Danfoss ADAP-KOOL AK-HP 780 Design Manual

Design Guide

Heat pump controller

with oil management

AK-HP 780

ADAP-KOOL® Refrigeration control systems

Contents

1. Introduction ............................................................................. 3

Application .................................................................................................. 3

Principles...................................................................................................... 4

2. Design of a controller ..............................................................7

Module survey ........................................................................................... 8

Common data for modules .................................................................10

Controller ...........................................................................................12

Extension module AK-XM 101A .................................................14

Extension module AK-XM 102A / AK-XM 102B .....................16

Extension module AK-XM 204A / AK-XM 204B .....................18

Extension module AK-XM 205A / AK-XM 205B .....................20

Extension module AK-OB 110 ....................................................22

Extension module AK-OB 101A..................................................23

Extension module EKA 163B / EKA 164B ................................ 24

Power supply module AK-PS 075 / 150 ...................................25

Preface to design ....................................................................................26

Functions ............................................................................................26

Connections ...................................................................................... 27

Limitations ......................................................................................... 27

Design of a compressor and pump control ..................................28

Procedure: ..........................................................................................28

Sketch .................................................................................................. 28

Functions ............................................................................................28

Connections ...................................................................................... 29

Planning table .................................................................................. 31

Length .................................................................................................32

Linking of modules ......................................................................... 32

Determine the connection points ............................................33

Connection diagram ...................................................................... 34

Supply voltage ................................................................................. 35

Ordering ..................................................................................................... 36

3. Mounting and wiring .............................................................37

Mounting ................................................................................................... 38

Mounting of analog output module ........................................ 38

Mounting of extension module on the basic module ....... 39

Wiring .......................................................................................................... 40

4. Conguration and operation ................................................43

Conguration ...........................................................................................45

Connect PC or PDA ......................................................................... 45

Authorization .................................................................................... 46

Unlock the conguration of the controllers ..........................47

System setup ....................................................................................48

Set plant type ................................................................................... 49

Set control of compressors ..........................................................50

Set oil management ....................................................................... 53

Setup control of the pump ..........................................................55

Setup Display .................................................................................... 56

Setup general alarm inputs ......................................................... 57

Setup separate thermostat functions ...................................... 58

Setup separate voltage functions ............................................. 59

Conguration of inputs and outputs .......................................60

Set alarm priorities..........................................................................62

Lock conguration ..........................................................................64

Check conguration .......................................................................65

Check of connections ............................................................................ 67

Check of settings.....................................................................................69

Schedule function .................................................................................. 71

Installation in network .......................................................................... 72

First start of control ................................................................................73

Start control ......................................................................................74

Manual capacity control ............................................................... 75

5. Regulating functions .............................................................77

Suction group ..........................................................................................78

Controlling sensor .........................................................................78

Reference ...........................................................................................79

Capacity control of compressors ...............................................80

Compressor timers ..................................................................81

Capacity distribution methods ........................................... 82

Power pack types – compressor combinations ............83

Load shedding ..........................................................................87

Safety functions ............................................................................... 88

Oil management..............................................................................90

Pump ...........................................................................................................92

General monitoring functions ...........................................................93

Miscellaneous ..........................................................................................94

Appendix A – Compressor combinations and coupling pat-

terns ............................................................................................................. 97

Appendix B - Alarm texts ...................................................................102

2 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

1. Introduction

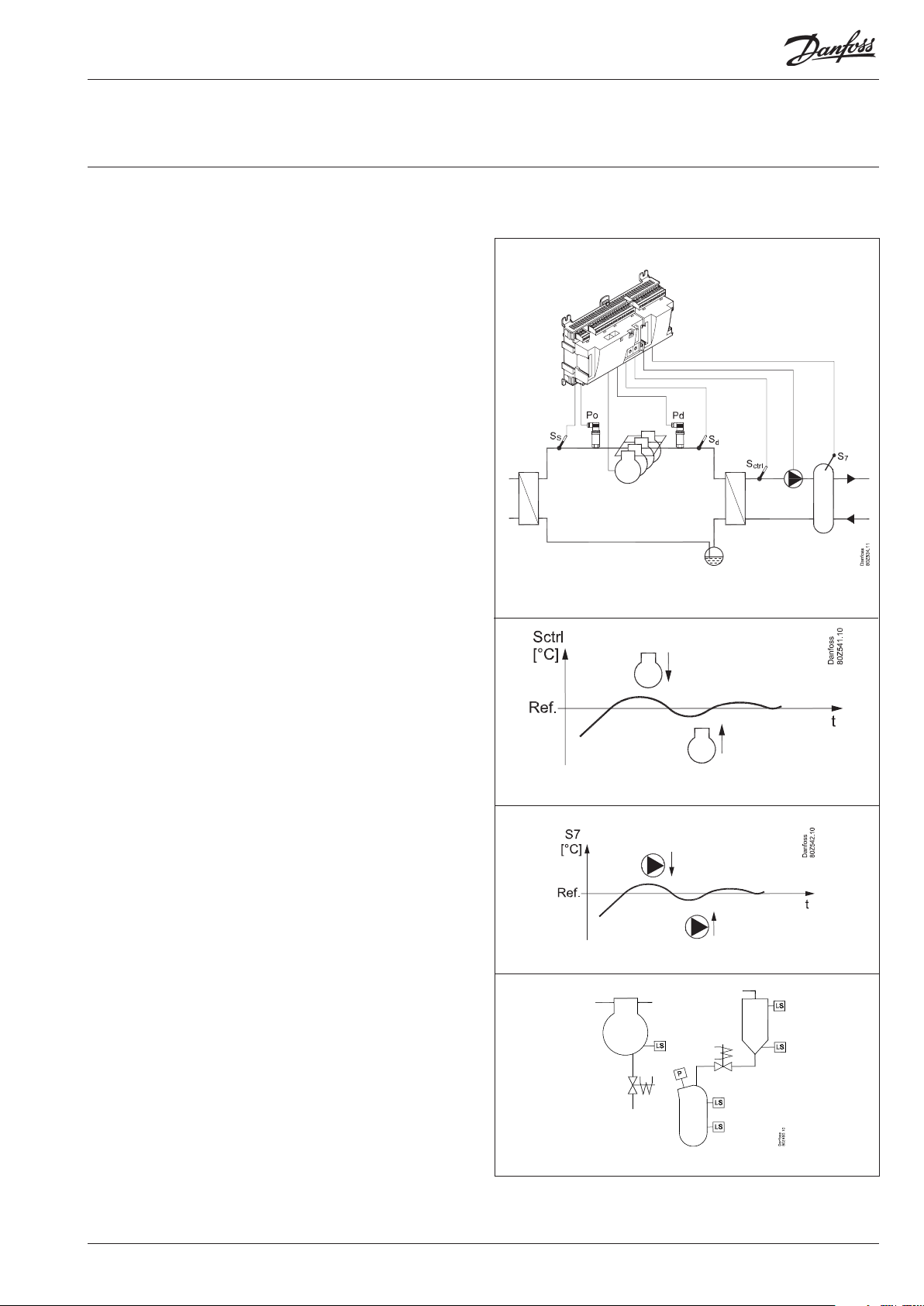

Application

AK-HP 780 is a complete heat pump regulating for capacity

control of compressors and temperature regulating of a receiver.

The controller is with oil management, making it suitable for CO2

plants.

The controller’s main function is to control compressors and

pump, so that operation all the time takes place at the energyoptimum pressure conditions. Both suction pressure and discharge pressure are monitored with the belonging safety function

and alarm function. Capacity control can be carried out by media

temperature Sctrl and S7.

Among the dierent functions are:

- Capacity control of up to 8 compressors

- Up to 3 unloaders for each compressor

- Oil management. Either shared or individual for all of the compressor's oil valves. Receiver pressure control.

- Speed control of one or two compressors

- Up to 6 safety inputs for each compressor

- Option for capacity limitation to minimize consumption peaks

- Safety monitoring of high pressure / low pressure / discharge

temperature

- Capacity control of a pump. Either On/O or speed control

- Safety monitoring of pump ow

- The status of the outputs and inputs is shown by means of lightemitting diodes on the front panel

- Alarm signals can be generated directly from the controller and

via data communication

- Alarms are shown with texts so that the cause of the alarm is

easy to see.

- Plus some completely separate functions that are totally independent of the regulation – such as alarm, thermostat and

pressure control functions, safety functions at cold start up, P0

limitation.

Example

Compressor control

Pump control

Oil management

SW = 1.4x

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 3

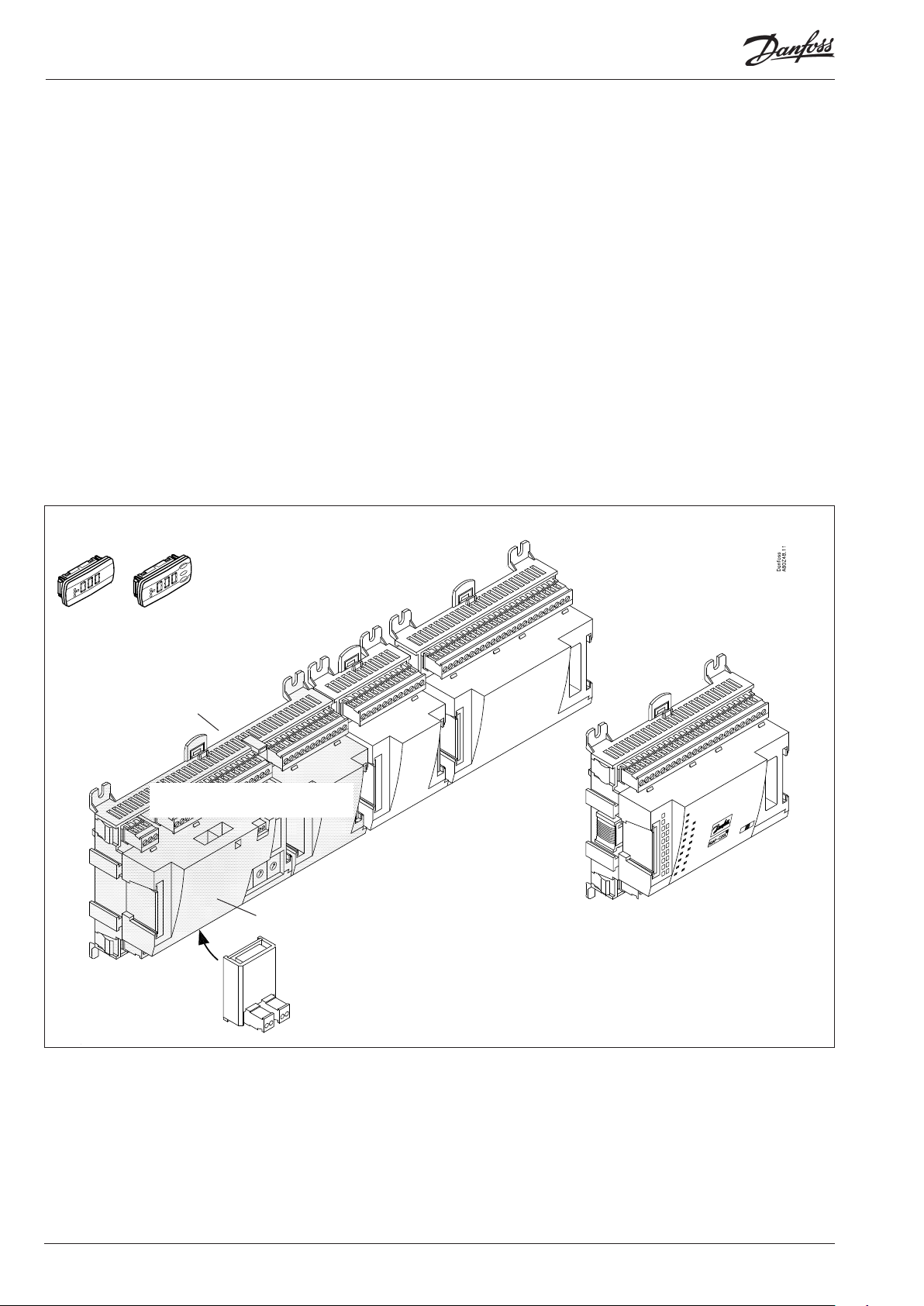

Principles

The great advantage of this series of controllers is that it can be

extended as the size of the plant is increased. It has been developed for heat pump control, but not for any specic application –

variation is created through the read-in software and the way you

choose to dene the connections.

It is the same modules that are used for each regulation and the

composition can be changed, as required. With these modules

(building blocks) it is possible to create a multitude of various

kinds of regulations. But it is you who must help adjusting the

regulation to the actual needs – these instructions will assist you

to nd your way through all the questions so that the regulation

can be dened and the connections made.

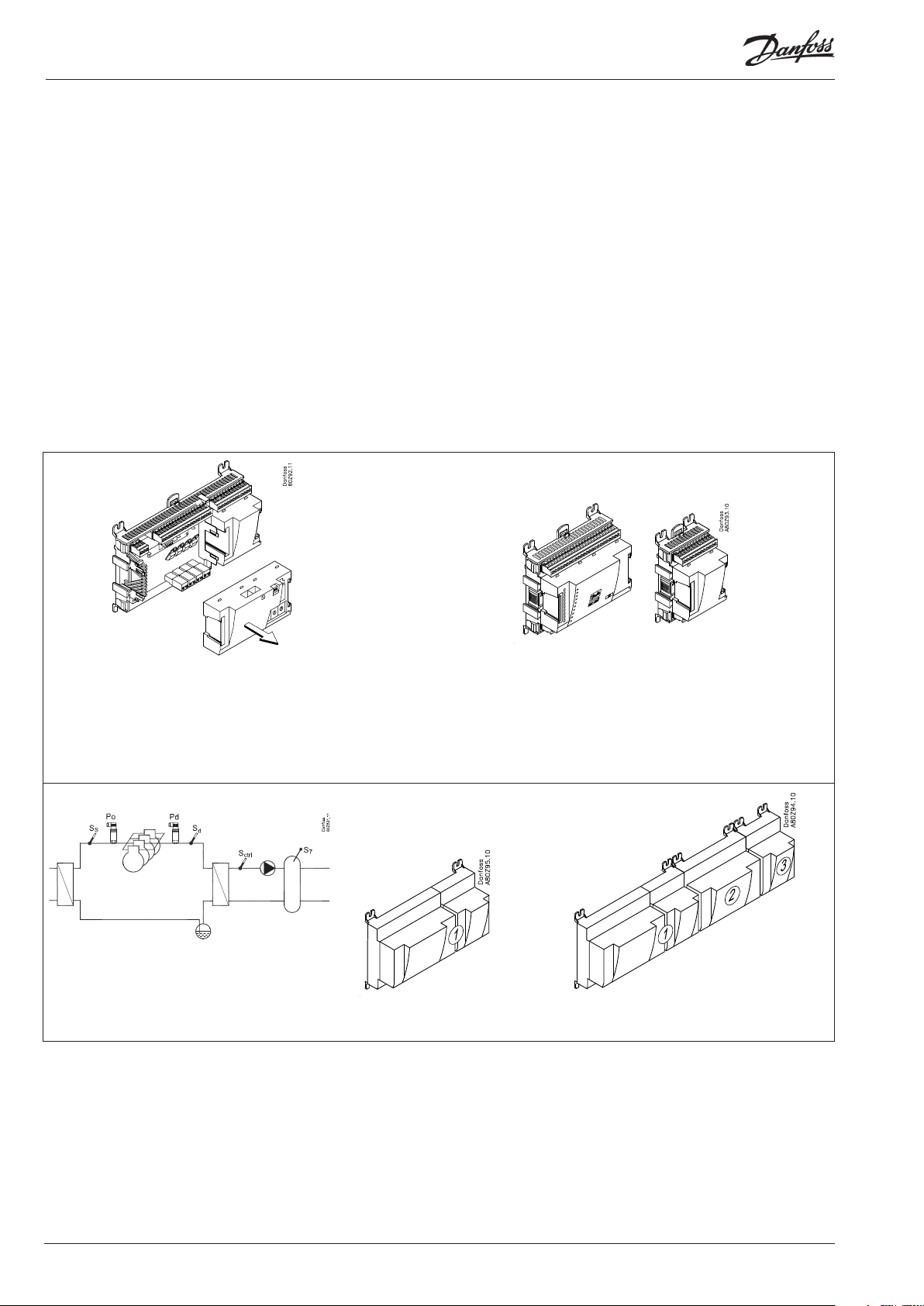

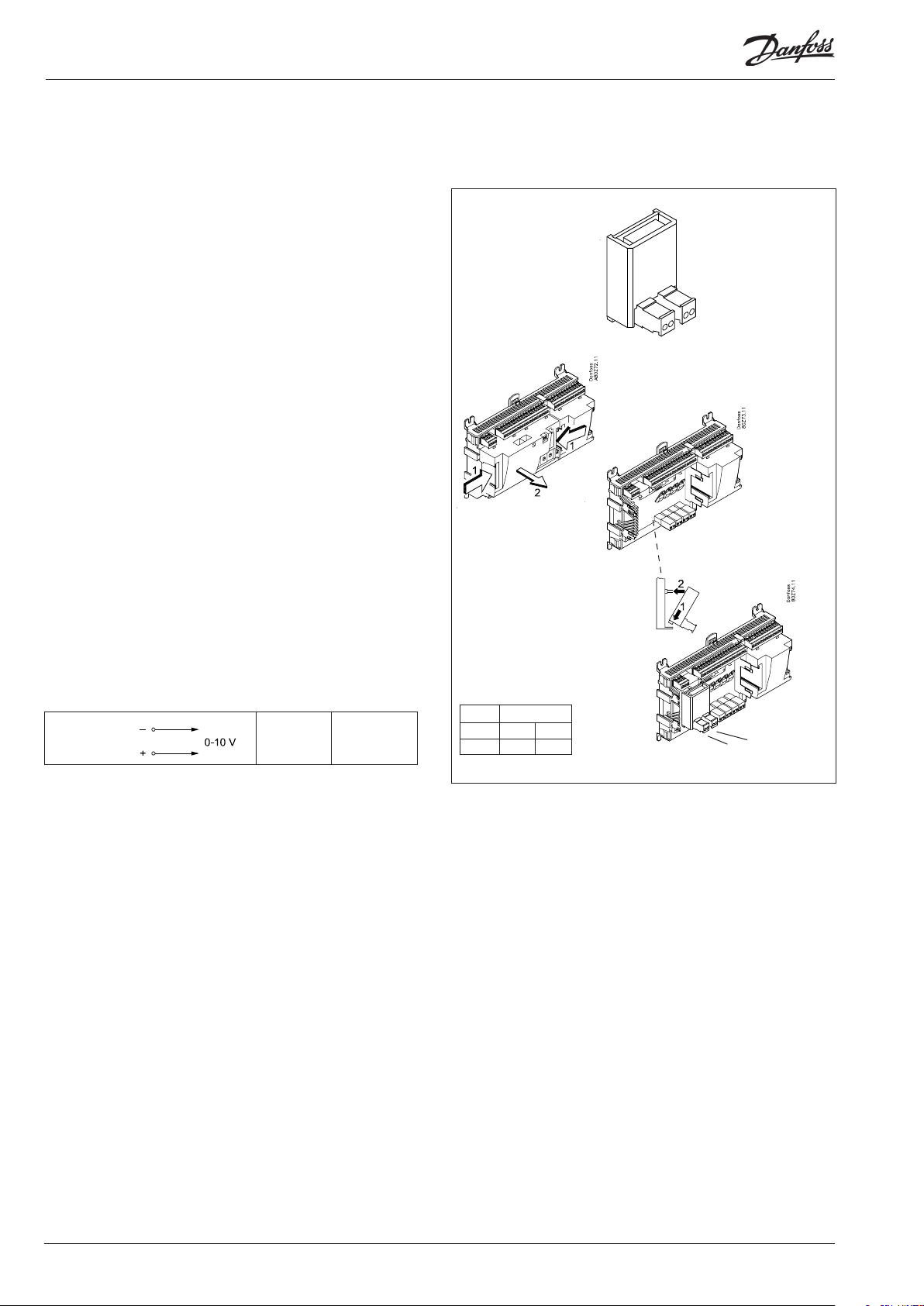

Controller

Top part

Advantages

• The controller’s size can “grow” as systems grow

• The software can be set for one or more regulations

• Several regulations with the same components

• Extension-friendly when systems requirements are changed

• Flexible concept:

- Controller series with common construction

- One principle – many regulation uses

- modules are selected for the actual connection requirements

- The same modules are used from regulation to regulation

Extension modules

Bottom part

The controller is the cornerstone of the regulation. The module has inputs and

outputs capable of handling small systems.

• The bottom part – and hence the terminals – are the same for all controller types.

• The top part contains the intelligence with software. This unit will vary according

to controller type. But it will always be supplied together with the bottom part.

• In addition to the software the top part is provided with connections for data

communication and address setting.

Examples

A regulation with few connections can

be performed with the controller module

alone

If the system grows and more functions have to be controlled, the regulation can be

extended.

With extra modules more signals can be received and more relays cut in and out –

how many of them – and which – is determined by the relevant application.

If there are many connections one or more

extension modules have to be mounted

4 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

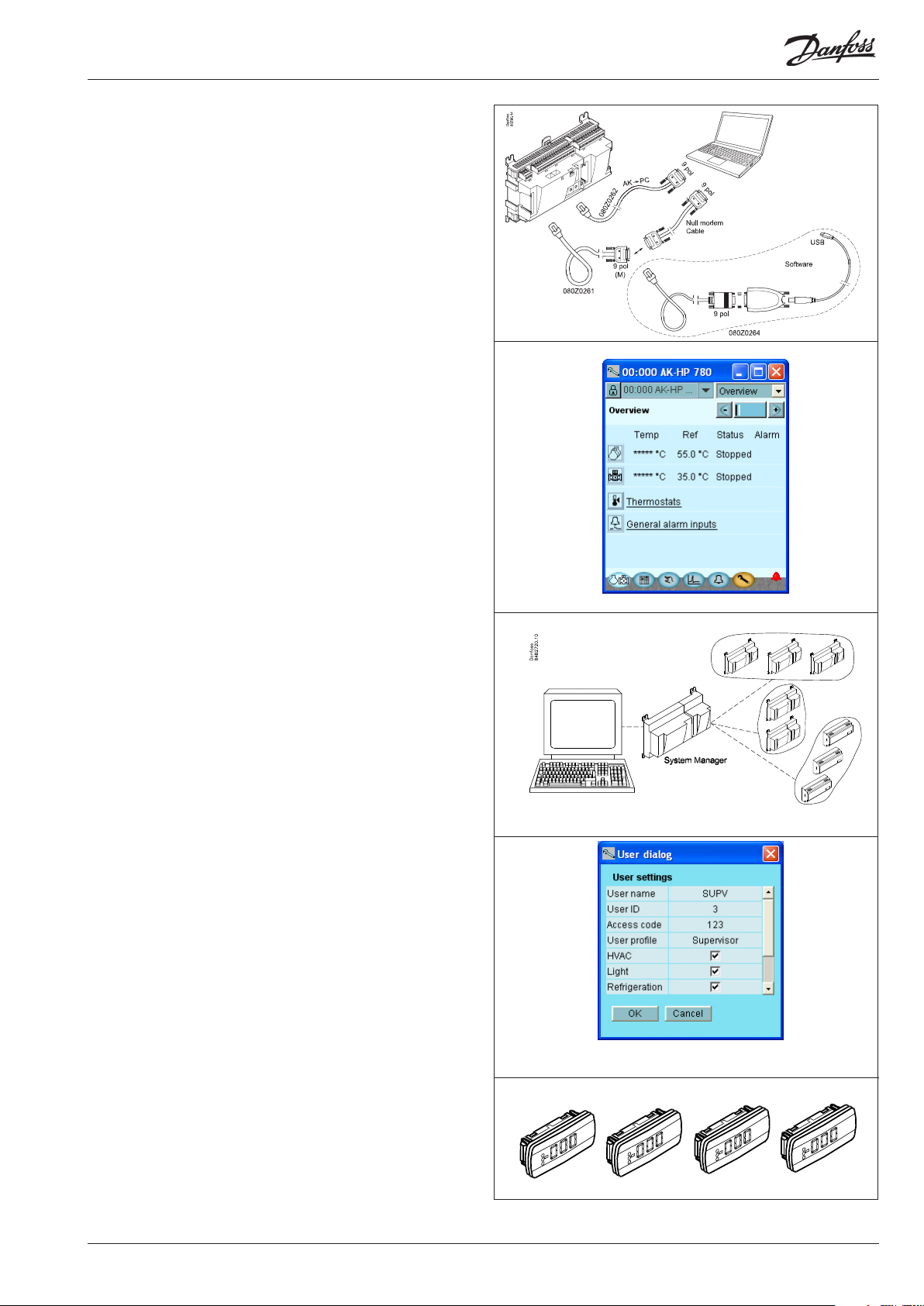

Direct connection

Setup and operation of an AK controller must be accomplished via

the “AK-Service Tool” software program.

The programme is installed on a PC, and setup and operation of

the various functions are carried out via the controller’s menu

displays.

Displays

The menu displays are dynamic, so that dierent settings in one

menu will result in dierent setting possibilities in other menus.

A simple application with few connections will give a setup with

few settings.

A corresponding application with many connections will give a

setup with many settings.

From the overview display there is access to further displays for

the compressor regulation and the pump regulation.

At the bottom of the display there is access to a number of general

functions, such as “time table”, “manual operation”, “log function”,

“alarms”, and “service” (conguration).

Network linking

The controller can be linked up into a network together with other

controllers in an ADAP-KOOL® refrigeration control system. After

the setup operation can be performed at a distance with, say, our

software program type AKM.

Users

The controller comes supplied with several languages, one of

which can be selected and employed by the user. If there are

several users, they may each have their choice of language. All

users must be assigned a user prole which either gives access to

full operation or gradually limits the operation to the lowest level

that only allows you “to see”.

Language selection is part of the service tool settings.

If the language selection is not available in the service tool for the

current regulator, English texts will be displayed.

External display

An external display can be tted in order for S7 (receiver temperature), P0 (suction pressure) and Pd (discharge pressure) readings

to be displayed.

A total of 4 displays can be tted and with one setting it is possible to choose between the following readings: suction pressure,

suction pressure in temperature,, Sctrl, Ss, Sd, discharge pressure,

discharge pressure in temperature and S7.

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 5

Light-emitting diodes

A number of light-emitting diodes makes it possible to follow the

signals that are received and transmitted by the controller.

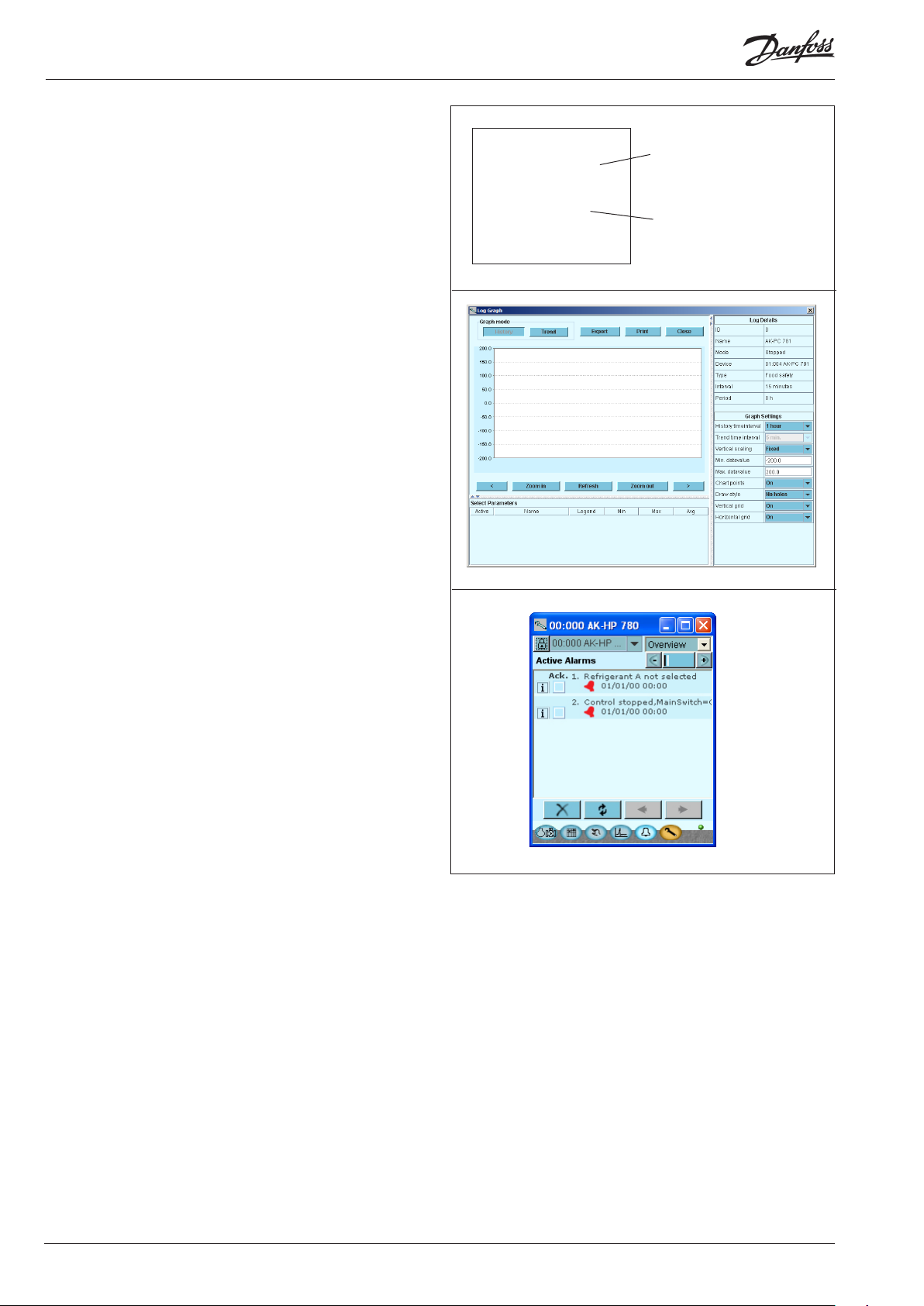

Log

From the log function you can dene the measurements you wish

to be shown.

The collected values can be printed, or you may export them to a

le. You can open the le in Excel.

If you are in a service situation you can show measurements in a

trend function. The measurements are then made real-time and

displayed instantly.

■ Power

■ Comm

■ DO1 ■ Status

■ DO2 ■ Service Tool

■ DO3 ■ LON

■ DO4

■ DO5 ■ Alarm

■ DO6

■ DO7

■ DO8 ■ Service Pin

Slow ash = OK

Quick ash = answer from gateway

Constantly ON = error

Constantly OFF = error

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

Alarm

The display gives you an overview of all active alarms. If you wish

to conrm that you have seen the alarm you can cross it o in the

acknowledge eld.

If you want to know more about a current alarm you can click on it

and obtain an information display on the screen.

A corresponding display exists for all earlier alarms. Here you can

upload information if you need further details about the alarm

history.

6 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

2. Design of a controller

This section describes how the controller is designed.

The controller in the system is based on a uniform connection

platform where any deviations from regulation to regulation is

determined by the used top part with a specic software and

by which input and output signals the relevant application will

require. If it is an application with few connections, the controller

module (top part with belonging bottom part) may be sucient.

If it is an application with many connections it will be necessary to

use the controller module plus one or more extension modules.

This section will give you a survey of possible connections plus

assistance in selecting the modules required by your actual

application.

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 7

Module survey

• Controller module – capable of handling minor plant requirements.

• Extension modules. When the complexity becomes greater

and additional inputs or outputs are required, modules can be

attached to the controller. A plug on the side of the module will

transmit the supply voltage and data communication between

the modules.

• Top part

The upper part of the controller module contains the

intelligence. This is the unit where the regulation is dened and

where data communication is connected to other controllers in a

bigger network.

• Connection types

There are various types of inputs and outputs. One type may, for

example, receive signals from sensors and switches, another may

receive a voltage signal, and a third type may be outputs with

relays etc. The individual types are shown in the table below.

Extension module with

additional analog inputs

• Optional connection

When a regulation is planned (set up) it will generate a need for

a number of connections distributed on the mentioned types.

This connection must then be made on either the controller

module or an extension module. The only thing to be observed

is that the types must not be mixed (an analog input signal must

for instance not be connected to a digital input).

• Programming of connections

The controller must know where you connect the individual

input and output signals. This takes place in a later conguration where each individual connection is dened based on the

following principle:

- to which module

- at which point (”terminals”)

- what is connected (e.g. pressure transmitter/type/

pressure range)

Extension module with additional

relay outputs and additional

analog inputs.

External display for

suction pressure etc.

Bottom part

Controller with analog inputs and

relay outputs.

Top part

Extension module with

2x analog output signals

The module with additional relay outputs is

also available in a version where the top part

is provided with change-over switches so

that the relays can be overridden.

8 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

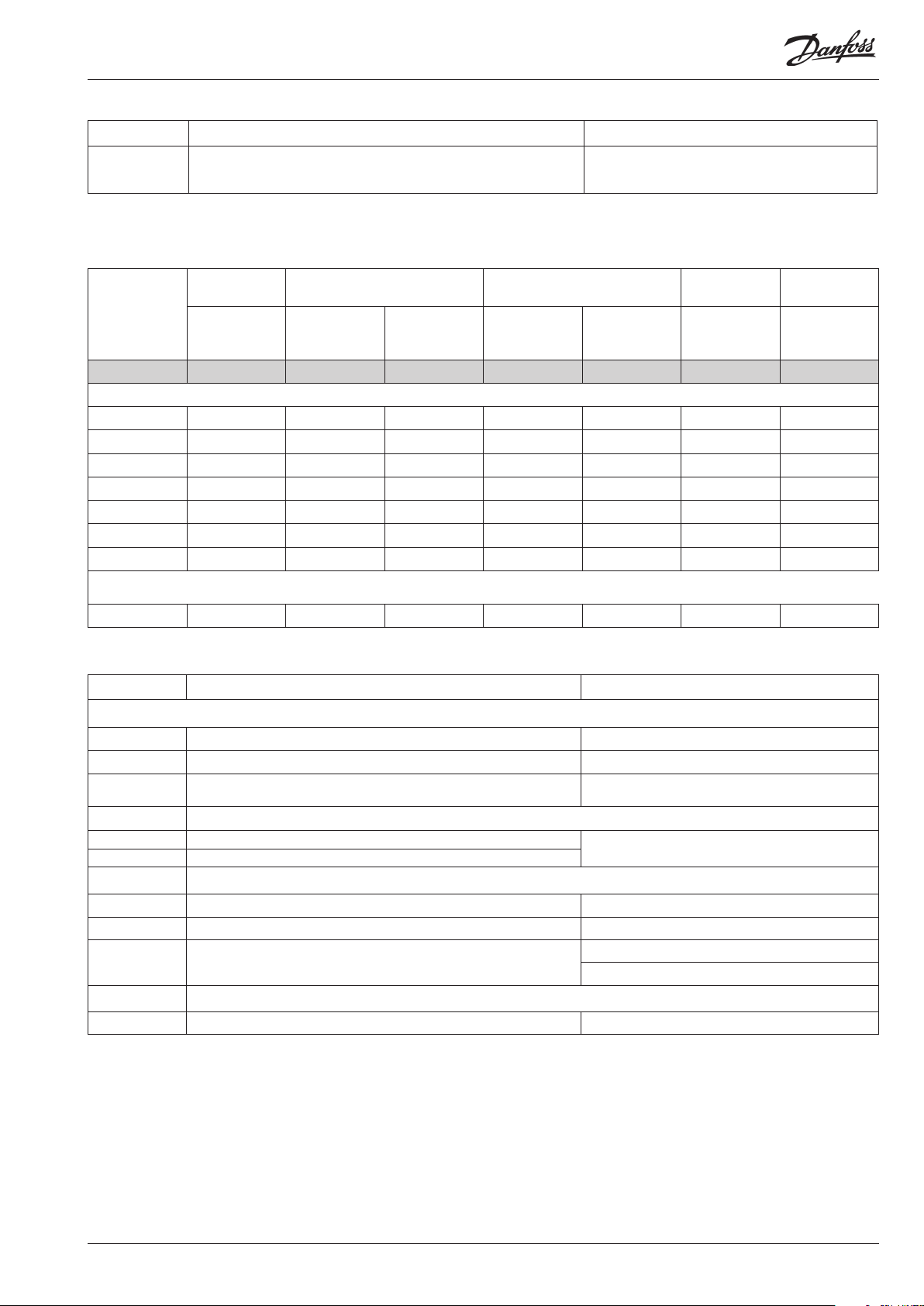

1. Controller

Type Function Application

AK-HP 780 Controller for heat pump control

Capacity control for heat pump operation.

Control of pump for hot water receiver.

Oil management

2. Extension modules and survey of inputs and outputs

Type Analog

inputs

For sensors, pressure transmitters

etc.

Controller 11 4 4 - - - -

Extension modules

AK-XM 101A 8

AK-XM 102A 8

AK-XM 102B 8

AK-XM 204A 8

AK-XM 204B 8 x

AK-XM 205A 8 8

AK-XM 205B 8 8 x

On/O outputs On/o supply voltage

Relay

(SPDT)

Solid state Low voltage

(DI signal)

(max. 80 V)

High voltage

(max. 260 V)

Analog

outputs

0-10 V d.c. For override of

Module with

switches

relay outputs

The following extension module can be placed on the PC board in the controller module. There is only room for one module.

AK-OB 110 2

3. AK operation and accessories

Type Function Application

Operation

AK-ST 500 Software for operation of AK controllers AK-operation

- Cable between PC and AK controller AK - Com port

-

Accessories Power supply module 230 V / 115 V to 24 V d.c.

AK-PS 075 18 VA

AK-PS 150 36 VA

Accessories External display that can be connected to the controller module. For showing, say, the receiver temperature

EKA 163B Display

EKA 164B Display with operation buttons

- Cable between display and controller

Accessories Real time clock for use in controllers that require a clock function, but are not wired with data communication.

AK-OB 101A Real time clock with battery backup. To be mounted in an AK controller

Cable between zero modem cable and AK controller /

Cable between PDA cable and AK controller

AK - RS 232

Supply for controller

Length = 2 m

Length = 6 m

On the following pages there is data specic to each module.

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 9

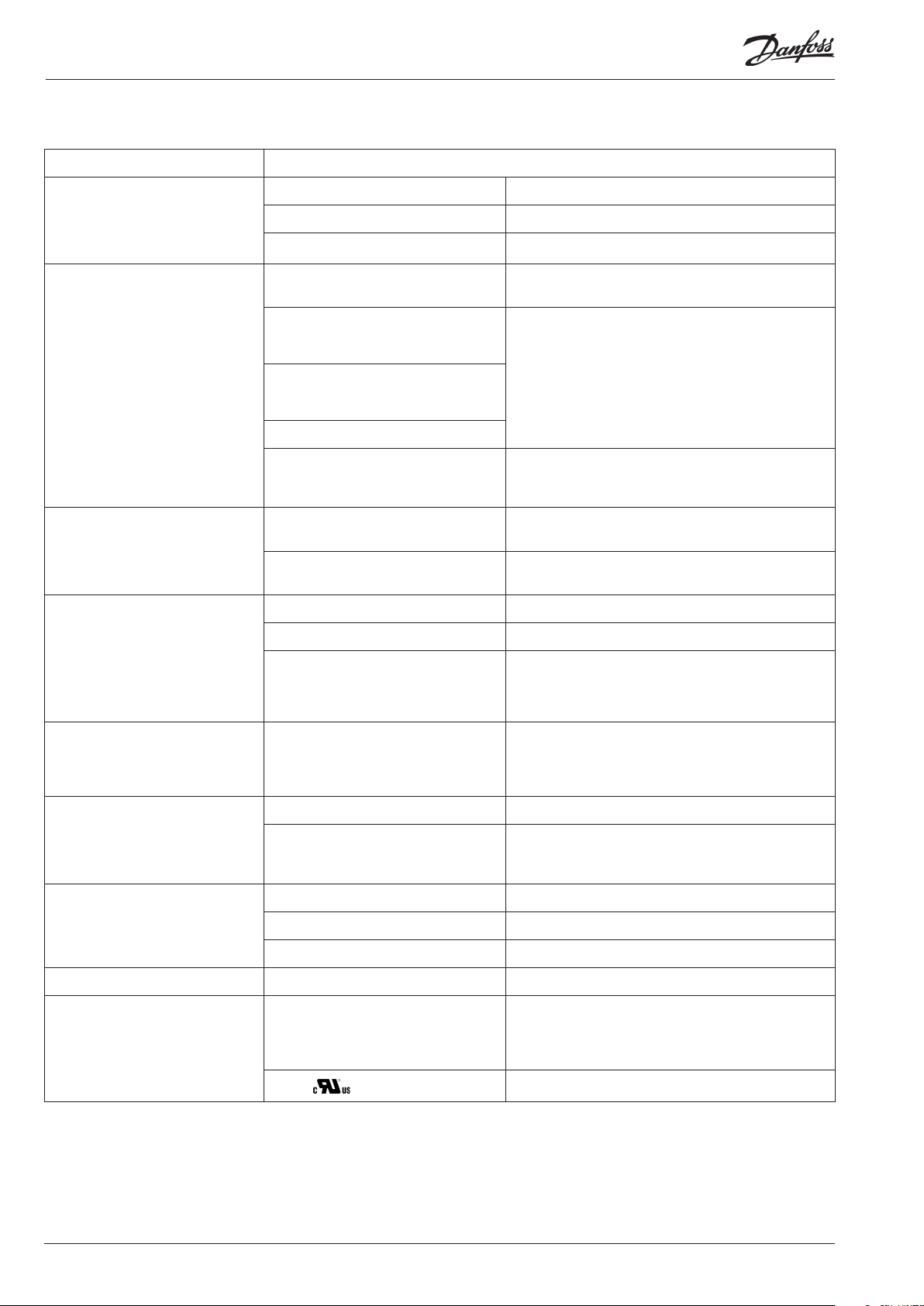

Common data for modules

Supply voltage 24 V d.c./a.c. +/- 20%

Power consumption AK-HP (controller) 8 VA

AK-XM 101, 102, 107 2 VA

AK-XM 204, 205 5 VA

Analog inputs Pt 1000 ohm /0°C Resolution: 0.1°C

Pressure transmitter type AKS 32R / AKS

2050

AKS 32 (1-5 V)

Other pressure transmitter:

Ratiometric signal

Min. and Max. pressure must be set

Voltage signal 0-10 V

Contact function (On/O ) On at R < 20 ohm

On/o supply voltage inputs Low voltage

Relay outputs

SPDT

0 / 80 V a.c./d.c.

High voltage

0 / 260 V a.c.

AC-1 (ohmic) 4 A

AC-15 (inductive) 3 A

U Min. 24 V

Accuracy: +/- 0.5°C

Resolution:1 mV

Accuracy +/- 10 mV

Max. connection of 5 pressure transmitters on one module

O at R > 2K ohm

(Gold -plated contacts not necessary)

O: U < 2 V

On: U > 10 V

O: U < 24 V

On: U > 80 V

Max. 230 V

Low and high voltage must not be connected to the same

output group

Solid state outputs Can be used for loads that are cut in and

out frequently, e.g. :

Oil valves

Ambient temperature During transport -40 to 70°C

During operation -20 to 55°C ,

Enclosure Material PC / ABS

Class IP10 , VBG 4

Mounting For mounting on panel wall or DIN rail

Weight with screw terminals Modules in 100- / 200- / controller-series Ca. 200 g / 500 g / 600 g

Approvals EU low voltage directive and EMC require-

ments are complied with

UL 873,

The mentioned data applies to all modules.

If data is specic, this is mentioned together with the module in question.

Capacitive load

The relays cannot be used for the direct connection of capacitive loads such

as LEDs and on/o control of EC motors.

All loads with a switch mode power supply must be connected with a suitable contactor or similar.

Max. 240 V a.c. , Min. 48 V a.c.

Max. 0,5 A,

Leak < 1 mA

Max. 1 AKV

0 to 95% RH (non condensing)

No shock inuences / vibrations

LVD tested according to EN 60730

EMC tested

Immunity according to EN 61000-6-2

Emission according to EN 61000-6-3

UL le number: E166834

10 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

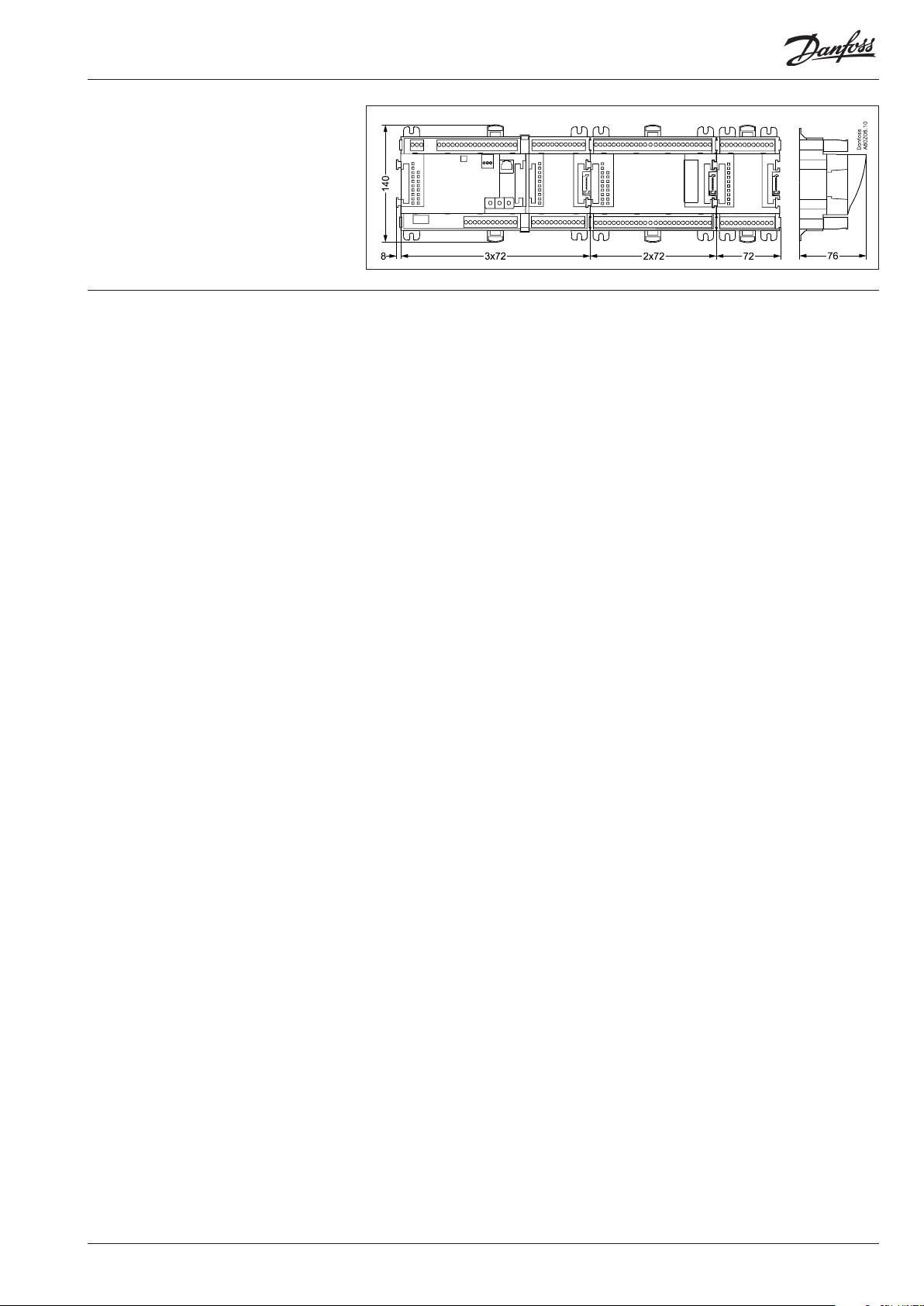

Dimensions

The module dimension is 72 mm.

Modules in the 100-series consist of one

module

Modules in the 200-series consist of two

modules

Controllers consist of three modules

The length of an aggregate unit = n x 72 + 8

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 11

Controller

Function

There are several controllers in the series. The function is

determined by the programmed software, but outwardly the

controllers are identical – they all have the same connection

possibilities:

11 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

8 digital outputs, with 4 Solid state outputs and 4 relay outputs

Supply voltage

24 V a.c. or d.c. to be connected to the controller.

The 24 V must not be retransmitted and used by other controllers

as it is not galvanically separated from inputs and outputs. In

other words, you must use a transformer for each controller. Class

II is required. The terminals must not be earthed.

The supply voltage to any extension modules is transmitted via

the plug on the right-hand side.

The size of the transformer is determined by the power

requirement of the total number of modules.

PIN

The supply voltage to a pressure transmitter can be taken either

from the 5 V output or from the 12 V output depending on

transmitter type.

Data communication

If the controller is to be included in a system, communication

must take place via the LON connection.

The installation has to be made as mentioned in the separate

instructions for LON communication.

Address setting

When the controller is connected to a gateway type AKA 245,

the controller’s address must be set between 1 and 119. (If it is a

system manager AK-SM .., then 1-999).

Service PIN

When the controller is connected to the data communication

cable the gateway must have knowledge of the new controller.

This is obtained by pushing the key PIN. The LED “Status” will ash

when the gateway sends an acceptance message.

Operation

The conguration operation of the controller must take place from

the software programme “Service Tool”. The program must be

installed on a PC, and the PC must be connected to the controller

via the network plug on the front of the unit.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row:

• Software status (slow ash = OK)

• Communication with Service Tool

• Communication on LON

• Alarm when LED ashes

- 3 LED’s that are not used

• “Service Pin” switch has been activated

Address

■ Power

■ Comm

■ DO1 ■ Status

■ DO2 ■ Service Tool

■ DO3 ■ LON

■ DO4

■ DO5 ■ Alarm

■ DO6

■ DO7

■ DO8 ■ Service Pin

Slow ash = OK

Quick ash = answer from gateway

Constantly ON = error

Constantly OFF = error

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

Keep the safety

distance!

Low and high

voltage must not

be connected to

the same output

group

A small module (option board) can be placed on the bottom part

of the controller. The module is described later in the document.

12 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

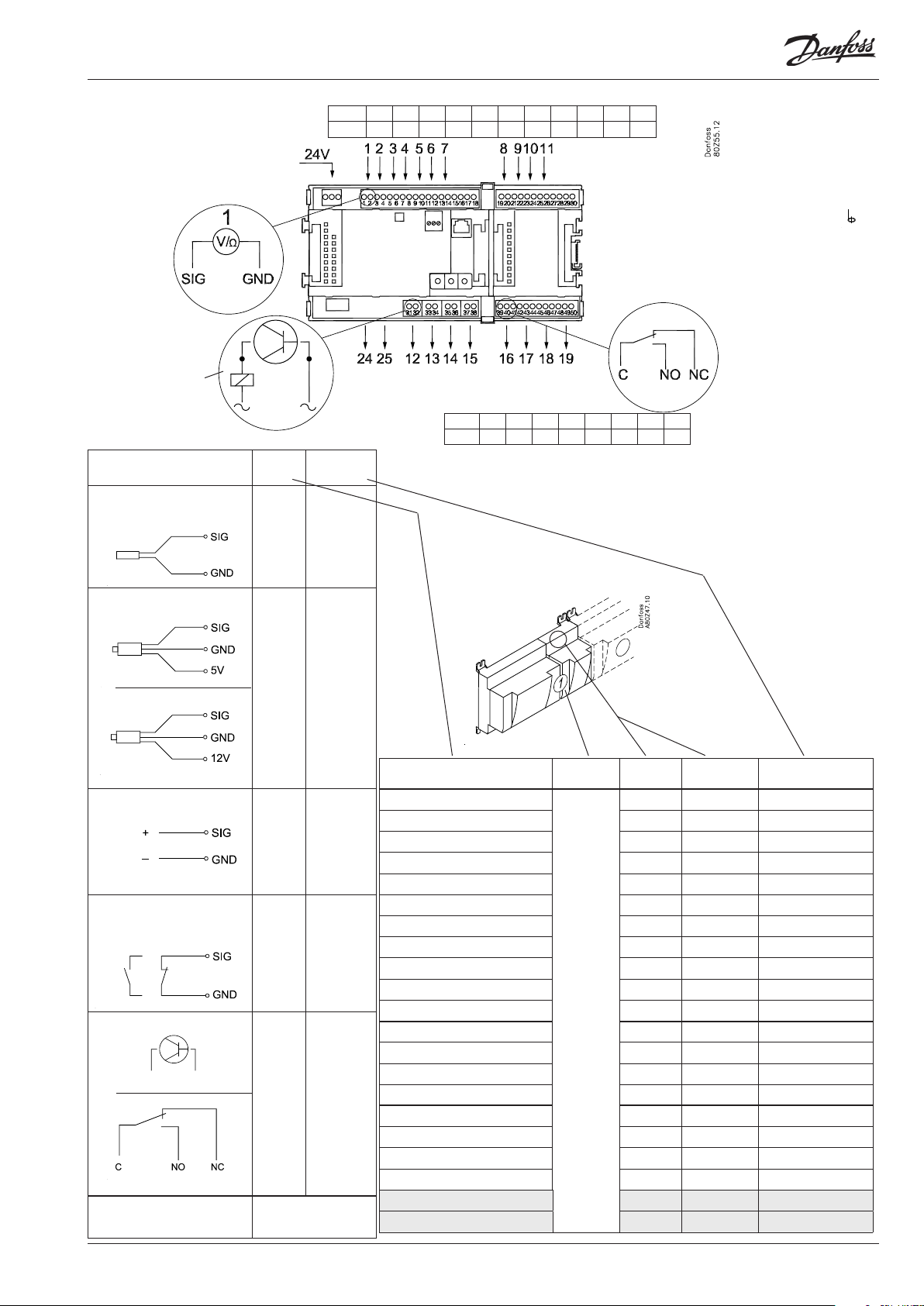

Point

Point 1 2 3 4 5 6 7 8 9 10 11

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8 AI9 AI10 AI11

Terminal 15: 12 V

Terminal 16: 5 V

Terminal 27: 12 V

Terminal 28: 5 V

Analog

inputs

on 1 - 11

Solid state outputs

on 12 - 15

Relay or coil

fx 230 V a.c.

Signal Signal

S

Pt 1000 ohm/0°C

Sctrl

S7

Saux1

Saux2

SS

Sd

P

AKS 32R

3: Brown

2: Blue

1: Black

P0

Pd

Prec.

AKS 32

3: Brown

2: Black

1: Red

U

...

On/O Ext.

Main

switch

Day/

Night

Level

switch

DO

Comp 1

Comp 2

Pump

Alarm

Solenoid

valve

Option Board

Please see the signal

on the page with the

module.

24 and 25 used

only when "Option board tted"

type

Pt 1000

AKS 32R /

AKS 2050

-1 - xx bar

AKS 32

-1 - zz bar

0 - 5 V

0 - 10 V

Active at:

Closed

/

Open

Active at:

On

/

O

Point 12 13 14 15 16 17 18 19

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

Signal Module Point

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 9 - 10

6 (AI 6) 11 - 12

7 (AI 7) 13 - 14

8 (AI 8) 19 - 20

9 (AI 9) 21 - 22

10 (AI 10) 23 - 24

1

11 (AI 11) 25 - 26

12 (DO 1) 31 - 32

13 (DO 2) 33 - 34

14 (DO 3) 35 - 36

15 (DO 4) 37 - 38

16 (DO 5) 39 - 40- 41

17 (DO6) 42 - 43 - 44

18 (DO7) 45 - 46 - 47

19 (DO8) 48 - 49 - 50

24 -

25 -

Terminal

17, 18, 29, 30:

(Cable screen)

Relay outputs on

16 - 19

Terminal

Signal type /

Active at

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 13

Extension module AK-XM 101A

Function

The module contains 8 analog inputs for sensors, pressure

transmitters, voltage signals and contact signals.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

Supply voltage to a pressure transmitter can be taken from either

the 5 V output or the 12 V output depending on transmitter type.

Light-emitting diodes

Only the two top LED’s are used. They indicate the following:

• Voltage supply to the module

• Communication with the controller is active (red = error)

14 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

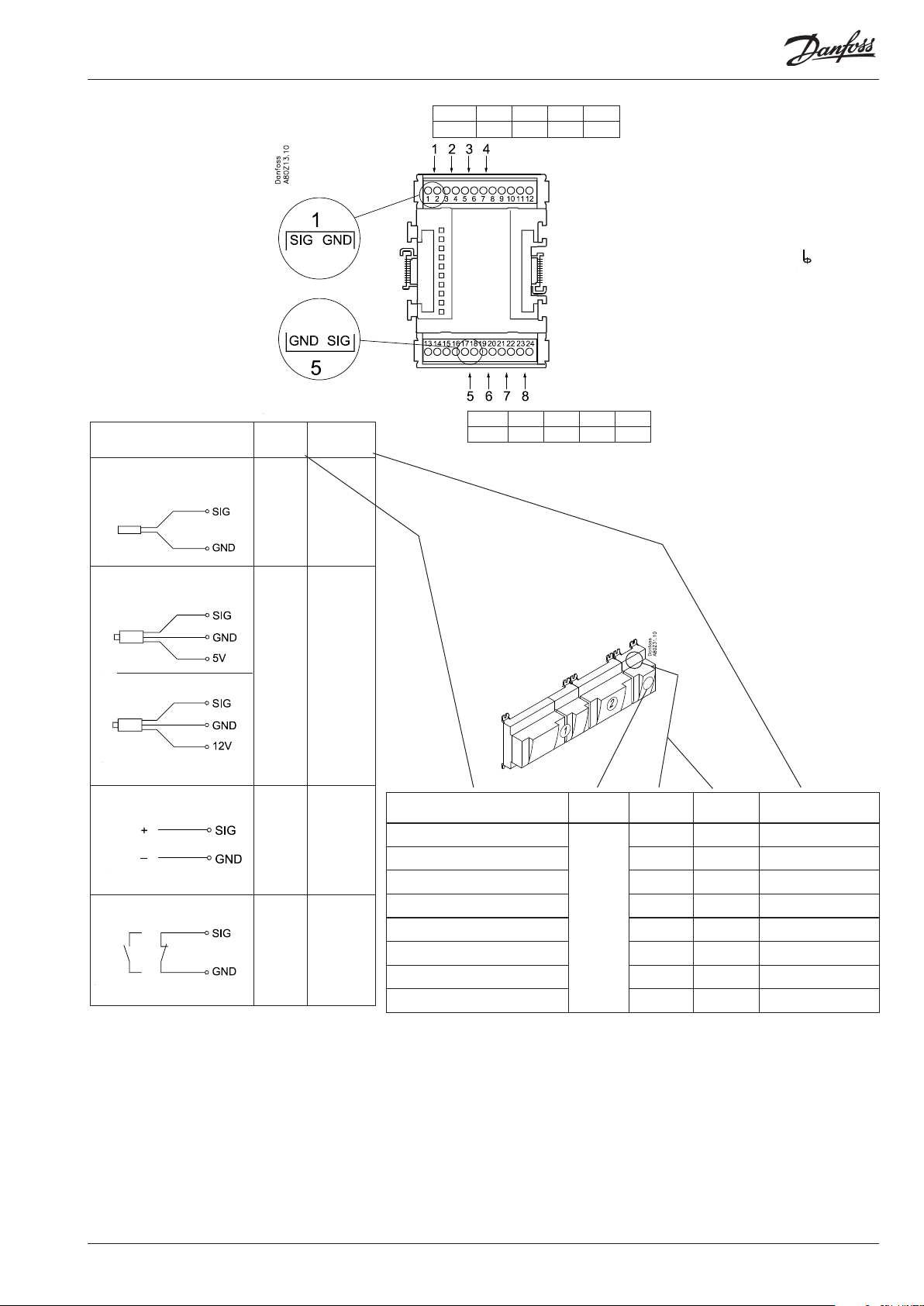

Point

Point 1 2 3 4

Type AI1 AI2 AI3 AI4

Terminal 9: 12 V

Terminal 10: 5 V

S

Pt 1000 ohm/0°C

P

AKS 32R

AKS 32

At the top the

signal input is

the left of the

two terminals.

At the bottom

the signal input

is the right of the

two terminals.

3: Brown

2: Blue

1: Black

3: Brown

2: Black

1: Red

Signal Signal

type

Sctrl

S7

Saux1

Pt 1000

Saux2

SS

Sd

AKS 32R /

P0

Pd

Prec.

AKS 2050

-1 - xx bar

AKS 32

-1 - zz bar

Terminal 15: 5 V

Terminal 16: 12 V

Terminal

11, 12, 13, 14:

(Cable screen)

Point 5 6 7 8

Type AI5 AI6 AI7 AI8

U

On/O

...

Ext.

Main

switch

Day/

Night

Level

switch

0 - 5 V

0 - 10 V

Active at:

Closed

/

Open

Signal Module Point

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 17 - 18

6 (AI 6) 19 - 20

7 (AI 7) 21 - 22

8 (AI 8) 23 - 24

Terminal

Signal type /

Active at

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 15

Extension module AK-XM 102A / AK-XM 102B

Function

The module contains 8 inputs for on/o voltage signals.

Signal

AK-XM 102A is for low voltage signals.

AK-XM 102B is for high voltage signals.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

Light-emitting diodes

They indicate:

• Voltage supply to the module

• Communication with the controller is active (red = error)

• Status of the individual inputs 1 to 8 (when lit = voltage)

AK-XM 102A

Max. 24 V

On/O:

On: DI > 10 V a.c.

O: DI < 2 V a.c.

AK-XM 102B

Max. 230 V

On/O:

On: DI > 80 V a.c.

O: DI < 24 V a.c.

16 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

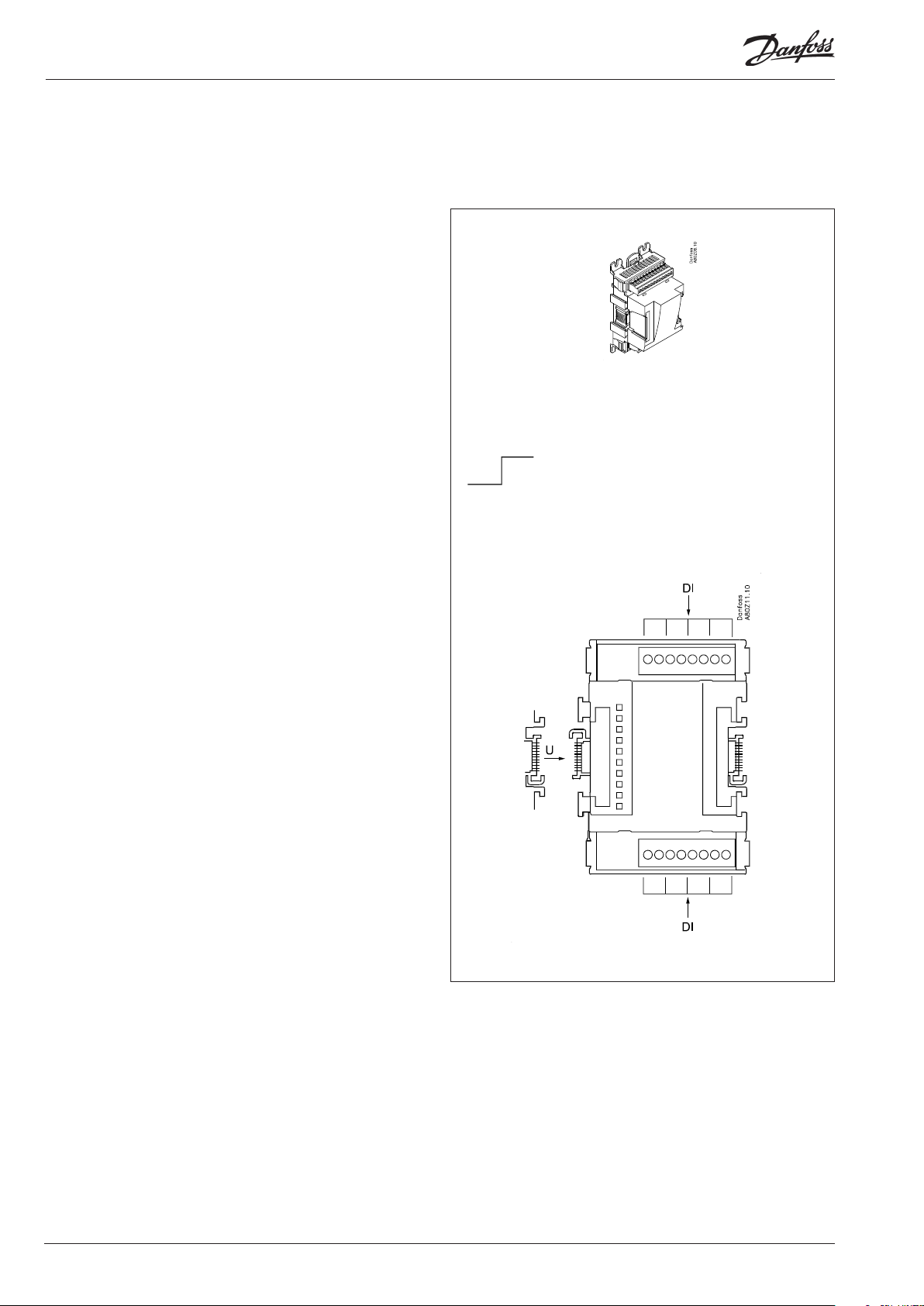

Point

DI

AK-XM 102A: Max. 24 V

AK-XM 102B: Max. 230 V

Signal Active at

Ext.

Main

switch

Day/

Night

Comp.

safety 1

Comp.

safety 2

Level

switch

Closed

(voltage on)

/

Open

(voltage o)

Point 1 2 3 4

Type DI1 DI2 DI3 DI4

Point 5 6 7 8

Type DI5 DI6 DI7 DI8

Signal Module Point Terminal Active at

1 (DI 1) 1 - 2

2 (DI 2) 3 - 4

3 (DI 3) 5 - 6

4 (DI 4) 7 - 8

5 (DI 5) 9 - 10

6 (DI 6) 11 - 12

7 (DI 7) 13 - 14

8 (DI 8) 15 - 16

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 17

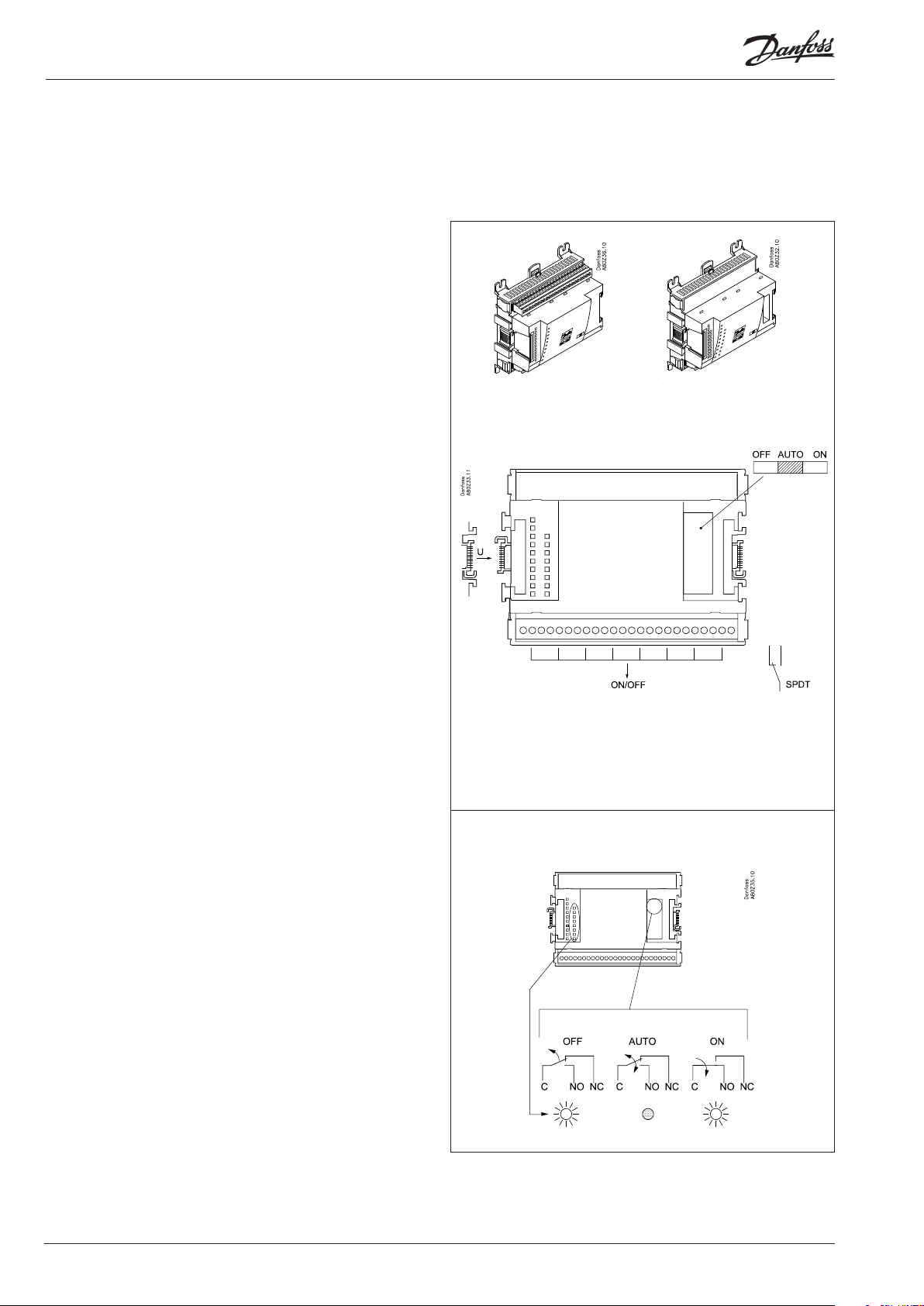

Extension module AK-XM 204A / AK-XM 204B

Function

The module contains 8 relay outputs.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

AK-XM 204B only

Override of relay

Eight change-over switches at the front make it possible to

override the relay’s function.

Either to position OFF or ON.

In position Auto the controller carries out the control.

Light-emitting diodes

There are two rows with LED’s. They indicate the following:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row: (AK-XM 204B only):

• Override of relays

ON = override

OFF = no override

AK-XM 204A AK-XM 204B

Fuses

Behind the upper part there is a fuse for each output.

Note

If the changeovers are used to override the compressor operation,

it is necessary to wire a safety relay into the circuit for oil management. Without this safety relay, the controller will fail to stop the

compressor if it should run out of oil. See Regulating functions.

Max. 230 V

AC-1: max. 4 A (ohmic)

AC-15: max. 3 A (Inductive)

AK-XM 204B

Override of relay

Keep the safety distance!

Low and high voltage

must not be connected to

the same output group

18 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

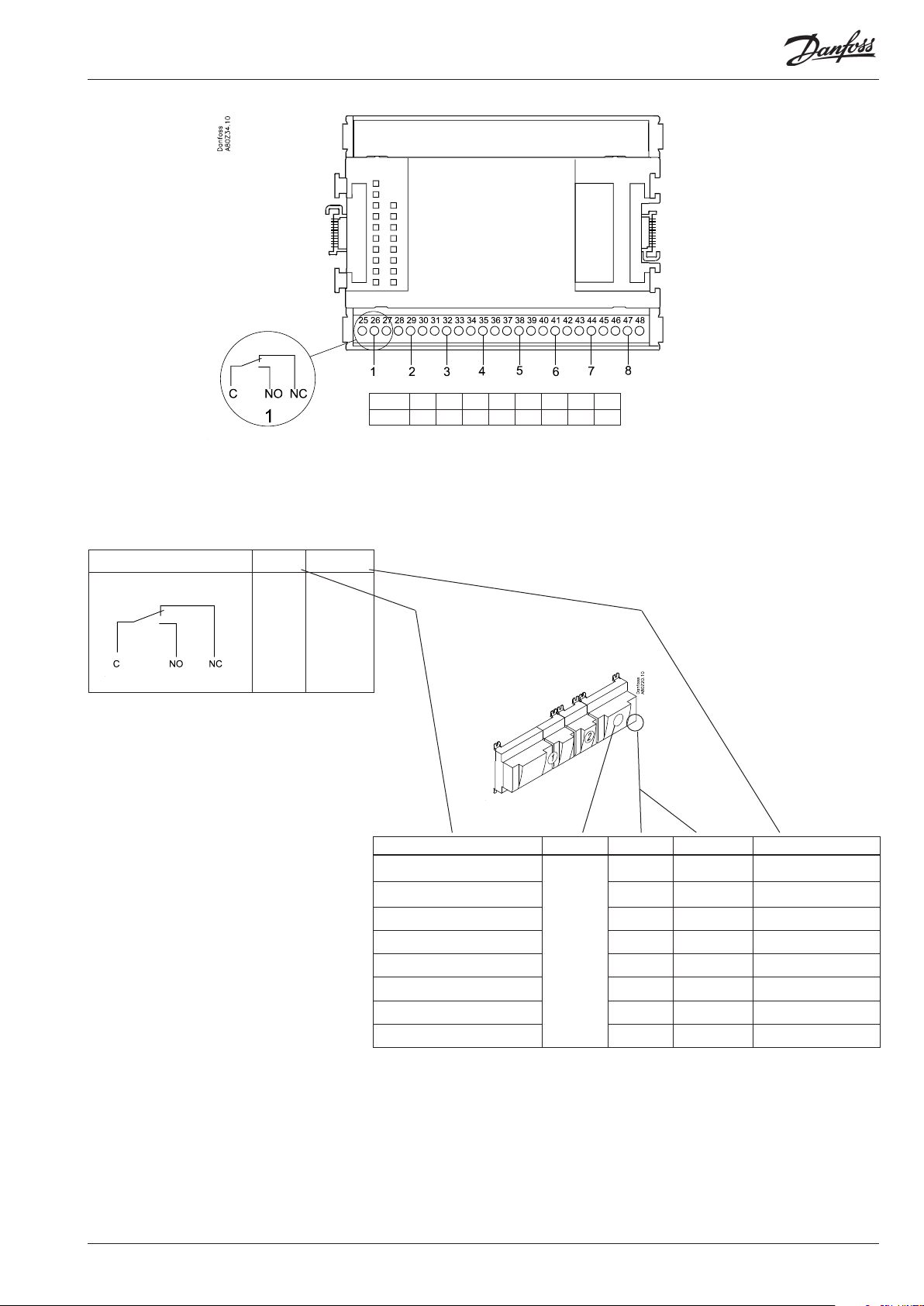

Point

DO

Signal Active at

Comp. 1

Comp. 2

Pump

Alarm

Solenoid

valve

On

/

O

Point 1 2 3 4 5 6 7 8

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

Signal Module Point Terminal Active at

1 (DO 1) 25 - 27

2 (DO 2) 28 - 30

3 (DO 3) 31 - 33

4 (DO 4) 34 -36

5 (DO 5) 37 - 39

6 (DO 6) 40 - 41 - 42

7 (DO 7) 43 - 44 - 45

8 (DO 8) 46 - 47 - 48

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 19

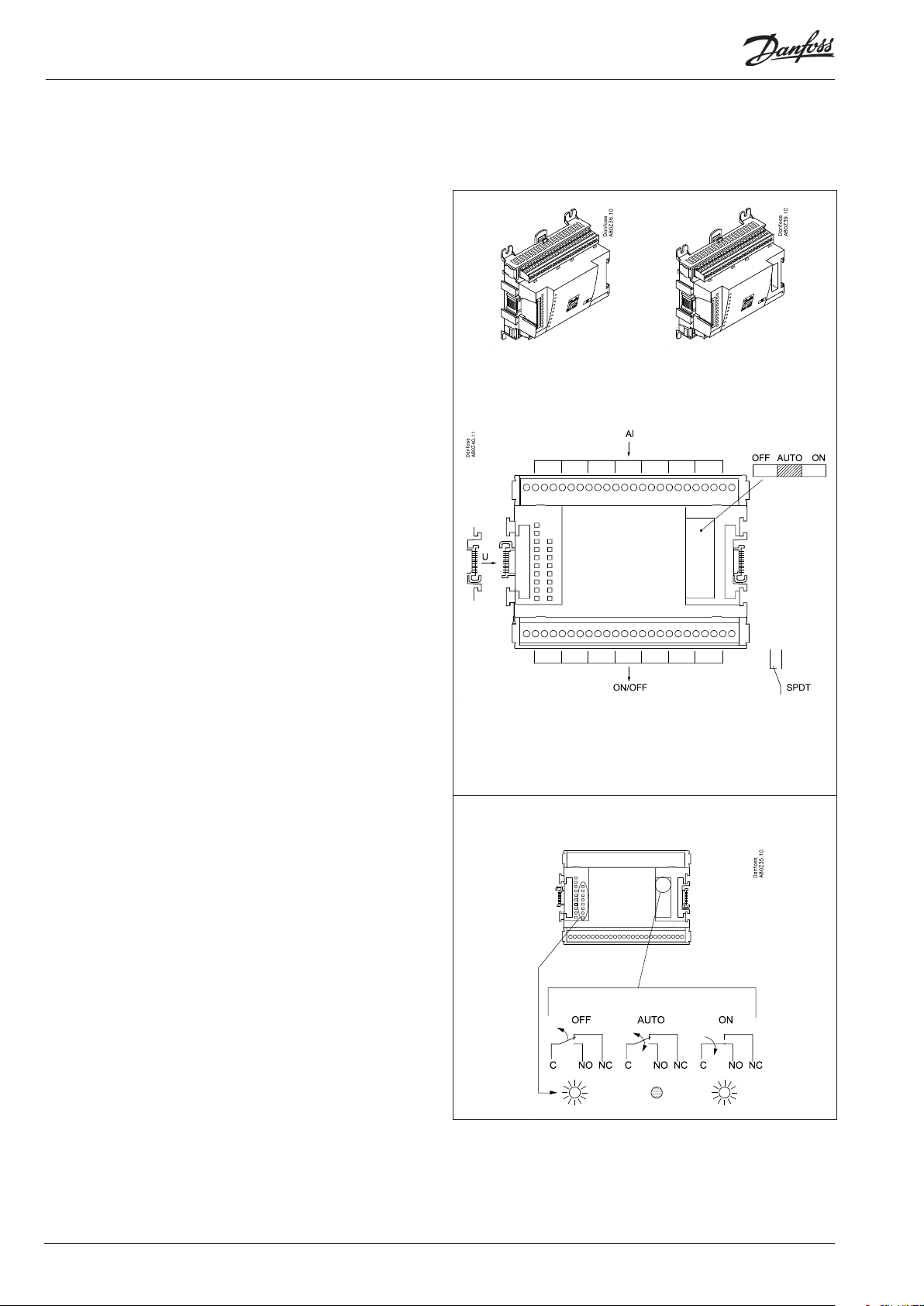

Extension module AK-XM 205A / AK-XM 205B

Function

The module contains:

8 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

8 relay outputs.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

AK-XM 205B only

Override of relay

Eight change-over switches at the front make it possible to

override the relay’s function.

Either to position OFF or ON.

In position Auto the controller carries out the control.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row: (AK-XM 205B only):

• Override of relays

ON = override

OFF = no override

AK-XM 205A AK-XM 205B

max. 10 V

Fuses

Behind the upper part there is a fuse for each output.

Note

If the changeovers are used to override the compressor operation,

it is necessary to wire a safety relay into the circuit for oil management. Without this safety relay, the controller will fail to stop the

compressor if it should run out of oil. See Regulating functions.

Max. 230 V

AC-1: max. 4 A (ohmic)

AC-15: max. 3 A (Inductive)

AK-XM 205B

Override of relay

Keep the safety distance!

Low and high voltage

must not be connected to

the same output group

20 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

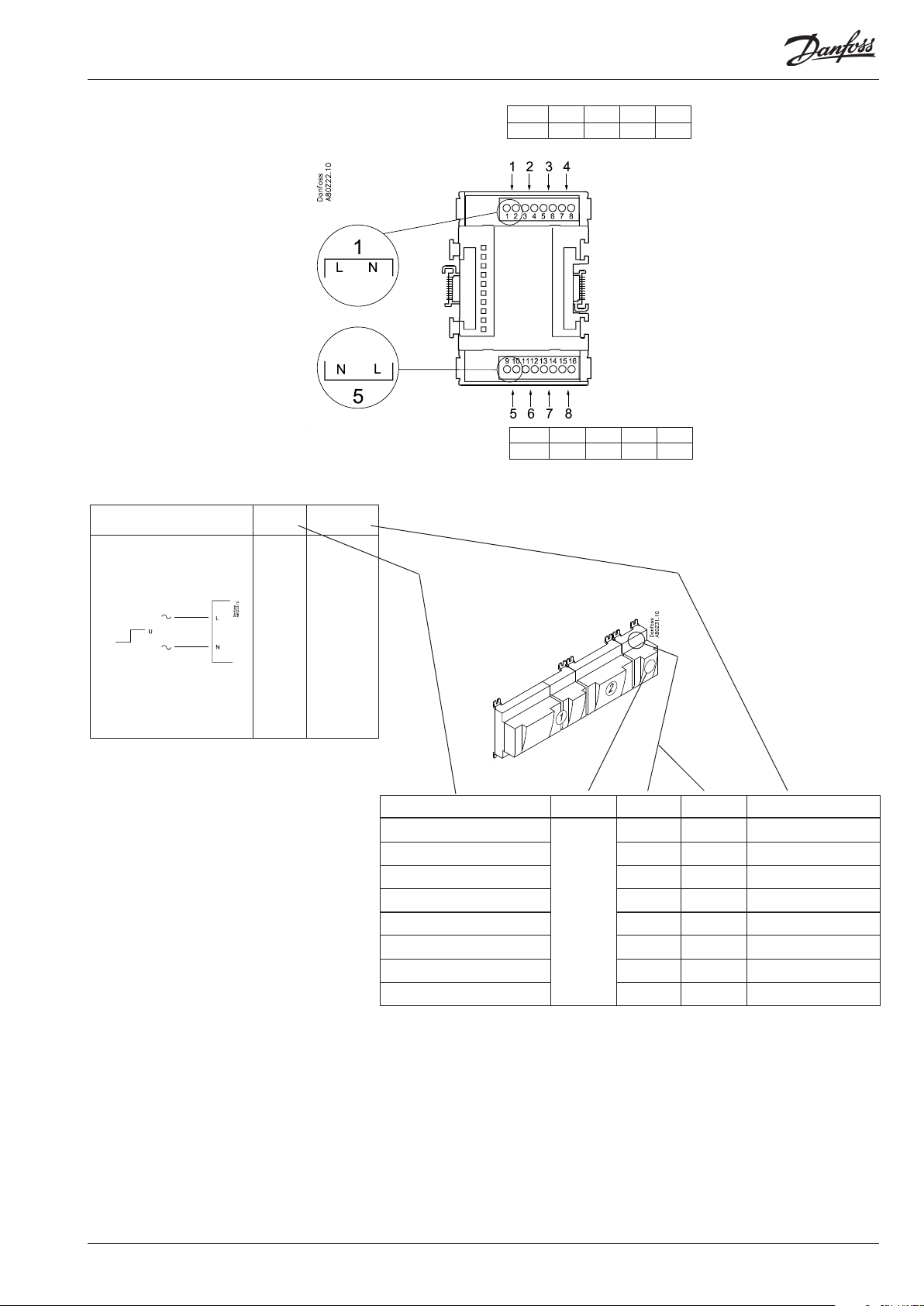

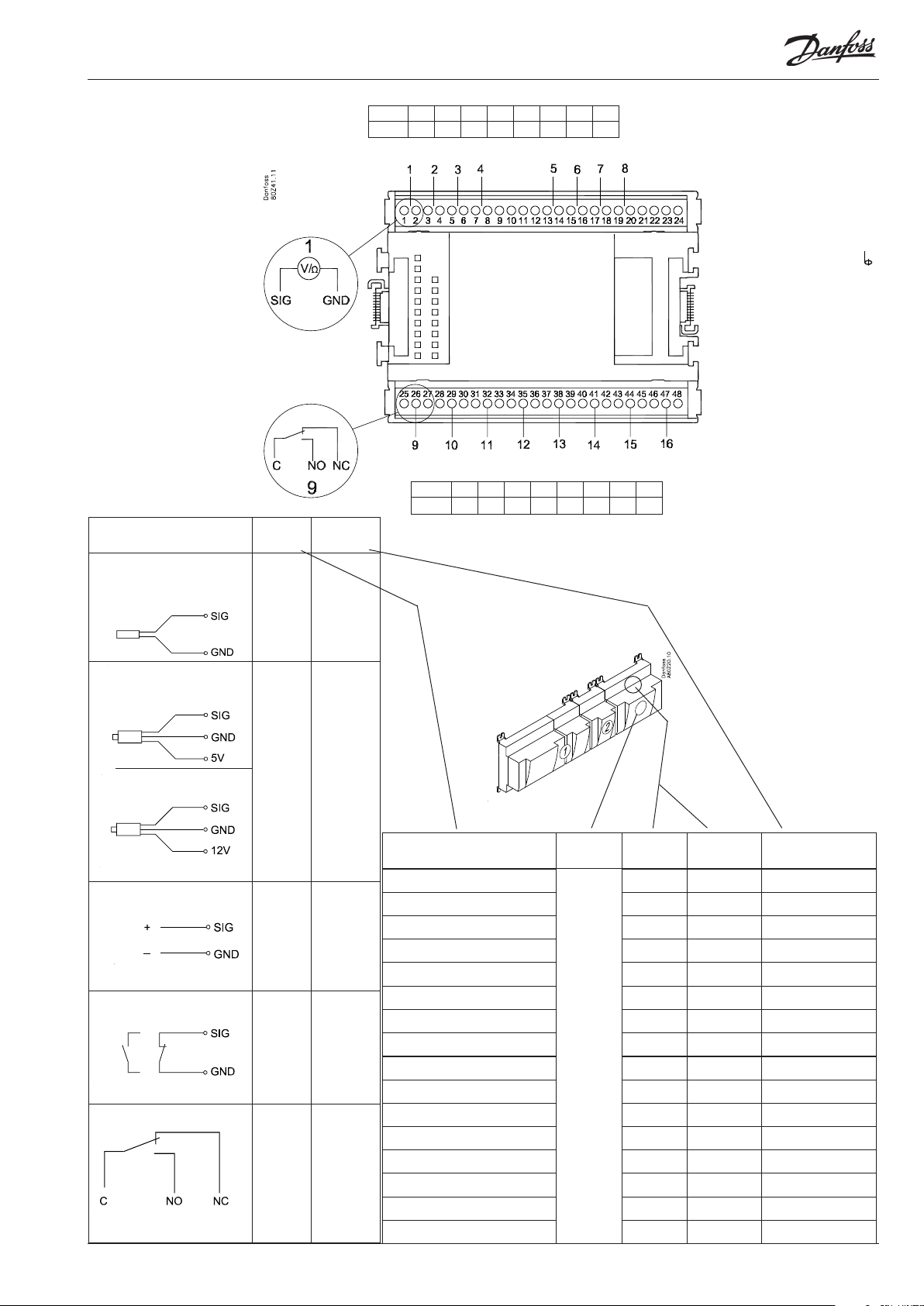

Point

S

Pt 1000 ohm/0°C

Signal Signal

type

Sctrl

S7

Saux1

Pt 1000

Saux2

SS

Sd

Point 1 2 3 4 5 6 7 8

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8

Terminal 9: 12 V

Terminal 10: 5 V

Terminal 21: 12 V

Terminal 22: 5 V

Terminal 11, 12, 23, 24 :

(Cable screen)

Point 9 10 11 12 13 14 15 16

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

P

AKS 32R

AKS 32

U

On/O

DO

3: Brown

2: Blue

1: Black

3: Brown

2: Black

1: Red

P0

Pd

Prec.

...

Ext. Main

switch

Day/

Night

Level

switch

Comp 1

Comp 2

Pump

Alarm

Solenoid

valve

AKS 32R /

AKS 2050

-1 - xx bar

AKS 32

-1 - zz bar

0 - 5 V

0 - 10 V

Active at:

Closed

/

Open

Active at:

on

/

O

Signal Module Point

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 13 - 14

6 (AI 6) 15 - 16

7 (AI 7) 17 - 18

8 (AI 8) 19 -20

9 (DO 1) 25 - 26 - 27

10 (DO 2) 28 - 29 - 30

11 (DO 3) 31 - 30 - 33

12 (DO 4) 34 - 35 - 36

13 (DO 5) 37 - 36 - 39

14 (DO6) 40 - 41 - 42

15 (DO7) 43 - 44 - 45

16 (DO8) 46 - 47 - 48

Terminal

Signal type /

Active at

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 21

Extension module AK-OB 110

Function

The module contains two analog voltage outputs of 0 – 10 V.

Supply voltage

The supply voltage to the module comes from the controller

module.

Placing

The module is placed on the PC board in the controller module.

Point

The two outputs have points 24 and 25. They are shown on the

earlier page where the controller is also mentioned.

Max. load

I < 2.5 mA

R > 4 kohm

AO

AO 0 - 10 V

Module

Point 24 25

Type AO1 AO2

1

AO2

AO1

22 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

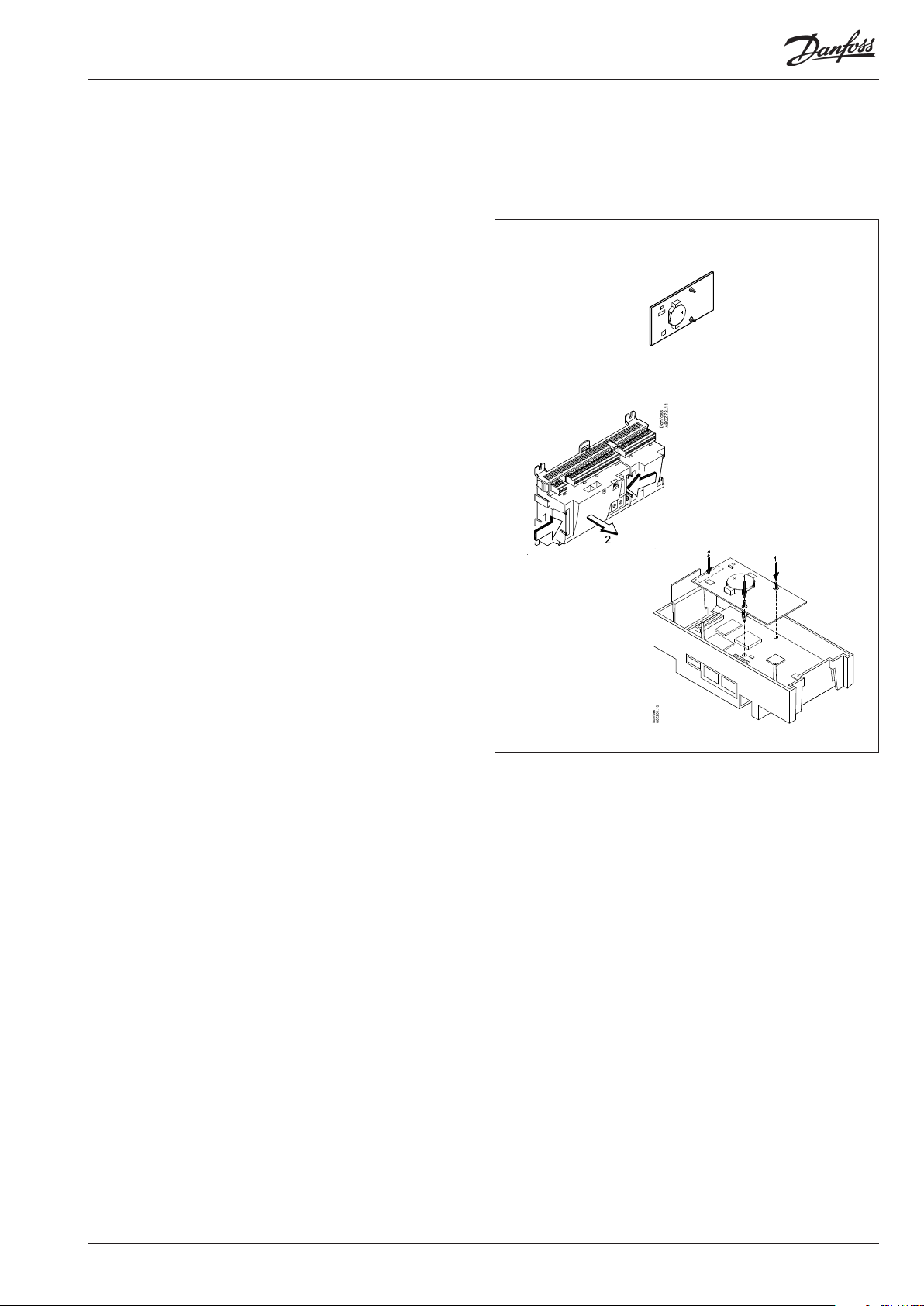

Extension module AK-OB 101A

Function

The module is a real time clock module with battery backup.

The module can be used in controllers that are not linked up in

a data communication unit together with other controllers. The

module is used here if the controller needs battery backup for the

following functions

• Clock function

• Fixed times for day/night change-over

• Saving of alarm log in case of power failure

• Saving of temperature log in case of power failure

Connection

The module is provided with plug connection.

Placing

The module is placed on the PC board inside the top part.

Point

No point for a clock module to be dened – just connect it.

Working life of the battery

The working life of the battery is several years – even if there are

frequent power failures.

An alarm is generated when the battery has to be replaced.

After the alarm there are still several months of operating hours

left in the battery.

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 23

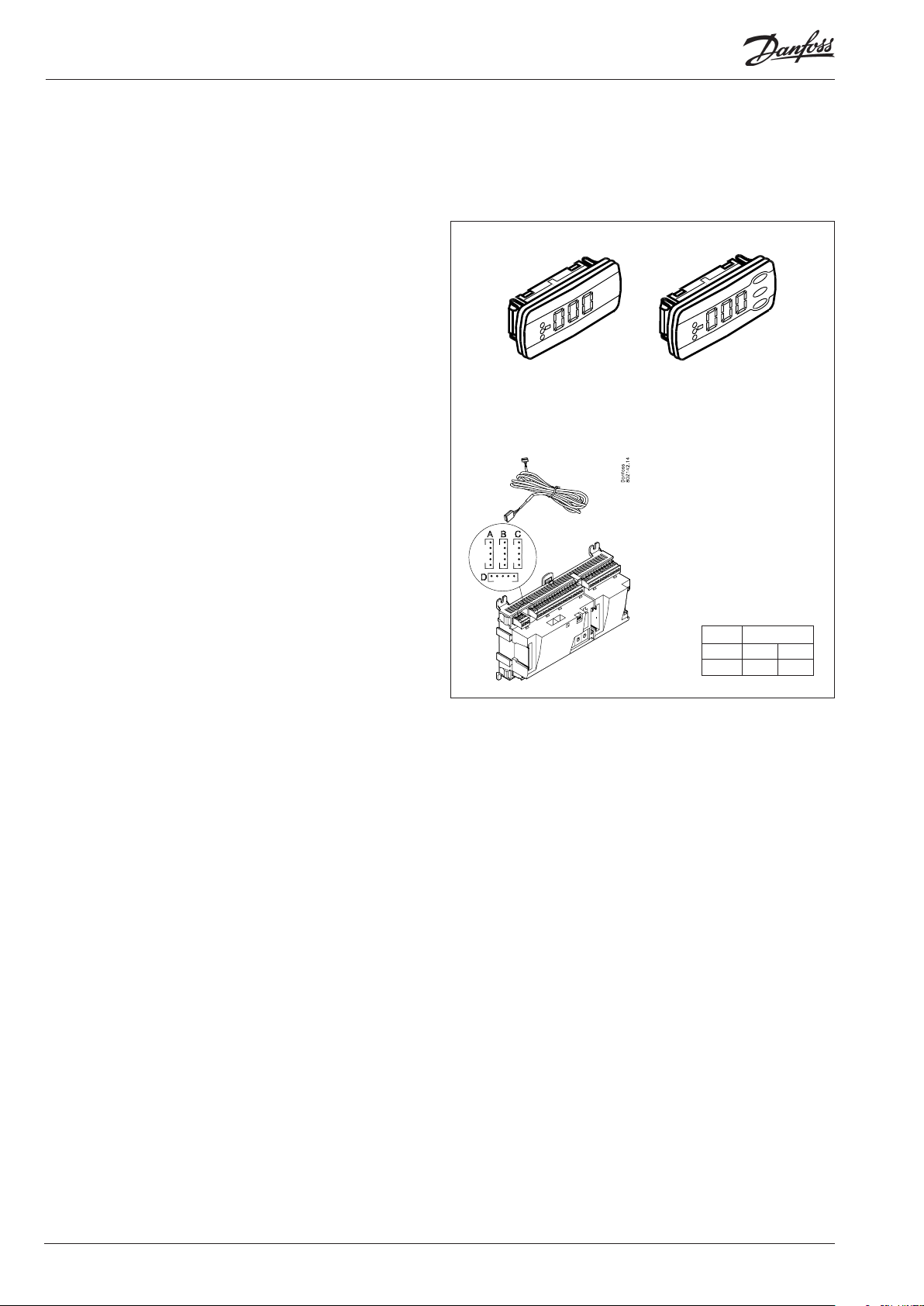

Extension module EKA 163B / EKA 164B

Function

Display of important measurements from the controller, e.g. re-

ceiver temperature, suction pressure or discharge gas pressure.

Setting of the individual functions can be performed by using the

display with control buttons.

It is the controller used that determines the measurements and

settings that can occur.

Connection

The extension module is connected to the controller module via

a cable with plug connections. You have to use one cable per

module. The cable is supplied in various lengths.

Both types of display (with or without control buttons) can be

connected to either display output A, B, C and D.

A: P0. Suction pressure in °C.

B: Pc. Condensing pressure in °C.

When the controller starts up, the display will show which output

is connected. - - 1 = output A, - - 2 = output B, etc.

Placing

The extension module can be placed at a distance of up to 15 m

from the controller module.

EKA 163B EKA 164B

Point

No point has to be dened for a display module – you simply connect it.

Module

Point - -

Type - -

1

24 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

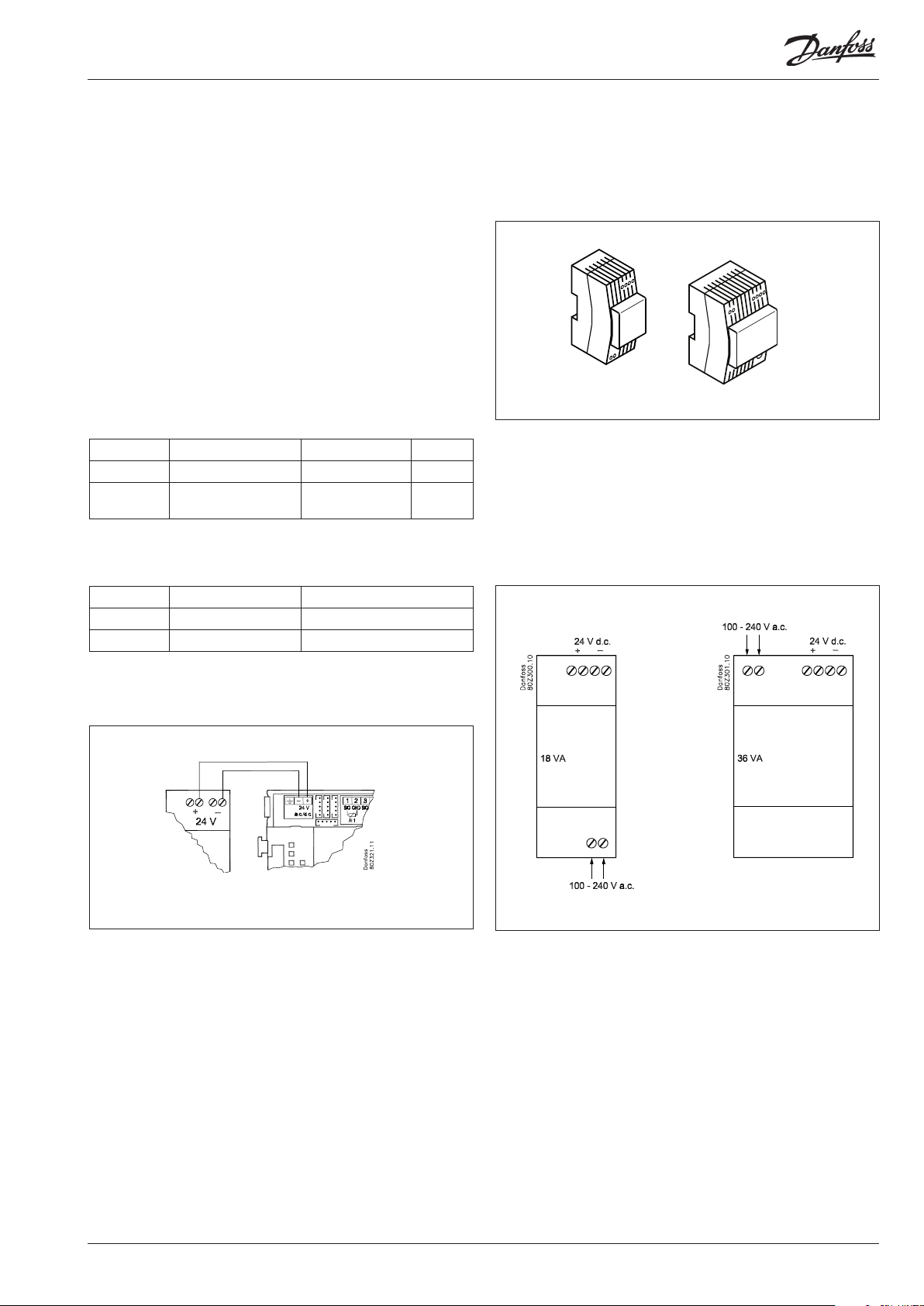

Power supply module AK-PS 075 / 150

Function

24 V supply for controller.

Supply voltage

230 V a.c or 115 V a.c. (from 100 V a.c. to 240 V a.c.)

Placing

On DIN-rail

Eect

Type Output tension Output current Power

AK-PS 075 24 V d.c. 0.75 A 18 VA

AK-PS 150 24 V d.c.

(adjustable)

1.5 A 36 VA

Dimension

Type High Width

AK-PS 075 90 mm 36 mm

AK-PS 150 90 mm 54 mm

Supply to a controller

Connections

AK-PS 075

AK-PS 150

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 25

Preface to design

Be aware of the following when the number of extension modules

is being planned. A signal may have to be changed, so that an

additional module may be avoided.

• An ON/OFF signal can be received in two ways. Either as a

contact signal on an analog input or as voltage on a low or highvoltage module.

• An ON/OFF output signal can be given in two ways. Either with a

relay switch or with solid state. The primary dierence is the permitted load and that the relay switch contains a cutout switch.

Mentioned below is a number of functions and connections

that may have to be considered when a regulation has to be

planned. There are more functions in the controller than the ones

mentioned here, but those mentioned have been included in

order that the need for connections can be established.

Functions

Clock function

Clock function and change-over between summer time and

winter time are contained in the controller.

The clock is zeroset when there is power failure.

The clock’s setting is maintained if the controller is linked up in a

network with a gateway, a system manager or a clock module can

be mounted in the controller.

Start/stop of regulation

Regulation can be started and stopped via the software. External

start/stop can also be connected.

Alarm function

If the alarm is to be sent to a signal transmitter, a relay output will

have to be used.

Extra temperature sensors and pressure sensors

If additional measurements have to be carried out beyond the

regulation, sensors can be connected to the analog inputs.

Forced control

The software contains a forced control option. If an extension

module with relay outputs is used, the module’s top part can

be with change-over switches – switches that can override the

individual relays into either OFF or ON position.

Wiring should be done with a safety relay. See Regulating functions.

Data communication

The controller module has terminals for LON data communication.

The requirements to the installation are described in a separate

document.

26 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

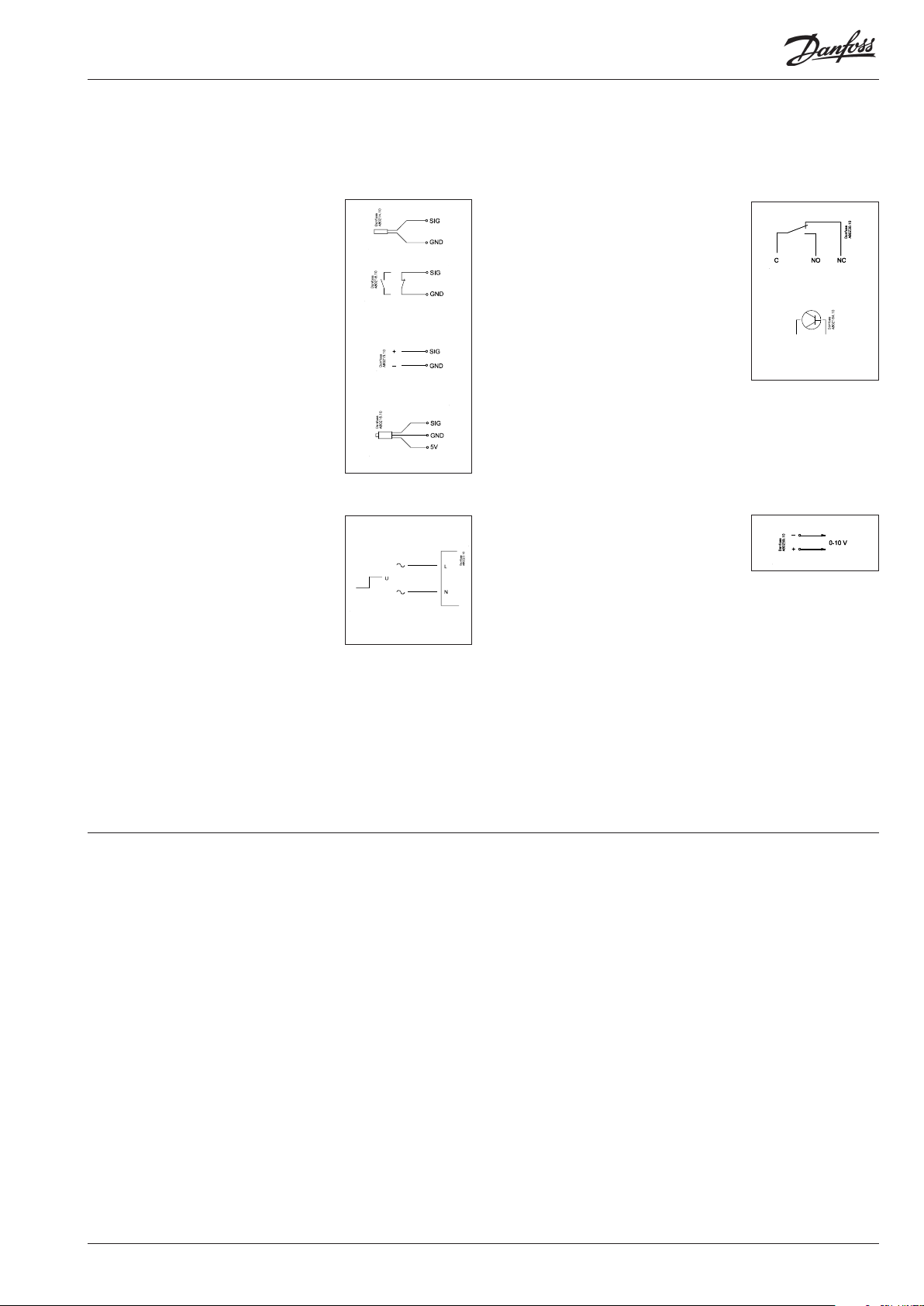

Connections

In principle there are the following types of connections:

Analog inputs ”AI”

This signal must be connected to two

terminals.

Signals can be received from the following

sources:

• Temperature signal from Pt 1000 ohm

temperature sensor

• Contact signal where the input is shortcircuited or ”opened”, respectively

• Voltage signal from 0 to 10 V

• Signal from pressure transmitter AKS 32,

AKS 32R or AKS 2050

The supply voltage is supplied from the

module’s terminal board where there is

both a 5 V supply and a 12 V supply.

When programming the pressure

transmitter’s pressure range must be set.

ON/OFF voltage inputs ”DI”

This signal must be connected to two

terminals.

• The signal must have two levels, either 0 V

or ”voltage” on the input.

There are two dierent extension

modules for this signal type:

- low-voltage signals, e.g. 24 V

- high-voltage signals, e.g. 230 V

ON/OFF output signals ”DO”

There are two types, as follows:

• Relay outputs

All relay outputs are with change-over

relay so that the required function can be

obtained when the controller is without

voltage.

• Solid state outputs

Reserved for AKV valves, but output can

cut an external relay in and out, as with a

relay output.

The output is only found on the

controller module.

When programming the function must be set:

• Active when the output is activated

• Active when the output is not activated.

Analog output signal ”AO”

This signal is to be used if a control signal is

to be transmitted to an external unit, e.g. a

frequency converter.

When programming the signal range must

be dened: 0-5 V, 1-5 V, 0-10 V or 2-10 V.

When programming the function must be set:

• Active when the input is without voltage

• Active when voltage is applied to the

input.

Limitations

As the system is very exible regarding the number of connected

units you must check whether your selection complies with the

few limitations there are.

The complexity of the controller is determined by the software,

the size of the processor, and the size of the memory. It provides

the controller with a certain number of connections from which

data can be downloaded, and others where coupling with relays

can be performed.

✔ The sum of connections cannot exceed 100

✔ The number of extension modules must be limited so that the

total power will not exceed 32 VA (including controller).

✔ No more than 5 pressure transmitters may be connected to one

controller module.

✔ No more than 5 pressure transmitters may be connected to one

extension module.

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 27

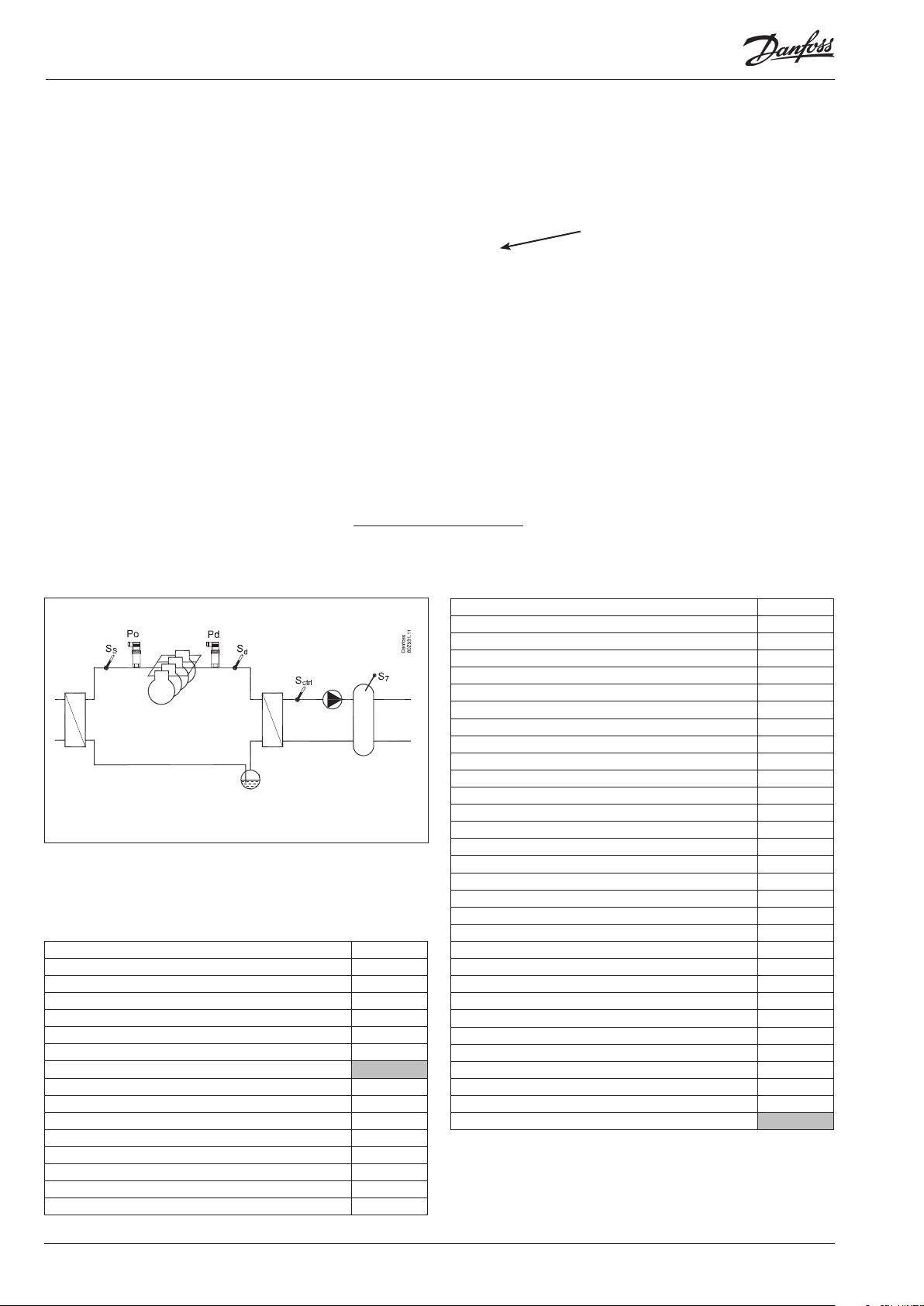

Design of a compressor and pump control

Procedure:

1. Make a sketch of the system in question

2. Check that the controller’s functions cover the required

application

3. Consider the connections to be made

4. Use the planning table. / Note down the number of connections

./ add up

5. Are there enough connections on the controller module? – If

not, can they be obtained by changing an ON/OFF input signal

from voltage signal to contact signal, or will an extension

module be required?

6. Decide which extension modules are to be used

7. Check that the limitations are observed

8. Calculate the total length of modules

9. The modules are linked together

10. The connection sites are established

11. Draw a connection diagram or a key diagram

12. Size of supply voltage/transformer

1

Follow these 12

steps

Sketch

Make a sketch of the system in question.

2

Functions

Application

Regulation of a compressor group x

Regulation of receiver temperature x

Regulation of compressor capacity

Regulation sensor = Sctrl x

PI-regulation x

Max. number of compressor steps 8

Max. number of unloaders each compressor 3

Identical compressor capacities x

Dierent compressor capacities x

Sequential operation (rst in / last out) x

Speed regulation of 1 compressor or 2 parallel compressors x

Run time equalisation x

Min. restart time x

Min. On-time x

AK-HP 780

Oil management

Oil injection in compressor. Shared or individual x

Receiver pressure control x

Monitoring of oil level in receiver x

Management of oil level in oil separator x

Reset of oil management x

Cutout of compressors at oil failure x

Safety relays during forced compressor control x

Temperature reference for Sctrl

Override via “night setback” x

Override via "0 -10 V signal" x

Regulation of receiver temperature

Regulation sensor. = S7 x

On/o control of pump x

Speed regulation of pump x

Safety functions

Min. suction pressure x

Max. suction pressure x

Max. discharge pressure x

Max. discharge gas temperature x

Min. / Max. superheat x

Safety monitoring of compressors x

Common high pressure monitoring of compressors x

General alarm functions with time delay 10

Miscellaneous

Extra sensors 7

Option for connection of separate display 4

Separate thermostat functions 5

Separate pressostat functions 5

Separate voltage measurements 5

Max. input and output 100

28 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

A bit more about the functions

3

Compressor

Regulation of up to 8 compressors. And up to 3 unloaders each

compressor.

Compressor No. 1 or 2 can be speed-regulated.

A signal is required from pressure transmitters P0 and Pd.

A signal is required from temperature sensors Ss and Sd.

P0 is also used to protect against a too low pressure.

Pd is also used to protect against a too high pressure.

Temperature reference

Sctrl is used as a regulating sensor.

The cut in and cut out of the compressors is determined by the

measured temperature.

Receiver

S7 is used as a regulating sensor.

One pump can be controlled based on the measured signal. Signals can be delivered so that the pump can be speed-controlled.

Speed regulation

The function requires an analog output module.

A relay output may be used for start/stop of the speed regulation.

Safety circuit

If signals are to be received from one or more parts of a safety

circuit, each signal must be connected to an ON/OFF input.

Day/night signal for lowering the temperature reference Sctrl.

The clock function can be used, but an external ON/OFF signal

may be used instead.

Separate thermostat and pressure control functions

A number of thermostats can be used according to your wishes.

The function requires a sensor signal and a relay output. In the

controller there are settings for cutin and cutout values. An associated alarm function may also be used.

Separate voltage measurements

A number of voltage measurements can be used according to

your wishes. The signal can for example be 0-10 V. The function

requires a voltage signal and a relay output. In the controller there

are settings for cutin and cutout values. An associated alarm function may also be used.

If you want to know more about the functions, go to

chapter 5.

Connections

Here is a survey of the possible connections. The texts can be read

in context with the table on page 31.

Analog inputs

Temperature sensors

• Sctrl

Must always be used as a regulating sensor for compressor

regulation.

• Ss (suction gas temperature)

Must always be used.

• Sd (discharge gas temperature)

Must always be used.

• S7 (receiver temperature)

Must always be used for regulation sensor for pump control.

• Saux (1-5), any extra temperature sensors

Up to ve additional sensors for monitoring and data collection may be connected. These sensors can be used for general

thermostat functions.

Pressure transmitters

• P0 Suction Pressure

Must always be used.

• Pd Discharge pressure

Must always be used.

• Prec. Oil receiver pressure. Must be used for oil receiver pressure

regulation.

• Paux (1-5)

Up to 5 extra pressure transmitters can be connected for monitoring and data collection.

These sensors can be used for general pressure switch functions.

Note. A pressure transmitter type AKS 32 or AKS 32R can supply

signals to a maximum of ve controllers.

Voltage signal

• Ext. Ref

Used if a reference override signal is received from another

control.

• Voltage inputs (1-5)

Up to 5 extra voltage signals can be connected for monitoring

and data collection. These signals are used for general voltage

input functions.

On/O-inputs

Contact function (on an analog input) or

voltage signal (on an extension module)

• Common safety input for all compressors (e.g. common highpressure/low-pressure pressure switch)

• Up to 6 signals from the safety circuit of each compressor

• Signal from the pumps safety circuit

• Any signal from the frequency converter’s safety circuit

• External start/stop of regulation

• External day/night signal (raise/lower the Sctrl- reference).

• DI alarm (1-10) inputs

Up to 10 no. extra on/o signals for general alarm for monitoring

and data collection can be connected.

On/o-outputs

Relay outputs

• Compressors

• Unloaders

• Pump

• Start/stop of liquid injection in heat exchanger

AK-HP 780 Heat pump controller RS8GF202 © Danfoss 2015-08 29

• ON/OFF signal for start/stop of speed regulation

• Alarm relay

• On/o signals from general thermostats (1-5), pressure switches

(1-5) or voltage input functions (1-5).

• Oil valves

• Safety relays for cutouts of compressors at oil failure

Solid state outputs

The solid state outputs on the controller module may be used

for the same functions as those mentioned under “relay outputs”.

(The output will always be “OFF” when the controller has a power

failure).

Analog output

• Speed regulation of pump.

• Speed regulation of the compressor

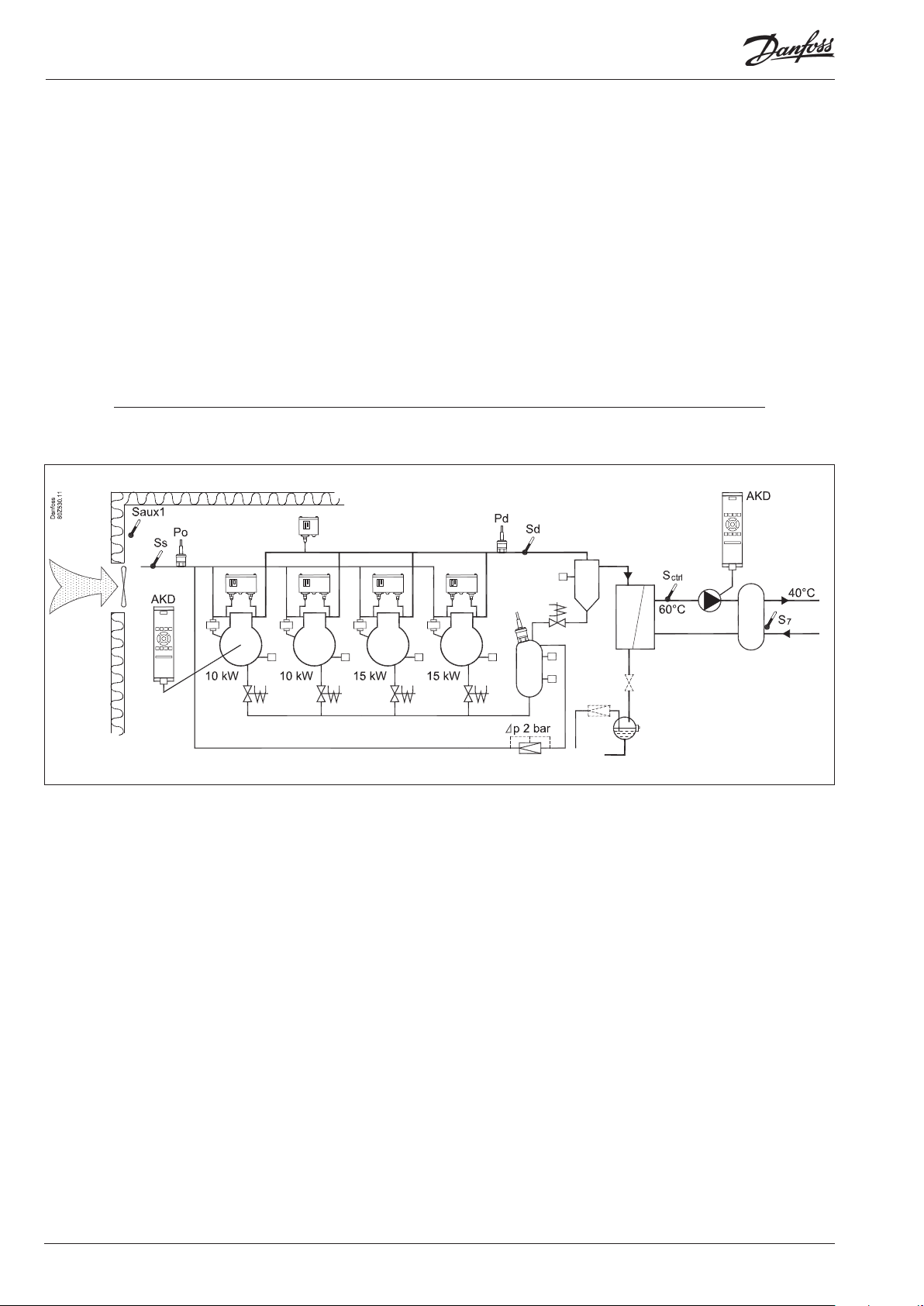

Example

Compressor Group

• Refrigerant CO2 (R744)

• 4 only compressors with "Best t". Speed control of one.

• Safety monitoring of each compressor

• Common high-pressure monitoring

• Sctrl setting 60°C, Night setback of 5 K

• Oil management of each compressor

• Pulse reset for stopped compressor (lack of oil)

Receiver

• Pump with speed control

• S7 reference 40°C

Oil Receiver:

• Monitoring of liquid level

• Control of pressure in oil receiver

Fan in plant room

• Thermostat control of fan in engine room

Safety functions:

• Monitoring of P0, Pd, Sd and superheat in suction line

• P0 max = 10°C, P0 min = -2°C

• Pd max = 50 °C

• Sd max = 120°C

• SH min = 5 °C, SH max = 35 °C

• Monitoring of low and high level in oil receiver

Other:

• Alarm output used

• External main switch used

Data from this example is used on the next page.

The result is that the following modules should be used:

• AK-HP 780 controller

• AK-XM 102B digital input module

• AK-XM 205B input and output module

• AK-OB 110 analog extension module

30 Heat pump controller RS8GF202 © Danfoss 2015-08 AK-HP 780

Loading...

Loading...