Page 1

Installation Guide

Danfoss Air Units

www.danfoss.com

Page 2

Danfoss A/S is not liable or bound by warranty if these

instructions are not adhered to during installation or service.

The English language is used for the original instructions.

Other languages are a translation of the original instructions.

(Directive 2006/42/EC)

© 2014 Copyright Danfoss A/S

Page 3

Installation Guide

GB

Installationsvejledning

Installationshandbuch

Instrukcja montażu

DK

DE

PL

Page 4

Installation Guide Danfoss Air Units

Table of Contents

1 Safety Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Before Start

3 Installation of Air Units

4 Installation of CCM Module and Air Dial

4.1 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Wireless connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Air Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.4 Mounting and removing CCM module and Air Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Connecting to Danfoss Link™ CC

5.1 Connecting the Air Unit to Danfoss Link™ CC, physical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2 Connecting the Air Unit to Danfoss Link™ CC, wireless inclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.3 Performing a network test after adding a new device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.4 Setting basic steps in the Danfoss Link™ CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Balancing of the Main Air Volume

7 Service Menu

8 Technical Specifications

8.1 a² Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8.2 a³ Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.3 w¹ Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.4 w² Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9 Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1 Safety Note

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Apart from the replacement of air filters and exterior cleaning of the system, any kind of maintenance will require the use of trained personnel.

2 Before Start

Check the Danfoss Air Unit packing list to ensure that the shipment is complete.

If a complete Danfoss Air Solution is ordered, a packing list for the Air Flex duct system is included.

Inspect to ensure that no parts or components have been damaged.

Standard delivery includes:

• Danfoss Air Unit

• Wall bracket (if w-model)

• CCM

• Cabels

Optional deliveries:

• Air Dial

• Danfoss Link™ CC

4 | © Danfoss | FEC | 2019.06

VIEWB402

Page 5

Installation Guide Danfoss Air Units

75 mm

6

3 Installation of Air Units

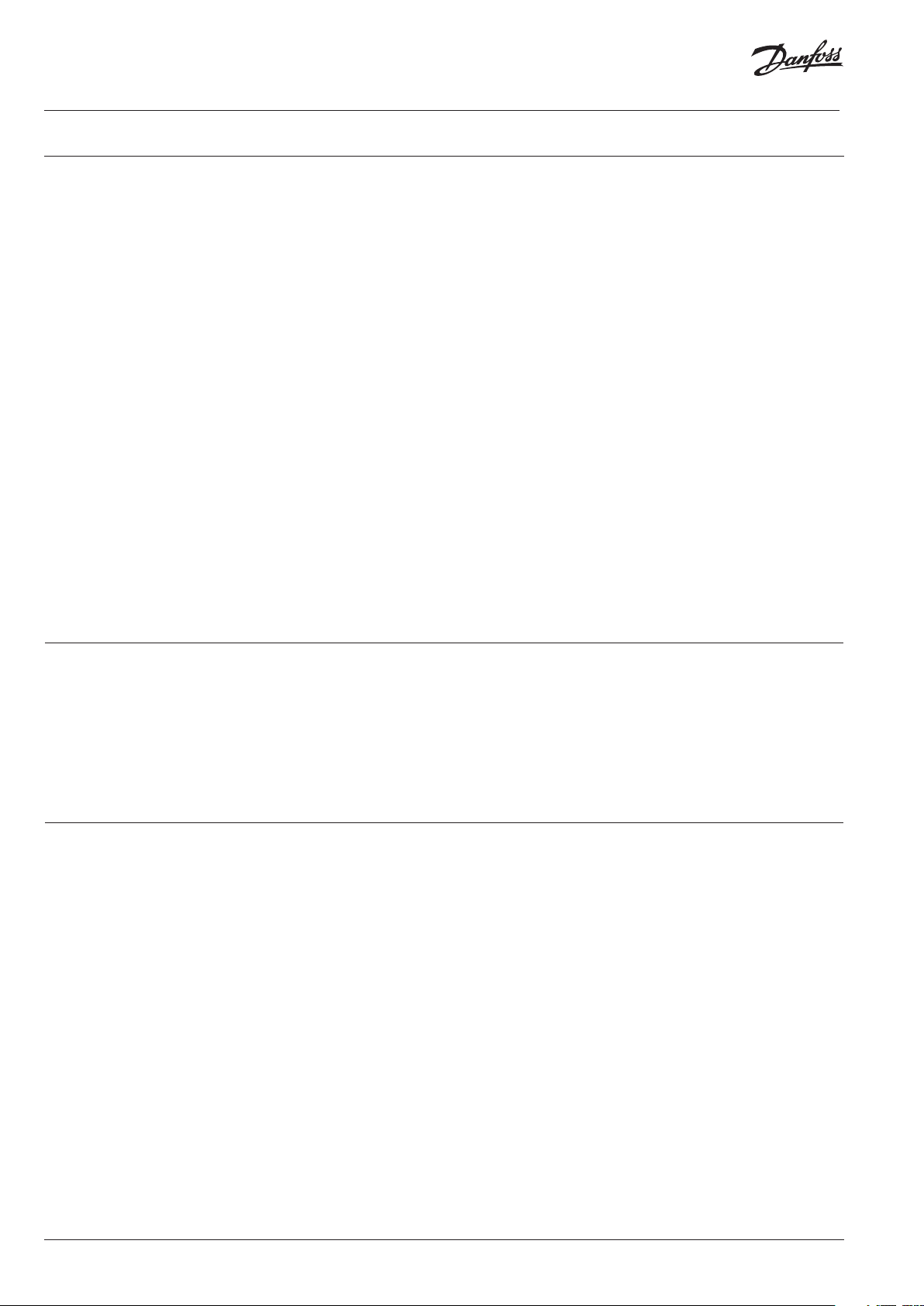

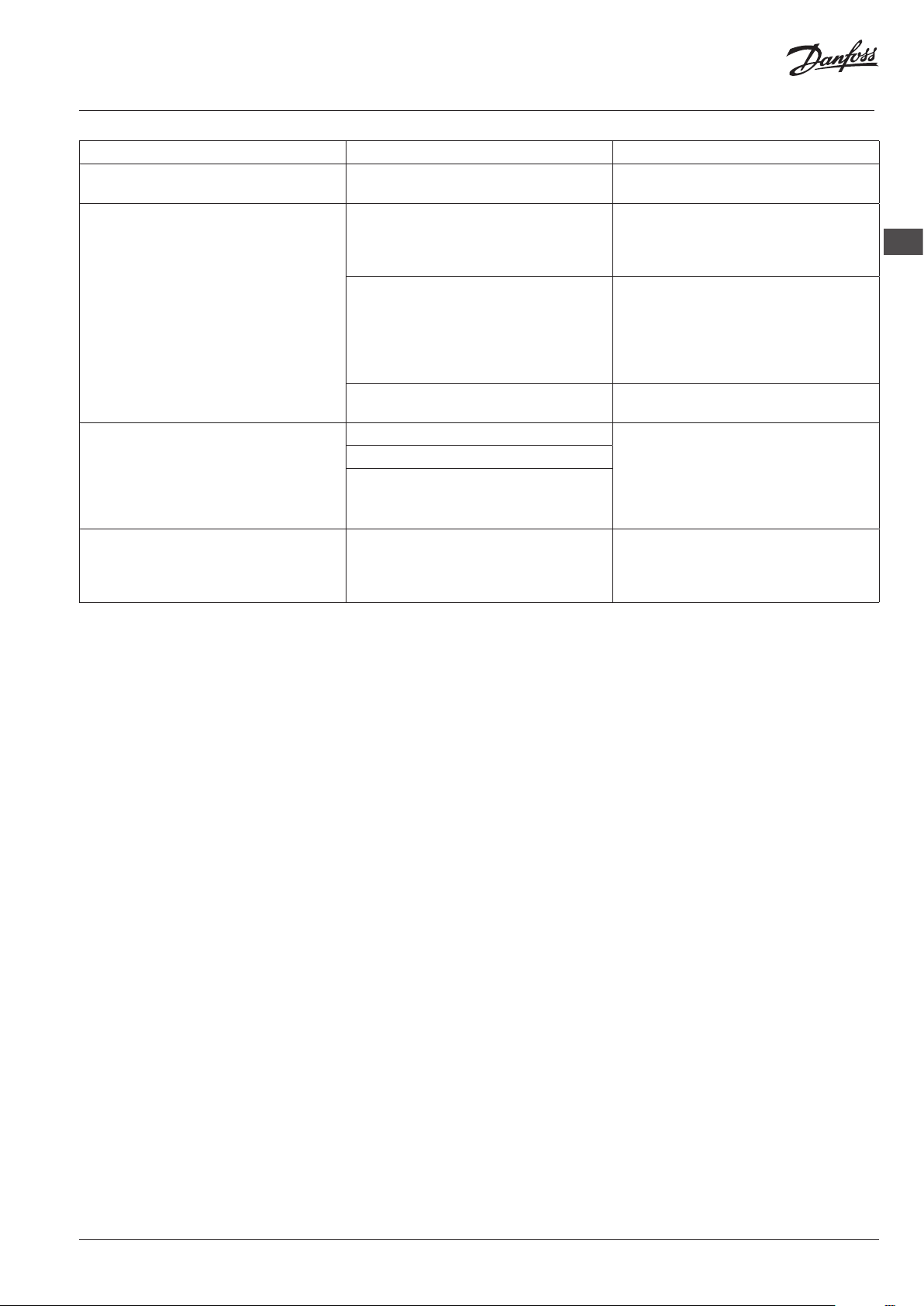

Attic Units a² and a³

1a. (a2 units) Mount spigots 1a as shown in picture to the right.

3

1b. (a

units) Pull out the spigots 1b. Never lift the unit in the spigots, as it can damage the unit*.

3

2. (a

units) Turn the spigots around and mount them using the included tapping screws (for power

drill, use lowest torque setting).

1a

2

a

3. Make a platform k for the unit of 16 mm plywood or MDF sheet around 50 mm wall batts.

4. Allow for 60 cm free space in front of unit, to assure service access.

5. Make sure the unit is mounted with a minor backward fall.

6. A siphon n must always be installed with the unit (to be ordered separately).

1b 1b

3

a

7. Mount the siphon on the joist m below the unit or in the room below the attic.

8. Connect the siphon to a drain o.

9. The condensate line l must be insulated where risk of freezing occurs.

10. Connect the hose to the unit outlet condensate spigot. Lead the connected pipe to the outlet,

allowing for a gradient of min. 1 cm/meter.

11. Remove the front panel and foam front, fill the condensate tray, check the outlet and reassemble

the front.

2 cm

2

4

*If the unit is lifted into the spigots, it might cause leakage between the steel cabinet and the polystyrene

core. The leakage can be fixed from the inside of the unit by sealing the spigots with an acrylicbased sealant.

Wall Units w¹ and w²

1. Place the mounting bracket j on the wall in desired position (75 mm from bracket bottom to unit top), mark up and drill holes.

Use screws suitable for the wall surface (not included).

2. Make sure that the bracket is mounted absolutely horizontal.

3. Hang the unit onto the bracket.

4. Attach the self-adhesive rubber separators k to the lower rear back plate.

5. Allow for 60 cm free space in front of unit, to assure service access.

6. A siphon l must always be installed with the unit (to be ordered separately).

7. Mount the siphon on the wall below the unit.

8. Connect the siphon to the drain n at the unit bottom.

9. The condensate line m must be insulated where risk of freezing occurs.

10. Connect the hose to the unit outlet condensate spigot. Lead the connected pipe to the outlet, allowing

for a gradient of min. 1 cm/metre.

11. Remove the front panel and foam front, fill the condensate tray, check the outlet and reassemble

the front.

1

2

3

GB

1a

3

5

6

5

4

In order to comply with safety standards and avoid the risk of malfunction, the supplied protection

shield must be mounted on top of the w¹-unit covering the connector plate.

Service Area

Additional space around the unit is required for the accessibility of service and maintenance.

2

For a

and a3 models, a solid surface must be established in front of the system with a ground

clearance of 1,2 m. Working environment can be deemed unwarrantable if

recommendations are not respected.

40 cm

30 cm

178 cm

VIEWB402

30 cm

Attic Units a2, a

60 cm

3

Wall Units w1, w

20 cm

40 cm

2

43/58 cm

60 cm

53/59 cm

© Danfoss | FEC | 2019.06 | 5

Page 6

Installation Guide Danfoss Air Units

!

4 Installation of CCM Module and Air Dial

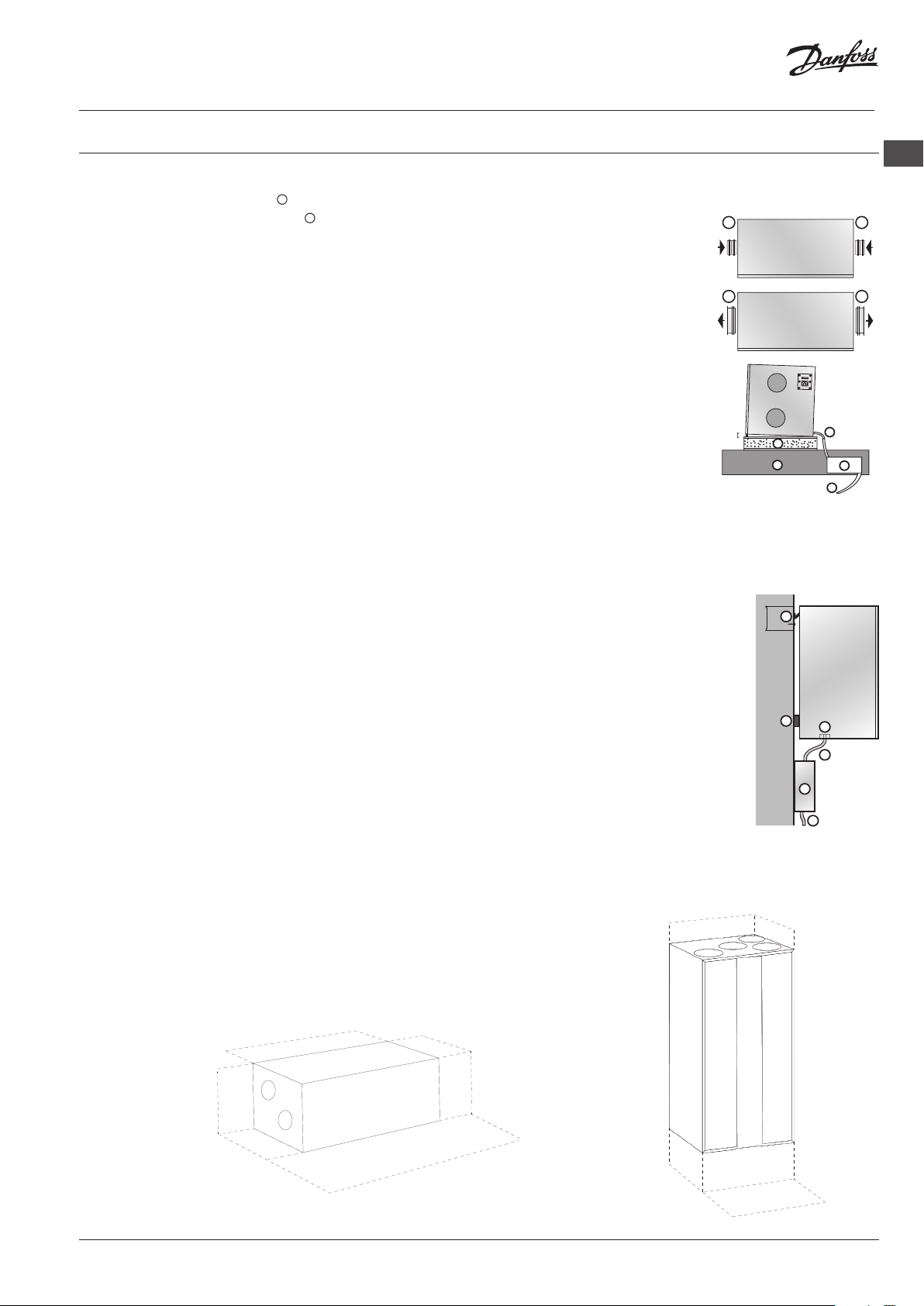

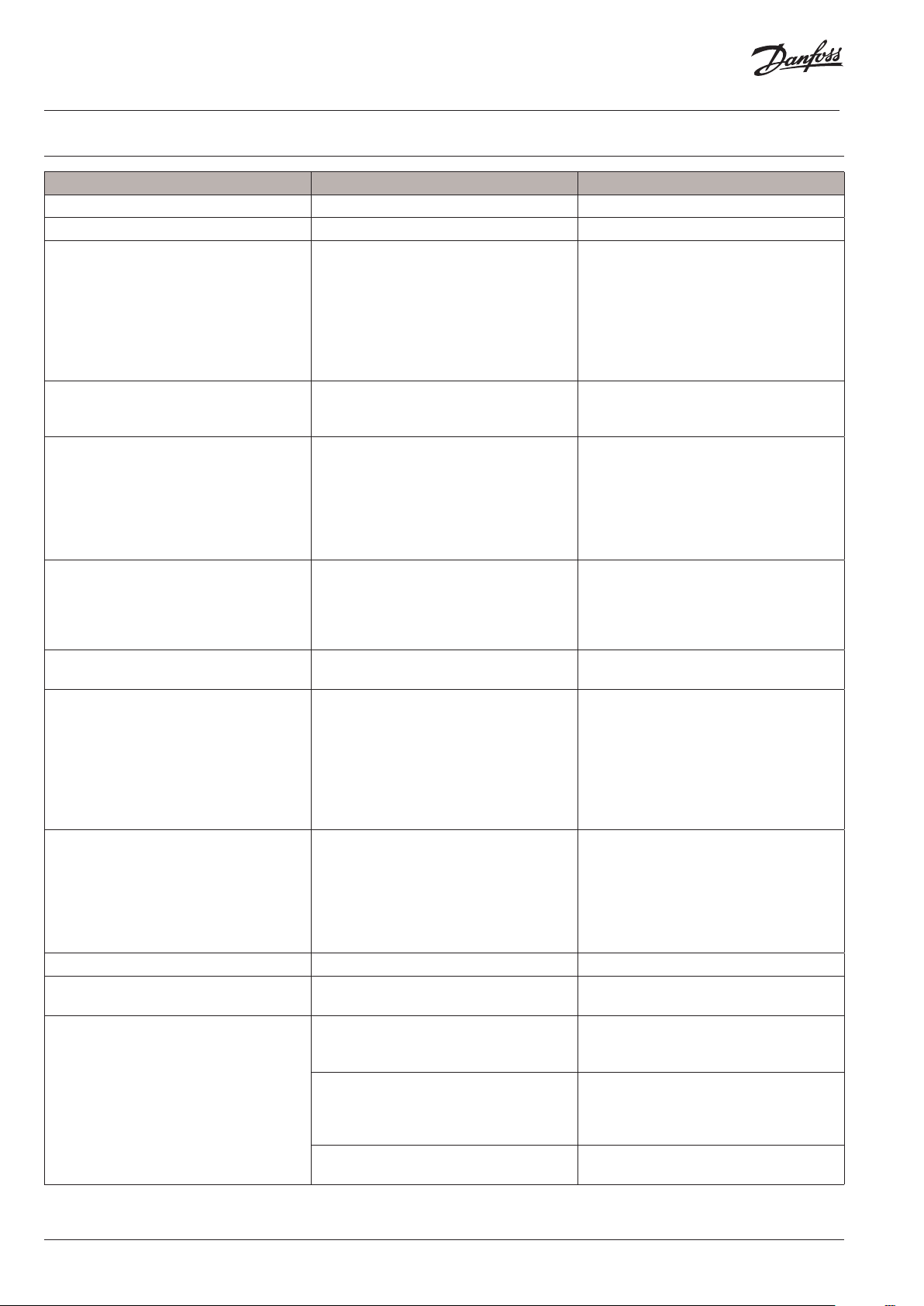

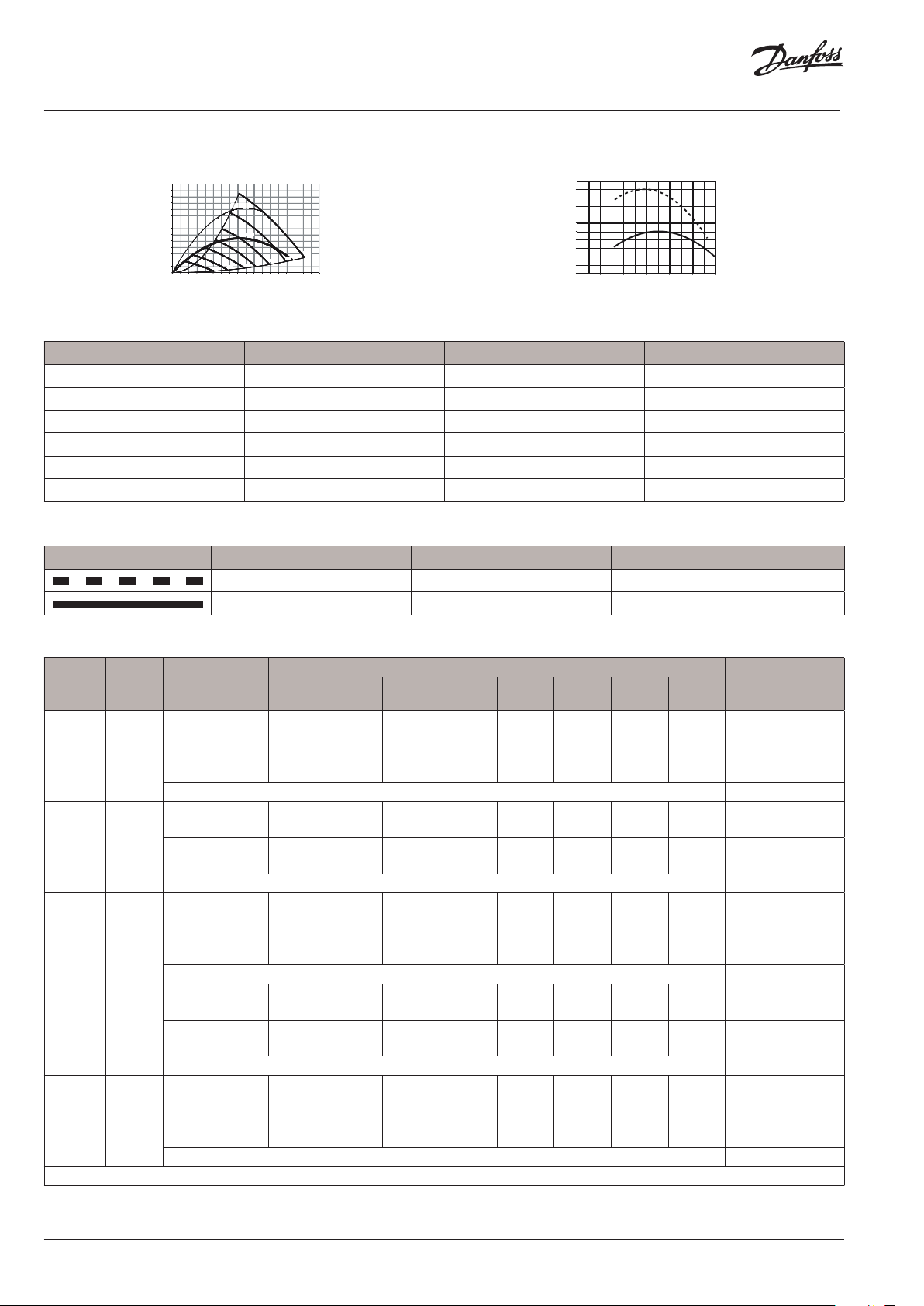

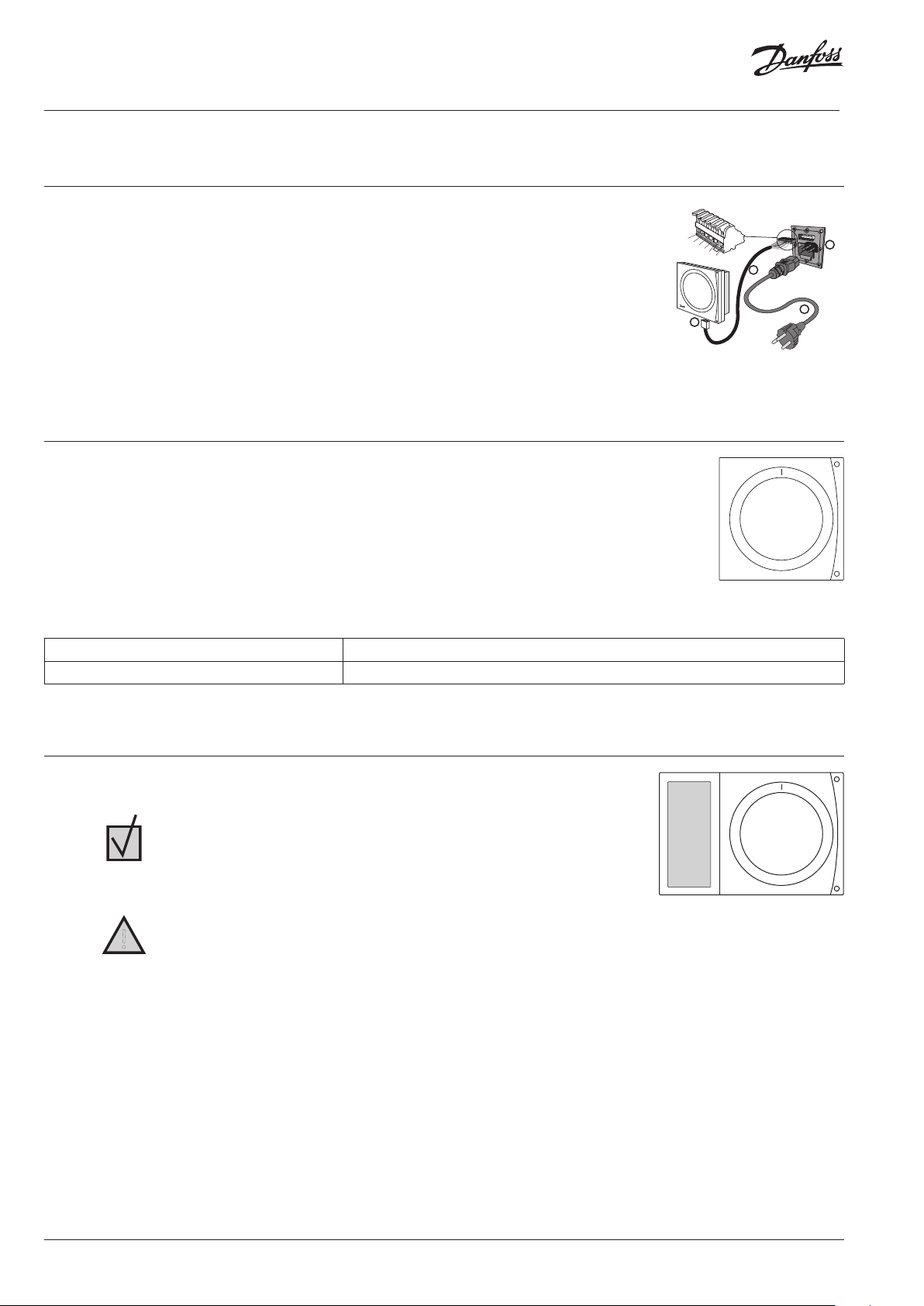

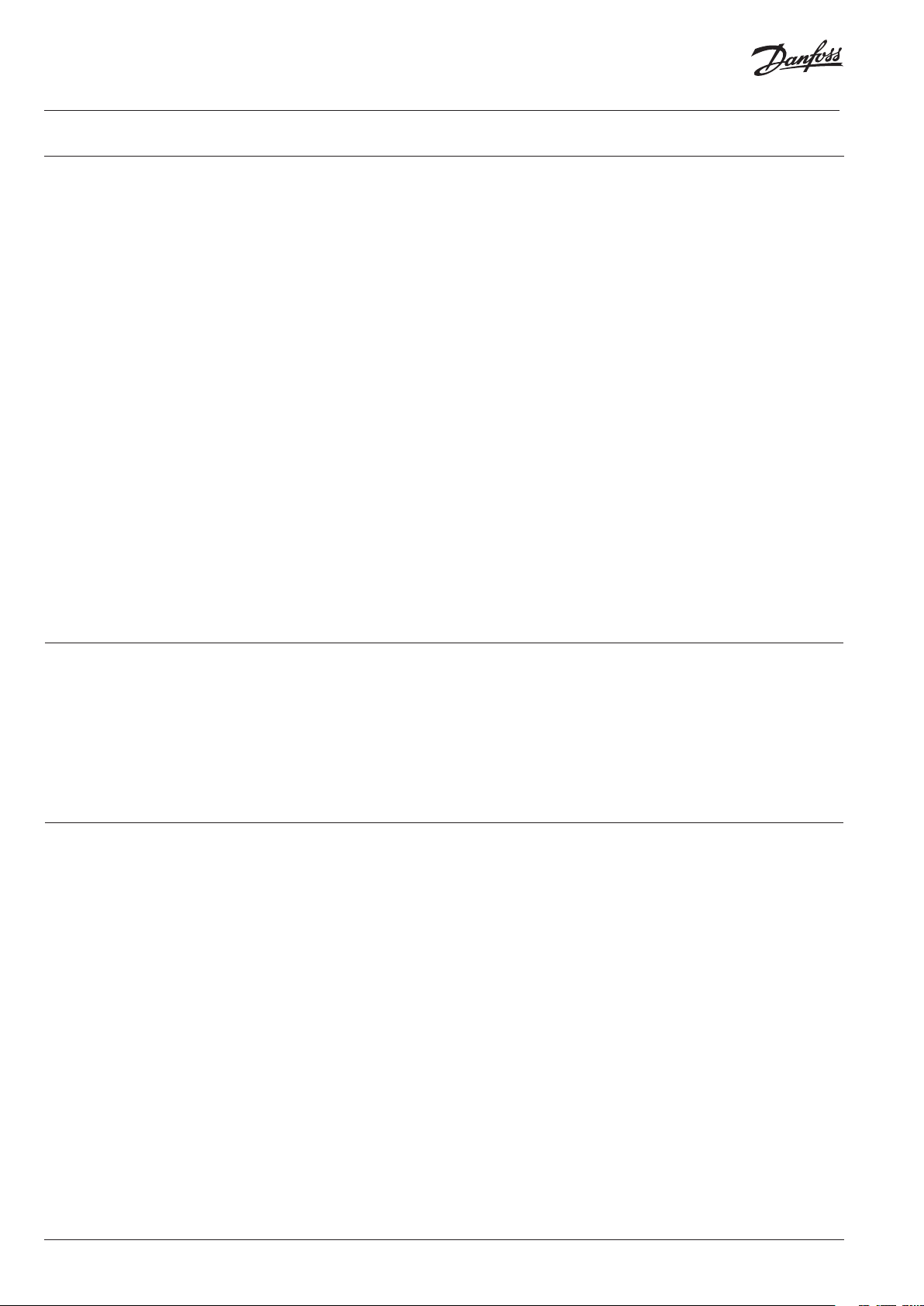

4.1 Electrical connections

1. Connect power cable m to Air unit l.

2. Plug in communication cable k between CCM module j and Air unit.

3. Check the signal. If it is too weak, the CCM module should be placed elsewhere, e.g. on the same

floor as as the Air Dial (see Air Dial Link Test).

4. If possible, place the CCM module close to an ethernet connection for future connection to PC.

5. If accessories (electrical preheating, electrical afterheating, water heating surface or geothermal

surface) are present, the pin on terminals.

Communication cable connections:

1. White/Orange, 2. Orange, 3. Black, 4. White/Blue, 5. Blue, 6. Black

Note! The communication cable can be extended up to 200 m. Use shielded cable , 22 or 24 AWG with 2 x twisted

pair.

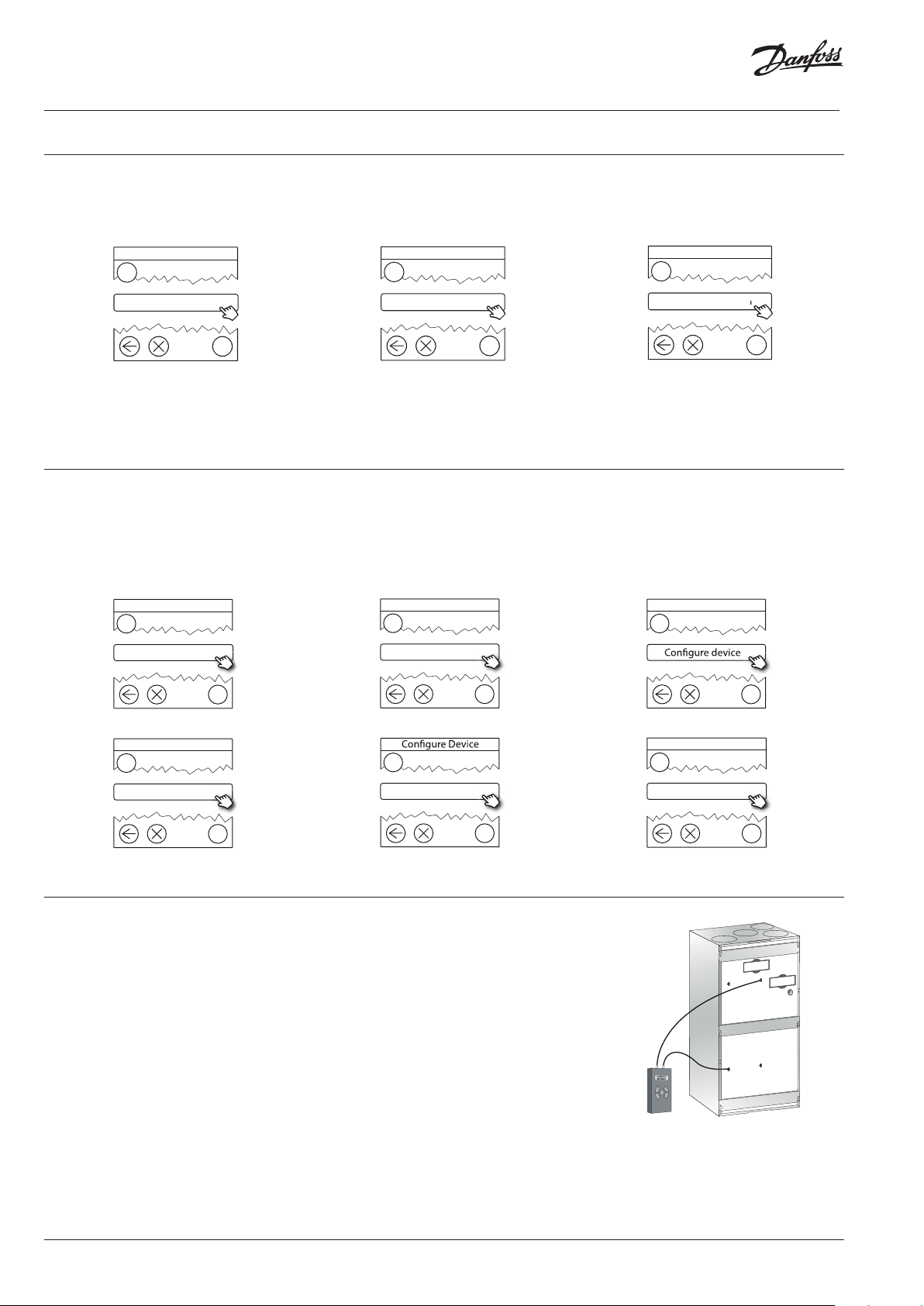

4.2 Wireless connection

When powering up the CCM module a green LED will flash slowly, indicating the CCM module has yet to be connected to the Air Dial.

To connect the Air Dial, insert the batteries. The Air Dial starts in installation mode and automatically guides

through the set-up.

1. Set language.

2. Create network (press button on CCM module and then press Air Dial).

3. Set basic step (setting up the main air volume).

4. Finish.

1

2

3

4

5

6

2

1

3

4

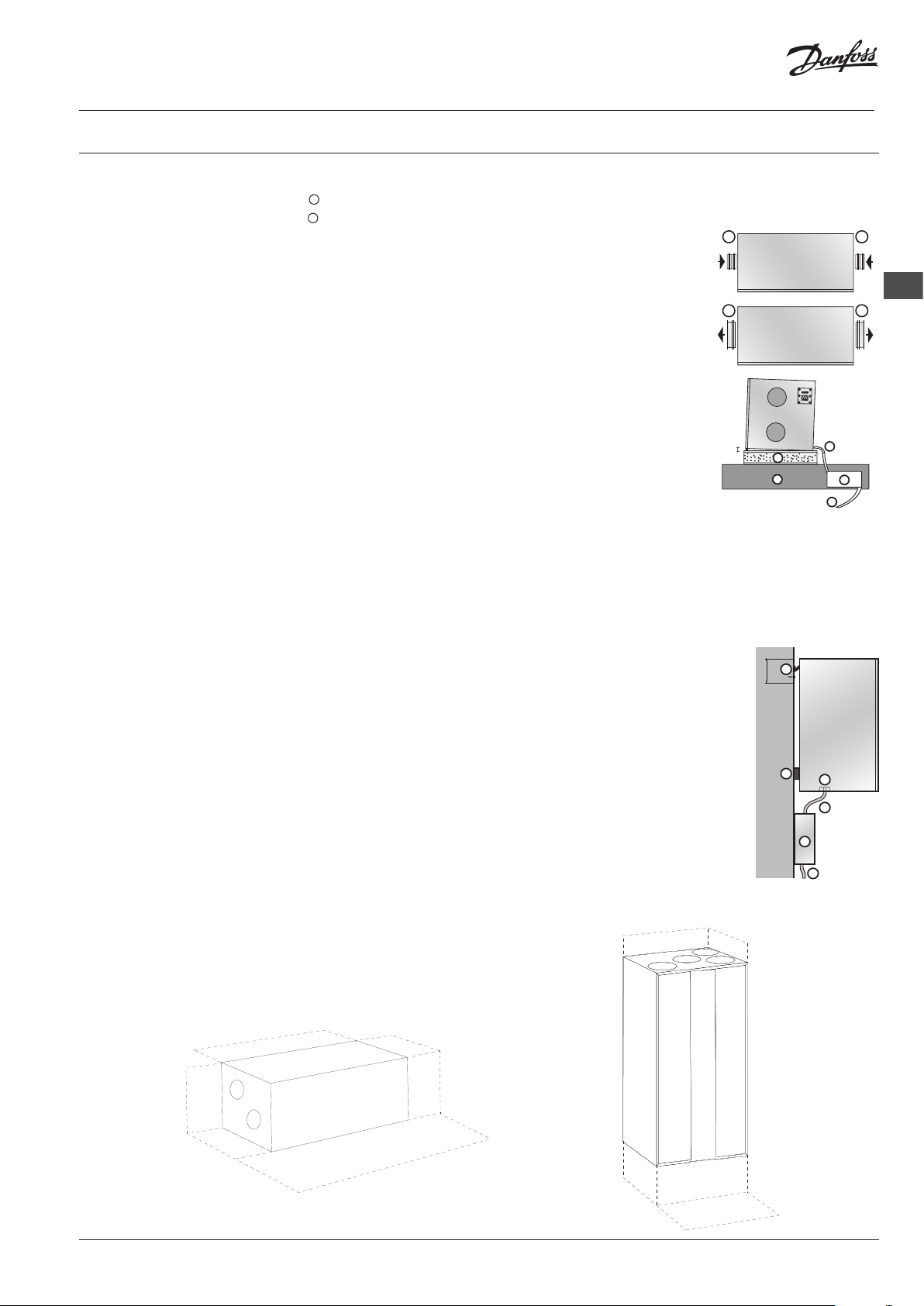

Green LED lights continuously Connected established

Red LED flashes slowly 5 times Connection attempt failed, see Troubleshooting

Tab. 2: LED blink patterns on the CCM

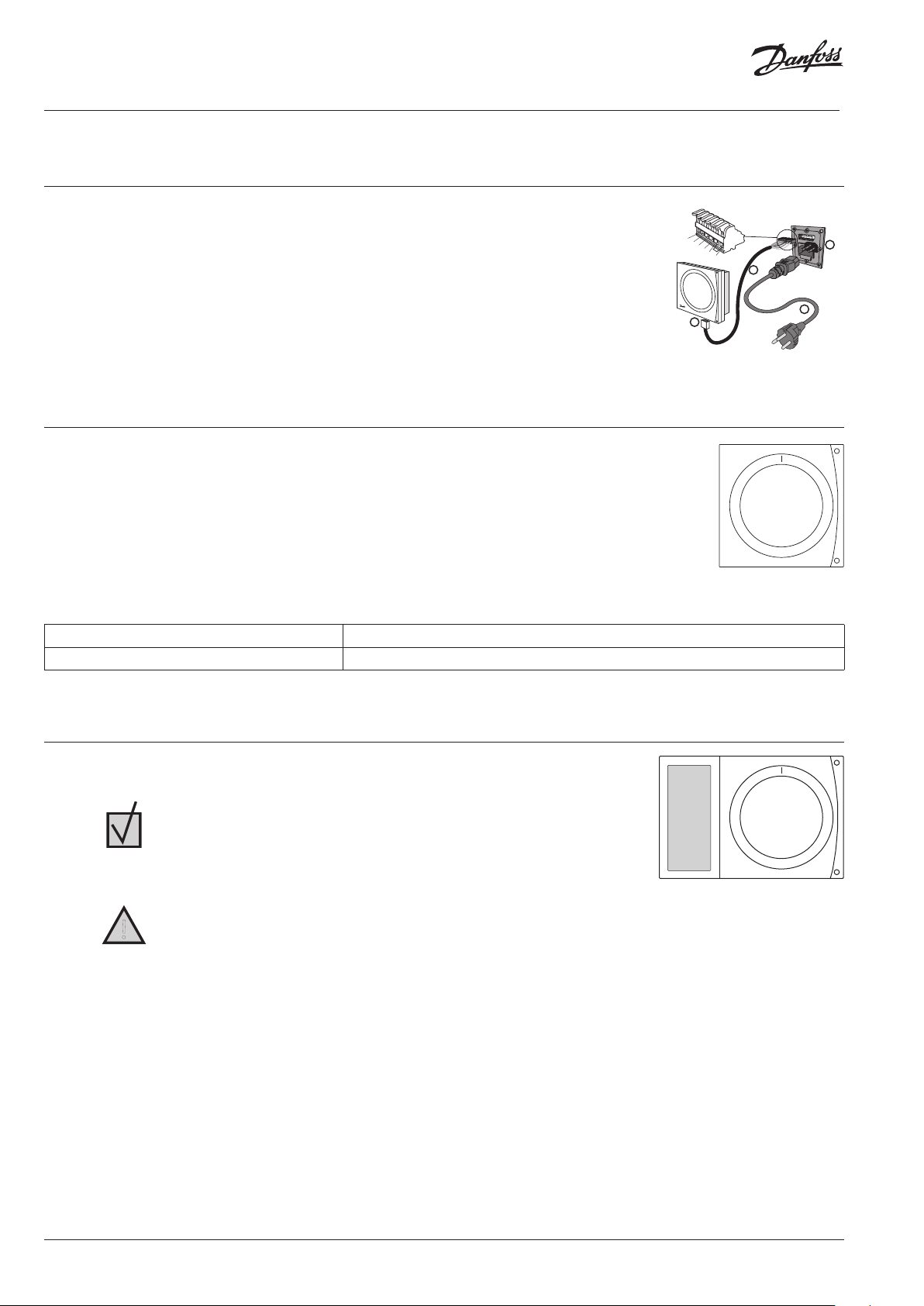

4.3 Air Dial

The Air Dial has an integrated temperature sensor. To ensure best possible performance,

place the Air Dial according to following guidelines:

• Place the Air Dial 80-150 cm above floor level.

• Place the Air Dial free of curtains etc.

• Place the Air Dial where the temperature is representative.

• Do not place the Air Dial in bathrooms.

• Do not place the Air Dial in direct sunlight.

• Do not place the Air Dial onto outer wall.

• Do not place the Air Dial directly above heat source.

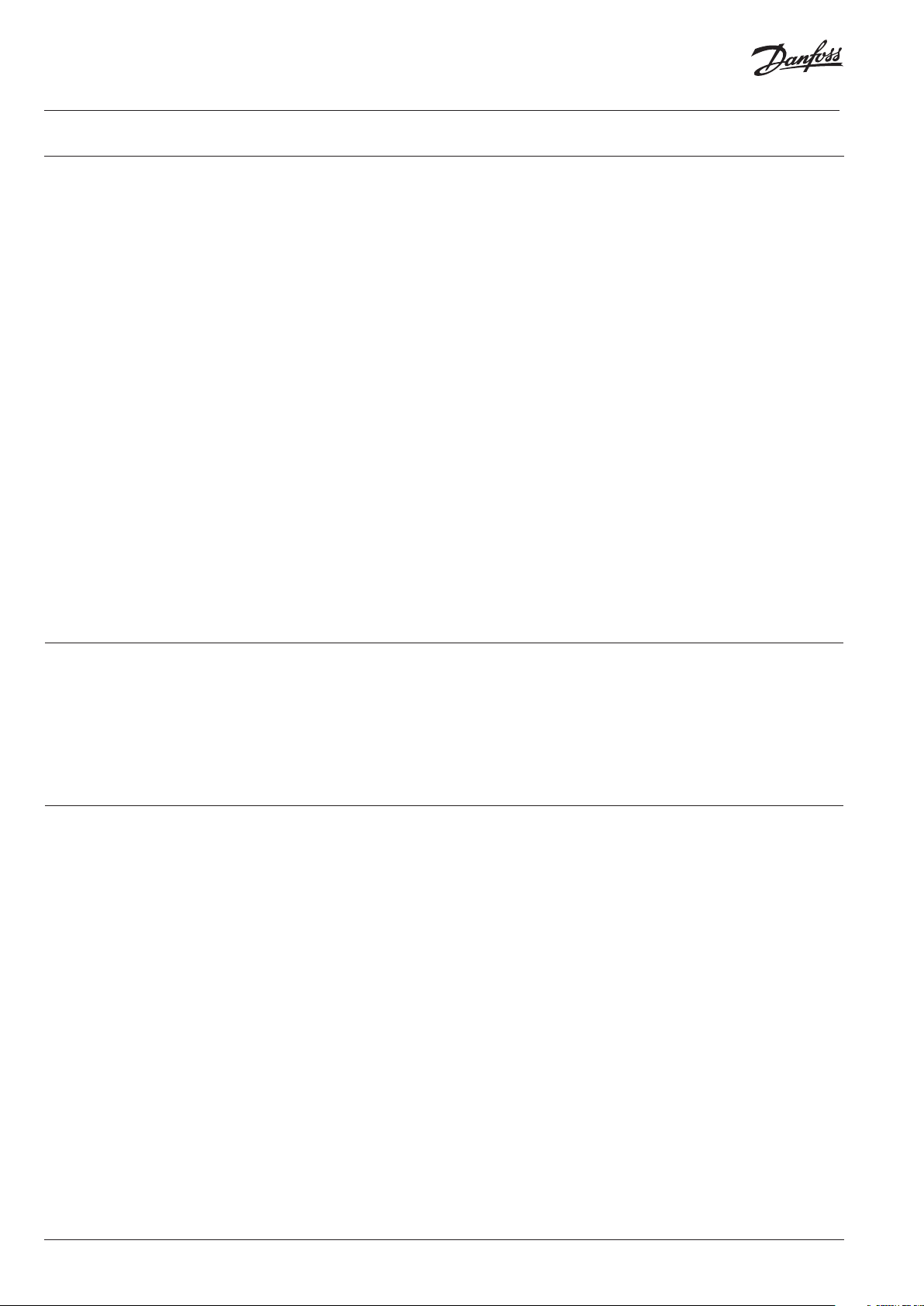

Air Dial Link Test

Before mounting the Air Dial permanently, perform a link test to ensure that transmission conditions are sufficient for the required location:

1. Press the Air Dial button for 5 seconds to access the Service Menu (The Service Menu remains visible for one hour).

2. Select the Link Test function.

3. The function shows if the transmission conditions are sufficient or not.

4. If the link test fails, see Troubleshooting.

6 | © Danfoss | FEC | 2019.06

VIEWB402

Page 7

Installation Guide Danfoss Air Units

2

2

1

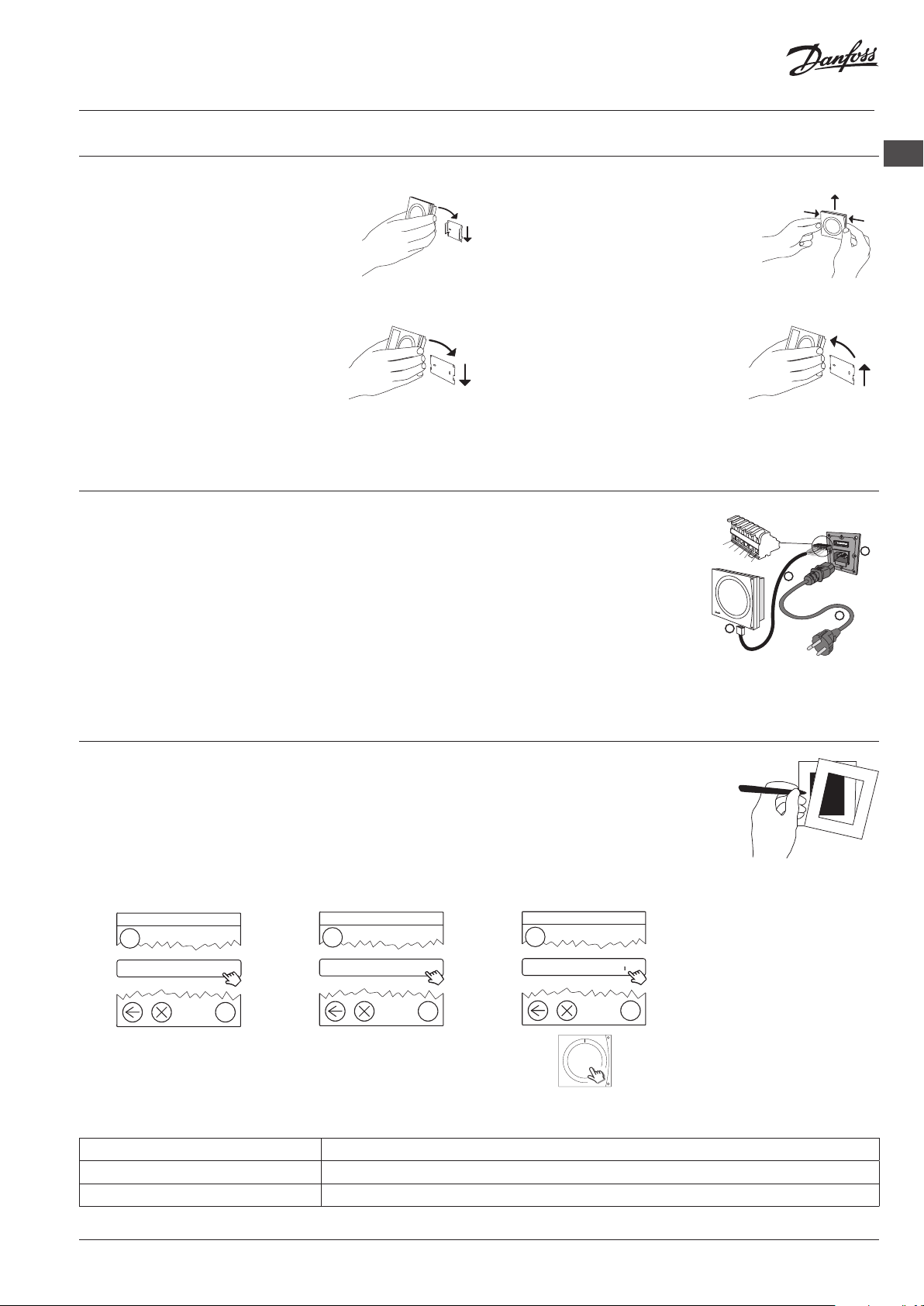

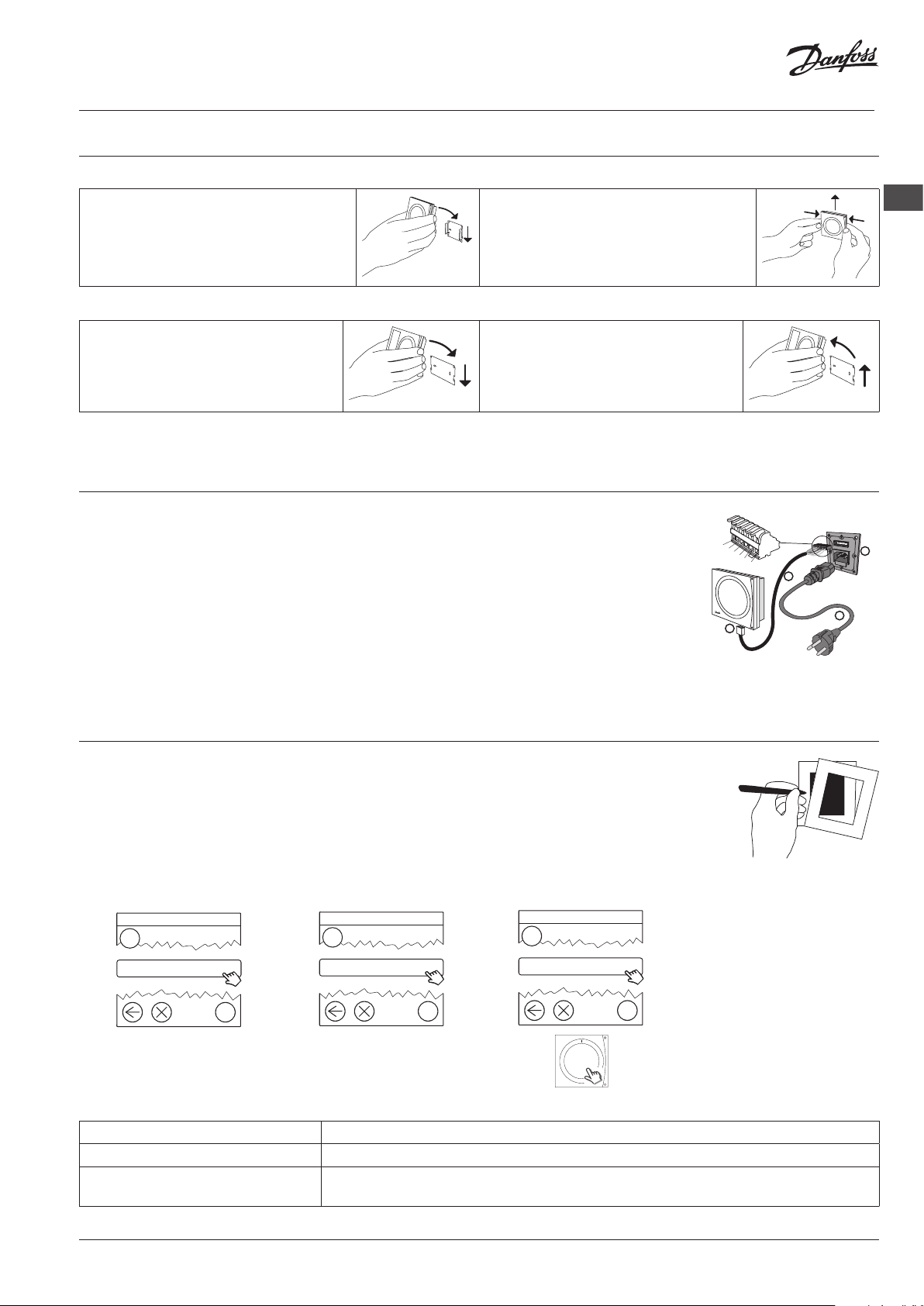

4.4 Mounting and removing CCM module and Air Dial

CCM Module

Mounting:

1. Place the CCM on the wall bracket.

2. Press downwards to click the CCM into

Removing:

1

1. Press in the two latches on the side.

2. Pull the CCM upwards.

place.

Air Dial

Mounting:

1. Place the CCM on the wall bracket.

2. Press downwards to click the CCM into

Removing:

1

1. Press in the two latches on the side.

2. Pull the CCM upwards.

place.

5 Connecting to Danfoss Link™ CC

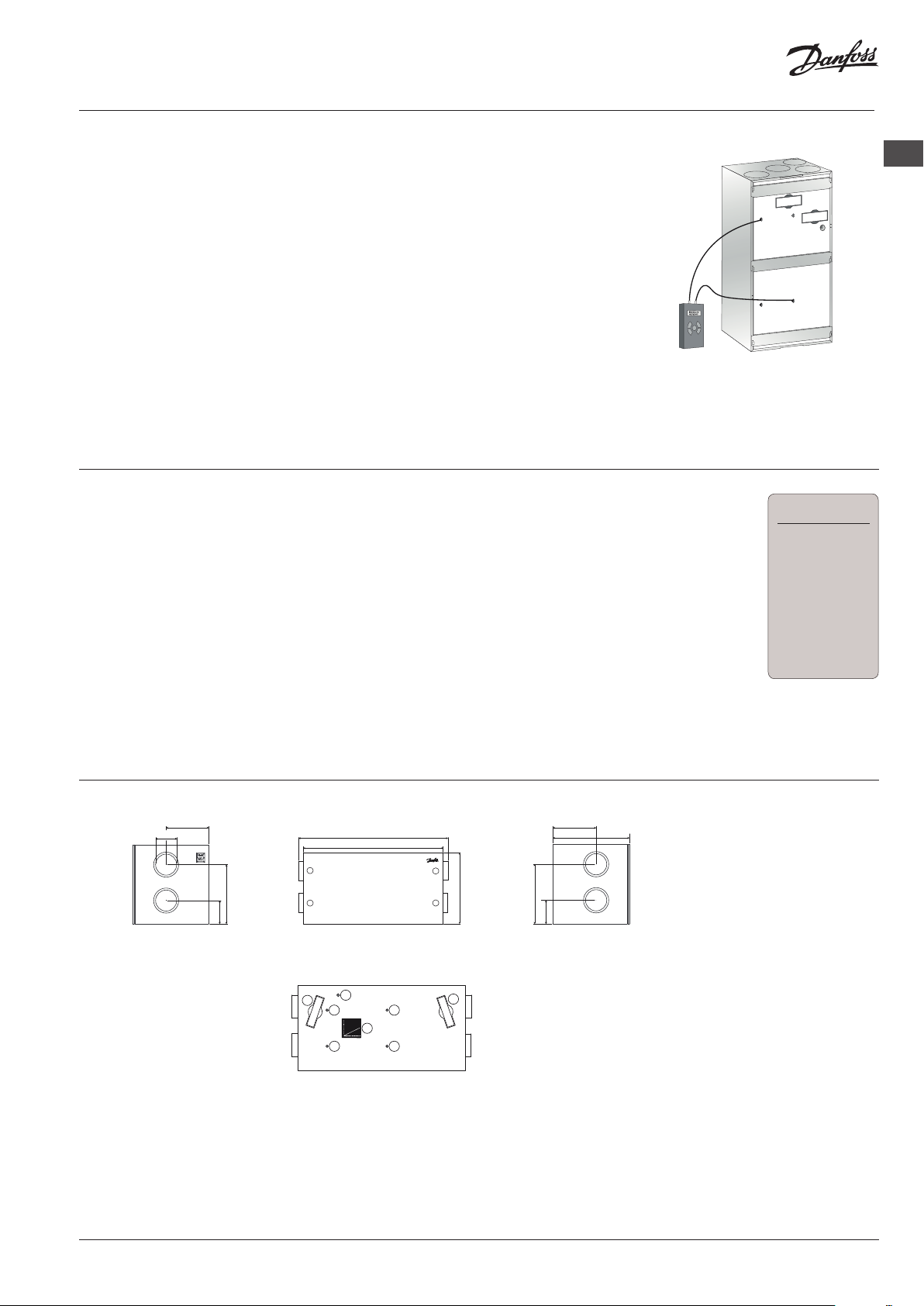

5.1 Connecting the Air Unit to Danfoss Link™ CC, physical installation

1. Connect power cable m to Air unit l.

2. Plug in communication cable k between CCM module j and Air unit.

3. If possible, place the CCM module close to an ethernet connection for future connection to PC.

4. If accessories (electrical preheating, electrical afterheating, water heating surface or geothermal

surface) are present, the pin on terminals 5 and 6 must be removed (also see the instructions

included with the accessories).

5. The Air Unit is now ready to be added to the Danfoss Link™ CC.

GB

2

1

1

2

3

4

5

6

2

1

1

2

3

4

Communication cable connections:

1. White/Orange, 2. Orange, 3. Black, 4. White/Blue, 5. Blue, 6. Black

Note! The communication cable can be extended up to 200 m. Use shielded cable , 22 or 24 AWG with 2 x twisted pair.

5.2 Connecting the Air Unit to Danfoss Link™ CC, wireless inclusion

• Remove the front cover of the Danfoss Link™ CC by gently pulling it off, pull near the edges of the

cover.

• Press the SETUP pin for 3 seconds to enter the service area.

Note!

• The Air Unit must be added to the network as a service device. For further instructions on the network inclusion, see the installation guide supplied with the Danfoss Link™ CC.

• Add any dedicated repeater units (CF-RU) BEFORE adding the Air Unit to the wireless network.

Service Options

1

Status and Diagnostics

?

Status and Diagnostics

2

Network

?

Note! During installation, the distance between the Danfoss Link™ CC

and the CCM must not exceed 1.5m.

Wireless Network Status

3

Start Network Test

?

Click here on the CCM

for adding the Air Unit

Green LED flashes slowly CCM module has not yet been connected to the Danfoss Link™ CC

Green LED lights continuously CCM module is now connected to the Danfoss Link™ CC

Red LED flashes slowly 5 times Connection attempt failed.

Tab. 2: LED blink patterns on the CCM

VIEWB402

© Danfoss | FEC | 2019.06 | 7

Page 8

Installation Guide Danfoss Air Units

System settings

5.3 Performing a network test after adding a new device

After finishing installation, perform a network test, to ensure that communication between added devices and the Danfoss Link™ CC is stable.

Note! Do not perform the network test before the Danfoss Link™ CC is mounted in its final position.

Service Options

1

Status and Diagnostics

Status and Diagnostics

2

Network

?

?

Wireless Network Status

3

Start Network Test

?

At the end of the network test the Danfoss Link™ CC awaits for all battery operated devices to wake up and report. Follow the instructions

given on the screen. If the network test is running smoothly, there will be no need for further interaction. If the network test is performing

slow, the Danfoss Link™ CC guides through troubleshooting and gives usefull tips for speeding up the process.

5.4 Setting basic steps in the Danfoss Link™ CC

Now the Air Unit has been added to the wireless system, and is ready for balancing of the air flow. If the Air Unit has just been added to the

system, the screen will prompt for setting the basic extract and supply air step.

If the system was started earlier/by others, enter the basic settings through the Service Menu by pressing the Air Dial button for 5 seconds.

Go through the following steps.

Service Options

1

Rooms and Devices

Rooms and Devices

2

Manage Devices

?

?

Manage Devices

3

?

Select Device

4

Air unit

?

5

System settings

?

6 Balancing of the Main Air Volume

To achieve the best possible performance, it is vital to balance the main air volumes (balancing will

also help protecting the house against fungus and dry rot). The system should not be balanced/

commisioned at outdoor temperatures below -3°C, as the system will go into frost protection mode

(indicated by a flashing icon on the display. If necessary to perform balancing at outdoor air temperatures below -3°C, remove power for 20 seconds to de-activate frost protection for 90 minutes.

Note! Close all doors and turn off the cooker hood.

1. Remove the front panel from unit by pulling the handles.

2. See the drawing of the duct system, where suggested pre-setting values for all air valves

are stated. Close the valves completely, and turn them full turns towards open (number

of turns as indicated on the duct system drawing). When setting up the systems for which

Danfoss has not dimensioned the duct system, set the supply and extract valves in accordance with the instructions of the project manager.

3. If dampers are included in the system, open these completely.

4. Mount measuring tubes between the unit’s measuring points on the extract side and differential pressure gauge.

5. Find the required flow on the system diagram (sticker on front cover) with the corresponding differential pressure value. If the

6

Set basic steps

?

Measuring the extract

8 | © Danfoss | FEC | 2019.06

VIEWB402

Page 9

Installation Guide Danfoss Air Units

450

325

1263

450

325

pressure is too low, adjust the fan step upwards until you reach the required pressure.

6. Move the measuring tubes to the measuring points on the supply side and use the same

procedure to set the supply air.

7. After the main air volumes have been adjusted, the set-up of individual valves needs to be

carried out. In most cases, this will entail minor changes to the chosen basic steps, but this

can be done in the room by adjusting the valves, or by using the Air Dial to fine tune basic

steps.

Adjusting an operational system

1. Press Air Dial for 5 seconds to get access to the Service menu.

2. Press ”set basic step” to activate the special commissioning mode (where all outside influences

3. are blocked - the installer controls the extract and supply air fans completely with 1-100%

Measuring the supply

fan speed). The Service menu remains visible for one hour and then disappears.

7 Service Menu

Press Air Dial for 5 seconds to access the Service Menu to change basic settings like language, filter timer, basic

steps etc.

System Reset

1. If the system has already been balanced, make a note of the basic fan steps for later use. The values are

found in the Service Menu: Service > Info > Basic Steps.

2. Remove and re-insert the Air Dial batteries while pressing the button until a beep is heard. The Air Dial is

now in start-up mode.

3. Remove the supply or communication cable.

4. While re-connecting the cable, press the CCM module button until only the green LED is flashing.

5. The system is now reset to factory settings.

GB

Service

Back

Info

Set filter timer

Set language

Set basic step

Link test

Accessories

8 Technical Specifications

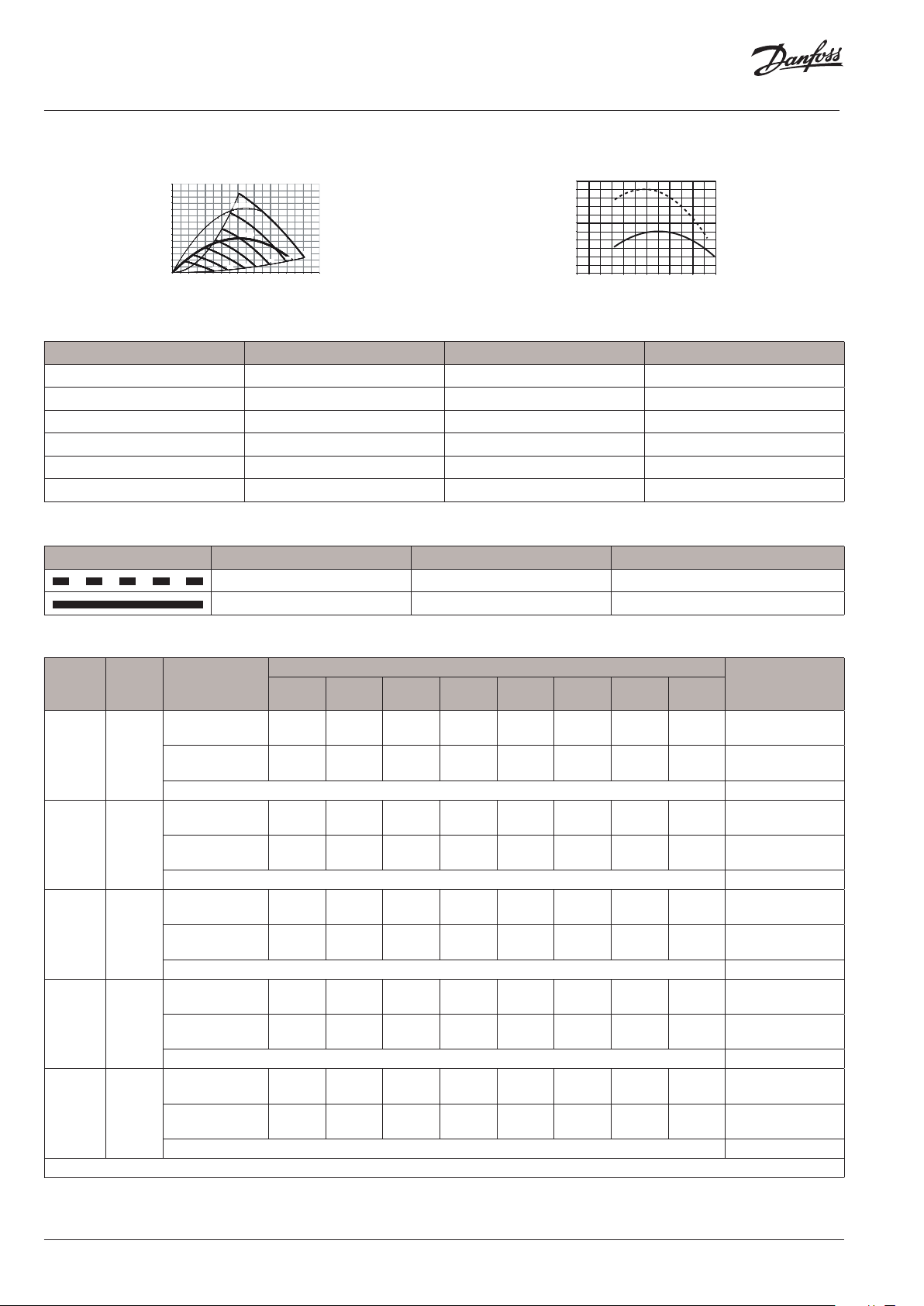

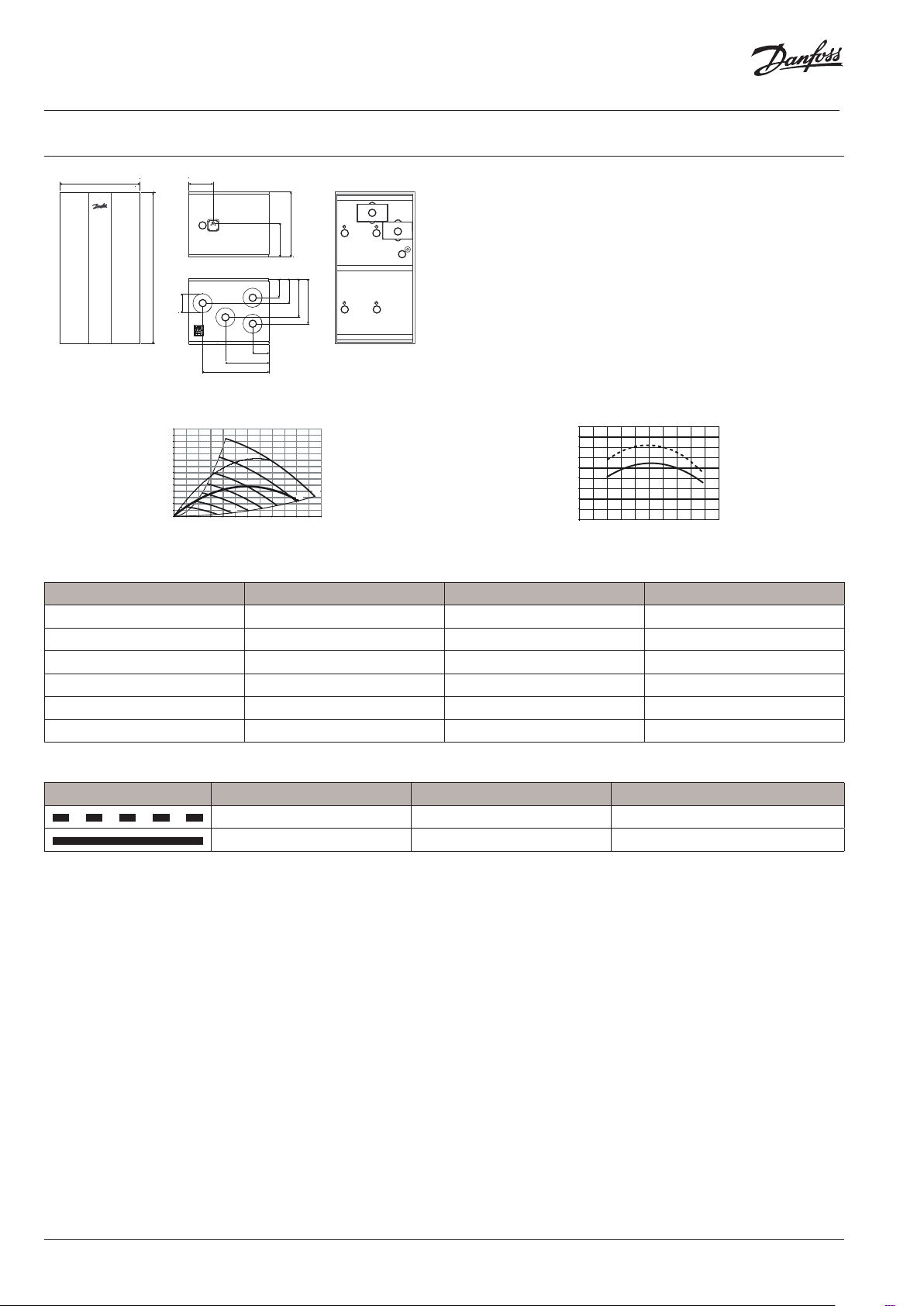

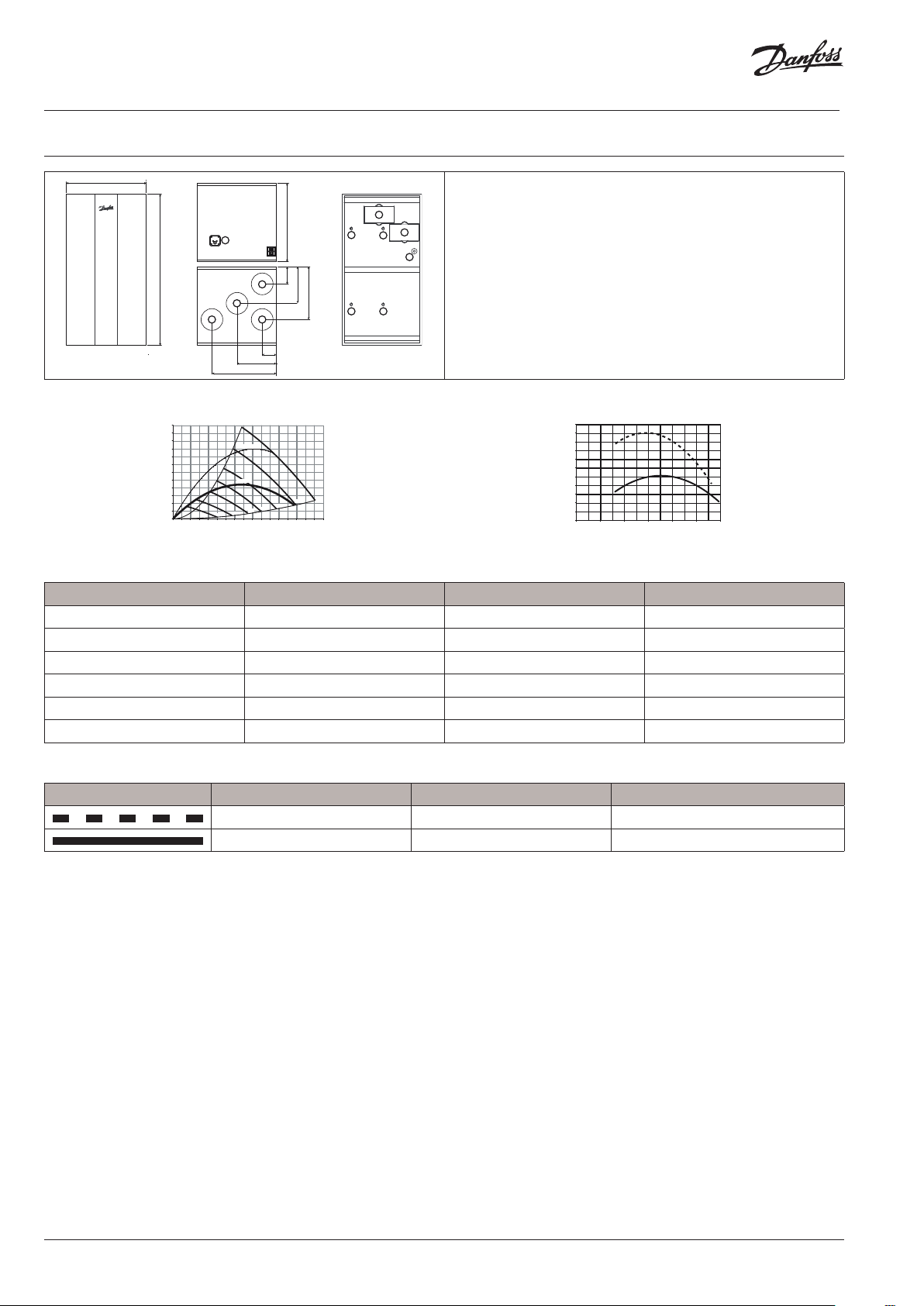

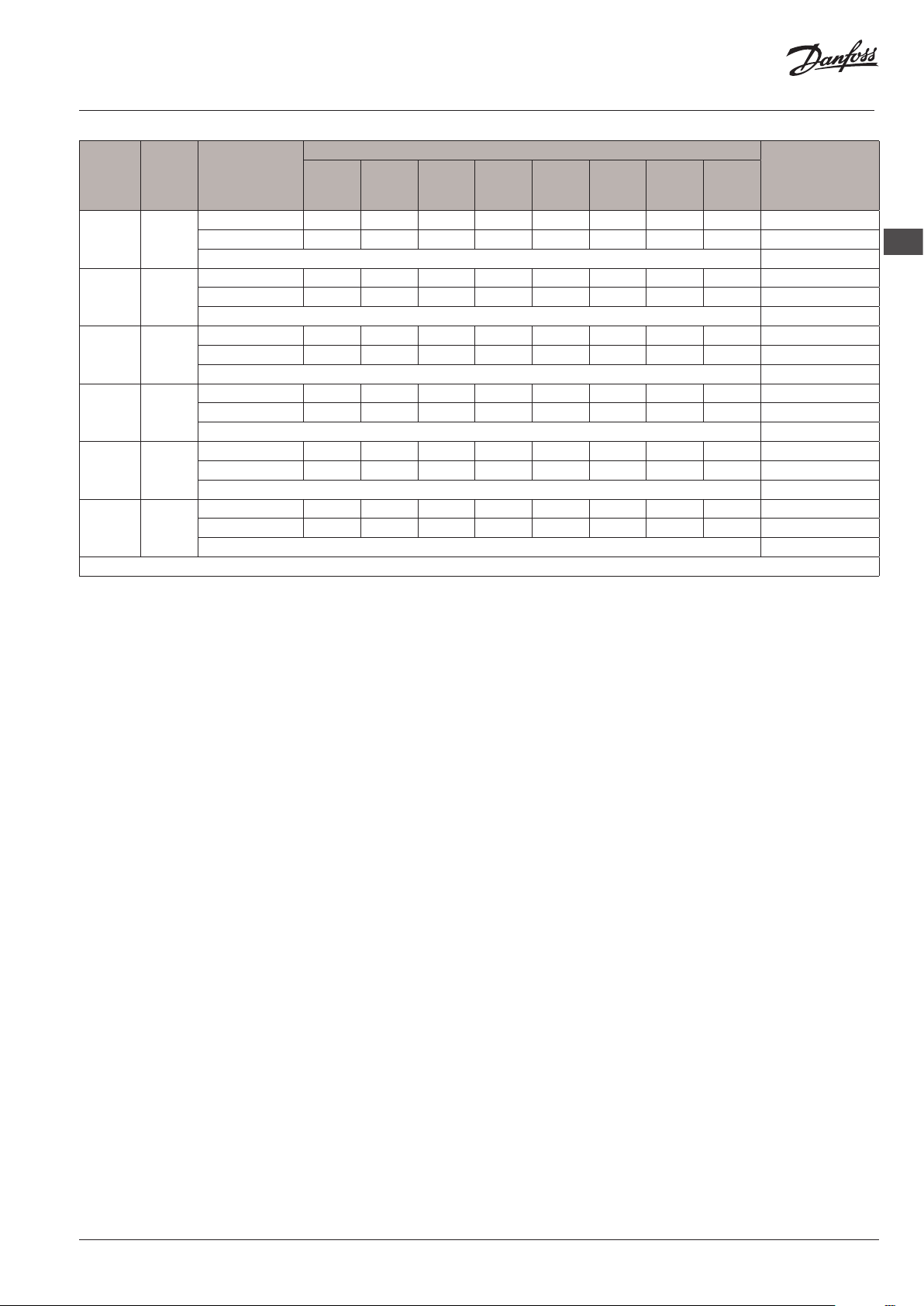

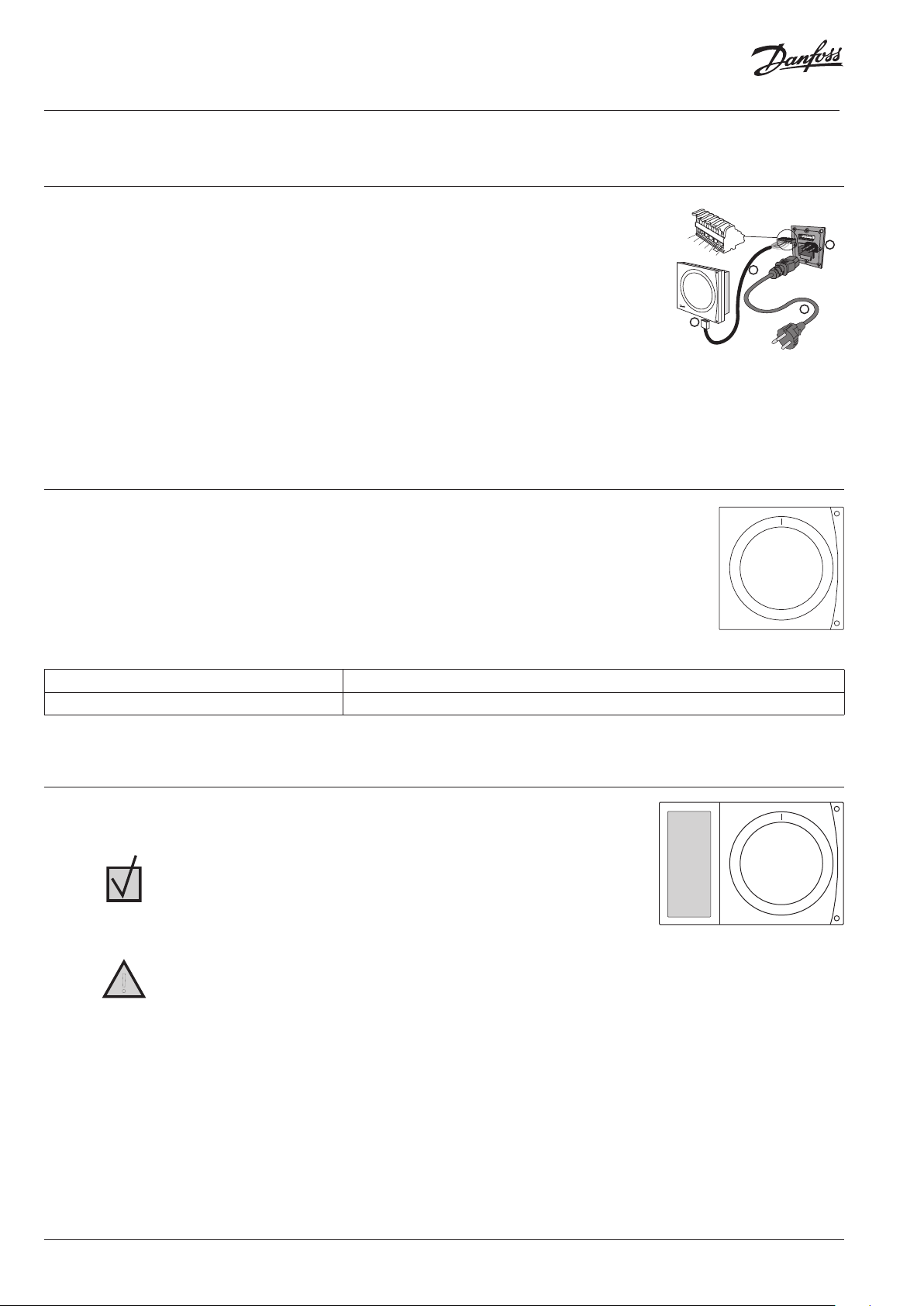

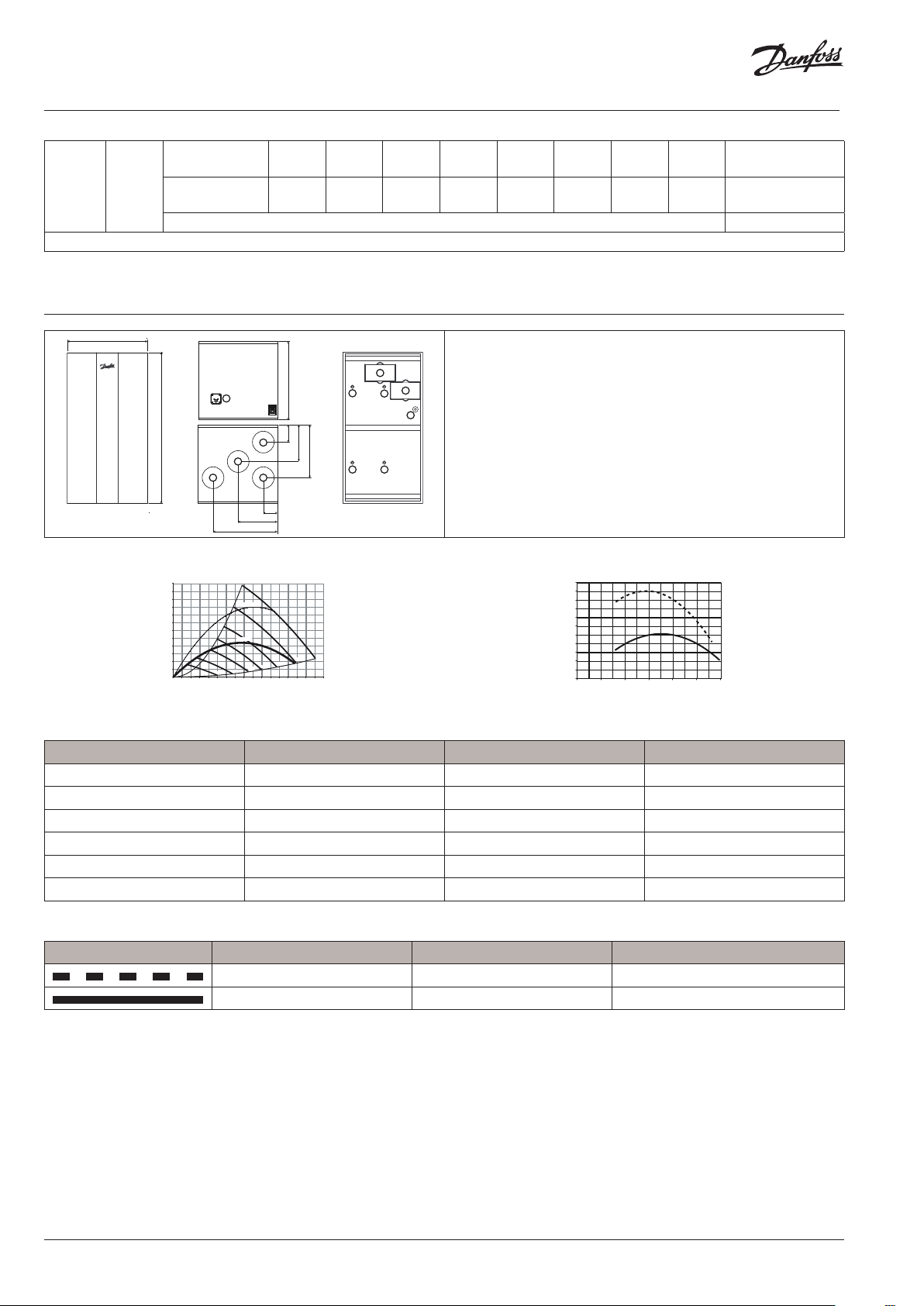

8.1 a² Unit

Dimensions

160

177

Front view (without front panel)

1180

3

4

4

1

5

3

6

1

600

2

j Filter, extract air

2

6

5

k Filter, supply air

l Flow chart (for balancing)

m Filter reset button

n Differential pressure for extract air

580

177

j Outdoor air

k Exhaust air

l Extract air

m Supply air

Weight of unit: 52 kg

o Differential pressure for supply air

VIEWB402

© Danfoss | FEC | 2019.06 | 9

Page 10

Installation Guide Danfoss Air Units

350

300

250

200

150

100

0 50 100 150 200 250 300 350

400 450

94%

0 50 100 150 200 250 300

Capacity

Pressure [Pa]

*0.45 W/m³/h

1000 J/m³

50

0

58%

46%

33%

21%

* 0.45 W/m³/h = “Passiv Haus” requirements

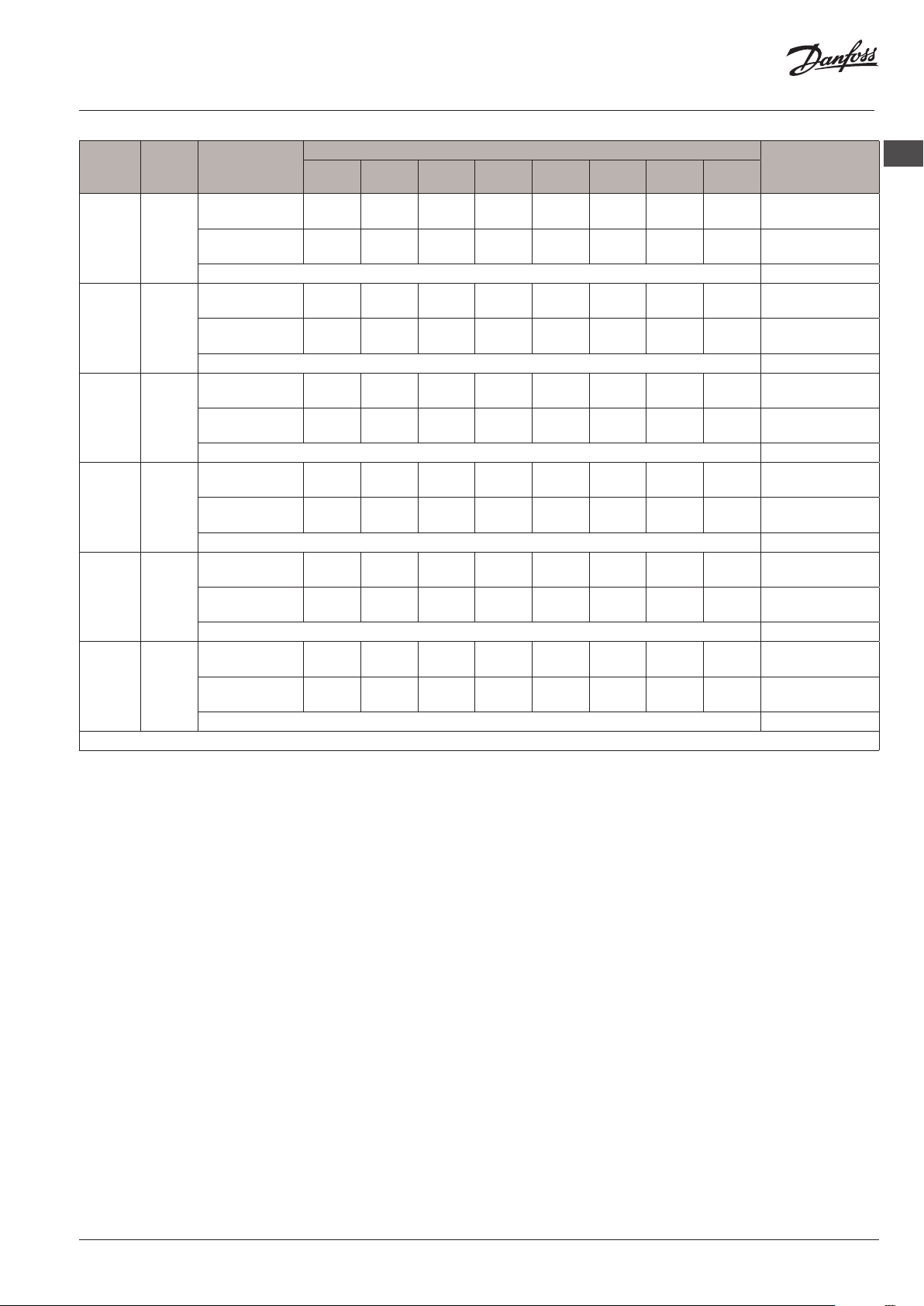

Flow [m³/h] Pext. [Pa] SFP [J/m³] P1 tot. [W]

160 50 615 27

220 70 728 44

220 100 854 52

260 70 783 57

260 100 894 65

300 90 936 78

Tab. 3: Capacity for the a² unit

Extract air Fresh air

t = 21 °C RH = 36% t = -3 °C RH = 80% with condensation and 5% imbalance

t = 20 °C RH = 38% t = 7 °C as acc. to EN13141-7 (dry)

Tab. 4: Temperature ratio for the a² unit

Temperature ratio

η [%]

93%

92%

91%

90%

89%

88%

87%

100%

85%

70%

Flow [m³/h]

86%

85%

84%

83%

Flow [m³/h]

Flow

m³/h

Pres-

sure Pa

162 70

162 100

216 70

216 100

250 100

Measured

at

63 125 250 500 1000 2000 4000 8000

Frequency band [Hz], sound power Lw (A) [dB(A)] Sound pressure

Lp(A) (standard*

room) [dB(A)]

Supply air duct 23 34 40 36 29 25 17 18

Extract air duct 23 33 39 37 29 24 18 18

Cabinet 40

Supply air duct 25 35 43 38 31 28 18 18

Extract air duct 25 36 42 39 30 25 17 18

Cabinet 41

Supply air duct 26 36 44 39 33 30 19 18

Extract air duct 28 36 43 41 34 29 18 18

Cabinet

Supply air duct 26 37 44 40 34 31 19 18 45

Extract air duct 27 37 45 42 35 30 19 18

Cabinet

Supply air duct 28 39 46 42 37 33 21 18 46

Extract air duct 30 39 48 45 38 33 20 18

* Values for sound pressure calculated for a standard room with A = 10 m², H = 2.4m and mean absorption 0.2.

Tab. 5: Sound data for the a² unit

10 | © Danfoss | FEC | 2019.06

Cabinet 49

VIEWB402

Page 11

Installation Guide Danfoss Air Units

440

528

1342

780

440

300

250

200

150

100

0 50 100 150

200 250 300

350 400

450 500

550 600

80%

81%

82%

83%

84%

85%

86%

87%

88%

89%

90%

0 50 100 150 200 250 300 350 400 450 500

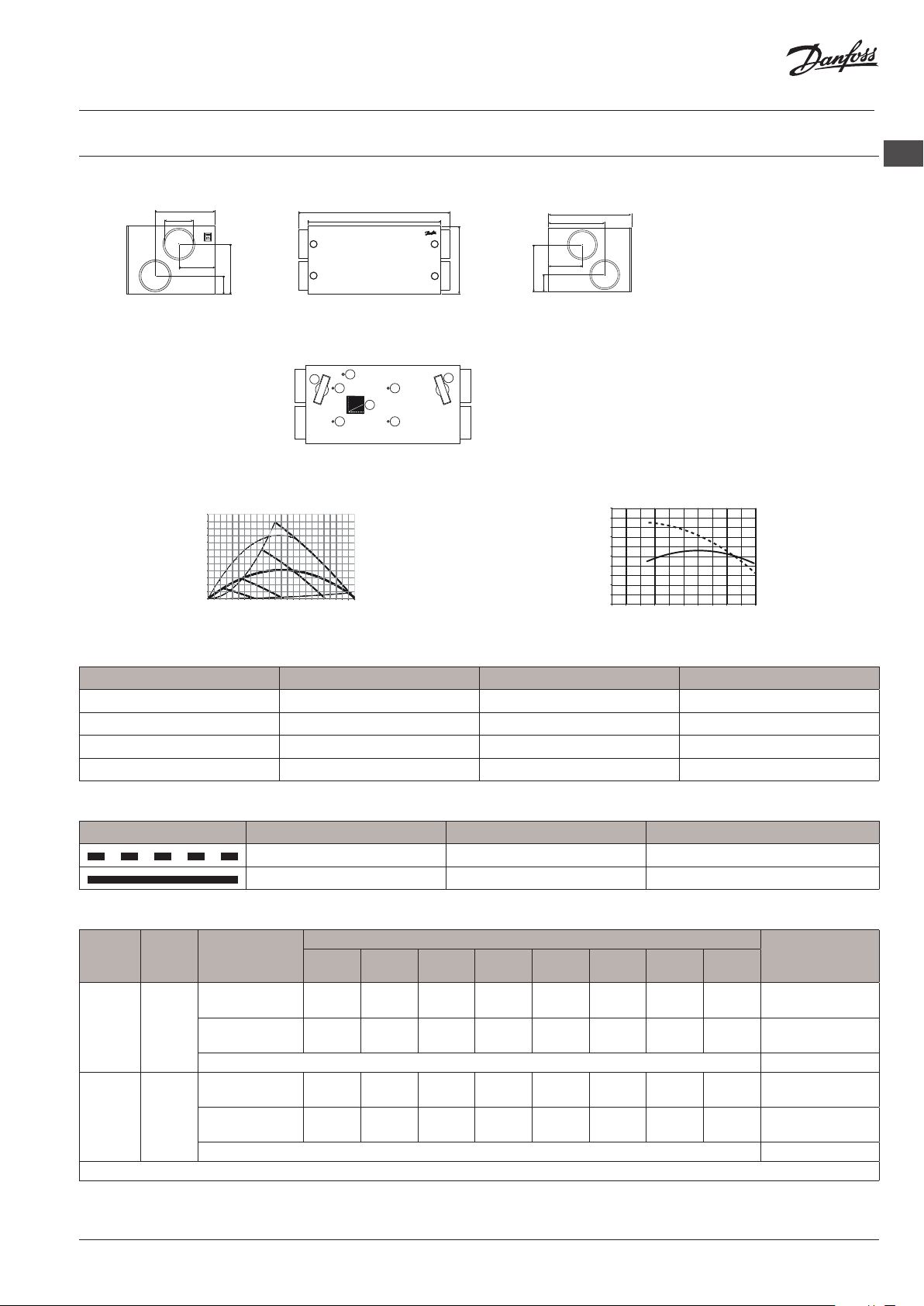

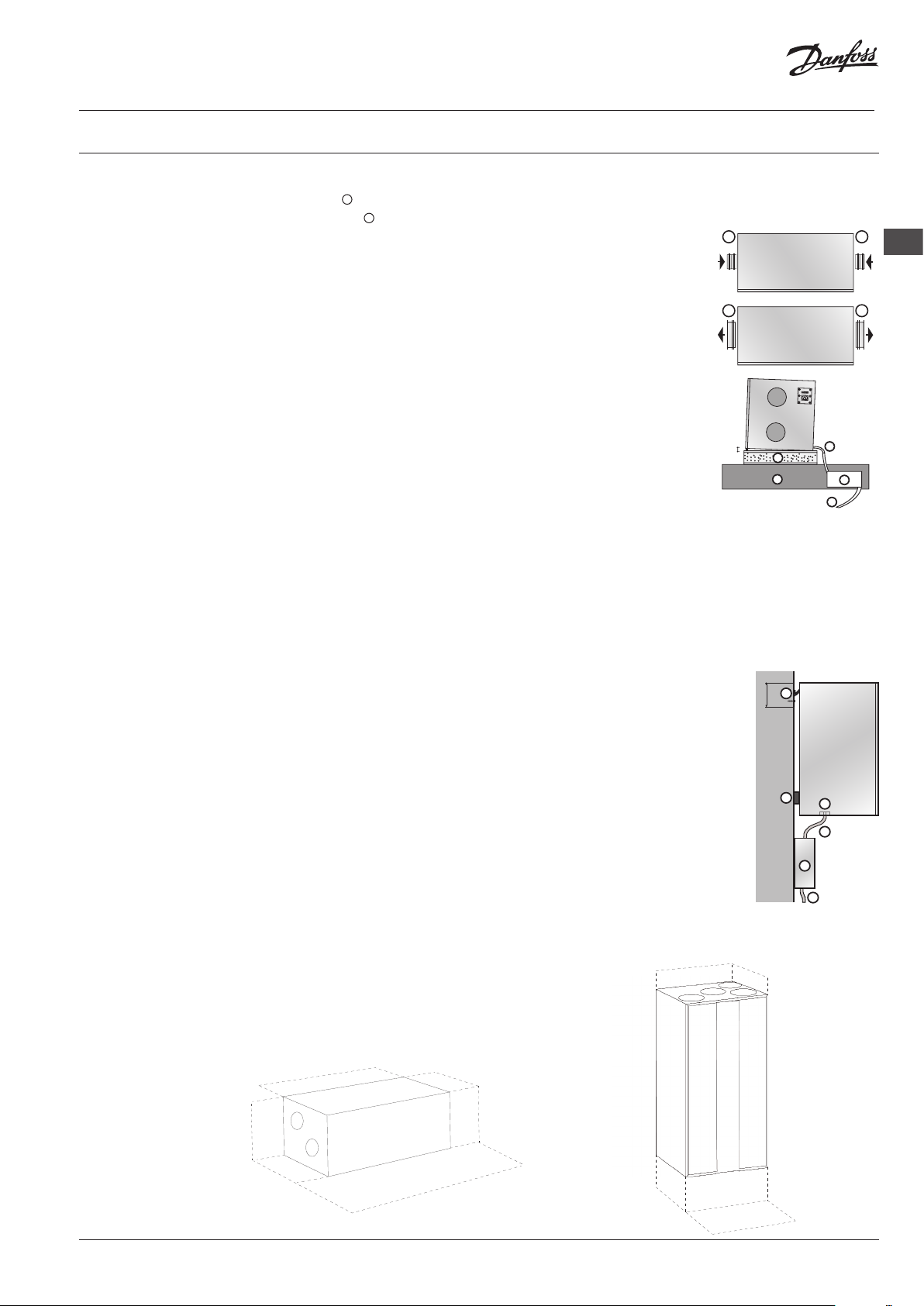

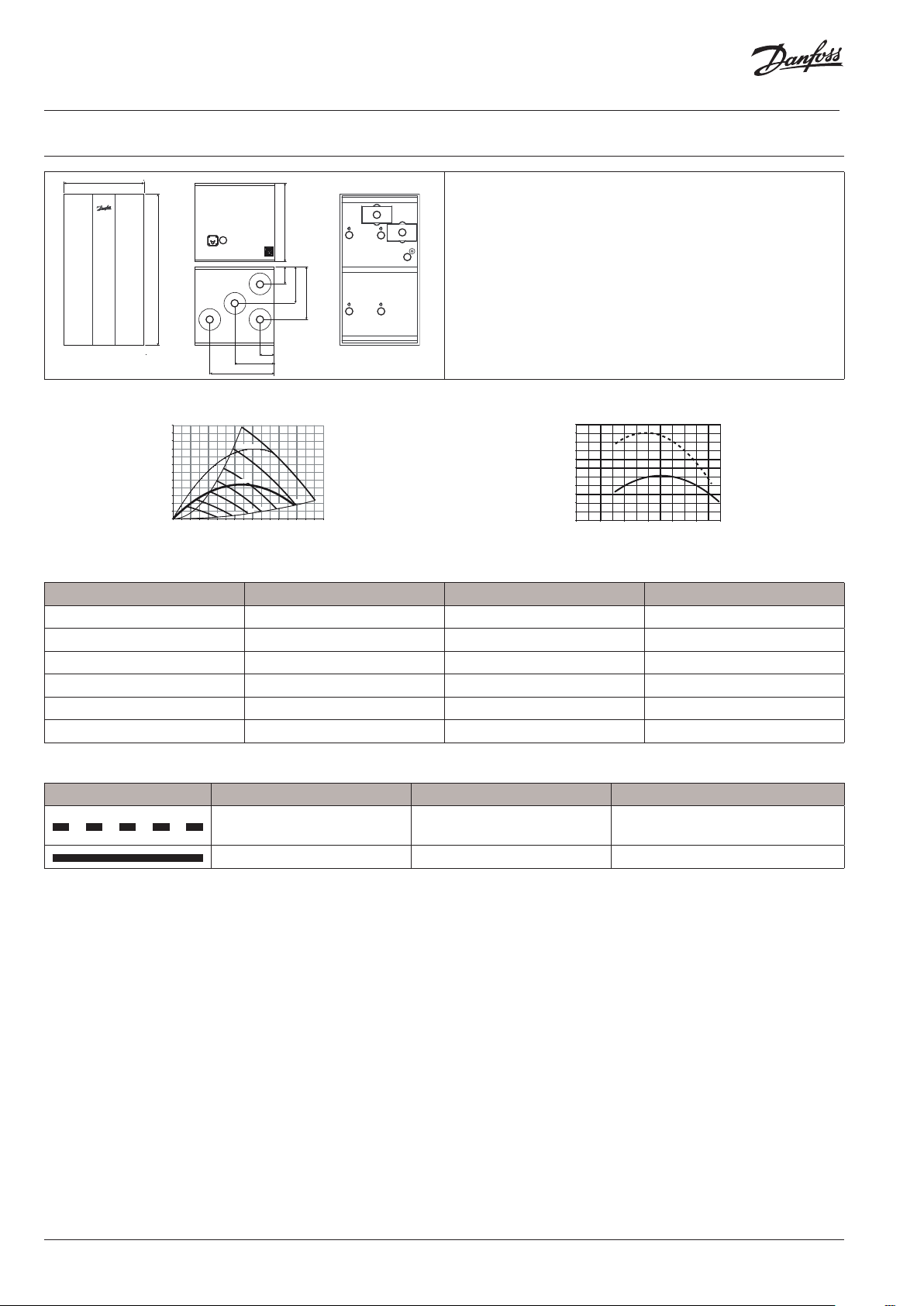

8.2 a³ Unit

Dimensions

250

318

160

Front view (without front panel)

Capacity

Pressure [Pa]

*0.45 W/m³/h

1000 J/m³

50

0

56%

40%

GB

1180

3

4

4

1

5

3

6

1

600

2

j Filter, extract air

2

6

5

k Filter, supply air

l Flow chart (for balancing)

m Filter reset button

n Differential pressure for extract air

528

318

160

o Differential pressure for supply air

Temperature ratio

η [%]

100%

82%

j Outdoor air

k Exhaust air

l Extract air

m Supply air

Weight of unit: 67 kg

* 0.45 W/m³/h = “Passiv Haus” requirements

Flow [m³/h] Pext. [Pa] SFP [J/m³] P1 tot. [W]

200 70 787 44

350 70 835 81

450 70 973 122

350 100 1000 97

Tab. 6: Capacity for the a³ unit

Extract air Fresh air

t = 21 °C RH = 36% t = -3 °C RH = 80% with condensation and 5% imbalance

t = 20 °C RH = 38% t = 7 °C as acc. to EN1314-7 (dry)

Tab. 7: Temperature ratio for the a³ unit

Flow

m³/h

Pres-

sure Pa

Measured

at

Supply air duct 35 45 56 49 47 44 31 16

350 70

Extract air duct 35 44 54 48 48 44 31 19

Cabinet 57

Flow [m³/h]

Frequency band [Hz], sound power Lw (A) [dB(A)] Sound pressure

63 125 250 500 1000 2000 4000 8000

Flow [m³/h]

Lp(A) (standard*

room) [dB(A)]

450 100

* Values for sound pressure calculated for a standard room with A = 10 m², H = 2.4m and mean absorption 0.2.

Tab. 8: Sound data for the a³ unit

VIEWB402

Supply air duct 39 48 62 55 52 50 37 22

Extract air duct 39 47 61 55 53 48 37 20

Cabinet 61

© Danfoss | FEC | 2019.06 | 11

Page 12

Installation Guide Danfoss Air Units

0 50 100 150 200

250 300

84%

85%

86%

87%

88%

89%

90%

91%

92%

93%

0 50 100 150 200 250

530

160

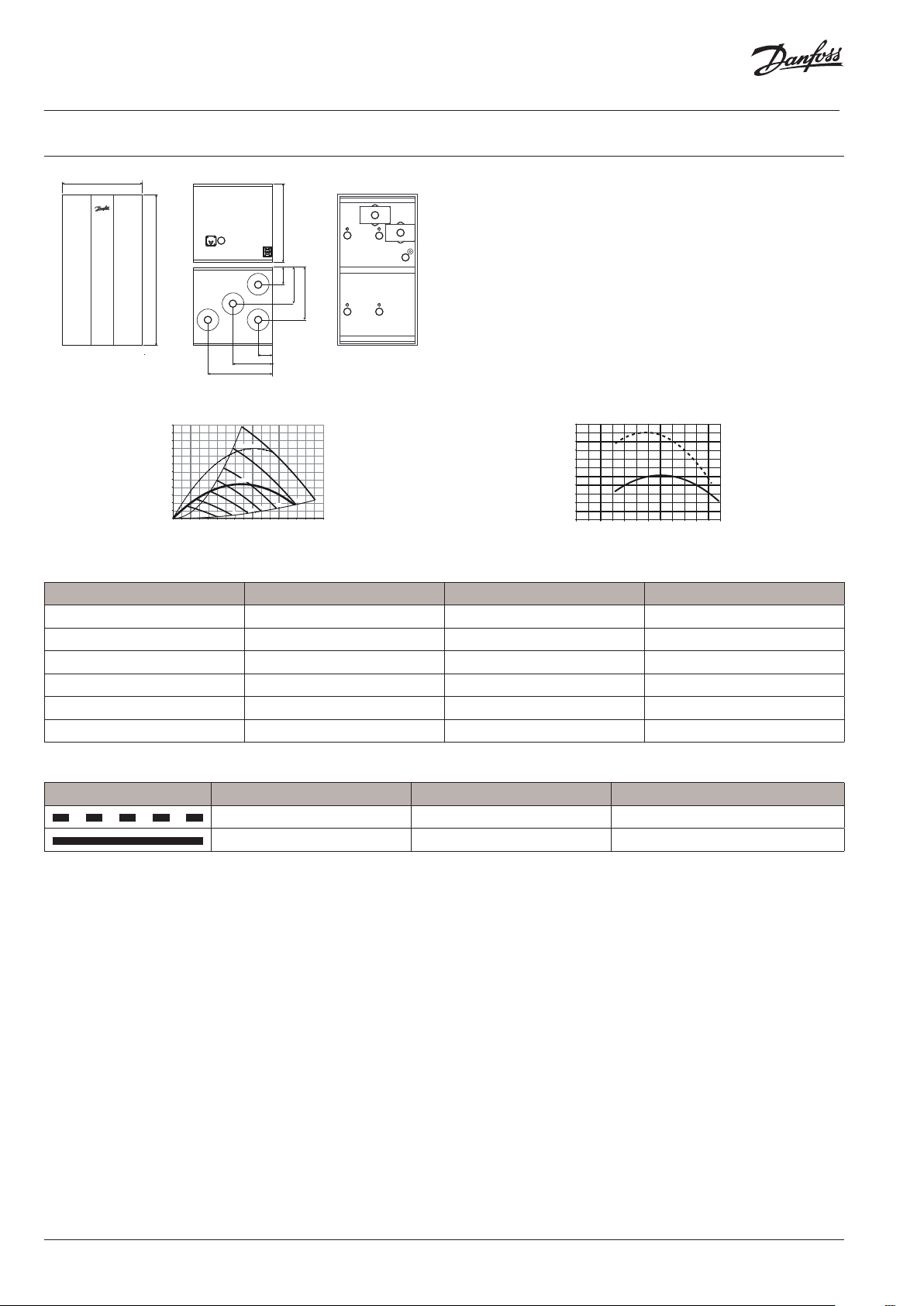

8.3 w¹ Unit

5

1005

125

1

3

2

4

108

287

438

Capacity

Pressure [Pa]

350

300

250

200

150

100

50

0

*0.45 W/m³/h

1000 J/m³

58%

46%

33%

21%

* 0.45 W/m³/h = “Passiv Haus” requirements

Flow [m³/h] Pext. [Pa] SFP [J/m³] P1 tot. [W]

100 35 588 16

100 55 682 19

140 60 710 28

140 70 759 30

180 70 798 40

180 100 945 47

Tab. 9: Capacity for the w¹ unit

j Supply air

k Extract air

l Exhaust air

m Outdoor air

n Condensate drain

224

430

6

7

89

10

o Filter, extract air

125

161

254

296

98

p Filter, supply air

q Differential pressure for extract air

r Differential pressure for supply air

s Filter reset button

Weight of unit: 31 kg

Temperature ratio

η [%]

100%

85%

70%

Flow [m³/h]

Flow [m³/h]

Tab. 10: Temperature ratio for the w¹ unit

12 | © Danfoss | FEC | 2019.06

Extract air Fresh air

t = 21 °C RH = 52% t = 5 °C RH = 80% with condensation and 5% imbalance

t = 20 °C RH = 38% t = 7 °C as acc. to EN13141-7 (dry)

VIEWB402

Page 13

Installation Guide Danfoss Air Units

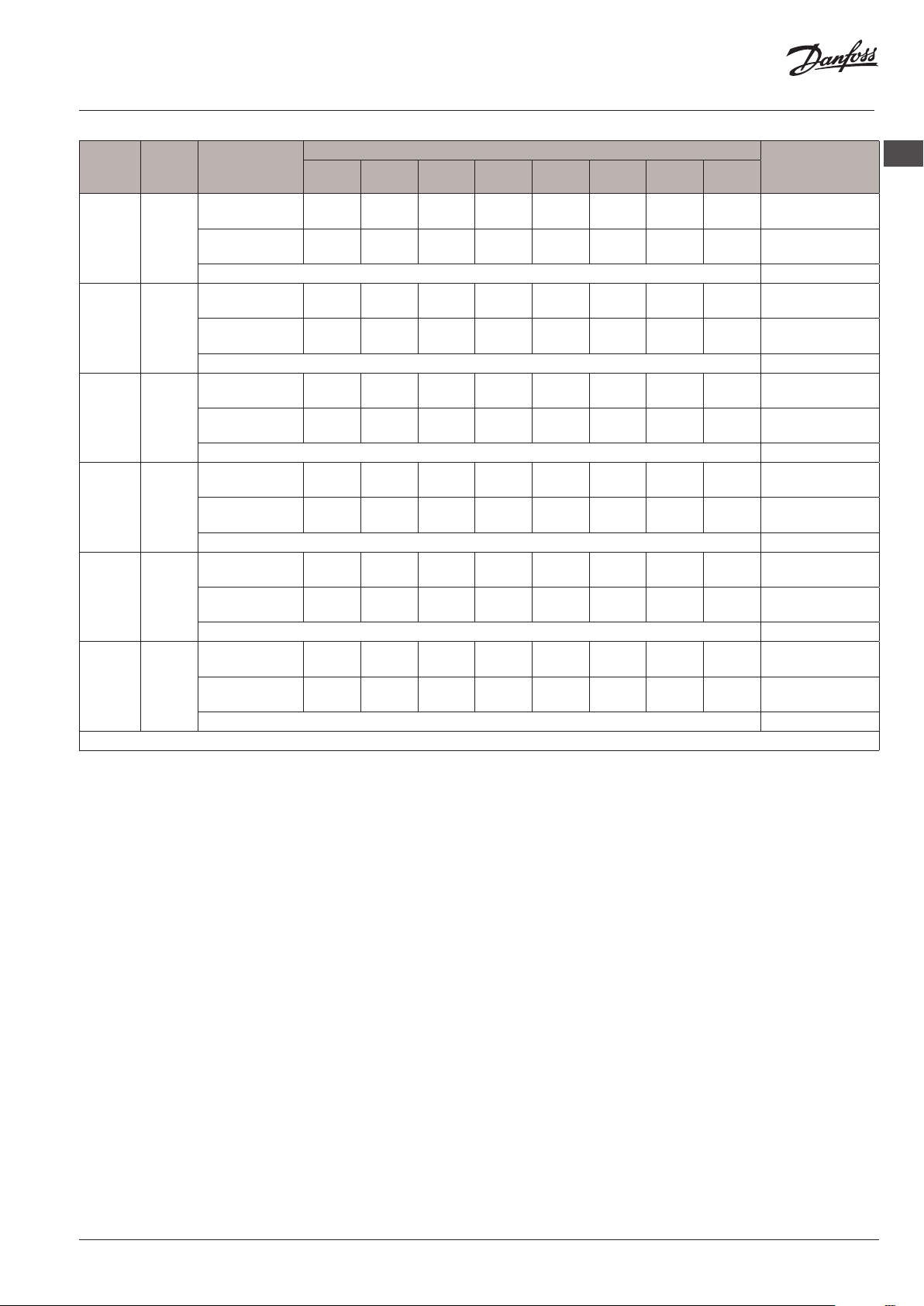

Flow

m³/h

126 70

126 100

162 70

162 100

216 70

Pres-

sure Pa

Measured

at

Supply air duct 20 30 41 42 38 30 19 18

Extract air duct 18 30 41 41 30 26 18 18

Cabinet 47

Supply air duct 22 32 46 45 39 32 21 18

Extract air duct 22 33 43 42 32 27 19 18

Cabinet 50

Supply air duct 23 31 43 46 41 33 22 18

Extract air duct 26 31 42 43 33 29 21 18

Cabinet 53

Supply air duct 28 33 44 48 43 35 23 18

Extract air duct 29 34 44 51 37 31 23 18

Cabinet 55

Supply air duct 28 33 44 54 46 37 28 18

Extract air duct 27 33 43 52 39 33 27 18

63 125 250 500 1000 2000 4000 8000

Frequency band [Hz], sound power Lw (A) [dB(A)] Sound pressure

Lp(A) (standard*

room) [dB(A)]

GB

Cabinet 57

Supply air duct 28 35 45 55 46 38 29 18

216 100

* Values for sound pressure calculated for a standard room with A = 10 m², H = 2.4m and mean absorption 0.2.

Tab. 11: Sound data for the w¹ unit

Extract air duct 32 34 44 52 40 34 28 18

Cabinet 56

VIEWB402

© Danfoss | FEC | 2019.06 | 13

Page 14

Installation Guide Danfoss Air Units

300

250

200

150

100

0 50 100

150 200

250 300

350 400

83%

84%

85%

86%

87%

88%

89%

90%

91%

92%

93%

94%

0 50 100 150 200 250 300

590

480

8.4 w² Unit

5

1055

1

3

2

4

110

295

Capacity

Pressure [Pa]

*0.45 W/m³/h

1000 J/m³

50

0

58%

46%

33%

21%

* 0.45 W/m³/h = “Passiv Haus” requirements

Flow [m³/h] Pext. [Pa] SFP [J/m³] P1 tot. [W]

160 50 700 31

220 70 832 51

220 100 963 59

260 70 892 64

260 100 996 72

280 90 1000 78

Tab. 12: Capacity for the w² unit

j Supply air

k Extract air

l Exhaust air

m Outdoor air

n Condensate drain

o Filter, extract air

p Filter, supply air

q Differential pressure for extract air

r Differential pressure for supply air

580

126

270

389

6

9

7

8

10

98

s Filter reset button

Weight of unit: 45 kg

Temperature ratio

η [%]

100%

85%

70%

Flow [m³/h]

Flow [m³/h]

Tab. 13: Temperature ratio for the w² unit

14 | © Danfoss | FEC | 2019.06

Extract air Fresh air

t = 21 °C RH = 36% t = -3 °C RH = 80% with condensation and 5% imbalance

t = 20 °C RH = 38% t = 7 °C as acc. to EN13141-7 (dry)

VIEWB402

Page 15

Installation Guide Danfoss Air Units

Flow

m³/h

126 50

162 70

162 100

216 70

216 100

Pres-

sure Pa

Measured

at

Supply air duct 20 30 34 36 23 19 17 18

Extract air duct 16 31 37 36 29 21 17 18

Cabinet 39

Supply air duct 23 33 35 40 32 24 18 18

Extract air duct 20 33 44 39 34 26 18 18

Cabinet 44

Supply air duct 25 36 42 42 34 28 18 18

Extract air duct 21 33 43 41 35 28 18 18

Cabinet 46

Supply air duct 25 34 42 42 35 28 19 18

Extract air duct 22 34 44 43 37 31 20 18

Cabinet 47

Supply air duct 26 36 43 44 36 30 20 18

Extract air duct 23 34 45 44 33 32 20 18

63 125 250 500 1000 2000 4000 8000

Frequency band [Hz], sound power Lw (A) [dB(A)] Sound pressure

Lp(A) (standard*

room) [dB(A)]

GB

Cabinet 49

Supply air duct 27 36 45 45 38 31 21 18

250 100

* Values for sound pressure calculated for a standard room with A = 10 m², H = 2.4m and mean absorption 0.2.

Tab. 14: Sound data for the w² unit

Extract air duct 24 37 47 45 40 34 22 18

Cabinet 53

VIEWB402

© Danfoss | FEC | 2019.06 | 15

Page 16

Installation Guide Danfoss Air Units

9 Troubleshooting

Error Cause Solution

Alarm: Filter error Air filters are dirty. Exchange air filters and reset alarm.

Alarm: Battery low Battery voltage in Air Dial is too low. Replace batteries (4 x AAA) in Air Dial.

Alarm: No connection to CCM/link test

failed

Alarm: No connection via modbus/link test

failed

Alarm: Room air too cold Central heating system is not supplying

Alarm: Fire One of four temperature sensors in Danfoss

Alarm: Sensor error Temperature sensor in Danfoss Air unit or

Abnormally large negative pressure inside

the house, doors binding

Condensation in window frames Air exchange is too low. Condensation

House temperatures are too high House thermostats are set too high. Turn down thermostats.

Bypass is disabled on ventilation system. Bypass is disabled on ventilation system. Enable Bypass in Main menu Bypass Auto

Noise from Air Unit a-type unit: vibration noise may occur if

Communication between Air Dial and CCM

module has failed, typically caused by an

obstacle between Air Dial and CCM module, e.g. steel piping, other steel objects,

insulation material clad with aluminum foil,

etc. Another cause can be other wireless

appliances that does not conform to wireless standards (radio noise).

Cable between CCM module and unit is

unplugged or defective.

heat. Room temperature is dropping, so the

unit turn off to reduce involuntary heat loss.

Alarm active if Air Dial measures a room

temperature below +10 °C.

Air Unit or temperature sensor in Air Dial

remote control has detected a temperature

higher than +70 °C. The Air Unit turns off

until all sensors indicate below +70 °C.

Air Dial is defective.

Discharge air flow is larger than supply air

flow. Either balancing was not carried out

correctly during set-up of the system or the

Air Unit is in extreme defrost conditions

(can occur at outdoor temperatures below

-12 °C).

occurs when humidity is high and surface

temperatures are low, typically in bathrooms or utility rooms, where clothes are

drip drying (some condensation in bathrooms following a shower is normal, but

should disappear within half an hour).

unit is mounted directly onto joists. Unit

should be mounted on a suitable platform.

w-type unit: vibration noise may occur if

rubber spacers are not fitted between unit

and wall and/or if silicone strip is not fitted

onto wall bracket.

Defective fan bearings will produce a ‘grinding noise’.

If an obstacle has been identified, move it. If

this is not possible, move CCM module to a

better location with a free ‘line of sight’.

If the error occurs due to other wireless

appliances in the house, try switching these

off one by one, to identify the faulty device.

If none of the above helps, contact Danfoss.

Check cable and reconnect if necessary.

If cable is connected, but error still occurs

- contact Danfoss.

Check if heating system is functional. If the

problem can not be solved, contact plumber/Danfoss. When error has been remedied,

shut down and restart ventilation system to

resume normal operation. Power can be

disconnected by pulling power cable from

system.

Examine all rooms, leave the house. When

error has been remedied, shut down and

restart ventilation system to resume normal

operation. Power can be disconnected by

pulling power cable from system.

Contact Danfoss. System continues to run,

but with limited functionality.

Imbalance of flow should be 4-10% in

favour of extract air, but if problems with

doors binding is permanent, contact Danfoss. If problems only arises during extreme

winter condition, it is due to the integrated

defrost function that reduces the supply air

(hence not a defect, but an expected, and

very rare occurrence).

Increase fan step Manual mode or change

to Demand mode or Programme mode.

Set Autoboost - on.

bypass.

Check that unit is mounted on platform,

according to installation manual.

Check that rubber spacers and silicone strip

are fitted, according to installation manual.

If fan ball bearing is suspected to be defective, contact Danfoss.

16 | © Danfoss | FEC | 2019.06

VIEWB402

Page 17

Installation Guide Danfoss Air Units

Noise from Air valves Air flow is too high. Noise is not a problem in a correctly sized

Pressure is too high over valve.

No silencer is fitted to main duct.

Frost icon in display The system is in defrost mode, because low

outdoor temperatures entail a risk of ice

forming in the heat exchanger.

and commissioned system. However, if air

valves are closed (e.g. during cleaning), a

hissing noise may occur.

This is not an error, but a standard mode.

The function stops automatically when the

outdoor temperature rises.

GB

VIEWB402

© Danfoss | FEC | 2019.06 | 17

Page 18

Installationsvejledning Danfoss Air ventilationsanlæg

Indholdsfortegnelse

1 Sikkerhedsnoter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 Før du starter

3 Installation af Air Units

4 Installation af CCM-modul og Air Dial

4.1 Elektriske tilslutninger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2 Trådløs forbindelse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Air Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 Montering og afmontering af CCM-modul og Air Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Tilslutning til Danfoss Link™ CC

5.1 Tilslutning af Air-enheden til Danfoss Link™ CC, fysisk installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Tilslutning af Air-enheden til Danfoss Link™ CC, trådløs tilslutning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Udførelse af en netværkstest efter tilføjelse af en ny enhed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Indstilling af grundtrin i Danfoss Link™ CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Afbalancering af hovedluftmængden

7 Servicemenu

8 Tekniske specifikationer

8.1 a²-enhed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 a³-enhed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.3 w¹ enhed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.4 w² enhed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9 Fejlfinding

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1 Sikkerhedsnoter

Dette apparat er ikke beregnet til at blive brugt af personer (herunder børn) med nedsat fysisk, sansemæssig eller psykisk formåen eller

med manglende erfaring og viden, medmindre de er under opsyn eller er blevet instrueret i brugen af apparatet af en person, der er

ansvarlig for deres sikkerhed.

Børn skal være under opsyn for at sikre, at de ikke leger med apparatet.

Ud over at skifte luftfilter og rengøre anlægget udvendigt, vil enhver form for service kræve uddannet personale.

2 Før du starter

Kontroller venligst, at leveringen af Danfoss Air-enheden er komplet ifølge følgesedlen.

Hvis du har bestilt en komplet Danfoss Air-løsning, medfølger der en komplet følgeseddel for Air Flex-kanalsystemet.

Kontroller dele og elementer for at sikre dig, at intet er beskadiget.

Bemærk! Danfoss Air Flex-kanaler er omfattet af gældende dansk lovgivning, og der henvises til:

• Dansk Standard DS 428: Norm for brandtekniske foranstaltninger ved ventilationssystemer.

• Dansk Standard DS 447: Norm for mekaniske ventilationsanlæg.

Standardlevering omfatter:

• Danfoss Air-enhed

• Vægbeslag (hvis w-model)

• CCM

• Kabler

Valgfri leveringer:

• Air Dial

• Danfoss LinkTM CC

18 | © Danfoss | FEC | 2019.06

VIEWB401

Page 19

Installationsvejledning Danfoss Air ventilationsanlæg

75 mm

6

3 Installation af Air Units

Loftsenhed a² og a³

1a. (a2 units) Bøj lasker ud i 90 graders vinkel og montér de 4 nipler 1a som vist på billedet til højre.

3

1b. (a

units) Træk indløbsringene ud af studsene 1b. Vend studsene om, og monter dem vha. de med-

følgende pladeskruer (til skruemaskine, brug laveste momentindstilling).

2. Lav en platform k til enheden af 16 mm krydsfiner/MDF omkring 50 mm murbatts.

3. Sørg for, at enheden monteres med et lille bagfald mod kondensstudsen. Se skitse.

4. Montér kanaler på nipler/indløbsringe. Lasker fastgøres til kanal og nippel, f.eks. med selvskærende

ventilationsskruer.

5. Der skal altid monteres en vandlås n til enheden (bestilles separat).

6. Montér vandlåsen på spæret m under enheden.

7. Forbind vandlåsen til et afløb o.

8. Kondensledningen l skal være isoleret, hvor der er risiko for frost.

9. Forbind slangen til kondensudløbsstudsen på enheden. Før den tilsluttede slange til afløb, og

sørg for en hældning på min. 1 cm/meter.

10. Fjern frontpanelet og skumfronten, fyld kondensbakken, kontroller afløbsfunktionen og saml

fronten igen.

NB: Løft aldrig anlægget i studsene. Løftes anlægget i studsene kan der opstå utæthed mellem stålkabinet

og polystyrenkernen. En utæthed kan udbedres ved at fuge studsene indefra med en akrylbaseret tætningsmasse.

1a

2

a

1b 1b

3

a

2 cm

2

4

3

6

DK

1a

5

Vægenhed w¹ og w²

1. Placer monteringsbeslaget j på den ønskede placering på væggen (75 mm fra bunden af beslaget til toppen af enheden),

mærk af og bor huller. Anvend skruer, der er egnet til vægoverfladen (skruer medfølger ikke).

2. Sørg for, at beslaget er monteret fuldstændigt i vatter.

3. Hæng enheden på beslaget.

4. Monter de selvklæbende gummiafstandsstykker k på den nederste, bagerste bagplade.

5. Beregn 60 cm fri plads foran enheden, så der sikres adgang i forbindelse med service.

6. Der skal altid monteres en vandlås l til enheden (bestilles separat).

7. Monter vandlåsen på væggen under enheden.

8. Slut vandlåsen til afløbet n i bunden af enheden.

9. Kondensledningen m skal være isoleret, hvor der er risiko for frost.

10. Forbind slangen til kondensudløbsstudsen på enheden. Før den tilsluttede slange til afløb, og sørg for en

hældning på min. 1 cm/meter.

11. Fjern frontpanelet og skumfronten, fyld kondensbakken, kontroller afløbsfunktionen og saml fronten

igen.

NB: For at overholde sikkerhedsstandarderne og undgå risikoen for funktionsfejl, skal det medfølgende

beskyttelsesskjold monteres oven på w¹-enheden, så det dækker forbindelsespladen.

Serviceareal

Det anbefales at fritholde områder omkring ventilationsanlægget af hensyn til

tilgængeligheden i forbindelse med service og vedligehold. For a2 og a3 modeller skal

der etableres fast underlag foran anlægget med en frihøjde på 1,2 m. Hvis anbefalinger ikke

overholdes kan servicering vurderes at være arbejdsmiljømæssigt uforsvarligt.

20 cm

43/58 cm

1

2

5

4

3

VIEWB401

30 cm

Loftsenhed a2, a

40 cm

30 cm

40 cm

60 cm

3

178 cm

Vægenhed w1, w

2

60 cm

53/59 cm

© Danfoss | FEC | 2019.06 | 19

Page 20

Installationsvejledning Danfoss Air ventilationsanlæg

!

4 Installation af CCM-modul og Air Dial

4.1 Elektriske tilslutninger

1. Slut forsyningsledningen m til Air-enheden l.

2. Tilslut CCM-kablet k mellem CCM-modulet j og Air-enheden.

3. Kontroller signalet. Hvis det er for svagt, skal CCM-modulet placeret et andet sted, fx på samme

etage som Air Dial (se afsnittet Linktest af Air Dial).

1

2

3

4. Hvis det er muligt, skal CCM-modulet placeres tæt på en ethernet-forbindelse for senere tilslutning til en pc.

5. Hvis der findes tilbehør (elforvarme, eleftervarme, vandvarmeflade eller geotermisk flade) skal

lusen på klemme 5 og 6 ernes (se også vejledningen, der følger med tilbehøret).

1

Stik på CCM-kabelet:

1. Hvid/orange, 2. Orange, 3. Sort, 4. Hvid/blå, 5. Blå, 6. Sort

Bemærk! CCM-kabelet kan forlænges til op til 200 m. Brug skærmet kabel på 22 eller 24 AWG med 2 x parsnoet.

4.2 Trådløs forbindelse

Når CCM-modulet startes, vil den grønne lysdiode blinke langsomt. Dette angiver, at CCM-modulet ikke er tilsluttet

Air Dial endnu.

For at tilslutte Air Dial sættes batterier i. Air Dial starter i installationstilstand og fører automatisk installatøren gennem opsætningen.

1. Indstil sprog.

2. Opret netværk (tryk på knappen på CCM-modulet, og tryk derefter på Air Dial).

3. Indstil basistrin (opsætning af hovedluftmængde).

4. Afslut.

4

5

6

2

3

4

Grøn lysdiode lyser konstant Forbindelse etableret

Rød lysdiode blinker langsomt fem gange Forsøg på tilslutning mislykkedes, se afsnittet Fejlfinding.

Tab. 2: Mønstre for blinkende lysdioder på CCM

4.3 Air Dial

Air Dial har en integreret temperaturføler. For at sikre bedst mulig ydeevne skal Air Dial placeres i henhold til følgende retningslinjer:

• Placer Air Dial 80-150 cm over gulvet.

• Placer Air Dial væk fra gardiner osv.

• Placer Air Dial, hvor temperaturen er repræsentativ.

• Placer ikke Air Dial på badeværelser.

• Air Dial må ikke placeres i direkte sollys.

• Air Dial må ikke placeres på en ydervæg.

• Air Dial må ikke placeres direkte over en varmekilde.

Air Dial Link Test

Inden Air Dial monteres permanent, skal der udføres en linktest for at sikre, at sendeforholdene er tilstrækkelige for den nødvendige

placering:

1. Tryk på Air Dial-knappen i 5 sekunder for at få adgang til Servicemenuen(Servicemenuen er synlig i en time).

2. Vælg funktionen Link Test.

3. Funktionen viser, om sendeforholdene er tilstrækkelige.

4. Hvis link testen ikke lykkes, skal du se fejlfinding.

20 | © Danfoss | FEC | 2019.06

VIEWB401

Page 21

Installationsvejledning Danfoss Air ventilationsanlæg

2

2

1

?

3

Tilføj service-enhed

Start registrering

Klik her for at tilføje

CCM-modulet til Air-enheden

4.4 Montering og afmontering af CCM-modul og Air Dial

CCM Module

Montering:

1. Placer CCM-modulet på vægbeslaget.

2. Tryk nedad for at klikke CCM på plads.

Afmontering:

1

1. Tryk de to paler på siden ind.

2. Træk CCM opad.

Air Dial

Montering:

1. Placer Air Dial på vægbeslaget.

2. Tryk nedad for at klikke Air Dial på plads.

Afmontering:

1

1. Løft Air Dial op.

2. Træk Air Dial væk.

5 Tilslutning til Danfoss Link™ CC

5.1 Tilslutning af Air-enheden til Danfoss Link™ CC, fysisk installation

1. Slut forsyningsledningen m til Air-enheden l.

2. Tilslut CCM-kablet k mellem CCM-modulet j og Air-enheden.

3. Hvis det er muligt, skal CCM-modulet placeres tæt på en ethernet-forbindelse for senere tilslutning til en PC.

4. Hvis der findes tilbehør (elforvarme, eleftervarme, vandvarmeflade eller geotermisk flade) skal

lusen på klemme n og o ernes (se også vejledningen, der følger med tilbehøret).

5. Air-enheden er nu klar til at blive tilføjet til Danfoss Link™ CC.

2

1

1

2

3

4

5

6

2

1

4

DK

1

2

3

Stik på CCM-kablet:

1. Hvid/orange, 2. Orange, 3. Sort, 4. Hvid/blå, 5. Blå, 6. Sort

Bemærk! CCM-kablet kan forlænges til op til 200 m. Brug skærmet kabel på 22 eller 24 AWG med 2 x parsnoet.

5.2 Tilslutning af Air-enheden til Danfoss Link™ CC, trådløs tilslutning

Bemærk!

Bemærk! Under installation må afstanden mellem Danfoss Link™ CC og

CCM ikke overstige 1,5 meter.

Grøn lysdiode blinker langsomt CCM-modulet er endnu ikke tilsluttet til Danfoss Link™ CC

Grøn lysdiode lyser konstant CCM-modulet er nu tilsluttet til Danfoss Link™ CC

Rød lysdiode blinker langsomt fem

gange

Tab. 2: Mønstre for blinkende lysdioder på CCM

• Fjern frontpanelet på Danfoss Link™ CC ved forsigtigt at trække det af. Træk nær kanterne af panelet.

• Tryk på knappen Setup i tre sekunder for at åbne serviceområdet.

• Air-enheden skal tilføjes til netværket som en serviceenhed. For yderligere vejledning om netværkstilslutning, se den medfølgende installationsvejledning til Danfoss Link™ CC.

• Tilføj eventuelle dedikerede repeater-enheder (CF-RU) FØR tilføjelse af Air-enheden til det trådløse netværk.

Service-funktioner

1

Rum og enheder

?

Rum og enheder

2

Tilføj service-enhed

?

Forsøg på tilslutning mislykkedes

VIEWB401

© Danfoss | FEC | 2019.06 | 21

Page 22

Installationsvejledning Danfoss Air ventilationsanlæg

Systemindstillinger

5.3 Udførelse af en netværkstest efter tilføjelse af en ny enhed

Efter færdiggørelsen af installationen skal der udføres en netværkstest for at sikre, at kommunikationen mellem alle tilføjede enheder og

Danfoss Link CC™ er stabil.

Bemærk! Udfør ikke netværkstesten, før Danfoss Link™ CC er monteret på sin endelige placering.

Service-funktioner

1

Status og fejlfinding

Status og fejlfinding

2

Netværk

?

?

Status for trådløst netværk

3

Start netværkstest

?

Ved afslutningen af netværkstesten afventer Danfoss Link™ CC, at alle batteridrevne enheder aktiveres og registreres. Følg anvisningerne på skærmen. Hvis netværkstesten kører uden problemer, vil der ikke være behov for yderligere interaktion. Hvis netværkstesten kører langsomt, guider

Danfoss Link™ CC dig gennem fejlfinding og giver nyttige tips til, hvordan processen gøres hurtigere.

5.4 Indstilling af grundtrin i Danfoss Link™ CC

Nu er Air-enheden tilføjet til det trådløse system og er klar til afbalancering af luftstrømningen. Hvis Air-enheden netop er blevet tilføjet til

systemet, vil skærmen anmode om indstilling af grundtrin for udsugnings- og indblæsningsluft.

Hvis systemet blev startet tidligere/af andre, indtastes de grundlæggende indstillinger ved hjælp af Servicemenuen ved at trykke på Air

Dial-knappen i 5 sekunder. Gennemgå følgende trin.

Service-funktioner

1

Rum og enheder

Rum og enheder

2

Håndter enheder

?

?

Håndter enheder

3

Konfigurer enhed

?

Vælg Enhed

4

Ventilationsanlæg

?

Konfigurer Enhed

5

Systemindstillinger

?

6 Afbalancering af hovedluftmængden

For at opnå den bedst mulige ydeevne er det afgørende, at hovedluftmængderne indreguleres (dette

vil bidrage til at beskytte huset mod svamp og råd). Systemet bør ikke indreguleres ved udetemperaturer under -3 °C, da det vil gå i frostbeskyttelsestilstand (angives ved et blinkende ikon på displayet). Hvis

indregulering er nødvendig ved udelufttemperaturer under -3 °C, skal strømforsyningen ernes i 20

sekunder for at deaktivere frostbeskyttelsen i 90 minutter.

Bemærk! Luk alle døre, og sluk for emhætten.

1. Fjern frontpanelet fra enheden ved at trække i håndtagene.

2. Se tegningen af kanalsystemet, hvor du finder de foreslåede forindstillingsværdier for alle

luftventiler. Luk ventilerne helt, og drej dem derefter hele omdrejninger rundt mod „åben“

(antal omdrejninger som angivet på tegningen af kanalsystemet). Ved indregulering af

systemer hvor Danfoss ikke har dimensioneret kanalsystemet, indstilles indblæsnings- og

udsugningsventiler iht. den projekteringsansvarliges anvisninger.

3. Hvis der indgår spjæld i systemet, åbnes disse helt.

4. Monter måleslanger mellem enhedens målepunkter på udsugningssiden og differenstrykmåleren.

6

Juster basistrin

?

Måling af udsugning

22 | © Danfoss | FEC | 2019.06

VIEWB401

Page 23

Installationsvejledning Danfoss Air ventilationsanlæg

450

325

1263

450

325

5. Find den påkrævede gennemstrømning på systemdiagrammet (klistermærke på fronten)

med den tilsvarende differenstrykværdi. Hvis trykket er for lavt, reguleres ventilatortrinet

op, indtil det ønskede tryk opnås.

6. Flyt måleslangerne til målepunkterne på indblæsningssiden, og benyt samme fremgangsmåde for indstilling af indblæsningsluften.

7. Når hovedluftmængderne er indreguleret, skal der foretages en indregulering på de enkelte ventiler. Dette vil i de fleste tilfælde medføre mindre ændringer på de valgte grundtrin,

men dette kan gøres i rummet vha. regulering af ventilerne eller ved at bruge Air Dial til at

finjustere grundtrinnene.

DK

Justering af et system i drift

1. Tryk på Air Dial i 5 sekunder for at få adgang til servicemenuen.

2. Tryk på „Basistrin“ for at aktivere den specielle indreguleringstilstand (hvor alle udefrakommende

påvirkninger blokeres – installatøren styrer udsugnings- og indblæsningsventilatoren helt med 1-100 % ventilatorhastighed).|| Servicemenuen vil forblive synlig i en time, hvorefter den vil forsvinde.

Måling af indblæsning

7 Servicemenu

Tryk på Air Dial i 5 sekunder for at få adgang til Servicemenuen for at ændre grundlæggende indstillinger, såsom

sprog, filtertimer, grundtrin osv.

Nulstilling af system

1. Hvis systemet allerede er indreguleret, skal ventilatorgrundtrinene noteres til senere brug. Værdierne kan

findes i Servicemenuen: Service > Info > Basistrin.

2. Fjern og isæt batterierne til Air Dial igen, mens der trykkes på knappen, indtil der høres et bip. Air Dial

befinder sig nu i opstartstilstand.

3. Fjern forsynings- eller CCM-kablet.

4. Mens kablet tilsluttes igen, trykkes der på CCM-modulknappen, indtil den grønne lysdiode blinker.

5. Systemet er nu nulstillet til fabriksindstillingerne.

8 Tekniske specifikationer

Service

Tilbage

Info

Filter

Sprog

Basis trin

Link test

Tilbehør

8.1 a²-enhed

Dimensioner

160

Set forfra (uden frontpanel)

VIEWB401

177

1180

3

4

4

1

5

3

6

1

600

2

j Filter, udsugning fra rum

2

6

5

k Filter, indblæsning

l Flowdiagram (til indregulering)

m Reset-knap til filter

n Differenstrykudtag for udsugning fra rum

580

177

j Udeluft

k Afkastluft

l Udsugning fra rum

m Indblæsning

Enhedens vægt: 52 kg

o Differenstrykudtag for indblæsning til rum

© Danfoss | FEC | 2019.06 | 23

Page 24

Installationsvejledning Danfoss Air ventilationsanlæg

350

300

250

200

150

100

0 50 100 150 200 250 300 350

400 450

94%

0 50 100 150 200 250 300

Kapacitet

Eksternt tryk [Pa]

*0.45 W/m³/h

1000 J/m³

100%

50

0

33%

21%

85%

70%

58%

46%

Virkningsgrad

η [%]

93%

92%

91%

90%

89%

88%

87%

86%

85%

84%

83%

Luftmængde [m³/h]

* 0.45 W/m³/h = „Passiv Haus“-krav

Luftmængde [m³/h] Pext. [Pa] SEL [J/m³] P1 tot. [W]

160 50 615 27

220 70 728 44

220 100 854 52

260 70 783 57

260 100 894 65

300 90 936 78

Tab. 3: Kapacitet for a²-enhed

Udsugning fra rum Udeluft

t = 21 °C RH = 36% t = -3 °C RH = 80% med kondens og 5 % ubalance

t = 20 °C RH = 38% t = 7 °C iht. EN13141-7 (tør)

Tab. 4: Luftkonditioner for virkningsgrader for a²-enheden

Luftmængde [m³/h]

Luft-

mæng-

de m³/h

162 70

162 100

216 70

216 100

250 100

* Værdier for lydtryk beregnet for et standardrum med A = 10 m², H = 2,4 m og gennemsnitlig dæmpning 0,2.

Tab. 5: Lyddata for a²-enhed

24 | © Danfoss | FEC | 2019.06

Tryk

[Pa]

Frekvensbånd [Hz], lydeffekt Lw (A) [dB(A)] Lydtryk Lp(A)

Målt ved:

Indblæsningskanal

Udsugningskanal

63 125 250 500 1000 2000 4000 8000

23 34 40 36 29 25 17 18

23 33 39 37 29 24 18 18

(standard* rum)

[dB(A)]

Kabinet 40

Indblæsning-

skanal

Udsugning-

skanal

25 35 43 38 31 28 18 18

25 36 42 39 30 25 17 18

Kabinet 41

Indblæsning-

skanal

Udsugning-

skanal

26 36 44 39 33 30 19 18

28 36 43 41 34 29 18 18

Kabinet

Indblæsning-

skanal

Udsugning-

skanal

26 37 44 40 34 31 19 18 45

27 37 45 42 35 30 19 18

Kabinet

Supply air

duct

Indblæsning-

skanal

28 39 46 42 37 33 21 18 46

30 39 48 45 38 33 20 18

Kabinet 49

VIEWB401

Page 25

Installationsvejledning Danfoss Air ventilationsanlæg

440

528

1342

780

440

300

250

200

150

100

0 50 100 150

200 250 300

350 400

450 500

550 600

80%

81%

82%

83%

84%

85%

86%

87%

88%

89%

90%

0 50 100 150 200 250 300 350 400 450 500

8.2 a³-enhed

Dimensioner

250

318

3

4

160

1180

1

600

2

Set forfra (uden frontpanel)

528

k Afkastluft

j Udeluft

DK

l Udsugning fra rum

318

160

m Indblæsning

Enhedens vægt: 67 kg

4

1

5

6

6

3

5

j Filter, udsugning fra rum

2

k Filter, indblæsning

l Flowdiagram (til indregulering)

m Reset-knap til filter

n Differenstrykudtag for udsugning fra rum

o Differenstrykudtag for indblæsning til rum

Kapacitet

Eksternt tryk [Pa]

*0.45 W/m³/h

1000 J/m³

50

0

56%

40%

100%

82%

Virkningsgrad

η [%]

Luftmængde [m³/h]

* 0.45 W/m³/h = “Passiv Haus”-krav

Luftmængde [m³/h] Pext. [Pa] SEL [J/m³] P1 tot. [W]

200 70 787 44

350 70 835 81

450 70 973 122

350 100 1000 97

Tab. 6: Kapacitet for a³-enhed

Luftmængde [m³/h]

Tab. 7: Luftkonditioner for virkningsgrader for a³-enhed

VIEWB401

Udsugning fra rum Udeluft

t = 21 °C RH = 36% t = -3 °C RH = 80% med kondens og 5 % ubalance

t = 20 °C RH = 38% t = 7 °C iht. EN131417-7 (tør)

© Danfoss | FEC | 2019.06 | 25

Page 26

Installationsvejledning Danfoss Air ventilationsanlæg

0 50 100 150 200

250 300

84%

85%

86%

87%

88%

89%

90%

91%

92%

93%

0 50 100 150 200 250

530

160

Luft-

mæng-

de m³/h

350 70

Tryk

[Pa]

Målt ved:

Indblæsningskanal

Udsugningskanal

63 125 250 500 1000 2000 4000 8000

35 45 56 49 47 44 31 16

35 44 54 48 48 44 31 19

Frekvensbånd [Hz], lydeffekt Lw (A) [dB(A)] Lydtryk Lp(A)

Kabinet 57

450 100

Indblæsningskanal

Udsugningskanal

39 48 62 55 52 50 37 22

39 47 61 55 53 48 37 20

Kabinet 61

* Værdier for lydtryk beregnet for et standardrum med A = 10 m², H = 2,4 m og gennemsnitlig dæmpning 0,2.

Tab. 8: Lyddata for a³-enhed

8.3 w¹ enhed

6

7

89

10

98

1005

125

5

1

2

287

438

430

224

125

161

3

4

108

254

296

j Indblæsning

k Udsugning fra rum

l Afkastluft

m Udeluft

n Kondensafløb

o Filter, udsugning fra rum

p Filter, indblæsning

q Differenstrykudtag for udsugning fra rum

r Differenstrykudtag for indblæsning til rum

s Reset-knap til filter

Enhedens vægt: 31 kg

(standard* rum)

[dB(A)]

Kapacitet

Eksternt tryk [Pa]

350

300

250

200

150

100

50

0

*0.45 W/m³/h

1000 J/m³

70%

58%

46%

33%

21%

* 0.45 W/m³/h = “Passiv Haus”-krav

Luftmængde [m³/h] Pext. [Pa] SEL [J/m³] P1 tot. [W]

100 35 588 16

100 55 682 19

140 60 710 28

140 70 759 30

180 70 798 40

180 100 945 47

Tab. 9: Kapacitet for w¹-enhed

Udsugning fra rum Udeluft

t = 21 °C RH = 52% t = 5 °C RH = 80% med kondens og 5 % ubalance

t = 20 °C RH = 38% t = 7 °C iht. EN13141-7 (tør)

Tab. 10: Luftkonditioner for virkningsgrader for w¹-enheden

26 | © Danfoss | FEC | 2019.06

100%

85%

Luftmængde [m³/h]

Virkningsgrad

η [%]

Luftmængde [m³/h]

VIEWB401

Page 27

Installationsvejledning Danfoss Air ventilationsanlæg

Luft-

mæng-

de m³/h

126 70

126 100

162 70

162 100

216 70

216 100

* Værdier for lydtryk beregnet for et standardrum med A = 10 m², H = 2,4 m og gennemsnitlig dæmpning 0,2.

Tab. 11: Lyddata for w¹-enheden

Tryk

[Pa]

Målt ved:

Indblæsningskanal

Udsugningskanal

Kabinet 47

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 50

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 53

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 55

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 57

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 56

63 125 250 500 1000 2000 4000 8000

20 30 41 42 38 30 19 18

18 30 41 41 30 26 18 18

22 32 46 45 39 32 21 18

22 33 43 42 32 27 19 18

23 31 43 46 41 33 22 18

26 31 42 43 33 29 21 18

28 33 44 48 43 35 23 18

29 34 44 51 37 31 23 18

28 33 44 54 46 37 28 18

27 33 43 52 39 33 27 18

28 35 45 55 46 38 29 18

32 34 44 52 40 34 28 18

Frekvensbånd [Hz], lydeffekt Lw (A) [dB(A)] Lydtryk Lp(A)

(standard* rum)

[dB(A)]

DK

VIEWB401

© Danfoss | FEC | 2019.06 | 27

Page 28

Installationsvejledning Danfoss Air ventilationsanlæg

300

250

200

150

100

0 50 100

150 200

250 300

350 400

83%

84%

85%

86%

87%

88%

89%

90%

91%

92%

93%

94%

0 50 100 150 200 250 300

590

8.4 w² enhed

6

9

7

8

98

1055

5

2

1

580

126

3

270

389

4

j Indblæsning

k Udsugning fra rum

l Afkastluft

m Udeluft

n Kondensafløb

10

o Filter, udsugning fra rum

p Filter, indblæsning

q Differenstrykudtag for udsugning fra rum

r Differenstrykudtag for indblæsning til rum

s Reset-knap til filter

110

295

Kapacitet

Eksternt tryk [Pa]

480

*0.45 W/m³/h

1000 J/m³

100%

50

0

46%

33%

21%

85%

70%

58%

Enhedens vægt: 45 kg

Virkningsgrad

η [%]

Luftmængde [m³/h]

* 0.45 W/m³/h = “Passiv Haus”-krav

Luftmængde [m³/h] Pext. [Pa] SEL [J/m³] P1 tot. [W]

160 50 700 31

220 70 832 51

220 100 963 59

260 70 892 64

260 100 996 72

280 90 1000 78

Tab. 12: Kapacitet for w²-enhed

Luftmængde [m³/h]

Udsugning fra rum Udeluft

t = 21 °C RH = 36% t = -3 °C RH = 80% med kondens og 5 % ubalance

t = 20 °C RH = 38% t = 7 °C iht. EN13141-7 (tør)

Tab. 13: Luftkonditioner for virkningsgrader for w²-enheden

28 | © Danfoss | FEC | 2019.06

VIEWB401

Page 29

Installationsvejledning Danfoss Air ventilationsanlæg

Luft-

mæng-

de

m³/h

126 50

162 70

162 100

216 70

216 100

250 100

* Værdier for lydtryk beregnet for et standardrum med A = 10 m², H = 2,4 m og gennemsnitlig dæmpning 0,2.

Tab. 14: Lyddata for w²-enhed

Tryk

[Pa]

Målt ved:

Indblæsningskanal

Udsugningskanal

Kabinet 39

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 44

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 46

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 47

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 49

Indblæsning-

skanal

Udsugning-

skanal

Kabinet 53

63 125 250 500 1000 2000 4000 8000

20 30 34 36 23 19 17 18

16 31 37 36 29 21 17 18

23 33 35 40 32 24 18 18

20 33 44 39 34 26 18 18

25 36 42 42 34 28 18 18

21 33 43 41 35 28 18 18

25 34 42 42 35 28 19 18

22 34 44 43 37 31 20 18

26 36 43 44 36 30 20 18

23 34 45 44 33 32 20 18

27 36 45 45 38 31 21 18

24 37 47 45 40 34 22 18

Frekvensbånd [Hz], lydeffekt Lw (A) [dB(A)]

Lydtryk Lp(A)

(standard* rum)

[dB(A)]

DK

VIEWB401

© Danfoss | FEC | 2019.06 | 29

Page 30

Installationsvejledning Danfoss Air ventilationsanlæg

9 Fejlfinding

Fejl Årsag Løsning

Alarm: Filterfejl Luftfiltre er snavsede. Udskift luftfiltre, og nulstil alarm.

Alarm: Lavt batteriniveau Batterispændingen i Air Dial er for lav. Udskift batterier (4 x AAA) i Air Dial.

Alarm: Ingen forbindelse til CCM/linktest

mislykkedes

Alarm: Ingen forbindelse via modbus/linktest mislykkedes

Alarm: Rumluft for kold Centralvarmesystemet leverer ikke varme.

Alarm: Brandfare En af de fire temperaturfølere i Danfoss

Alarm: Følerfejl En temperaturføler i Danfoss Air-enheden

Unormalt stort undertryk inde i huset, døre

binder

Kondens i vinduesrammer Luftudskiftet er for lavt. Der dannes

Husets temperatur er for høj Husets termostater er indstillet for højt. Skru ned for termostaterne.

Bypass er slået fra på ventilationssystemet Bypass er slået fra på ventilationssystemet. Aktiver bypass i menupunktet Hovedmenu

Kommunikationen mellem Air Dial og

CCMmodulet er mislykkedes. Dette forårsages typisk af en forhindring mellem Air Dial

og CCMmodulet, fx stålrør, andre stålgenstande, el-installationer eller isoleringsmateriale, der er beklædt med aluminiumsfolie

osv. En anden årsag kan være andre trådløse

apparater, som ikke er i overensstemmelse

med trådløse standarder (radiostøj).

Kablet fra CCM-modulet til enheden er

taget ud eller er defekt.

Rumtemperaturen falder, så enheden

slukker for at reducere ufrivilligt varmetab.

Alarm aktiveres, hvis Air Dial måler en rumtemperatur under +10 °C.

Air-enheden eller temperaturføleren i Air

Dial-ernbetjeningen har registreret en

temperatur på mere end +70 °C. Air-enheden slukkes, indtil alle følere angiver en

temperatur på mindre end +70 °C.

eller Air Dial er defekt.

Afkastluftstrømmen er større end indblæsningsluftstrømmen. Enten er indreguleringen af hovedluftmængderne ikke blevet

korrekt udført under opsætningen af systemet, eller Air-enheden er gået i ekstrem

afisningstilstand (kan ske ved udetemperaturer under -12 °C).

kondens, når luftfugtigheden er høj, og

overfladetemperaturen er lav. Dette sker

ofte i badeværelser eller bryggerser, hvor

der dryptørres tøj (en vis kondens i badeværelser efter badning er normalt, men

bør forsvinde inden for en halv time under

normale omstændigheder).

Hvis en forhindring er blevet fundet, skal

den flyttes. Hvis dette ikke er muligt, flyttes

CCM-modulet til en bedre placering med

en fri „sigtelinje“. Hvis fejlen opstår på grund

af andre trådløse apparater i huset, så prøv

på skift at slukke for dem for at finde det

fejlbehæftede apparat. Hvis intet af ovenstående hjælper, bedes du kontakte din

installatør.

Kontroller kablet, og tilslut det om nødvendigt igen. Hvis kablet er tilsluttet, men

der stadig opstår fejl, skal du kontakte din

installatør.

Kontroller, om varmesystemet fungerer.

Hvis problemet ikke kan løses, skal du kontakte din installatør. Når fejlen er udbedret,

skal ventilationssystemet lukkes ned og

genstartes for at genetablere normal drift.

Strømmen kan afbrydes ved at trække

forsyningsledningen ud af systemet.

Undersøg alle rum, forlad bygningen. Når

fejlen er udbedret, skal ventilationssystemet lukkes ned og genstartes for at genetablere normal drift. Strømmen kan afbrydes

ved at trække forsyningsledningen ud af

systemet

Kontakt din installatør.

Systemet kører videre, men med begrænset

funktionalitet.

Ubalancen på hovedluftmængden bør

være 4-10 % i rumudsugningens favør, men

hvis der er et permanent problem med

døre, der binder, skal du kontakte Danfoss.

Hvis problemerne kun opstår under

ekstreme vinterforhold, skyldes det den

indbyggede afisningsfunktion, der reducerer indblæsningsluften (og er således ikke

en defekt, men en forventelig og meget

sjælden hændelse).

Øg ventilatortrinet i Manuel tilstand eller

skift til enten Behov-tilstand eller

Ugeprogram-tilstand.

Slå Autoboost til.

Bypass Auto bypass

30 | © Danfoss | FEC | 2019.06

VIEWB401

Page 31

Installationsvejledning Danfoss Air ventilationsanlæg

Støj fra Air-enheden A-type-enhed: Der kan opstå vibrationsstøj,

hvis enheden er monteret direkte på strøer.

Enheden bør monteres på en passende

platform.

W-type-enhed: Der kan opstå vibrationsstøj, hvis der ikke er monteret gummiafstandsstykker mellem enheden og

væggen, og/eller hvis der ikke er monteret

silikonestrips på vægbeslaget.

Defekte ventilatorkuglelejer vil fremkalde

en „slibelyd“.

Støj fra luftventiler Luftstrømningen er for høj. Støj er ikke et problem i et korrekt dimen-

Trykket er for højt over ventilen.

Der er ikke monteret en lyddæmper på

hovedkanalen.

Frost-ikon på displayet Systemet er i afisningstilstand, da lave ude-

temperaturer medfører risiko for isdannelse

i varmeveksleren.

Kontroller, at enheden er monteret på

en platform i henhold til installationsmanualen.

Kontroller, at gummiafstandsstykker og

silikonestrips er monteret i henhold til

installationsmanualen.

Hvis du har mistanke om, at ventilatorkuglelejet er defekt, skal du kontakte din

installatør.

sioneret og indkørt system. Hvis luftventilerne er lukkede (fx under rengøring), kan

der dog opstå en hvislende lyd.

Dette er ikke en fejl, men en almindelig

tilstand. Funktionen stopper automatisk,

når udetemperaturen stiger.

DK

VIEWB401

© Danfoss | FEC | 2019.06 | 31

Page 32

Installationshandbuch Danfoss Air Units

Inhaltsverzeichnis

1 Sicherheitshinweis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 Vorbemerkungen

3 Installation von Air Units

4 Installation des CCM-Moduls und des Air Dial

4.1 Elektrische Anschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.2 Funkverbindung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3 Air Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.4 Montage und Demontage des CCM-Moduls und des Air Dial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5 Anschluss an den Danfoss Link™ CC

5.1 Verbinden der Air Unit mit dem Danfoss Link™ CC, physische Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Verbinden der Air Unit mit dem Danfoss Link™ CC, drahtlose Einbindung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3 Durchführung eines Netzwerktests nach dem Hinzufügen eines neuen Geräts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.4 Einstellung der Grundschritte im Danfoss Link™ CC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Einregulieren der Gesamtluftmenge

7 Servicemenü

8 Technische Spezifikationen