sec.

AKS 4100

1.0.0

QUICK SETUP

• Press to confirm.

AKS 4100

1.0.0

STORE NO

• Press or to select between

STORE NO or STORE YES.

Press to confirm.

Default screen appears:

AKS 4100

DISTANCE

5000 mm

Quick Setup completed

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 9

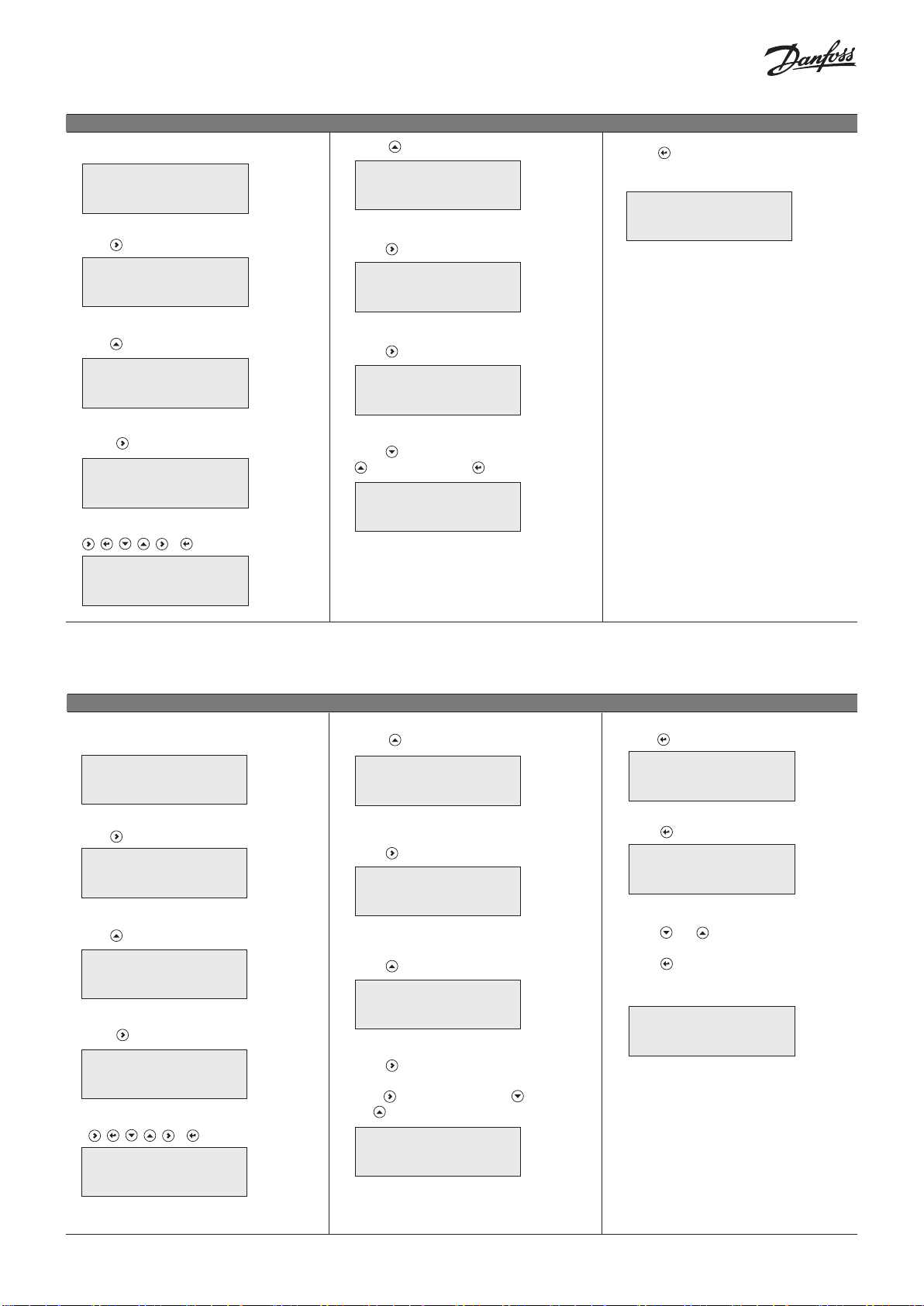

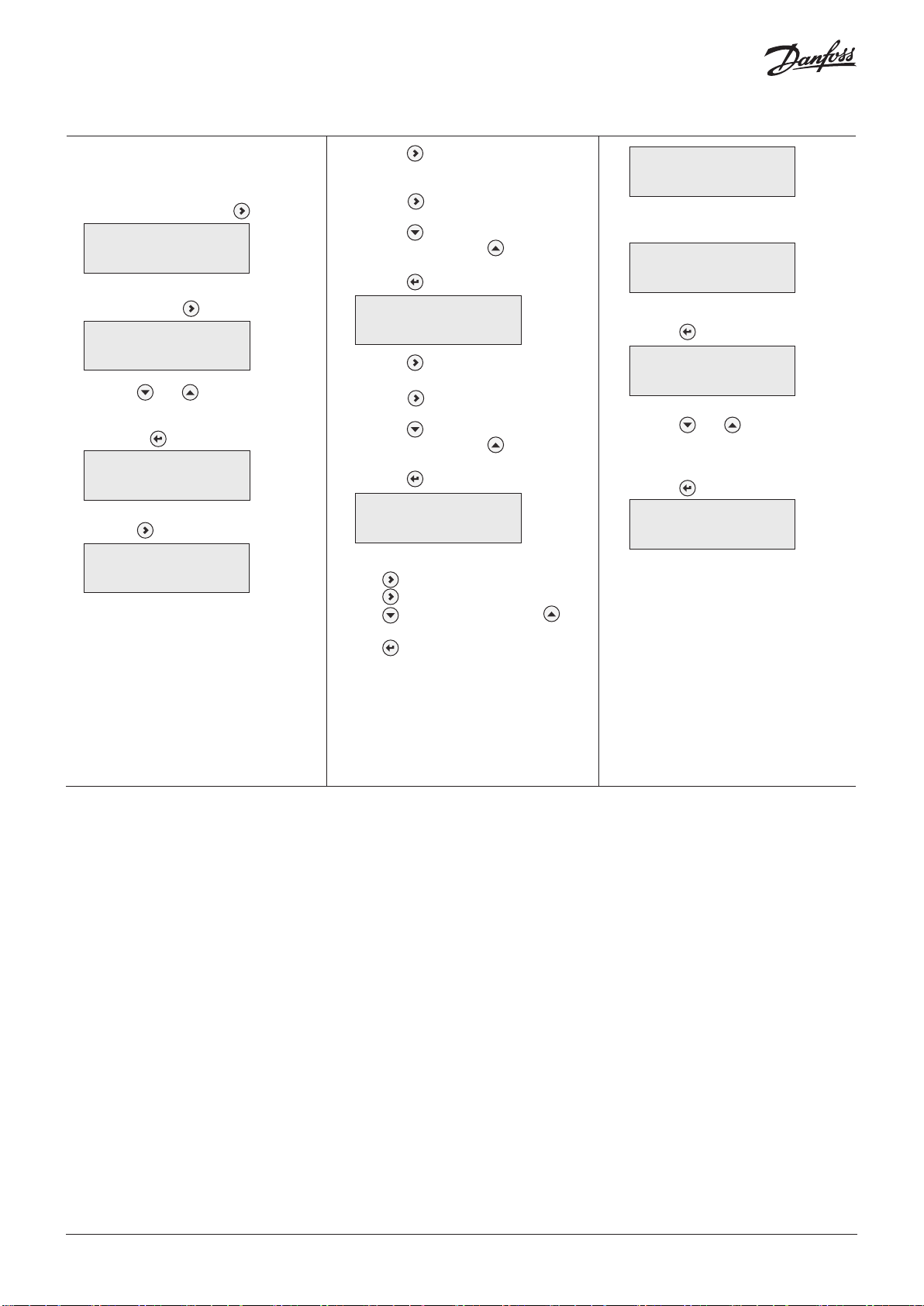

How to force mA output (all values below are only examples)

Default screen

DISTANCE

5000 mm

AKS 4100

• Press

AKS 4100

1.0.0

QUICK SETUP

• Press

AKS 4100

2.0.0

SUPERVISOR

• Press

AKS 4100

2.0.0

___________

Enter password:

AKS 4100

2.1.0

INFORMATION

• Press

AKS 4100

2.2.0

TESTS

• Press

AKS 4100

2.2.1

SET OUTPUT

• Press

AKS 4100

SET OUTPUT

3.5 mA

• Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

SET OUTPUT

8 mA

• Press 4 times to return to default

screen.

Default screen appears:

AKS 4100

DISTANCE

5000 mm

Force mA completed and disabled

Optional Procedure

If the temperature condition in the stand pipe is known, a constant (dielectric constant of the refrigerant gas) can be entered

(parameter 2.5.3 GAS EPS.R), in order to obtain lower Top and Bottom Dead Zone values (see fig. 6).

How to enter dielectric constant of refrigerant gas (all values below are only examples)

Default screen

AKS 4100

DISTANCE

5000 mm

• Press

AKS 4100

1.0.0

QUICK SETUP

• Press

AKS 4100

2.0.0

SUPERVISOR

• Press 4 times.

AKS 4100

2.5.0

APPLICATION

• Press

AKS 4100

2.5.1

TRACING VEL.

• Press 2 times.

AKS 4100

2.5.3

GAS EPS. R

• Press to confirm.

AKS 4100

2.5.3

GAS EPS. R

• Press 3 times.

AKS 4100

1.0.0

STORE NO

• Press or to select between

STORE NO or STORE YES.

Select STORE YES by pressing

Default screen appears:

• Press

AKS 4100

2.0.0

___________

Enter password:

AKS 4100

2.1.0

INFORMATION

• Press to check/change GAS EPS.R.

(Select the correct value from the tables

below and on page 8)

Press to change cursor position.

Press to decrease the value or to

increase the value.

AKS 4100

GAS EPS. R

1.066

DISTANCE

5000 mm

Entering the dielectric constant of

refrigerant gas completed

AKS 4100

10 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

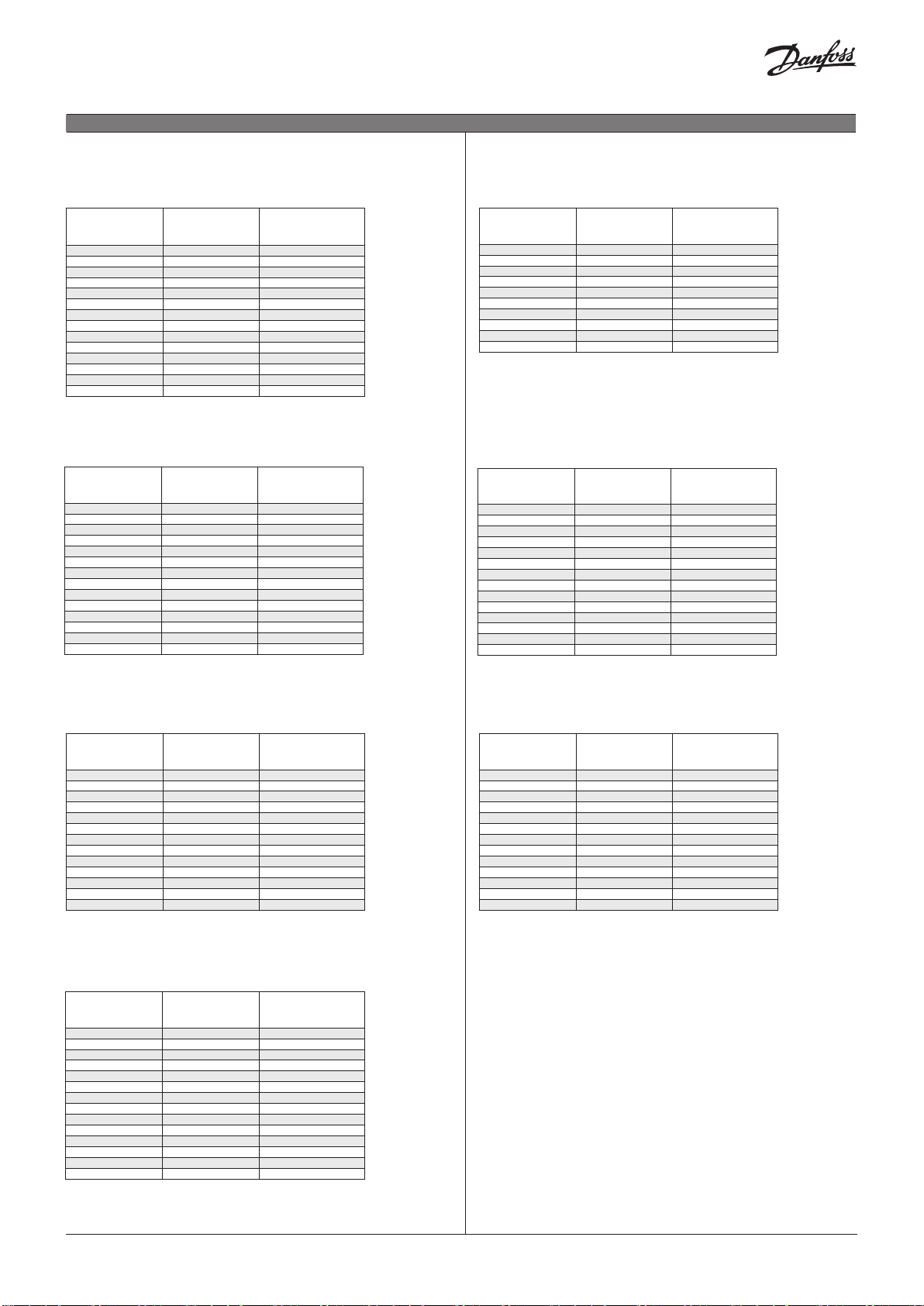

Saturated vapour dielectric constant (default value: 1.066)

R717 (NH3)

Temperature range:

-60 – 50 °C / -76 – 122 °F

Temperature

[°C]

-60 – -42 -76 – -43 1.00

-41 – -18 42 – 0 1.01

-17 – -5 1 – 23 1.02

-4 – 4 24 – 39 1.03

5 – 12 40 – 54 1.04

13 – 18 55 – 64 1.05

19 – 24 65 – 75 1.06

25 – 28 76 – 82 1.07

29 – 33 83 – 91 1.08

34 – 37 92 – 99 1.09

38 – 40 100 – 104 1.10

41 – 44 105 – 111 1.11

45 – 47 112 – 117 1.12

48 – 50 118 – 122 1.13

Temperature

[°F]

R22

Temperature range:

-60 – 48 °C / -76 – 118 °F

Temperature

[°C]

-60 – -50 -76 – -58 1.00

-49 – -25 57 – -13 1.01

-24 – -10 -12 – 14 1.02

-9 – 0 15 – 32 1.03

1 – 8 33 – 46 1.04

9 – 15 47 – 59 1.05

16 – 21 60 – 70 1.06

22 – 26 71 – 79 1.07

27 – 31 80 – 88 1.08

32 – 35 89 – 95 1.09

36 – 39 96 – 102 1.10

40 – 42 103 – 108 1.11

43 – 45 109 – 113 1.12

46 – 48 114 – 118 1.13

Temperature

[°F]

Dielectric constant

of refrigerant gas

Parameter 2.5.3

GAS EPS.R

Dielectric constant

of refrigerant gas

Parameter 2.5.3

GAS EPS.R

R744 (CO2)

Temperature range:

-56 – 15 °C / -69 – 59 °F

Temperature

[°C]

-56.0 – -42.0 -69 – -43 1.01

-41.0 – -28.0 -42 – -18 1.02

-27.0 – -17.0 -17 – 2 1.03

-16.0 – -9.0 3 – 16 1.04

-8.0 – -3.0 17 – 27 1.05

-2.0 – 2 28 – 36 1.06

3 – 7 37 – 45 1.07

8 – 11 46 – 52 1.08

12 – 14 53 – 58 1.09

15 59 1.10

Temperature

[°F]

R134a

Temperature range:

-60 – 50 °C / -76 – 122 °F

Temperature

[°C]

-60 – -42 -76 – -43 1.00

-41 – -18 -42 – -0 1.01

-17 – -4 1 – 25 1.02

-3 – 5 26 – 41 1.03

6 – 13 42 – 56 1.04

14 – 20 57 – 68 1.05

21 – 25 69 – 77 1.06

26 – 30 78 – 86 1.07

31 – 34 87 – 94 1.08

35 – 38 95 – 100 1.09

39 – 42 101 – 108 1.10

43 – 45 109 – 113 1.11

46 – 48 114 – 119 1.12

49 – 50 120 – 122 1.13

Temperature

[°F]

Dielectric constant

of refrigerant gas

Parameter 2.5.3

GAS EPS.R

Dielectric constant

of refrigerant gas

Parameter 2.5.3

GAS EPS.R

R410A

Temperature range:

-65 – 15 °C / -85 – 59 °F

Temperature

[°C]

-65 – -47 -85 – -52 1.01

-46 – -35 -51 – -31 1.02

-34 – -26 -30 – -14 1.03

-25 – -19 -13 – -2 1.04

-18 – -13 -1 – 9 1.05

-12 – -8 10 – 18 1.06

-7 – -4 19 – 25 1.07

-3 – 0 26 – 32 1.08

1 – 4 33 – 40 1.09

5 – 7 41 – 45 1.10

8 – 10 46 – 50 1.11

11 – 12 51 – 54 1.12

13 – 15 55 – 59 1.13

Temperature

[°F]

R507

Temperature range:

-60 – 15 °C / -76 – 59 °F

Temperature

[°C]

-60 – -48 -76 – -54 1.01

-47 – -36 -53 – -32 1.02

-35 – -28 -31 – -18 1.03

-27 – -21 -17 – -6 1.04

-20 – -15 -17 – -5 1.05

-14 – -10 -4 – 14 1.06

-9 – -6 13 – 22 1.07

-5 – -2 23 – 29 1.08

-1 – 2 30 – 36 1.09

3 – 5 37 – 41 1.10

6 – 8 42 – 47 1.11

9 – 11 48 – 52 1.12

12 – 13 53 – 56 1.13

14 – 15 57 – 59 1.14

Temperature

[°F]

Dielectric constant

of refrigerant gas

Parameter 2.5.3

GAS EPS.R

Dielectric constant

of refrigerant gas

Parameter 2.5.3

GAS EPS.R

R404A

Temperature range:

-60 – 15 °C / -76 – 59 °F

Temperature

[°C]

-60 – -47 -76 – -52 1.01

-46 – -35 -51 – -31 1.02

-34 – -26 -30 – -14 1.03

-25 – -19 -13 – -2 1.04

-18 – -14 -1 – 7 1.05

-13 – -9 8 – 16 1.06

-8 – -4 17 – 25 1.07

-3 – 0 26 – 32 1.08

1 – 3 33 – 38 1.09

4 – 6 39 – 43 1.10

7 – 9 44 – 49 1.11

10 – 12 50 – 54 1.12

13 – 15 55 – 59 1.13

Temperature

[°F]

Dielectric constant

of refrigerant gas

Parameter 2.5.3

GAS EPS.R

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 11

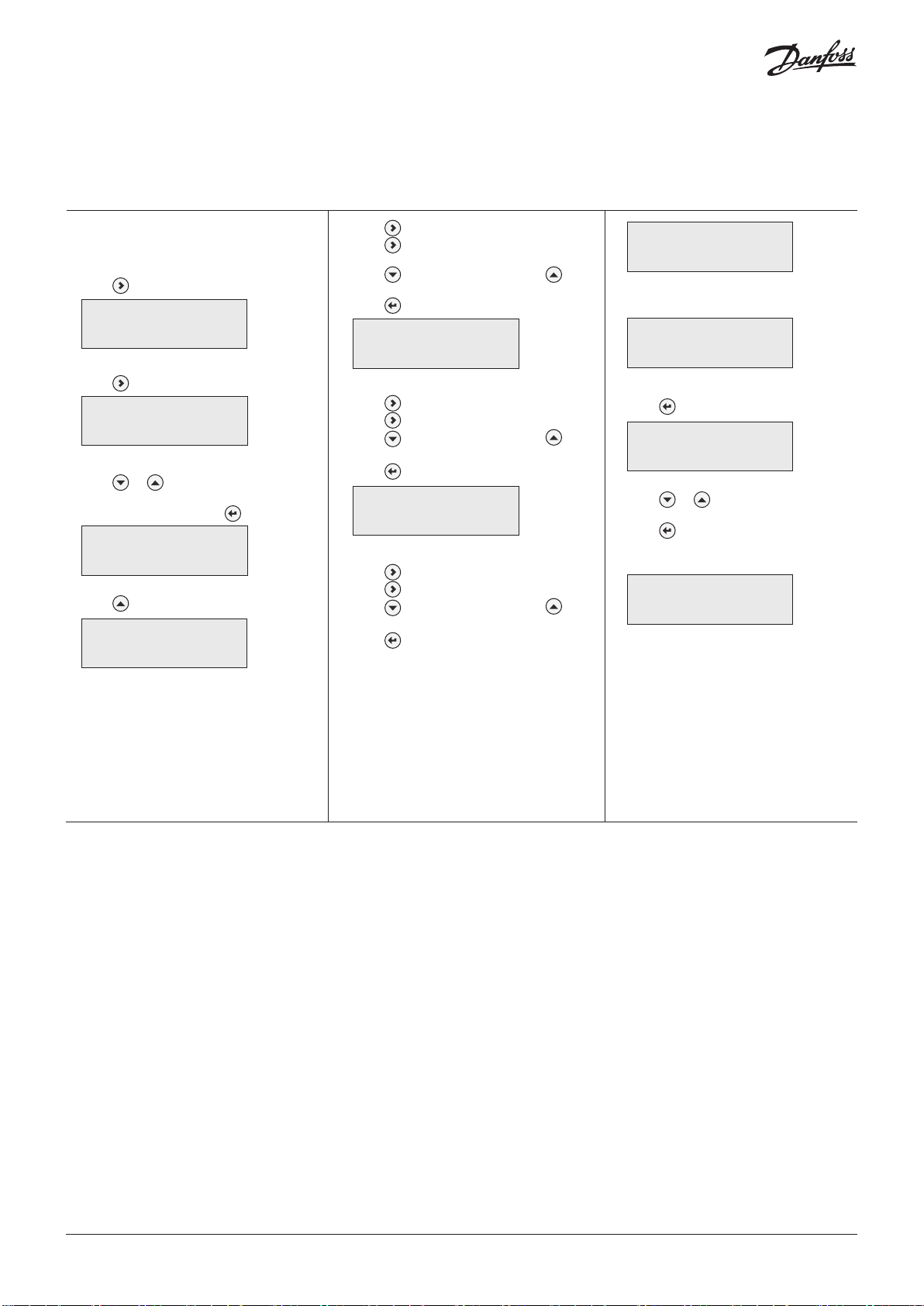

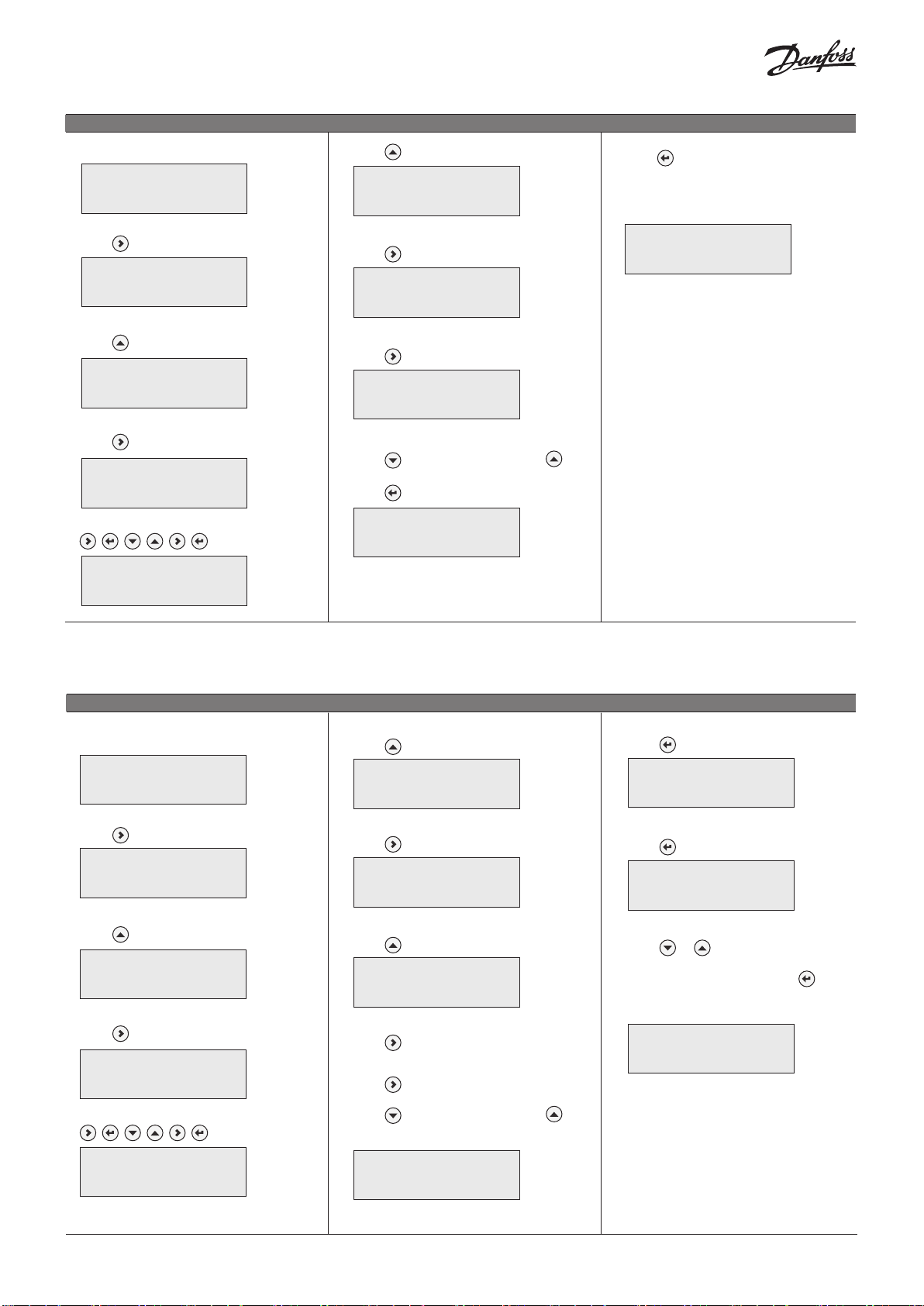

How to change the language setting (Default: English)

Default screen

DISTANCE

5000 mm

AKS 4100

• Press

AKS 4100

1.0.0

QUICK SETUP

• Press

AKS 4100

2.0.0

SUPERVISOR

• Press

AKS 4100

2.0.0

___________

• Go to SUPERVISOR menu (see page 7).

• Go to parameter 2.9.4 Reset Factory.

• Select RESET FACTORY YES

Enter password:

AKS 4100

2.1.0

INFORMATION

• Press 6 times

AKS 4100

2.7.0

DISPLAY

• Press

AKS 4100

2.7.1

LANGUAGE

• Press

LANGUAGE

ENGLISH

AKS 4100

Reset to factory setting

• Press or to see the language

possibilities

Press to confirm.

AKS 4100

2.7.1

LANGUAGE

• Press 3 times

AKS 4100

1.0.0

STORE NO

• Press or to select between

STORE NO or STORE YES.

Select STORE YES by pressing

Default screen appears:

AKS 4100

DISTANCE

5000 mm

Language setup completed

• Press 3 times to return to default screen.

Factory reset completed.

12 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

中文

请注意,AKS 4100/4100U 总是*安装在

立管内。立管通常应用于下列情况:

• 检修 AKS 4100/4100U

• 罐体内存在高导热的泡沫

• 液体呈现湍流和翻腾状态

制冷剂

AKS 4100/4100U 专用于测量最常用制冷剂的

液位,包括二氧化碳、氨、HCFC、HFC 和非腐

蚀性气体/液体。

基本参数

AKS 4100/4100U 是一款回路供电的无源二线制

4 – 20 mA 传感器。

供电电压

14 – 30 V DC最小/最大值

端子最大输出为22 mA

负载

RL [Ω] ≤((Uext -14 V)/20 mA)

– 默认(差错输出设为 3.6 mA)

RL [Ω] ≤((Uext -14 V)/22 mA)

– 默认(差错输出设为 22 mA)

电缆封套

AKS 4100 PG 13, M20×1.5;

(电缆直径:6-8 mm(0.24-0.31in.)

AKS 4100U ¾ in. NPT

接线端子(弹簧承载)

0.5-1.5 mm2 (~20-15 AWG)

防护等级

IP 67(~NEMA 4X )

制冷剂温度

-60 – 100 °C / -76 – 212 °F

制冷剂

丹佛斯认可适用的制冷剂:

R717 / NH3: -40 – 50 °C / -40 – 122 °F

R744 / CO2: -50 – 15 °C / -58 – 59 °F

HCFC:

R22: -50 – 48 °C / -58 – 118 °F

HFC:

R404A: -50 – 15 °C / -58 – 59 °F

R410A: -50 – 15 °C / -58 – 59 °F

R134A -40 – 50 °C / -40 – 122 °F

环境温度

-40 – 80 °C / -40 – 175 °F

HMI:-20 – 60 °C / -4 – 140 °F

操作压力

-1 – 100 barg / -14.5 – 1450 psig

用长 5 m(197 in.) Ø2 mm / 0.08 in.的不锈

钢线缆进行机械连接:

AKS 4100 1" G 管罗纹。包括铝制垫片

AKS 4100U ¾ in. NPT

(详情请参阅《技术手册》)

机械安装

机械安装前的准备

从机械连接件上卸下信号转换器(用 5' mm 六

角扳手,参阅图7)。将红色保护盖安装到机械

连接件的顶部,使之免受潮气或污垢的影响。

装箱清单(图1)

① 信号转换器(带/不带 HMI)

② 机械连接件,带 5 m(197 in.)

Ø2 mm(0.08 in.)不锈钢线

③ 同轴管道

④ 附件包:

终端连接器(包括 3mm 螺丝组)

3 mm 螺丝(每根管道螺丝)

安装信号转换器前用于保护机械连接件 ②

的红色保护盖

组装分段的同轴套管

请确保不锈钢线缆没有出现永久性折痕

或永久性的扭结。

1. 手持不锈钢线末端,将它穿过每根管道顶部

的塑料垫片的中心孔(图2)。让整条不锈钢

线缆穿过管道并伸出管道底端。若管道不止

一根,请重复上述步骤。

2. 组装管道① 和 ②(图3)。使用17 mm 开口

扳手拧紧装好的部件。

3. 若管道不止一根,请重复上述步骤(图3)。

4. 组装之前,先拆下信号转换器和机械连接

件,并将红色保护盖装在机械连接件上。

将完全组装好的管道装到机械连接件 ② 上。

5. 用 3mm 六角扳手拧紧固定螺钉 ④,以锁紧

每一管段(图3)。

6.将不锈钢线缆拉出终端连接器(图4)。

7.将终端连接器紧贴组装好的管道底端。

用3mm 六角扳手拧紧螺钉(图4)。

8.用钳子拉紧不锈钢线缆(图4),确保信号线

缆的张力正确。

用 3 mm 六角扳手拧紧2颗螺钉,以锁定不锈

钢线缆。

9. 从终端连接器外约 20 mm(0.8 in.)剪断不锈

钢线缆(图5)。

10.将探测器安装到立管之前,先测量探测器长

度(无信号转换器)(图6)。

用扭力扳手拧紧连接件(图1,第2条),力矩

值为 120 Nm(89 lb/ft)。

标定探测器长度,针对 HMI 快速设置标定 4

mA 和 20 mA:

探测器长度

参阅丹佛斯产品标签上的探头长度,或者测量

探头长度(图6)。

标定 4 mA :(最大测量范围)

= 传感器长度

– 底部死区(图6)

标定 20 mA :(最大测量范围)

= 顶部死区(图6)

示例(AKS 4100)

给定条件:

探测器长度:1200 mm

制冷剂:CO2, –35℃

在快速设置中调整气体常数 Er

探头长度:

= 1200 mm

标定 4 mA 设置(最大测量范围):

= 探测器长度(1200 mm)

–底部死区(参阅图6)

(170 mm)= 1030 mm (40.9 in.)

标定 20 mA 设置(最大测量范围):

= 顶部死区(参阅图6)

= 120 mm(4.7 in.)

第17页:

制冷剂气体的介电常数 2.5.3 GAS EPS.R

= 1.02

如何安装 AKS 4100/4100U 转换器(图7)

1. 使用信号转换器里面的 5mm 内六角扳手拧开

固定螺栓与通风螺栓。

2.向下推动信号转换器,直至它停在机械连接件

上。

3. 转动信号转换器至想要的位置。

4. 用 5 mm 内六角扳手拧紧固定螺栓。

5. 用 5 mm 内六角扳手拧紧通风螺栓。

电气安装/连接

输出端子(图 8和 图 9):

1.电流输出 –

2.电流输出 +

3.接地端子

电气安装步骤

1. 用 2.5 mm 内六角扳手松开顶盖。

2. 从壳体上取下端子舱盖。

3. 不要从端子舱盖上卸下电缆。将端子舱盖近壳

体放置。

4. 将钢缆连接到设备。上紧线缆入口封套。

5. 将端子舱盖安装到机壳上。

6. 用 2.5 mm 内六角扳手拧紧顶盖。

注意:

无论是否具有机械连接件,信号转换器都可以

进行参数设置。

启动

• 将转换器连接到电源。

• 将转换器通电。

若设备带选配的 HMI 显示屏,则仅在:

10秒后屏幕将显示“启动”。20秒后屏幕将显

示软件版本号。30秒后显示默认屏幕(图13)。

将 AKS 41/41U 改为 AKS 4100/4100U 时需要注意。

注意:

AKS 41/41U 支持交流和直流电源,而 AKS

4100/4100U 只能使用直流电源。按照图10的说

明进行操作。

连接到控制器或 PLC

按照图11或12的说明进行操作。

注意:

AKS 4100/4100 检测到错误,电

流输出就会被设为 3.6 mA,设备

状态将标记为 1、2、3。

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 13

注意:

无论是否装有机械连接件,均可对信号转换器进行编程。

快速设置(下面所有数值均为举例)

应用:二氧化碳:

• 将设备连接到电源(参阅“电气安装/连

接”一节)。

• 连按 3 次。

AKS 4100

快速设置?

是 否

• 按下

AKS 4100

探头类型

线缆式

• 按下 或 ,,在SINGLE(电缆形

式), COAXIAL (同轴形式)D14或

COAXIAL (同轴形式)D22之间选择一项。

按下 以示确认。

AKS 4100

液体CO2?

是 否

• 按下 (YES)以示确认

AKS 4100

气相Er

001.000

• 按下 更改GAS EPS.R.

(从第8页的表格中选择正确的数值)

按下 更改游标位置。

按下 调低数值,或者按 调高数值。

按下 以示确认。

AKS 4100

探头长度

05000 mm

• 按下 更改探头长度。

按下 更改游标位置。

按下 调低数值,或者按 调高数值。

按下 以示确认。

AKS 4100

4mA对应量程

04946 mm

• 按下 更改标度 4 mA。

按下 更改游标位置。

按下 调低数值,或者按 调高数值。

按下 以示确认。

AKS 4100

20mA对应量程

00070 mm

• 按下 更改标度 20 mA。

按下 更改游标位置。

按下 调低数值,或者按 调高数值。

按下 以示确认。

AKS 4100

快速设置

完成 8

• 等待快速设置完成。倒数8秒

AKS 4100

1.0.0

快速设置

• 按下 以示确认。

AKS 4100

1.0.0

保存设置 NO

• 按下 或 ,在 STORE NO (保存

否) 和 STORE YES (保存 是)

之间进行选择。按下 以示确认。

显示默认屏幕:

AKS 4100

距离

5000 mm

快速设置完成

您可以连按两次 ,以便对设置进行检查。

AKS 4100

同轴套管式 D14 2200 mm

(0%) 4 mA 1900 mm

(100%) 20 mA 70 mm

按下 ,返回默认屏幕。

14 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

若使用其他制冷剂:

• 将设备连接到电源(参阅“电气安装/连接”

一节)。

• 按下 3次。

AKS 4100

快速设置?

是 否

• 按下

AKS 4100

探头类型

线缆式

• 按下 或 ,在SINGLE(电缆形式)和

COAXIAL (同轴形式)之间进行选择。选择

COAXIAL并按下 以示确认。

AKS 4100

液体CO2?

是 否

• 按下 (NO)以示确认

AKS 4100

探头长度

05000 mm

• 按下 更改探头长度。

按下 更改游标位置。

按下 调低数值,或者按 调高数值。

按下 以示确认。

AKS 4100

4mA对应量程

04946 mm

• 按下 更改标度 4 mA。

按下 更改游标位置。

按下 调低数值,或者按 调高数值。

按下 以示确认。

AKS 4100

20mA对应量程

00070 mm

• 按下 更改标度 20 mA。

按下 更改游标位置。

按下 调低数值,或者按 调高数值。

按下 以示确认。

AKS 4100

快速设置

完成 8

• 等待快速设置完成。倒数8秒

AKS 4100

1.0.0

快速设置

• 按下 以示确认。

AKS 4100

1.0.0

保存设置 NO

• 按下 或 ,在 STORE NO (保存 否)

和 STORE YES (保存 是)之间进行选择。

按下 以示确认。

显示默认屏幕:

AKS 4100

距离

5000 mm

快速设置完成

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 15

默认屏幕

距离

5000 mm

• 按下

AKS 4100

AKS 4100

1.0.0

快速设置

如果强制 mA 输出(下面所有数值均为举例)

• 按下

AKS 4100

2.2.0

测试

• 按下

AKS 4100

2.2.1

测试电流

• 按下 4次返回默认屏幕。

显示默认屏幕

AKS 4100

距离

5000 mm

强制 mA 完成并禁用

• 按下

AKS 4100

2.0.0

操作员

• 按下

AKS 4100

2.0.0

___________

输入密码:

AKS 4100

2.1.0

信息

• 按下

AKS 4100

测试电流

3.5 mA

• 按下 调低数值,或者按下

调高数 值。按下 以示确认。

AKS 4100

测试电流

8 mA

可选步骤

若已知立管的温度条件,可以输入一个常数(制冷剂气体的介电常数)(参数 2.5.3 GAS EPS.R),以降低顶端和底端死区的数值(参阅图6)

如何输入制冷剂气体的介电常数(以下所有数值均为举例)

默认屏幕

距离

5000 mm

AKS 4100

• 按下 4次

AKS 4100

工况参数

2.5.0

• 按下 以示确认。

AKS 4100

2.5.3

气相Er

• 按下

AKS 4100

1.0.0

快速设置

• 按下

AKS 4100

2.0.0

操作员

• 按下

AKS 4100

2.0.0

___________

输入密码:

AKS 4100

2.1.0

信息

16 | AN23828644201102-000501

• 按下

AKS 4100

2.5.1

追従速度

• 按下 2次

AKS 4100

2.5.3

气相Er

• 按下 ,以便检查/修改 GAS EPS.R.

(从下表和第8页的表格中选择正确的数值)

按下 更改游标位置。按下 调低数值,

或 者按调高数值。

AKS 4100

气相Er

1.066

• 按下 3次

AKS 4100

1.0.0

保存设置 NO

• 按下 或 ,在STORE NO(保存 否)

和STORE YES(保存 是)之间进行选择。

按下 3选择STORE YES(保存 是)

显示默认屏幕:

AKS 4100

距离

5000 mm

输入制冷剂气体的介电常数

© Danfoss | DCS (ms) | 2020.12

饱和蒸气的介电常数

R717 (氨)

温度范围:

-60 – 50 °C / -76 – 122 °F

温度

[°C]

-60 – -42 -76 – -43 1.00

-41 – -18 42 – 0 1.01

-17 – -5 1 – 23 1.02

-4 – 4 24 – 39 1.03

5 – 12 40 – 54 1.04

13 – 18 55 – 64 1.05

19 – 24 65 – 75 1.06

25 – 28 76 – 82 1.07

29 – 33 83 – 91 1.08

34 – 37 92 – 99 1.09

38 – 40 100 – 104 1.10

41 – 44 105 – 111 1.11

45 – 47 112 – 117 1.12

48 – 50 118 – 122 1.13

温度

[°F]

R22

温度范围:

-60 – 48 °C / -76 – 118 °F

温度

[°C]

-60 – -50 -76 – -58 1.00

-49 – -25 57 – -13 1.01

-24 – -10 -12 – 14 1.02

-9 – 0 15 – 32 1.03

1 – 8 33 – 46 1.04

9 – 15 47 – 59 1.05

16 – 21 60 – 70 1.06

22 – 26 71 – 79 1.07

27 – 31 80 – 88 1.08

32 – 35 89 – 95 1.09

36 – 39 96 – 102 1.10

40 – 42 103 – 108 1.11

43 – 45 109 – 113 1.12

46 – 48 114 – 118 1.13

温度

[°F]

制冷剂气体的介电常数

参数 2.5.3

GAS EPS.R

制冷剂气体的介电常数

参数 2.5.3

GAS EPS.R

R744 (

二氧化碳

)

温度范围:

-56 – 15 °C / -69 – 59 °F

温度

[°C]

-56.0 – -42.0 -69 – -43 1.01

-41.0 – -28.0 -42 – -18 1.02

-27.0 – -17.0 -17 – 2 1.03

-16.0 – -9.0 3 – 16 1.04

-8.0 – -3.0 17 – 27 1.05

-2.0 – 2 28 – 36 1.06

3 – 7 37 – 45 1.07

8 – 11 46 – 52 1.08

12 – 14 53 – 58 1.09

15 59 1.10

温度

[°F]

R134a

温度范围:

-60 – 50 °C / -76 – 122 °F

温度

[°C]

-60 – -42 -76 – -43 1.00

-41 – -18 -42 – -0 1.01

-17 – -4 1 – 25 1.02

-3 – 5 26 – 41 1.03

6 – 13 42 – 56 1.04

14 – 20 57 – 68 1.05

21 – 25 69 – 77 1.06

26 – 30 78 – 86 1.07

31 – 34 87 – 94 1.08

35 – 38 95 – 100 1.09

39 – 42 101 – 108 1.10

43 – 45 109 – 113 1.11

46 – 48 114 – 119 1.12

49 – 50 120 – 122 1.13

温度

[°F]

制冷剂气体的介电常数

参数 2.5.3

GAS EPS.R

制冷剂气体的介电常数

参数 2.5.3

GAS EPS.R

R410A

温度范围:

-65 – 15 °C / -85 – 59 °F

温度

[°C]

-65 – -47 -85 – -52 1.01

-46 – -35 -51 – -31 1.02

-34 – -26 -30 – -14 1.03

-25 – -19 -13 – -2 1.04

-18 – -13 -1 – 9 1.05

-12 – -8 10 – 18 1.06

-7 – -4 19 – 25 1.07

-3 – 0 26 – 32 1.08

1 – 4 33 – 40 1.09

5 – 7 41 – 45 1.10

8 – 10 46 – 50 1.11

11 – 12 51 – 54 1.12

13 – 15 55 – 59 1.13

温度

[°F]

R507

温度范围:

-60 – 15 °C / -76 – 59 °F

温度

[°C]

-60 – -48 -76 – -54 1.01

-47 – -36 -53 – -32 1.02

-35 – -28 -31 – -18 1.03

-27 – -21 -17 – -6 1.04

-20 – -15 -17 – -5 1.05

-14 – -10 -4 – 14 1.06

-9 – -6 13 – 22 1.07

-5 – -2 23 – 29 1.08

-1 – 2 30 – 36 1.09

3 – 5 37 – 41 1.10

6 – 8 42 – 47 1.11

9 – 11 48 – 52 1.12

12 – 13 53 – 56 1.13

14 – 15 57 – 59 1.14

温度

[°F]

制冷剂气体的介电常数

参数 2.5.3

GAS EPS.R

制冷剂气体的介电常数

参数 2.5.3

GAS EPS.R

R404A

温度范围:

-60 – 15 °C / -76 – 59 °F

温度

[°C]

-60 – -47 -76 – -52 1.01

-46 – -35 -51 – -31 1.02

-34 – -26 -30 – -14 1.03

-25 – -19 -13 – -2 1.04

-18 – -14 -1 – 7 1.05

-13 – -9 8 – 16 1.06

-8 – -4 17 – 25 1.07

-3 – 0 26 – 32 1.08

1 – 3 33 – 38 1.09

4 – 6 39 – 43 1.10

7 – 9 44 – 49 1.11

10 – 12 50 – 54 1.12

13 – 15 55 – 59 1.13

温度

[°F]

制冷剂气体的介电常数

参数 2.5.3

GAS EPS.R

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 17

如何修改语言设置(默认:英文)

默认屏幕

距离

5000 mm

• 按下

• 按下

• 按下

• 进入SUPERVISOR(查看)菜单(参见第7页)

• 进入参数2.9.4 恢复出厂设置

• 选择RESET FACTORY YES(恢复出厂设置:是)

• 按下 三次,返回默认屏幕

恢复出厂完成

AKS 4100

AKS 4100

1.0.0

快速设置

AKS 4100

2.0.0

操作员

AKS 4100

2.0.0

___________

输入密码:

AKS 4100

2.1.0

信息

• 按下 6次

AKS 4100

2.7.0

显示

••按下

AKS 4100

2.7.1

语言

•按下

AKS 4100

语言

中文

重置为出厂设定

• 按下 或 查看语言选项

按下 以示确认。

AKS 4100

2.7.1

语言

• 连按 3次

AKS 4100

1.0.0

保存设置 NO

• 按下 或 ,在 STORE NO(保存 否)

和STORE YES(保存 是)之间进行选择。

按下 选择 STORE YES(保存 是)

显示默认屏幕:

AKS 4100

距离

5000 mm

语言设置完成

18 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

日本語

AKS 4100/4100U は必ず直立管 (柱/バイパ

ス/静止筒) に設置するようにしてください。

直立管は以下の場合に使用されます:

• AKS 4100用の整備

• タンク内にアワが多くある場合

• 液体が非常に激しく乱れている場合

HMI 付きまたはなしの AKS 4100/4100U 同軸バ

ージョン は、C O2 に使用しない場合は動作設定を

変更する必要はありません。

プリセット:

4 mAプローブ長 - 100 mm (4 インチ)

20 mA120 mm (5 インチ)

冷媒

AKS 4100/4100U は、特にR744 (CO2)、R717

(アンモニア)、HCFC、HFCといった最も広く使用さ

れている冷媒や非腐食性ガス/液体のレベルを計

測するために設計されています。

基本データ

AKS 4100/4100U は、ループ給電のパッシブ 2 線

~20 mA センサーです。

供給電圧

端子における最大出力 22 mA における最小/最

大値

負荷

RL [Ω] ≤ ((Uext -14 V)/20 mA).

– デフォルト (エラー出力は 3.6 mA に設定)

RL [Ω] ≤ ((Uext -14 V)/22 mA).

– (エラー出力は 22 mA に設定)

ケーブ ルグランド

AKS 4100 PG 13、M20×1.5 ;

(ケーブル径:

6~8 mm (0.24~0.31インチ)

AKS 4100U ½ インチ NPT

端子 (バネ懸架式)

0.5~1.5 mm2 (~20-15 AWG)

保護構造

IP 67 (~NEMA タイプ 4X)

冷媒温度

-60 – 100 °C / -76 – 212 °F

冷媒

リストにある冷媒は Danfoss が認定したもので

す:

R717 / NH3: -40 – 50 °C / -40 – 122 °F

R744 / CO2: -50 – 15 °C / -58 – 59 °F

HCFC:

R22: -50 – 48 °C / -58 – 118 °F

HFC:

R404A: -50 – 15 °C / -58 – 59 °F

R410A: -50 – 15 °C / -58 – 59 °F

R134A: -40 – 50 °C / -40 – 122 °F

周囲温度

-40 – 80 °C / -40 – 175 °F

HMI の場合:-20 – 60 °C / -4 – 140 °F

処理圧力

-1 – 100 barg / -14.5 – 1450 psig

5 m (197 インチ) Ø2 mm (0.08 インチ) ステンレ

ス ケーブルによる機械プロセス接続部:

AKS 4100 G1 インチ管ネジ。

アルミニウム製ガスケット付属

AKS 4100U ¾ インチ NPT

(詳細は技術カタログを参照)

機械設置

機械設置前の準備

信号変換器を機械プロセス接続部から外します

(5´mm 六角レンチを使用。図 6 を参照)。赤色の

保護カバーを機械プロセス接続部に取り付けて湿

気やほこりから保護します。

付属品の内容 (図 1)

信号変換器 (HMI がある場合とない場合が

ありま す)

5 m (197 インチ) Ø2 mm (0.08 インチ) ステ

レス ケーブルによる機械プロセス接続部

チューブ

バッグ内容:

エンドコネクタ (3 mm の取り付けネジ含む)

3 mm の取り付けネジ (チューブ 1 本につき

ネジ 1 本)

信号コンバータを取り付ける前に機械プロセ

接続部を保護するための赤色のカバ

設定ラベル

分割されている同軸プローブの組立

ステンレスワイヤが完全に曲がったり折

れたりしないように

注意してください。

1. ステンレスワイヤの端を各チューブの上にあ

4

るプラスチック製スペーサーの中央の穴に通

します (図 2 を参照)。ステンレスワイヤの全体

をチューブに通して下から出します。チューブ

が複数ある場合にはこの手順を繰り返します。

2. チューブ と を組み立てます(図 3 を参照)

。17 mm レンチを組み立てた部品を固定しま

す。

3. チューブが複数ある場合にはこの手順を繰り

返します (図 3 を参照)。

4. 組み立てる前に、信号コンバータと機械プロ

セス接続部を外し、機械プロセス接続部に赤

い保護キャップを取り付けます。組み立てたチ

ューブを機械プロセス接続部 にねじ込 み

ます。

5. 取り付けネジ を 3 mm 六角レンチで締めて

各チューブを固定します (図 3 を参照)。

6. エンド コネクタを通してステンレスワイヤを

引っ 張ります (図.4 を参照)。

7. エンドコネクタを組み立てたチューブの下に

取り付けます。

取り付けネジを 3 mm 六角レンチで締め付け

ます(図 4 を参照)。

8. エンドコネクタから伸びるステンレスワイヤの

端をプライヤーで引っ張り (図 4)、信 号 ケ ー ブ

ルが適切に張られていることを確認します。

2 本の取り付けネジを 3 mm 六角レンチで締

めて、ステンレスワイヤを固定します。

9. ステンレスワイヤをエンドコネクタの下約

20 mm (0.8 インチ) で切断します (図 5 を参

照)。

10. (信号コンバータなしの) プローブ長を、組み立てた

プローブを直立管に取り付ける前に測定します

(図 6 を参照)。

トルクレンチを使用して、機械プロセス接続

部 (図 1 の項目 2) を 120 Nm (89 lb/ft) まで締

め付けます。

工場出荷時の設定に戻す必要がある場合

HMI クイック セットアップのプローブ長、スケー

ル 4 mA および 20 mA

プローブ長:

Danfoss 製品のラベルにあるプローブ長を参考

するか、プローブ長を計測します (図 6 を参照)。

スケール 4 mA:(最大計測範囲の場合)

= プローブ長

– 下部デッドゾーン (図 6 を参照)

スケール 20 mA: (最大計測範囲の場合)

= 上部デッドゾーン (図 6 を参照)

例 (AKS 4100)

条件:

プローブ長:1200 mm

冷媒:CO2, –35°C

ガス定数 Er は必ずクイック セットアップで調整

プローブ長:

= 1200 mm

SCALE 4 mA 設定の最大計測範囲:

= プローブ長 (1200 mm)

ン

– 下部デッドゾーン (図 6 を参照)

(170 mm) = 1030 mm (40.9 インチ)

SCALE 20 mA 設定の最大計測範囲:

= 上部デッドゾーン (図 6 を参照)

= 120 mm (4.7 インチ)

ス

8 ペ ージ より:

冷媒ガスの誘電率パラメータ 2.5.3 GAS

EPS.R

= 1.02

AKS 4100/4100U コンバータの取り付け方法 (図

7 を参照)

1. 信号変換器の位置決めネジと通気ネジを5 mm

の六角レンチで外してください。

2. 信号変換器を下方向に止まるまで押し込み、

機械プロセス接続部と確実に勘合させます。

3. 信号変換器を希望する向きに回します。

4. 位置決めネジを5mmの六角レンチで締め付け

てください。

5. 通気ネジを5mmの六角レンチで締め付けてく

ださい。

電気接続

出力端子 (図 8 および 9)

1. 電流出力 –

2. 電流出力 +

3. 接地端子

電気接続の手順

1. 2.5 mm 六角レンチを使用してカバー止めを緩

めます。

2. 筐体から端子部品カバーを取り外します。

3. ワイヤは端子部品カバーから外してはなりませ

ん。筐体の横に端子部品カバーを置きます。

4. ワイヤを装置に接続します。ケーブル入口金物

を締め付けます。

5. 端子部品カバーを筐体に取り付けます。

6. 2.5 mm 六角レンチを使用してカバー止めを緩

めます。

注:

信号コンバータは、機械プロセスコネクタ付き、ま

たはなしでプログラム することができます。

起動:

• コンバータを電点に接続します。

• コンバータに通電します。

HMI ディスプレイ オプションのある装置のみ:

10 秒後に「Starting up」と画面に表示されます。

20 秒後にソフトウェアのバージョン番号が画面に

表示されます。30 秒後にデフォルト画面

(図 13) が表示されます。

AKS 41/41U から AKS 4100/4100U に変更すると

きの注意点:

注 意してくだ さ い : AKS 41/41U は交流および直流

電源で使用できますが、AKS 4100/4100U は直流

電源でのみ使用できます。図 10 の説明に従ってく

ださい。

コントローラまたは PLC への接続

に

図 11 または 12 の説明 に従ってください。

注:

AKS 4100/4100 がマーカー 1、2、3 のよう

なエラーを検知した場合には、電流出力は

3.6 mA に設定されます (4 ページ参照)。

ク イ ック セット アッ プ →

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 19

注:

信号コンバータは、機械プロセスコネクタ付き、またはなしでプログラムすることができます。

高速設置 (以下の値はすべて一例です)

CO2 を使用する場合:

• 装置を電源に接続します (「電気接続」の

セクション を参 照してくだ さい )。

• を 3 回押します。

AKS 4100

クイックセットアップ?

はい いいえ

• を押します。

AKS 4100

プローブタイプ

ケーブル式

• または を押して、「シングルケー

ブル式」、「同軸式 D14」、または「同

軸式 D22」を選択します。「パイプ式 D14」

を選択し、 を押して確 定します。

AKS 4100

液体CO2?

はい いいえ

• (確認実行) を押して確定します。

AKS 4100

气相Er?

001.000

• を押して「ガス誘電率」に変更します。

(以下の表および 8 ページの表から正し

い値を選択します)

を押してカーソルの位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

• を押して確定します。

AKS 4100

プローブ長さ

05000 mm

• を押して「プローブ長さ」に 変更しま

す。

を押してカーソルの位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

を押して確 定します。

AKS 4100

4mA位置

04946 mm

• を押して「4mA位置」に変更します。

を押してカーソルの位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

を押して確 定します。

AKS 4100

20mA位置

00070 mm

• を押して「20mA位置」に変更します。

を押してカーソルの位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

を押して確 定します。

AKS 4100

クイックセットアップ

コンプリート8

• クイックセットアップが完了するまで 8

秒間待ちます。

AKS 4100

1.0.0

クイックセットアップ?

• を押して確定します。

AKS 4100

1.0.0

保存中止

• または を押して「保存中止」または

「保存」のいずれかを選択します。

を押して確 定します。

デフォルト画面が表示されます:

AKS 4100

距離

5000 mm

クイックセットアップ完了

を 2 回押して設定を確認することが

できます。

AKS 4100

パイプ式 D14 2200 mm

(0%) 4 mA 1900 mm

(100%) 20 mA 70 mm

を押してデフォルト画面に戻

ります。

20 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

その他すべての冷媒

• 装置を電源に接続します (「電気接続」の

セクション を参 照してくだ さい )。

• を 3 回押します。

AKS 4100

クイックセットアップ

はい いいえ

• を押します。

プローブタイプ

ケーブル式

AKS 4100

• または を押して、「ケーブル式」、

「パイプ式D14」、または「パイプ式D22」

を選択します。「パイプ式 D14」

を選択し、

を押して確 定します。

液体CO2?

はい いいえ

AKS 4100

• (確認中止) を押して確定します。

プローブ長さ

05000 mm

AKS 4100

• を押して「プローブ長さ」に 変更しま

す。

を押してカーソルの位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

を押して確 定します。

AKS 4100

4mA位置

04946 mm

• を押して「4mA位置」に変更します。

を押してカーソルの位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

を押して確 定します。

AKS 4100

20mA位置

00070 mm

• を押して「20mA位置」に変更します。

を押してカーソルの位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

を押して確 定します。

AKS 4100

クイックセットアップ

コンプリート8

• 高速設置が完了するまで待ちます。

8 秒間カウントダウンされます。

AKS 4100

1.0.0

クイックセットアップ?

• を押して確定します。

AKS 4100

1.0.0

保存中止

• または を押して「保存中止」または

「保存実行」のいずれかを選択します。

を押して確 定します。

デフォルト画面が表示されます:

AKS 4100

距離

5000 mm

クイックセットアップ完 了

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 21

強制的に mA 出力にするには (以下の値はすべて一例です)

デフォルト画 面

距離

5000 mm

AKS 4100

• を押します。

AKS 4100

1.0.0

クイックセットアップ

• を押します。

AKS 4100

2.0.0

スーパーバイザー

• を押します。

AKS 4100

2.0.0

___________

パスワードを入力します:

AKS 4100

2.1.0

イン フォメ ーション

• を押します。

AKS 4100

2.2.0

テスト

• を押します。

AKS 4100

2.2.1

出力設定

• を押します。

AKS 4100

出力設定

3.5 mA

• を押して値を減らすか、 を押して

値を増やします。

を押して確 定します。

AKS 4100

出力設定

8 mA

• を 4 回押してデフォルト画面に戻り

ます。

デフォルト画面が表示されます:

AKS 4100

距離

5000 mm

オプ ション の 手 順

直立管の温度条件を理解している場合には、定数 (冷媒ガスの誘電率) を入力 (パラメータ 2.5.3 ガス誘電率) して、上部および下部

デッドゾーンの下限値を得ることができます (図 6 を参照)。

冷媒ガスの誘電率の入力方法 (以下の値はすべて一例です)

デフォルト画 面

AKS 4100

距離

5000 mm

• を 4 回押します。

AKS 4100

2.5.0

アプリケーション

• を押して確定します。

AKS 4100

2.5.3

ガス誘電率

• を押します。

AKS 4100

1.0.0

クイックセットアップ

• を押します。

AKS 4100

2.5.1

追従速度

• を 3 回押します。

AKS 4100

1.0.0

保存中止

• を押します。

AKS 4100

2.0.0

スーパーバイザー

• を押します。

AKS 4100

2.0.0

___________

パスワードを入力します:

AKS 4100

2.1.0

イン フォメ ーション

• を 2 回押します。

AKS 4100

2.5.3

ガス誘電率

• を押して「ガス誘電率」を確認/変更し

ます。

(以下の表および 8 ページの表から正し

い値を選択します)

を押してカーソルの

位置を変更します。

を押して値を減らすか、 を押して

値を増やします。

AKS 4100

ガス誘電率

1.066

• または を押して

「保存中止」または「 保存」を選択

します。

を押して「保存」を選択します。

デフォルト画面が表示されます:

AKS 4100

距離

5000 mm

冷媒ガスの誘電率の入力が完了

22 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

飽和蒸気誘電率 (デフォルト値:1.066)

R717 (NH3)

温度範囲:

-60 – 50 °C / -76 – 122 °F

温度

[ °C ]

-60 – -42 -76 – -43 1.00

-41 – -18 42 – 0 1.01

-17 – -5 1 – 23 1.02

-4 – 4 24 – 39 1.03

5 – 12 40 – 54 1.04

13 – 18 55 – 64 1.05

19 – 24 65 – 75 1.06

25 – 28 76 – 82 1.07

29 – 33 83 – 91 1.08

34 – 37 92 – 99 1.09

38 – 40 100 – 104 1.10

41 – 44 105 – 111 1.11

45 – 47 112 – 117 1.12

48 – 50 118 – 122 1.13

温度

[ °F ]

R22

温度範囲:

-60 – 48 °C / -76 – 118 °F

温度

[ °C ]

-60 – -50 -76 – -58 1.00

-49 – -25 57 – -13 1.01

-24 – -10 -12 – 14 1.02

-9 – 0 15 – 32 1.03

1 – 8 33 – 46 1.04

9 – 15 47 – 59 1.05

16 – 21 60 – 70 1.06

22 – 26 71 – 79 1.07

27 – 31 80 – 88 1.08

32 – 35 89 – 95 1.09

36 – 39 96 – 102 1.10

40 – 42 103 – 108 1.11

43 – 45 109 – 113 1.12

46 – 48 114 – 118 1.13

温度

[ °F ]

冷媒ガスの誘電率パ

ラメータ 2.5.3 GAS

EPS.R

冷媒ガスの誘電率パ

ラメータ 2.5.3 GAS

EPS.R

R744 (CO2)

温度範囲:

-56 – 15 °C / -69 – 59 °F

温度

[ °C ]

-56.0 – -42.0 -69 – -43 1.01

-41.0 – -28.0 -42 – -18 1.02

-27.0 – -17.0 -17 – 2 1.03

-16.0 – -9.0 3 – 16 1.04

-8.0 – -3.0 17 – 27 1.05

-2.0 – 2 28 – 36 1.06

3 – 7 37 – 45 1.07

8 – 11 46 – 52 1.08

12 – 14 53 – 58 1.09

15 59 1.10

温度

[ °F ]

R134a

温度範囲:

-60 – 50 °C / -76 – 122 °F

温度

[ °C ]

-60 → -42 -76 → -43 1.00

-41 → -18 -42 → -0 1.01

-17 → -4 1 → 25 1.02

-3 → 5 26 → 41 1.03

6 → 13 42 → 56 1.04

14 → 20 57 → 68 1.05

21 → 25 69 → 77 1.06

26 → 30 78 → 86 1.07

31 → 34 87 → 94 1.08

35 → 38 95 → 100 1.09

39 → 42 101 → 108 1.10

43 → 45 109 → 113 1.11

46 → 48 114 → 119 1.12

49 → 50 120 → 122 1.13

温度

[ °F ]

冷媒ガスの誘電率パ

ラメータ 2.5.3 GAS

EPS.R

冷媒ガスの誘電率パ

ラメータ 2.5.3 GAS

EPS.R

R410A

温度範囲:

-65 – 15 °C / -85 – 59 °F

温度

[ °C ]

-65 – -47 -85 – -52 1.01

-46 – -35 -51 – -31 1.02

-34 – -26 -30 – -14 1.03

-25 – -19 -13 – -2 1.04

-18 – -13 -1 – 9 1.05

-12 – -8 10 – 18 1.06

-7 – -4 19 – 25 1.07

-3 – 0 26 – 32 1.08

1 – 4 33 – 40 1.09

5 – 7 41 – 45 1.10

8 – 10 46 – 50 1.11

11 – 12 51 – 54 1.12

13 – 15 55 – 59 1.13

温度

[ °F ]

R507

温度範囲:

-60 – 15 °C / -76 – 59 °F

温度

[ °C ]

-60 – -48 -76 – -54 1.01

-47 – -36 -53 – -32 1.02

-35 – -28 -31 – -18 1.03

-27 – -21 -17 – -6 1.04

-20 – -15 -17 – -5 1.05

-14 – -10 -4 – 14 1.06

-9 – -6 13 – 22 1.07

-5 – -2 23 – 29 1.08

-1 – 2 30 – 36 1.09

3 – 5 37 – 41 1.10

6 – 8 42 – 47 1.11

9 – 11 48 – 52 1.12

12 – 13 53 – 56 1.13

14 – 15 57 – 59 1.14

温度

[ °F ]

冷媒ガスの誘電率パ

ラメータ 2.5.3 GAS

EPS.R

冷媒ガスの誘電率パ

ラメータ 2.5.3 GAS

EPS.R

R404A

温度範囲:

-60 – 15 °C / -76 – 59 °F

温度

[ °C ]

-60 – -47 -76 – -52 1.01

-46 – -35 -51 – -31 1.02

-34 – -26 -30 – -14 1.03

-25 – -19 -13 – -2 1.04

-18 – -14 -1 – 7 1.05

-13 – -9 8 – 16 1.06

-8 – -4 17 – 25 1.07

-3 – 0 26 – 32 1.08

1 – 3 33 – 38 1.09

4 – 6 39 – 43 1.10

7 – 9 44 – 49 1.11

10 – 12 50 – 54 1.12

13 – 15 55 – 59 1.13

温度

[ °F ]

冷媒ガスの誘電率パ

ラメータ 2.5.3 GAS

EPS.R

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 23

言語設定の変更方法 (デフォルト:日本語)

デフォルト画 面

AKS 4100

距離

5000 mm

パスワードを入力します:

AKS 4100

2.1.0

イン フォメ ーション

• を押します。

AKS 4100

1.0.0

クイックセットアップ

• を押します。

AKS 4100

2.0.0

スーパーバイザー

• を押します。

AKS 4100

2.0.0

___________

• を 6 回押します。

AKS 4100

2.7.0

表示

• を押します。

AKS 4100

2.7.1

言語

• を押します。

AKS 4100

言語

日本語

工場出荷時の設定にリセットする

• 「スーパーバイザー」メニューに移動します (7 ページを参照)。

• パラメータ 2.9.4 の工場設定リセットに移動します。

• 「工 場設定リセット」を選 択します。

• または を押して言語の選択肢を

表示します。

を押して確 定します。

AKS 4100

2.7.1

言語

• を 3 回押します。

AKS 4100

1.0.0

保存中止

•

または を押して「保存中止」または

「 保存」を選択します。

を押して「 保存実行」を選択します。

デフォルト画面が表示されます:

距離

5000 mm

AKS 4100

言語設定完了

• を 3 回押してデフォルト画面に戻ります。

工場出荷時状態へのリセットが完了します。

24 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

РУССКИЙ

Уровнеме AKS 4100/4100U тросовой

версии, всегда устанавливается

на вертикальной трубе

(измерительной колонке и т.д.).

Установка в измерительную колонку

необходима:

• Для обслуживания AKS 4100/4100U

• Если в сосуде происходит вспенивание.

• В случае турбулентности в сосуде.

AKS 4100/4100U коаксиальной версии

с интерфейсом HMI или без него не

требует настройки, в случае работы с

CO2 необходима настройка.

Заводская настройка:

4 мА : длина троса - 100 мм (4".)

20 мА: 120 мм (5 ".)

Хладагенты

AKS 4100/4100U специально разработан

для применения со всеми широко

распространёнными хладагентами,

включая R744 (CO2) и R717 (аммиак), HCFC,

HFC, а также неагрессив-ными газами и

жидкостями.

Основные тех. характеристики

AKS 4100/4100U это пассивный

2-проводной, уровнемер.

Питающее напряжение

14-30 В постоянного тока (мин./макс.

величина) для тока 22 мА на выходе.

Нагрузка

RL [Ω] ≤ ((Uвнеш. -14 В)/20 мА).

– По умолчанию (значение выходного

сигнала, при котором выдаётся сообщение

об ошибке, установлено на 3,6 мА)

RL [Ω] ≤ ((Uвнеш. -14 В)/22 мА).

– (значение выходного сигнала, при

котором выдаётся сообщение об ошибке,

установлено на 22 мА)

Кабельный ввод

AKS 4100 PG 13, M20×1.5 ; (диаметр кабеля:

6-8 мм (0.24-0.31".)

AKS 4100U ½". NPT

Клеммы (с подпружиненными зажимами)

0.5-1.5 мм2 (~20-15 AWG)

Степень защиты

IP 67 (~NEMA тип 4X)

Температура хладагента

-60 – 100 °C / -76 – 212 °F

Хладагенты

Использование данных уровнемеров с

перечисленными далее хладагентами

опробовано и одобрено компанией

«Данфосс»:

R717 / NH3: -40 – 50 °C / -40 – 122 °F

R744 / CO2: -50 – 15 °C / -58 – 59 °F

HCFC:

R22: -50 – 48 °C / -58 – 118 °F

HFC:

R404A: -50 – 15 °C / -58 – 59 °F

R410A: -50 – 15 °C / -58 – 59 °F

R134A -40 – 50 °C / -40 – 122 °F

Температура окружающей среды:

-40 – 80 °C / -40 – 175 °

Для HMI : -20 – 60 °C / -4 – 140 °F

Рабочее давление:

от –1 изб. до 100 изб. (от –14.5 фунт/дюйм2

до 1450 фунт/дюйм2)

Механическое соединение тросовой

модификации 5 м (197" .) Ø2 (0.08".)

AKS 4100 с трубной резьбой G1.

AKS 4100U с трубной резьбой ¾ in. NPT

Монтаж устройства

Подгатовка к монтажу уровнемера

Отсоедините преобразователь сигнала

от штуцера (используте ключ на 5 мм,

© Danfoss | DCS (ms) | 2020.12

См. Рис. 7). Штуцер закройте заглушкой,

поставляемой в комплекте. Это позволит

избежать

Комплектность (Рис. 1)

Преобразователь сигнала (с или без HMI)

Штуцер с 5 метровым тросом (5 м (197".)

Ø2мм (0.08 ".)) из нержавеющей стали

Направляющие трубки.

Дополнительные принадлежности:

– комплект винтов, размер 3 мм;

– красная крышка, служащая для защиты

соединительного штуцера, до того

момента, пока к нему не будет

присоединён преобразователь сигналов;

– бирка с данными по настройке датчика.

Сборка коаксиальных трубок.

Обратите внимание что трос не

должен и меть замятостей и

перегибов, по всей своей длине.

1. Возьмите конец нержавеющего троса

ипропустите через центральное

отверстие направляющей (см.Рис. 2).

Пропустите трос через всю длину трубки,

если у вас более одной трубки повторите

операцию.

2. Соедините трубки и (см.Рис. 3).

Используйте ключ на 17 для затяжки.

3. Если у вас более одной трубки повторите

операцию (см.Рис. 3).

4. После отсоединения преобразователя

от штуцера, оденьте защитную заглушку,

что бы предотвратить попадание грязи.

Накрутите трубку штуцер.

5. Затяните на каждой трубке крепежные

винты используя 3 мм ключ (см.Рис. 3).

6. Проденьте трос через концевой

соединитель (см.Рис.4).

7. Установите концевой соединитель на

последнюю трубку. Затяните крепежный

винт (см.Рис. 4).

8. При помощи пасатижей натяните

трос с усилием указанным на Рис.4.

Закрепите трос 2мя винтами,

при помощи ключа.

9. Обрежте трос отступив от концевого

соединителя 20 мм (0.8")(см.Рис. 5).

10.

Измерьте длину измерительной части

уровнимера, без учета

присоединительного штуцера. (см.Рис. 6).

Используя манаметрический ключ

затените штуцер (Рис. 1, поз.2) с усилием

120 Нм.

Если необходима дополнительная

настройка

Длина измерительной части, значения 4

мА и 20 мА необходимо провести быструю

настройку через HMI.

Длина измерительной части:

Длину можно узнать из каталога или

измерить (см.Рис. 6).

4 мА определение значения точки =

Максимальная измеряемая длина

– Нижняя мертвая зона (см.Рис. 6)

20 мА определение значения точки =

Верхняя мертвая зона(см.Рис. 6)

Пример (AKS 4100)

Дано:

Длина измеряемой части: 1200 мм

Хладагент: CO2, -35 °C

Величина диэлектрической

проницаемости (εr) всегда вводится через

меню «Быстрая настройка»

Длина измеряемой части = 1200 мм:

4 mA определение значения точки =

= Длина измеряемой части (1200 мм)

– Нижняя мертвая зона (см.Рис. 6)

(170 мм) = 1030 мм (40.9")

20 mA определение значения точки=

= Верхняя мертвая точка (см.Рис. 6)

= 120 мм (4.7")

Используя таблицу на странице 8:

Диэлектрическая проницаемость.

Параметр 2.5.3 GAS EPS.R = 1.02

Установка преобразователя сигнала

AKS 4100/4100U (см.Рис. 7)

1. Открутите крережный и вентиляционный

винты на преобразователе сигнала при

помощи шестигранного ключа 5 мм.

2. Прижмите преобразователь сигнала,

чтобы он плотно сидел на штуцере

волновода.

3. Поверните преобразователь сигнала в

требуемое положение.

4. Затяните крепежный винт шестигранным

ключом 5 мм.

5. Затяните вентиляционный винт

шестигранным ключом 5 мм.

Электрическое подключения

Выходные клемы (Рис.8 и 9):

1. Выходной ток –

2. Выходной ток +

3. Клема заземления

Порядок электрического подключения

1. Ослабьте стопорный винт крышки при

помощи ключа-шестигранника,

имеющего размер 2,5 мм.

2. Снимите крышку от клеммной коробки.

Положите крышку клеммной коробки

рядом с корпусом.

3. Подключите провода к прибору. Затяните

кабельный ввод.

4. Подключите провода к прибору. Затяните

кабельный ввод.

5. Установите крышку клеммной коробки на

корпус.

6. Затяните стопорный винт при помощи

ключа-шестигранника, имеющего размер

2.5 мм

Обратите внимание:

Преобразователь сигнала можно настроить

как в сборе со штуцером, так и отдельно.

Включение:

• Подсоедините питание.

Только для уровнимеров с HMI: После 10

секунд на дисплее отобразится "Starting up".

А после 20 секунд на дисплее отобразится

версия прошивки уровнемера. Через 30

секунд дисплей перейдет в рабочий режим

(Рис. 13).

При замене AKS 41/41U на AKS

4100/4100U:

Внимание:

AKS 41/41U мог работать от двух типов

питания AC и DC в свою очередь AKS

4100/4100U использует только тип DC

Пример подключения см.Рис.10.

Подключение к контройлеру или PLC

Следуйте инструкциям на Рис. 11 or 12.

Внимание:

В случае если AKS 4100/4100U во

время работы обнаружит ошибку и

отобразит 1, 2 или 3 (см. стр. 4 пункт

№5). То выходной сигнал будет равен 3.6 мА.

БЫСТРАЯ НАСТРОЙКА →

AN23828644201102-000501 | 25

Внимание:

TПреобразователь сигнала можно настроить как в сборе со штуцером, так и отдельно.

Quick Setup (all values below are only examples)

Когда датчик используется с CO2:

• Подключите прибор к источнику

питания (см.инструкцию по монтажу

для более подробного описания

электрического подключения).

• Нажмите трижды кнопку .

AKS 4100

БЫСТРАЯ НАСТРОЙКА?

ДА НЕТ

• Нажмите кнопку

ВЫБРАТЬ ТИП

ТРОСОВЫЙ

AKS 4100

• Нажмите или что бы выбрать

тросовый, коаксиальный D14 или

коаксиальный D22. Выберите коак. D14

и нажмите для подтверждения.

ХЛАДАГЕНТ CO2 ?

ДА НЕТ

AKS 4100

• Нажмите Да(YES)

Er газа?

AKS 4100

001.000

• Нажмите для изменения величины

диэлектрической проницаемости

хладагента GAS EPS.R. (соответст вующее значение диэлектрической

проницаемости выбирается из

таблицы на стр. 8).

Нажмите для перемещения

курсора.

Нажмите для уменьшения зада

ваемой величины или для её

увеличения.

• Нажмите для подтверждения

• Нажмите для выбора длины

измеряющей части уровнимера (PROBE

LENGTH).

Нажмите для перемещения

курсора.

Нажмите для уменьшения зада ваемой величины или для её

Нажмите для подтверждения

• Нажмите чтобы задать на шкале

измерения (SCALE) величину 4 мА.

Нажмите для перемещения

курсора.

Нажмите для уменьшения зада-

ваемой величины или для её

Нажмите для подтверждения

Нажмите чтобы задать на шкале

измерения (SCALE) величину 20 мА.

Нажмите для перемещения

курсора.

Нажмите для уменьшения зада-

ваемой величины или для её

увеличения.

Нажмите для подтверждения

Длина сенсора

AKS 4100

05000 mm

увеличения.

AKS 4100

Шкала 4мА

04946 mm

увеличения.

AKS 4100

Шкала 20 мА

00070 mm

AKS 4100

БЫСТРАЯ НАСТРОЙКА

ЗАВЕРШЕНО ЧЕРЕЗ 8

• Подождите, пока режим «Быстрая на стройка» 8-ми секундную задержку.

AKS 4100

БЫСТРАЯ НАСТРОЙКА

• Нажмите для подтверждения

1.0.0

AKS 4100

1.0.0

Сохранить НЕТ

• Нажмите или чтобы выбрать со хранение (STORE YES) или не

сохранение (STORE NO)

произведённых изменений.

Нажмите для подтверждения

Дистанция

5000 mm

AKS 4100

Быстрая настройка

закончена

Вы можете проверить введённые Вами

настройки, нажав кнопку дважды.

КОАКСИАЛ. D14 2200 mm

(0%) 4 mA 1900 mm

(100%) 20 mA 70 mm

Нажмите

ся к показаниям, выводимым на экран

по умолчанию.

AKS 4100

, чтобы вернуть-

26 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

Для всех остальных хладагентов:

• Подключите прибор к источнику

питания (см.инструкцию по монтажу

для более подробного описания

электрического подключения).

• Нажмите трижды кнопку .

AKS 4100

БЫСТРАЯ НАСТРОЙКА?

ДА НЕТ

• Нажмите кнопку

AKS 4100

ВЫБРАТЬ ТИП

ТРОСОВЫЙ

• Нажмите или что бы выбрать

тросовый, коаксиальный D14 или

коаксиальный D22. Выберите коак. D14

и нажмите для подтверждения.

AKS 4100

ХЛАДАГЕНТ CO2 ?

ДА НЕТ

• Нажмите НЕТ (NO)

AKS 4100

Длина сенсора

05000 mm

• Нажмите для выбора длины

измеряющей части уровнимера (PROBE

LENGTH).

Нажмите для перемещения

курсора.

Нажмите для уменьшения зада ваемой величины или для её

увеличения.

Нажмите для подтверждения

Шкала 4мА

04946 mm

• Нажмите чтобы задать на шкале

AKS 4100

измерения (SCALE) величину 4 мА.

Нажмите для перемещения

курсора.

Нажмите для уменьшения зада-

ваемой величины или для её

увеличения.

Нажмите для подтверждения

Шкала 20 мА

00070 mm

AKS 4100

• Press to change of SCALE 20 mA.

Press to change the cursor position.

Press to decrease the value or to

increase the value.

Press to confirm.

AKS 4100

БЫСТРАЯ НАСТРОЙКА

ЗАВЕРШЕНО ЧЕРЕЗ 8

• Подождите, пока режим «Быстрая на стройка» 8-ми секундную задержку.

AKS 4100

1.0.0

БЫСТРАЯ НАСТРОЙКА

• Нажмите для подтверждения

AKS 4100

1.0.0

Сохранить НЕТ

• Нажмите или чтобы выбрать со хранение (STORE YES) или не

сохранение (STORE NO)

произведённых изменений.

Нажмите для подтверждения

AKS 4100

Дистанция

5000 mm

Быстрая настройка

закончена

© Danfoss | DCS (ms) | 2020.12

AN23828644201102-000501 | 27

Проверка выходного сигнала мА (все значения приведены в качевстве примера)

AKS 4100

QUICK SETUP ?

Начальное меню

Дистанция

5000 mm

AKS 4100

• Нажмите

AKS 4100

БЫСТРАЯ НАСТРОЙКА

1.0.0

• Нажмите

AKS 4100

2.0.0

Супервизор

• Нажмите

AKS 4100

2.0.0

___________

Введите пароль:

AKS 4100

2.1.0

Информация

• Нажмите

AKS 4100

2.2.0

Тестирование

• Нажмите

AKS 4100

2.2.1

Тест вых.тока

• Нажмите

AKS 4100

Тест вых.тока

3.5 mA

• Нажмите или для изменения

значения.

Нажмите для подтверждения .

AKS 4100

Тест вых.тока

8 mA

• Нажмите 4 раза для возврата в

рабочее меню уровнемера.

Начальное меню:

AKS 4100

Дистанция

5000 mm

Проверка выходного сигнала

закончена и отключена.

Дополнительная настройка

Если известны температурные условия в трубе, то может быть введена величина диэлектрической проницаемости хладагента

(параметр 2.5.3 GAS EPS.R). Это поможет сократить размеры верхней и нижней мёртвых зон

Введение величины диэлектрической проницаемости (все величины приведены ниже только в качестве примера)

Начальное меню

Дистанция

5000 mm

AKS 4100

• Нажмите

AKS 4100

БЫСТРАЯ НАСТРОЙКА

1.0.0

• Нажмите

AKS 4100

2.0.0

Супервизор

• Нажмите

AKS 4100

2.0.0

___________

Введите пароль:

AKS 4100

2.1.0

Информация

• Нажмите 4 раза

AKS 4100

2.5.0

Применение

• Нажмите

AKS 4100

2.5.1

Скор.слежения

• Нажмите 2 раза

AKS 4100

2.5.3

Er газа

• Нажмите , чтобы изменить величину

диэлектрической проницаемости (Er

газа). Выберите соответствующую

величину из таблиц на стр. 7 и 8

Нажмите для изменения по ложения

курсора.

Нажмите или для изменения

значения.

AKS 4100

Er газа

1.066

• Нажмите для подтверждения .

AKS 4100

2.5.3

Er газа

• Нажмите 3 раза

AKS 4100

Сохранить НЕТ

.

1.0.0

• Нажмите или для выбора

Сохранить НЕТ или Сохранить ДА.

Нажмите для подтверждения .

Появится экран со значениями по

умолчанию:

Дистанция

5000 mm

AKS 4100

Введение величины

диэлектрической

проницаемости закончено.

28 | AN23828644201102-000501

© Danfoss | DCS (ms) | 2020.12

Диэлектрическая проницаемость насыщенного пара (величина, принятая по умолчанию: 1,006)

R717 (NH3)

Температурный диапазон:

-60 – 50 °C / -76 – 122 °F

Температура

[°C]

-60 – -42 -76 – -43 1.00

-41 – -18 42 – 0 1.01

-17 – -5 1 – 23 1.02

-4 – 4 24 – 39 1.03

5 – 12 40 – 54 1.04

13 – 18 55 – 64 1.05

19 – 24 65 – 75 1.06

25 – 28 76 – 82 1.07

29 – 33 83 – 91 1.08

34 – 37 92 – 99 1.09

38 – 40 100 – 104 1.10

41 – 44 105 – 111 1.11

45 – 47 112 – 117 1.12

48 – 50 118 – 122 1.13

Температура

[°F]

R22

Температурный диапазон:

-60 – 48 °C / -76 – 118 °F

Температура