Page 1

AK2-SC 255

Reference Manual

RE FR IG ER ATI ON A ND

AI R CONDITIONING

Users Manual

Page 2

AK2-SC 255 Rack Controller

System Reference Manual

RS.8D.M1.22 AK2-SC 255 Reference Manual 1

Page 3

2 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 4

AK2-SC 255 Rack Controller

System Reference Manual

What this manual

covers This manual covers configuration and operation of the Danfoss AK2-SC 255 Rack

Controller and systems based upon it. In this manual we very often refer to the

controller as “SC 255,’ a shortened version of its official name.

This manual is intended for the user who requires detailed information about any

aspect of the controller’s operation and software.

Although the manual does not at this time have an index, the Table of Contents that

follows this page is quite extensive and should be a useful guide to the text.

Other manuals for

this system Other Danfoss manuals that you should have are the On Site Guide for the AK2-SC

255, which covers installation and start-up of the controller, and the AK2 I/O Module

manual, which details installation and operation of the I/O modules and their software

interface using the AK2-SC 255 and earlier controllers.

If you can, you should check the Danfoss web site at

select the menu item for product literature. The AK2-SC 255 literature will be in the

Supermarket electronics section.

DISCLAIMER Where this manual discusses control and monitoring of equipment not manufactured

by Danfoss, or discusses interface to software not published by Danfoss, the accuracy of the text is in some cases dependent upon information furnished by the manufacturers of such non-Danfoss products, and Danfoss cannot be held responsible for

the accuracy of lthe information. Nevertheless, we have made every effort to ascertain correct information from all parties invol

Copyright © 1999, 2003, 2004, 2005 Danfoss Inc. All rights reserved.

At Danfoss, continuous improvement to documentation goes hand-in-hand

with the product refinement and quality for which Danfoss is justifiably world

famous. We welcome your suggestions for additions or improvements to any

of our manuals or other literature. Please address your comments to:

Danfoss Inc.

Literature Department

7941 Corporate Drive

Baltimore, MD 21236-4925

T elephone: (410) 931-8250

F AX: (410) 931-8256

www.acr.danfoss.com and

RS.8D.M1.22 AK2-SC 255 Reference Manual 3

Page 5

Table of Contents

P ART ONE Configuration

1.1 Initial Configuration ........................................................................................................1 1 - 12

Introduction ..................................................................................................................................... 11

Battery ..................................................................................................................................... 11

Authorization codes .............................................................................................................................. 11 - 12

Using Menus ..................................................................................................................................... 12

Selection of units and languages ................................................................................................................. 12

1.2 Configuring Refrigeration............................................................................................. 13 - 63

Starting with a partially configured AK2-SC 255........................................................................................ 13

Starting with a completely un-configured AK2-SC 255 .............................................................................. 14

Navigation and making changes.................................................................................................................. 14

Entering numerals ..................................................................................................................................... 14

Entering labels ..................................................................................................................................... 14

Constrained fields .............................................................................................................................. 14 - 15

Configuring Rack Info..........................................................................................................................15 - 16

Adding a rack ..................................................................................................................................... 16

Configuring Suction Info ...................................................................................................................... 16 - 19

Configuring two-stage systems ...................................................................................................... 19 - 20

Configuring compressors...................................................................................................................... 20 - 22

Compressor oil and safety information...........................................................................................22 - 23

Neutral Zone control ............................................................................................................................. 23

Compressor capacity staging patterns ........................................................................................... 24 - 25

Configuring Evaporators ...................................................................................................................... 25 - 31

Case lights button .................................................................................................................................. 27

Configuring AK2-SC 255 refrigeration circuits..................................................................................... 28

Configuring defrost 32 - 33

Configuring evaporators ....................................................................................................................... 33 - 34

Configuring condensers ........................................................................................................................34 - 46

Aircooled condensers..................................................................................................................... 35 - 42

Split condenser control ............................................................................................................. 39 - 40

Reaction zone and time................................................................................................................... 40

Enviroguard systems ...................................................................................................................... 41 - 42

Evaporative condensers .................................................................................................................42 - 47

Pump, louver, and sump schedules...........................................................................................44 - 45

Inverter settings; freeze protection; dump valve...................................................................... 45 - 46

Dump schedules....................................................................................................................... 46 - 47

Receiver configuration ................................................................................................................................ 47

Heat reclaim configuration ...................................................................................................................47 - 49

Refrigeration alarms configuration ....................................................................................................... 49 - 50

Board & Points configuration...................................................................................................................... 50

Navigation ..................................................................................................................................... 51

Board & Points, relay outputs (digital outputs) ..............................................................................51 - 52

Board & Points, sensor inputs (analog inputs) ............................................................................... 52 - 54

Board & Points, on-off inputs (digital inputs)................................................................................. 54 - 55

4 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 6

Board & Points, variable outputs (analog outputs)...................................................................................... 56

Board & Points, other controllers (case controllers, VFDs, etc., that are on the 255 network) ..........57 - 62

AKC 16x circuits, board & points........................................................................................................ 57

Network re-scan and initialization................................................................................................... 58

Navigation ..................................................................................................................................... 58

EKC circuits, board & points ......................................................................................................... 58 - 60

Network re-scan and initialization............................................................................................59 - 60

Wink ..................................................................................................................................... 60

Degree Master board & points ...................................................................................................... 60 - 61

Locate procedure ............................................................................................................................ 61

Activating the service pin from the display .....................................................................................61

Initialization ..................................................................................................................................... 61

Wink ..................................................................................................................................... 61

VLT and AKD drives, board & points........................................................................................... 61 - 62

DCU circuits, board & points ............................................................................................................... 62

1.3 Configuring HV AC ..........................................................................................................63 - 1 13

Introduction63 - 64

RTU Configuration ..............................................................................................................................64 - 76

R TU fan configuration ................................................................................................................... 64 - 66

RTU cooling configuration .............................................................................................................66 - 69

R TU heating configuration ............................................................................................................. 69 - 72

RTU dehumidification configuration...............................................................................................72 - 75

R TU air damper configuration .......................................................................................................75 - 76

R TU alarms configuration ..................................................................................................................... 76

R TU board & points configuration........................................................................................................ 76

AHU Configuration ..............................................................................................................................76 - 80

AHU fan configuration ..................................................................................................................76 - 78

AHR outside air coil configuration.................................................................................................79 - 80

RTC Configuration ..............................................................................................................................80 - 93

R TC fan configuration....................................................................................................................80 - 83

RTC cooling configuration..............................................................................................................83 - 84

R TC heating configuration ............................................................................................................. 85 - 86

RTC dehumidification configuration............................................................................................... 86 - 87

R TC air damper configuration........................................................................................................87 - 89

RTC schedules ..................................................................................................................................... 89

RTC alarm configuration....................................................................................................................... 89

R TC I/O points configuration ......................................................................................................... 89 - 92

Relay outputs (digital outputs)......................................................................................................... 90

Sensor inputs (analog inputs) ................................................................................................... 90 - 91

On-off inputs (digital inputs) ....................................................................................................91 - 92

RTC I/O variable outputs (analog outputs) ..............................................................................92 - 93

R TC address and Initialization........................................................................................................93 - 94

Seasons 4 Smart Coil configuration......................................................................................................94 - 98

Fan configuration, Seasons 4 Smart Coil............................................................................................... 94

Cooling configuration, Seasons 4 Smart Coil..................................................................................95 - 96

Heating configuration, Seasons 4 Smart Coil ................................................................................. 96 - 97

Dehumidification configuration, Seasons 4 Smart Coil...................................................................98 - 99

Condenser configuration, Seasons 4 Smart Coil ...................................................................................99

Alarms configuration, Seasons 4 Smart Coil......................................................................................... 99

RS.8D.M1.22 AK2-SC 255 Reference Manual 5

Page 7

Board & points configuration, Seasons 4 Smart Coil ............................................................................ 99

ClimaTECH configuration................................................................................................................ 100 - 109

Fan configuration, ClimaTECH................................................................................................... 100- 101

Cooling configuration, ClimaTECH............................................................................................ 101 - 102

Heating configuration, ClimaTECH ........................................................................................... 102 - 103

Dehumidification configuration, ClimaTECH............................................................................. 103 - 104

Economizer configuration, ClimaTECH .............................................................................................. 104

Alarm configuration, ClimaTECH....................................................................................................... 105

Schedule configuration, ClimaTECH .................................................................................................. 105

I/O configuration, ClimaTECH ........................................................................................................... 105

Relay outputs (digital outputs), ClimaTECH ................................................................................. 106

Sensor inputs (analog inputs), ClimaTECH........................................................................ 106 - 107

On-off inputs (digital inputs), ClimaTECH........................................................................... 107 - 108

Address and Initialization, ClimaTECH ........................................................................................ 108

Uploading ClimaTECH configuration to the AK2-SC 255 .................................................. 108 - 109

1.4 Lighting Configuration ................................................................................................110 - 1 1 4

Beginning configuration ..............................................................................................................................110

AK2-SC 255 lighting zone setup ........................................................................................................110 -11 3

Board & points configuration, lighting ........................................................................................................113

Powerlink configuration..............................................................................................................................113

Cutler-Hammer configuration ....................................................................................................................113

Powerlink and Cutler-Hammer board & point configuration .....................................................................113

Locate procedure ....................................................................................................................................114

1.5 Energy Meter Configuration (including demand limiting) .......................................114 - 121

Installation ....................................................................................................................................114

Configuration ...........................................................................................................................114 - 118

W attnode Plus configuration ......................................................................................................................118

About soft starts ....................................................................................................................................119

Configuring demand limiting ............................................................................................................... 119-121

HV AC demand limiting .............................................................................................................. 119 - 120

Lighting demand limiting...................................................................................................................... 120

How demand limiting works....................................................................................................... 120 - 121

1.6 Configuring Alarms...................................................................................................... 121 - 140

The Configure Alarms menu..................................................................................................................... 121

Configuring refrigeration alarms ...................................................................................................... 122 - 135

Alarms suspended ...............................................................................................................

....... 123 - 124

Suspending rack alarms ...................................................................................................................... 124

Configuring alarm settings.......................................................................................................... 124 - 126

Analog alarms .......................................................................................................................... 126 - 127

Field limits and units for analog alarms ......................................................................................... 127

Disabling alarms ................................................................................................................................... 127

What alarms are needed? ......................................................................................................................... 127

(Some) Frequently Asked Questions.................................................................................................. 127-128

T ypes of suction alarms, listed .................................................................................................................. 128

Compressor alarms .......................................................................................................................... 128 - 129

Circuit alarms .......................................................................................................................... 129 - 132

AK2-SC 255 circuits.................................................................................................................. 130 - 131

AKC 164 circuits ....................................................................................................................... 131 - 132

6 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 8

1.6 Configuring Alarms (continued)........................................................................... 121 - 132

EKCK, DCU, and Degree Master circuits......................................................................................... 132

AKC 165 subcooling circuits............................................................................................................... 132

Condenser alarms ................................................................................................................................... 133

“Other” rack alarms ............................................................................................................................ 134

Configuring Bitzer rack alarms ........................................................................................................ 134 - 135

HVAC alarm configuration .............................................................................................................. 135 - 138

AHU, RTU, and SC4 alarms .............................................................................................................. 136

RTC alarms ................................................................................................................................... 137

ClimaTECH alarms....................................................................................................................137 - 138

Miscellaneous alarms ....................................................................................................................... 138 - 140

Example miscellaneous alarm .................................................................................................... 139 - 140

Number of alarms field ....................................................................................................................... 140

1.7 Miscellaneous Points Configuration......................................................................... 140 - 154

Starting configuration ................................................................................................................................141

Plan strategy first ................................................................................................................................... 141

Miscellaneous relay outputs ............................................................................................................. 141 - 142

Miscellaneous sensor inputs ...................................................................................................................... 142

Miscellaneous on-off inputs....................................................................................................................... 142

Specifying miscellaneous conversiosn.............................................................................................. 142 - 143

Miscellaneous calculations ............................................................................................................... 143 - 144

Point creation .......................................................................................................................... 144 - 145

Custom strategy example ................................................................................................................. 145 - 153

Creating the miscellaneous points -- Sensor inputs .................................................................... 145 - 146

Writing the custom strategy ................................................................................................................ 146

Data definitions .......................................................................................................................... 146 - 148

The rules area .......................................................................................................................... 148 - 149

Writing rules .......................................................................................................................... 149 - 150

Creating the miscellaneous points relay output ........................................................................... 151- 154

Configuring Authorization........................................................................................................... 154

Configuring Units and Languages ............................................................................................. 155

PART TWO Using the Status Screens and Service Functions

Authorization -- “Just Looking” .............................................................................................................................. 157 - 158

Geeting Authorized to make changes ...................................................................................................................... 158 - 159

Units and Languages -- Selecting .................................................................................................................................... 159

2.1 Navigation and Making Changes ............................................................................. 159 - 164

Getting back to the icon menu................................................................................................................... 162

Viewing and changing setting.................................................................................................................... 162

Changing numeric values .......................................................................................................................... 162

Changing list fields .................................................................................................................................. 163

Changing the “From” and “T o” times ....................................................................................................... 163

Changing the days of the week and holidays ............................................................................................ 164

Changin g label fi elds ................................................................................................................................. 164

RS.8D.M1.22 AK2-SC 255 Reference Manual 7

Page 9

2.2 Using the Service Screens....................................................................................... 165 - 167

Auto/Manual Relays ....................................................................................................................... 165 - 166

<Reset> ................................................................................................................................... 166

Sensor adjustment ................................................................................................................................... 166

Maintenance hours ..........................................................................................................................166 - 167

Bd/Pt locations ................................................................................................................................... 167

2.3 Using the Smart Case Controller Screens............................................................... 168 - 174

Introduction .......................................................................................................................... 168 - 171

Evaporator settings .......................................................................................................................... 171 - 172

Evaporator schedules ................................................................................................................................ 172

Evaporator service .......................................................................................................................... 172 - 174

Manual operation........................................................................................................................ 172 - 173

AKC 16x shutdown ............................................................................................................................ 173

Case cleaning .......................................................................................................................... 173 - 174

2.4 Using the Refrigeration Screens for Refrigeration Circuits.................................. 174 - 175

Evaporator Status screen ................................................................................................................. 174 - 175

Evaporator settings screen ........................................................................................................................ 175

Evaporator Schedules screen, Evaporator Alarms screen, and Evaporator Service screen ..................... 175

2.5 Using the Communications Screens......................................................................... 176 - 187

Host Network screen ................................................................................................................................ 176

I/O Network Status screen .............................................................................................................. 176 - 177

List Points .......................................................................................................................... 177 - 179

List Nodes .......................................................................................................................... 179 - 180

IP Network (Ethernet) ..................................................................................................................... 180 - 181

Alarm routing for Ethernet ............................................................................................................... 181 - 182

Printer Settings screen ..................................................................................................................... 182 - 183

Modem configuration ....................................................................................................................... 183 - 186

Messages screen ................................................................................................................................... 186

2.6 Using the History Screens (for History Retrieval) .................................................. 187 - 192

Selecting points to view............................................................................................................................. 189

Displaying history .......................................................................................................................... 189 - 191

Graphing history .......................................................................................................................... 191 - 192

Stat (for statistics) ................................................................................................................................... 192

2.7 Using the Alarms Screens.......................................................................................... 193 - 197

The Alarms menu .......................................................................................................................... 193 - 194

The Active Alarms screen ............................................................................................................... 194 - 195

The Cleared Alarms screen ...................................................................................................................... 195

The Alarm Status screen.................................................................................................................. 195 - 196

The Network Alarms screen ..................................................................................................................... 196

The Alarm Service screen ............................................................................................................... 196 - 197

2.8 Overrides ............................................................................................................ 198 - 200

Overrides using service screens ........................................................................................................ 198-199

Overriding sensor values ........................................................................................................................... 199

Overrides using RO8S switches .............................................................................................................. 199

8 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 10

Overrides using the Manager’s Override box.................................................................................. 199 - 200

Keyswitch Override for refrigeration high temperature alarms................................................................ 200

2.9 Using the Audit Trail................................................................................................... 200 - 202

RS.8D.M1.22 AK2-SC 255 Reference Manual 9

Page 11

10 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 12

PART ONE

Configuration

1 - 1. Initial Configuration

Battery The unit’s backup battery power is automatically enabled when the unit is first

Note: We use the formal type designation “AK2-SC 255” occasionally in this manual, but

most often you will see the short form of the name: “SC 255.”

Configuration of an AK2-SC 255 is easy using the keypad and display, and even

easier using Danfoss AKA 65 Network Interface software running opn a PC connected to the controller. This chapter describes configuration from the AK2-SC 255

keypad. You can easily adapt these instructions for the PC keyboard and mouse after

reading Chapter 3, “Using AKA 65 Software on Your PC.”

We will address configuration of each area of a supermarket control system in this

section of the manual. Initial configuration for equipment start-up may be limited to

such items as are necessary to check out the mechanical equipment or provide basic

service. The configuration can be changed or added to at any time later.

externally powered. Note that if you receive the unit partially configured, the battery

will have been enabled. Normal battery life is a minimum of ten months, but the

battery is only used when main power is interrupted. In a unit which rarely experiences power interruptions, the battery can last as long as eight years.

If the battery is disabled (by removing it, or when it ultimately discharges completely)

any information stored in the unit (set points, schedules, etc.) will be lost. Do not

remove the battery.

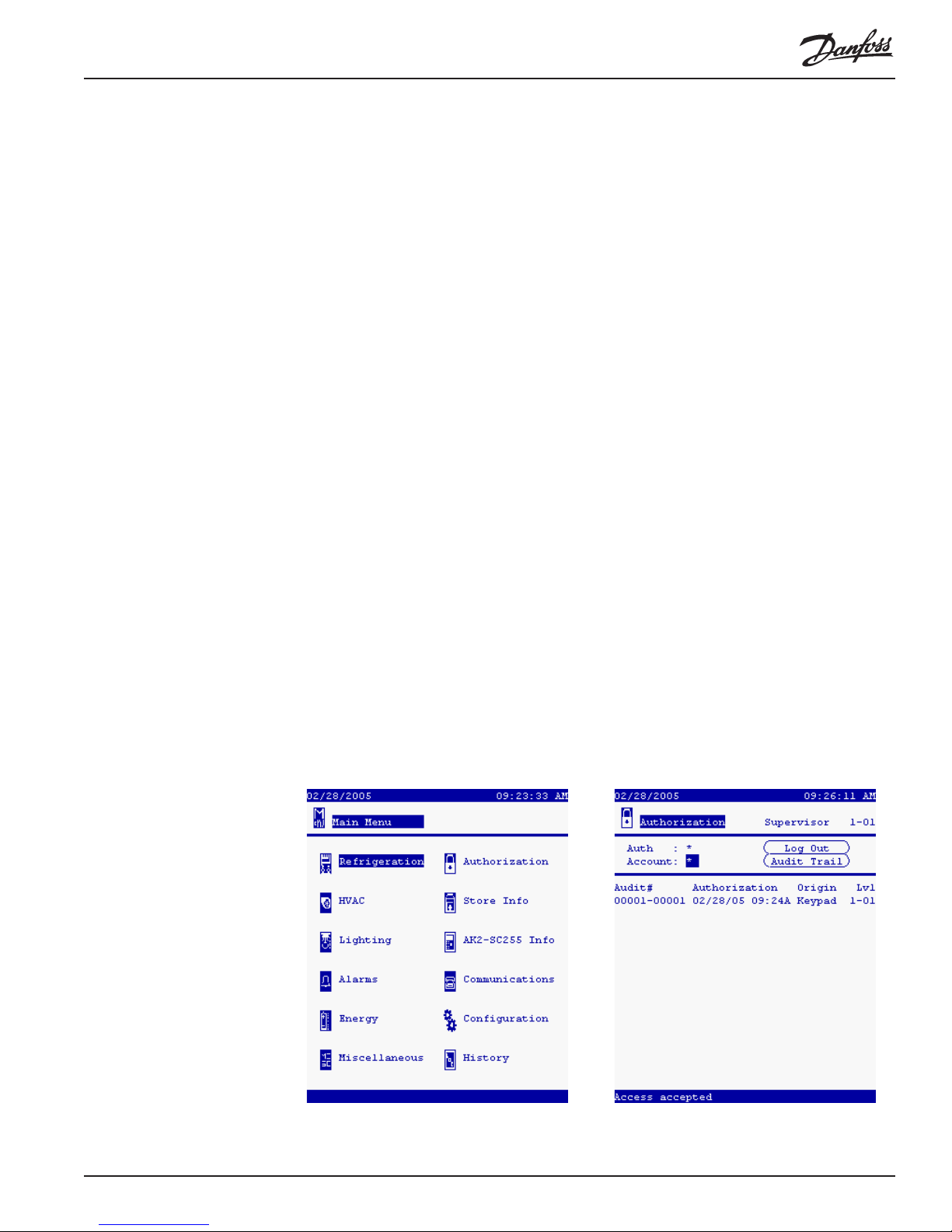

Authorization codes When the SC 255 is turned on for the first time, the Main Menu will appear as at left

below:

Before you can enter configuration information, you must select Authorization and

RS.8D.M1.22 AK2-SC 255 Reference Manual 1 1

Page 13

enter a valid authorization code and account code. Using the right arrow , move the

cursor to Authorization and press ENTER. The Authorization Menu will appear as

at right above, with the cursor in the Auth field.

When you have entered the access code and account number given to you by the

system owner, you will see the words Authorization accepted appear briefly in

reverse video at the very bottom of the screen. In the upper right, the screen will

show what the authorization level is.

After initial configuration, you will be able to make changes by several different

avenues, which are discussed in Chapter 5, “Using the System.”

Using menus To select from any SC 255 menu, first use the arrow keys to move the cursor to the

item you want, then press the ENTER key. You can use the EXIT key to retrace

your steps level by level.

Selection of Units

and Language Before using the system, you may wish to change the language used on the screens,

the units used for pressure and temperature, or the date and time format. These

settings will be for the local PC only, and will not af fect the displays of any SC 255 in

the system. To change the displayed units, select Store Information from the main

menu and then choose Units/Languages. In the Configuration Units/Languages

screen, select the language you want to see in the controller screens, then select

either psi or bar for pressure; either °F or °C for temperature; and either % or fc

(footcandles) for light level.

12 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 14

1 - 2. Configuring Refrigeration

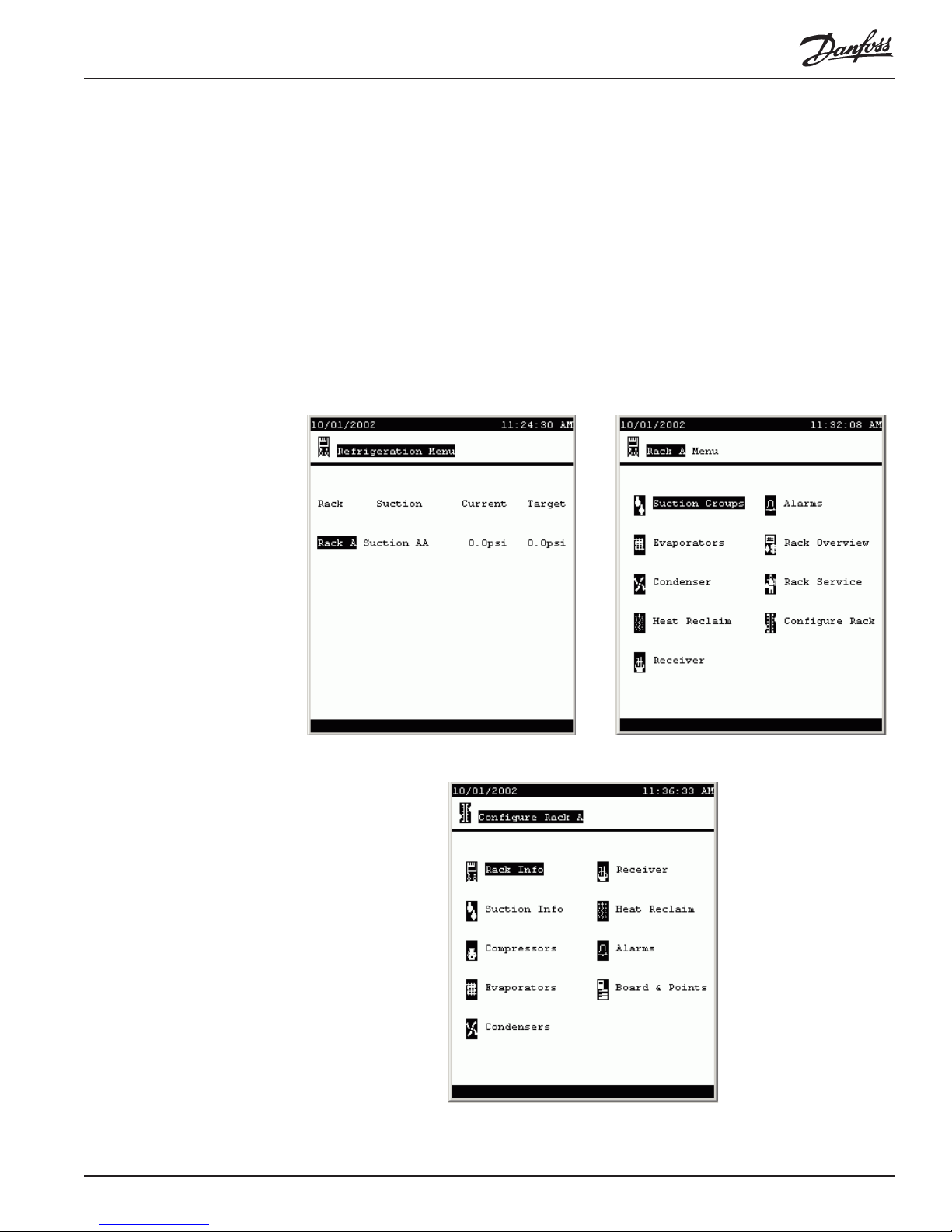

There are two “routes” you may need to navigate to begin configuring refrigeration.

One begins by selecting Refrigeration from the Main menu, and the other by

selecting Configuration.

Starting with a

Partially Configured

AK2-SC 255 If the AK2-SC 255 you are working with was supplied with a rack, the controller may

have been partially configured by the rack manufacturer. In that case, when you

select Refrigeration from the Main Menu, the SC 255 will display the Refrigeration

Menu (left). It lists the rack or racks that are partly configured. If you want to

change or add to the configuration of one of these racks, move the cursor to the rack

name and press ENTER. The Rack menu (right) will appear. In this example, only

one rack has been previously configured.

Select Configure Rack and the Configure Rack menu appears.

Now select the type of information you want to supply. We’ll cover a typical cat-

RS.8D.M1.22 AK2-SC 255 Reference Manual 1 3

Page 15

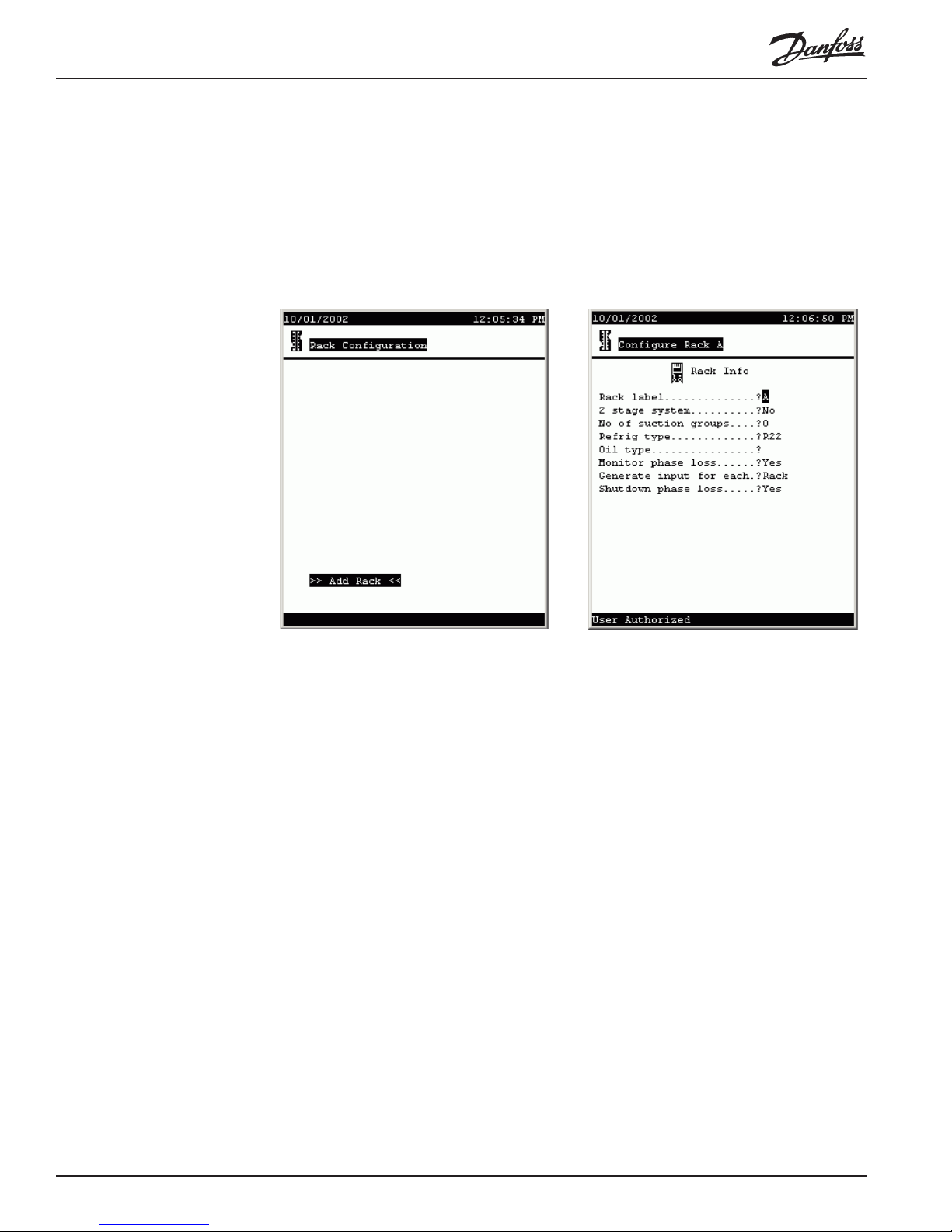

Starting with a

Completely

Un-configured

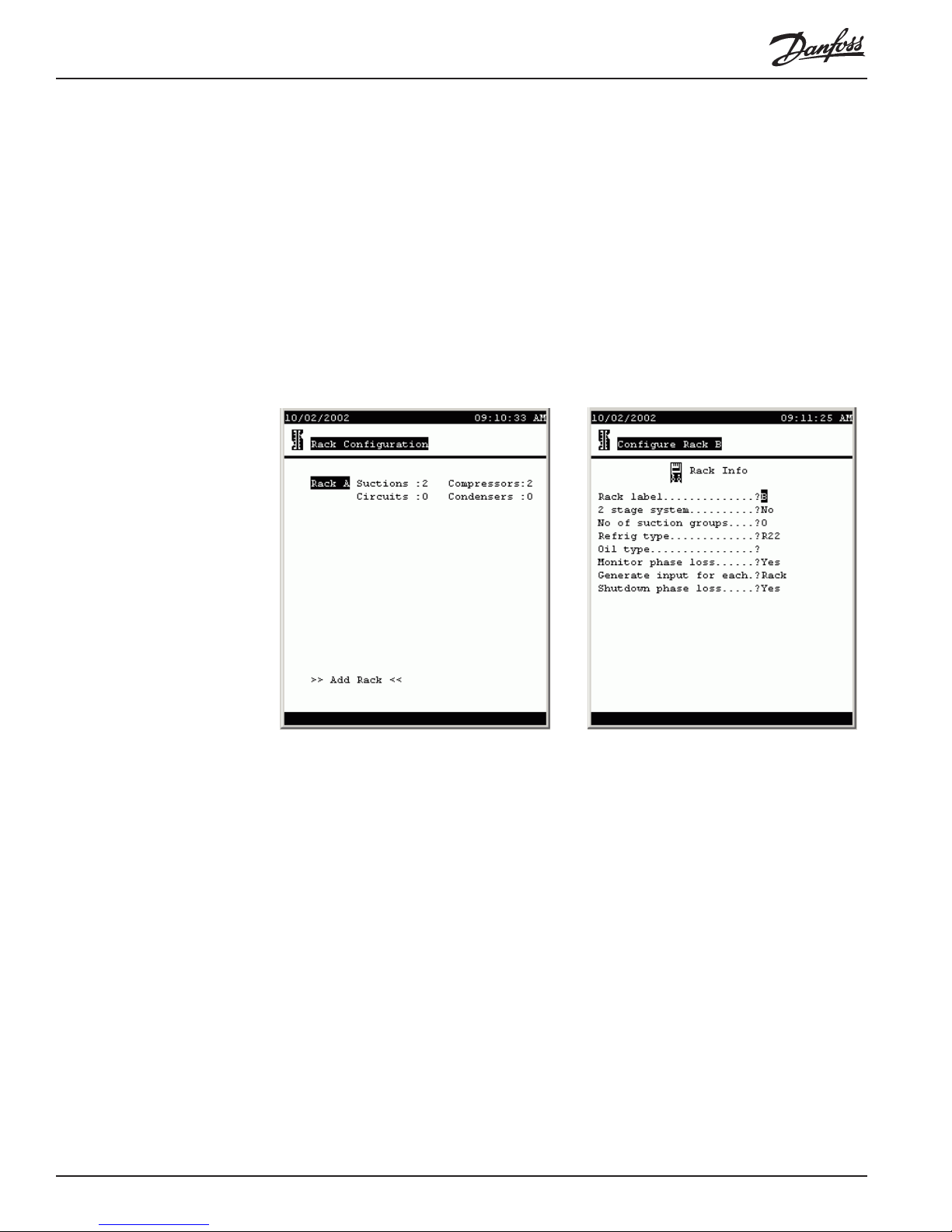

AK2-SC 255

egory right after we talk briefly about the other “route” configuration may take.

If the AK2-SC 255 you are working with has no refrigeration configuration at all,

select Refrigeration from the Main menu, and the Rack Configuration menu will

appear (left). The only selection which can be made from this screen is Add Rack.

Selecting Add Rack takes you to the Configure Rack, Rack Info screen (right).

Navigation and

making changes The Configure Rack A screen shown at right above has information fields that can be

changed by any user with a proper authorization code. To make changes, use the

arrow keys to move the cursor to the field you want to change

Entering numerals To enter numerals for a field like No of suction groups, use the numeral keys on the

controller keypad., then press ENTER.

Entering labels Labels are entries that you need to spell out. The Rack label field contains a label

one character in length. The Oil type field is also a label field, but it is 9 characters

long, allowing you to spell out a word or words indicating the oil type, for example,

“Mineral.”

To enter a label, place the cursor on the field, then press the +/- key. This action

toggles the function of the arrow keys so that the UP and DOWN arrows scroll

through the alphabet and all the other possible characters. Once the character you

want in that space appears, use the RIGHT arrow to move to the next space (when

the field has more than one space). Again, use the UP and DOWN arrows to reach

the character you want. When all the characters in the field are as you want them,

press ENTER to save the entry.

Constrained fields The Rack label field is a constrained field. It will only accept an upper case letter,

even though lower case letters appear as you scroll through the characters. The No

of suction groups field is also constrained. It will only accept a single numeric

character from 0 to 5, because a single AK2-SC 255 can control up to 5 suction

14 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 16

Selecting from list boxes

groups. Note that in the case of this particular field, entering a 0 (zero) will pop up a

warning box letting you know that a zero response here will eliminate the suction

groups already configured and will delete all information stored for the rack; you will

be asked to confirm the entry.

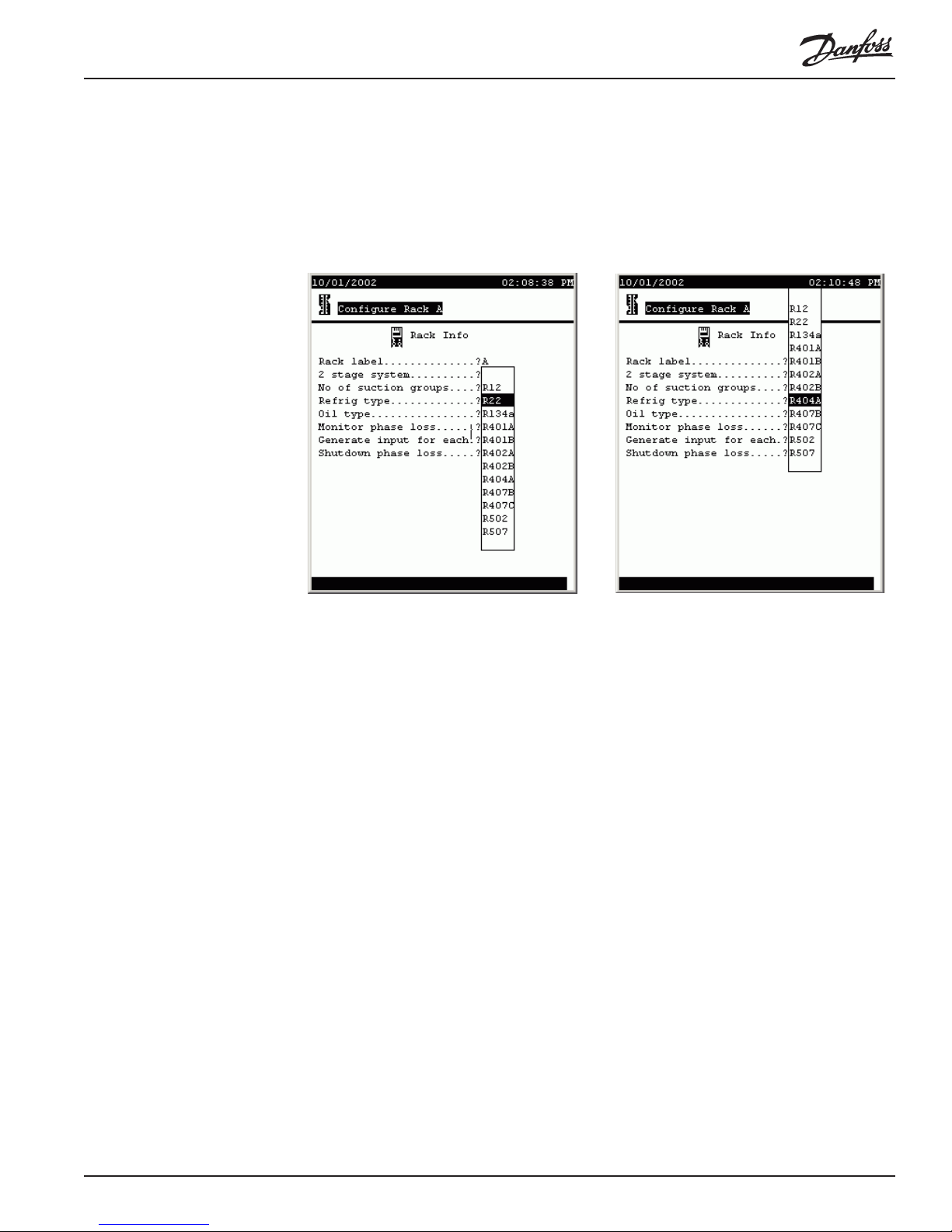

The next pair of illustrations shows how the controller uses list boxes.

The list box appears, as shown at left above, when you move the cursor to the field

and then press the +/- key (or, at your PC, right click). Then, using the UP and

DOWN arrow keys, you can move the cursor to make a selection. In the example at

right, R404A has been chosen. The cursor actually stayed in the same position, but

the “window” moved.

When you have put the list box’s cursor on the selection you want, press ENTER to

save your selection.

Some list boxes contain only two choices (for example, Yes and No in the Monitor

phase loss field). Some may contain many choices. When that is the case, one of the

lines in the box will contain three dots. When the cursor is moved to the three dots,

additional choices appear.

Now that we understand navigation and making changes, we can go on to a discussion of each of the configuration screens.

Configuring Rack Info In the rack Info screens, the following are the fields, and their possible contents:

Rack label (Upper case letters, A to Z) The “name” of the rack.

2 stage system (List box: Yes, No)

No of suction groups (0 to 5) Note that for a rack with existing configura-

tion, entering and confirming a 0 will cause deletion of

all existing rack information.

Refrig type (List box) The kind of refrigerant.

Oil type (9 characters, not constrained)

Monitor phase loss (List box: Yes, No) Whether or not there will be a

RS.8D.M1.22 AK2-SC 255 Reference Manual 1 5

Page 17

digital input from a phase loss monitor.

Generate input for each [appears only after a Yes answer to the preceding

question] (List box) Whether there is a phase loss

input for each rack or each suction group.

Shutdown phase loss [appears only after a Yes answer to the Monitor phase

loss question] (List box: Yes, No)

When all of the items on the Rack Info screen have been configured, press MENU to

return to the Main Menu.

Adding a Rack There is only one way to add a rack. From the Main Menu select Configuration,

then Refrigeration, and the Rack Configuration screen appears. At the bottom left of

the screen are the words >> Add Rack<<. Move the cursor there and press

ENTER. A new Rack Info screen will appear.

Notice that the Rack Label field contains the letter B by default, since the previously

configured rack was rack A. You can change the default label if you want.

Configuring

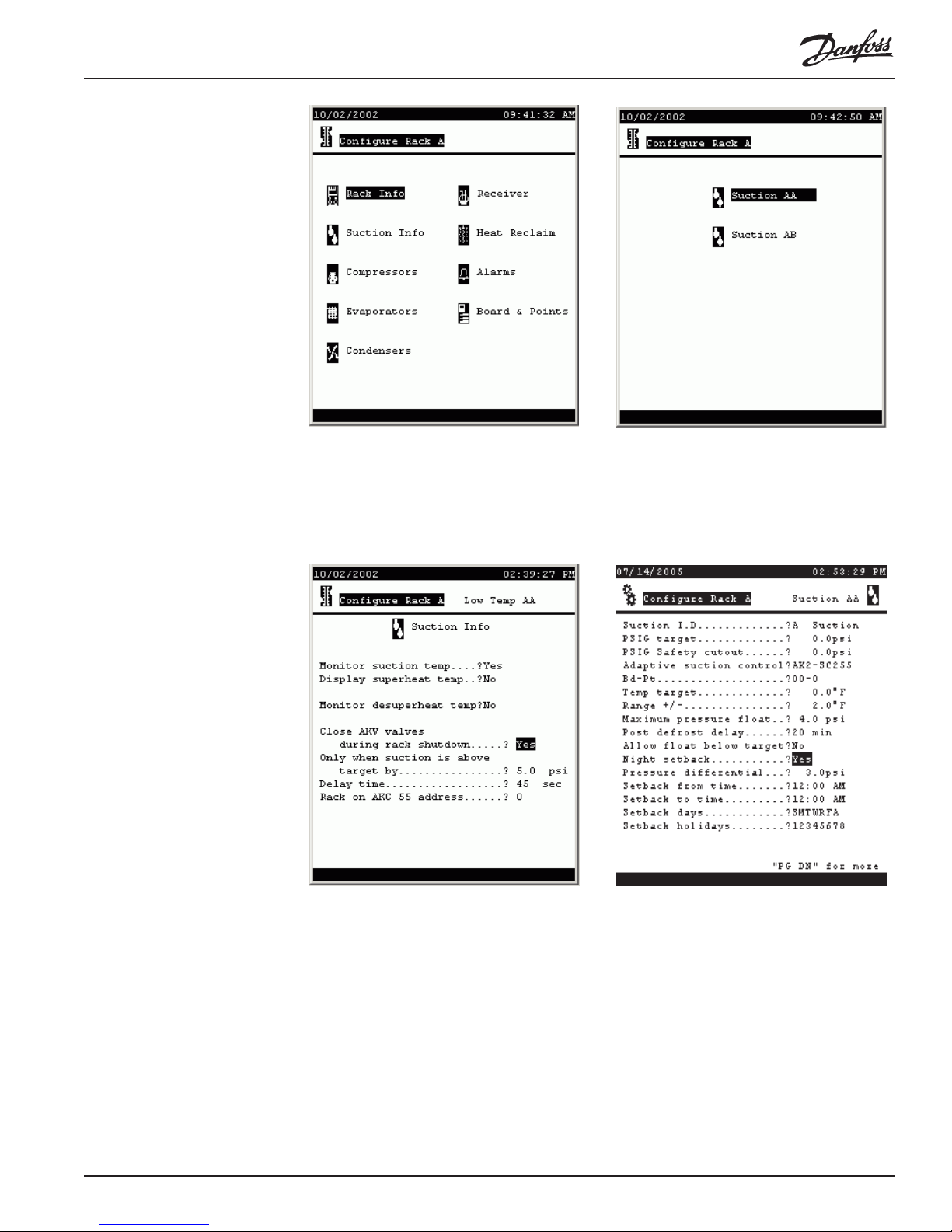

Suction Info T o configure a suction group, press MENU to return to the Main Menu, then select

Configuration, then Refrigeration. The Rack Configuration screen appears as at

left above. Select the rack and a Configure Rack menu appears (as at left below) .

16 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 18

Once at suction configuration menu shown at right above, select the suction group you

want to configure and press ENTER. The Suction Info screen for that group will

appear as at right below. As you configure, questions may appear that are not

included on the default screen. The screen at left below shows all the possible lines

revealed.

The fields and their contents are as follows:

Suction I.D. (2 label fields: the first is a list box: A to Z; the second

PSIG target (-50.0 to 500.0) The pressure that the controller will

RS.8D.M1.22 AK2-SC 255 Reference Manual 1 7

is 9 characters not constrained) This is the identification you wish to assign to the suction group. The entry

will modify the screen title. For example, if you enter a

B in the first field and Low Temp in the second, the

right portion of the screen title for the configuration

and status screens for this group will read Low Temp

AB.

maintain, subject to capabilities of mechanical equip-

Page 19

ment, for this suction group.

PSIG Safety cutout (-50.0 to 150.0) The gauge pressure at which the

controller will stop the compressors in this suction

group.

Adaptive suction control (List box)

None: No adaptive suction control.

AK2-SC 255: Target pressure is adjusted based on

discharge temperature of a single fixture.

AKC 16x: Adaptive control of individual evaporators

by an AKC 164 or AKC 161 Smart Case Controller.

Sensor: Target pressure is adjusted based on any

sensor on the AKC 55 I/O network

Dynamic: The SC 255 analyzes the performance of

every case on each individual circuit, and adjusts target

pressure intelligently by using the case sensor that

varies most from the setpoint.

Bd-Pt (For the first group, to the left of the hyphen, 01 to 99;

for the second group, to the right of the hyphen, 1 to 8).

The board and point address of the fixture sensor used

by the adaptive control algorithm. (Does not appear

when dynamic adaptive control is selected.) Note that

board and point numbers use a different format with

AK2 modules. See the AK2 I/O user manual for more

information.

Temp target (-50.0 to 100.0) The temperature that the adaptive

control algorithm will seek to maintain in the fixture.

(Does not appear when dynamic adaptive control is

selected.)

Range +/- (0.0 to 100.0) The dead band around the temperature

target. As long as the fixture temperature remains in

this range, the suction pressure target will not be

modified. (Does not appear when dynamic adaptive

control is selected.)

Maximum pressure float (0 to 99.9) The number of psig that the adaptive

algorithm will be allowed to cumulatively add or

subtract from the suction pressure target.

Post defrost delay (0 to 60) The number of minutes after termination of

defrost during which there will be no target adjustment.

(Does not appear when Sensor is selected as the type

of adaptive control.)

Allow float below target (List box: Yes, No) Determines whether or not the

adaptive algorithm will be allowed to adjust suction

pressure below the target if fixture temperature is

above target temperature + range.

Night setback (List box: Yes, No) Determines whether or not suction

pressure will be offset according to a schedule to be

specified in the following lines.

Setback from time (Time field) The start time for night setback.

Setback to time (Time field) The ending time for night setback.

Setback days (Days selection field) The days on which night setback

will be effective.

18 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 20

Setback holidays (Holidays selection field) The holiday numbers on

which night setback will occur. Holiday numbers are

defined in Store Info configuration.

At the bottom right of the Suction Info screen are the words “PG DN” for more.

Use the controller’s PG DN key to reach the next screen; shown at left is the default

screen in which not all the questions and fields appear; the screen on the right shows

all the fields.

Configuring

two-stage systems

The fields and their contents are as follows:

Monitor suction temp (List box: Yes, No)

Display superheat temp (List box: Y es, No)

Monitor desuperheat temp (List box: Yes, No)

Close EEV valves during

rack shutdown (List box: Yes, No)

If suct above target by (0 to 999.9) Number of psig above target when AKV

valves will be closed during rack shutdown.

Delay time (0 to 45) Number of seconds after suction pressure

reaches target + the number specified in the preceding

field that AKV valves will be closed.

Rack on AK2-SC 255 address

(0 to 15) The address of the SC 255 controlling the

rack that serves these EEVs.

Press EXIT to return to the Configure Rack Menu and continue refrigeration configuration.

and de-superheaters If (and only if) a rack is configured as a two-stage system, the

suction configuration for each suction group will include a special page for the low

side. The screen looks like this:

RS.8D.M1.22 AK2-SC 255 Reference Manual 1 9

Page 21

The fields and their contents are as follows:

Is this 2-stage low side (List box: Yes, No) Is this the low side of the two?

Low side shutdown:

Shutdown on hi suct PSI (List box: Yes, No) Whether or not to shut down the

low side compressors when high side reaches a

specified suction pressure.

High side suct. PSI (-99.0 to 200.0) The high side suction pressure at

which the low side will be shut down.

Control desuperheater (List box: Yes, No) Whether or not de-superheater

control is implemented on this rack.

Controlling sensor (List box:)

Desuper In AA: Control is based on a sensor moni-

toring the liquid in temperature at the de-superheater.

Desuper Out AA: Control is based on a sensor

monitoring the liquid out temperature at the de-superheater.

Suction Temp AA: Control is based on a sensor

monitoring suction temperature.

Desuperheating temp (-50.0 to 200.0)

Range +/- (1.0 TO 10.0)

Configuring

compressors To begin configuring compressors, select Compressors from the Configure Rack

menu. The first page of the screen looks like this:

20 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 22

The fields and their contents are as follows:

No. of compressors (0 to 9)

Proof type (List box:) The means by which proof of compressor

operation is monitored.

None: No proof

OI: A digital input (on-of f input) is used for proof.

CT: A current transformer is used for proof.

Bitzer: Proof is obtained from a Bitzer electronic

module.

Reset Bitzer with RO (List box: Yes, No) Whether or not Bitzer compres-

sors are reset by a digital output (relay output).

Compressor size (1 to 500) The capacity of the compressor.

No. of unloaders (0 to 4) The number of compressor unloader stages.

Unloader capacity % (1 field per unloader: 0-99) The percent of capacity

shed by the respective unloader.

Inverter control (List box:) Type of variable speed control.

None: No inverter control

VO: An inverter is controlled by an analog output

(variable output).

VLT: A Danfoss VLT adjustable frequency drive is

used.

Inverter min. speed (1.0 to 150.0) The minimum percentage of rated

speed at which the inverter will run the compressor.

Inverter max speed (1.0 to 150.0) The maximum percentage of rated

speed at which the inverter will run the compressor.

RPM at max speed (1 to 9999) The RPM that will be displayed at maxi-

mum percentage.

Inverter max resets (0 to 10) The number of resets after which the

inverter will be put in override.

Inverter proof delay (0-99) The number of seconds without proof that must

elapse before an inverter reset occurs.

Min time between resets (0 to 99) The number of seconds that must elapse

before second and subsequent inverter resets.

RS.8D.M1.22 AK2-SC 255 Reference Manual 2 1

Page 23

Configuring other

compressors in the

suction group Paging down, you will find a page for each compressor in the suction group. These

subsequent screens will have only questions pertaining to the individual compressors,

not the rack questions found at the top of the screen for compressor number one.

Compressor oil and

safety information After basic operating data has been entered for all compressors, paging down will

produce this screen:

The fields and their contents are as follows:

Oil control (List box: Yes, No) Whether or not oil control is

implemented.

Type of oil monitor (List box:)

Sensor Input: An analog input (sensor input) is used

to monitor oil pressure.

On/Off: A digital input (on-off input) is used to monitor

an oil pressure switch.

Copeland: A Copeland oil monitor is used.

Lockout comp on oil fail (List box: Yes, No) Whether or not compressors will

be locked out when an oil failure is detected.

Low oil pressure diff (0 to 50) The oil pressure differential, when an analog

sensor input is used, that will cause compressor

shutdown.

Oil pressure delay (0 to 255) When an analog sensor is used, the number

of seconds after oil failure is detected before compressors are reset.

No of oil reset attempts (0 to 10) After oil failure is detected, the number of

reset attempts before compressors are locked out.

Min time between resets (0 to 60) After a reset (whether successful or not) the

number of minutes that must elapse before another

reset attempt.

Monitor comp disch temp (List box: Yes, No) Whether or not compressor

discharge temperature is monitored.

22 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 24

Stop comps on high temp (List box: Yes, No) Whether or not compressors are to

be shut down on high discharge temperature.

Cutout (0.0 to 300.0) The discharge temperature at which

compressors are to be cut out.

Cutin (0.0 to 300.0) After a cut-out on high discharge

temperature, the discharge temperature at which

compressors are to be cut in.

Stop comps on low temp (List box: Yes, No) Whether or not comrpessors are to

be cut out on low discharge temperature.

Lockout (0 to 255) The number of minutes that must elapse

before a lockout on low discharge temperature. (See

note on next field).

below (0 to 300) The temperature that discharge must be

below for the time specified in the preceding field

before lockout on low discharge temperature occurs.

Note: If discharge temperature rises above the

setpoint, the time for lockout will restart from zero.

Disch pressure safety (List box: Yes, No) Whether or not comrpessors are to

be cut out on high discharge pressure.

Cutout (0.0 to 500.0) The discharge pressure at which com-

pressors are to be cut out.

Cutin (0.0 to 500.0) After a cut-out on high discharge

pressure, the discharge pressure at which compressors

are to be cut in.

Unload before cutout (List box: Yes, No) Whether or not comrpessors are to

be unloaded before being cut out.

Neutral Zone

control The next page of compressor configuration deals with neutral zone control. Basically,

neutral zone control acts to bring the current pressure toward target pressure more

quickly the greater the difference between the two. The screen looks like this:

The default settings are as shown in the screen above. It is recommended that the

values not be changed without a thorough understanding of the algorithm. A thorough

explanation of neutral zone control is available as an appendix to this manual.

RS.8D.M1.22 AK2-SC 255 Reference Manual 2 3

Page 25

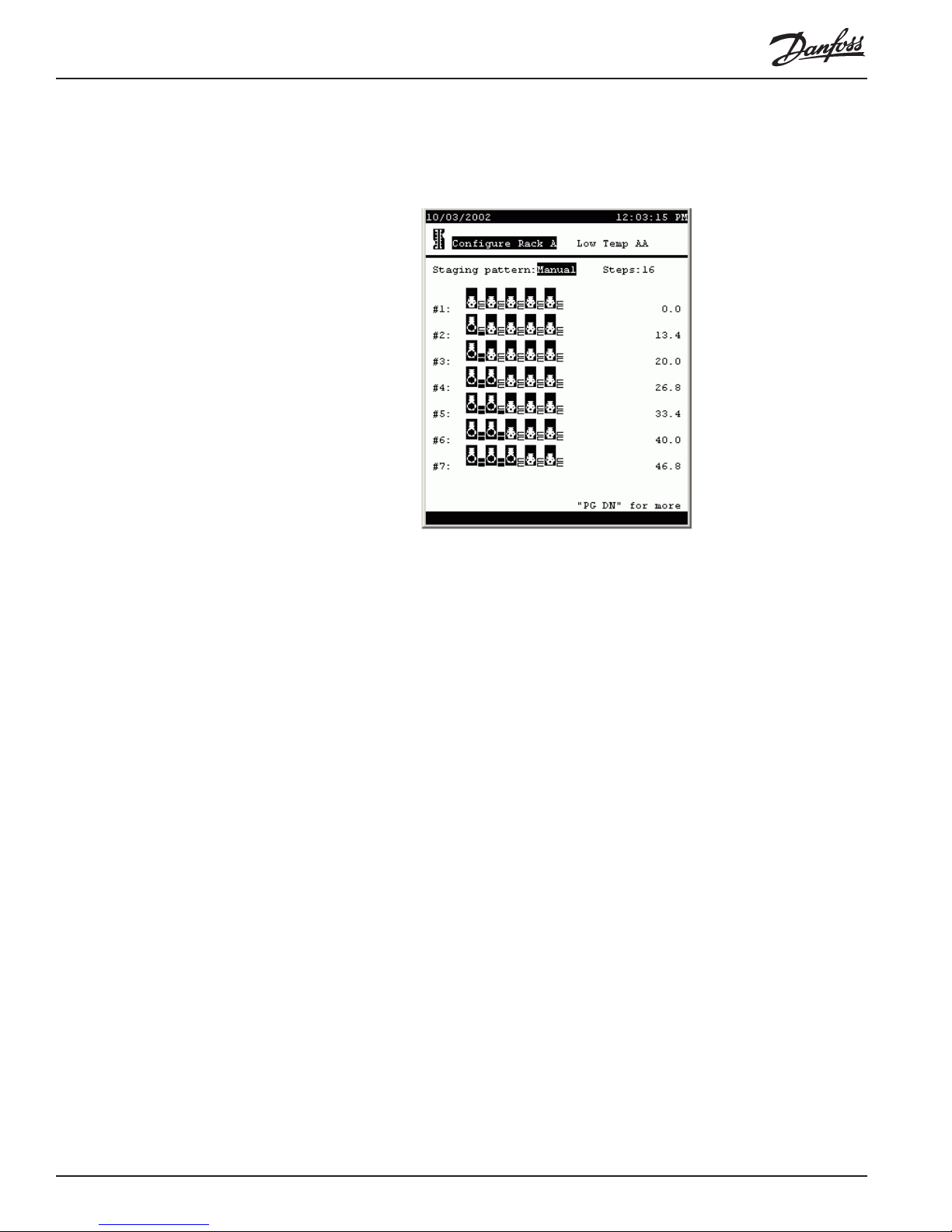

Compressor capacity

staging patterns Paging down from the neutral zone screen reveals the compressor staging pattern

screen:

In the default screen, the staging pattern is Auto, for automatic staging, and there is

no selection for Steps. The controller will stage rack capacity in the smallest steps

possible from lowest total capacity to highest, automatically selecting the compressors

combination to run for each stage (based on the the configured compressor capacities

available on the rack).

When there are a large number of steps, manual staging can be used to eliminate

needlessly small steps and compressor cycling.

T o use manual staging, select Manual from the pattern list box, then specify the

number of steps you want. The display that results will show a row compressor icons

for each stage. A compressor’s unloaders are represented by the small rectangles to

the right of the compressor icon.

In the sample screen, compressors are all 20 HP and each has 2 unloaders. Each

unloader is 33% of compressor capacity. These settings were determined on the

configuration page for each compressor.

Stage #1 is fixed at zero capacity and cannot be changed.

To change stage #2 or any higher stage, move the cursor to a compressor icon and

press enter. You will notice that the “piston” in the icon moves. When it is up, the

compressor is on. If there are unloaders on a compressor, subsequent clicks on the

compressor icon will turn the unloader steps on, one at a time. The small rectangles

will change color to indicate that the step is on. When all steps are on for a compressor, the next click on the icon will turn everything off.

As you change a stage’s capacity, the number in the right column of the screen will

24 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 26

change for that stage, giving the total horsepower you have selected for that stage.

You can change the number of steps at any time.

Configuring

evaporators To begin configuration of evaporators, return to the Configure Rack menu and select

Evaporators. Or, from the Main Menu (which you can always reach with the

MENU key) select Configuration, Refrigeration, the particular rack, and Evaporators.

The evaporator menu will initially look like as on the left below , with no evaporators

listed, but as soon as you enter a number in answer to the top question, and select

from the Type list box for some of the evaporators, the screen will look something

like the one at right:

There are six kinds of evaporator control shown. In this manual, we will discuss the

configuration of SC 255 circuits and AKC 16x circuits. For the other types of evaporators, please see the manuals on the individual controllers. In the future, when a

Danfoss Case Control manual is created, we will remove the AKC 16x material from

this manual.

First, the changeable fields in the Evaporator Menu (shown above on the right) are as

follows:

Number of circuits (1 to 40) The number of circuits in the suction group.

Dewpoint method (List box:)

Dewpoint: A dewpoint sensor or sensors will be used

for anti-sweat control.

Calc Dewpoint: Dewpoint for anti-sweat control will

be calculated using the values of relative humidity and

temperature sensors.

Dewpoint sensor to use [If Dewpoint has been selected](List box:) How anti-

sweat control dewpoint will be determined if a

dewpoint sensor is used.

Min Dewpoint: The lowest-reading of a number of

dewpoint sensors will be used.

Max Dewpoint: The highest-reading of a number of

RS.8D.M1.22 AK2-SC 255 Reference Manual 2 5

Page 27

dewpoint sensors will be used.

Average: The average of a number of dewpoint

sensors will be used.

Dewpoint 1: A single dewpoint sensor will be used for

control.

[others]: Other dewpoint sensors, if they exist, will be

listed also.

Humidity sensor to use: [If Calc Dewpoint has been selected](List box:) How

dewpoint will be determined if a humidity sensor is

used.

Min Humidity: The lowest-reading of a number of

humidity sensors will be used.

Max Humidity: The highest-reading of a number of

humidity sensors will be used.

Average: The average of a number of humidity

sensors will be used.

Inside RH 1: A single humidity sensor will be used

for control.

[others]: Other humidity sensors, if they exist, will be

listed also.

Auto defrost schedules (List box: Disabled, Enabled)

Enabling this option will cause the controller to suggest

a defrost schedule based on the following two additional questions.

Maximum concurrent electric defrosts

[Appears only if Auto defrost schedules is enabled]

(0 to 20) The number of electric defrosts that can be

underway concurrently .

Include dripdown time [Appears only if Auto defrost schedules is enabled]

(List box: Yes, No) Answering “Yes” will cause a drip

down period to follow defrost before refrigeration is

allowed. The length of the drip down period will be that

specified by the user when defrost schedules are autoconfigured.

Type (List box:) [for each individual evaporator] the type of

evaporator control.

AK2-SC 255/SUBC: A subcooler controlled as an

SC 255 circuit.

AK2-SC 255: The circuit is controlled by the SC

255’s algorithms.

AKC 16x: Control is at the fixture by AKC 161 or

AKC 164 Smart Case Controllers.

EKC: Control is at the fixture by EKC 201 controllers.

Deg Master: Control is at the fixture by Hill/PHOENIX Degree Master controllers.

DCU: Control is at the fixture by DCU case controllers.

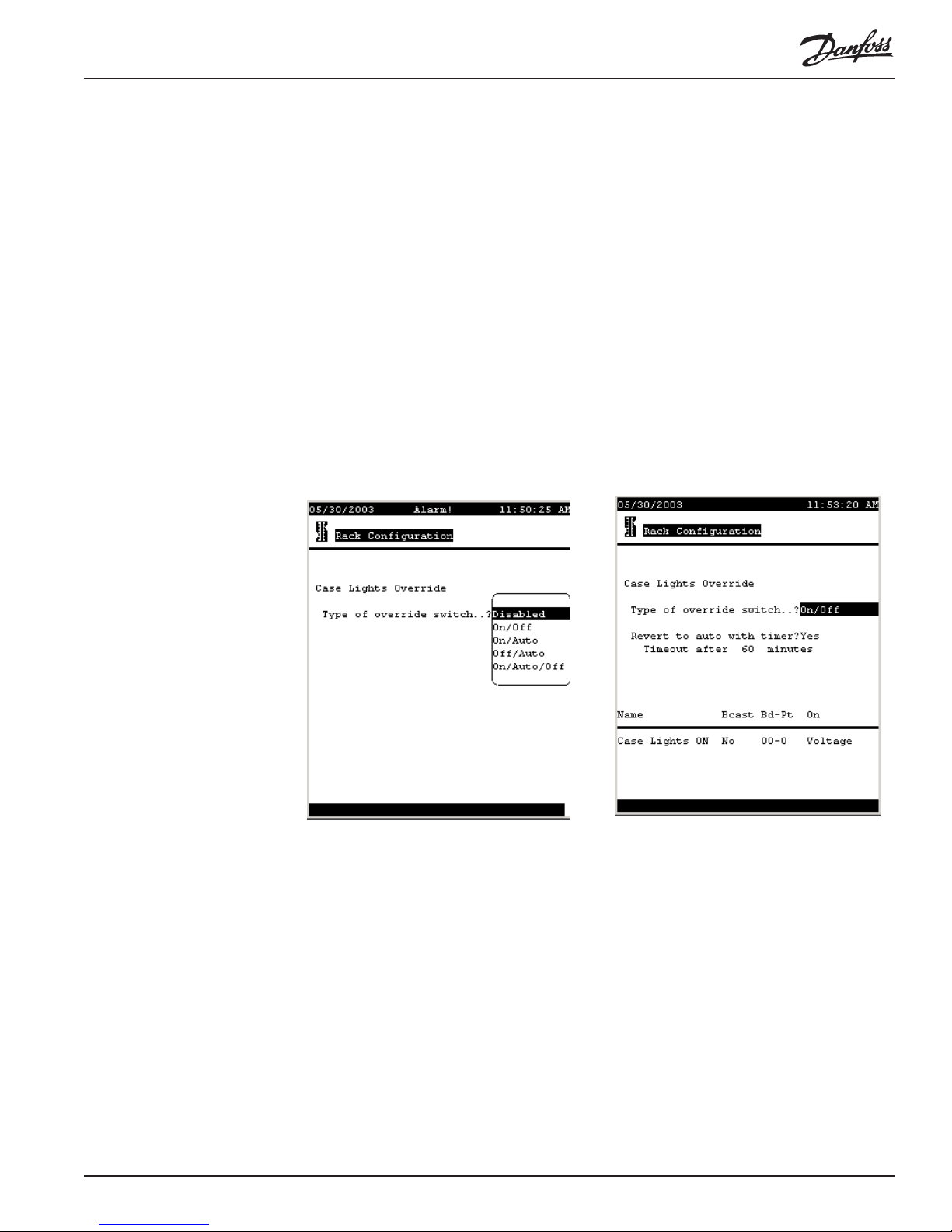

Case lights button In the lower left corner of the screen body is a button, CASE LIGHTS. Selecting this

button and pressing ENTER will open the configuration screen for a case lights

26 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 28

override switch. The screen at left below appears (with the list box closed) when the

CASE LIGHTS button is activated. The fields on the screen and their meanings are

as follows:

Type of override switch (List box)

Disabled: There is no override switch configured.

On/Off: A two-position override switch allows the

lights to be switched on or off.

On/Auto: Choices are ON or automatic operation.

Off/Auto: Choices are OFF or automatic operation.

On/Auto/Off: All three choices are available with a

three position switch being installed.

Depending upon configuration and the equipment

present, dewpoint for anti-sweat control can be read

from a dewpoint sensor, or it can be calculated using

the values of relative humidity and temperature sen-

sors.

Configuring AK2-SC 255

subcooling circuits When subcooler valves are controlled directly by the SC 255 (that is, when an AKC

RS.8D.M1.22 AK2-SC 255 Reference Manual 2 7

Page 29

165 Subcooling Controller is not used) configuration begins by selecting AK2-SC 255/

SUBC in the Type column for the circuit on the Evaporator Menu, then moving the

cursor to the word Setup for that evaporator and pressing ENTER. A screen like the

one at left below will appear. The same screen with all its fields revealed appears as

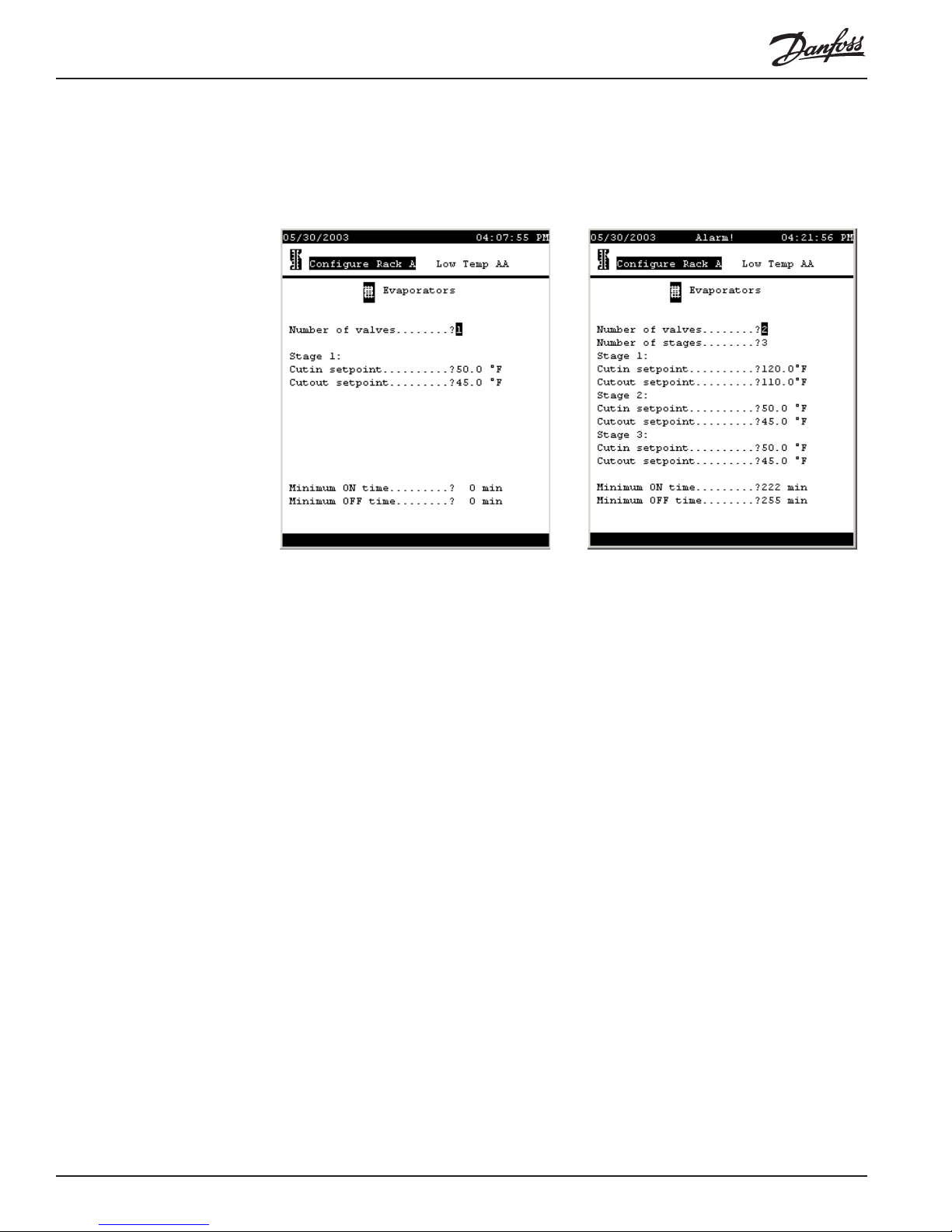

at right.

The fields are as follows:

Number of valves (0 to 2) The number of valves used for subcooling.

Number of stages (1 to 3) With one valve, there can be only 1 stage of

subcooling. W ith two valves, there can be two stages

(one valve open or two). If there are two valves

feeding subcoolers of different capacities, then there

can be three stages (only valve 1 open, only valve 2

open, or both valves open).

Cutin setpoint (0.0 to 120.0, each stage has a separate setpoint) The

temperature at which the subcooling stage will become

active. Temperature is measured by a sensor at the

liquid outlet of the subcooler.

Cutout setpoint: (0.0 to 110.0, each stage has a separate setpoint) The

temperature at which the subcooling stage will shut

down.

Minimum ON time (0 to 255) The minimum time in minutes each stage

must remain active after being cut in.

Minimum OFF time (0 to 255) The minimum time in minutes each stage

must remain off after being cut out.

Configuring

AK2-SC 255

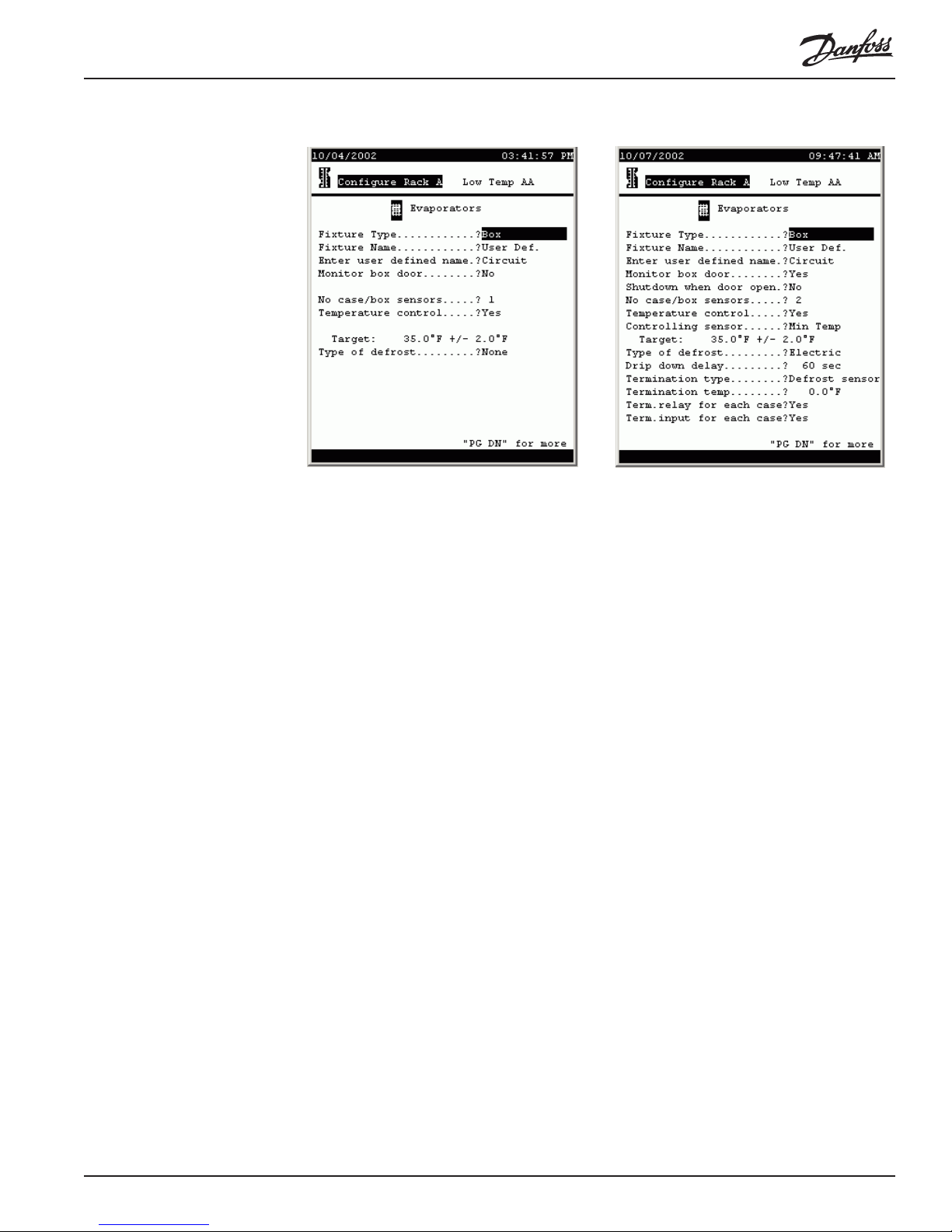

refrigeration circuits If there is not a distributed controller at the fixture (AKC 161, AKC 164, Degree

Master, or DCU), refrigeration can be controlled directly by the AK2-SC 255. Configuration of such circuits starts by selecting AK2-SC 255 in the Type column for the

circuit on the Evaporator menu, then moving the cursor to the word Setup for that

evaporator and pressing ENTER. A screen like the one at left below will appear. The

28 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 30

same screen with all its fields revealed appears as at right.

The fields are as follows:

Fixture Type (List box) Various types of fixture can be selected:

box, multi-deck, single deck, service, etc.

Fixture Name (List box) There is a large selection of common fixture

names for each of the fixture types that can be selected above, and there is a selection User Def. After

making that selection, you will be able to spell out your

own name on the following line.

Enter user defined name (Label) The name of a user-defined fixture. Any of

the characters in the AK2-SC 255 character set can be

used, including upper and lower case letters and

symbols.

Monitor box door (List box: Yes, No) Whether or not a box door switch

will be monitored (appears for boxes only).

Shutdown when door open (List box: Yes, No) Whether or not to shut down

refrigeration when the box door is open.

No case/box sensors (0 to 15) The number of sensors in this fixture or

circuit.

Temperature control (List box: Yes, No) Whether or not temperature contol

will be used.

Controlling sensor (List box:)

Min Temp The lowest of the sensors in the fixture or

on the circuit will be used for temperature control.

Max Temp The highest of the sensors in the fixture

or on the circuit will be used for temperature control.

Average The average of all the sensors in the fixture

or on the circuit will be used for temperature control.

[circuit names] The name of each sensor will be

listed, and any can be selected. That sensor , then, will

be used for temperature control.

Target: (-99.0 to 150.0 [target] 1.0 to 20.0 [range] The target

RS.8D.M1.22 AK2-SC 255 Reference Manual 2 9

Page 31

temperature and the range about the target, used in

temperature control. The range is the amount above or

below target that the actual sensor temperature is

allowed to change before a control action is taken.

Type of defrost (List box) Various types of defrost can be chosen:

None, Hot Gas, Time Off, Air, or Electric.

Drip down delay (1 to 600) The number of seconds that refrigeration

will remain off after termination of defrost.

Termination type [Defrost time settings made on the pages that follow

must also be considered. If a minimum defrost time

is used, that time must elapse regardless of the

settings made on this page. If a defrost duration is

specified, either that time must elapse OR the

requirements set on this page must be satisfied for

defrost to terminate.]

(List box) Various termination strategies are listed.

Defrost sensor There is a dedicated defrost tem-

perature sensor that will be used to terminate defrost.

Disch air snsr The fixture discharge air sensor will

be used to terminate defrost at a set temperature.

On/Off Input An electrical switch (such as a Klixon

is wired to a digital input (on-off input) and will be used

to terminate defrost.

None: Defrost is terminated strictly on time.

Hot gas return: Hot gas defrost is terminated when a

return air sensor reaches a setpoint.

Termination temp (-99.0 to 200.0) The defrost temperature sensor value

at which defrost will terminate.

Term.relay for each case (List box: Yes, No) Whether or not there is a termina-

tion relay for each case.

Term.relay for each case (List box: Yes, No) Whether or not there is a termina-

tion input each case.

®

Paging down produces the next page:

30 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 32

[Defrost time settings made on this and the following pages work with the

termination settings on the preceding page. If a minimum defrost time is used,

that time must elapse AND the settings for defrost termination temperature or

switch must be satisfied. If a defrost duration is specified, either that time must

elapse OR the requirements set on this page must be satisfied for defrost to

terminate.]

The fields are as follows:

Use min defrost time (List box: Yes, No) Whether or not minimum defrost

time will be used.

Minimum defrost time (1 to 180) The number of minutes defrost must be on

before termination.

Antisweat control (List box: Yes, No) Whether or not anti-sweat heaters

will be controlled by the AK2-SC 255. When you

configure an evaporator and answer Yes to the antisweat control question, a relay output is created which

is then wired to a relay controlling the anti-sweat

heaters. The name of the relay output will be

“Antisweat” + the name of the evaporator or circuit,

then the rack, suction group, and circuit number (for

example, Produce AA3).

ON when dewpoint above (0.0 to 100.0) The dewpoint above which anti-sweat

heaters will be on constantly.

Cycle above dewpoint (0.0 to 100.0) The dewpoint above which anti-sweat

heaters will be cycled. Cycling will occur unless the

dewpoint rises above the setpoint.specified in the

previous line.

Antisweat cycle time (2 to 999) The time interval on which anti-sweat

cycling is based.

Fan control (List box: Yes, No) Answer Yes if fans are to be

controlled during and after defrost. If you answer No,

fans will run continuously during both refrigeration and

defrost.

Fans on during defrost (List box: Yes, No) The answer determines whether or

not fans will run during defrost.

Stop fan on high temp (List box: Yes, No) Whether or not fans are to be

stopped when temperature rises above a setpoint to be

specified in the next line.

Fan stop temp (-58.0 to 99.9) The temperature at which fans will be

stopped.

Fan delay control (List box: Yes, No) A Yes answer will cause fans to

remain off after defrost termination for a specified

period of time or until a specified temperature is

reached. The time or temperature is determined by the

next two questions.

Start fan on time (List box: Yes, No) The answer determines whether or

not fan delay ends after a specified time.

Delay time (0 to 20) The number of minutes before fans start

after defrost terminates.

RS.8D.M1.22 AK2-SC 255 Reference Manual 3 1

Page 33

Fan starting temp (-58.0 to 99.9) The temperature at which fans will be

started after fan delay, if fans are not started on time.

Monitor door position (List box: Yes, No) Whether or not an alalog sensor

input is created to monitor the position of the door. This

sensor reads in percent and will be seen on the status

screen for the circuit. An alarm can be based on it.

Configuring Defrost Defrost configuration begins on the next setup page for an evaporator circuit.

The fields are as follows:

No of defrosts per day (0 to 12) The number of defrosts each day.

Defrost duration (1 to 180) The number of minutes after which defrost

will terminate, if termination has not occurred on a

setting configured in the previous screen. Often called

“fail-safe” defrost time.

Defrost start time (time of day; one field for each of the number of

defrosts configured in the first line of the screen) The

time each defrost will initiate.

Allow defrost skip (List box: Yes, No) When Yes is selected, The SC 255

has the ability to determine, based on analysis of

current and accumulated data, to determine if each

defrost is needed. When a defrost is not needed, it is

not initiated, thus reducing energy cost and enhancing

product life.

Min time between defrost (1 to 255) Minimum number of hours between de-

frosts.

Override on dewpoint (List box: Yes, No) Whether or not to override defrost

skipping on a dewpoint setting (next question).

Don’t skip when DP above (1.0 to 3276.0) Defrost will occur regardless of

skipping calculations whenever dewpoint is above this

setting.

32 AK2-SC 255 Reference Manual RS.8D.M1.22

Page 34

Dual Temp control (List box: Yes, No) A Yes answer allows the circuit to

be used in two temperature ranges and creates a digital

input for changeover of temperature range.

Alt target, Range (-50.0 to 150.0, 1.0 to 20.0) The second temperature

and range for a dual temperature evaporator.

Dual Temp relay needed (List box: Yes, No)

Alt target, Range (-50.0 to 150.0, 1.0 to 20.0) The second temperature

and range for a dual temperature evaporator.

Num of shutdn schedules (0 to 8) The number of shutdown schedules that will

be entered on the page(s) immediately following this

one.

Generate shutdown OI (List box: Yes, No) Whether or not a digital input (on-

off input) will be configured by which refrigeration can

be shut down for cleaning or other service.

Shutdown schedules Paging down, we reach the shutdown page(s):

There are two schedules per page. Each schedule has a field for time on, time off,

days (of the week) and holidays. AM and PM are entered by selecting the first

character, using the +/- key to toggle the arrow keys to edit mode, then using the up

or down arrow to change the character to A or P as needed. The same means is used

to select the days of the week (once the cursor is placed in the space to the right of

the question) and holidays.

Holidays are given dates when Store Info is configured.

Configuring

evaporator alarms Evaporator alarms are configured on the last page for each evaporator. The right

illustration shows the screen when it is opened for the first time. The right illustration

shows the screen with all of its fields revealed. Additional information will be found in

section (Chapter 4-5) on alarms.

RS.8D.M1.22 AK2-SC 255 Reference Manual 3 3

Page 35

Each alarm has three fields:

[Alarm level] (List box)

Disabled: The alarm is deactivated, but any settings

remain in memory , so that they will be at hand when

the alarm is reactivated.

Log only: When the alarm occurs, the fact will be

recorded in memory, but the alarm will not be commu-

nicated beyond the SC 255 (over telephone line or

network).

Normal: When the alarm occurs, it will be communi-

cated beyond the SC 255 one time over telephone line

or network, to the locations specified in the alarm

routing screen.

Critical: When the alarm occurs, it will be communi-

cated beyond the SC 255 multiple times to each

destination defined in the alarm routing screen at the