1

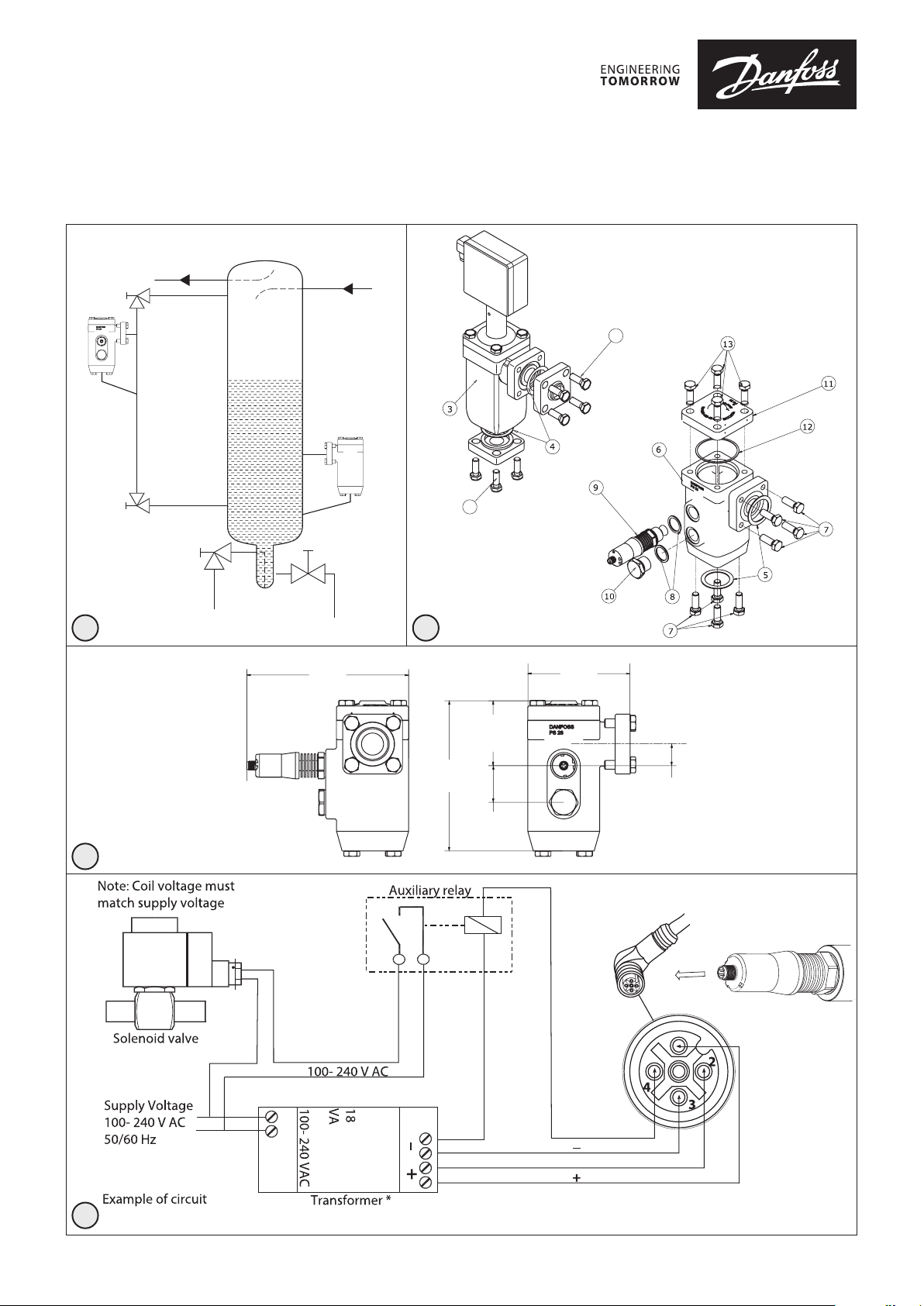

205 mm

[8 in]

140 mm

[5 1/2 in]

220 mm

[8 5/8 in]

88 mm

[3 1/2 in]

50 mm

[2 in]

29 mm

[1 1/8 in]

2

Installation guide

AKS 38

LLS 4000 retrofit

148R9529

1

2

1

220 mm

[8 5/8 in]

2

140 mm

[5 1/2 in]

148R9529

[8 in]

205 mm

88 mm

[3 1/2 in]

[2 in]

50 mm

29 mm

[1 1/8 in]

3

24 V DC

1

24 V DC

Black

White

Green

Red

4

* Danfoss code number 080Z0053, AK-PS 075, or similar

© Danfoss | DCS (ms) | 2021.04 AN375739676136en -000101 | 1

45°

ENGLISH

Refrigerants

Applicable to:

Ammonia R717

HCFC R22, R507A

HFC

R407A, R404A, R410A, R134A, R513A

Temperature range

-50 °C/+65 °C (-58 °F/149 °F)

Pressure range

AKS 38 retrofit house is designed for a max.

working pressure of 28 bar (406 psig).

Electrical data (LLS 4000)

Power Supply: 24 V DC +/-25%, 80 mA

Standard power supply of type: SELV

(Separated Extra Low Voltage) with current

limit of max. 8 A.

Solid state relay: Max 30 V DC, 200 mA.

M12, 4 pin electrical connection.

Enclosure

AKS 38 Retrofit house: IP65

LLS 4000: IP66 /IP67

Liquid Level differential

The AKS 38 retrofit house is equipped

with 2 connections with 50 mm distance

(fig. 3), that can be used for mounting:

- 1 x LLS 4000 + plug (Hi/Lo level

control, default configuration)

- 2 x LLS 4000 (ON/OFF level control,

require additional LLS 4000)

For ON/OFF level control only, 1 x LLS 4000

can be used in combination with a time

delay via an externally managed time

delay.

The time delay shall be set with care

and provide an effective differential

NOT higher than 50 – 75 mm under

all conditions.

Installation

IMPORTANT

AKS 38 Retrofit house must

always be installed in a vertical

position (fig. 1 and 2).

AKS 38 is supplied with new bolts and

gaskets (fig. 2, pos. 5+7) for the retrofitting.

The external surfaces of the flanges must

be protected against corrosion with a suitable protective coat after installation.

To avoid an oil seal forming which would

affect the LLS 4000 measuring the bottom

connecting pipe must have an incline

towards the liquid separator.

Shut-off valves should be mounted as

close as possible to the retrofit house for

service (fig. 1).

Installing the retrofit house (fig. 2)

• Unscrew the 4 bolts on the side flange of

the existing AKS 38 (fig. 2, pos. 1)

• Unscrew the 4 bolts on the bottom flange

(fig. 2, pos. 2)

• Remove the old AKS 38 housing (fig. 2,

pos. 3) and scrap the old gaskets

(fig. 2, pos. 4)

• Install the new gaskets (fig. 2, pos. 5) and

position the retrofit housing (fig. 2, pos. 6)

to the flanges

• Fasten new 4 × M12×35 stainless steel

bolts (fig. 2, pos. 7) in each flange.

Tighten diagonally to a max. tightening

torque: 74 Nm (55 ft-lb)

Installing the LLS 4000 and ¾” plug (fig. 2)

• Install the 2 alu gaskets (fig. 2, pos. 8)

• Fasten the LLS 4000 (fig. 2, pos. 9) and ¾”

plug (fig. 2, pos. 10). Max. tightening

torque: 10 Nm/7.4 ft-lb pre-tightening

+ 45 degrees clockwise rotation

Max. tightening torque:

10 Nm/7.4 ft-lb pre-tightening +

45 degrees clockwise rotation.

Electrical installation (fig. 4)

The wiring diagram (fig. 4) is an example

and serves as an overall guide to the actual

installation.

24 V DC transformer for LLS 4000/4000U:

Danfoss code number 080Z0053,

AK-PS 075, or similar.

AK-PS 075 data:

Input Voltage

100 – 240 V AC

50 – 60 Hz

0.4 A (120 V AC) /

0.2 A (230 V AC)

Output Voltage:

24 V DC

0.75 A

18 VA

Observe:

Auxiliary relay:

Coil voltage: 24 V DC

Contact rating: Must match load of the

connected field coil (voltage and load)

The Auxiliary relay and the Transformer are

not included in the AKS 38 Retrofit kit.

Maintenance

IMPORTANT

The AKS 38 Retrofit housing

must be evacuated before

opening to air.

Replacing the flange gaskets

(fig. 2, pos. 5)

• Unscrew the 4 bolts on the side flange

(fig. 2, pos. 7)

• Unscrew the 4 bolts on the bottom

flange (fig. 2, pos. 7)

• Remove both gaskets (fig. 2, pos. 5)

• Install the new gaskets

• Fasten 4 bolts in each flange. Tighten

diagonally to a max. tightening torque:

74 Nm (55 ft-lb)

Replacing the top cover gasket

(fig. 2, pos. 12)

• Unscrew the 4 bolts (fig. 2, pos. 13)

• Remove the top cover (fig. 2, pos. 11)

• Remove the gasket (fig. 2, pos. 12)

• Install the new gasket

• Fasten 4 × bolts (fig. 2, pos. 13). Tighten

diagonally to a max. tightening torque:

74 Nm (55 ft-lb)

© Danfoss | DCS (ms) | 2021.04

AN375739676136en -000101 | 2

Loading...

Loading...