Page 1

Data Sheet

Electronic Torque Limiting (ETL) Solutions

Series 45 Pumps

The new Series 45 Pressure Compensating/Load

Sensing with Electronic Torque Limiting control

(PC/LS with ETL), offers the next generation in system

performance, efficiency, and innovation. Specifically

designed with Tier 4 engines in mind this newlydeveloped proprietary system allows operators to

maximize the total performance potential of their

machine.

The Series 45 Electronic Torque Limiting control is

designed to be fitted into existing pressure

compensated/load sensing or mechanical torque

control (MTC) systems. ETL unlocks total system

performance potential by allowing infinite

adjustment of torque limit settings through the

electronic proportional control. PLUS+1® Compliant,

available with GUIDE programmable software and

precompiled electronic controls, this system solution

can be quickly and easily implemented into current or

new applications.

A flexible, modular product line allows for either the

standalone pump to be purchased, or the entire

system. Full system integration can be achieved

quickly and easily with the Danfoss pre-programmed

controllers and GUIDE software blocks. Ready to

operate hardware and software significantly reduces

machine development and testing time, keeping time

to market at a minimum by quickly fitting the system

to your specific needs.

Features

Pressure compensator/load sensing

pump with electronic torque limiting

control (PC/LS with ETL)

•

Available in 12/24 volt configurations

•

Normally closed control (NC), removal

of signal to control or angle sensor

defaults system to regular PC/LS

functionality, allows for maximum

uptime

•

Similar hardware configuration as

current electric controls

•

Can be easily implemented into PC/LS

systems

Angle sensor

•

Measures real time swashplate angle

(displacement) of the pump with high

resolution

•

Proven hardware with no interference

parts

•

Redundant (dual) integrated sensors

‒

‒

•

PLUS+1® compliance block

‒

Improved measurement accuracy

Easy sensor fault detection

Easy calibration of sensor and

diagnostics

•

Also available with other common

control configurations (PC, PC/LS, RP,

ON/OFF)

•

IP67 and IP69K Rating with a 4 pin

DEUTSCH connector

•

Same package size as current electrical

controls

Comprehensive technical literature is

online at www.danfoss.com

©

Danfoss | January 2019 L1430954 | AI00000201en-000202 | 1

Page 2

Data Sheet

Series 45 ETL

Optional features

•

GUIDE Programmable Electronic Torque

Limiting Software

Optimized ETL software package for

‒

plug & perform functionality

Available in the work function

‒

control library

Easy to program software blocks

‒

with GUIDE, ideal for adding to

existing GUIDE blocks

Simple for integration of user inputs,

‒

outputs and additional sensors

Incorporates Danfoss dual path

‒

propel expertise

Available for use with other PLUS+1

‒

®

Preprogrammed MC12 electronic

controller

•

Easy to follow service screens for

programing

•

12 Pin connector can be added to

current machine

•

Easy tuning/ calibrations with CANBus

integration for plug and perform

operation

•

Free downloadable and easy to follow

simple service tool allows for fast

prototyping and improved time to

production

applications.

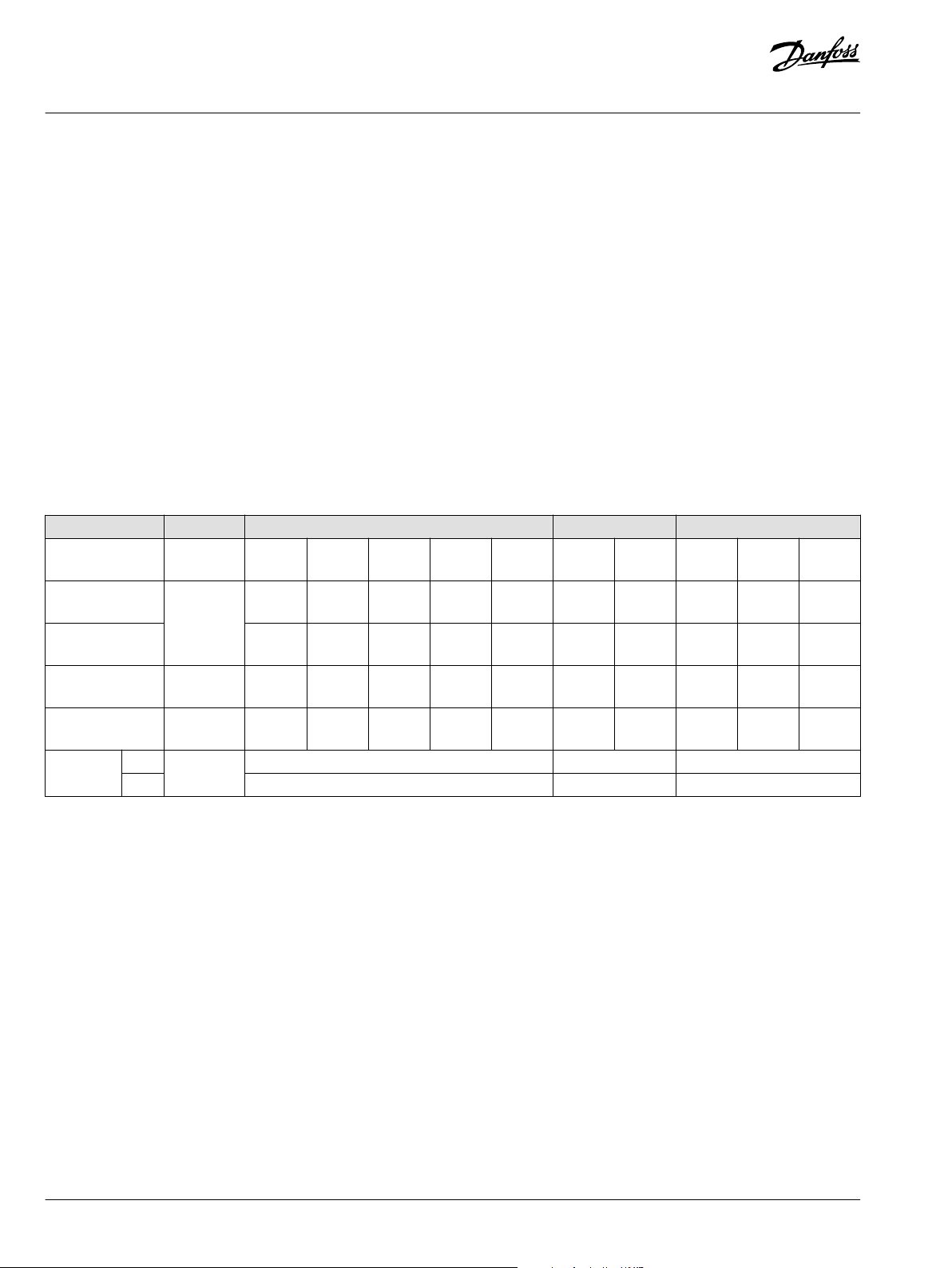

Technical specifications

Specification Unit Frame J Frame F Frame E

Maximum

displacement

Continuous working

pressure

Maximum working

pressure

Continuous input

speed

Theoretical flow l/min [US

*

Weight

*

Weight values based on CAD geometry without auxiliary flange and PC/LS control

cm3 [in3] 45 [2.75] 51 [3.11] 60 [3.66] 65 [3.97] 75 [4.58] 74 [4.52] 90 [5.49] 100 [6.1] 130 [7.93] 147 [8.97]

bar [psi] 310

[4500]

400

[5800]

min-1 (rpm) 2800 2700 2600 2500 2400 2400 2200 2450 2200 2100

126 [33.3] 137.7

gal/min]

Axial kg [lb] 23.1 [51.0] 29.5 [65.0] 52.0 [115.0]

Radial 27.3 [60.2] 32.6 [71.9] 26.0 [123.3]

310

[4500]

400

[5800]

[36.4]

310

[4500]

400

[5800]

156 [41.2] 162 [42.9] 180 [47.5] 177.6

260

[3770]

350

[5075]

260

[3770]

350

[5075]

310

[4500]

400

[5800]

[46.9]

260

[3770]

350

[5075]

198 [52.3] 245 [64.7] 286 [75.6] 309 [81.6]

310

[4500]

400

[5800]

310

[4500]

400

[5800]

260

[3770]

350

[5075]

2 | © Danfoss | January 2019 L1430954 | AI00000201en-000202

Page 3

P108777

93.6

[3.68]

87.3

[3.44]

30.5

[1.2]

43.5

[1.71]

42.5

[1.67]

29.5

[1.16]

100.7

[3.96]

33.2

[1.31]

(115.9)

[(4.56)]

approximate

wire length

131.5

[5.18]

P108778

36.9

[1.45]

86.8

[3.42]

94.1

[3.7]

36

[1.42]

43.2

[1.7]

110.7

[4.36]

122.4

[4.82]

approximate

wire length

131.5

[5.18]

36

[1.42]

36.9

[1.45]

Data Sheet

Series 45 ETL

Frame J

Frame F

©

Danfoss | January 2019 L1430954 | AI00000201en-000202 | 3

Page 4

Frame E

P108835

Outlet port

36

[1.42]

36

[1.42]

(120)

([4.39])

approximate

wire length

131.5 [5.18]

126.9

[5]

59.4

[2.34]

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 | © Danfoss | January 2019 L1430954 | AI00000201en-000202

Loading...

Loading...