Page 1

MAKING MODERN LIVING POSSIBLE

Technical Information

Series 45

G Frame

powersolutions.danfoss.com

Page 2

Technical Information Series 45 G Frame Pumps

Contents

Frame G

Design ........................................................................................................................................................................................... 4

Specifications ............................................................................................................................................................................. 5

Performance G74B .................................................................................................................................................................... 6

Performance G90C ................................................................................................................................................................... 7

Order code ................................................................................................................................................................................... 8

Controls....................................................................................................................................................................................... 10

Pressure compensated control (PC) ........................................................................................................................... 10

Remote PC control (RP) ................................................................................................................................................... 10

Load sensing control (LS) ............................................................................................................................................... 11

Load sensing control with internal bleed orifice (LB) .......................................................................................... 11

Input shafts ............................................................................................................................................................................... 12

Auxiliary mounting pads ...................................................................................................................................................... 13

SAE-A auxiliary mounting pad ..................................................................................................................................... 13

SAE-B auxiliary mounting pad ..................................................................................................................................... 13

Displacement limiter.............................................................................................................................................................. 14

SAE-C auxiliary mounting pad ..................................................................................................................................... 14

Installation drawings ............................................................................................................................................................. 15

Running cover .................................................................................................................................................................... 15

Adjustable displacement limiter ................................................................................................................................. 15

Axial ported endcap ........................................................................................................................................................ 16

Radial ported endcap ...................................................................................................................................................... 18

11058670 • Rev BA • Sep 20132

Page 3

Technical Information Series 45 G Frame Pumps

This information was removed from:

Series 45 Axial Piston Open Circuit Pumps Technical Information Manual 520L0519

Rev E November 2006

For more information regarding the Series 45 product line refer to the current version of 520L0519.

11058670 • Rev BA • Sep 2013 3

Page 4

Technical Information Series 45 G Frame Pumps

T

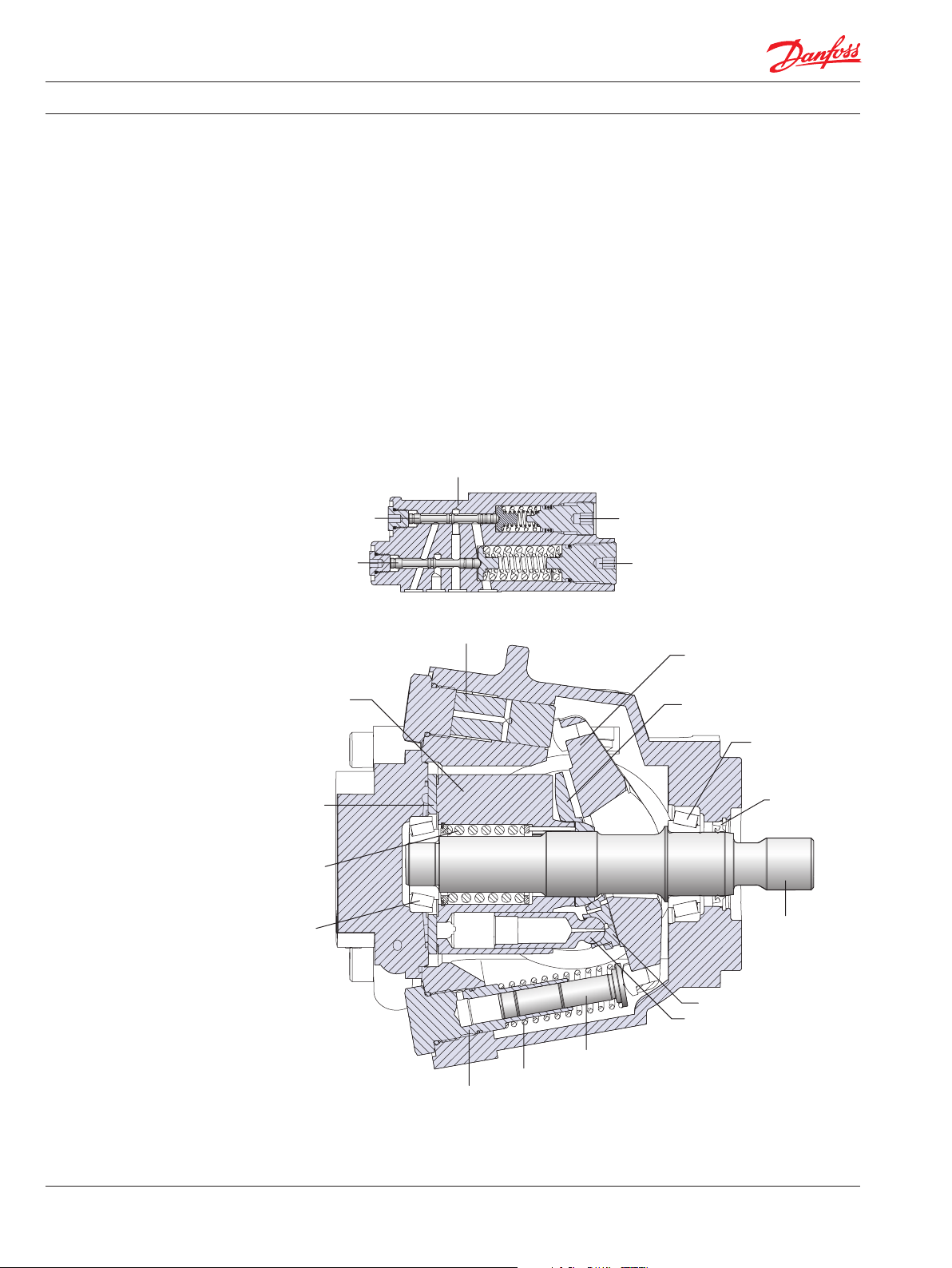

Design

Series 45 Frame G pumps have a dual servo piston design with a cradle-type swashplate set in

polymer-coated journal bearings. The bias piston increases swashplate angle. The displacement

piston decreases swashplate angle. At equal pressure, the larger diameter displacement piston

overpowers the bias piston. Nine reciprocating pistons displace fluid from the pump inlet to the

pump outlet as the cylinder block rotates on the pump input shaft. The block spring holds the piston

slippers to the swashplate via the slipper retainer. The cylinder block rides on a bi-metal valve plate

optimized for high volumetric efficiency and low noise. Tapered roller bearings support the input

shaft and a viton lip-seal protects against shaft leaks.

An adjustable one spool (PC only, not shown) or two spool (LS) control senses system pressure and

load pressure (LS controls). The control ports system pressure to the displacement piston to control

pump output flow.

Frame G cross section

LS control

(attached to endcap)

LS spool

PC spool

LS adjustment

PC adjustment

Displacement piston

Swashplate

Cylinder

block

Valve

plate

Cylinder

block

spring

apered

roller

bearing

Bias piston guide

Bias spring

Bias piston

Slipper retainer

Tapered roller

bearing

Shaft seal

Input shaft

Slipper

Piston

P104 002E

11058670 • Rev BA • Sep 20134

Page 5

Technical Information Series 45 G Frame Pumps

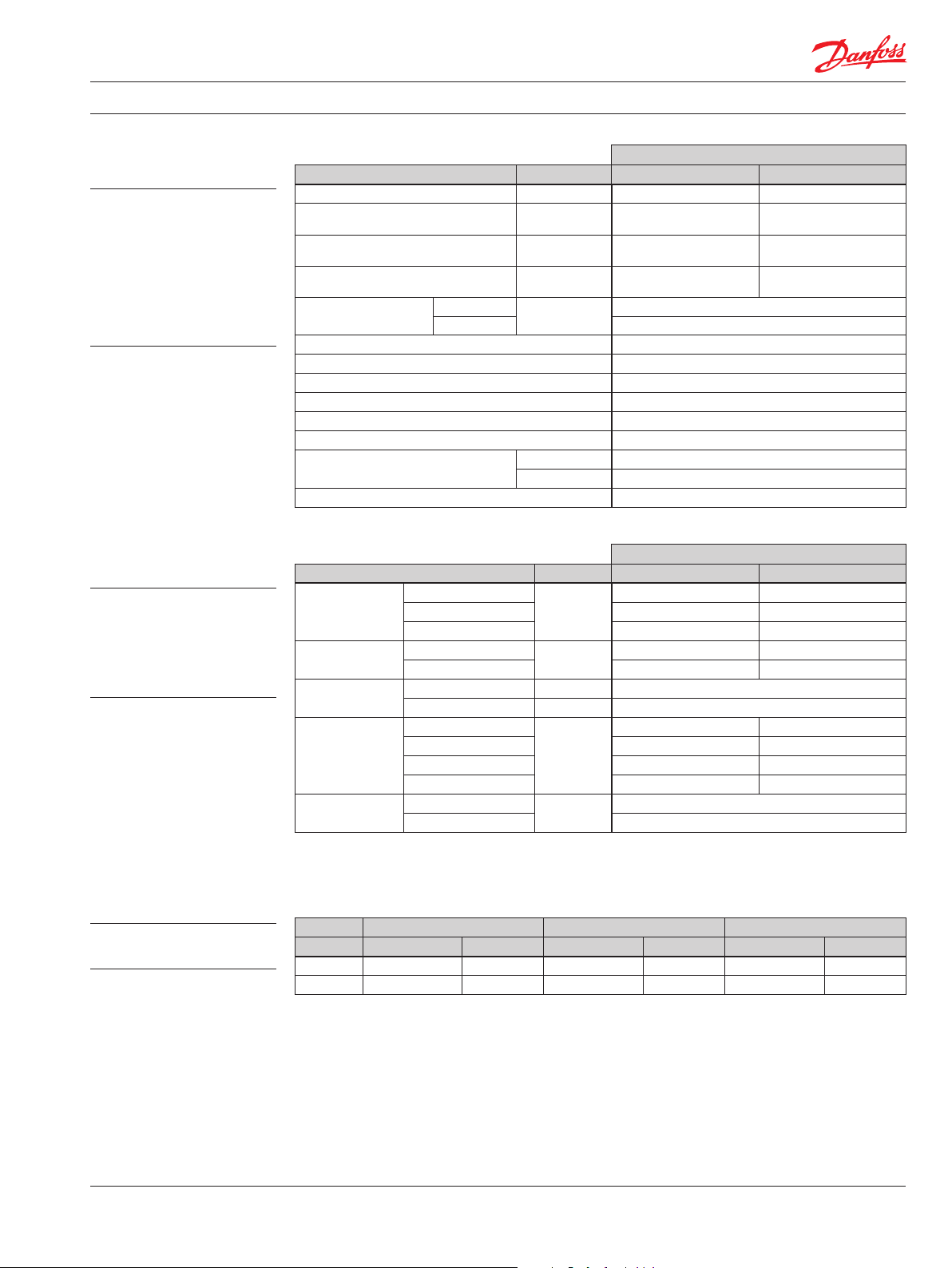

Specifications

For general operating

parameters, including fluid

viscosity, temperature, and

inlet and case pressures,

see page 13. For system design

parameters, including

installation, filtration,

reservoir, and line velocities,

see page 15.

For definitions of pressure and

speed ratings, see page 14. For

more information on external

shaft loads, see page 16;

mounting flange loads,

see page 17.

Features and options

Feature Unit G74B G90C

Maximum Displacement cm³ [in³] 74 [4.52] 90 [5.49]

Flow at rated speed (theoretical) l/min

Input torque at maximum

displacement (theoretical)

Mass moment of inertia of internal

rotating components

Weight Axial ports kg [lb] 29 [63]

Radial ports 36 [80]

Rotation Clockwise, Counterclockwise

Mounting SAE-C

Auxiliary mounting (See page 74 ) SAE-A, SAE-B, SAE-BB, SAE-C

System ports (type) 4-bolt split flange

System ports (location) Axial, Radial

Control types (See page 71) PC, Remote PC, LS, LS with internal bleed

Shafts (See page 73) Splined 14 tooth, 17 tooth

Displacement limiters (See page 75 ) Optional, adjustable

[US gal/min]

N•m/bar

[lbf•in/1000 psi]

kg•m²

[slug•ft²]

Straight Ø 31.75 mm [1.25 in]

177.6

[46.9]

1.178

[719]

0.00630

[0.00465]

Ratings

Rating Units G74B G90C

Input speed

Working pressure continuous bar [psi] 310 [4 495] 260 [3770]

External shaft

loads

Bearing life at 140 bar [2030 psi] B10 hours 41 383 19 847

Mounting flange

load moments

1. Input speeds are valid at 1 bar absolute [0 in Hg vac] inlet pressure. See Inlet p ressure vs. speed charts.

1

minimum min-1 (rpm) 500 500

continuous 2400 2200

maximum 2800 2600

maximum 400 [5800] 350 [5075]

External moment (Me) N•m [lbf•in] 300 [2655]

Thrust in (Tin), out (T

at 210 bar [3045 psi] 9048 4339

at 260 bar [3770 psi] 4062 194 8

at 310 bar [4495 psi] 2101 —

Vibratory (continuous) N•m [lbf•in] 1580 [14 000]

Shock (max) 5650 [50 000]

) N [lbf] 2900 [650]

out

Model

198

[52.3]

1.432

[874]

0.00650

[0.00480]

Model

For more information on noise

levels, see page 19.

Sound levels

dB(A) 210 bar [3045 psi] 260 bar [3770 psi] 310 bar [4495 psi]

Model 1800 mi n-1(rpm) Rated speed 1800 min-1(rpm) Rated speed 1800 min-1(rpm) Rated speed

G74B 75 78 74 76 75 77

C90C 74 76 75 77 — —

2. S ound data was collec ted in a semi-anechoic chamber. Values have b een adjusted (-3 dB) to refle ct anechoic levels.

11058670 • Rev BA • Sep 2013 5

2

Page 6

Technical Information Series 45 G Frame Pumps

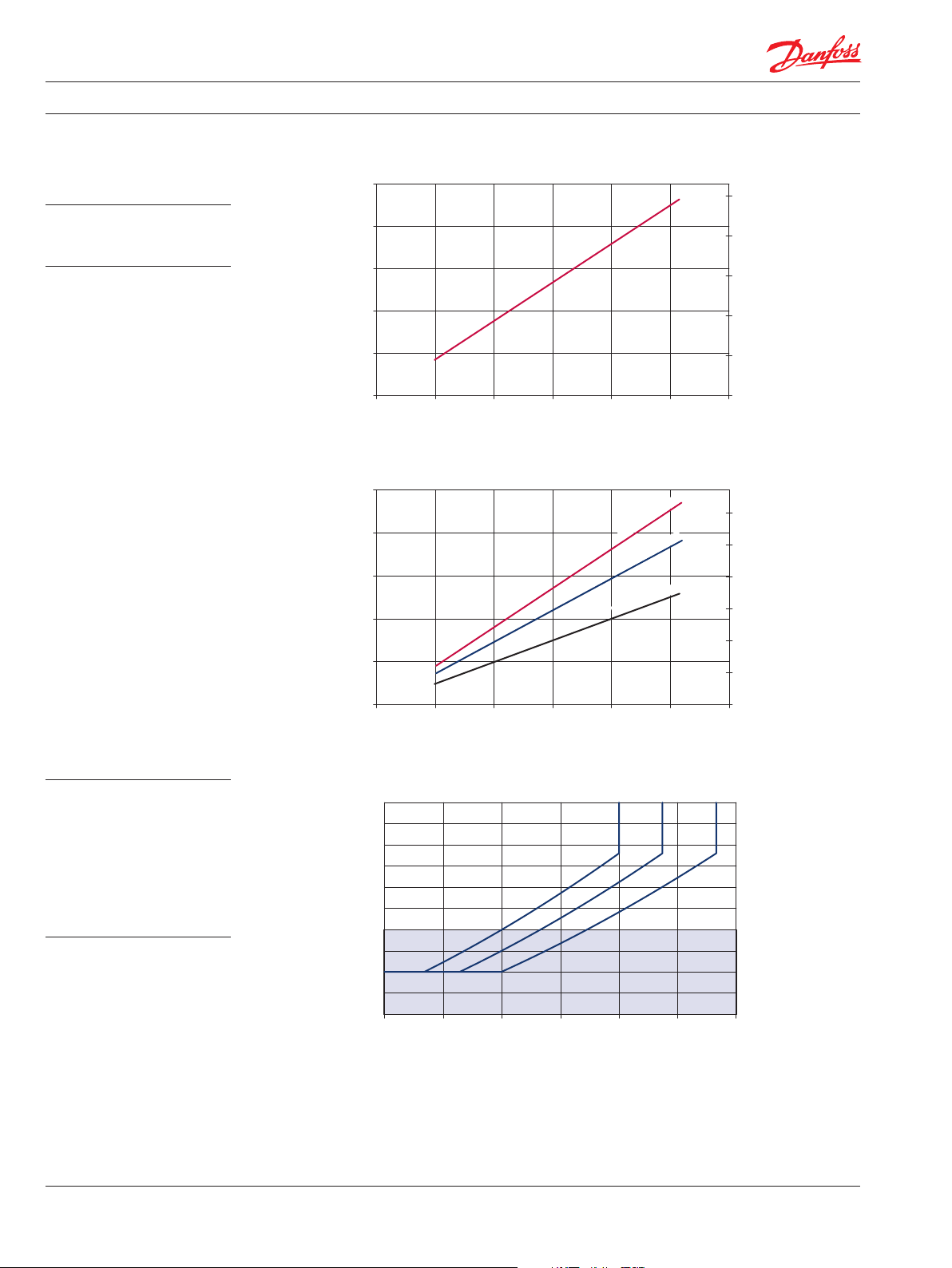

Performance

G74B

Flow and power data valid at

49°C [120°F] and viscosity of

17.8 mm²/sec [88 SUS].

Flow vs. speed

200

160

120

80

Flow (l/min)

40

Input power vs. speed

100

80

60

40

Power (kW)

20

0

0 500 1000 1500 2000 2500

Speed min(rpm)

-1

260 bar [3770 psi]

210 bar [3045 psi]

140 bar [2030 psi]

P104 004E

50

40

30

20

Flow (US gal/min)

10

0

120

100

80

60

Power (hp)

40

20

The chart on the right shows

allowable inlet pressure and

speed at various

displacements. Greater speeds

and lower inlet pressures are

possible at reduced

displacement. Operating

outside of acceptable limits

reduces pump life.

0

Inlet pressure vs. speed

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

Inlet Pressure (bar abs)

0.7

0.6

0 500 1000 1500 2000 2500

Speed min(rpm)

2000 2200 2400 2600 2800 3000

Shaft Speed min(rpm)

-1

100% 90%80%

-1

P104 005E

P104 015E

0

8

6

4

2

0

3

6

9

(psi gauge)

ac)

(in Hg v

11058670 • Rev BA • Sep 20136

Page 7

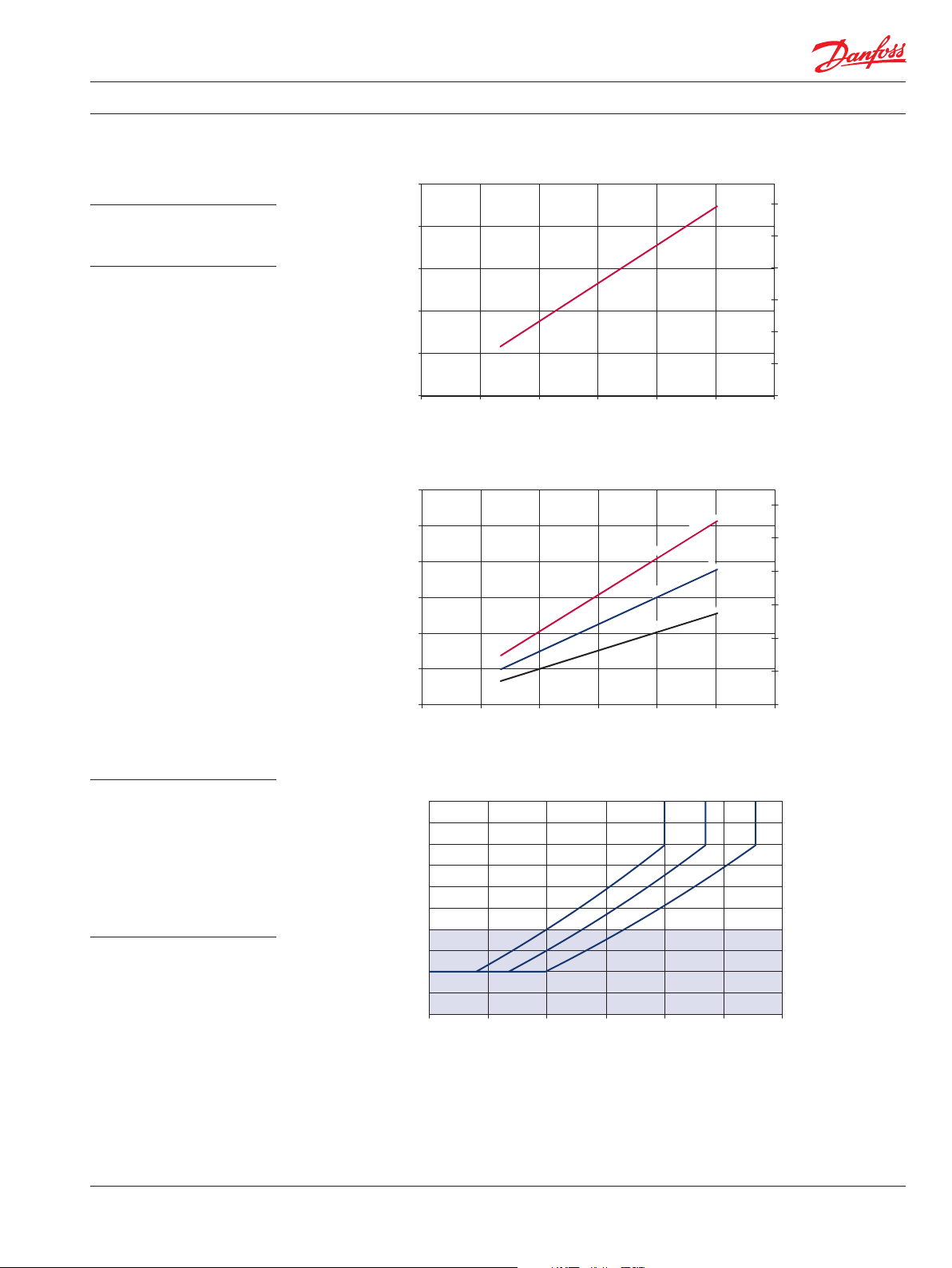

Technical Information Series 45 G Frame Pumps

Performance

G90C

Flow and power data valid at

49°C [120°F] and viscosity of

17.8 mm²/sec [88 SUS].

Flow vs. speed

250

200

150

100

Flow (l/min)

50

Input power vs. speed

120

100

80

60

40

Power (kW)

0

0 500 1000 1500 2000 2500

Speed min(rpm)

-1

255 bar [3698

697

[2

bar

186

r [1798 p

a

b

4

12

psi]

psi]

60

50

40

30

20

Flow (US gal/min)

10

0

P104 006E

150

125

100

si]

75

50

Power (hp)

The chart on the right shows

allowable inlet pressure and

speed at various

displacements. Greater speeds

and lower inlet pressures are

possible at reduced

displacement. Operating

outside of acceptable limits

reduces pump life.

20

0

Inlet pressure vs. speed

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

Inlet Pressure (bar abs)

0.7

0.6

0 500 1000 1500 2000 2500

Speed min(rpm)

1800 2000 2200 2400 2600 2800

Shaft Speed min(rpm)

-1

100% 90%80%

-1

P104 007E

P104 015E

25

0

8

6

4

2

0

3

6

9

(psi gauge)

ac)

(in Hg v

11058670 • Rev BA • Sep 2013 7

Page 8

Technical Information Series 45 G Frame Pumps

Order Code

J K

R S P C D E F G H 1 2 3 1 2 3 L M N

R Product

GR G Frame, variable displacement open circuit pump

S Rotation

L Left hand (counterclockwise)

R Right hand (clockwise)

P Displacement and pressure rating

074B 074 cm³/rev [4.52 in³/rev], 310 bar [4495 psi] continuous working pressure

090C 090 cm³/rev [5.49 in³/rev], 260 bar [3770 psi] continuous working pressure

C Control type

PC Pressure compensated control 100-280 bar [1450-4060 psi]

BC Pressure compensated control 290-310 bar [4205-4495 psi]

RP Remote pressure compensated control 100-280 bar [1450-4060 psi]

BP Remote pressure compensated control 290-310 bar [4205-4495 psi]

LS Load sensing / pressure compensating control 100-280 bar [1450-4060 psi]

BS Load sensing / pressure compensating control 290-310 bar [4205-4495 psi]

LB Load sensing / pressure compensating control with internal bleed orifice 100-280 bar [1450 -4060 psi]

BB Load sensing / pressure compensating control with internal bleed orifice 290 -310 bar [4205-4495 psi]

D PC setting (2 digit code, 10 bar increments)

Example 10 = 100 bar

10–31 100 to 310 bar [1450 to 4495 psi] (074B)

10–26 100 to 260 bar [1450 to 3770 psi] (090C)

E Load sensing setting (2 digit code, 1 bar increments)

Example 20 = 20 bar

10–30 10 to 40 bar [145 to 435 psi]

NN Not applicable (use with PC controls)

F Not used

NN Not applicable

11058670 • Rev BA • Sep 20138

Page 9

Technical Information Series 45 G Frame Pumps

Order Code

(continued)

J K

R S P C D E F G H 1 2 3 1 2 3 L M N

G Pilot orifice

N Standard

H Gain orifice

3 Standard

J1 Input shaft

S1 14 tooth, 12/24 pitch (ANSI B92.1 1970 - Class 5)

S2 17 tooth, 12/24 pitch (ANSI B92.1 1970 - Class 5)

K4 Ø 31.75 mm [1.25 in], straight keyed

J2 Auxiliary mounting flange

N None

A SAE-A, 9-tooth coupling

T SAE-A, 11-tooth coupling

B SAE-B, 13-tooth coupling

V SAE-BB, 15-tooth coupling

C SAE-C, 14-tooth coupling

J3 System port size and location

Code Location Port type Inlet size Outlet size

2 Radial 4-bolt split-flange 2 in. 1 in.

4 Axial 4-bolt split-flange 2 in. 1 in.

K1 Shaft seal

A Single lip seal, viton

K2 Mounting flange and housing port style

1 SAE-C 4-bolt, SAE O-ring boss housing ports

K3 Not used

N Not applicable

L Displacement limiter

NNN None

AAA Adjustable, factory set at max angle (074B)

CAA Adjustable, factory set at max angle (090C)

M Special hardware

NNN None

N Special features

NNN None

11058670 • Rev BA • Sep 2013 9

Page 10

Technical Information Series 45 G Frame Pumps

M2

L2

M4

M2

Controls

Specifications

Schematic diagram

Pressure compensated control (PC)

PC control setting range

Model bar psi

G74B 100 –310 1450–4495

G90C 100 –260 1450–3770

PC schematic

B

L2

L1

S

P104 332

Remote PC control (RP)

Response/recovery times*

(ms) Response Recovery

G74B 35 130

G90C 40 140

* For definitions, see page 9.

Legend

B = Outlet

S = Inlet

L1, L2 = Case drain

M2 = System pressure gauge port

M4 = Servo pressure gauge port

Specifications

Schematic diagram

PC control setting range

Model bar psi

G74B 100 –310 1450–4495

G90C 100 –260 1450–3770

Remote PC schematic

X

B

P104 333

S

L1

X

M4

Response/recovery times*

(ms) Response Recovery

G74B 35 130

G90C 40 140

* For definitions, see page 10.

Legend

B = Outlet

S = Inlet

L1, L2 = Case drain

M2 = System pressure gauge port

M4 = Servo pressure gauge port

X = Remote PC port

11058670 • Rev BA • Sep 201310

Page 11

Technical Information Series 45 G Frame Pumps

M2

SL

M4

M2

M4

Controls (continued) Load sensing control (LS)

Specifications

Schematic diagram

PC setting range

Model bar psi

G74B 100 –310 1450–4495

G90C 100 –260 1450–3770

LS Schematic

X

B

L2

S

P104 331

L1

Response/recovery times*

(ms) Response Recovery

G74B 35 10 0

G90C 40 130

* For definitions, see page 11

LS setting range

Model bar psi

All 10–30 145–435

X

Legend

B = Outlet

S = Inlet

L1, L2 = Case drain

M2 = System pressure gauge port

M4 = Servo pressure gauge port

X = LS signal port

Specifications

Schematic diagram

Load sensing control with internal bleed orifice (LB)

PC setting range

Model bar psi

G74B 100 –310 1450–4495

G90C 100 –260 1450–3770

LB Schematic

X

X

Response/recovery times*

(ms) Response Recovery

G74B 35 10 0

G90C 40 130

* For definitions, see page 11.

LS setting range

Model bar psi

All 10–30 145–435

Legend

B = Outlet

B

S = Inlet

L1, L2 = Case drain

M2 = System pressure gauge port

M4 = Servo pressure gauge port

X = LS signal port

L2

P104 330

1

11058670 • Rev BA • Sep 2013 11

Page 12

Technical Information Series 45 G Frame Pumps

[1.89 ± 0.024]

[0.31

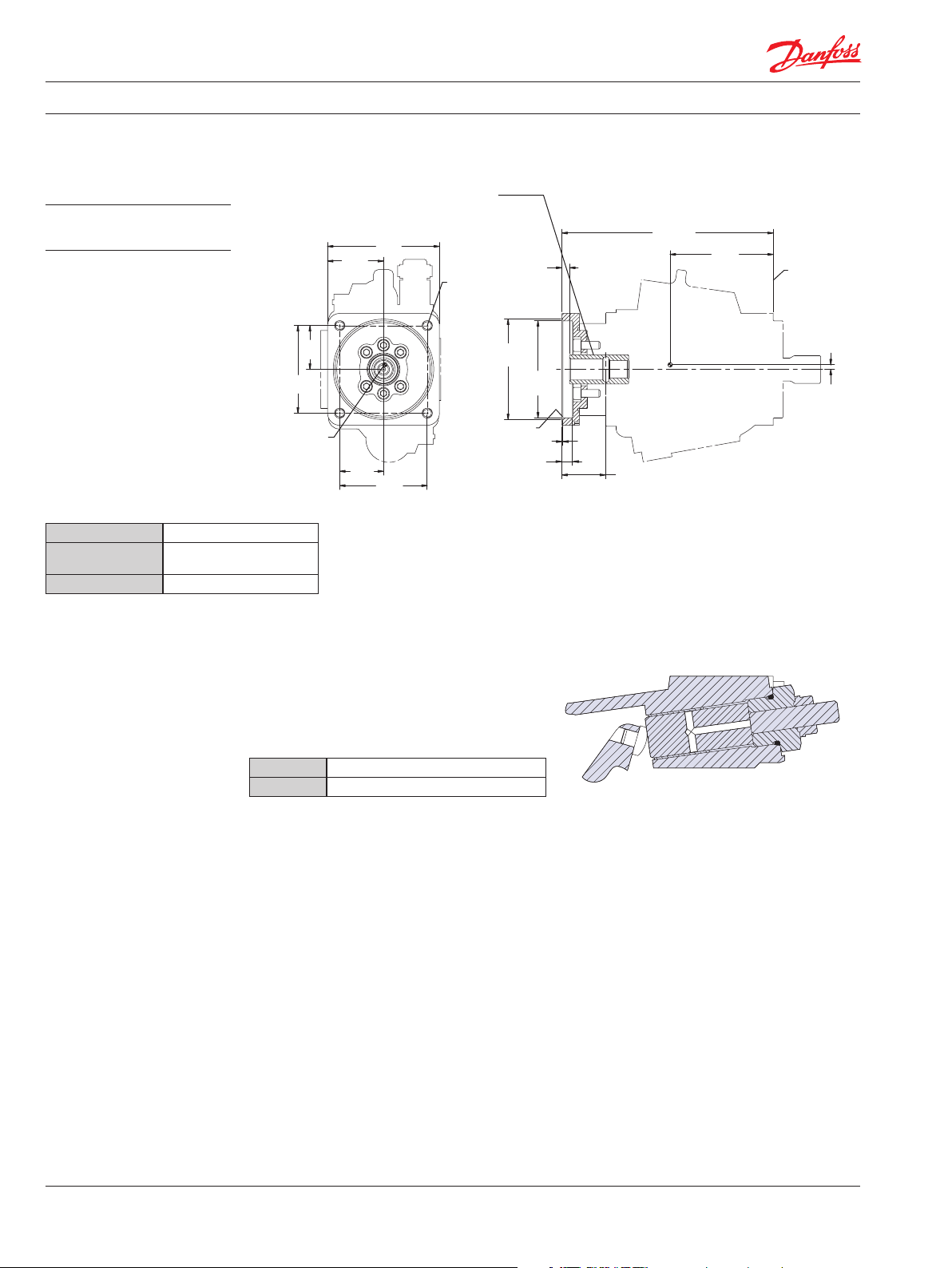

Mounting

flange

P104 034E

Input Shafts

Shaft data

Code Description

S1 14 tooth spline

12/24 pitch

(ANSI B92.1 1970 - Class 5)

Maximum torque rating¹

N•m [lbf•in] Drawing

734 [6500]

47.6 ± 0.6

[1.84 ± 0.024]

25.52 [1.005] max

Mounting

flange

8 ± 0.8

[0.31 ± 0.03]

29.634 [1.167] pitch |

14 teeth 12/24 pitch

30` pressure angle

fillet root side fit

Compatible with

ANSI b92.1-1970

Class 5 also mates with

flat root side fit

Ø28 ± 0.15

[1.102 ± 0.006]

Coupling must not

protrude beyond

this point

Ø31.14 ± 0.08

[1.226 ± 0.003]

P104 032E

S2 17 tooth spline

12/24 pitch

(ANSI B92.1 1970 - Class 5)

K4 Ø 31.75 mm [1.25 in]

Straight keyed

1017 [9000]

734 [6495]

53.97 ± 0.6

[1.874 ± 0.024]

30.75 max

[1.211]

Mounting

flange

48.06 ± 0.6

8 ± 0.8

± 0.03]

8 ± 0.8

[0.31 ± 0.03]

Coupling must not

protrude beyond

this point

A

A

Ø31.72

[1.249 ± 0.001]

Coupling must not

protrude beyond

this point

+0

7.94

-0.05

+0

[0.313 ]

-.002

Sq. Key x 28.56 lg

Section A-a

± 0.02

35.983 [1.417] pitch

17 teeth 12/24 pitch

30` pressure angle

fillet root side fit

compatible with

ANSI b92.1-1970

Class 5 also mates with

flat root side fit

Ø36.66 ± 0.08

[1.443 ± 0.003]

Ø34 ± 0.15

[1.339 ± 0.006]

P104 033E

[1.125]

35.2 ± 0.13

±0.01]

[1.39

1. See Input shaf t torque ratings, page 18 for an explanation of maximum torque.

11058670 • Rev BA • Sep 201312

Page 13

Technical Information Series 45 G Frame Pumps

Auxiliary Mounting Pads

SAE-A auxiliary mounting pad

Dimensions

See page 18 for mating pump

pilot and spline dimensions.

106.4

[4.19]

53.2

[2.09]

Coupling-sae 11t:

11 tooth spline, 16/32 pitch

17.463 [0.6875] pitch ø

Fillet root side fit

Per ANSI b92.1-1970, Class 6

Coupling-sae:

9 tooth spline, 16/32 pitch

14.288 [0.5625] pitch ø

Fillet root side fit

Per ANSI b92.1-1970, Class 6

Approximate

Center of

Gravity

O-ring seal required

Ref 82.27 [3.239] i.D.

2.62 [0.103] cross section

3/8 -16 unc-2b THD

17.8 [0.70] min THD depth

2x

Specifications

Coupling 9-tooth 11 -tooth

Spline minimum

engagement

Maximum torque 107 N•m [950 lbf•in] 147 N•m [1300 lbf•in]

Dimension A 21.1 mm [0.83 in] 16.1 mm [0.63 in]

13.5 mm [0.53 in] 15 mm [0.59 in]

Ø88.6

[3.49]

Ø82.6

[3.252

+0.08-0.00

+0.003-0.000

1.9

[0.077]

278.07

[10.95]

A

Min coupling

Clearance

132

[5.2]

Mounting

Flange

[0.24]

6

]

58.5

[2.30]

P104 042E

SAE-B auxiliary mounting pad

Dimensions

87

[3.43]

174

[6.85]

146

[5.75]

73

[2.87]

Coupling-sae b-b:

15 tooth spline, 16/32 pitch

23.813 [0.9375] pitch ø

Fillet root side fit

per ANSI b92.1-1970, class 6

Coupling-sae b:

13 tooth spline, 16/32 pitch

20.638 [0.8125] pitch

Fillet root side fit

per ANSI b92.1-1970, Class 6

1/2-13 unc-2b

Thd thru

19.7 [0.76] min

the depth

2x

Approximate

center of

gravity

See page 18 for mating pump

pilot and spline dimensions.

Specifications

Coupling 13- tooth 15- tooth

Spline minimum

engagement

Maximum torque 249 N•m [2200 lbf•in] 339 N•m [3000 lbf•in]

Dimension A 20.7 mm [0.81 in] 12.7 mm [0.5 in]

14.2 mm [0.56 in] 18.9 mm [0.74 in]

Ø105.64

[4.16]

Ø101.65

[4.002

O-ring seal required

Ref 101.32 [3.989] i.D.

1.78 [0.07] cross section

11±0.13

[0.43±0.01]

1.3

[0.05]

+0.08-0.0

+0.003-0.00

]

A

min coupling

clearance

54.1

[2.13]

273.69

[10.78]

132

[5.20]

Mounting

flange

[0.24]

P104 071E

6

11058670 • Rev BA • Sep 2013 13

Page 14

Technical Information Series 45 G Frame Pumps

Auxiliary Mounting Pads

(continued)

SAE-C auxiliary mounting pad

Dimensions

See page 18 for mating pump

pilot and spline dimensions.

Specifications

Coupling 14-tooth

Spline minimum

engagement

Maximum torque 339 N•m [3000 lbf•in]

18.3 mm [0.72 in]

57.3

[2.26]

114.6

[4.51]

Approximate

center of

gravity

73.25

[2.88]

57.3

[2.26]

Coupling-SAE C:

14 tooth spline, 16/32 pitch

29.633 (1.1667) pitch ø

Flat root side fit

Per ANSI B92.1-1970, Class 6

146.5

[5.77]

114.6

[4.51]

1/2 -13 UNC-2b THD thru

22.7 [0.89] min thd depth

4x

Ø131.57

[5.18]

Ø127.03

[5.001 ]

O-ring seal required

Ref 120.37 [4.379] i.D.

1.78 [0.07] cross section

14 ± 0.13

[0.551 ±0.005]

+.002

0

+0.05

0

10.09

[0.4]

Min coupling

clearance

1.3

[0.051]

Ø57.1

[2.25]

Min shaft

clearance

276.69

[10.89]

135

[5.31]

Mounting

flange

P104 072E

[0.24]

6

Displacement limiter G Frame open circuit pumps are available with an

optional adjustable displacement limiter. This

adjustable stop limits the pump’s maximum

displacement.

Setting range

G74B 56 to 74 cm³ [3.39 to 4.52 in³]

G90C 68 to 90 cm³ [4.12 to 5.49 in³]

Displacement limiter cross-section

P104 026

1. See Input shaf t torque ratings, page 19 for definitions of continuous and maximum torque.

11058670 • Rev BA • Sep 201314

Page 15

Technical Information Series 45 G Frame Pumps

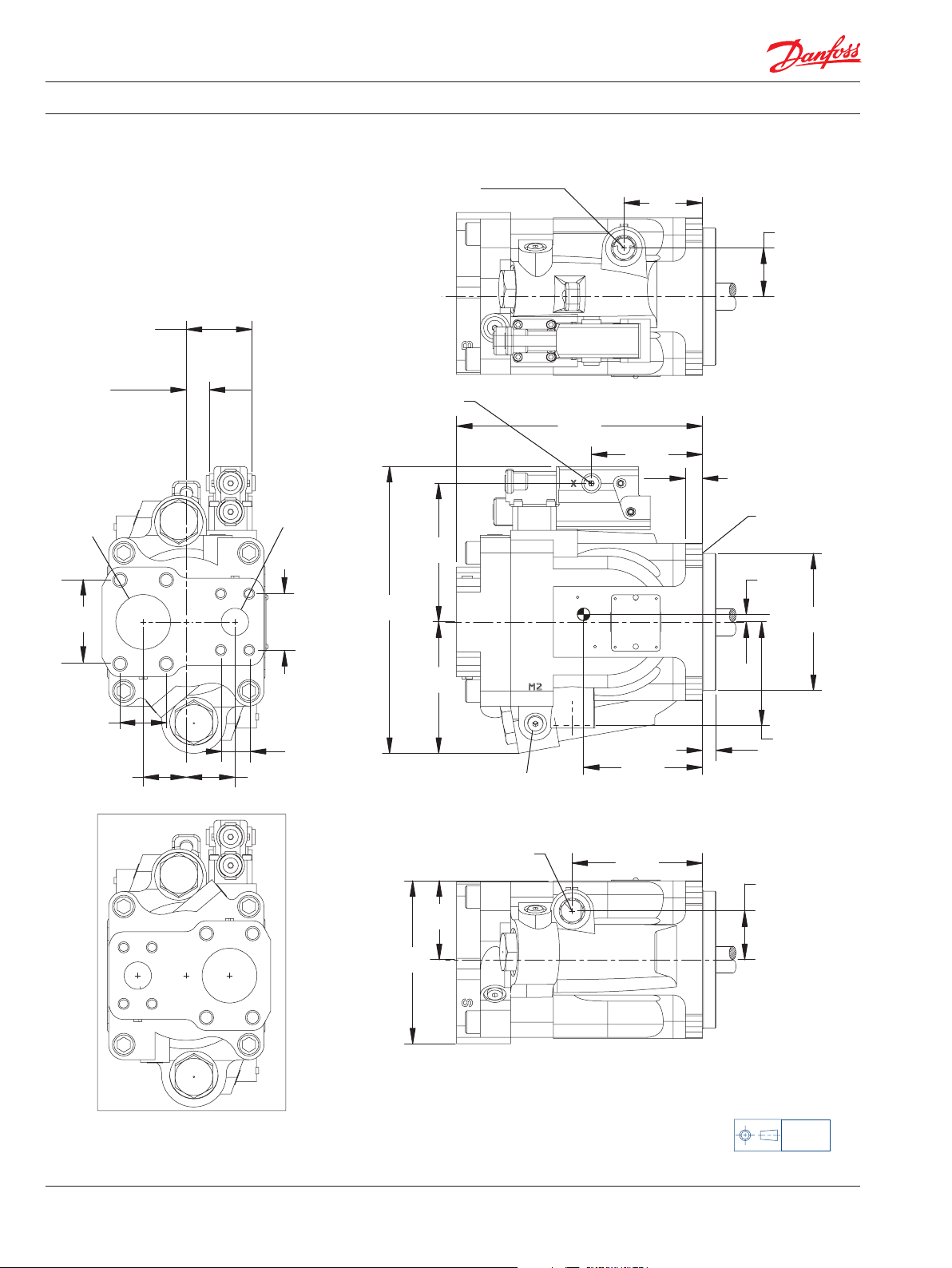

Installation Drawings Running cover

Dimensions

Approximate

center of

gravity

264.2

[10.4]

128

[5.04]

Mounting

flange

6

[0.24]

Adjustable displacement limiter

Dimensions

208.74 MAX

[8.218]

P106 078E

102.84

[4.05]

P104 073E

11058670 • Rev BA • Sep 2013 15

Page 16

Technical Information Series 45 G Frame Pumps

Third-angle

Installation Drawings

(continued)

60.7

[2.39]

21.3

[0.84]

LS signal

Port X

alternate

Ø50.8 [2]

System port S

(Inlet port)

207 Bar [3000 PSI]

Split flange boss

Per ISO 6162

SAE J518

(CODE 61)

with 1/2-13 UNC

x 27 [1.063]

Min THD

77.77

[3.062]

LS signal

Port X

Axial ported endcap

Ø25.4 [1]

System port B

(Outlet port)

345 Bar [3000 PSI]

Split flange boss

Per ISO 6162

SAE J518

(CODE 61)

with 3/8-16 UNC

x 27 [0.866]

Min THD

52.37

[2.062]

Case drain port L1

Per ISO 11926-1

SAE J1926/1

7/8 -14

LS signal porT X

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

128.5

[5.06]

265.76

[10.463]

System ports S and B

227.74

[8.97]

102.84

[4.05]

72.74

[2.86]

15.64 4X

[0.62]

45

[1.77]

R1 MAX

[0.04]

7

[0.28]

Ø126.975 ± 0.025

[4.999 ± 0.001]

42.88

[1.688]

40

[1.57]

Clockwise rotation

Counterclockwise rotation

45

[1.77]

26.19

[1.031]

121.76

[4.79]

System pressure gage port M2

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

Case drain port L2

Per ISO 11926-1

SAE J1926/1

7/8 -14

73

[2.87]

151

[5.94]

110

[4.33]

120.74

[4.75]

12.7

[0.5]

45

[1.77]

96

[3.78]

Case drain

Port L2

P106 174E

projection

mm [in]

11058670 • Rev BA • Sep 201316

Page 17

Technical Information Series 45 G Frame Pumps

Third-angle

Axial ported endcap (continued)Installation Drawings

(continued)

LS standby

Pressure adjustment

Pc pressure

adjustment

Ø14.3

[0.56]

Approximate

center of

gravity

114.5

[4.51]

CcwCw

57.25

[2.25]

Ls signal port x

Alternate

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

128.5

[5.06]

96

[3.78]

Case drain

port L1

102.84

[4.05]

Servo pressure gage port M4

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

57.25

[2.25]

114.5

[4.51]

P104 074e

projection

mm [in]

11058670 • Rev BA • Sep 2013 17

Page 18

Technical Information Series 45 G Frame Pumps

Third-angle

72.74

[2.95]

[3.23]

Installation Drawings

(continued)

60.7

[2.39]

LS SIGNAL

PORT X

21.3

[0.84]

LS SIGNAL

PORT X

ALTERNATE

SYSTEM

PORT S

(inlet)

Radial ported endcap

LS signal port X

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

System

Port B

(outlet)

265.76

[10.463]

128.5

[5.06]

Case drain port L1

Per ISO 11926-1

SAE J1926/1

7/8 -14

256.04

[10.08]

212.74

[8.38]

102.84

[4.05]

[2.86]

15.64 4X

[0.62]

[0.24]

45

[1.77]

R1 MAX

[0.04]

6

Ø126.975 ± 0.025

[4.999 ± 0.001]

System

Port B

(outlet)

82

[3.23]

75

[2.95]

Clockwise rotation

75

82

Counterclockwise rotation

System

Port S

(inlet)

Ø25.4 [1]

System port B

(outlet port)

345 Bar [5000 PSI]

Split flange boss

Per ISO 6162

SAE J518

(CODE 61)

with 3/8-16 UNC

x 27 [0.866]

MIN THD

Outlet

121.76

75

[2.95]

82

[3.23]

Inlet

[4.79]

Case drain porT L2

Per ISO 11926-1

SAE J1926/1

7/8 -14

124

[4.88]

System pressure gage port M2

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

120.74

[4.75]

12.7

[0.5]

45

[1.77]

96

[3.78]

Case drain

Port L2

P106 175E

projection

mm [in]

11058670 • Rev BA • Sep 201318

Page 19

Technical Information Series 45 G Frame Pumps

Servo pressure gage port M4

Third-angle

Installation Drawings

(continued)

PC pressure

Adjustment

Approximate

center of

gravity

57.25

[2.25]

Radial ported endcap (continued)

LS standby

Pressure adjustment

Ø14.3

[0.56]

114.5

[4.51]

CCWCW

57.25

[2.25]

114.5

[4.51]

LS signal port X

Alternate

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

128.5

[5.06]

96

[3.78]

Case drain

port L1

102.84

[4.05]

215.74

[8.49]

Per ISO 11926-1

SAE J1926/1

7/16 -20 UNF

Ø50.8 [2]

System port S

(Inlet port)

207 Bar [3000 PSI]

Split flange boss

Per ISO 6162

SAE J518

(Code 61)

with 1/2-13 UNC

x 27 [1.063]

MIN THD

P104 075E

projection

mm [in]

11058670 • Rev BA • Sep 2013 19

Page 20

Products we off er:

Bent Axis Motors

Closed Circuit Axial Piston

Pumps and Motors

Displays

Electrohydraulic Power

Steering

Electrohydraulics

Hydraulic Power Steering

Integrated Systems

Joysticks and Control

Handles

Microcontrollers and

Software

Open Circuit Axial Piston

Pumps

Orbital Motors

P LUS+1® GUIDE

Proportional Valves

Sensors

Steering

Transit Mixer Drives

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions that

excel in the harsh operating conditions of the mobile off -highway market. Building on our extensive

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad range of off -highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off -highway vehicles are at work, so is Danfoss.

We off er expert worldwide support for our customers, ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmueller-

Local address:

inverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Danfoss

Power Solutions US Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

11058670 • Rev BA • Sep 2013 www.danfoss.com © Danfoss A/S, 2013-09

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions

22F, Block C, Yishan Rd

Shanghai 200233, China

Phone: +86 21 3418 5200

Loading...

Loading...