Page 1

DESCRIPTION

The ACW109D Proportional Rotary Position Controller provides a means of steering a mobile machine. The Controller

senses direction of a wheel or track, compares that direction

to an error signal generated by a remote sensor and supplies

an output for corrective action. In most installations the

ACW109D will occupy the same location assigned to a

feedback transducer in automatic steering control applications.

In a typical application, the ACW109D will obtain direction

informationfromaremotesensorsuchasthe'DQIRVV

ACX104.

The signal will be compared to therotational position of

the Controller input shaft. A pulse widthmodulated

output signal drives an MCV103/113 Flow Control

Servovalve, which moves a cylinder to reposition the

wheels or tracks.

Steering alignment is a common application.

ACW109D

Proportional Rotary Position Controller

BLN-95-8928-4 Issued: March 1992

FEATURES

• Capable of driving a servovalve directly, without additional signal amplification

• Adjustable sensitivity

• Solid state circuitry

• Reverse polarity and short circuit protection

ORDERING INFORMATION

SPECIFY

1. Model Number ACW109D

2. Sensor; ACX104

3. Servovalve; MCV103/113

4. Cables; KW01013, KW01009

• Wiring connections made through MS type connector

• Designed to withstand the vibration associated with mobile equipment

• Can be connected for external bias or remote centering

TABLE A. INFORMATION NECESSARY TO SPECIFY

THE CONTROLLER.

ORDER NUMBER KILOHM POTENTIOMETER

ACW109D1000 10 90°

ACW109D1018 10 342°

ACW109D1026 20 342°

© Danfoss, 2013-09 BLN-95-8928-4 1

Page 2

TECHNICAL DATA

MODELS

Three models are available, dependent upon the mobile

machine’s steering application. See Table B.

TABLE B.

MODEL PROPORTIONAL RATED

1

GAIN TRAVEL

2

ACW109D1000 1.75°±15°

ACW109D1018 7.0°±57°

ACW109D1026 14.0°±114°

Shaft angle change required for full valve

1

drive when set at maximum gain.

Shaft angle change required to match the

2

±3V rated output of the ACX104.

INPUT VOLTAGE

10 to 15 Vdc, 0.5 ampere maximum

OUTPUT VOLTAGE

0 to ±6 Vdc with 12 Vdc supply voltage.

SHAFT ROTATION

The shaft rotates the full 360 angular degrees without

stops.

SHAFT OPERATING TORQUE

No more than 50 inch grams throughout the range of

travel.

NULL POINT

Null point of the Controller is located by a roll pin and

two molded stops on the bearing block. At null, the

longer end of the roll pin is centered between the stops,

and parallel to the case. The short roll pin permits 360°

shaft rotation.

VIBRATION

Withstands a vibration test designed for mobile equipment controllers that includes two parts:

1. Cycling from 5 to 2000 Hz over a range of ±1.5 g’s to

±8.0 g’s for a period of one hour (if there are four

resonant points), for two hours (if there are two or

three resonant points), or for three hours (if there is

one or no resonant point). Cycling test performed on

each of the three major axes.

2. Resonance dwell for one million cycles over a range

of ±1.5 g’s to ±8.0 g’s for each of the four most severe

resonant points on each of the three major axes.

SHOCK

Withstands a shock test designed for mobile equipment

devices that consists of three shocks of 50 g’s and 11

milliseconds duration in both directions of the three

major axes for a total of 18.

OPERATING TEMPERATURE

-18° to +77° C (0° to +170° F)

STORAGE TEMPERATURE

-40° to +77° C (-40° to +170° F)

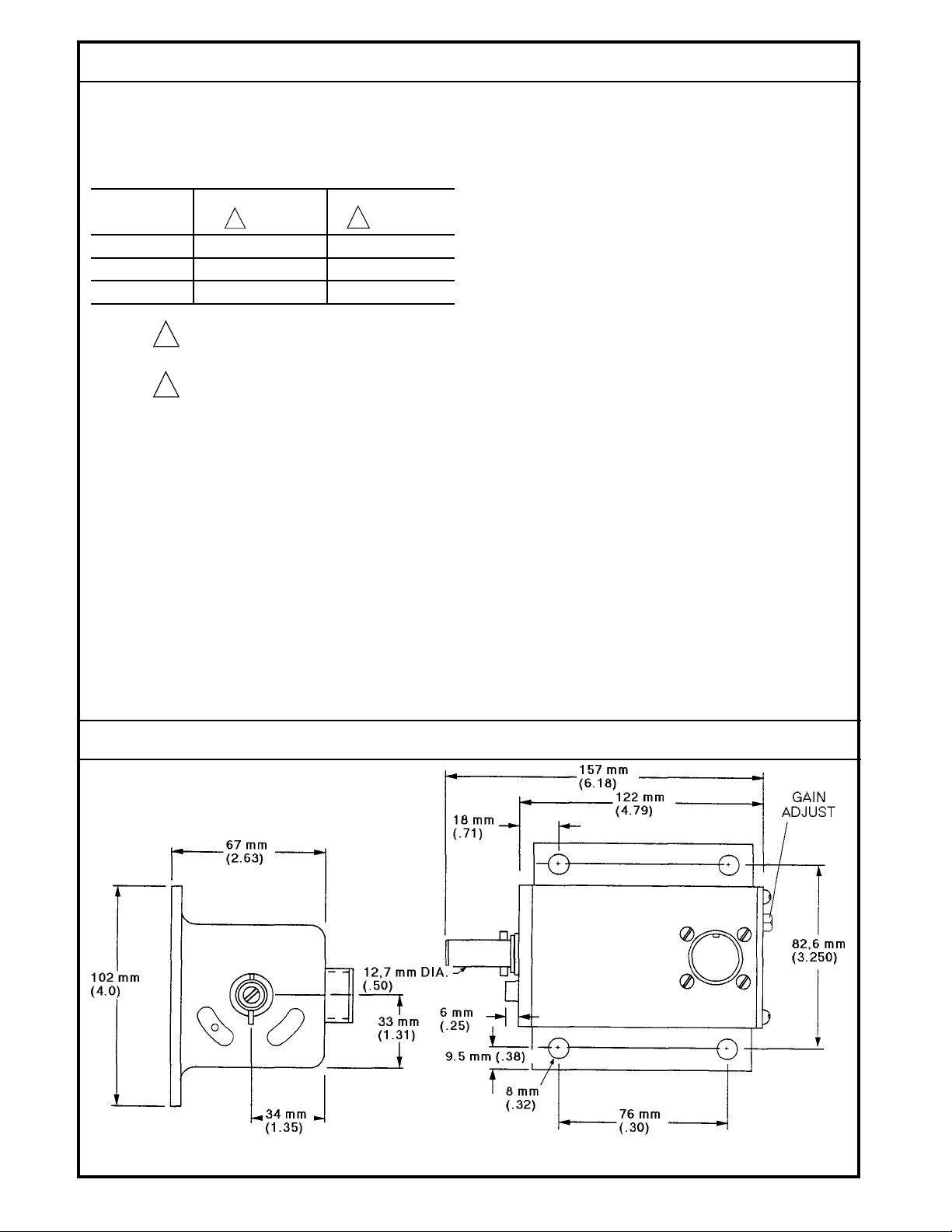

DIMENSIONS

Refer to the Dimensions diagram.

WEIGHT

0.8 kilograms (1 pound, 12 ounces)

DIMENSIONS

BLN-95-8928-4

298C

Mounting Dimensions of the ACW109D in Millimeters (Inches).

2

Page 3

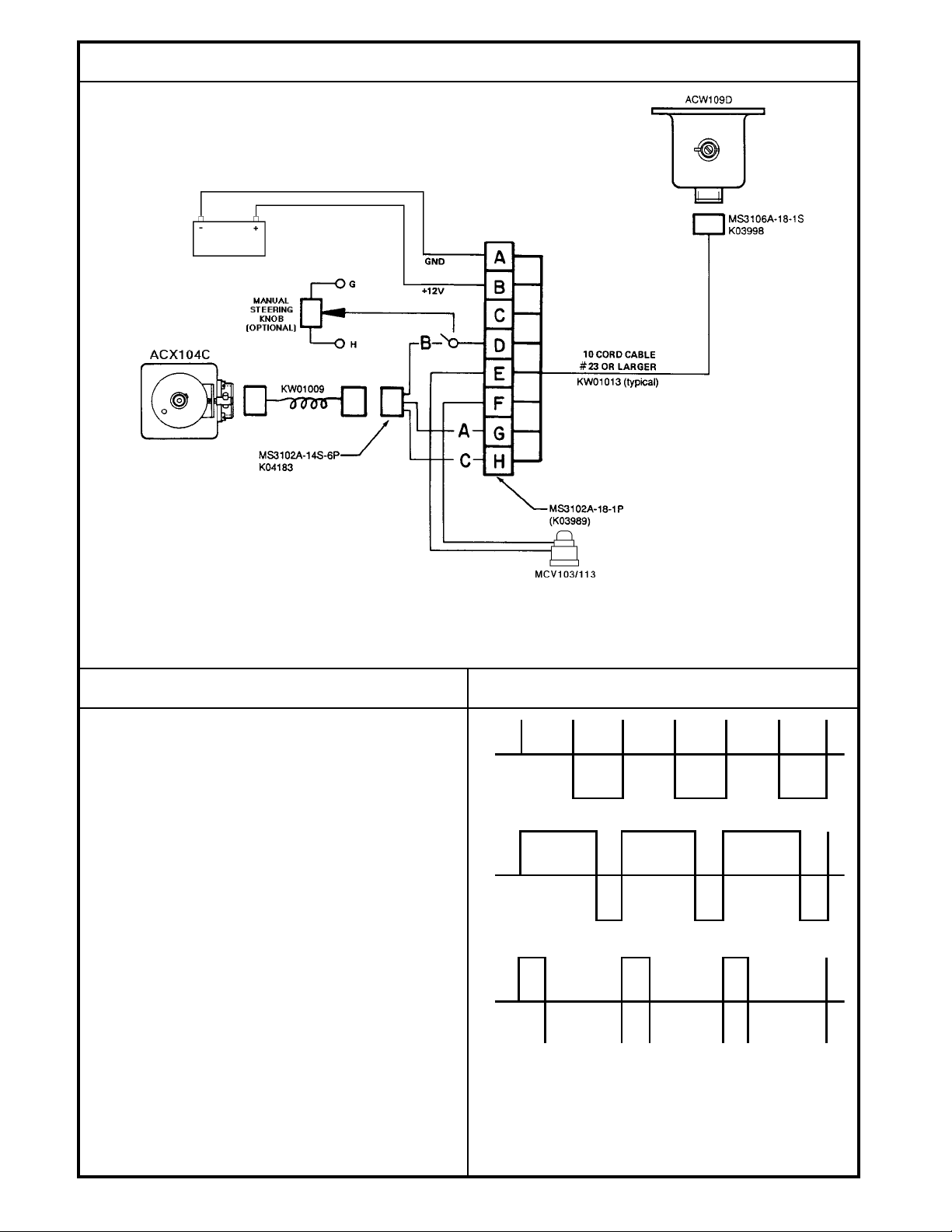

CONNECTION DIAGRAM (Typical)

Wiring Diagram for the ACW109D Used as Electronic Tie Rod.

THEORY OF OPERATION

The output of the ACW109D is a square wave signal used to

operate the MCV103/113 Flow Control Servovalve. This

signal alternately puts a positive 6 Volts on Pin F of the MS

connector, then on Pin E of the connector. See the Typical

Output Signal diagram. Valve control is obtained by increasing the duration of the signal on one pin while decreasing the

duration of the signal on the other.

When at null (neutral) control position, the duration of the 6

Volt output on one pin equals the duration of the 6 Volt output

on the other pin. Because of the frequency of the cycling (250

to 600 Hz), the valve remains centered.

As the shaft is turned clockwise from its null position, the

duration of the signal from Pin F becomes longer and the

duration of the signal from Pin E becomes shorter, the

opposite being true when the shaft is turned counterclockwise.

370D

TYPICAL OUTPUT SIGNAL

F

PULSE RELATION AT NULL

E

F

PULSE DRIVING TOWARD PIN E

E

As the correction in control is made and the steering position

aligns with the sensor, the signals will become balanced and

the servovalve will center.

BLN-95-8928-4

966

3

Page 4

CUSTOMER SERVICE

NORTH AMERICA

ORDER FROM

Danfoss (US) Company

Customer Service Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

Phone: (763) 509-2084

Fax: (763) 559-0108

DEVICE REPAIR

For devices in need of repair or evaluation, include a

description of the problem and what work you believe

needs to be done, along with your name, address and

telephone number.

RETURN TO

Danfoss (US) Company

Return Goods Department

3500 Annapolis Lane North

Minneapolis, Minnesota 55447

EUROPE

ORDER FROM

Danfoss (Neumünster) GmbH & Co.

Order Entry Department

Krokamp 35

Postfach 2460

D-24531 Neumünster

Germany

Phone: 49-4321-8710

Fax: 49-4321-871-184

BLN-95-8928-4

4

Loading...

Loading...