Data Sheet

Fan speed controller

Accessory

Type ACCSCS

Electronic controller suitable for fan speed control

ACCSCS are designed to regulate the speed of

fans and pumps proportionally and

continuously. They function as a simple voltage

regulator whose command signal (0..10 V or

4..20 mA or PWM) comes from an external

regulating device.

It’s possible to connect more than one motor in

parallel provided that the maximum input

regulating current is less than the controller

nominal current.

Features:

Three phase model

• Power 400 V

• Input voltage three phase 400 V AC -15 +10%,

50/60 Hz

• Output voltage 30 – 99% of supply line

• Command signal 0 – 10 V, 4 – 20 mA and

PWM 5 / 10 V

• Aux output supply 10 V aux power (Imax = 50

mA) for external potentiometer

• Output relay that commute in case of phase

loss or overtemperature

AI205486421156en-000702

Features

Description

Power supply

400 V AC

Test

According to EN60730 this device provides a type 1 action, it is an incorporated controller suitable for assembly on a at

surface and for use in conditions of normal pollution.

Storage conditions

-20 – 70 °C

Index of protection

Plastic covering which is self-extinguishing: IP55

EMC (Electro-Magnetic Compatibility

The controller has a built-in suppression lter to meet all required CE directives. Danfoss controls are designed to be installed inside a machine or a standard electrical cabinet and is therefore considered a component. It is the installer’s responsibility to observe the criteria of compatibility to guarantee compliance with the directives.

Wiring

• All wiring should conform to local regulations and must be made by authorized personnel only.

• All connections wires must ensure ecient insulation also at temperatures exceeding 80 °C.

• Attach the controller to a non-painted plate with anti-corrosive treatment. If the length of the motor cable exceeds 5 m,

use shielded cable. To avoid dispersion currents, both ends of the motor cable shield, the motor earth, and the

controller earth must be connected to the same earth pole.

• If the control cable length exceeds 2 m, use shielded cable, connecting the shield only at the end of the controller.

• Ensure that the control 0 V is not connected to earth. If the power, motor and control cables exceed 10 m, make sure

they are separated by at least 0.3 m to avoid creating a coupling eect.

• To protect the power line and the regulator, the installation technician must install extra-rapid fuses upstream of the

power supply. If a dierential circuit breaker is installed, it must be of the delayed action type.

Features

Description

Product No.

080G0217

080G0218

080G0219

080G0220

Power - 400 V AC

5.5 K V A

8 K V A

13 K V A

19 K V A

Current nom (Arms)

8 A

12 A

20 A

28 A

Input voltage

Three phase 400 V AC -15 +10%, 50/60 Hz

Output voltage

30 – 99% of supply line

Command signal

Signal 0 – 10 V, 4 – 20 mA, PWM 5/10 V and Modbus

Analog output

10 V (max load 50 mA)

Digital output

Emergency relay 1 A-250 V AC / 3 A-30 V DC

Protections

Class II at the input terminal block (4 K V)

Class I as regards the accessible parts

Phase lost, overheating (the regulator restores automatical)

Operating temperature

-10 – 50 °C (-20 °C when the power is maintained)

Max heat sink tempearture

75 °C

Storage temperature

-20 – 80 °C

Protection degree

Self-extinguishing plastic covering IP55

Dimensions (mm) - LxHxP

230 x 165 x 150

230 x 265 x 165

230 x 265 x 230

340 x 270 x 235

Fan speed controller, Accessory

Product specication

General features

Table 1: General features

Technical data

Table 2: Three phase

Modbus address

Example: Request by the MASTER to read the variable “output voltage” identied with address 0x0B: 01 03 00 0B 00

01.

Request by the MASTER to write on the variable “Modbus input command” identied with address 0x401: 01 06 04 01

00 01.

CAUTION:

The regulation command via Modbus requires rewriting in its address within the time out (default 30 seconds) even

if the value remains unchanged.

Over the time out, in absence of any other command signal, the regulator switch OFF the power outputs.

© Danfoss | Climate Solutions | 2021.03 AI205486421156en-000702 | 2

Vout %

V2

V1

limit V1

IN.MIN IN.MAX 100%

command

1

Danfoss

80G8092A

Vout %

V2

V2

V1

limit V1

IN.MIN IN.MAX 100%

command

2

Danfoss

80G8092B

HEX

address

Variable

Unit

Reading/

Writing

Min. value

Max. value

Description

0x00B

Voltage output

%L–

–

Indicates the output percentage voltage / speed

0x00D

Alarm

NumL–

–

0=no error

1=phase lost

3=over temperature

5=incorrect settings

6=timeout MDB

0x400

Stop regulation

Num

L/S01

Write the value 1 to enable writing and disable the

running place to 0 to re-enable the running

0x421

Regulator address

Num

L/S

(1)

1

247

Indicates the modbus address (slave) - default 0x01

0x422

Baudrate

Num

L/S

(1)

1

3

(=1 if 9600bps)

(=2 if 19200)

(=3 if 38400) - default =2

0x423

Stop Bit

Num

L/S

(1)

1

2

(=1 if 1 stop bit)

(=2 if 2 stop bit) - default=1

0x424

Parity

Num

L/S

(1)

1

3

(=1 if no parity)

(=2 if even parity)

(=3 if odd parity) - default =1

0x425

Timeout

Sec

L/S

(2)

1

240

Indicates the time within which the master must renew his command regulation

0x401

Command by Modbus

%

L/S

(2)

0

100

Variable for command the regulation (0-100) by

Modbus

0x402

Min. input%L/S

(2)

10

Max input

Voltage signal command / speed V1

0x403

Max input%L/S

(2)

Min. input

100

Voltage signal command / speed V2

0x404

Min. V1 voltage

%

L/S

(2)

Lim. min. motor

Max. V2 Voltage

Voltage / speed of IN.MIN. command signal point

0x405

Max. V2 voltage

%

L/S

(2)

Min. V1 voltage

Lim. max. motor

Voltage / speed of IN.MAX. command signal point

0x407

Reset

Num

L/S

(2)

1

3

(=2 to reset and load the controller’s default values)

(=3 to restart the regulator after changing the

parameter / s when is required the reboot)

0x40A

Lim. Speed V1

%

L/S

(2)

Lim. min. motor

V2 limit

Voltage that replaces V1, when V1 LIMIT>V1

0x411

Kick start

Num

L/S

(2)

0

1

(=0 kick start enable)

(=1 kick start able)

0x41E

Regulation prole

Num

L/S

(2)

1

2

(=1 linear prole)

(=2 axial fans prole)

Fan speed controller, Accessory

Table 3: Modbus address

(1)

(1)

Necessary reebot after writing the changes.

Necessary reebot after writing the changes.

(2)

(2)

Writing possible only if the parameter “Adjustment Lock” is set to 1.

Writing possible only if the parameter “Adjustment Lock” is set to 1.

Figure 1: Voltage graph 1

Figure 2: Voltage graph 2

© Danfoss | Climate Solutions | 2021.03 AI205486421156en-000702 | 3

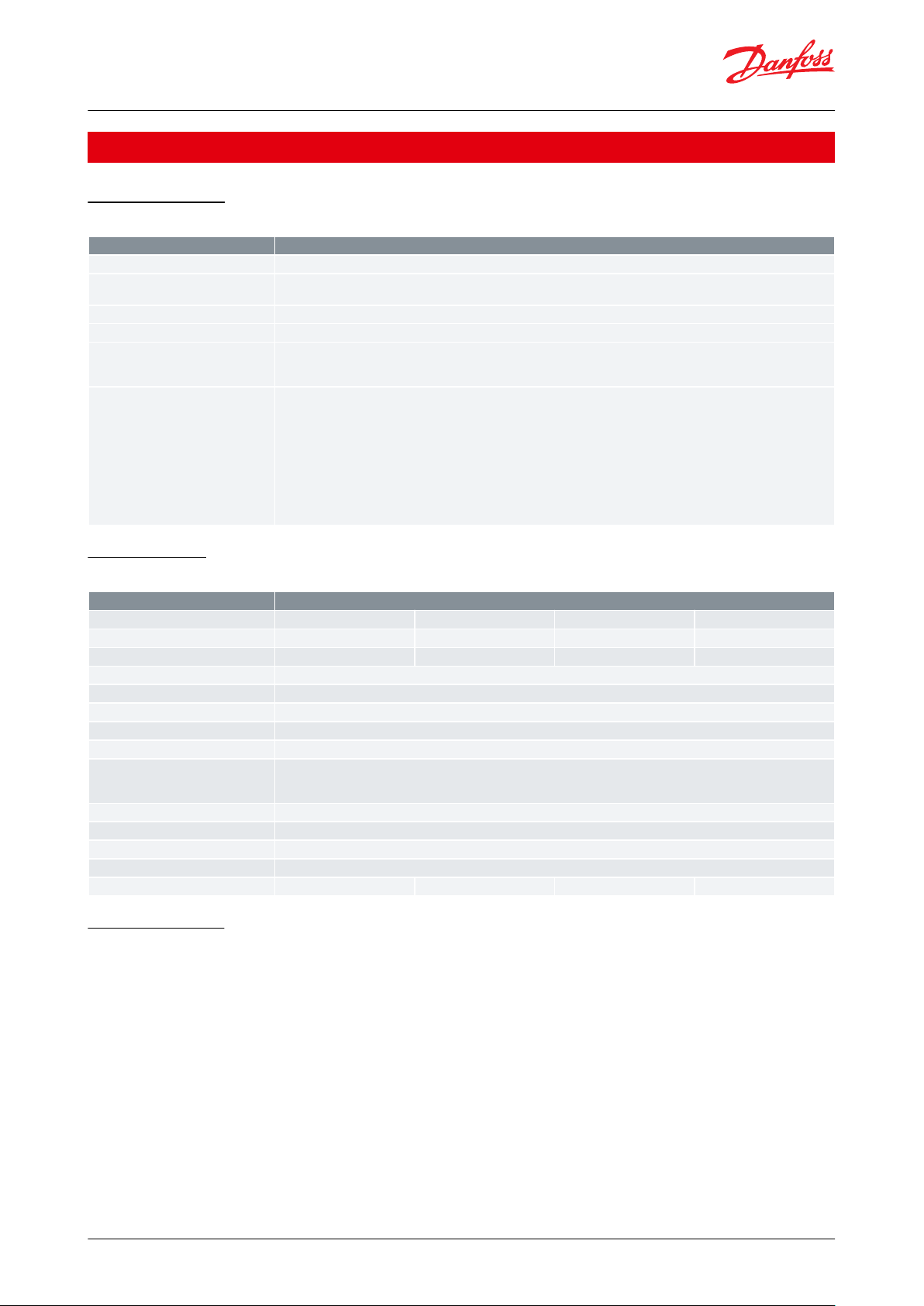

080G0217

080G0218 - 080G0219

080G0220 - 080G0279

Danfoss

80G8094B

T3

T2

T1

PE

L1

L2

L3

DL4

DL5

DL3

DL1

DL2

0.10

+V

NC

COM

NO

+5

IN1

0V

4.20

T+

T-

0V

I4I3I2

I1

0V

motor

power supply

LED

command

Danfoss

80G8094C

T1/U

T2/V

T3/W

PE

L3/T

L2/S

L1/R

I4

I3

I2

I1

0V

T+

T-

0V

IF

IF

motor

power supply

DL5

DL4

LED

commandcommand

DL3

DL1

DL2

LED

0.10

+V

NC

COM

NO

+5

IN1

0V

4.20

Danfoss

80G8094D

L3/T

L3/T

28/40

50

60

PE/

PE/

0.10

+V

NC

COM

NO

+5

IN1

0V

4.20

command

command

power supply

power supply

motor

motor

T+

T-

0V

IF

IF

I4I3I2

I1

0V

T3/W

T3/W

L2/S

L2/S

L1/R

L1/R

T2/V

T2/V

T1/U

T1/U

M6

E10

DL2

DL1

DL3

DL4

DL5

LED

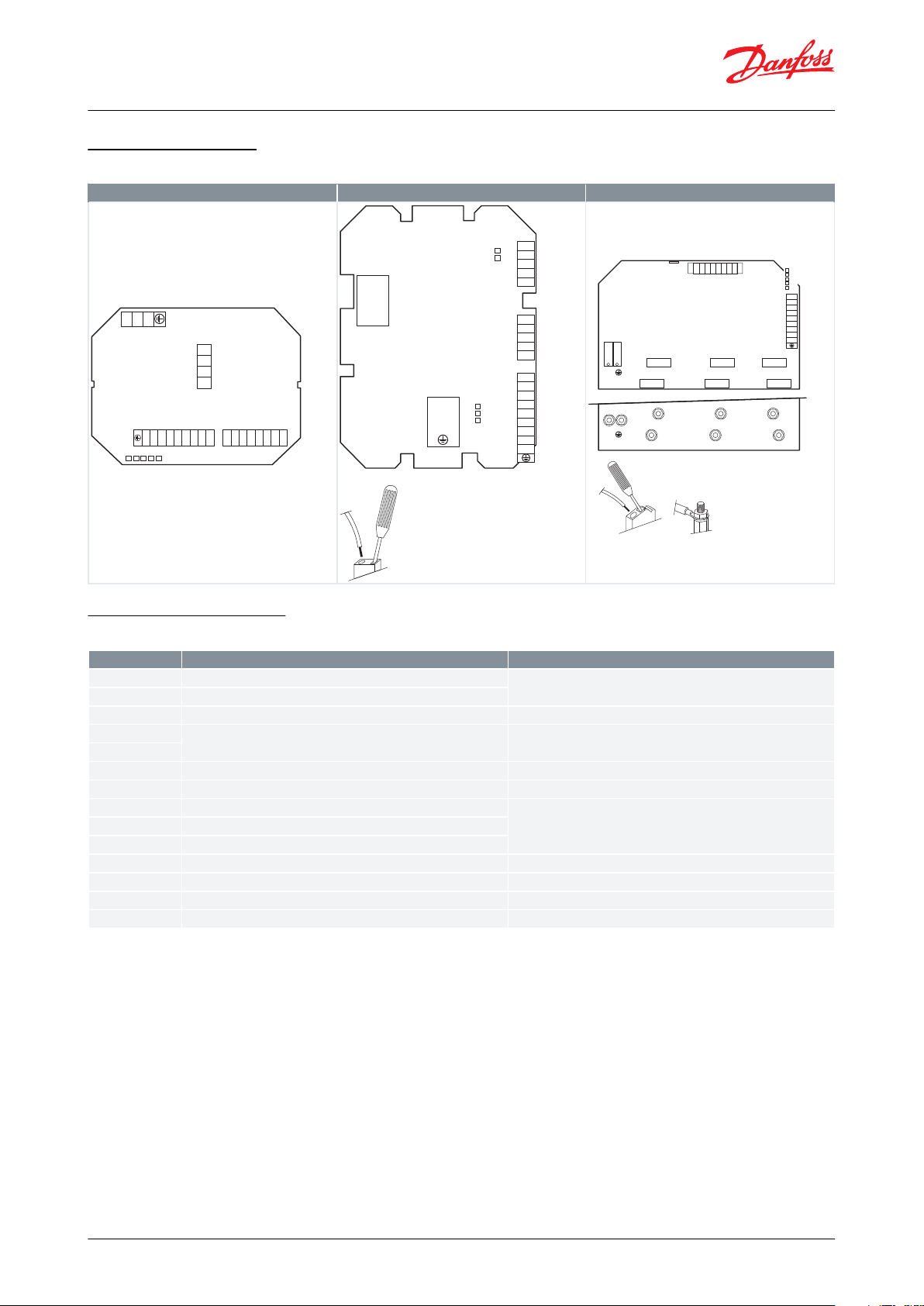

Name

Description

Application

T1 +

Serial RS485, Modbus RTU - slave

Serial connection line to a Master controlled device

T1 -

Serial RS485, Modbus RTU - slave

0 V

Ground I/O

Ground I/O

IF

Pwm input 2..20 kHz (Ri = 500 Ω, 5..24 V)

Variable frequency command input IF (only on request)

IF

0.10

Analog input, type 0 – 10 V (Ri = 40 kΩ)

0 – 10 V analog command input

+ V

Aux. supply output 12 V= (max 30 mA)

External potentiometer supply for manual command

NC

Relay 1 contact output normally closed

Programmable output. With standard setting for Defect, the relay is enabled (NO-COM eachother closed) and is disabled in emergency case

COM

Relay 1 common contact output (1A-250 V~ / 3 A-30 V=)

NO

Relay 1 contact output norm. open

+5 V

Output aux. supply 5 V= (max 15 mA)

/

IN 1

Analog input pwm (5 – 15 V, 100 Hz frequency)

PWM input command with variable average value

0 V

Ground I/O

Ground for analgical input

4.20

Analog input , type 4 – 20 mA (Ri = 100 Ω)

4..20 mA analog command input

Fan speed controller, Accessory

Connection diagram

Table 4: Three phase connection diagram

Controls terminal board

Table 5: Controls terminal board

© Danfoss | Climate Solutions | 2021.03 AI205486421156en-000702 | 4

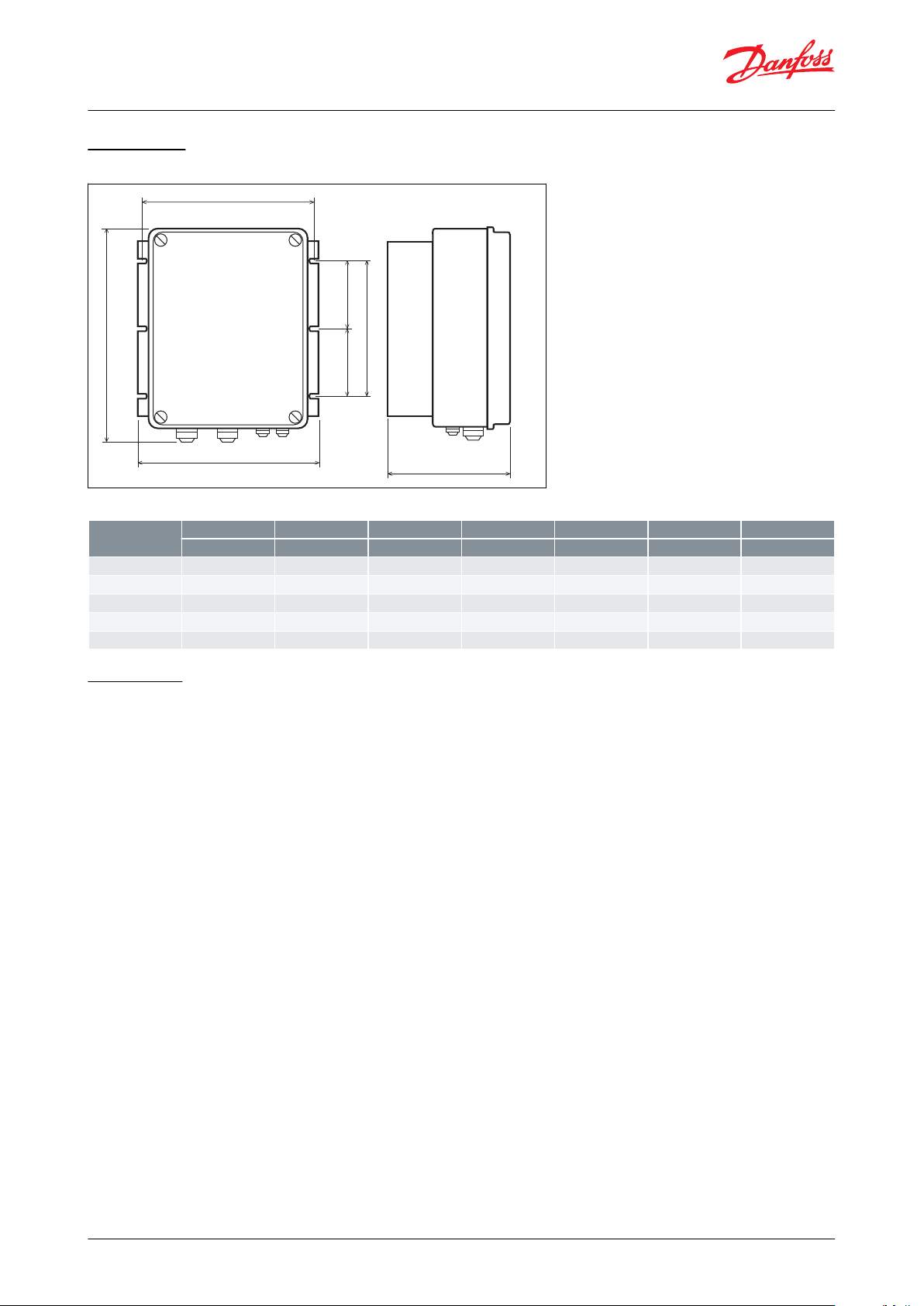

C

B

D

F

E

F

A

Danfoss

80G8090.01

Code No.

ABCDEFWeight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[kg]

080G0217

230

165

150

21580-

2.5

080G0218

230

265

165

215

170-4

080G0219

230

265

230

215

170-4.8

080G0220

340

270

235

322

165-7

080G0279

230

165

150

21580-

2.5

Fan speed controller, Accessory

Dimensions

Figure 3: Three phase

Table 6: Dimensions

Installation

Mechanical installation:

The ACCSCS regulator must be wall-mounted vertically, in order to guarantee adequate dispersion of heat in the

area of air circulation and prevent obstructions to air ow in the dissipator zone. ACCSCS has IP55 grade protection,

anyway protect it from corrosive liquids, gas, heat sources and position it preferably sheltered from the sun’s rays.

Make sure that it does not undergo vibrations.

Electrical installation:

All wiring should conform to local regulations and must be made by authorized personnel only. To protect the

power line and the regulator, the installation technician must install extra-rapid semiconductor fuses upstream of

the power supply adequate for the load and with a value of I²xt less than the value given in the table below. If a

dierential circuit breaker is installed, it must be of the delayed action type. The data are related to operate at 400 V

~ 50 Hz. For 230 V voltage supply or models at 440 / 460 V all current data are the same. Max current refers to an

enviroment temperature of 50 °C for a maximum time of 10 second every 5 minutes.

© Danfoss | Climate Solutions | 2021.03 AI205486421156en-000702 | 5

Description

Code No.

ACCSCS, Three Phase Reg. 400 V AC, 8A

080G0217

ACCSCS, Three Phase Reg. 400 V AC, 12A

080G0218

ACCSCS, Three Phase Reg. 400 V AC, 20A

080G0219

ACCSCS, Three Phase Reg. 400 V AC, 28A

080G0220

ACCSCS, Three Phase Reg. 400 V AC, 8A, I

080G0279

Document type

Document topic

EU Declaration of conformity

EMC directive 2014/30/EU

EN61800-3: 2004 +A1: 2012

LVD directive 2015/35/EU:

EN60730-1: 2011

RoHS directive 2011/65/EU and 2015/863/EU:

EN 50581: 2012

Fan speed controller, Accessory

Ordering

Product part numbers

Table 7: Product part numbers

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI205486421156en-000702 | 6

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI205486421156en-000702 | 7

Loading...

Loading...